Explainable Prediction of UHPC Tensile Strength Using Machine Learning with Engineered Features and Multi-Algorithm Comparative Evaluation

Abstract

1. Introduction

2. Materials and Methodologies

2.1. Database Preparation and Pre-Processing

2.1.1. Experimental Database Acquisition and Engineered Feature Selection

2.1.2. Data Preprocessing

2.2. Algorithm Selection and Hyperparameter Optimization

2.2.1. Algorithm Selection

- (1)

- Bayesian Ridge Regression (BRR)

- (2)

- Support Vector Regression (SVR)

- (3)

- Artificial Neural Network (ANN)

- (4)

- Random Forest (RF)

- (5)

- Gradient Boosting Regression Tree (GBRT)

- (6)

- Lightweight Gradient Booster (LightGBM)

- (7)

- Categorical Boosting (CatBoost)

2.2.2. Hyperparameter Optimization

2.3. SHAP Interpretability Analysis

2.3.1. Theoretical Basis of SHAP Values

2.3.2. Feature Importance Quantification Method

2.3.3. Explanatory Analysis Strategies

2.4. Experimental Setup and Evaluation Metrics

2.4.1. Sample Division and Validation Strategy

2.4.2. Evaluation Indexes

2.5. Flow Chart

- First, sample data are collected through a literature review.

- Second, feature selection, feature fusion, missing value imputation, outlier handling, data standardization, data encoding, and data partitioning are performed on the sample data.

- Third, seven ML algorithms are selected, and models are trained using five-fold cross-validation under both default hyperparameter values and hyperparameter tuning conditions, and model performance is evaluated using an independent test set.

- Fourth, the seven algorithms’ performance is compared both with default and tuned hyperparameters and between their pre- and post-tuning states.

- Finally, based on SHAP values, a global importance-ranking analysis of the factors influencing the UHPC tensile strength is performed, and an in-depth analysis of the nonlinear relationship between tensile strength and key influencing factors is conducted with the combination of PDP.

3. Results and Discussion

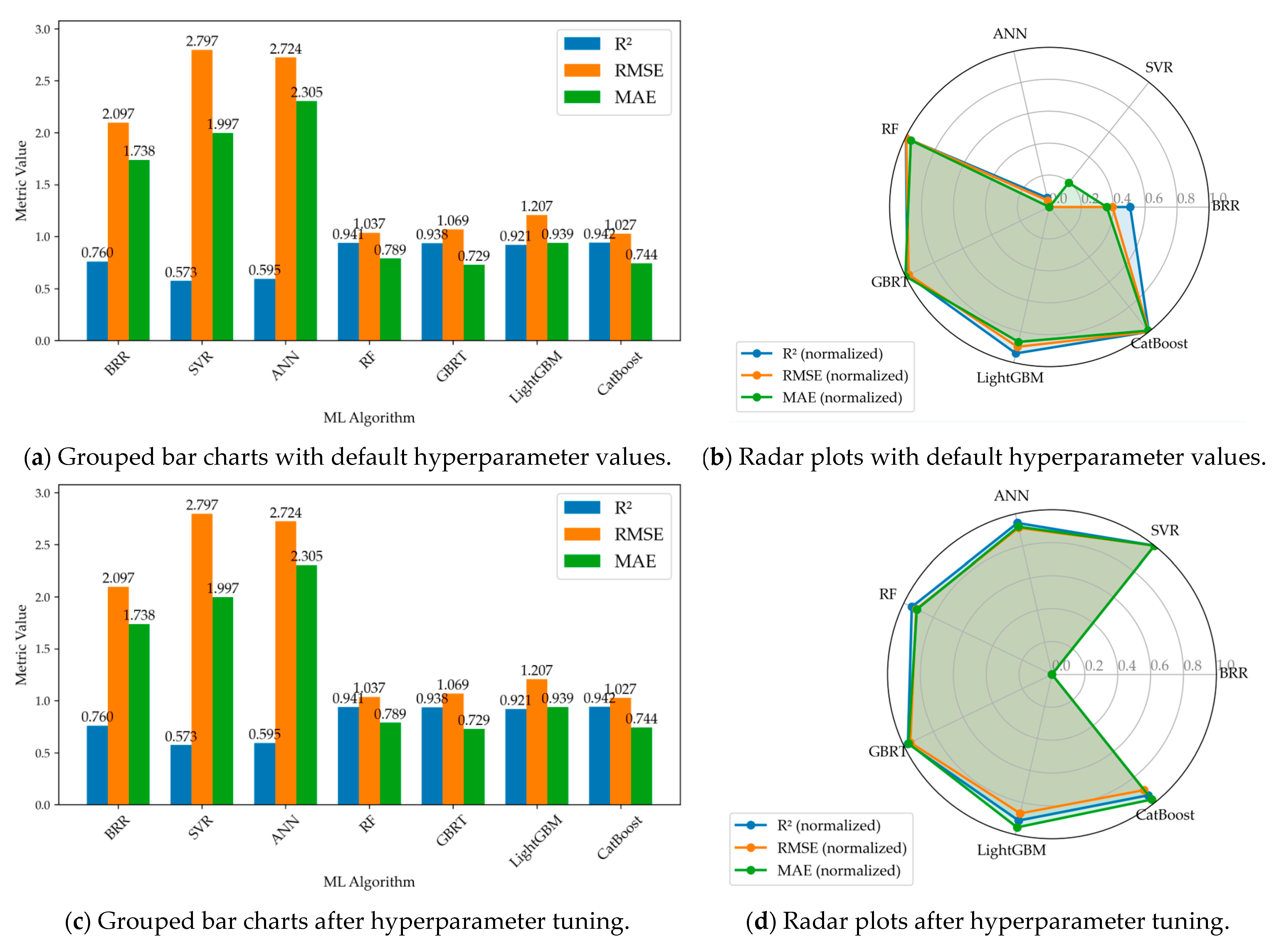

3.1. Multi-Algorithm Comparative Evaluation

3.2. Model Interpretation

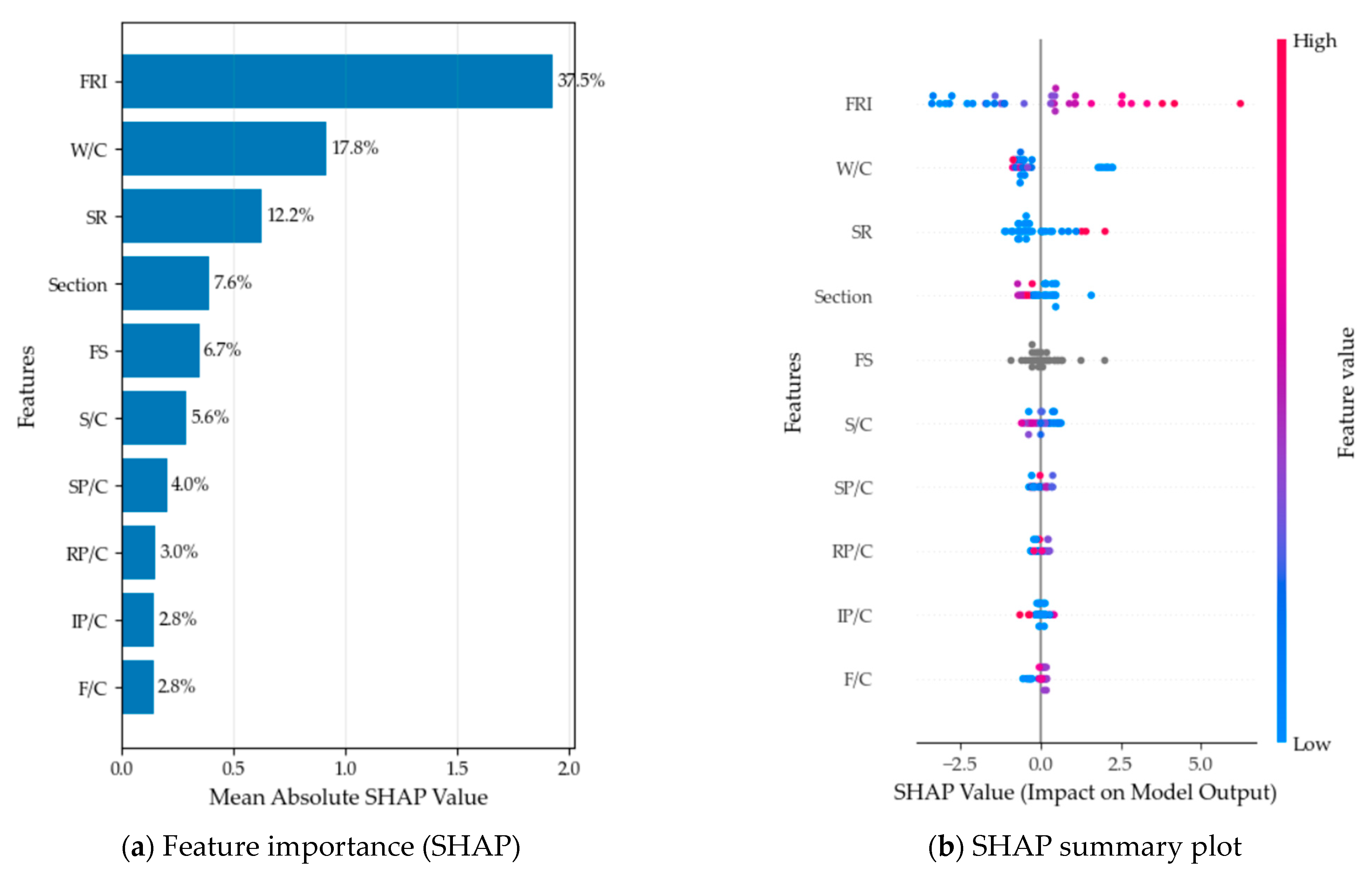

3.2.1. Feature Importance Analysis

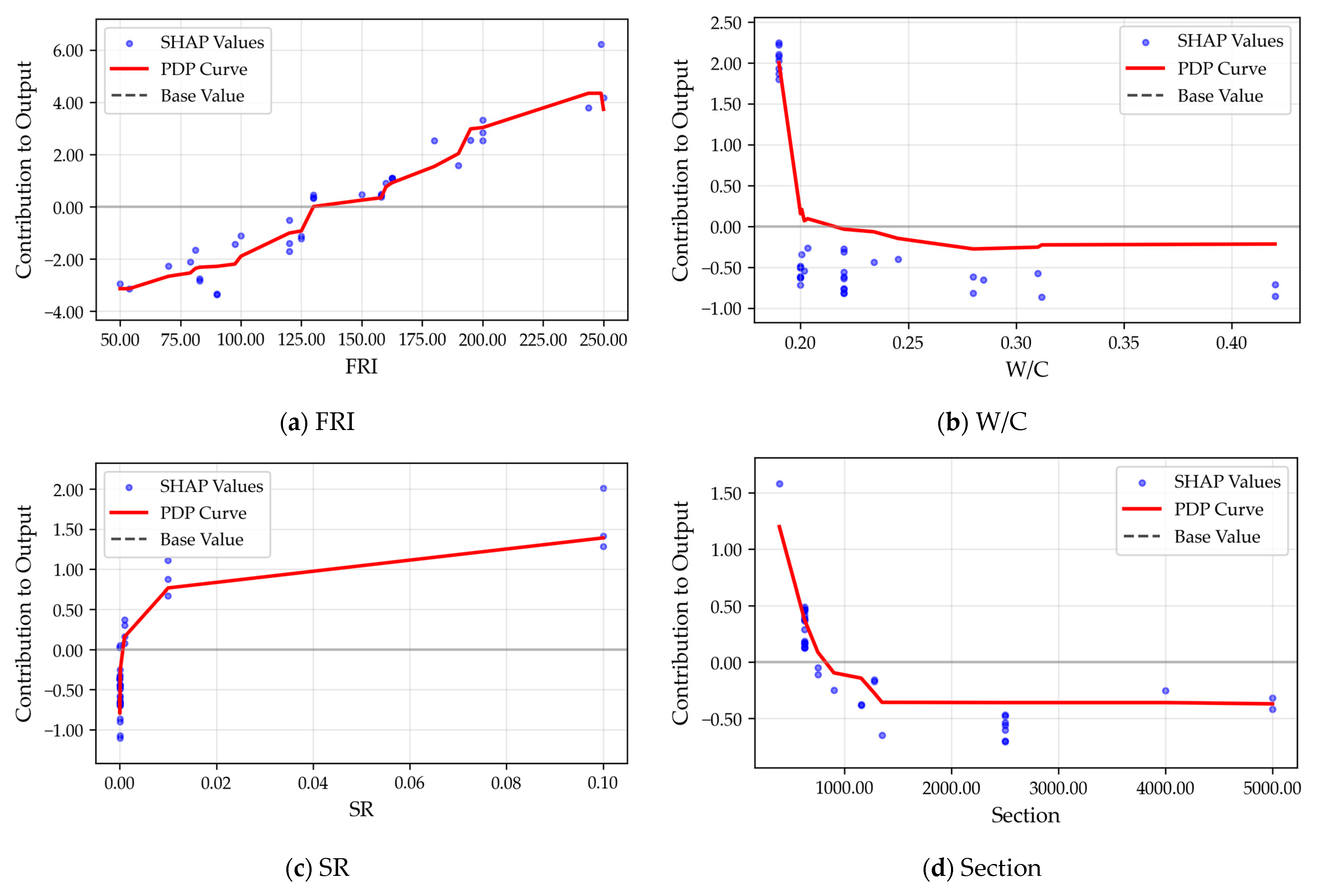

3.2.2. Marginal Effect Analysis of Key Features

4. Conclusions

- (1)

- To maximize the utility of the limited dataset, several feature engineering strategies are implemented on the basis of material science analysis. These strategies include missing value imputation, outlier handling, feature selection, and feature fusion. This ensures that the feature variables are consistent with the physical and mechanical principles of UHPC while satisfying the data distribution and interpretability requirements of ML algorithms. Consequently, it prevents the occurrence of model bias resulting from the absence of physical laws or improper algorithm adaptation.

- (2)

- The quantitative evaluation of seven ML algorithms reveals that, under default hyperparameter settings, ensemble algorithms such as RF, GBRT, LightGBM, and CatBoost exhibit superior prediction performance, as indicated by an R2 value > 0.92. Conversely, traditional ML algorithms, including BRT, SVR, and ANN, demonstrate a comparatively inferior model performance. After hyperparameter tuning, the model performance of ensemble algorithms exhibits only a marginal improvement. In contrast, the conventional ML algorithms, including SVR and ANN, have shown substantial progress, attaining a model performance that is comparable to that of ensemble models. With regard to the R2 value, the performance enhancements for RF, GBRT, LightGBM, CatBoost, ANN, and SVR after hyperparameter tuning are 0.43%, 1.28%, 2.06%, 0.21%, 58.82%, and 66.67%, respectively. Both conventional and ensemble models with hyperparameter tuning consistently achieve R2 values greater than 0.94. However, the BRR algorithm demonstrates a suboptimal performance, irrespective of the application of hyperparameter tuning.

- (3)

- A comparison of the performance of various ML algorithms reveals that CatBoost demonstrates superior performance when evaluated under hyperparameter tuning. Through the implementation of hyperparameter tuning, a modest enhancement in performance is observed, as indicated by an increase in the R2 value of 0.21%. However, it should be noted that this process requires a substantial duration of 1208.4 s, which is notably more time-consuming in comparison to all other ML algorithms. This finding suggests that the selection of the algorithm and the tuning of hyperparameters may require a trade-off between model performance and computational cost.

- (4)

- Feature importance ranking indicates that the fiber reinforcing index, FRI, exerts a predominant influence on UHPC tensile strength prediction, with a contribution of 37.5%, followed by the water-to-cement ratio. Additionally, different tensile test strain rates and specimen cross-sectional dimensions can lead to different experimental results. It is imperative that such disparities be taken into consideration during the formulation of the experimental design, thereby ensuring that conclusions drawn do not deviate from the actual conditions under investigation.

- (5)

- The utilization of the PDP in conjunction with the SHAP scatter plot is indicative of the nonlinear relationship between UHPC tensile strength and four key factors. The critical thresholds for each factor are identified by FRI, W/C, SR, and Section.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gurusideswar, S.; Shukla, A.; Jonnalagadda, K.N.; Nanthagopalan, P. Tensile Strength and Failure of Ultra-High Performance Concrete (UHPC) Composition over a Wide Range of Strain Rates. Constr. Build. Mater. 2020, 258, 119642. [Google Scholar] [CrossRef]

- Abellan-Garcia, J.; Fernández, J.; Khan, M.I.; Abbas, Y.M.; Carrillo, J. Uniaxial Tensile Ductility Behavior of Ultrahigh-Performance Concrete Based on the Mixture Design—Partial Dependence Approach. Cem. Concr. Compos. 2023, 140, 105060. [Google Scholar] [CrossRef]

- Dagenais, M.-A.; Massicotte, B.; Boucher-Proulx, G. Seismic Retrofitting of Rectangular Bridge Piers with Deficient Lap Splices Using Ultrahigh-Performance Fiber-Reinforced Concrete. J. Bridge Eng. 2018, 23, 04017129. [Google Scholar] [CrossRef]

- Abellán-García, J.; Guzmán-Guzmán, J.S. Random Forest-Based Optimization of UHPFRC under Ductility Requirements for Seismic Retrofitting Applications. Constr. Build. Mater. 2021, 285, 122869. [Google Scholar] [CrossRef]

- Bae, Y.; Pyo, S. Ultra High Performance Concrete (UHPC) Sleeper: Structural Design and Performance. Eng. Struc. 2020, 210, 110374. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The Influence of Steel Fibres on Compressive and Tensile Strength of Ultra High Performance Concrete: A Review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent Trends in Ultra-High Performance Concrete (UHPC): Current Status, Challenges, and Future Prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Akiba, T.; Sano, S.; Yanase, T.; Ohta, T.; Koyama, M. Optuna: A Next-Generation Hyperparameter Optimization Framework. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, Anchorage, AK, USA, 4–8 August 2019. [Google Scholar] [CrossRef]

- Hiew, S.Y.; Teoh, K.B.; Raman, S.N.; Kong, D.; Hafezolghorani, M. A Generalised Predictive Model for the Mechanical Properties of Mono/Hybrid Fibre-Reinforced Ultra-High-Performance Concrete. Constr. Build. Mater. 2024, 426, 136154. [Google Scholar] [CrossRef]

- Tao, Z.; Qiu, M.; Wille, K.; Zhu, Y.; Pan, R.; Li, Z.; Shao, X. Effects of Specimen Thickness and Fiber Length on Tensile and Cracking Behavior of UHPFRC: Uniaxial Tensile Test and Micromechanical Modeling. Cem. Concr. Compos. 2025, 155, 105828. [Google Scholar] [CrossRef]

- Que, Z.; Tang, J.; Wei, H.; Zhou, A.; Wu, K.; Zou, D.; Yang, J.; Liu, T.; De Schutter, G. Predicting the Tensile Strength of Ultra-High Performance Concrete: New Insights into the Synergistic Effects of Steel Fiber Geometry and Distribution. Constr. Build. Mater. 2024, 444, 137822. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of Strain Hardening Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) under Direct Tensile Loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Kim, D.J.; El-Tawil, S.; Naaman, A.E. Rate-Dependent Tensile Behavior of High Performance Fiber Reinforced Cementitious Composites. Mater. Struct. 2009, 42, 399–414. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Khayat, K.H.; Gao, X. Simplified Analytical Model to Assess Key Factors Influenced by Fiber Alignment and Their Effect on Tensile Performance of UHPC. Cem. Concr. Compos. 2022, 127, 104395. [Google Scholar] [CrossRef]

- Nithurshan, M.; Elakneswaran, Y. A Systematic Review and Assessment of Concrete Strength Prediction Models. Case Stud. Constr. Mater. 2023, 18, e01830. [Google Scholar] [CrossRef]

- Song, H.; Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Maślak, M.; Czarnecki, S.; Aslam, F. Predicting the Compressive Strength of Concrete with Fly Ash Admixture Using Machine Learning Algorithms. Constr. Build. Mater. 2021, 308, 125021. [Google Scholar] [CrossRef]

- Zhou, R.; Tang, Y.; Li, H.; Liu, Z. Predicting the Compressive Strength of Ultra-High-Performance Concrete Using a Decision Tree Machine Learning Model Enhanced by the Integration of Two Optimization Meta-Heuristic Algorithms. J. Eng. Appl. Sci. 2024, 71, 43. [Google Scholar] [CrossRef]

- Albaijan, I.; Mahmoodzadeh, A.; R Flaih, L.; Hashim Ibrahim, H.; Alashker, Y.; Hussein Mohammed, A. Evaluating the Tensile Strength of Reinforced Concrete Using Optimized Machine Learning Techniques. Eng. Fract. Mech. 2023, 292, 109677. [Google Scholar] [CrossRef]

- Li, Q.-F.; Song, Z.-M. High-Performance Concrete Strength Prediction Based on Ensemble Learning. Constr. Build. Mater. 2022, 324, 126694. [Google Scholar] [CrossRef]

- Thai, H.-T. Machine Learning for Structural Engineering: A State-of-the-Art Review. Structures 2022, 38, 448–491. [Google Scholar] [CrossRef]

- Luo, D.; Wang, K.; Wang, D.; Sharma, A.; Li, W.; Choi, I.H. Artificial Intelligence in the Design, Optimization, and Performance Prediction of Concrete Materials: A Comprehensive Review. npj Mater. Sustain. 2025, 3, 14. [Google Scholar] [CrossRef]

- Fan, D.; Chen, Z.; Cao, Y.; Liu, K.; Yin, T.; Lv, X.-S.; Lu, J.-X.; Zhou, A.; Sun Poon, C.; Yu, R. Intelligent Predicting and Monitoring of Ultra-High-Performance Fiber Reinforced Concrete Composites—A Review. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108555. [Google Scholar] [CrossRef]

- Kang, M.-C.; Yoo, D.-Y.; Gupta, R. Machine Learning-based Prediction for Compressive and Flexural Strengths of Steel Fiber-reinforced Concrete. Constr. Build. Mater. 2021, 266, 121117. [Google Scholar] [CrossRef]

- Jang, D.; Bang, J.; Yoon, H.N.; Seo, J.; Jung, J.; Jang, J.G.; Yang, B. Deep Learning-based LSTM Model for Prediction of Long-term Piezoresistive Sensing Performance of Cement-based Sensors Incorporating Multi-walled Carbon Nanotube. Comput. Concr. 2022, 30, 301–310. [Google Scholar] [CrossRef]

- Zhou, Z.; Qiao, P. Direct Tension Test for Characterization of Tensile Behavior of Ultra-High Performance Concrete. J. Test. Eval. 2020, 48, 2730–2749. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Y.; Yang, Y.; Su, L.; Xie, S. Splitting Tensile Strength of Basalt Fiber Reinforced Coral Aggregate Concrete: Optimized XGBoost Models and Experimental Validation. Constr. Build. Mater. 2024, 416, 135133. [Google Scholar] [CrossRef]

- Abellan-Garcia, J.; García-Castaño, E.; Fernández-Gómez, J.; Khan, M.I.; Abbas, Y.M. Modeling the Ductility Characteristics of Ultrahigh-Performance Fiber-Reinforced Concrete Using a Precise, Computation-Efficient, and Comprehensive Data-Driven Random Forests-Based Approach. Mater. Today Commun. 2023, 37, 106953. [Google Scholar] [CrossRef]

- Diab, A.Y.; Ferche, A.C. Prediction of Tensile Properties of Ultra-High-Performance Concrete Using Artificial Neural Network. ACI Struct. J. 2024, 121, 57–69. [Google Scholar] [CrossRef]

- Cakiroglu, C. Explainable Data-Driven Ensemble Learning Models for the Mechanical Properties Prediction of Concrete Confined by Aramid Fiber-Reinforced Polymer Wraps Using Generative Adversarial Networks. Appl. Sci. 2023, 13, 11991. [Google Scholar] [CrossRef]

- Alyami, M.; Nassar, R.-U.-D.; Khan, M.; Hammad, A.W.; Alabduljabbar, H.; Nawaz, R.; Fawad, M.; Gamil, Y. Estimating Compressive Strength of Concrete Containing Rice Husk Ash Using Interpretable Machine Learning-Based Models. Case Stud. Constr. Mater. 2024, 20, e02901. [Google Scholar] [CrossRef]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Assessment of Compressive Strength of Ultra-High Performance Concrete Using Deep Machine Learning Techniques. Appl. Soft Comput. 2020, 95, 106552. [Google Scholar] [CrossRef]

- Al Sarfin, M.d.A.; Banerji, S.; Zaker Esteghamati, M.; Sorensen, A. Prediction of Compressive Strength of UHPC Mix Designs Based on Mix Components Using Machine Learning Techniques. In Proceedings of the Third International Interactive Symposium on Ultra-High Performance Concrete, Wilmington, DE, USA, 4–7 June 2023; Iowa State University Digital Press: Wilmington, DE, USA, 2023. [Google Scholar]

- Ke, L.; Qiu, M.; Chen, Z.; Zhou, J.; Feng, Z.; Long, J. An Interpretable Machine Learning Model for Predicting of CFRP-Steel Epoxybonded Interface. Compos. Struct. 2023, 326, 117639. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, X.; Zhu, P.; Li, Z.; Wang, Y. Prediction of Flexural Ultimate Capacity for Reinforced UHPC Beams Using Ensemble Learning and SHAP Method. Buildings 2025, 15, 969. [Google Scholar] [CrossRef]

- Bergstra, J.; Bergstra, J.; Bengio, Y.; Bengio, Y. Random Search for Hyper-Parameter Optimization. J. Mach. Learn. Res. 2012, 13, 281–305. [Google Scholar]

- Kamolov, S. Comprehensive Analysis of Machine Learning Models for Predicting Concrete Compressive Strength. Ann. Math. Comput. Sci. 2024, 23, 119–130. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Khan, M.I. Robust Machine Learning Framework for Modeling the Compressive Strength of SFRC: Database Compilation, Predictive Analysis, and Empirical Verification. Materials 2023, 16, 7178. [Google Scholar] [CrossRef] [PubMed]

- Joy, R.A. Fine Tuning the Prediction of the Compressive Strength of Concrete: A Bayesian Optimization Based Approach. In Proceedings of the 2021 International Conference on Innovations in Intelligent Systems and Applications (INISTA), Kocaeli, Turkey, 25 August 2021; pp. 1–6. [Google Scholar]

- Lundberg, S.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. In Proceedings of the Conference on Neural Information Proceedings Systems (NIPS 2017), Long Beach, CA, USA, 25 November 2017; pp. 1–10. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y. Splitting Tensile Strength Prediction of Sustainable High-Performance Concrete Using Machine Learning Techniques. Environ. Sci. Pollut. Res. 2022, 29, 89198–89209. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Zhu, Y.; Chen, G. Utilizing Ensemble Learning in the Classifications of Ductile and Brittle Failure Modes of UHPC Strengthened RC Members. Archiv. Civ. Mech. Eng. 2024, 24, 86. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Zhu, Y.; Chen, G. Ensemble-Learning Model Based Ultimate Moment Prediction of Reinforced Concrete Members Strengthened by UHPC. Eng. Struct. 2024, 305, 117705. [Google Scholar] [CrossRef]

- Qian, Y.; Sufian, M.; Accouche, O.; Azab, M. Advanced Machine Learning Algorithms to Evaluate the Effects of the Raw Ingredients on Flowability and Compressive Strength of Ultra-High-Performance Concrete. PLoS ONE 2022, 17, e0278161. [Google Scholar] [CrossRef]

- Kirange, M.; Mahajan, L.; Department of Civil Engineering, R.C. Patel Institute of Technology Predicting Strength of Concrete by Ensemble Technique. Res. Eng. Struct. Mater. 2023, 9, 1039–1060. [Google Scholar] [CrossRef]

- Guo, Y. Optimized Decision Tree Algorithms to Estimate Ultimate Strain of Concrete Wrapped by Aramid Fiber-Reinforced Polymer. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 210. [Google Scholar] [CrossRef]

- Abellán-García, J.; Ortega-Guzmán, J.J.; Chaparro-Ruiz, D.A.; García-Castaño, E. A Comparative Study of LASSO and ANN Regressions for the Prediction of the Direct Tensile Behavior of UHPFRC. Adv. Civ. Eng. Mater. 2022, 11, 235–262. [Google Scholar] [CrossRef]

- Wille, K.; Xu, M.; El-Tawil, S.; Naaman, A.E. Dynamic Impact Factors of Strain Hardening UHP-FRC under Direct Tensile Loading at Low Strain Rates. Mater. Struct. 2016, 49, 1351–1365. [Google Scholar] [CrossRef]

- Hiew, S.Y.; Teoh, K.B.; Raman, S.N.; Hung, C.-C.; Chaen, Y.X.; Kong, D.; Hafezolghorani, M. A Unified Tensile Constitutive Model for Mono/Hybrid Fibre-Reinforced Ultra-High-Performance Concrete (UHPC). Cem. Concr. Compos. 2024, 150, 105553. [Google Scholar] [CrossRef]

- Pyo, S.; Wille, K.; El-Tawil, S.; Naaman, A.E. Strain Rate Dependent Properties of Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) under Tension. Cem. Concr. Compos. 2015, 56, 15–24. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Wu, X.; Xu, G. Quantitative Analysis of Steel Fibers on UHPFRC Uniaxial Tensile Behavior Using X-CT and UTT. Constr. Build. Mater. 2023, 368, 130349. [Google Scholar] [CrossRef]

- Wang, J.-Y.; Guo, J.-Y. Damage Investigation of Ultra High Performance Concrete under Direct Tensile Test Using Acoustic Emission Techniques. Cem. Concr. Compos. 2018, 88, 17–28. [Google Scholar] [CrossRef]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-Hardening UHP-FRC with Low Fiber Contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-T.; Yen, C.-H. Workability, Fiber Distribution, and Mechanical Properties of UHPC with Hooked End Steel Macro-Fibers. Constr. Build. Mater. 2020, 260, 119944. [Google Scholar] [CrossRef]

- Abellán-García, J.; Fernández-Gómez, J.A.; Torres-Castellanos, N.; Núñez-López, A.M. Tensile Behavior of Normal-Strength Steel-Fiber Green Ultra-High-Performance Fiber-Reinforced Concrete. Constr. Build. Mater. 2021, 118, 127–138. [Google Scholar] [CrossRef]

- Paschalis, S.; Lampropoulos, A. Fiber Content and Curing Time Effect on the Tensile Characteristics of Ultra High Performance Fiber Reinforced Concrete. Struct. Concr. 2017, 18, 577–588. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N.; Kang, S.-T.; Yoon, Y.-S. Size Effect in Ultra-High-Performance Concrete Beams. Eng. Fract. Mech. 2016, 157, 86–106. [Google Scholar] [CrossRef]

- Lin, J.-X.; Luo, R.-H.; Su, J.-Y.; Guo, Y.-C.; Chen, W.-S. Coarse Synthetic Fibers (PP and POM) as a Replacement to Steel Fibers in UHPC: Tensile Behavior, Environmental and Economic Assessment. Constr. Build. Mater. 2024, 412, 134654. [Google Scholar] [CrossRef]

- Donnini, J.; Lancioni, G.; Chiappini, G.; Corinaldesi, V. Uniaxial Tensile Behavior of Ultra-High Performance Fiber-Reinforced Concrete (Uhpfrc): Experiments and Modeling. Compos. Struct. 2021, 258, 113433. [Google Scholar] [CrossRef]

- Saqif, M.A.; El-Tawil, S. Characterization of the Tension Softening Behavior of UHPC. Constr. Build. Mater. 2023, 409, 134063. [Google Scholar] [CrossRef]

- Ouyang, X.; Huang, Y.; Hu, X.; Yin, J.; Shi, C. Evaluation of Tensile Failure Behavior of Ultra High Performance Concrete under Double-Edge Wedge Splitting and Direct Tension Loadings. J. Build. Eng. 2024, 90, 109480. [Google Scholar] [CrossRef]

- Tu, L.; Zhao, H.; Tan, C.; Cao, J.; Yi, D.; Qiu, M. Prediction of Tensile Strain Capacity of Ultra-High Performance Concrete Based on Crack Characteristics. Constr. Build. Mater. 2025, 458, 139632. [Google Scholar] [CrossRef]

- Song, Y.; Wang, F.; Yang, W.; Liang, R.; Zhan, D.; Xiang, M.; Yang, X.; Xu, R.; Lu, M. High-Performance Prediction of Soil Organic Carbon Using Automatic Hyperparameter Optimization Method in the Yellow River Delta of China. Comput. Electron. Agric. 2025, 236, 110490. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y. Hybrid Prediction Method for Wind Speed Combining Ensemble Empirical Mode Decomposition and Bayesian Ridge Regression. IEEE Access 2020, 8, 71206–71218. [Google Scholar] [CrossRef]

- Ye, M.; Li, L.; Yoo, D.-Y.; Li, H.; Zhou, C.; Shao, X. Prediction of Shear Strength in UHPC Beams Using Machine Learning-Based Models and SHAP Interpretation. Constr. Build. Mater. 2023, 408, 133752. [Google Scholar] [CrossRef]

- Boser, B.E.; Guyon, I.M.; Vapnik, V.N. A Training Algorithm for Optimal Margin Classifiers. In Proceedings of the Fifth Annual Workshop on Computational Learning Theory; ACM: Pittsburgh, PA, USA, 1992; pp. 144–152. [Google Scholar]

- Solhmirzaei, R.; Salehi, H.; Kodur, V. Predicting flexural capacity of ultrahigh-performance concrete beams: Machine learning–based approach. J. Struct. Eng. 2022, 148, 04022031. [Google Scholar] [CrossRef]

- Ergen, F.; Katlav, M. Machine and Deep Learning-Based Prediction of Flexural Moment Capacity of Ultra-High Performance Concrete Beams with/out Steel Fiber. Asian J. Civ. Eng. 2024, 25, 4541–4562. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Statist. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

- Ke, G.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Ye, Q.; Liu, T.-Y. LightGBM: A highly efficient gradient boosting decision tree. Adv. Neural Inf. Process. Syst. 2017, 30, 3146–3154. [Google Scholar]

- Uddin, M.N.; Ye, J.; Deng, B.; Li, L.; Yu, K. Interpretable Machine Learning for Predicting the Strength of 3D Printed Fiber-Reinforced Concrete (3DP-FRC). J. Build. Eng. 2023, 72, 106648. [Google Scholar] [CrossRef]

- Rahman, J.; Ahmed, K.S.; Khan, N.I.; Islam, K.; Mangalathu, S. Data-Driven Shear Strength Prediction of Steel Fiber Reinforced Concrete Beams Using Machine Learning Approach. Eng. Struct. 2021, 233, 111743. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D. Comparative Study on Hyperparameter Tuning for Predicting Concrete Compressive Strength. Buildings 2025, 15, 2173. [Google Scholar] [CrossRef]

- Almutiri, T.; Alomar, K.; Alganmi, N. Integrating Multi-Omics Using Bayesian Ridge Regression with Iterative Similarity Bagging. Appl. Sci. 2024, 14, 5660. [Google Scholar] [CrossRef]

- Qiu, M.; Shao, X.; Zhu, Y.; Hussein, H.H.; Li, F.; Li, X. Effect of Aspect Ratios of Hooked End and Straight Steel Fibers on the Tensile Strength of UHPFRC. J. Mater. Civ. Eng. 2022, 34, 04022131. [Google Scholar] [CrossRef]

| Category | No. | Name | Symbol | Unit | Data Type and Range |

|---|---|---|---|---|---|

| Experimental condition | 1 | Strain rate | SR | 1/s | N (0.833 × 10−5~0.1) |

| Specimen sizes | 2 | Sectional area | Section | mm2 | N (390~5000) |

| UHPC components | 3 | Fiber type | FS | - | C (N, S, H, T) |

| 4 | Fiber reinforcing index | FRI | - | N (0~487.5) | |

| 5 | Water/cement | W/C | - | N (0.19~0.42) | |

| 6 | Water reducer/cement | SP/C | - | N (0.005~0.033) | |

| 7 | Sand/cement | S/C | - | N (0.3~3.1) | |

| 8 | Inert powder/cement | IP/C | - | N (0~0.94) | |

| 9 | Reactive powder/cement | RP/C | - | N (0~1) | |

| 10 | Silica fume/cement | F/C | - | N (0.125~0.5) | |

| Target variable | 11 | Tensile strength | TS | MPa | N (4.4~24.9) |

| Algorithm | Key Hyperparameters | Physical Significance | Optimization Search Range | Type |

|---|---|---|---|---|

| BRR | alpha_1 | Shape parameter of gamma prior | [−8, 2] | Continuous |

| alpha_2 | Inverse scale parameter of gamma prior | [−8, 2] | Continuous | |

| lambda_1 | Shape parameter of gamma prior | [−8, 2] | Continuous | |

| lambda_2 | Inverse scale parameter of gamma prior | [−8, 2] | Continuous | |

| SVR | C | Penalty coefficient (regularization strength) | [0.1, 100] | Continuous |

| gamma | RBF kernel function scale parameter | [0.001, 1] | Continuous | |

| epsilon | Loss function tolerance | [0.01, 1] | Continuous | |

| tol | Minimum improvement threshold | [0.00001, 0.01] | Continuous | |

| max_iter | Maximum iterations | [1000, 10000] | Integer | |

| ANN | hidden_layer_sizes | Hidden layer neuron structures | (50, 200) | Category/integer tuple |

| alpha | L2 regularization coefficient (explicit regularization) | [0.0001, 0.1] | Continuous | |

| learning_rate_init | Initial learning rate | [0.0001, 0.1] | Continuous | |

| tol | Minimum improvement threshold | [0.00001, 0.01] | Continuous | |

| max_iter | Maximum number of epochs | [200, 2000] | Integer | |

| RF | n_estimators | Number of trees | [50, 500] | Integer |

| max_depth | Maximum depth of single tree (structural regularization) | [3, 20] | Integer | |

| min_samples_split | Minimum number of samples for node splitting | [2, 10] | Integer | |

| min_samples_leaf | Minimum number of samples required for leaf nodes | [1, 10] | Integer | |

| max_features | Maximum number of feature subsets | [0.1, 1.0] | Integer | |

| GBRT | learning_rate | Learning rate (shrinkage step) | [0.01, 0.3] | Continuous |

| n_estimators | Number of trees | [50, 500] | Integer | |

| max_depth | Maximum depth of a single tree | [3, 20] | Integer | |

| min_samples_split | Minimum number of samples required for a node to continue splitting | [2, 10] | Integer | |

| min_samples_leaf | Minimum number of samples required for leaf nodes | [1, 10] | Integer | |

| LihgtGBM | learning_rate | Learning rate (shrinkage step) | [0.01, 0.3] | Continuous |

| n_estimators | Number of trees | [100, 2000] | Integer | |

| max_depth | Maximum depth of single tree | [3, 10] | Integer | |

| num_leaves | Maximum number of leaves in a single tree | [20, 100] | Integer | |

| min_child_samples | Minimum number of samples required for a leaf node | [5, 50] | Integer | |

| CatBoost | learning_rate | Learning rate | [0.01, 0.3] | Continuous |

| depth | Depth of tree | [4, 10] | Integer | |

| l2_leaf_ reg | L2 regularization coefficient | [1, 10] | Continuous | |

| border_count | Number of numerical feature bins | [50, 255] | Integer | |

| iterations | Number of iterations | [100, 2000] | Integer |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zeng, T.; Zeng, Y.; Zhu, P. Explainable Prediction of UHPC Tensile Strength Using Machine Learning with Engineered Features and Multi-Algorithm Comparative Evaluation. Buildings 2025, 15, 3217. https://doi.org/10.3390/buildings15173217

Zhang Z, Zeng T, Zeng Y, Zhu P. Explainable Prediction of UHPC Tensile Strength Using Machine Learning with Engineered Features and Multi-Algorithm Comparative Evaluation. Buildings. 2025; 15(17):3217. https://doi.org/10.3390/buildings15173217

Chicago/Turabian StyleZhang, Zhe, Tianqin Zeng, Yongge Zeng, and Ping Zhu. 2025. "Explainable Prediction of UHPC Tensile Strength Using Machine Learning with Engineered Features and Multi-Algorithm Comparative Evaluation" Buildings 15, no. 17: 3217. https://doi.org/10.3390/buildings15173217

APA StyleZhang, Z., Zeng, T., Zeng, Y., & Zhu, P. (2025). Explainable Prediction of UHPC Tensile Strength Using Machine Learning with Engineered Features and Multi-Algorithm Comparative Evaluation. Buildings, 15(17), 3217. https://doi.org/10.3390/buildings15173217