Mechanical Behavior Analysis of Pipe Roof Using Different Arrangements in Tunnel Construction

Abstract

1. Introduction

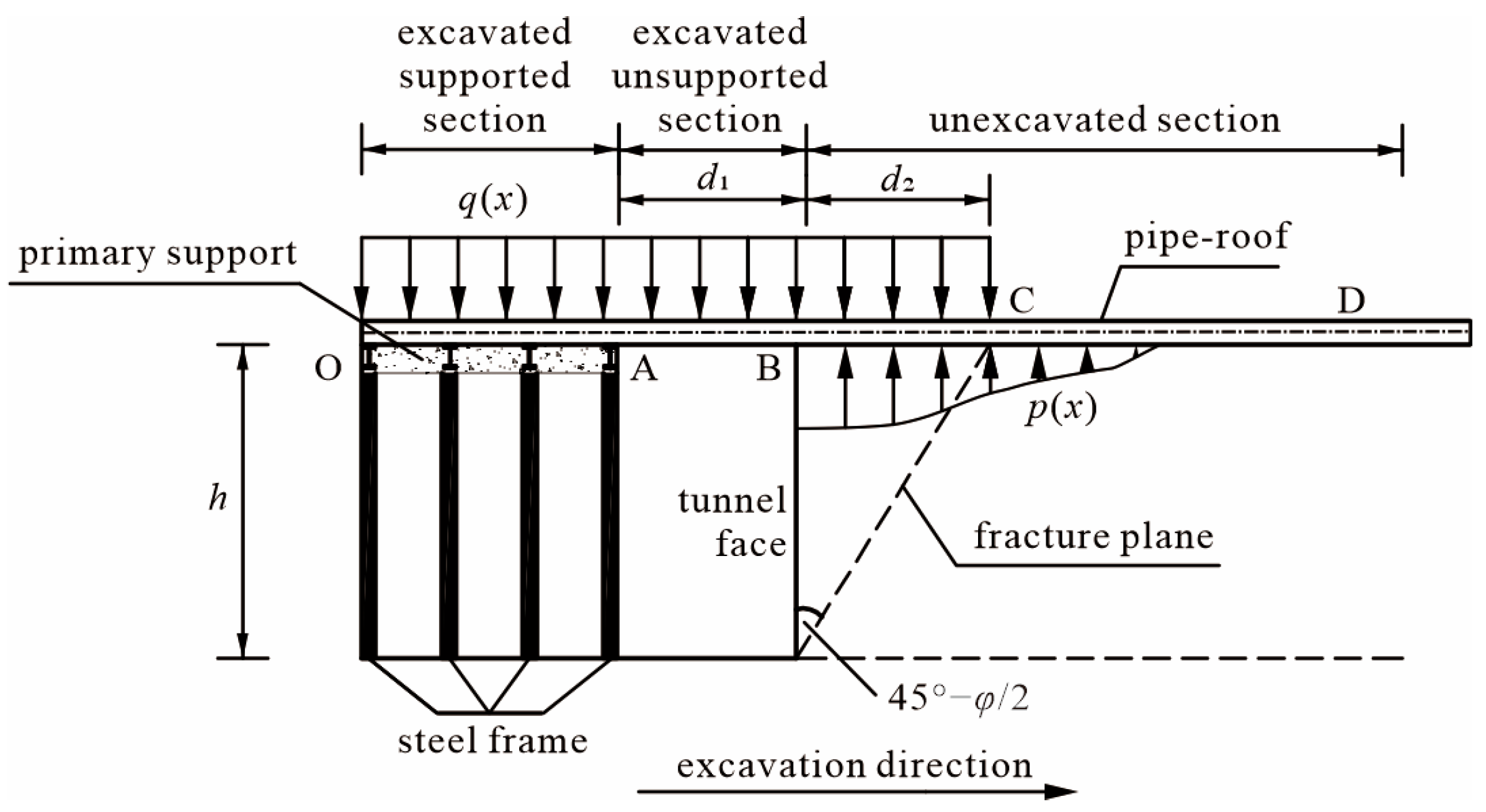

2. Modeling Assumptions and Mechanical Models

2.1. Modeling Assumptions

- (1)

- The pipe roof is modeled as a beam embedded in a Pasternak elastic foundation, while the viscoelastic response of the grouting materials and the creep behavior of the weak surrounding rock are neglected.

- (2)

- The maximum loosening range of the surrounding rock in front of the tunnel face (within the fracture plane) is considered as the range of longitudinal load acting on the pipe roof. The angle between the tunnel face and the fracture plane is 45° φ/2. Assuming the fracture plane starts at the toe of the slope in front of the tunnel face, the range of loads acting on the pipe roof in front of the tunnel face is determined as d = h × tan(45° φ/2).

- (3)

- The load q(x) is assumed to be uniformly distributed, and the pipe roof experiences zero surrounding rock pressure in the area where the surrounding rock is not loosened.

- (4)

- The pipe roof and the initial support jointly bear the pressure of the surrounding rock in the OA section. In the junction between the initial support and the pipe roof, the assumption is made that the pipe roof and initial support undergo deformation concurrently.

- (5)

- Considering the delayed effect of the initial support, point A can be considered as a fixed end with the certain initial displacement and the rotation . The value of initial displacement can be determined based on the measured settlement at this location.

- (6)

- The surrounding rock pressure is determined based on the formula provided in the “Specifications for Design of Highway Tunnels” (JTG D70-2004) [33].

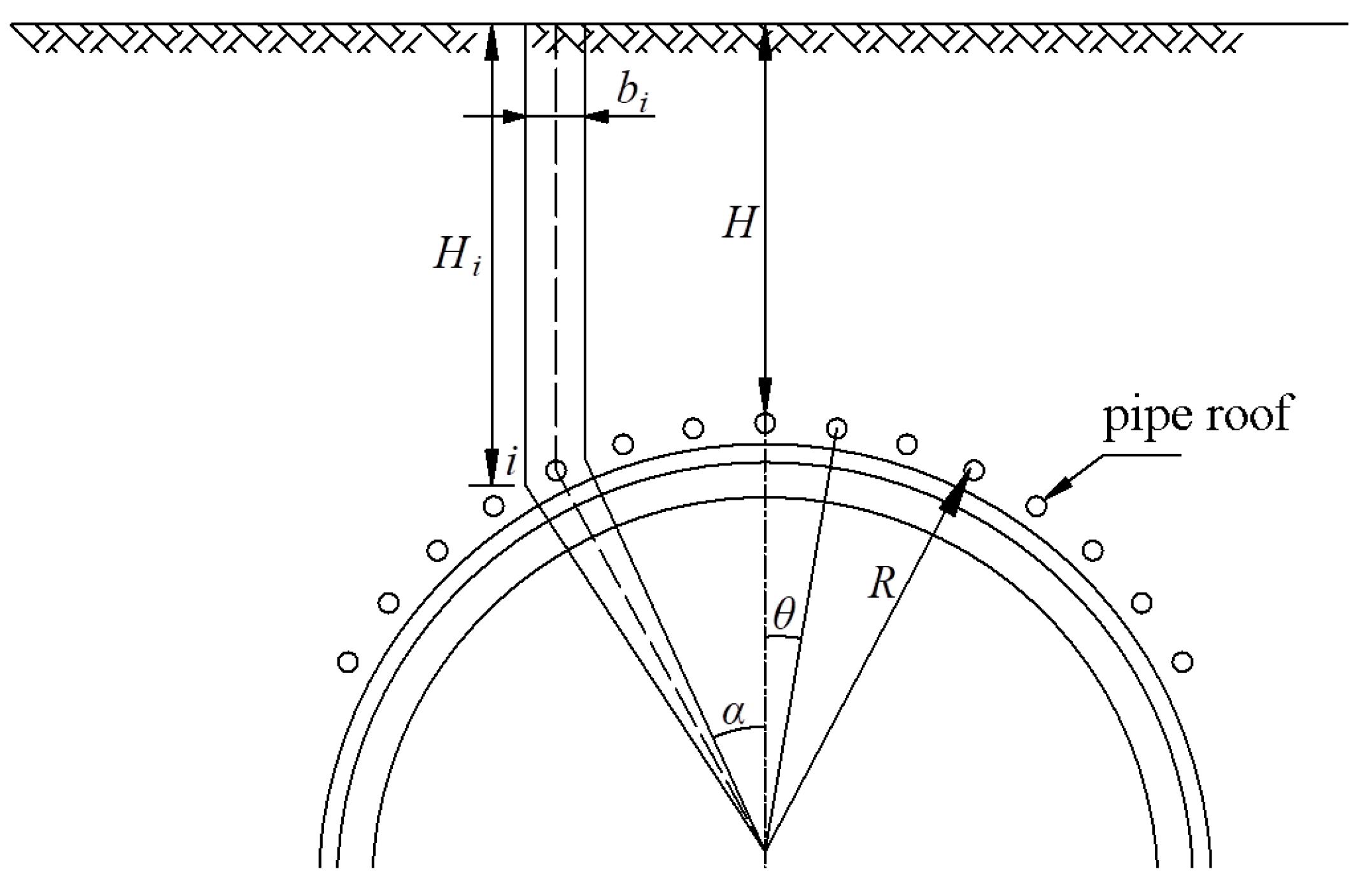

2.2. Mechanical Models of the Pipe Roof

- (1)

- Model establishment

- (2)

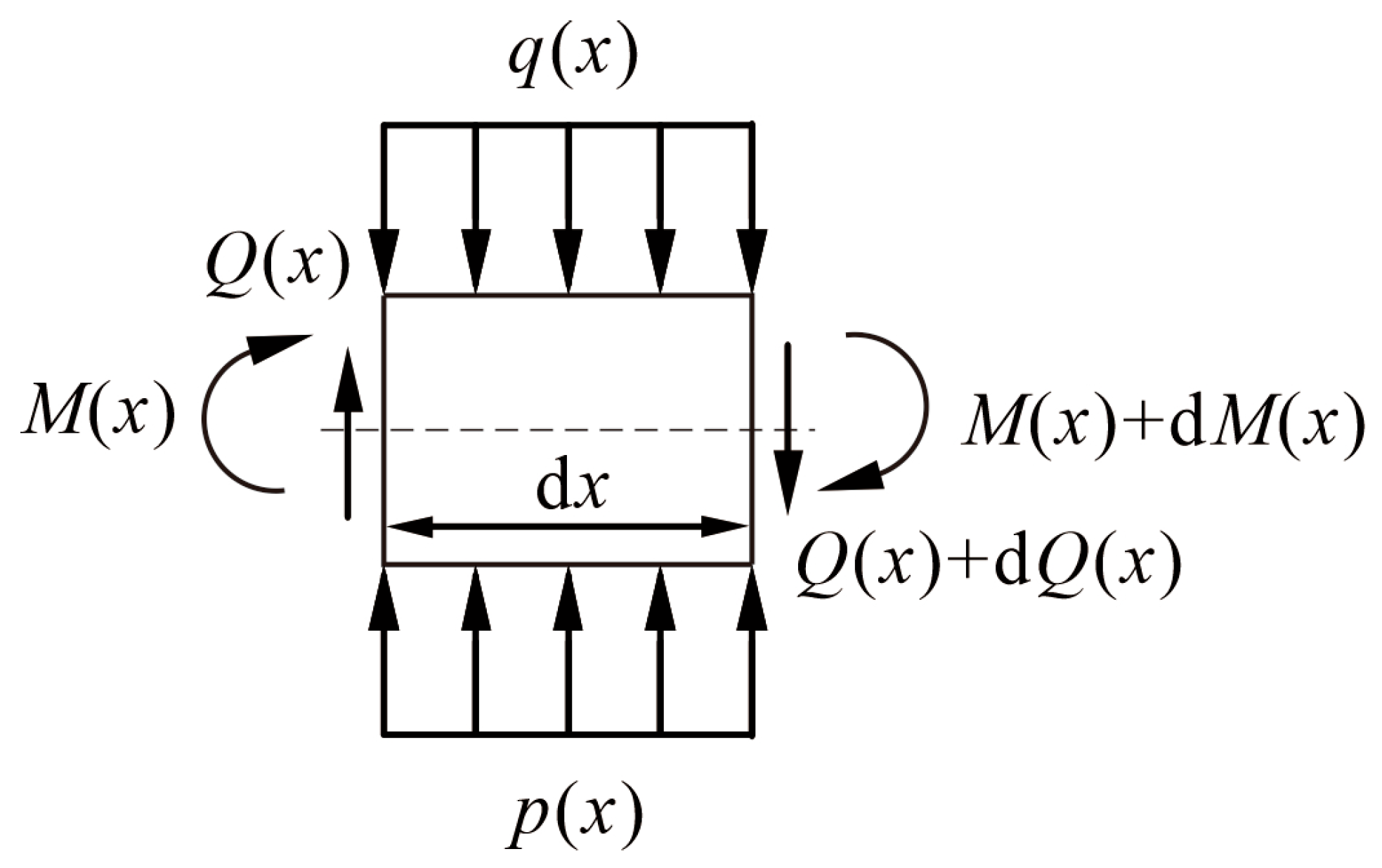

- Deflection differential equation

- (1)

- Model a

- (2)

- Model b

3. Solution of the Elastic Foundation Beam Model

3.1. Solution of the Deflection Differential Equations for the Pipe Roof

- (1)

- Model a

- (2)

- Model b

3.2. Deflection Equation of Pipe Roof: In–Out ASA

- (1)

- Model a

- (2)

- Model b

3.3. Deflection Equation of Pipe Roof: Out–In ASA

- (1)

- Model a

- (2)

- Model b

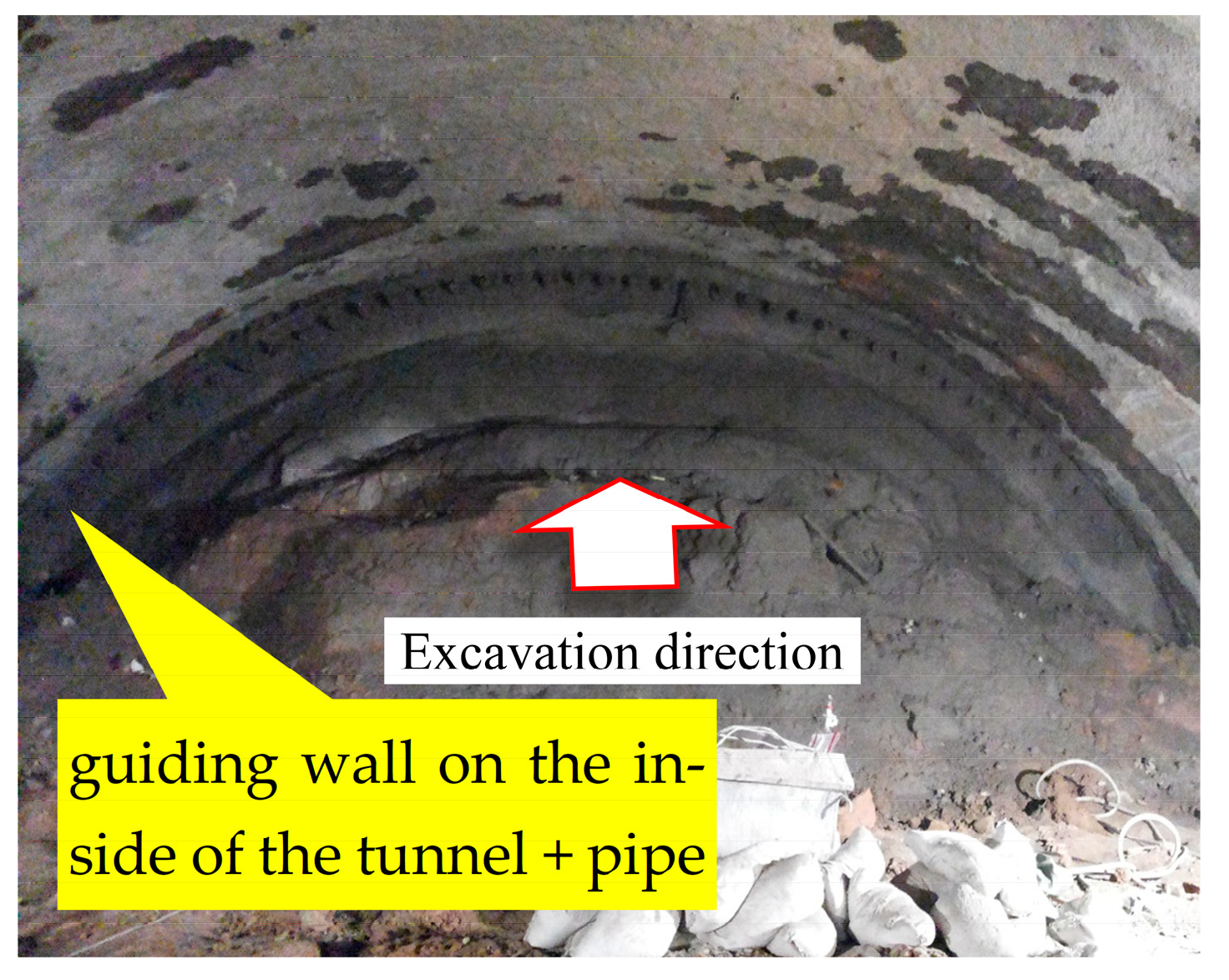

4. General Situation of Construction and Measured Results

4.1. Topography and Geology

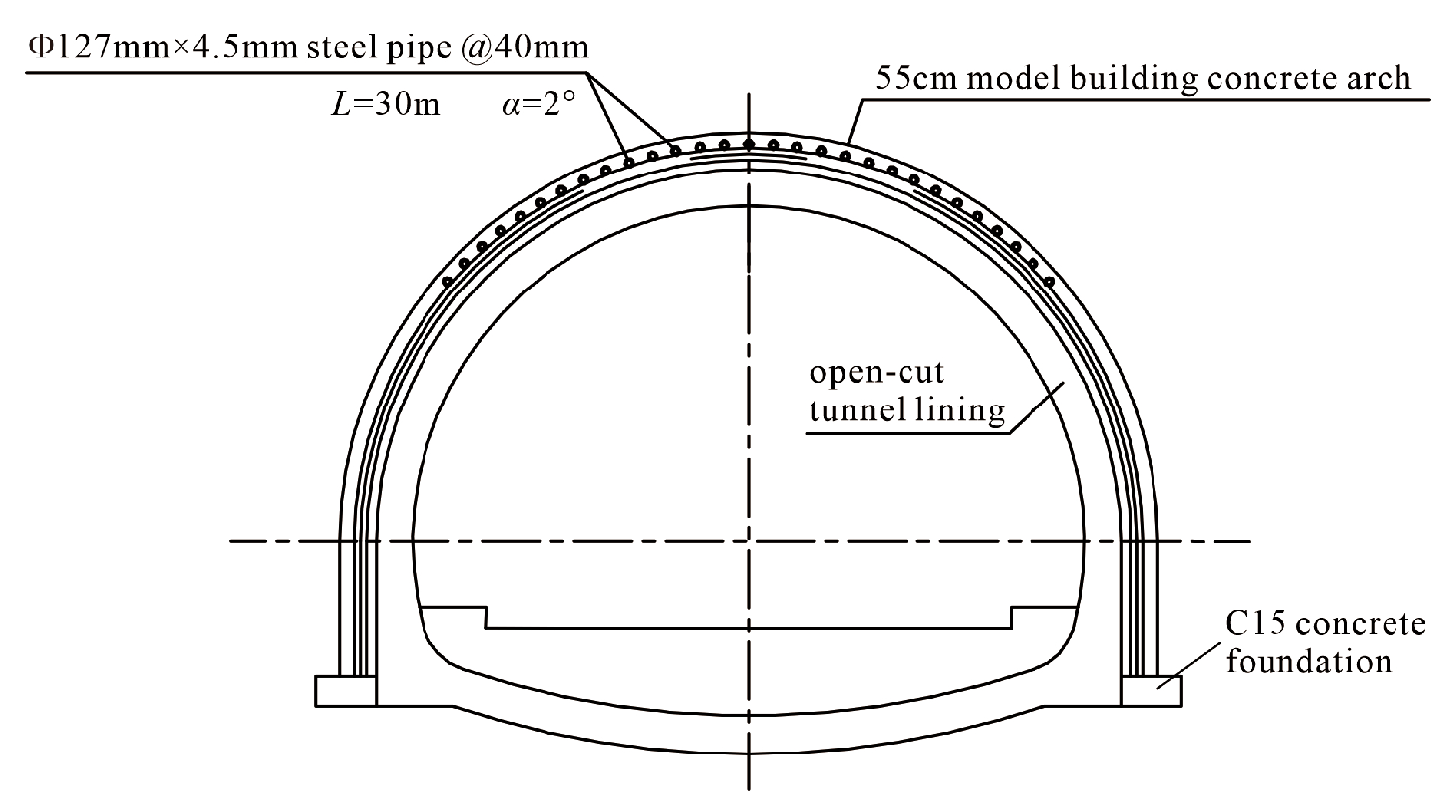

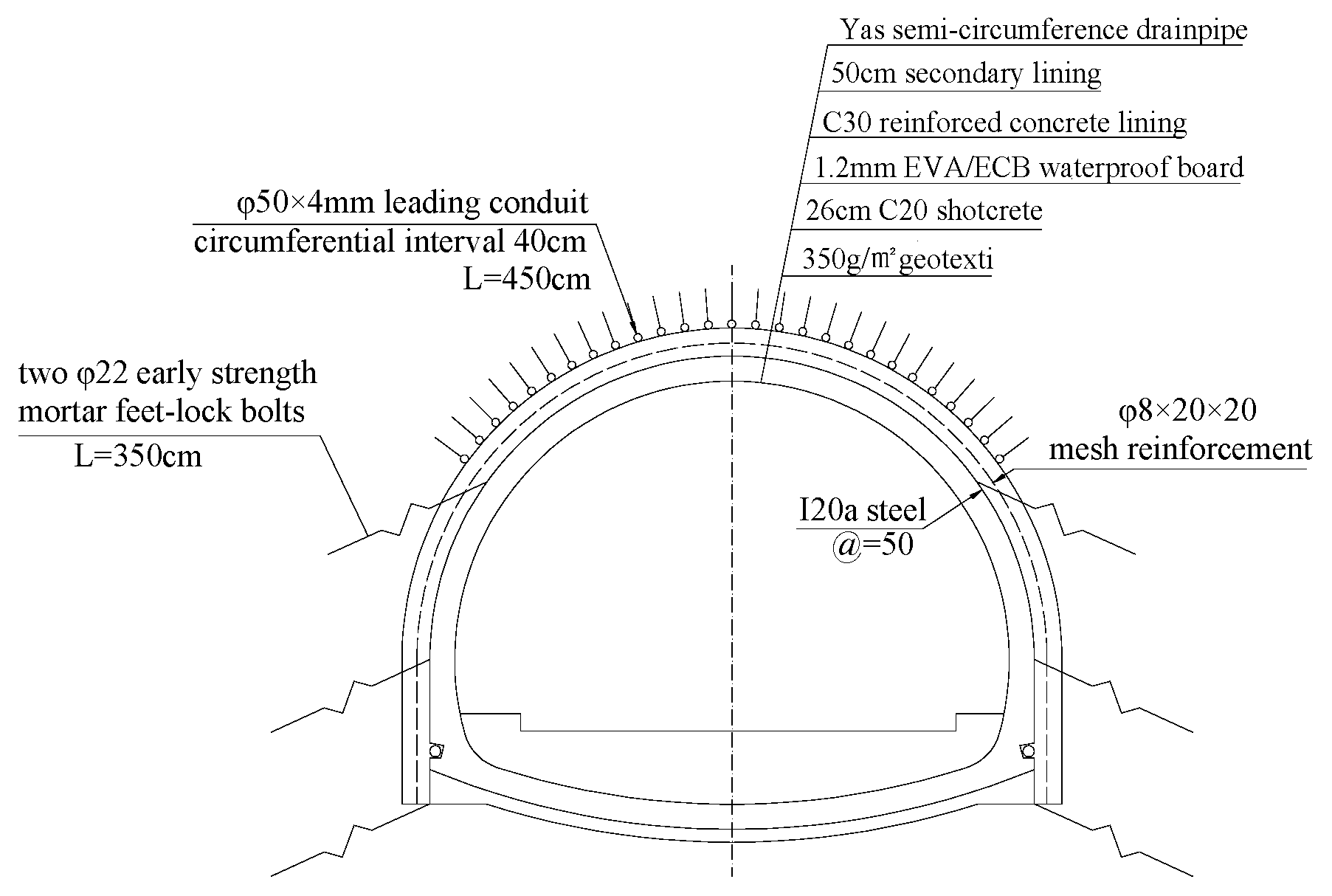

4.2. Design and Construction of the Left-Line Tunnel Entrance

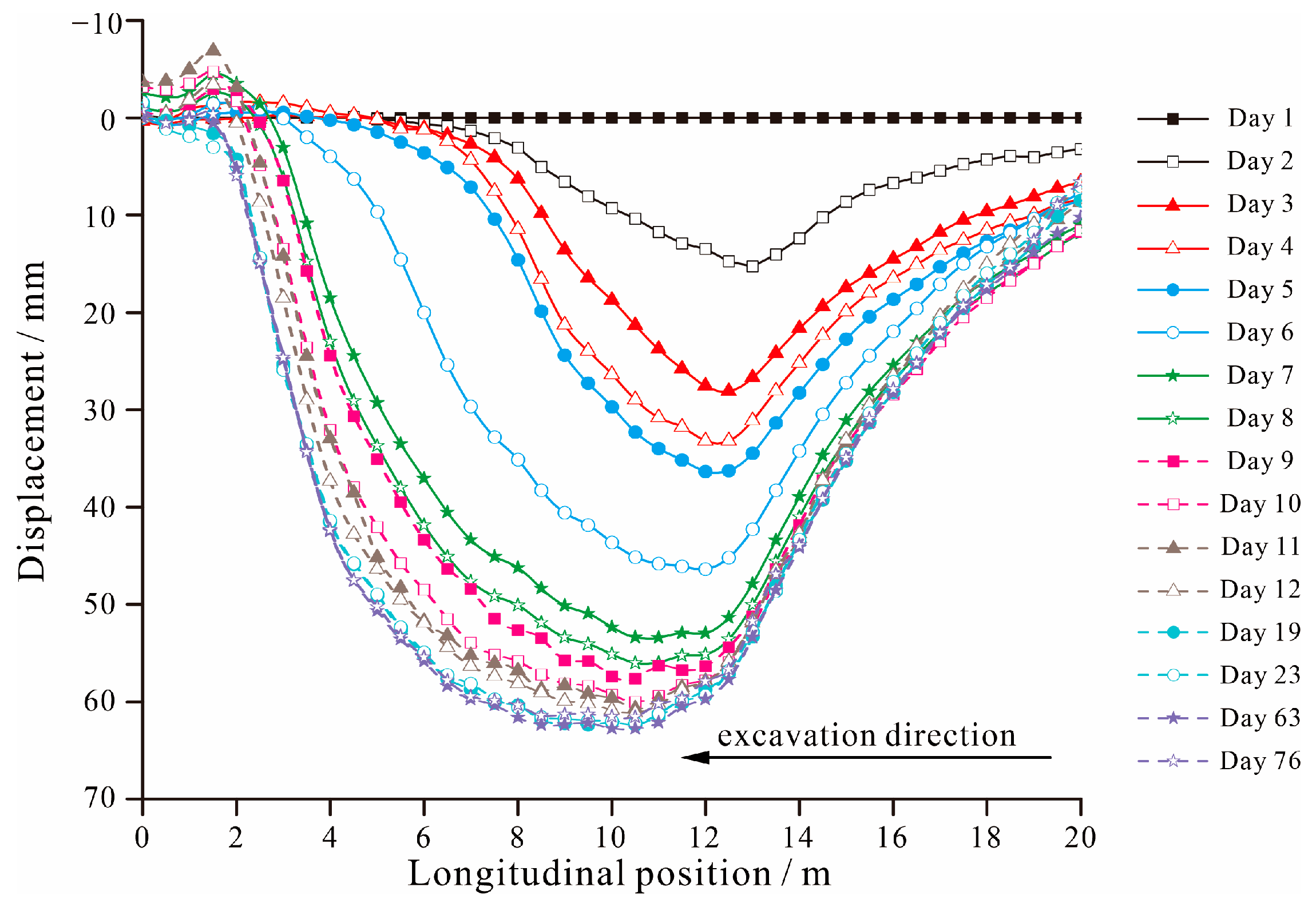

4.3. Measured Results Analysis of the Left-Line Tunnel Entrance

5. Discussion on the Theoretical Solution

5.1. Comparison and Validation with Measured Results

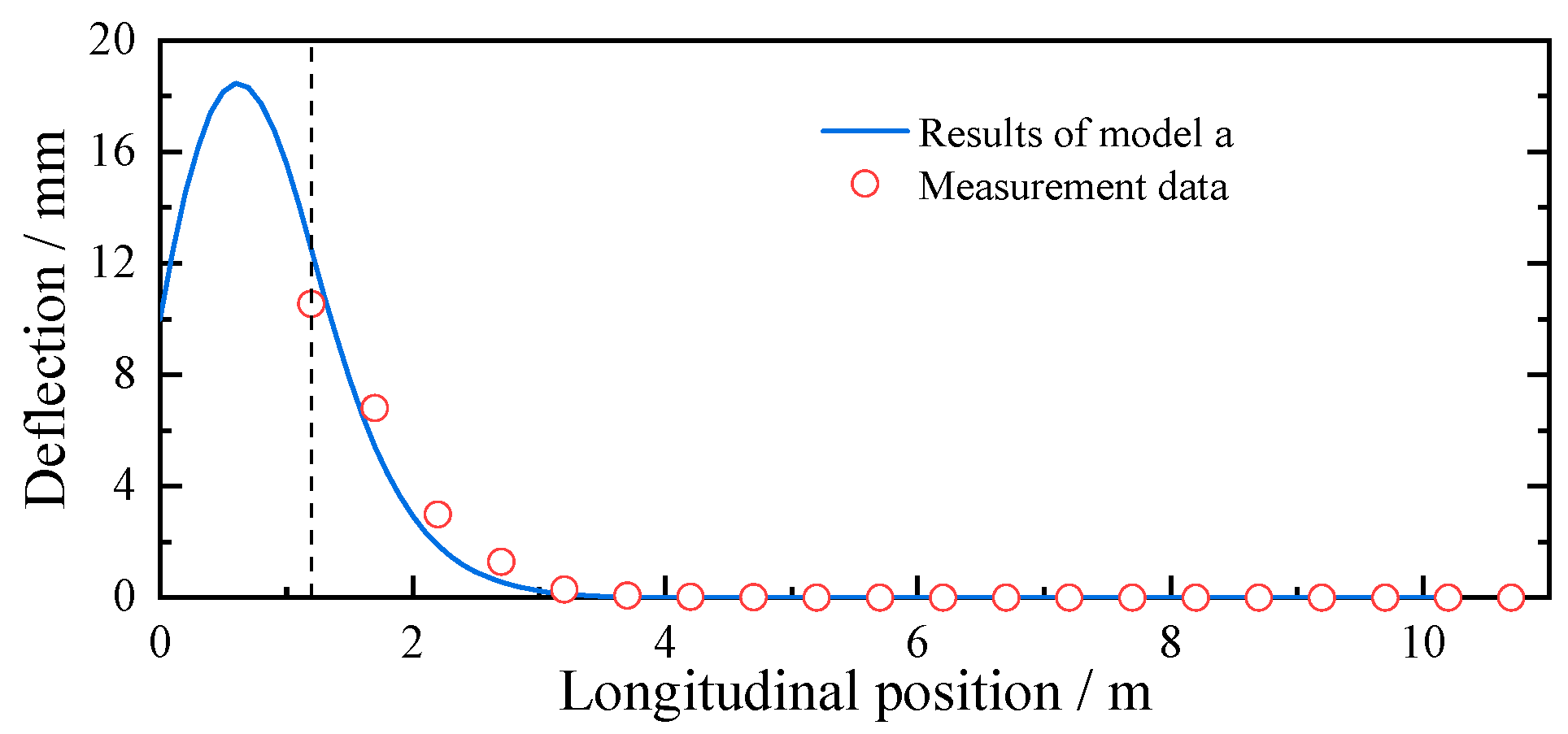

- (1)

- Model a

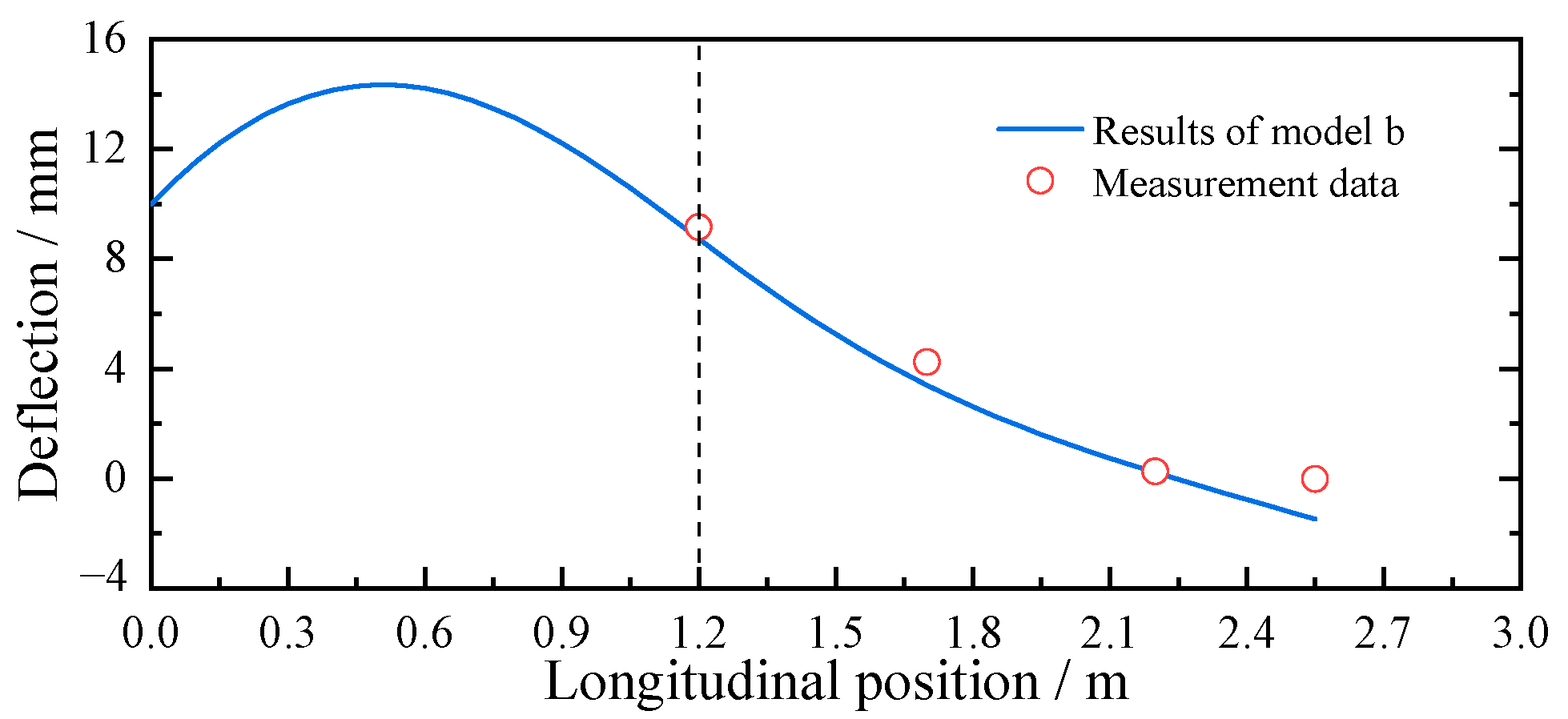

- (2)

- Model b

- (3)

- Error Analysis

5.2. Parametric Sensitivity Analysis of Model b

6. Conclusions

- (1)

- The corresponding boundary conditions for the In–Out ASA and Out–In ASA models are proposed based on the actual site conditions. Using the Pasternak two-parameter elastic foundation beam method, deflection calculation approaches for the pipe roof in both In–Out ASA and Out–In ASA models are established.

- (2)

- Field monitoring results indicate that the pipe roof settlement increases progressively with tunnel excavation but stabilizes after the installation of the initial support. Slight upward deflection near the embedded portal arch suggests strong end restraint, contributing to slope stability and overall deformation control. The settlement profile is “trough-shaped,” with minimal displacement at both ends and a maximum near the center, reflecting cumulative effects of excavation-induced loading and boundary conditions. Meanwhile, the Pasternak elastic foundation beam model proposed in this study fits the measured data well, with a maximum error not exceeding 18.4%, validating the rationality of the theoretical solution presented.

- (3)

- The results of the parameter sensitivity analysis indicate that the pipe roof deflection curves for both excavation methods are positively correlated with the initial displacement and rotation, as well as the length of the excavated unsupported section, and negatively correlated with the shear stiffness of the elastic foundation layer and the subgrade reaction coefficient. When the tunnel face is far from the exit, there is little difference between the two excavation methods. However, when the tunnel face is within the excavation disturbance range near the exit, the deflection of the In–Out ASA method is greater than that of the Out–In ASA, and the peak deflection is closer to the tunnel face. This is because the anchoring effect of the portal arch at the exit is absent, causing the pipe roof to be treated as a free end at the exit, which increases the load and the deflection. In addition, the deflection of the pipe roof shows a significant positive correlation with the rock stress. Therefore, when construction conditions at the tunnel exit are met, the Out–In ASA method is recommended. If conditions for advanced support outside the tunnel are lacking, the In–Out ASA method can be used. However, it is necessary to install initial support promptly, reasonably design the excavation advance length, and ensure effective grouting under poor surrounding rock conditions to control pipe roof deformation.

- (4)

- The theoretical solution presented in this study is developed and validated under a set of reasonable assumptions. It can be further improved in the following aspects: (a) The treatment of boundary conditions could be further refined by incorporating rotational spring stiffness or partially restrained conditions, thereby providing a closer representation of realistic end restraints in practice. (b) The applicability of the model may be enhanced by considering 3D effects and the arching interaction between pipe roofs, supported by numerical simulations and field monitoring, to better assess the influence of complex boundary conditions and spatial coupling on the mechanical response.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guan, B.S. Deformation of tunnels with soft surrounding rocks and its control. Tunnel Constr. 2011, 31, 1–17. [Google Scholar]

- Tao, K.; Li, X.L.; Shi, H.L. Construction technology and quality control of big-long pipe-roof in shallowly buried section of tunnel. Road Mach. Constr. Mech. 2010, 27, 65–69. [Google Scholar]

- Gou, D.M.; Yang, J.S.; Zhang, G. Deformation monitoring and mechanical behaviors of pipe-roof in shallow tunnels. Chin. J. Rock Mech. Eng. 2007, 26, 1258–1264. [Google Scholar]

- Wang, H.T.; Jia, J.Q.; Yu, S. Mechanical behavior and parameter optimization of pipe roof reinforcement applied in tunnel. China J. Highw. Trans. 2010, 23, 78–83. [Google Scholar]

- Zheng, J.J.; Zhang, R.J.; Yang, Q.N. Mechanical mechanism of pipe roofs with variable coefficient of subgrade reaction in shallow tunnels. Chin. J. Geotech. Eng. 2009, 31, 1165–1171. [Google Scholar]

- Jia, J.Q.; Wang, H.T.; Tu, B.X.; Meng, G. Analytical approach and field monitoring for mechanical behaviors of pipe roof reinforcement. Rock Soil Mech. 2010, 31, 1858–1864. [Google Scholar]

- Li, J.; Tan, Z.S.; Yu, Y.; Ni, L.S. Analysis of deformation monitoring and mechanical behaviors of big pipe-roof for shallow-buried large-span tunnel to underpass highway. Chin. J. Rock Mech. Eng. 2011, 30, 3002–3008. [Google Scholar]

- Dong, X.P.; Zhou, S.H.; Hu, X.P. 3D analysis of function of pipe roof applied in soft ground. Chin. J. Geotech. Eng. 2006, 28, 841–846. [Google Scholar]

- Guenther, M.V.; Wulf, S. Optimization of excavation and support in pipe roof supported tunnel sections. Tunn. Undergr. Space Technol. 2006, 21, 404. [Google Scholar] [CrossRef]

- Hefny, A.M.; Tan, W.L.; Pathegama, R.G.; Sharma, J.; Zhao, J. Numerical analysis for umbrella arch method in shallow large scale excavation in weak rocks. Tunn. Undergr. Space Technol. 2004, 19, 1–7. [Google Scholar] [CrossRef]

- Shi, Y.F.; Cai, L.P.; Yang, J.S.; Hu, W.T. Combination reinforcement mechanism of sub-horizontal jet-grouting and pipe roof in water-rich soft stratum. Chin. J. Geotech. Eng. 2015, 37, 101–106. [Google Scholar]

- Yang, Z.F. Study on mechanical characteristics of tunnel entrance reinforced with pipe roof in deep accumulation. Road Mach. Constr. Mech. 2017, 34, 100–103. [Google Scholar]

- Yoo, C.; Shin, H.Y. Deformation behavior of tunnel face reinforced with longitudinal pipes-laboratory and numerical investigation. Tunn. Undergr. Space Technol. 2003, 18, 303–319. [Google Scholar] [CrossRef]

- Hisatake, M.; Ohno, S. Effects of pipe roof supports and the excavation method on the displacements above a tunnel face. Tunn. Undergr. Space Technol. 2008, 23, 120–127. [Google Scholar] [CrossRef]

- Shin, J.H.; Choi, Y.K.; Kwon, O.Y. Model testing for pipe-reinforced tunnel heading in a granular soil. Tunn. Undergr. Space Technol. 2008, 23, 241–250. [Google Scholar] [CrossRef]

- Zhou, S.H. Principles of pipe roof applied to shallow-buried tunnels in soft ground. Chin. J. Rock Mech. Eng. 2005, 24, 2565–2570. [Google Scholar]

- Bai, Q.; Zhao, W.; Sun, Y.; Wang, X. Pipe Curtain Deformation and Surface Subsidence Caused via Excavation of Transverse Pilot Tunnel under Pipe Curtain Support. Sustainability 2023, 15, 11967. [Google Scholar] [CrossRef]

- Chen, S.L.; Chang, S.W.; Qiu, Z.Y.; Tang, C.W.; Zhang, X.L.; Chen, Y. Numerical Model for Rectangular Pedestrian Underpass Excavations with Pipe Roof Preconstruction Method: A Case Study. Appl. Sci. 2023, 13, 5952. [Google Scholar] [CrossRef]

- Jia, P.J.; Zhao, W.; Du, X.; Chen, Y.; Zhang, C.Z.; Bai, Q.; Wang, Z.G. Study on ground settlement and structural deformation for large span subway station using a new pre-supporting system. R. Soc. Open Sci. 2019, 6, 6181035. [Google Scholar] [CrossRef]

- Jia, P.J.; Zhao, W.; Khoshghalb, A.; Ni, P.P.; Jiang, B.F.; Yang Chen, Y.; Li, S.G. A new model to predict ground surface settlement induced by jacked pipes with flanges. Tunn. Undergr. Space Technol. 2020, 98, 103330. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Wu, S.Z.; He, Z.W.; Wei, Y. Field test and numerical simulation of ground settlement in super shallow buried station excavation supported by transverse pipe roof. Front. Earth Sci. 2023, 11, 1136270. [Google Scholar] [CrossRef]

- Lu, B.; Dong, J.C.; Zhao, W.; Du, X.; Cheng, C.; Bai, Q.; Wang, Z.G.; Zhao, N.C.; Han, J.Y. Novel pipe-roof method for a super shallow buried and large-span metro underground station, Undergr. Space 2022, 7, 134–150. [Google Scholar]

- Li, Z.; Yue, X.; Wu, G. Calculation and Analysis of Pipe Joint Settlement Control in Large Back Silting Immersed Tube Tunnel. Sustainability 2023, 15, 7446. [Google Scholar] [CrossRef]

- Chen, L.J.; Zhang, Y.L. Double parameters elastic foundation beam model of feet-lock pipes. Chin. J. Rock Mech. Eng. 2016, 35, 989–999. [Google Scholar]

- Fu, D.X.; Deng, B.; Yang, M.H.; Zhen, B.B. Analytical solution of overlying pipe deformation caused by tunnel excavation based on Pasternak foundation model. Sci. Rep. 2023, 13, 921. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.S.; Kao, C.J.; Shi, J.Y. Dynamic analysis of cylindrical foundations under torsional loading via generic discrete-element models simulating soil stratum. Sci. Rep. 2023, 13, 19163. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Deng, B.; Yang, M.; Fu, D.X. A new approach for evaluating continuous and discontinuous pipeline deformation induced by soil tunnel excavation. Sci. Rep. 2023, 13, 12661. [Google Scholar] [CrossRef]

- Wu, Y.H.; Xiao, C.J.; Chen, F.Q.; Cai, G. Study on mechanical characteristics of pipe umbrella support in shallow buried tunnels. Tunn. Undergr. Space Technol. 2024, 145, 105578. [Google Scholar] [CrossRef]

- Luo, Y.B.; Chen, J.X.; Liu, B.; Chen, L.J.; Xie, J.T. Analysis of Pipe-Roof in Tunnel Exiting Portal by the Foundation Elastic Model. Math. Probl. Eng. 2017, 7, 1–12. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, X.H.; Zhang, X.; Long, L.Y.; Bai, Y.; Huang, B.S. Advancing Shallow Tunnel Construction in Soft Ground: The Pipe-Umbrella Box Jacking Method. Transport. Res. Rec. 2024, 2678, 150–168. [Google Scholar] [CrossRef]

- Wang, H.; Qin, W.M.; Jiao, Y.Y. Stability assessment for highway with large span box culvert jacking underneath: A case study. Can. Geotech. J. 2013, 50, 585–594. [Google Scholar] [CrossRef]

- Li, R.; Zhang, D.L.; Wu, P.; Fang, Q.; Li, A.; Cao, L.Q. Combined Application of Pipe Roof Pre-SUPPORT and Curtain Grouting Pre-Reinforcement in Closely Spaced Large Span Triple Tunnels. Appl. Sci. 2020, 10, 3186. [Google Scholar] [CrossRef]

- JTG D70-2004; Specifications for Design of Highway Tunnels. China Communications Press: Beijing, China, 2004.

- Luo, Y.B.; Chen, J.X.; Huang, P.; Tang, M.Q.; Qiao, X.; Liu, Q. Deformation and mechanical model of temporary support sidewall in tunnel cutting partial section. Tunn. Undergr. Space Technol. 2017, 61, 40–49. [Google Scholar] [CrossRef]

- Luo, Y.B.; Chen, J.X.; Chen, Y.; Diao, P.S.; Qiao, X. Longitudinal deformation profile of a tunnel in weak rock mass by using the back analysis method. Tunn. Undergr. Space Technol. 2018, 71, 478–493. [Google Scholar] [CrossRef]

- Hu, B. Research on Advance Supporting Effect of Pipe Roof of Dingjiashan Tunnel in Soft and Crumble Surrounding Rocks. Master’s Thesis, Huazhong University of Science & Technology, Wuhan, China, 2011. [Google Scholar]

- Chen, C.N.; Huang, W.Y.; Tseng, C.T. Stress redistribution and ground arch development during tunneling. Tunn. Undergr. Space Technol. 2011, 26, 228–235. [Google Scholar] [CrossRef]

- Rong, Y.; Du, W.; Sun, Y.; Xiong, F.; Liu, L.; Yu, S.; Jie, G. Study on Stress Deformation of Pipe Shed in Shallow Buried Tunnel Considering Micro-Arch Effect. Adv. Civ. Eng. 2024, 2024, 6651993. [Google Scholar] [CrossRef]

- Barounis, N.; Philpot, J. Estimation of the static vertical subgrade reaction modulus ks from CPT for shallow foundations on cohesionless soils. SESOC J. 2017, 30, 58–63. [Google Scholar]

- Barounis, N.; Philpot, J. Estimation of the static vertical subgrade reaction modulus ks from CPT. In Cone Penetration Testing 2018, Proceedings of the 4th International Symposium on Cone Penetration Testing (CPT'18), Delft, The Netherlands, 21–22 June 2018; CRC Press: Boca Raton, FL, USA, 2018; pp. 123–128. [Google Scholar]

| E | I | k | Gp | d2 | b | γ | φ |

|---|---|---|---|---|---|---|---|

| GPa | m4 | kN/m3 | kN/m | m | m | kN/m3 | ° |

| 69.89 | 12.77 | 40,000 | 10,000 | 1.35 | 0.4 | 20 | 22 |

| MaxAE | MaxRE | RMSE | MAE | R2 | |

|---|---|---|---|---|---|

| Model a | 1.939 | −18.4% | 0.595 | 0.257 | 0.949 |

| Model b | 1.459 | 19.8% | 0.871 | 0.692 | 0.945 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Gao, B.; Chen, J.; Wang, C.; Wang, M.; Qiao, X. Mechanical Behavior Analysis of Pipe Roof Using Different Arrangements in Tunnel Construction. Buildings 2025, 15, 3221. https://doi.org/10.3390/buildings15173221

Luo Y, Gao B, Chen J, Wang C, Wang M, Qiao X. Mechanical Behavior Analysis of Pipe Roof Using Different Arrangements in Tunnel Construction. Buildings. 2025; 15(17):3221. https://doi.org/10.3390/buildings15173221

Chicago/Turabian StyleLuo, Yanbin, Benxian Gao, Jianxun Chen, Chuanwu Wang, Miao Wang, and Xiong Qiao. 2025. "Mechanical Behavior Analysis of Pipe Roof Using Different Arrangements in Tunnel Construction" Buildings 15, no. 17: 3221. https://doi.org/10.3390/buildings15173221

APA StyleLuo, Y., Gao, B., Chen, J., Wang, C., Wang, M., & Qiao, X. (2025). Mechanical Behavior Analysis of Pipe Roof Using Different Arrangements in Tunnel Construction. Buildings, 15(17), 3221. https://doi.org/10.3390/buildings15173221