Numerical Study: Substrate Thickness and Type of Roof Structure and Their Impact on the Thermal Behavior of Green Roofs

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Design

2.2. Methodology

2.2.1. Simulation Model

2.2.2. Boundary Conditions

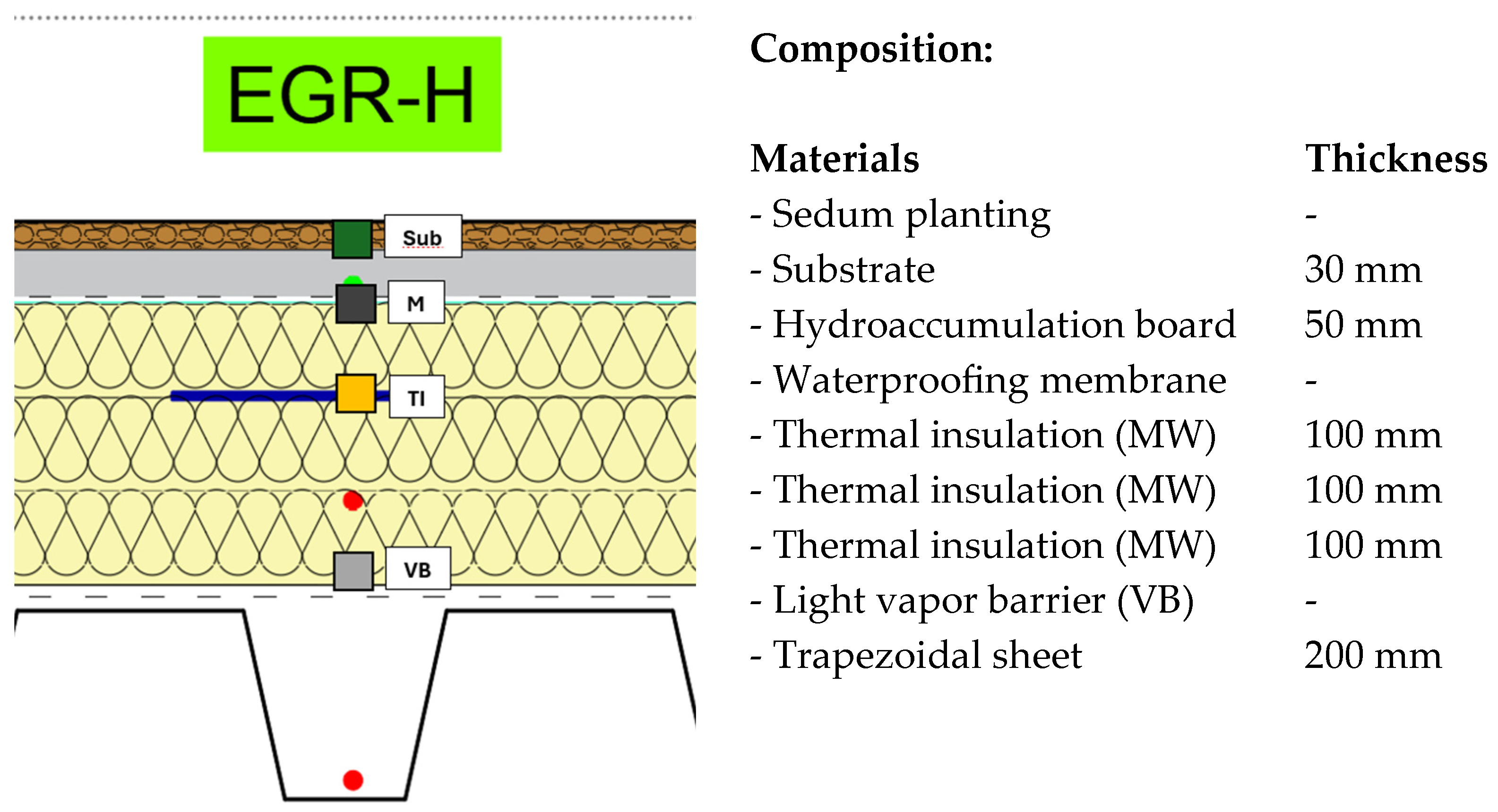

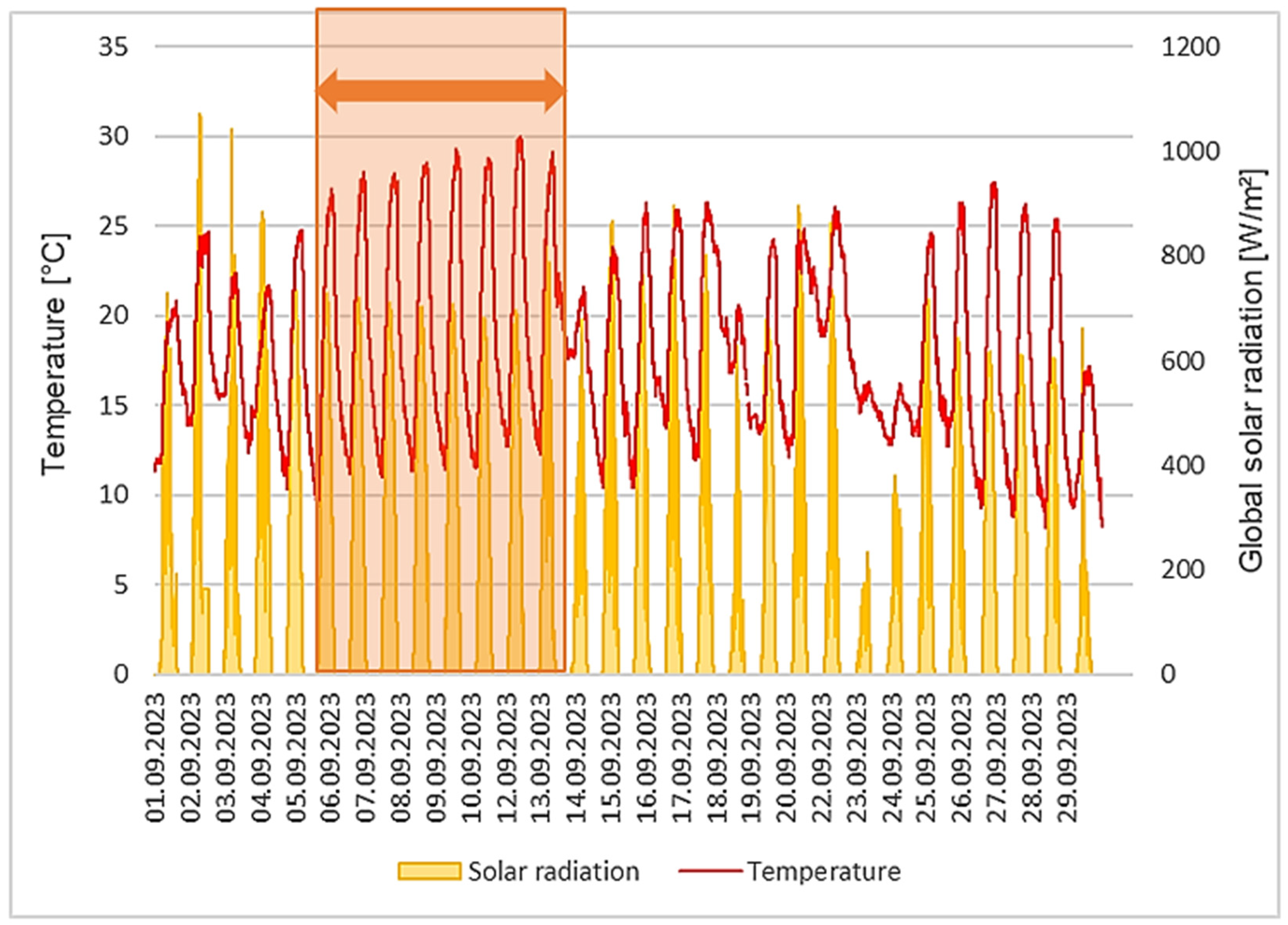

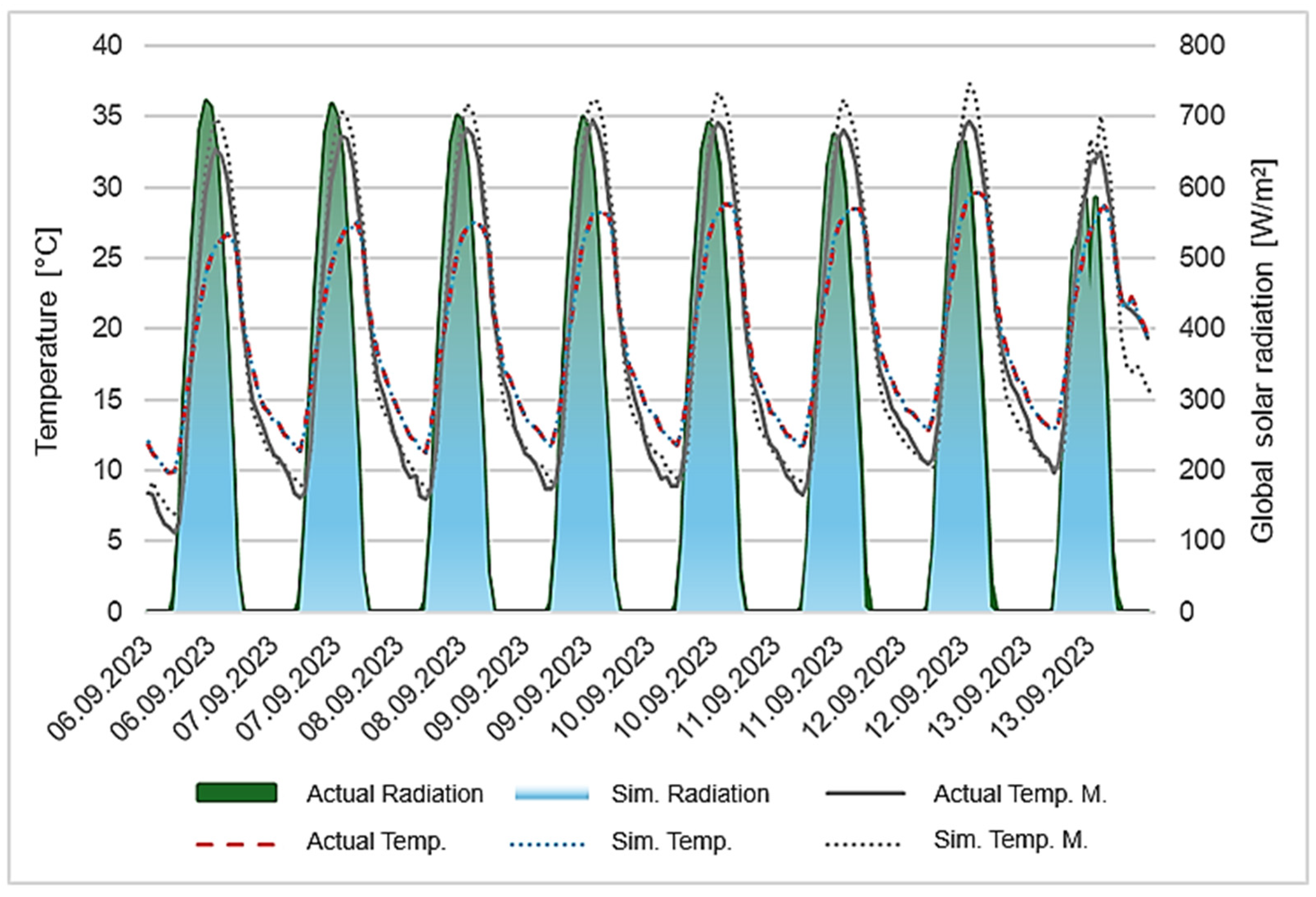

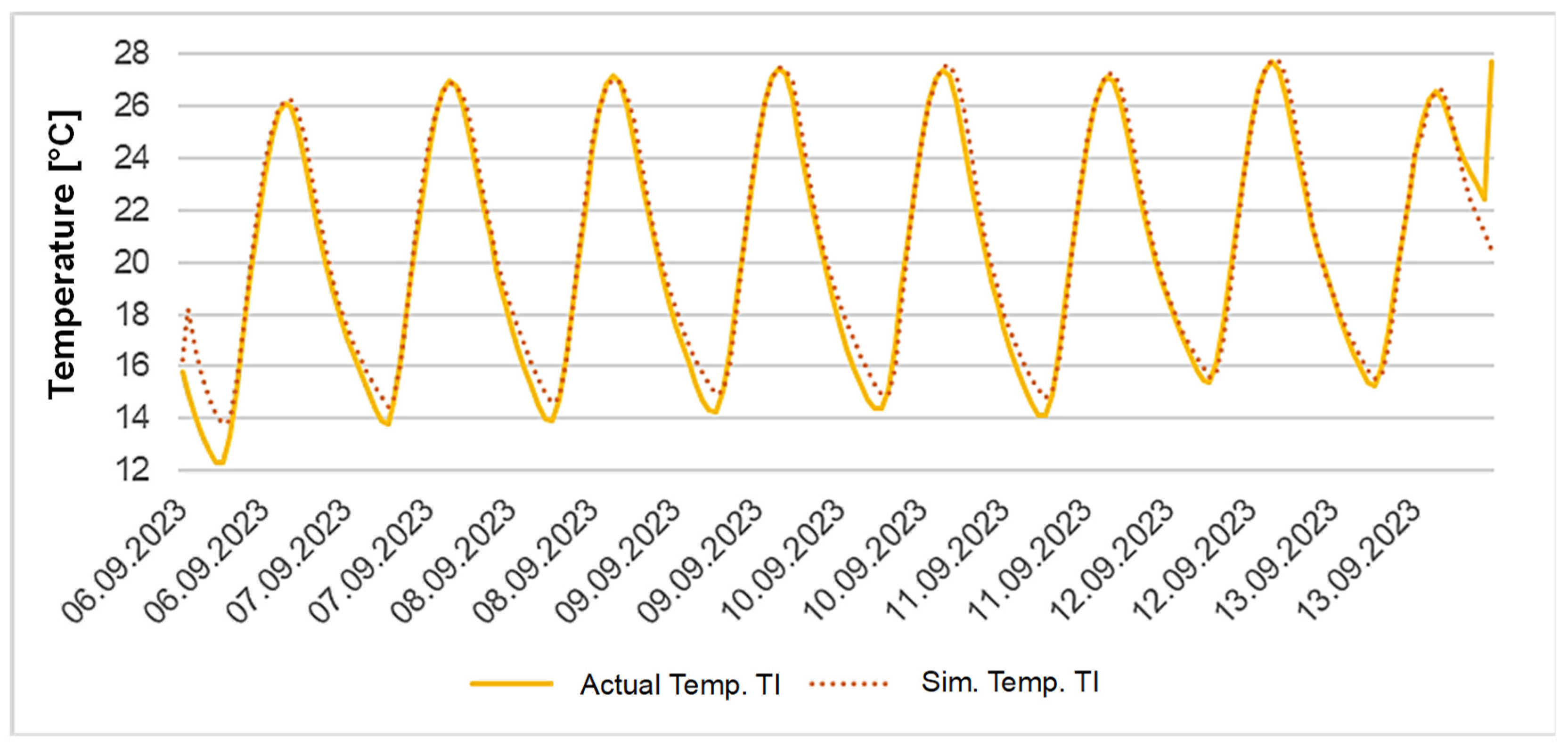

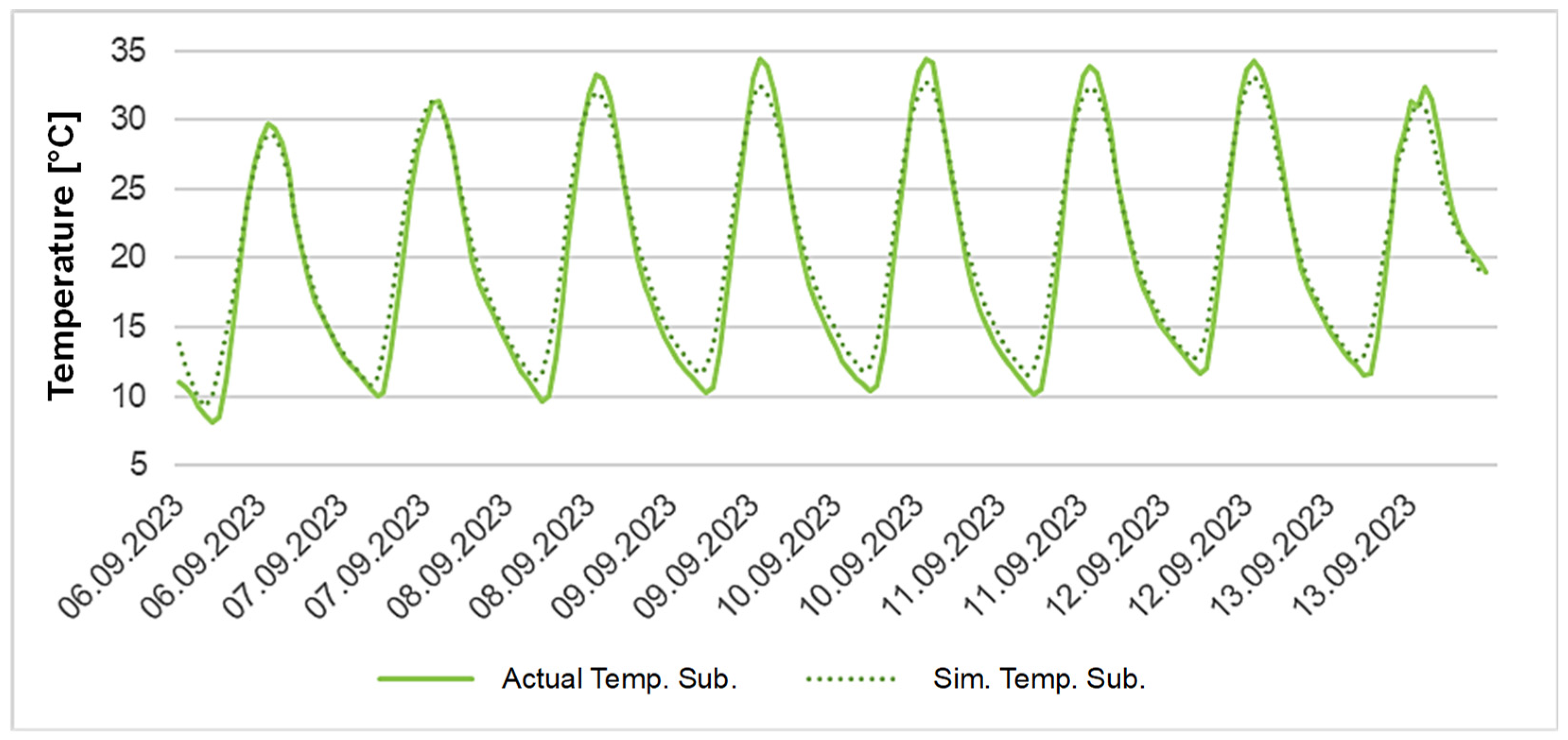

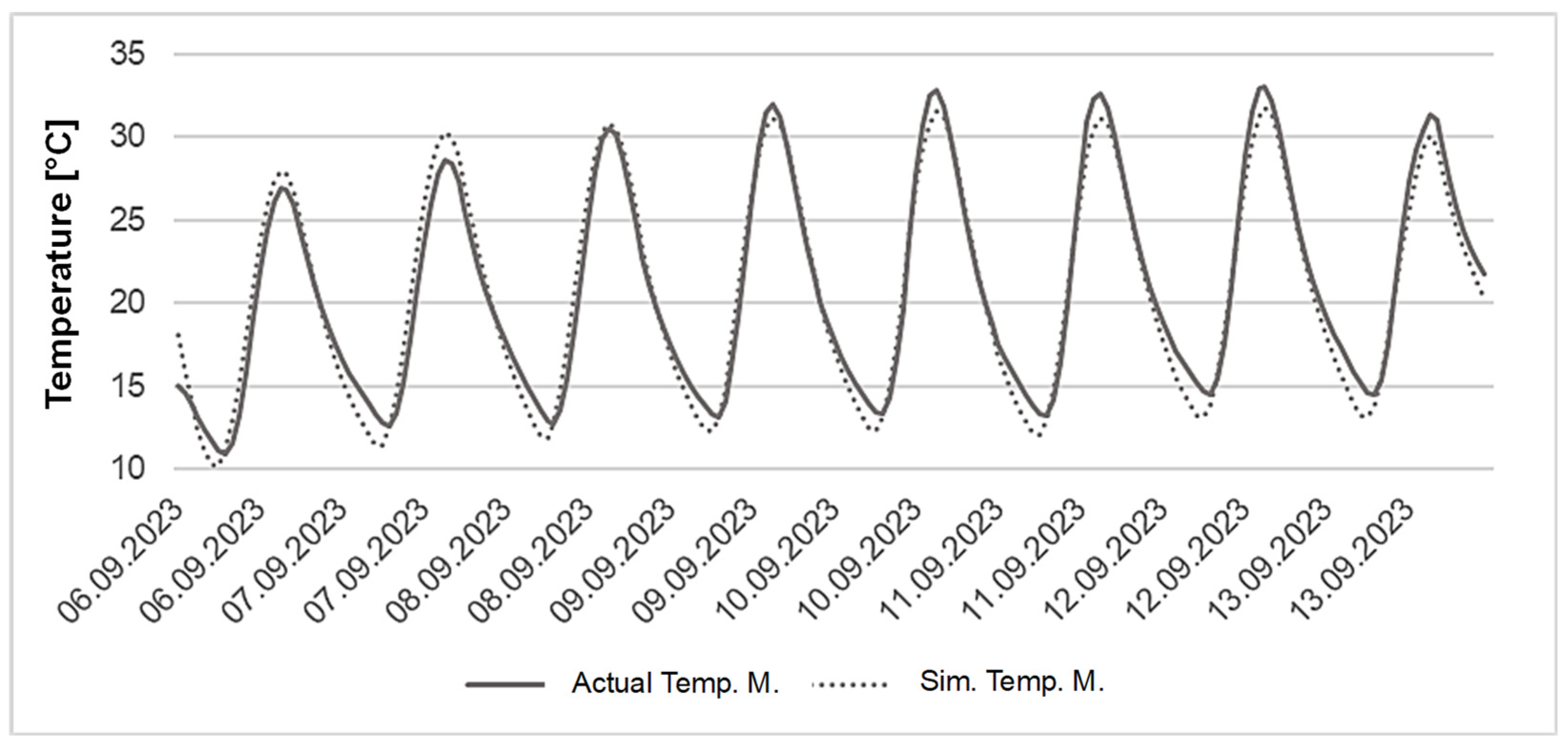

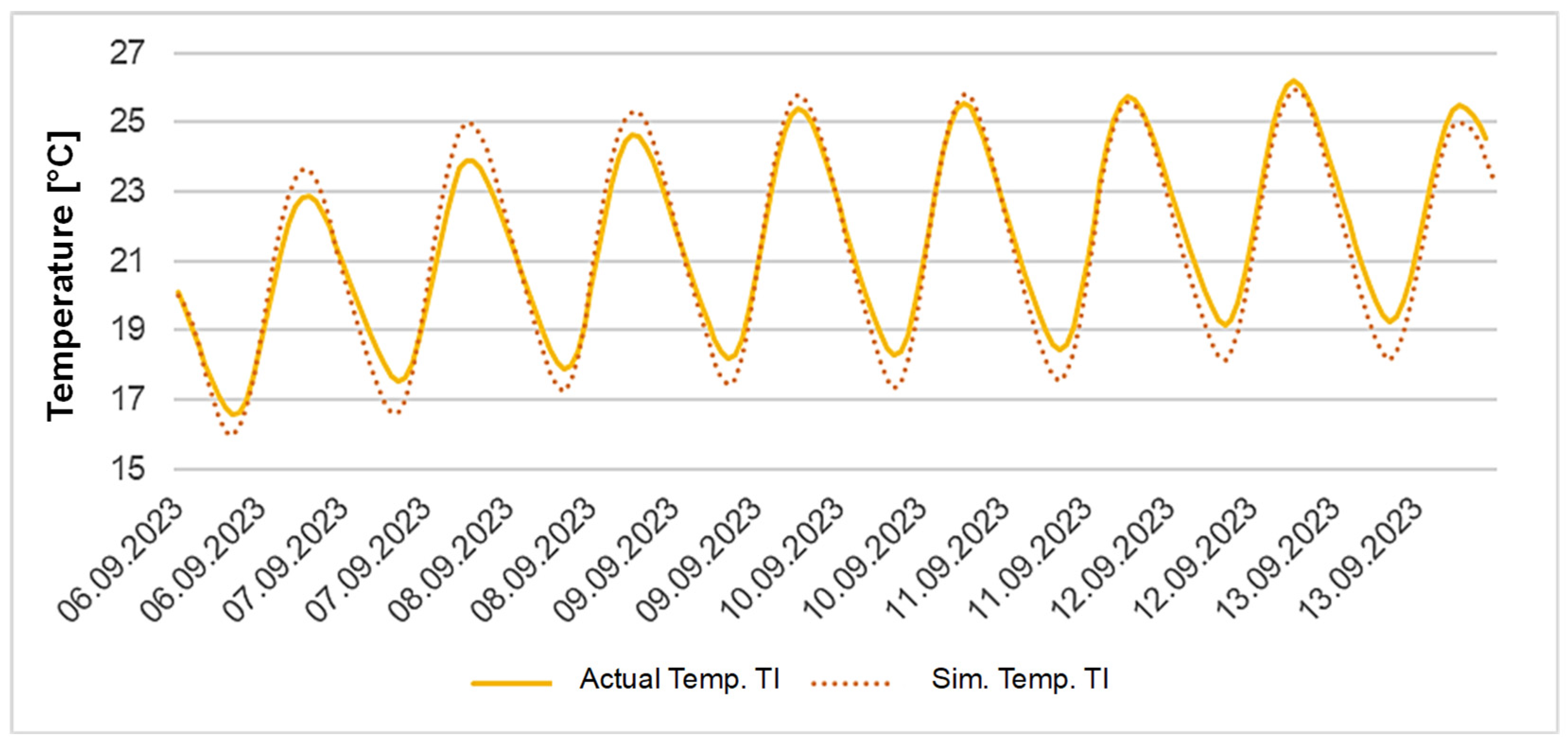

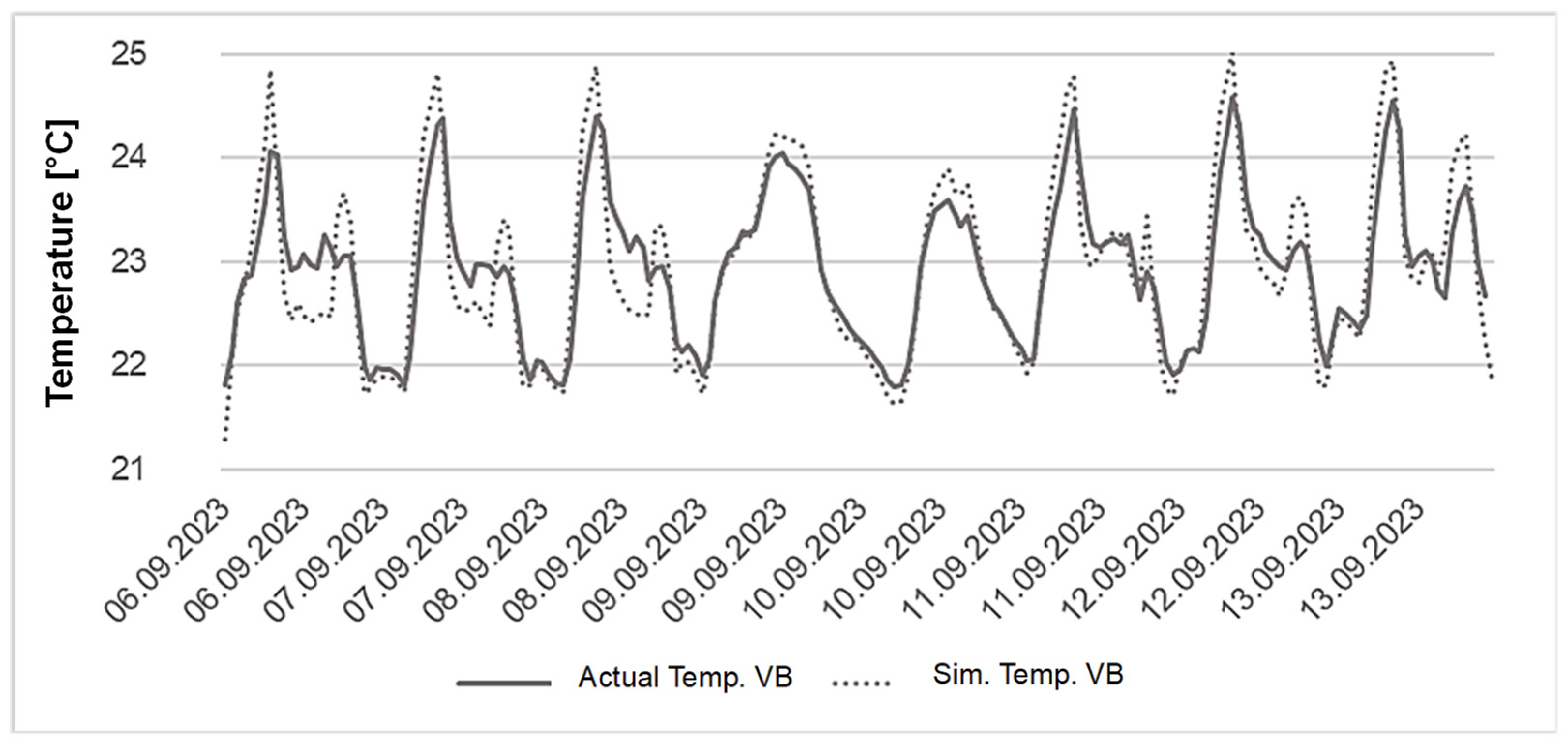

2.3. Validation of the HAM Simulation Model with In-Situ Measurements

- Sensors in individual layers of the roof (especially in the substrate, thermal insulation, under the waterproofing, and at the level of the vapor barrier);

- A temperature and relative humidity sensor in the interior;

- A complete weather station with CSV output, operating with one-minute sampling intervals.

2.4. Model Variants for Parametric Study

- V1: modification of the type of load-bearing layer from the original trapezoidal sheet metal to a reinforced concrete slab (200 mm thick), with an unchanged vegetation layer, in order to analyze its accumulation capacity for the thermal response of the roof structure;

- V2: modification of the thickness of the vegetation substrate from 30 mm to 200 mm while maintaining the original load-bearing layer (transition from extensive to intensive vegetation structure);

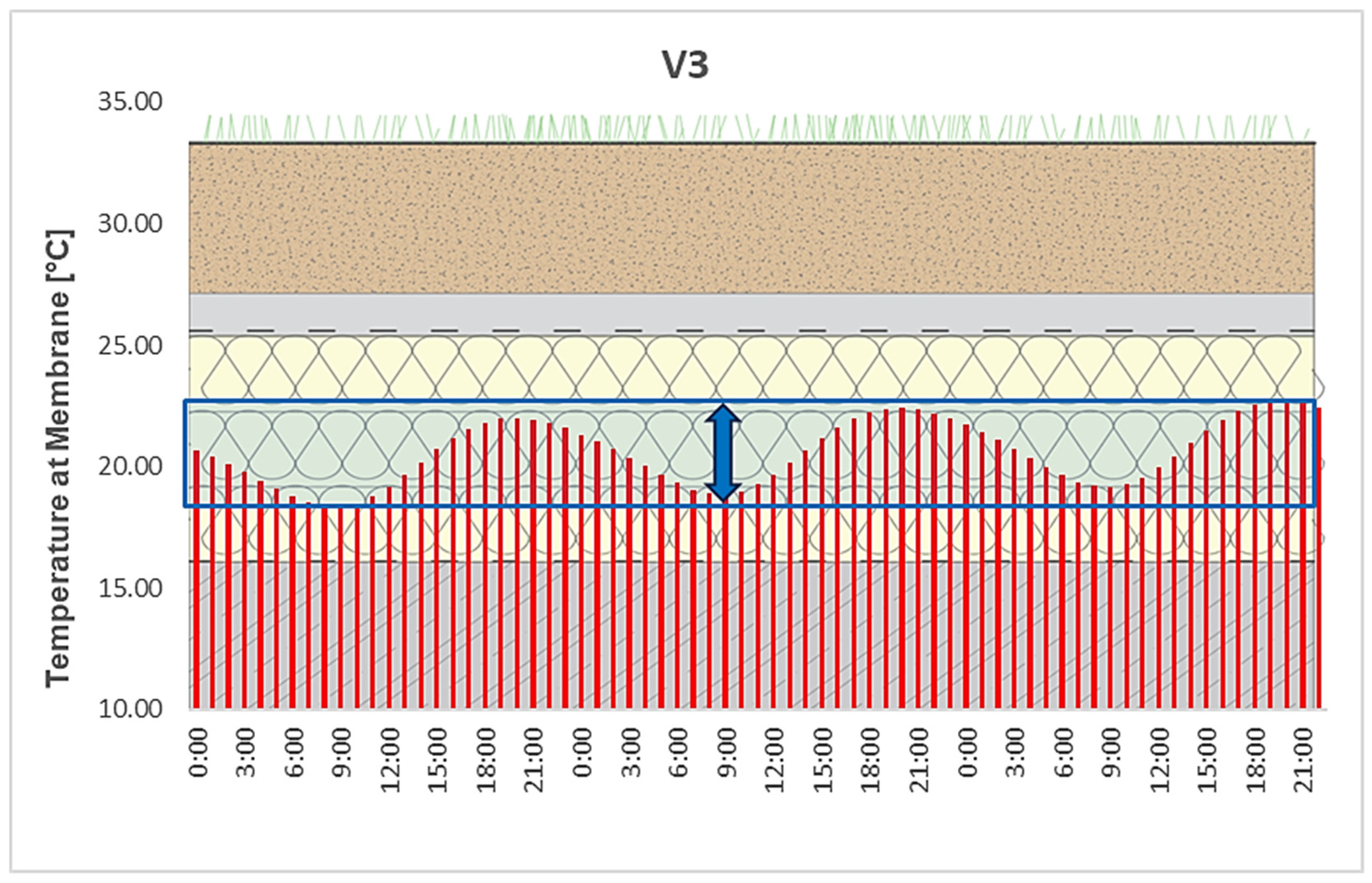

- V3: combination of both modifications—reinforced concrete load-bearing slab and increased substrate thickness.

3. Results

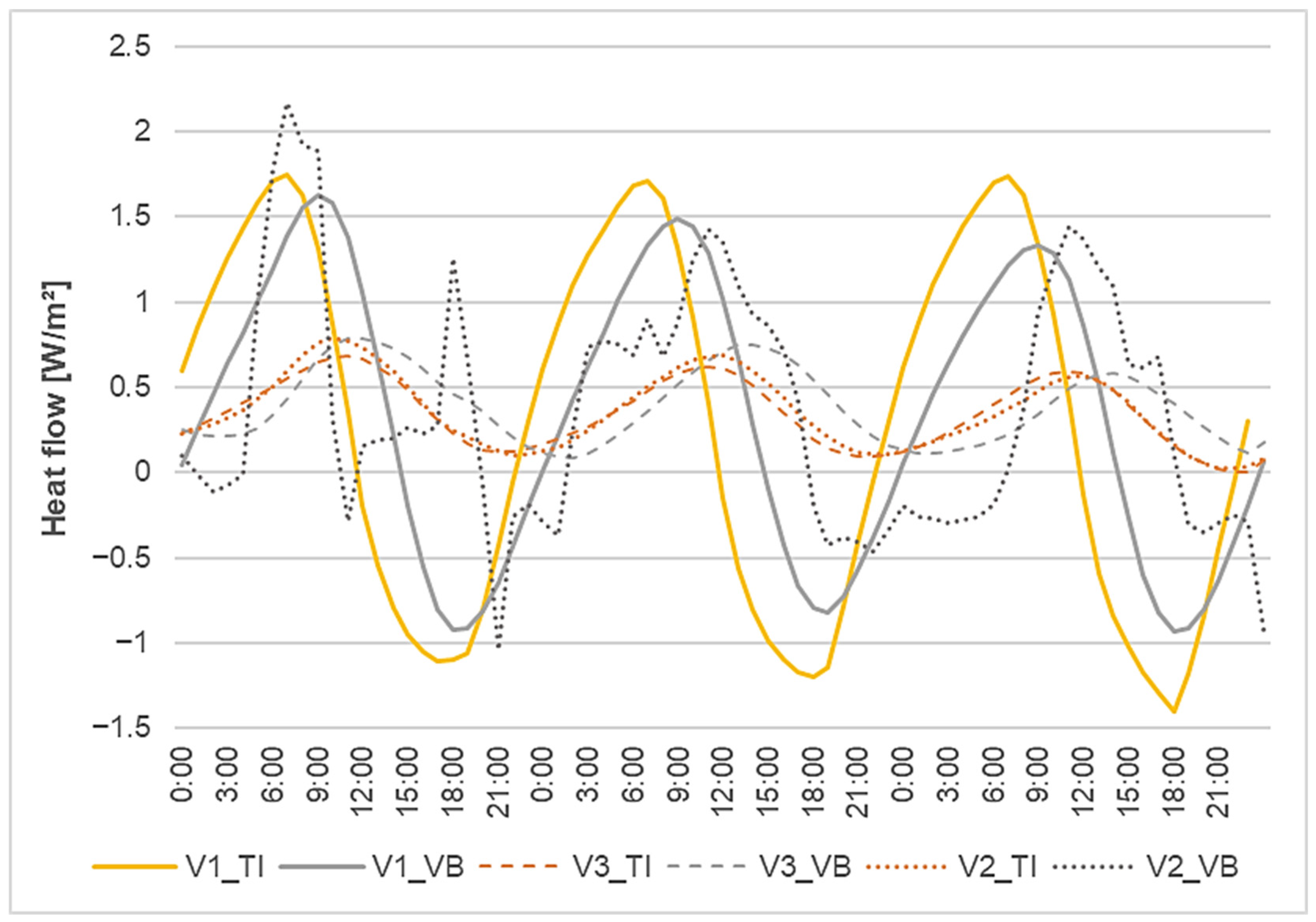

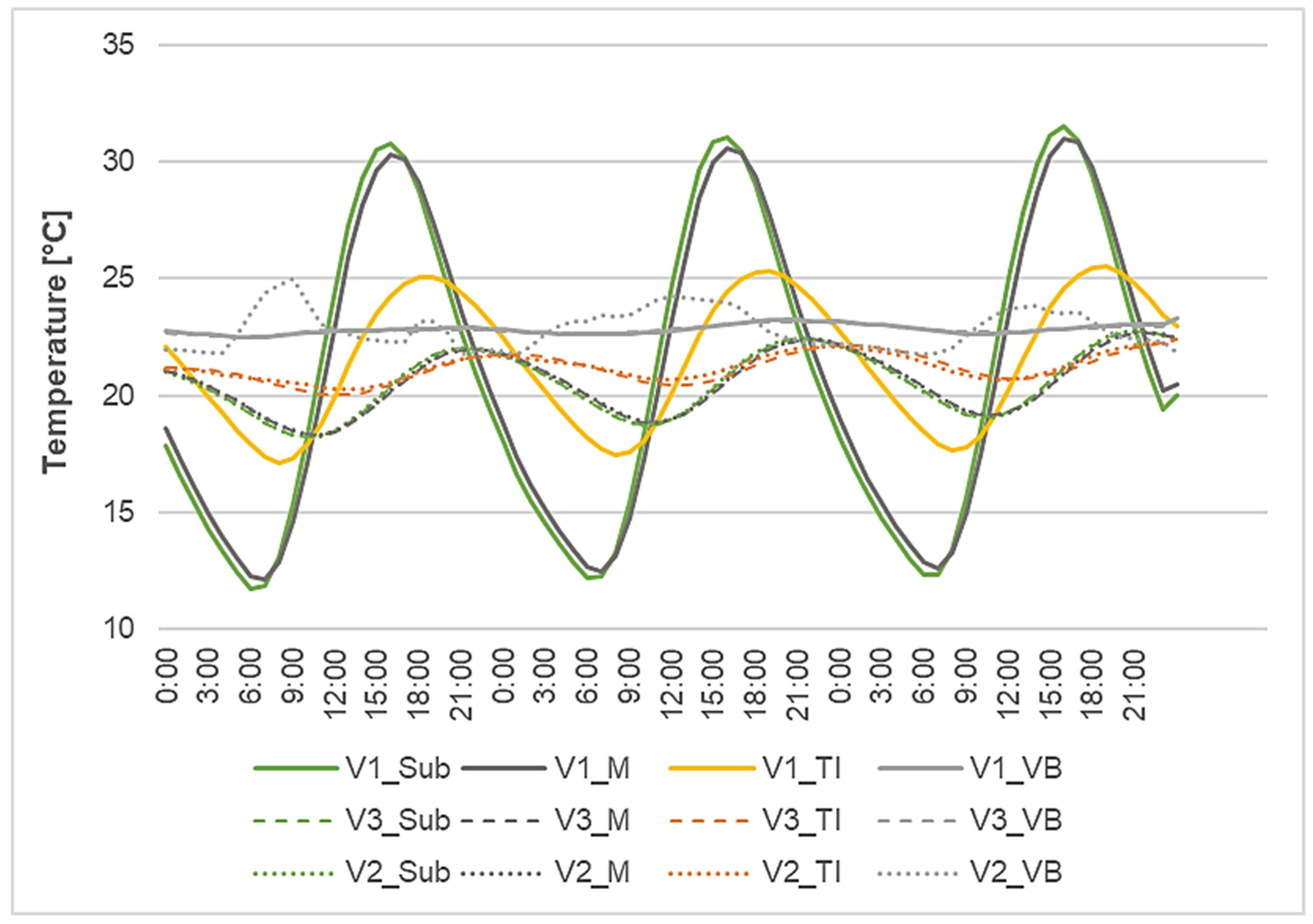

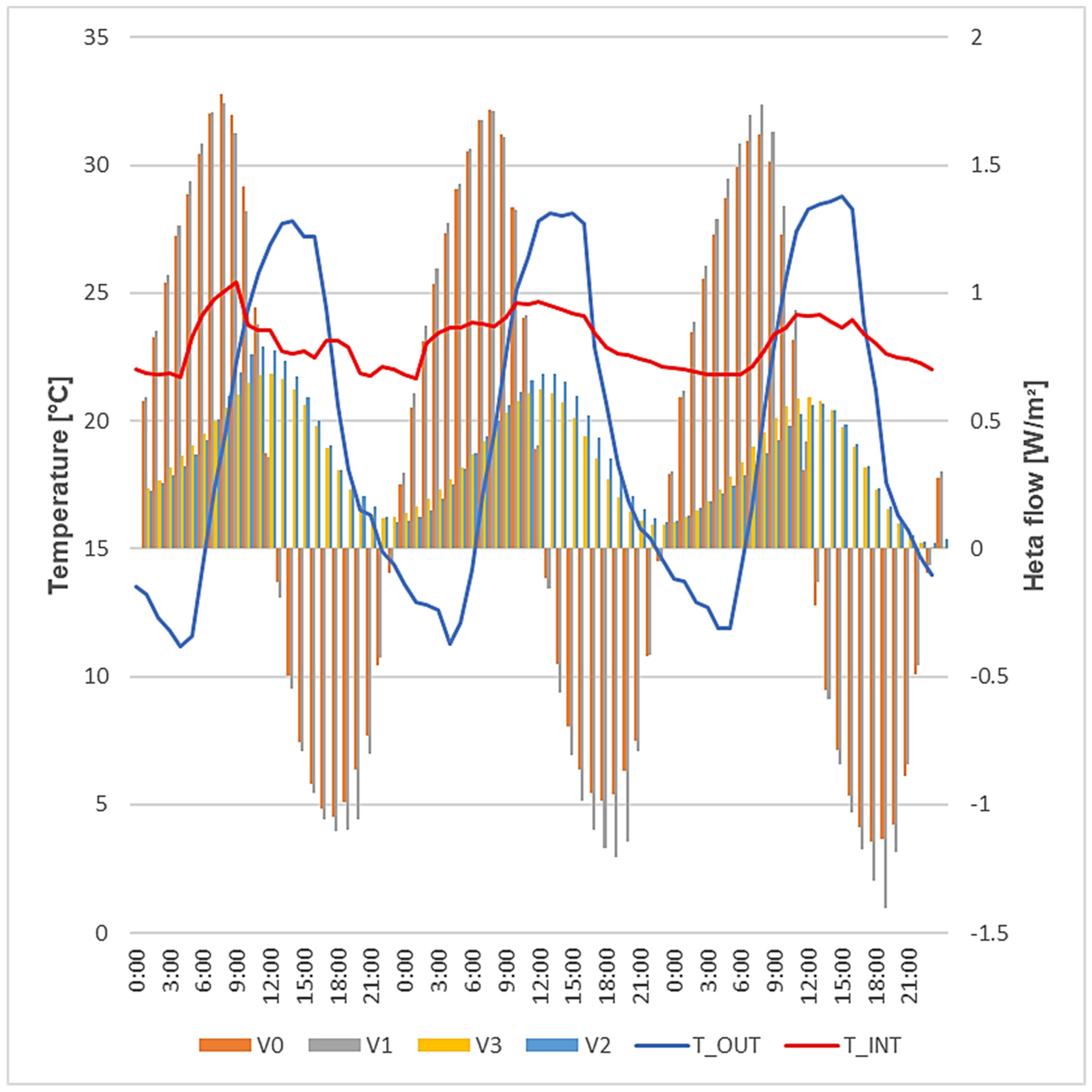

- At the interface between the vegetation substrate and the hydroaccumulation board (Sub);

- At the level of waterproofing membrane (M);

- Under the top layer of thermal insulation (TI);

- At the interface between the vapor barrier (VB) and the supporting structure.

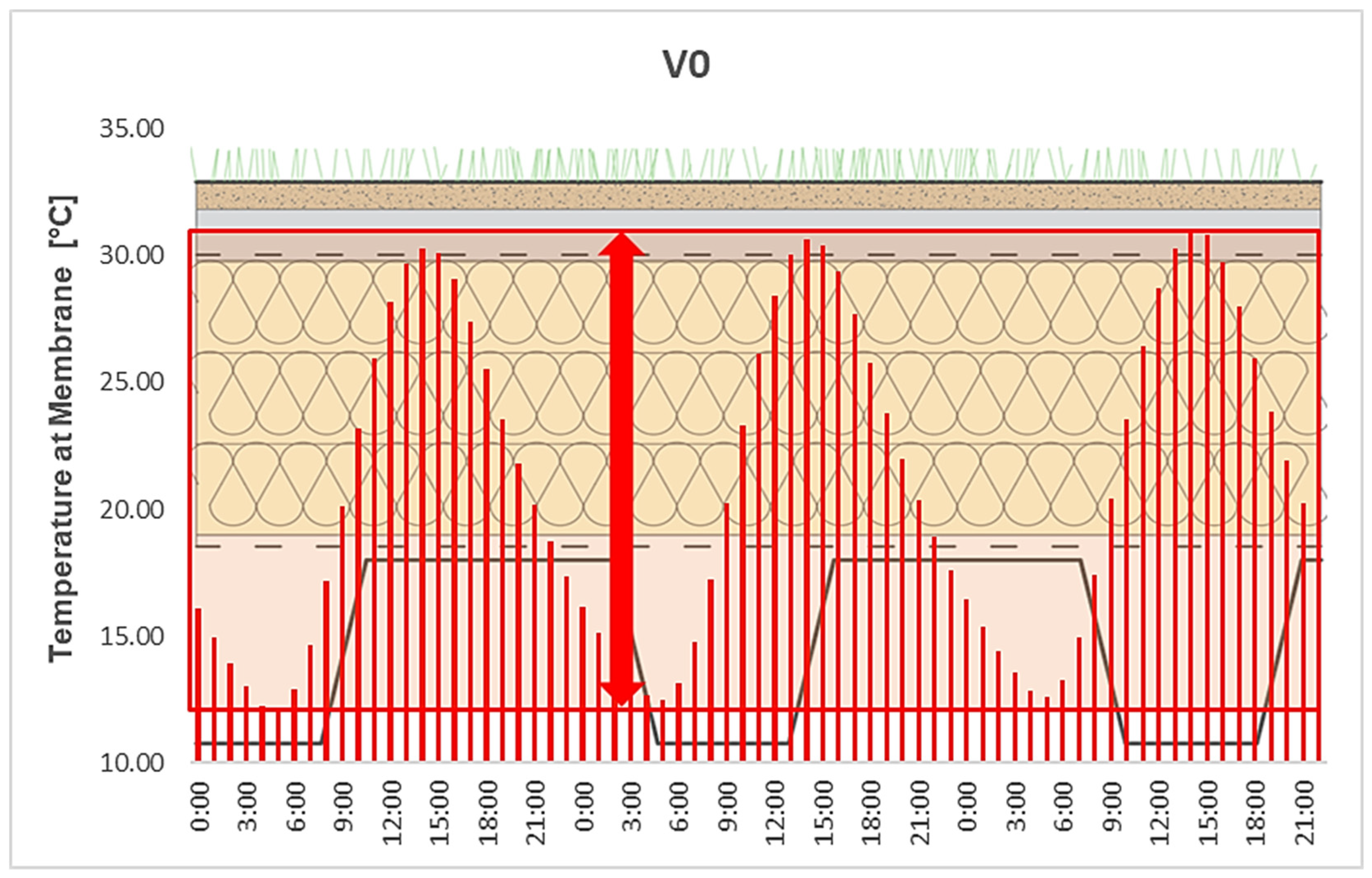

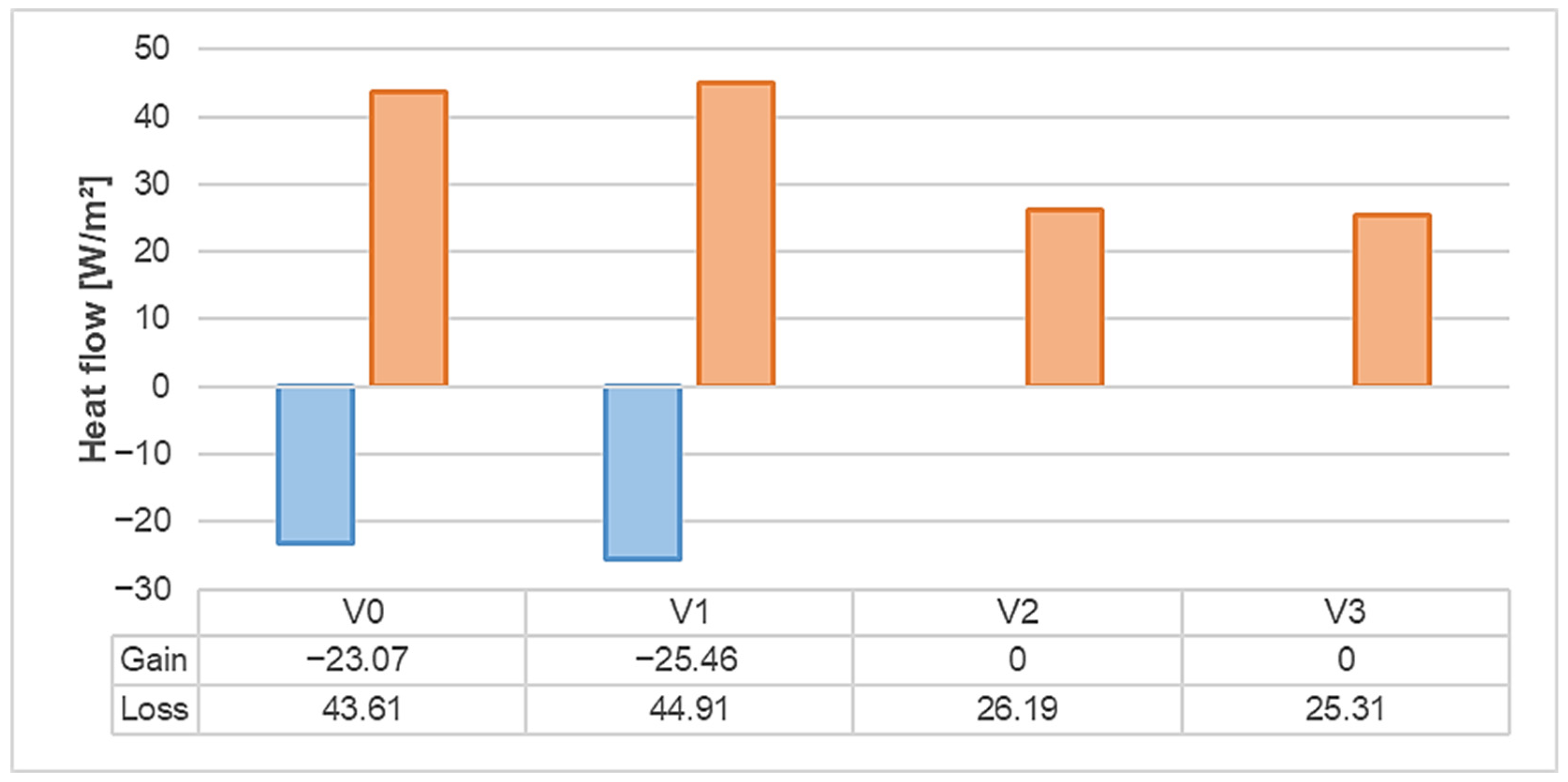

3.1. Comparison of Variants with Reference Solution (V0)

3.2. Comparison of Variants

4. Discussion

4.1. Impact of Material Changes on Structural Weight and Thermal Performance

4.2. Limitations and Recommendations

- Long-term monitoring of experimental roofs in various climatic conditions to capture interannual variability and vegetation dynamics;

- Development and assessment of lightweight or hybrid solutions that can balance thermal performance with structural constraints in industrial and lightweight buildings;

- Integration of economic and life cycle assessments as a complement to hygrothermal analysis to support decision-making in sustainable construction;

- Expansion of parametric studies to include additional design variables, such as different vegetation types, water-retention systems, or reflective membranes, aiming for comprehensive optimization.

5. Conclusions

- Variant V1 (concrete slab):

- The concrete supporting structure exerts only a minor effect on the stabilization of heat flow in the lower layers (especially above in the vapor barrier);

- The influence on the thermal performance of the roof structure is marginal, since the thickness of the thermal insulation layer remains the primary factor determining temperature distribution.

- Variant V2 (thicker substrate):

- Significantly reduces heat flow fluctuations, e.g., by up to 82% in the substrate and by half in the thermal insulation;

- There is a phase shift of maximum temperatures by 6 h, which is beneficial for thermal balancing;

- Significant cooling effect of the substrate—the temperature difference between the reference V0 and V2 reaches up to 8 °C.

- Variant V3 (combined—concrete slab and thicker substrate):

- Achieves the most effective stabilization of temperatures and heat flows throughout the entire structure;

- Temperature and flow fluctuations are significantly dampened—by a factor of 4 to 6 compared to V0;

- Temperature differences are reduced, e.g., in M from 21 °C (V0) to 6 °C (V3).

- There is no overheating or night cooling in the interior—thanks to the accumulation of concrete and substrate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dutta Pramanik, P.; Mukherjee, B.; Pal, S.; Pal, T.; Singh, S.P. Green Smart Building: Requisites, Architecture, Challenges, and Use Cases. In Research Anthology on Environmental and Societal Well-Being Considerations in Buildings and Architecture; IGI Global: Hershey, PA, USA, 2019; pp. 1–50. ISBN 9781522597544. [Google Scholar]

- Cascone, S. Green Roof Design: State of the Art on Technology and Materials. Sustainability 2019, 11, 3020. [Google Scholar] [CrossRef]

- Bevilacqua, P. The Effectiveness of Green Roofs in Reducing Building Energy Consumptions across Different Climates. A Summary of Literature Results. Renew. Sustain. Energy Rev. 2021, 151, 111523. [Google Scholar] [CrossRef]

- Penn, A. Living Roofs; Taschen: Cologne, Germany, 2022. [Google Scholar]

- Vera, S.; Pinto, C.; Tabares-Velasco, P.C.; Bustamante, W.; Victorero, F.; Gironás, J.; Bonilla, C.A. Influence of Vegetation, Substrate, and Thermal Insulation of an Extensive Vegetated Roof on the Thermal Performance of Retail Stores in Semiarid and Marine Climates. Energy Build. 2017, 146, 312–321. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Sodoudi, S. The Effectiveness of Cool and Green Roofs in Mitigating Urban Heat Island and Improving Human Thermal Comfort. Build. Environ. 2022, 217, 109082. [Google Scholar] [CrossRef]

- Santamouris, M. Cooling the Cities—A Review of Reflective and Green Roof Mitigation Technologies to Fight Heat Island and Improve Comfort in Urban Environments. Sol. Energy 2014, 103, 682–703. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, Z.; Zhang, S.; Ge, D. Stormwater Retention and Detention Performance of Green Roofs with Different Substrates: Observational Data and Hydrological Simulations. J. Environ. Manag. 2021, 291, 112682. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Meng, Q. Dynamic Heat Transfer Model of Vertical Green Façades and Its Co-Simulation with a Building Energy Modelling Program in Hot-Summer/Warm-Winter Zones. J. Build. Eng. 2022, 58, 105008. [Google Scholar] [CrossRef]

- Ponechal, R. Simulácie Budov; EDIS—Vydavateľské Centrum Žilinskej Univerzity: Žilina, Slovakia, 2015. [Google Scholar]

- Guattari, C.; Evangelisti, L.; Asdrubali, F.; De Lieto Vollaro, R.L. Experimental Evaluation and Numerical Simulation of the Thermal Performance of a Green Roof. Appl. Sci. 2020, 10, 1767. [Google Scholar] [CrossRef]

- Poljak, M.; Ponechal, R. Microclimatic Monitoring—The Beginning of Saving Historical Sacral Buildings in Europe. Energies 2023, 16, 1156. [Google Scholar] [CrossRef]

- Ponechal, R.; Barňák, P.; Ďurica, P. Comparison of Simulation and Measurement in a Short-Term Evaluation of the Thermal Comfort Parameters of an Office in a Low-Carbon Building. Buildings 2022, 12, 349. [Google Scholar] [CrossRef]

- Sun, T.; Bou-Zeid, E.; Wang, Z.-H.; Zerba, E.; Ni, G.-H. Hydrometeorological Determinants of Green Roof Performance via a Vertically-Resolved Model for Heat and Water Transport. Build. Environ. 2013, 60, 211–224. [Google Scholar] [CrossRef]

- Vertaľ, M.; Zozulák, M.; Vašková, A.; Korjenic, A. Hygrothermal Initial Condition for Simulation Process of Green Building Construction. Energy Build. 2018, 167, 166–176. [Google Scholar] [CrossRef]

- Sailor, D.J. A Green Roof Model for Building Energy Simulation Programs. Energy Build. 2008, 40, 1466–1478. [Google Scholar] [CrossRef]

- Pianella, A.; Aye, L.; Chen, Z.; Williams, N.S.G. Substrate Depth, Vegetation and Irrigation Affect Green Roof Thermal Performance in a Mediterranean Type Climate. Sustainability 2017, 9, 1451. [Google Scholar] [CrossRef]

- Wu, D.; Wang, Z.; Yang, J.; Liu, X.; Wang, T. Analysis and Application of Heat Transfer Coefficient in Roof Greening Modules. J. Asian Archit. Build. Eng. 2025, 1–9. [Google Scholar] [CrossRef]

- de Araújo Moura, C.; de Freitas, B.B.; Alves Filho, A.P.; Albuquerque, C. Green Roofs on Shipping Containers: How Substrate Thickness Affects Thermal Performance. Buildings 2024, 14, 1246. [Google Scholar] [CrossRef]

- Reyes, R.; Bustamante, W.; Gironás, J.; Pastén, P.A.; Rojas, V.; Suárez, F.; Vera, S.; Victorero, F.; Bonilla, C.A. Effect of Substrate Depth and Roof Layers on Green Roof Temperature and Water Requirements in a Semi-Arid Climate. Ecol. Eng. 2016, 97, 624–632. [Google Scholar] [CrossRef]

- Jamei, E.; Thirunavukkarasu, G.; Abuseif, M.; Seyedmahmoudian, M.; Mekhilef, S.; Stojcevski, A.; Chau, H.-W. Simulation-Based Study on the Effect of Green Roofs on Summer Energy Performance in Melbourne. Land 2023, 12, 2105. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.-H.; Rahmatollahi, N.; Hou, H. The Impact of Roof Systems on Cooling and Building Energy Efficiency. Appl. Energy 2024, 376, 124339. [Google Scholar] [CrossRef]

- Kulumkanov, N.; Nadeem, A.; Tokbolat, S. Green Roof Energy Performance in Different Climate Zones: A Simulation Study. J. Phys. Conf. Ser. 2023, 2600, 092027. [Google Scholar] [CrossRef]

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Assessment of the Impact of Green Roofs and Walls on Building Energy Performance: A Scientific Review. Energies 2024, 17, 5160. [Google Scholar] [CrossRef]

- Versini, P.-A.; Castellanos-Diaz, L.A.; Ramier, D.; Tchiguirinskaia, I. Evapotranspiration Evaluation Using Three Different Protocols on a Large Green roof in the Greater Paris Area. Earth Syst. Sci. Data 2024, 16, 2351–2366. [Google Scholar] [CrossRef]

- Tudiwer, D.; Vertal’, M.; Korjenic, A.; Čakyová, K. Abbildung Der Wärmedämmenden Wirkung Eines Fassadengebundenen Begrünungssystems in Einem Simulationsmodell. Bauphysik 2019, 41, 155–161. [Google Scholar] [CrossRef]

- Vertal, M.; Cakyova, K.L.; Pencik, J.; Beckovsky, D.; Vargova, A.; Jan, V. Thermal Performance of Two Different Green Roofs throughout Three Winters in Slovakia. Energy Build. 2025, 344, 116024. [Google Scholar] [CrossRef]

- Zirkelbach, D.; Mehra, S.-R.; Sedlbauer, K.-P.; Künzel, H.-M.; Stöckl, B. A Hygrothermal Green Roof Model to Simulate Moisture and Energy Performance of Building Components. Energy Build. 2017, 145, 79–91. [Google Scholar] [CrossRef]

- Libralato, M.; De Angelis, A.; Tornello, G.; Saro, O.; D’Agaro, P.; Cortella, G. Evaluation of Multiyear Weather Data Effects on Hygrothermal Building Energy Simulations Using WUFI Plus. Energies 2021, 14, 7157. [Google Scholar] [CrossRef]

- Shugai, G. Modeling and Simulation of Non-Newtonian Fluid Flow Using COMSOL Multiphysics®. Annu. Trans. Nord. Rheol. Soc. 2025, 33, 117–126. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Bakkour, A.; Amziane, S.; Belarbi, R. A Comparative Study of Energy Performance of Green, White, and Gravel Roofs in a Temperate Climate through In-Situ Measurement and Dynamic Simulation. Energy Build. 2024, 320, 114630. [Google Scholar] [CrossRef]

- Nusser, B.; Teibinger, M. Coupled Heat and Moisture Transfer in Building Components-Implementing WUFI Approaches in COMSOL Multiphysics. In Proceedings of the Comsol Conference Europe, Milan, Italy, 10–12 October 2012. [Google Scholar]

- Patent PP 50032-2009. Available online: https://wbr.indprop.gov.sk/WebRegistre/Patent/Detail/50032-2009?csrt=14595615948903669724 (accessed on 29 July 2025).

- Chabada, M.; Durica, P.; Juras, P. Experimental Analysis of the Influence of Seasonality on the Temperature Regime of Extensive Roofs in Central Europe. Buildings 2024, 14, 812. [Google Scholar] [CrossRef]

- de Myttenaere, A.; Golden, B.; Le Grand, B.; Rossi, F. Mean Absolute Percentage Error for Regression Models. Neurocomputing 2016, 192, 38–48. [Google Scholar] [CrossRef]

- Chen, P.-Y. Effects of Meteorological Variables and Substrate Moisture on Evapotranspiration and Thermal Performance of a Green Roof in a Subtropical Climate. Ecol. Eng. 2022, 180, 106663. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Srebric, J. A Heat Transfer Model for Assessment of Plant Based Roofing Systems in Summer Conditions. Build. Environ. 2012, 49, 310–323. [Google Scholar] [CrossRef]

- Charpentier, S. Simulation of Water Regime and Sensible Heat Exchange Phenomena in Green Roof Substrates. Vadose Zone J. 2015, 14, vzj2014.07.0090. [Google Scholar] [CrossRef]

| Simulation Tool | Application | Strengths | Limitations | Suitability for Green Roof Studies |

|---|---|---|---|---|

| WUFI (Fraunhofer IBP, Germany) | Coupled heat and moisture (HAM) in multilayer assemblies | Validated against experiments, good representation of transient hygrothermal processes, practical input of material properties | Simplified vegetation model (empirical evapotranspiration), limited representation of plant physiology | High—suitable for hygrothermal parametric studies |

| EnergyPlus (US DOE) | Whole-building energy balance | Strong for HVAC, comfort and annual performance, integration with weather files | Limited treatment of transient moisture, vegetation represented in a simplified manner | Medium—useful for energy demand, less accurate for HAM in substrates |

| TRNSYS University of Wisconsin–Madison, Solar Energy Laboratory (USA) | Dynamic building energy simulation | Modular structure, good for system integration and long-term performance | Limited hygrothermal detail in multilayer structures | Medium—good for annual system studies, weaker for substrate-level processes |

| COMSOL Multiphysics COMSOL AB, Sweden | General Multiphysics PDE solver | High flexibility, possibility to couple plant physiology, detailed physics | Requires high expertise, significant computational resources | High (research level)—best for detailed process detail, not practical for parametric studies |

| Layer | Density [kg/m3] | Porosity [m3/m3] | Specific Heat Capacity [J/kgK] | Thermal Conductivity [W/mK] | Diffusion Resistance [-] |

|---|---|---|---|---|---|

| Sedum | 1500 | 0.5 | 1000 | 0.2 | 5 |

| Substrate | 1300 | 0.65 | 1500 | 0.9 | 3.3 |

| Hydroaccumulation Board | 250 | 0.9 | 1400 | 1 | 5.7 |

| Waterproofing Membrane | 1900 | 0.001 | 1000 | 0.5 | 30,000 |

| Thermal insulation | 100 | 0.95 | 800 | 0.045 | 1 |

| Vapor Barrier | 113 | 0.001 | 1810 | 0.27 | 67,800 |

| Trapezoidal Sheet | 7800 | 0.001 | 450 | 46 | 6400 |

| Exterior (Left Side) | ||

|---|---|---|

| Name | Unit | Value |

| Heat Resistance/Includes Long-wave Radiation | [(m2K)/W] | 0.0526/Yes |

| Short-wave Radiation Absorptivity | [-] | 0.6 |

| Long-wave Radiation Absorptivity | [-] | 0.9 |

| Adhering Fraction of Rain | [-] | 1.0 |

| Explicit Radiation Balance | [-] | Yes |

| Terrestrial Short-wave Reflectivity | [-] | 0.2 |

| Terrestrial Long-wave Emissivity | [-] | 0.9 |

| Terrestrial Long-wave Reflectivity | [-] | 0.1 |

| Cloud Index | [-] | 0.1 |

| Temperature at Level | Temperature Difference | Fluctuation of Actual Roof [°C] | Fluctuation Simulation [°C] | Fluctuation Difference | Mean Absolute Percentage Error (MAPE) [%] | |

|---|---|---|---|---|---|---|

| MAX | MIN | |||||

| M | 2.60 | 1.42 | 29.15 | 30.33 | 1.18 | 4.05 |

| TI | 0.09 | 1.48 | 15.41 | 14.02 | 1.39 | 9.02 |

| VB | 0.34 | 0.16 | 3.27 | 3.76 | 0.49 | 14.99 |

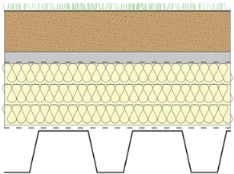

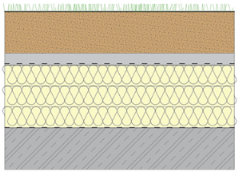

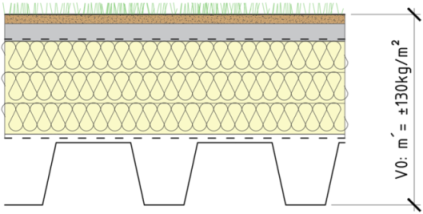

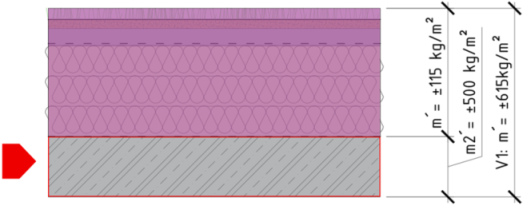

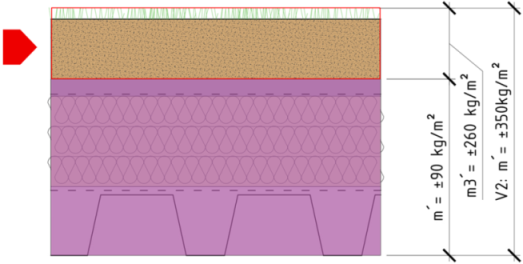

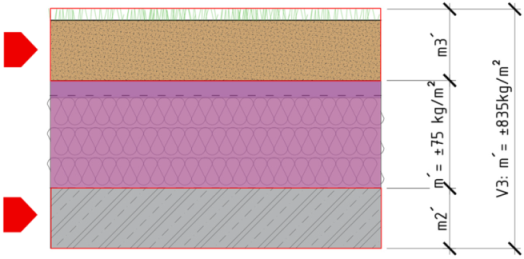

| Variant | Change | Main Purpose | Graphic Scheme |

|---|---|---|---|

| V0 | Reference green roof | Real structure Calibration model |  |

| V1 | Modification of supporting structure (sheet metal → reinforced concrete) | Investigates the accumulation capacity of reinforced concrete |  |

| V2 | Modification of substrate thickness (30 mm → 200 mm) | Impact of substrate thickness |  |

| V3 | Combination V1 and V2 | Synergy of both changes |  |

| Temperature [°C] | ||||||

|---|---|---|---|---|---|---|

| M | VB | |||||

| MAX | MIN | Difference | MAX | MIN | Difference | |

| V0 | 31.29 | 10.34 | 20.96 | 25.04 | 20.00 | 5.04 |

| V1 | 31.27 | 10.30 | 20.97 | 23.35 | 20.00 | 3.35 |

| V2 | 23.05 | 17.19 | 5.86 | 25.16 | 20.00 | 5.16 |

| V3 | 23.05 | 17.13 | 5.92 | 23.31 | 20.00 | 3.35 |

| Variant | Graphic Scheme | Percentage of Weight |

|---|---|---|

| V0 |  | 100% |

| V1 |  | 473% |

| V2 |  | 269% |

| V3 |  | 642% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chabada, M.; Juras, P. Numerical Study: Substrate Thickness and Type of Roof Structure and Their Impact on the Thermal Behavior of Green Roofs. Buildings 2025, 15, 3240. https://doi.org/10.3390/buildings15173240

Chabada M, Juras P. Numerical Study: Substrate Thickness and Type of Roof Structure and Their Impact on the Thermal Behavior of Green Roofs. Buildings. 2025; 15(17):3240. https://doi.org/10.3390/buildings15173240

Chicago/Turabian StyleChabada, Marek, and Peter Juras. 2025. "Numerical Study: Substrate Thickness and Type of Roof Structure and Their Impact on the Thermal Behavior of Green Roofs" Buildings 15, no. 17: 3240. https://doi.org/10.3390/buildings15173240

APA StyleChabada, M., & Juras, P. (2025). Numerical Study: Substrate Thickness and Type of Roof Structure and Their Impact on the Thermal Behavior of Green Roofs. Buildings, 15(17), 3240. https://doi.org/10.3390/buildings15173240