Sustainable Material Recovery from Demolition Waste: Knowledge Management and Insights from a Public Sector Building Renovation

Abstract

1. Introduction

- This study considers ACPs as demolition waste for material recovery.

- The data used in the analysis come from a case study in Bangkok, Thailand and secondary sources in the construction-related literature.

- All units in this study are calculated in kg of ACPs.

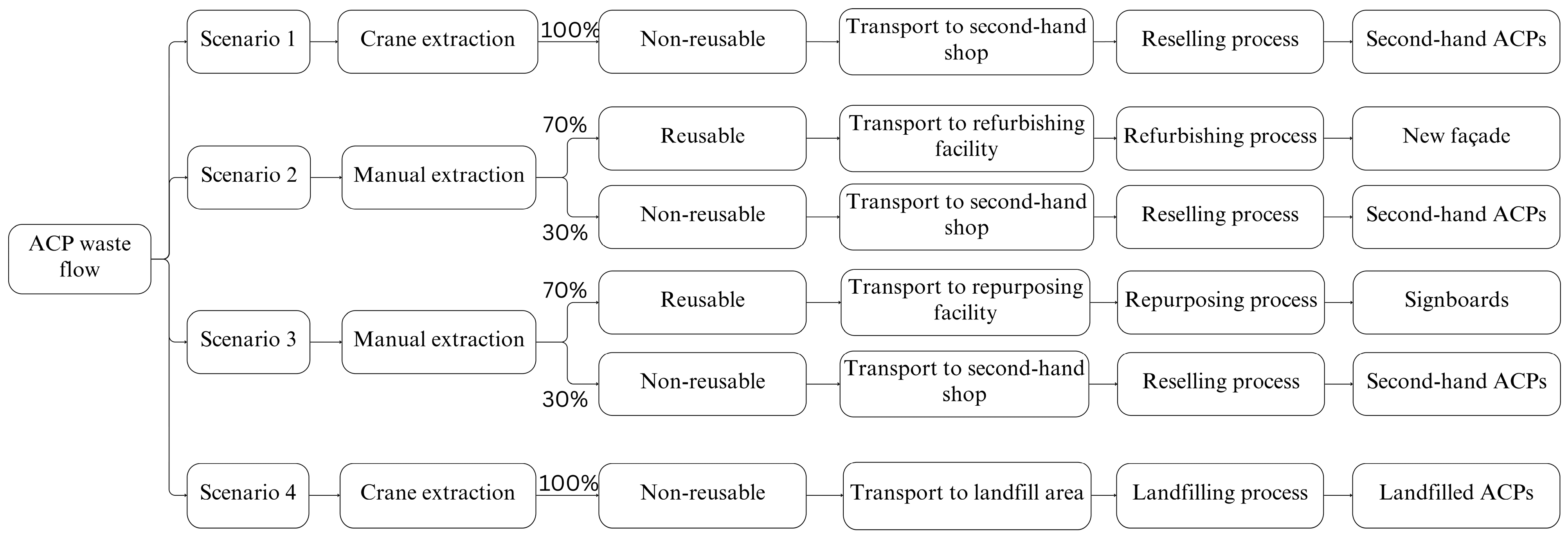

- This study reuses 70% of ACP waste in refurbishing and repurposing scenarios (based on interviews), and the rest is sold at second-hand shops. The 70% recovery rate is consistent with other studies. For example, in the U.S., regulations for C&D waste recovery require at least 70% of C&D waste to be reused [24]. Caro et al. [25] estimated that 70% of aluminum achieved from demolition waste can be recycled. Saez and Osmani stated that the C&D waste recovery rate could be up to 95%, depending on regional conditions and the availability of recycling technologies.

- In the landfilling scenario, all ACP waste is dumped in landfills, and, in the reselling scenario, it is sold to a second-hand shop.

- The reselling scenario includes ACP dismantling and transportation to second-hand shops and does not include operations at the second-hand shops.

- The refurbishing scenario includes ACP dismantling, transportation to the refurbishing facility, and the refurbishing process to achieve new facades. Refurbished ACP facades maintain similar shapes and sizes to the old ACP facades; thus, only grinding, painting, and adhesive are required in the refurbishing process.

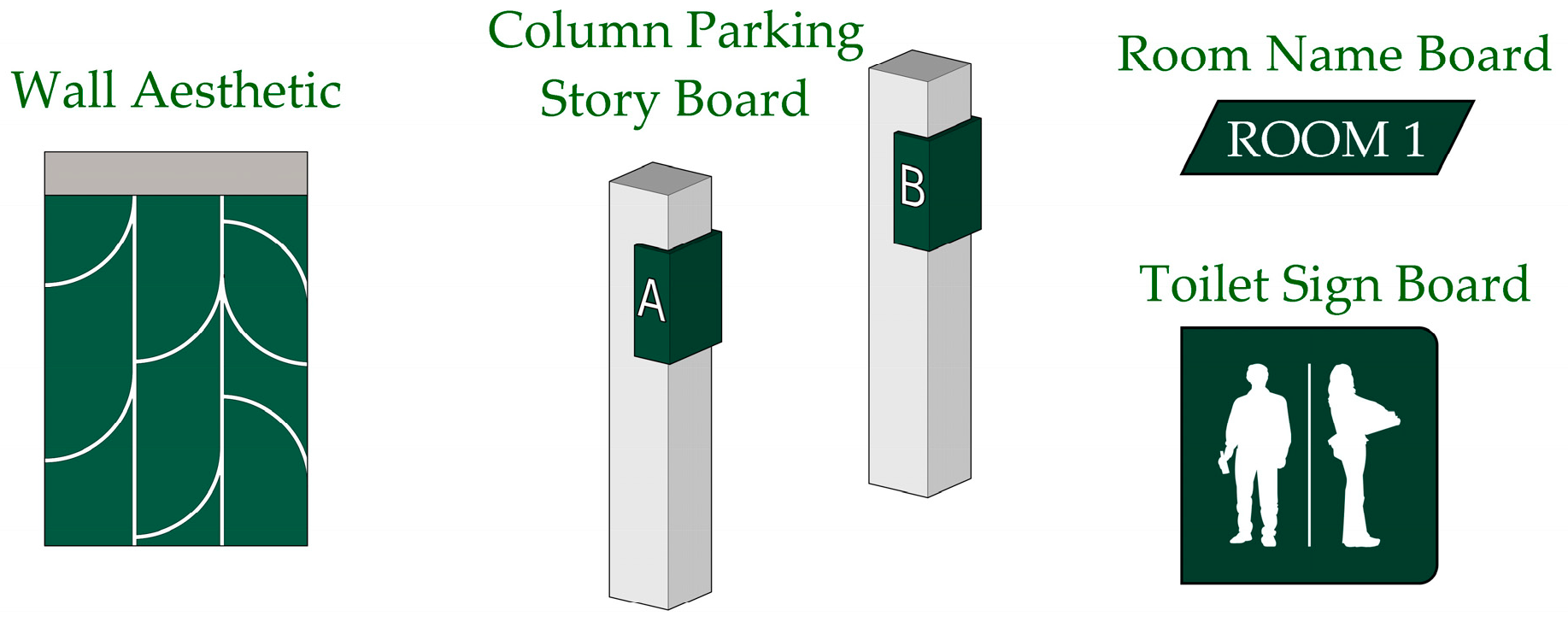

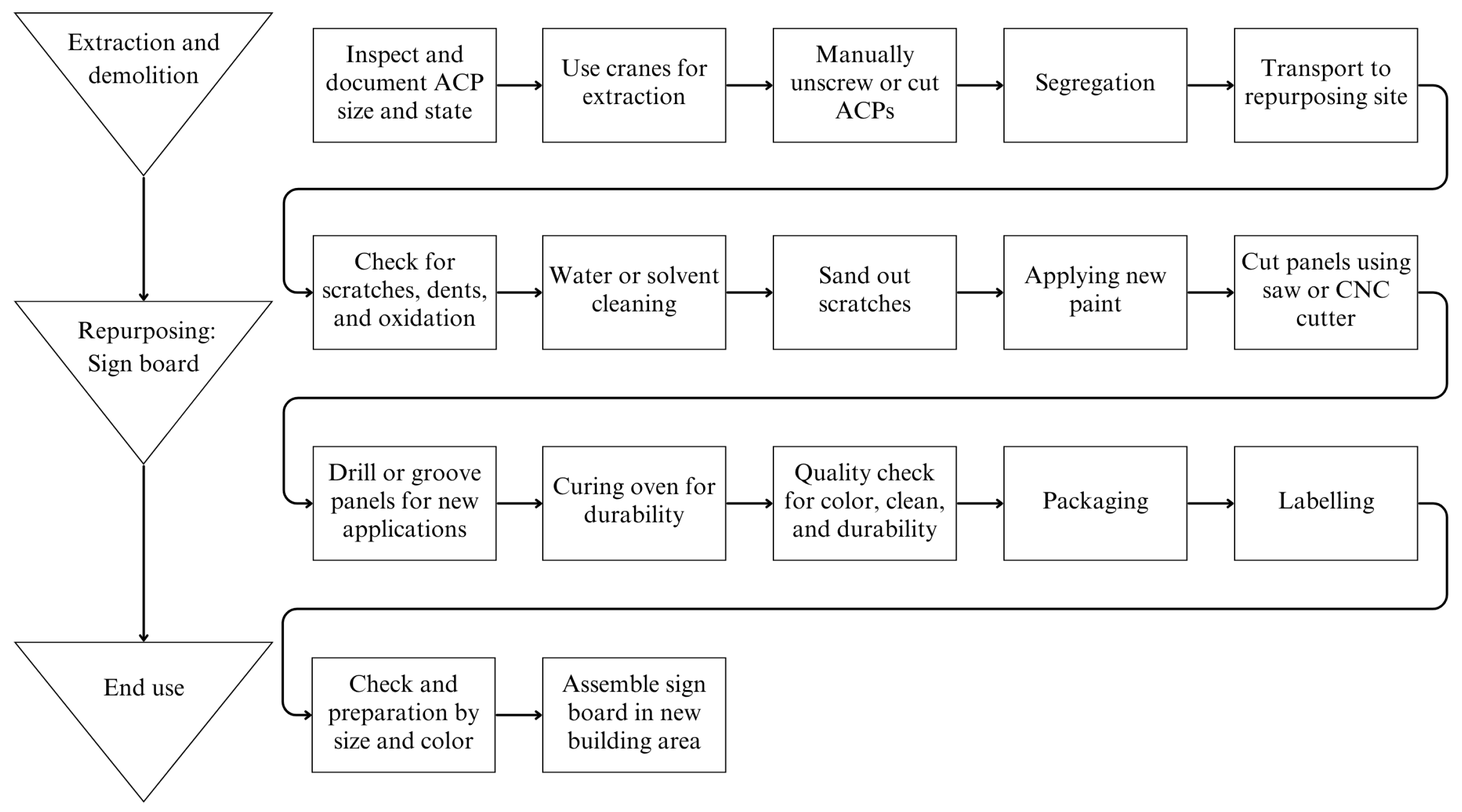

- The repurposing scenario includes dismantling ACPs, transportation to the repurposing facility, and the repurposing process to create signboards.

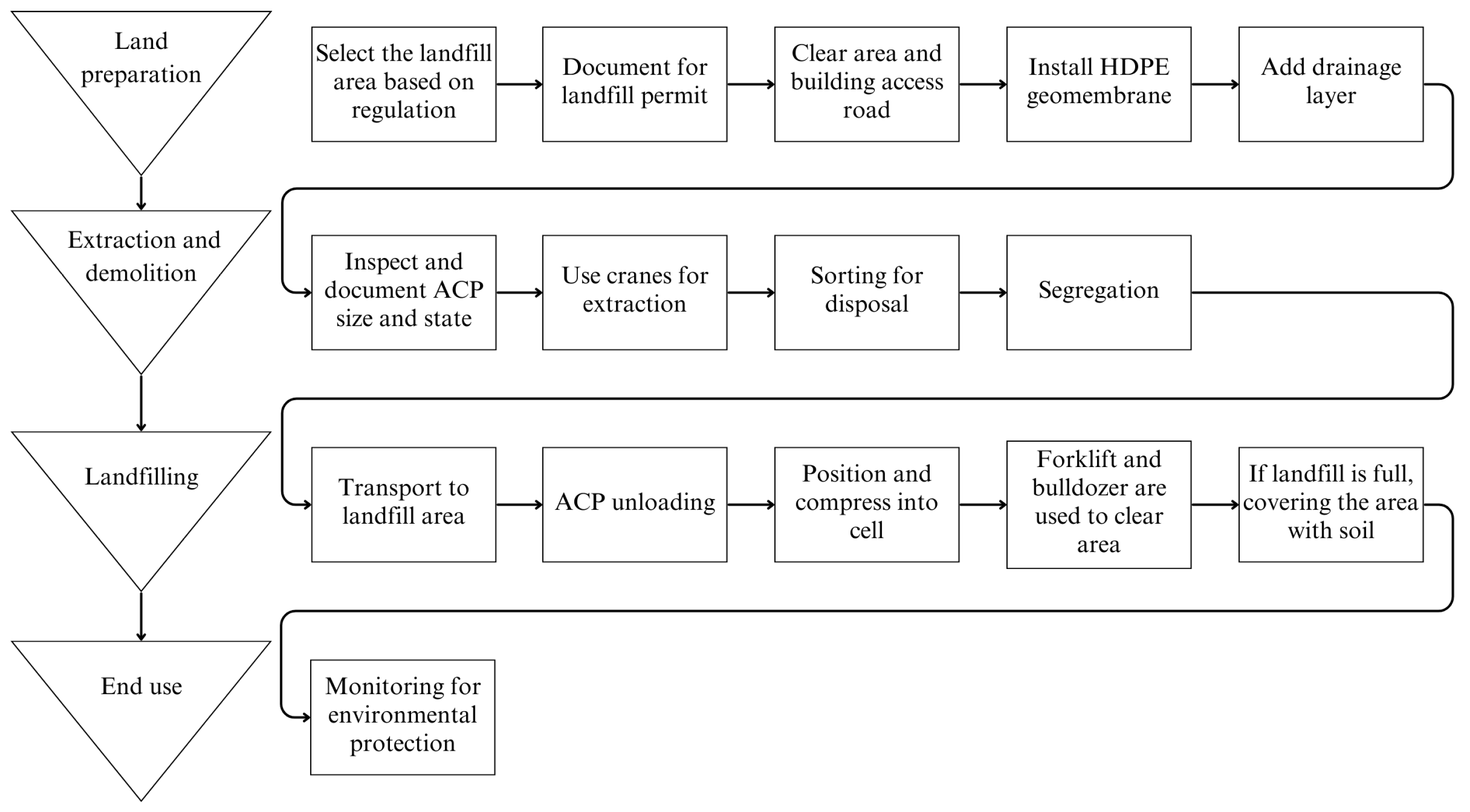

- The landfilling scenario includes ACP dismantling, transportation to landfills, and landfill preparation, but it does not include operations at the landfills.

- The economic-related data cover the virgin material (aluminum) extraction process, ACP waste management, transportation, and sales of second-life products.

- The environmental-related data cover virgin material extraction and the avoidance of new virgin materials and does not include impacts incurred during ACP and signboard production.

- The social-related data cover new employment, corporate social responsibility (CSR) campaigns, reimbursement, and medical bills from ACP waste management, as well as legal permissions.

- Landfill space is explicitly purchased to dispose of C&D waste.

- Carbon credit refers to environmental-related savings achieved from the end-of-life management of ACP waste, while carbon tax refers to an environmental-related cost from the refurbishing and repurposing processes.

2. Literature Review

2.1. C&D Waste Situation in Thailand

2.2. KM Practices in the Construction Industry

2.3. LEED Certification

- MR Credit 1—Building Lifecycle Impact Reduction: Encouraging whole-building lifecycle assessment (LCA) to inform design choices and reduce environmental impacts.

- MR Credit 2—Construction and Demolition Waste Management: Diverting C&D waste from landfills through reuse and recycling.

- MR Credit 3—Materials Reuse: Encouraging the reuse of existing building materials in renovations or new constructions.

- MR Credit 4—Recycled Content: Using products with recycled content and reducing the demand for virgin materials.

- MR Credit 5—Regional Materials: Using building materials extracted, processed, and manufactured within a defined radius of the project site.

- MR Credit 6—Rapidly Renewable Materials: Using materials with short harvest cycles or rapidly renewable wood.

- MR Credit 7—Certified Wood: Using wood products certified by the Forest Stewardship Council or other approved certification programs.

- MR Credit 8—Furniture and Medical Furnishings: Using furniture and medical furnishings that meet specific sustainability criteria.

- MR Credit 9—Material Ingredients: Optimizing ingredients for building products, including transparency and health assessments.

- MR Credit 10—Whole-Building LCA: Assessing the environmental impacts of building materials over their entire lifecycles.

- MR Credit 11—Health Product Declaration: Using health product declarations.

- MR Credit 12—Sourcing Raw Materials: Sourcing raw materials by considering extraction practices and social impacts.

- MR Credit 13—Material Ingredient Optimization: Optimizing material ingredients through manufacturer-led initiatives.

- MR Credit 14—Product Transparency and Optimization: Supporting transparency in material sourcing.

- MR Credit 15—Design for Flexibility: Designing for future adaptability and deconstruction to minimize waste.

2.4. Circular Economy and Sustainability Concepts

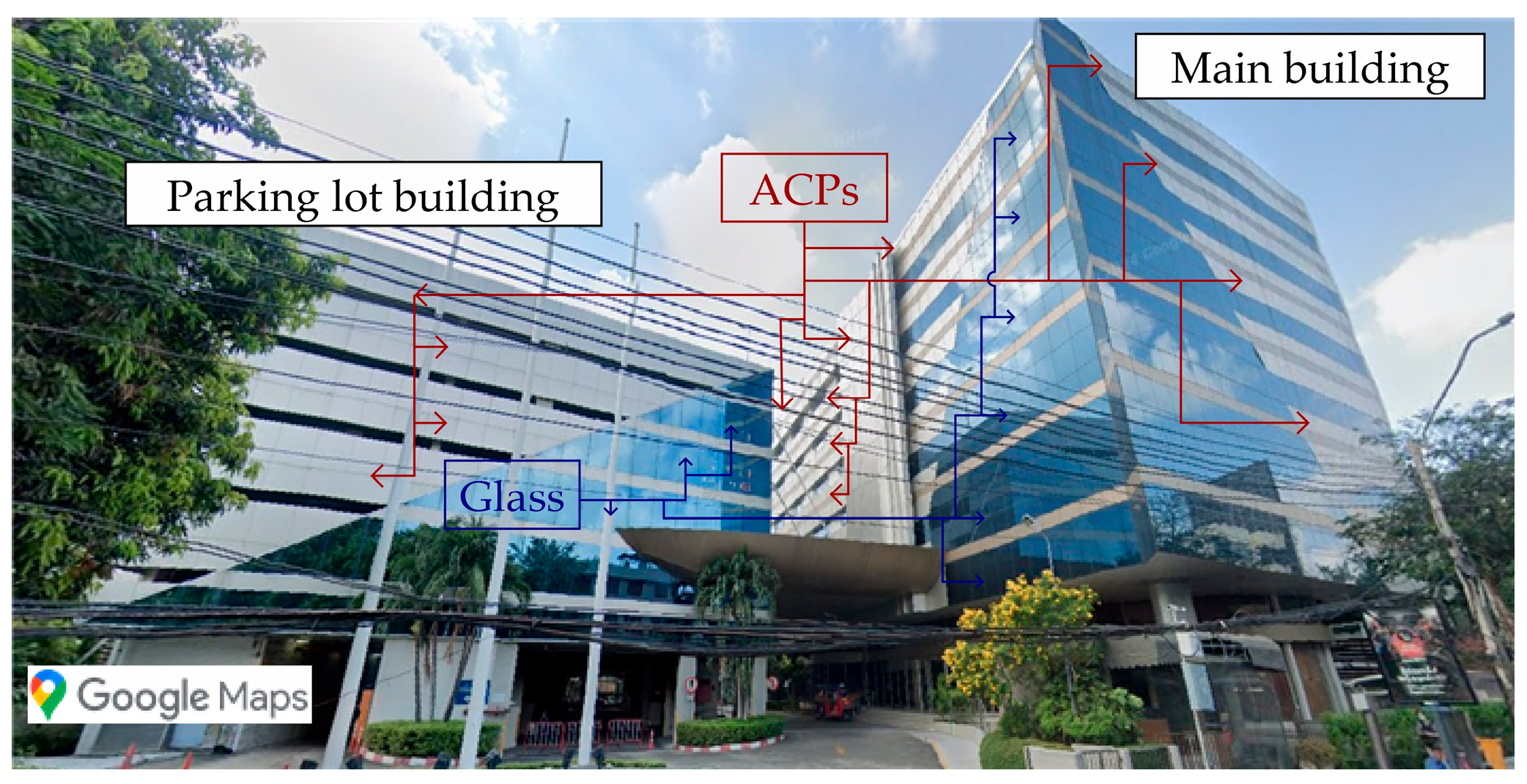

2.5. Details of Case Study

2.5.1. Background of Case Study

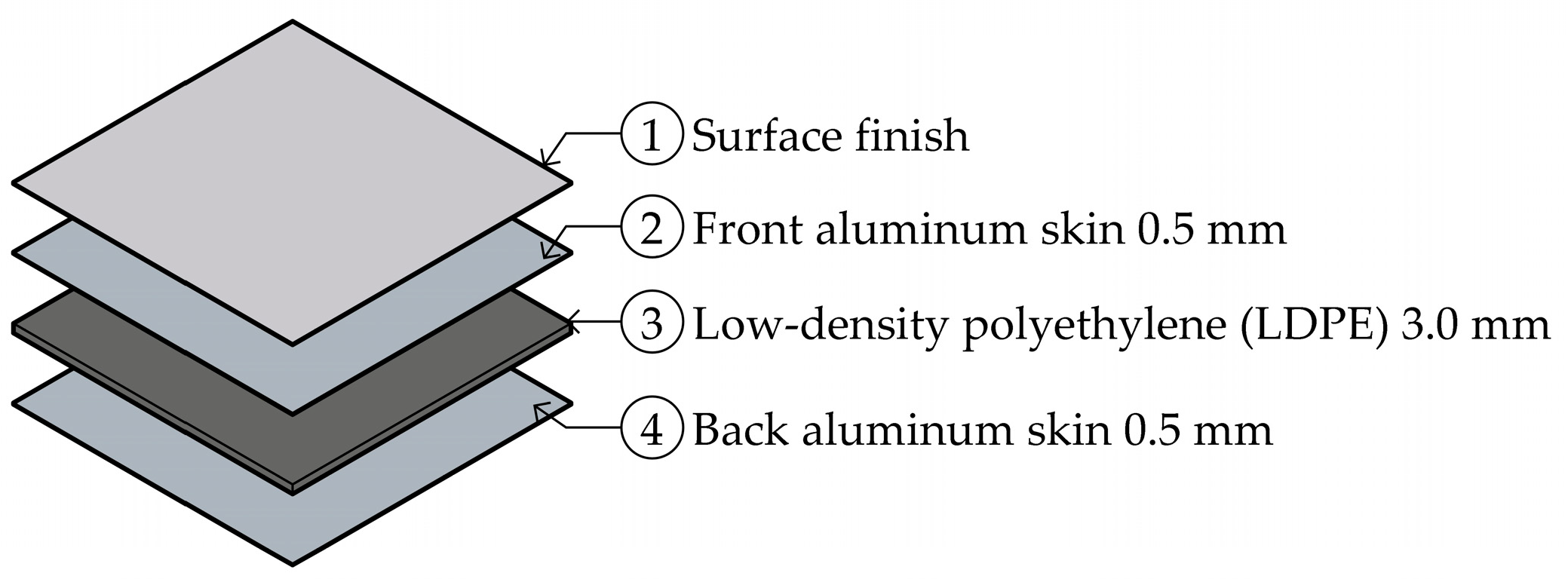

2.5.2. Details of ACP Waste in This Case Study

3. Materials and Methods

3.1. The Use of KM to Achieve ACP Waste Recovery Scenarios

- The literature related to demolition waste and its end-of-life uses in Thailand and abroad is reviewed and discussed with team members to gain knowledge of current practices.

- Key stakeholders, including the owner, contractors, designers, and demolition companies, meet regularly to brainstorm possible means of and challenges in recovering and reusing demolition waste in building renovation.

- Challenges and lessons learned from previous projects are also discussed among stakeholders to find the best solutions.

- Data required for the analysis, including the end-of-life management scenarios, implementation processes, costs, and benefits, are collected from secondary sources, onsite interviews, and observations. Primary data—mostly confidential data related to the costs and benefits of ACP waste recovery—must be safely stored and assigned access permissions. They could be recorded in Google Docs and shared among stakeholders.

- Possible scenarios are examined with the green standard, specifically LEED, to plan future steps for certification.

- The study results are published as reports and manuscripts. They are expected to be used as guidelines for implementation in future projects.

3.2. ACP Waste Recovery Scenarios

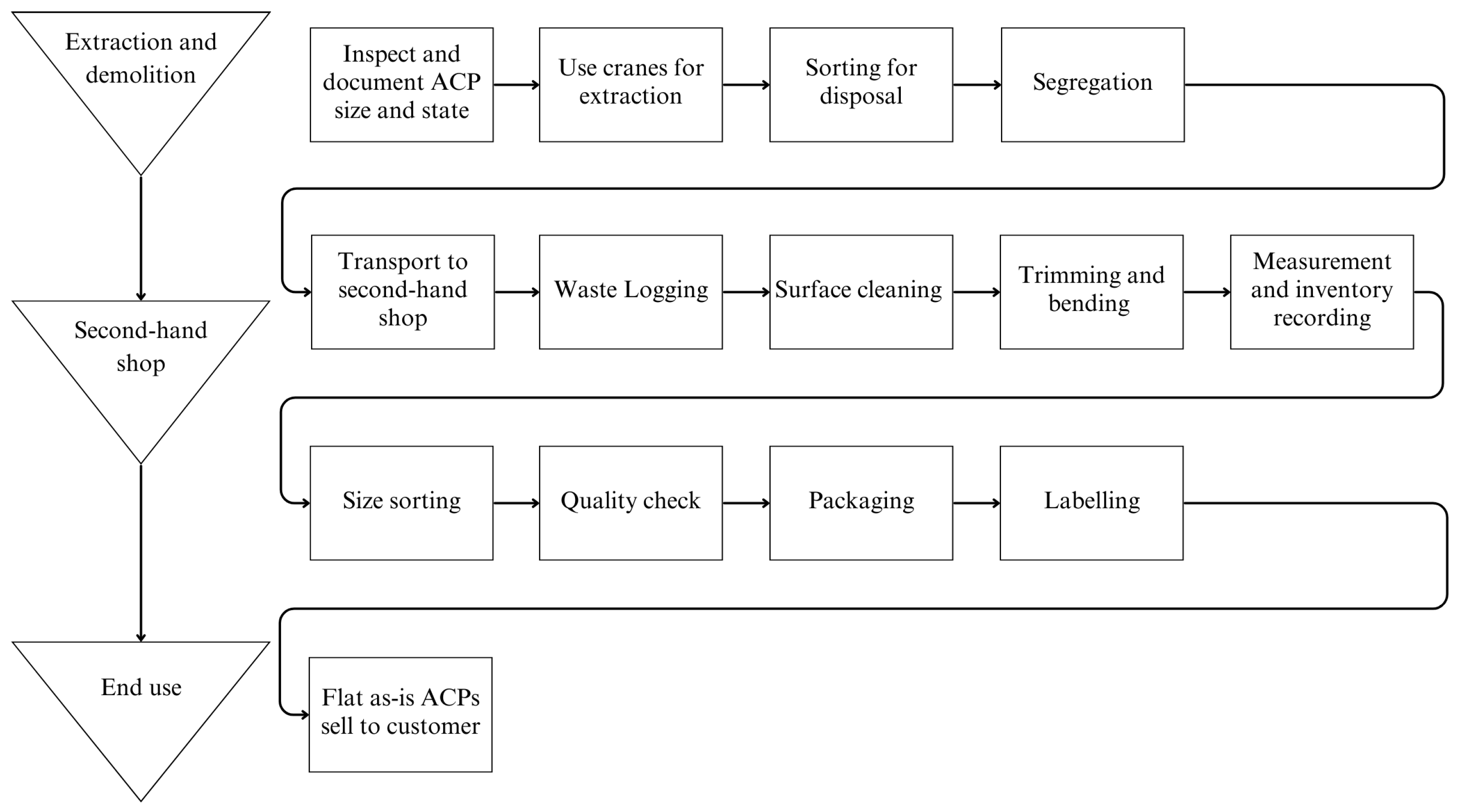

3.2.1. Scenario 1: Reselling

3.2.2. Scenario 2: Refurbishing

3.2.3. Scenario 3: Repurposing

3.2.4. Scenario 4: Landfilling

3.3. Cost/Benefit Analysis

3.4. Data for the Analysis

3.4.1. ACP Waste-Related Data

3.4.2. Economic-Related Data

3.4.3. Environmental-Related Data

- CO2eq emissions: CO2 emissions are from aluminum extraction, diesel combustion during transportation, and electricity generation using fossil fuels. For example, the carbon footprint from manufacturing virgin aluminum is estimated at 13.5 kg CO2eq/kg of aluminum. Avoiding 1 ton of virgin aluminum production can save 13.5 tons of CO2eq emissions [77].

- Particulate matter (PM): The improper burning and mechanical cutting of ACPs can release PM, endangering workers and nearby communities. Johnson et al. [78] indicated that an increase in PM2.5 raises the respiratory illness rate by 5% per 10 µg/m3 exposure, leading to higher healthcare burdens and lost productivity. In this study, the release of PM occurs through ACP dismantling, diesel combustion, fossil fuel electricity generation, and aluminum extraction.

- Metal depletion: Aluminum mining requires large-scale bauxite extraction and chemical processing. Every ton of virgin aluminum consumes about 4 tons of bauxite and produces 2 tons of red mud, a hazardous byproduct [81].

- Fuel depletion: Fuel is required in transportation, refurbishing, and repurposing processes. Primary aluminum production consumes about 15 MWh/ton of electricity [82]. This is crucial in Thailand, as much of the electricity generation is still based on fossil fuels. Renewable energy, such as biomass and solar power, may reduce the fossil fuel dependency and GHG emissions [83].

- Landfill disposal: ACP disposal in landfills consumes landfill space and may generate groundwater contamination from leachates [84].

3.4.4. Social-Related Data

3.5. Flow of ACP Waste Management

4. Analysis Results

4.1. CBA Results of Scenario 1 (Reselling)

- Investment in equipment and tools: This includes pressure washers and an edge trimming machine, which are estimated at USD 305.02.

- Labor: Laborers are required to load ACPs onto trucks for transportation. This process takes about three months.

- o

- Manual dismantling takes three months and three laborers, costing 3 × 349 × 3 = USD 3141.

- o

- According to Appendix A, seven laborers are required at the second-hand shop for the ACP preparation process. Preparing one kg of ACPs takes 0.15 h at a labor rate of USD 1.3/h. With 22,596.84 kg of ACP waste (usable ACPs), it costs 0.15 × 1.3 × 22,596.84 = USD 4406.38.

- o

- The total labor cost is then 3141 + 4406.38 = USD 7547.38.

- Transportation: ACP waste is transported to second-hand shops, and the cost comprises truck rental and fuel consumption.

- o

- For truck rental, the cost is calculated from the number of trips and the truck rental fee: 4 × 152 = USD 608.

- o

- The fuel cost is calculated from the distance between the demolition site and the second-hand shop, the fuel consumption rate, the fuel price, and the number of trips: 78/4.5 × 1 × 4 = USD 69.33.

- o

- This yields a total transportation cost of USD 677.33.

- Material handling: ACP dismantling uses a crane. The crane is rented for USD 485/month for three months, or USD 485 × 3 = USD 1455.

- Carbon tax: CO2eq emissions occur during diesel combustion, with an emission factor of 2.68 kg CO2eq/L.

- o

- Transportation to the second-hand shop requires 69.33 L.

- o

- Cranes consume fuel at 10 L/h. With a maximum of 160 h working/month and a three-month working period, the fuel consumption is 10 × 160 × 3 = 4800 L.

- o

- The carbon tax is then (69.33 + 4800) × 2.68 × 0.0052 = USD 67.86.

- PM: PM is generated from demolition activities and diesel fuel combustion.

- o

- For ACP dismantling, PM is generated at 22,596.84 × 0.00214 = 48.36 kg PM (see Appendix A).

- o

- PM is generated at (69.33 + 4800) × 0.0013 = 6.33 kg for diesel combustion.

- o

- The PM-related cost is (48.36 + 6.33) × 0.45 = USD 24.61.

- Fuel depletion: Fuel depletion is calculated by converting diesel consumption to oil equivalents.

- o

- Four trips of ACP waste transportation to the second-hand shop consume 69.33 L of diesel fuel.

- o

- The fuel consumption for cranes is 10 × 160 × 3 = 4800 L.

- o

- According to Appendix A, about 0.85 kg of oileq is equivalent to one liter of diesel. With USD 0.26/L, the total fuel depletion cost is (69.33 + 4800) × 0.85 × 0.26 = USD 1076.12.

- Water depletion: Water depletion is calculated from the water used to clean the ACP waste. Using 0.00071 m3 per kg, the water depletion cost is 22,596.84 × 0.00071 × 0.58 = USD 9.31.

- Reimbursement and medical bills: These costs arise from occupational health risks during ACP dismantling. According to the Office of Social Security [97], the average direct reimbursement per injury is USD 1584. With approximately 2.3 injuries per project, it incurs a reimbursement cost of 1584 × 2.3 = USD 3643.2.

- CSR: This cost, approximately USD 9164, covers a community health check, dust mitigation, and tree planting activities.

4.2. CBA Results of Scenario 2 (Refurbishing)

- Investment in equipment and tools:

- o

- The refurbishing process requires pressure washers, orbital sanders, saw cutters, and spray guns, which are estimated at USD 1515.

- o

- Unused ACPs are sold at second-hand shops that require pressure washers and edge trimming machines for their operations. The equipment cost is estimated at USD 305.02.

- o

- The total investment cost is 1515 + 305 = USD 1820.02.

- Labor: Laborers must extract ACPs from old buildings (manual dismantling) and load them onto trucks for transportation. They are also required for the refurbishing process.

- o

- Manual dismantling takes three months and three laborers, costing 3 × 349 × 3 = USD 3141.

- o

- According to Appendix A, seven laborers are required in the refurbishing process. Refurbishing one kg of ACPs takes 1.82 h at a labor rate of USD 1.3/h. With 15,817.79 kg of ACP waste (usable ACPs), it costs 1.82 × 1.3 × 15,817.79 = USD 37,424.89.

- o

- The labor cost at the second-hand shops for operating 6779.05 kg of ACP waste (usable ACPs) is 0.15 × 1.3 × 6779.05 = USD 1321.91.

- o

- The total labor cost is 3141 + 37,424.89 + 1321.91 = USD 41,887.8.

- Electricity: At a consumption rate of 0.0194 kWh/kg, the electricity cost for the refurbishing process is 0.0194 × 15,817.79 × 0.13 = USD 39.89.

- Transportation: Usable ACP waste is transported to facilities for refurbishment, while the unusable amount is transferred to second-hand shops.

- o

- For truck rental, transporting 15,817.79 kg of ACP waste requires three trips and one trip to a second-hand shop. One truck rental trip is USD 152. This incurs 4 × 152 = USD 608 for 6-wheel truck rental.

- o

- The fuel consumption for travel from the demolition site to the refurbishing facility is about 41.8 km/trip. With fuel efficiency of 4.5 km/L and a fuel cost of USD 1/L, this incurs a cost of 41.8/4.5 × 1 × 3 = USD 27.87. A trip to a second-hand shop, with an average distance of 78 km/trip, costs 78/4.5 × 1 × 1 = USD 17.33.

- o

- The total transportation cost is then 608 + 27.87 +17.33 = USD 653.2.

- Material handling: The forklift handles ACP waste in a refurbishing facility. With a rental cost of USD 606/month and a three-month processing period, this incurs a material handling cost of USD 606 × 3 = USD 1818.

- Materials: Paints and adhesives are used for refurbishing ACPs, costing (1.04 + 0.91) × 15,817.79 = USD 30,844.69.

- Storage: Temporary storage is required before ACPs are transported to facilities. This costs 137 × 3 = USD 411.

- New ACP facades: To produce new facades, 30% of new ACPs (i.e., 6779.05 kg of unusable ACP waste) must be purchased. At the ACP cost of USD 1.85/kg, this incurs a cost of 1.85 × 6779.05 = USD 12,541.24.

- Carbon tax: Carbon tax is calculated from new aluminum extraction, diesel combustion, and electricity generation.

- o

- New aluminum materials are required to create new ACP facades (i.e., 6779.05 kg of unusable ACP waste). The extraction of aluminum materials emits approximately 13.9 kg of CO2eq/kg of new facade [98]. CO2eq emissions are calculated as 6779.05 × 13.9 = 94,228.8 kg of CO2eq.

- o

- Transportation to refurbishing facilities requires 45.2 L of diesel, which has an emission factor of 2.68 kg CO2eq/L. This generates CO2eq emissions of 45.2 × 2.68 = 121.14 kg CO2eq.

- o

- According to the Energy Policy and Planning Office [99], electricity generation in Thailand produces emissions of 0.399 kg CO2eq/kWh. This electricity consumption (306.87 kWh) is for refurbishing equipment. This incurs CO2eq emissions of 0.399 × 306.87 = 122.44 kg CO2eq.

- o

- The carbon tax is calculated as (94,228.8 + 121.14 + 122.44) × 0.0052 = USD 491.26.

- PM generation: PM is generated during ACP dismantling, diesel combustion, electricity generation, and aluminum extraction.

- o

- PM is generated at 22,596.84 × 0.00214 = 48.36 kg PM for ACP dismantling.

- o

- Transportation to the refurbishing facility consumes 45.2 L of diesel, equivalent to 45.2 × 0.0013 = 0.059 kg PM.

- o

- According to the Energy Policy and Planning Office [99], Thailand’s electricity generation generates 0.006 kg PM/kWh. Electricity consumption of 306.87 kWh may produce 0.006 × 306.87 = 1.84 kg PM.

- o

- Aluminum extraction produces 0.00586 kg of PM/kg of ACP; thus, producing 6779.05 kg of ACPs generates 6779.05 × 0.00586 = 39.73 kg PM.

- o

- The PM-related cost is then (48.36 + 0.059 + 1.84 + 39.73) × 0.45 = USD 40.49.

- Water consumption: Water is used in new ACP facade production and operations at second-hand shops.

- o

- With 6779.05 kg of new ACP production, the water cost is USD 786.37 × 0.2 × 0.58.

- o

- The operations at second-hand shops incur a water cost of 6779.05 × 0.00071 × 0.58 = USD 2.79.

- o

- The total water consumption cost is USD 789.16.

- Metal depletion: Aluminum extraction for new ACP facades (equivalent to 6779.05 kg of Feeq) contributes to the irreversible depletion of finite mineral resources. This incurs a cost of 6779.05 × 0.25 = USD 1694.76.

- Fuel depletion: Fuel consumption occurs in transportation and refurbishing processes.

- o

- According to Appendix A, about 0.85 kg of oileq is equivalent to one L of diesel. The trip to the refurbishing facility costs 45.2 L of diesel, resulting in fuel depletion of 45.2 × 0.85 = 38.42 kg oileq.

- o

- About 1.1 kg of oil is consumed per kg of new ACP production, resulting in 6779.05 × 1.1 = 7456.96 kg.

- o

- In Thailand, electricity is generated mainly from natural gas and coal, with fossil fuels. Fuel consumption is estimated at 0.3 kg oil/kWh. With 306.87 kWh required for refurbishing, fuel depletion is 0.3 × 306.87 = 92.06 kg of oil.

- o

- The fuel depletion cost is calculated as (38.42 + 7456.96 + 92.06) × 0.26 = USD 1972.73.

- Reimbursement and medical bills: Reimbursement is from ACP dismantling and aluminum extraction.

- o

- Aluminum dismantling costs USD 3643.2 for reimbursement, on average.

- o

- According to Carlos-Rivera et al. [100] and Fontcha et al. [101], the average medical cost of aluminum extraction (non-fatal injuries) is USD 266/case, with an average of four cases/project. With only 30% of aluminum extracted for unusable ACP waste, this may cause 4 × 0.3 = 1.2 cases, with a reimbursement cost of 266 × 1.2 = USD 319.20.

- o

- The total reimbursement cost is 3643.2 + 319.2 = USD 3962.40.

- CSR: Aluminum extraction (for unusable ACP waste, i.e., 30% of ACP waste) generates environmental impacts, and the company needs to compensate the communities through health checks and tree planting campaigns, which cost approximately 9164 × 0.3 = USD 2749.20.

- Savings from refurbished facades: Refurbished ACPs can be used as facades, avoiding the production of new facades. This saves 1.85 × 15,817.79 = USD 29,262.91.

- Sales of ACP waste: With ACP waste of 6779.05 kg, it can be sold at second-hand shops for 0.31 × 6779.05 = USD 2101.51.

- Carbon credit: The recovery of 15,817.79 kg ACPs can reduce CO2eq emissions by 15,817.79 × 13.9 = 219,867.28 kg CO2eq, incurring a carbon credit of 219,867.28 × 0.0052 = USD 1143.30.

- PM reduction: ACP recovery reduces PM by 15,817.79 × 0.00586 = 92.69 kg PM and saves 92.69 × 0.45 = USD 41.71.

- Water savings: Water saved from ACP recovery is 15,817.79 × 0.2 × 0.58 = USD 1834.86.

- Metal savings: With an estimated depletion saving rate of USD 0.25/kg Feeq, the metal savings are 15,817.79 × 0.25 = USD 3954.45.

- Fuel savings: Material recovery saves fuel by 15,817.79 × 1.1 = 17,399.57 kg oileq. This saves 17,399.57 × 0.26 = USD 4523.89.

- Savings in CSR cost: Material recovery (usable ACP waste) promotes a green image of the company and reduces the CSR cost by 9164 × 0.7 = USD 6414.80.

- New employment: Refurbishing usable ACPs creates job opportunities equivalent to 15,817.79 × 1.82 = 28,788.38 h. The labor rate of USD 1.3/h means that the benefit from new employment is 28,788.38 × 1.3 = USD 37,424.89.

- Savings from legal permission: Refurbishing reduces the use of landfills. Legal permission for land use and impacts to the community costs about USD 74/m2. Refurbishing 15,817.79 kg of ACPs saves landfill space by 23.1 m2, bringing the savings to 74 × 23.1 = USD 1709.40.

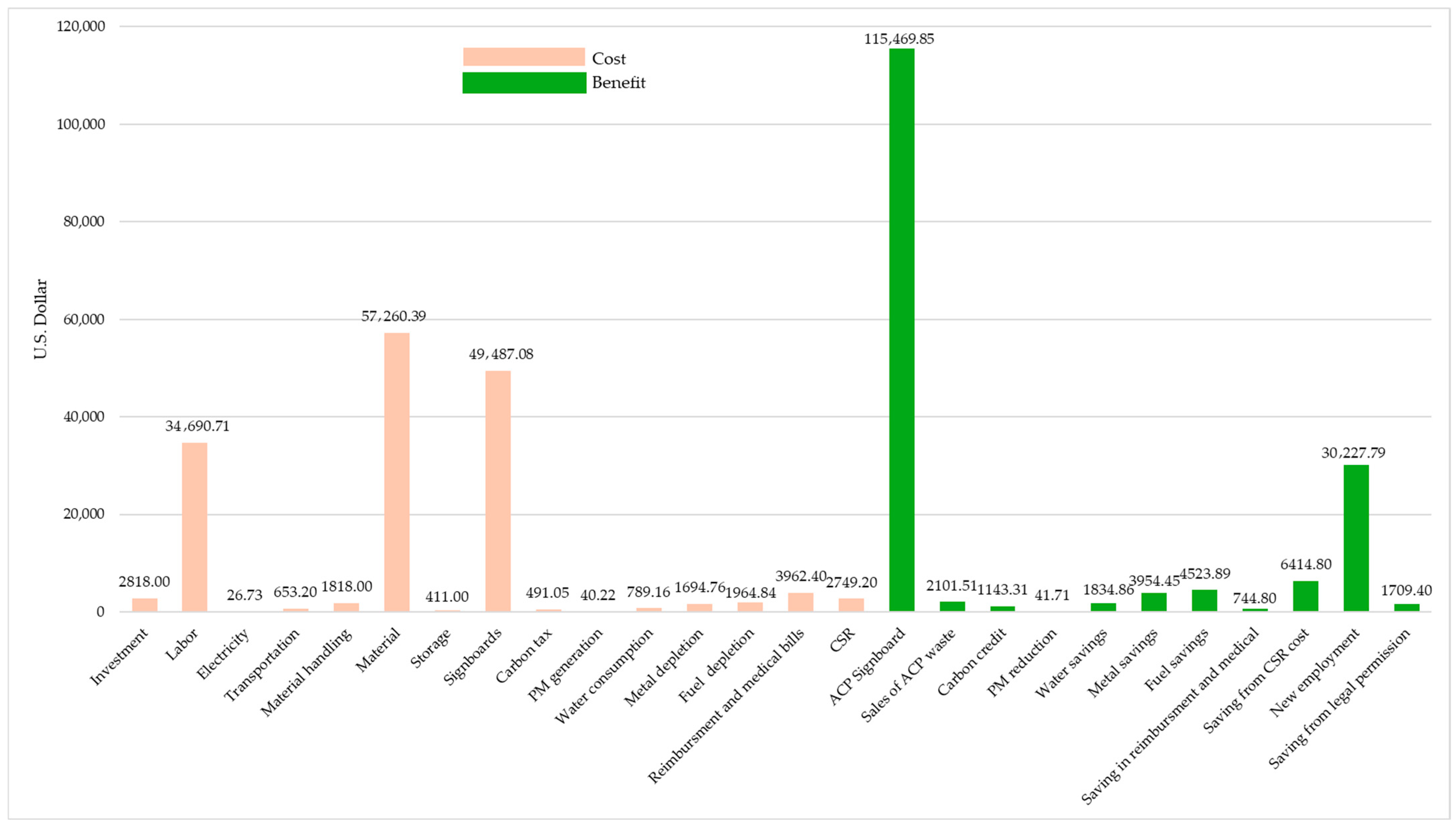

4.3. CBA Results of Scenario 3 (Repurposing)

- Investment in equipment and tools:

- o

- The repurposing process requires pressure washers, saw cutters, spray guns, hole saws, hot glue guns, mounting equipment, and a sticker-format printer, which are estimated at USD 2513.

- o

- Unused ACPs are sold at second-hand shops that require pressure washers and edge trimming machines for their operations. The equipment cost is estimated at USD 305.02.

- o

- The total investment cost is 2513 + 305.02 = USD 2818.02.

- Labor: Laborers must extract ACPs from old buildings (manual dismantling) and load them onto trucks for transportation. They are also required at the repurposing facility.

- o

- Manual dismantling takes three months and three laborers, costing 3 × 349 × 3 = USD 3141.

- o

- Seven laborers are required in the repurposing process. At a labor rate of USD 1.3/h, repurposing one kg of ACPs takes 1.47 h. With 15,817.79 kg of ACP waste (usable ACPs), it costs 1.47 × 1.3 × 15,817.79 = USD 30,227.8.

- o

- Seven laborers are required in the second-hand ACP preparation process. With 6779.05 kg of ACP waste (usable ACPs), it costs 0.15 × 1.3 × 6779.05 = USD 1321.91.

- o

- The total labor cost is 3141 + 30,227.8 +1321.91 = USD 34,690.71.

- Electricity: At a consumption rate of 0.013 kWh/kg, the electricity cost for the repurposing process is 0.013 × 15,817.79 × 0.13 = USD 26.73.

- Transportation: Usable ACP waste is transported to repurposing facilities, while the unusable amount is transferred to second-hand shops.

- o

- For truck rental, transporting 15,817.79 kg of ACP waste requires three trips and one trip to the second-hand shop. One truck rental trip is USD 152. This incurs 4 × 152 = USD 608 for a 6-wheel truck rental.

- o

- The fuel consumption for travel from the demolition site to the repurposing facility is about 41.8 km/trip. With fuel efficiency of 4.5 km/L and a fuel cost of USD 1/L, this incurs a cost of 41.8/4.5 × 1 × 3 = USD 27.87. A trip to a second-hand shop, with an average distance of 78 km/trip, costs 78/4.5 × 1 × 1 = USD 17.33.

- o

- The total transportation cost is then 608 + 27.87 +17.33 = USD 653.2.

- Material handling: A forklift handles ACP waste in a repurposing facility. With a rental cost of USD 606/month and a three-month processing period, this incurs a material handling cost of USD 606 × 3 = USD 1818.

- Materials: Adhesives, graphic films, LED light, and polyurethane framing are used for ACP repurposing, costing (0.91 + 1.4 + 0.75 + 0.56) × 15,817.79 = USD 57,260.39.

- Storage: Temporary storage is required for three months before ACPs are transported to the facilities. This costs 137 × 3 = USD 411.

- Signboards: In total, 30% of new LED signboards (equivalent to 6779.05 kg of unusable ACP waste) must be purchased. At a cost of USD 7.3/kg, this incurs a cost of USD 7.3 × 6779.05 = USD 49,487.07.

- Carbon tax: Carbon tax is calculated from new aluminum extraction, diesel combustion, and electricity generation.

- o

- New aluminum materials are required to create new signboards (i.e., 6779.05 kg of unusable ACP waste). The extraction of aluminum materials emits approximately 13.9 kg of CO2eq/kg of new signboards [98]. CO2eq emissions are calculated as 6779.05 × 13.9 = 94,228.8 kg of CO2eq.

- o

- Transportation to repurposing facilities requires 45.2 L of diesel, which has an emission factor of 2.68 kg CO2eq/L. This generates CO2eq emissions of 45.2 × 2.68 = 121.14 kg CO2eq.

- o

- Electricity consumption of 0.013 × 15,817.79 = 205.63 kWh is required for equipment utilization to repurpose ACPs. This incurs CO2eq emissions of 205.63 × 0.399 = 82.05 kg CO2eq.

- o

- The carbon tax is calculated as (94,228.8 + 121.14 + 82.05) × 0.0052 = USD 491.05.

- PM generation: PM is generated during ACP dismantling, diesel combustion, electricity generation, and aluminum extraction.

- o

- PM is generated at 22,596.84 ×0.00214 = 48.36 kg PM for ACP dismantling.

- o

- Transportation to the repurposing facility consumes 45.2 L of diesel, equivalent to 45.2 × 0.0013 = 0.059 kg PM.

- o

- Electricity consumption of 205.63 kWh may produce 0.006 × 205.63 = 1.23 kg PM.

- o

- Aluminum extraction produces 0.00586 kg of PM/kg of ACP; thus, producing 6779.05 kg of ACPs generates 6779.05 × 0.00586 = 39.73 kg PM.

- o

- The PM-related cost is then (48.36 + 0.059 + 1.23 + 39.73) × 0.45 = USD 40.22.

- Water consumption: Water is used in new ACP production and the operations at the second-hand shops.

- o

- With 6779.05 kg of new ACP production, the water cost is USD 786.37 × 0.2 × 0.58.

- o

- The operations at the second-hand shops incur a water cost of 6779.05 × 0.00071 × 0.58 = USD 2.79.

- o

- The total water consumption cost is USD 789.16.

- Metal depletion: Aluminum extraction (equivalent to 6779.05 kg of Feeq) contributes to the irreversible depletion of finite mineral resources, which incurs a cost of USD 1694.76 (6779.05 × 0.25).

- Fuel depletion: Fuel consumption occurs in transportation and repurposing processes.

- o

- A trip to the repurposing facility costs 45.2 L of diesel, resulting in fuel depletion of 45.2 × 0.85 = 38.42 kg oileq.

- o

- About 1.1 kg of oil is consumed per kg of new ACP production, resulting in 6779.05 × 1.1 = 7456.96 kg.

- o

- With 205.63 kWh required for repurposing, fuel depletion is 0.3 × 205.63 = 61.69 kg oileq.

- o

- The fuel depletion cost is (38.42 + 7456.96 + 61.69) × 0.26 = USD 1964.84.

- Reimbursement and medical bills: Reimbursement is from ACP dismantling and aluminum extraction.

- o

- Aluminum dismantling costs USD 3643.2 for reimbursement, on average.

- o

- In total, 30% of aluminum is extracted for unusable ACP waste; this carries a reimbursement cost of 266 × 4 × 0.3 = USD 319.2.

- o

- The total reimbursement cost is 3643.2 + 319.2 = USD 3962.4.

- CSR: Aluminum extraction (for unusable ACP waste, i.e., 30% of ACP waste) generates environmental impacts, and the company needs to compensate the communities through health checks and tree planting campaigns, which costs approximately 9164 × 0.3 = USD 2749.2.

- ACP signboards: Using repurposed ACPs as signboards avoids the production of new signboards, saving USD 7.3 × 15,817.79 = USD 115,469.87.

- Sales of ACP waste: With ACP waste of 6779.05 kg, it can be sold at second-hand shops for 0.31 × 6779.05 = USD 2101.51.

- Carbon credit: The recovery of 15,817.79 kg ACPs can reduce CO2eq emissions by 15,817.79 × 13.9 = 219,867.28 kg CO2eq, incurring a carbon credit of 219,867.28 × 0.0052 = USD 1143.3.

- PM reduction: ACP recovery reduces PM by 15,817.79 × 0.00586 = 92.69 kg PM and saves 92.69 × 0.45 = USD 41.71.

- Water savings: Water saved from ACP recovery is 15,817.79 × 0.2 × 0.58 = USD 1834.86.

- Metal savings: With an estimated depletion saving rate of USD 0.25/kg Feeq, the metal savings are 15,817.79 × 0.25 = USD 3954.45.

- Fuel savings: Material recovery saves fuel amounting to 15,817.79 × 1.1 = 17,399.57 kg oileq. This saves 17,399.57 × 0.26 = USD 4523.89.

- Savings in reimbursement and medical bills: Material recovery reduces medical bills by 266 × 4 × 0.7 = USD 744.8.

- Savings in CSR cost: Material recovery (usable ACP waste) promotes a green image of the company and reduces the CSR cost by 9164 × 0.7 = USD 6414.8

- New employment: Refurbishing usable ACPs creates job opportunities equivalent to 15,817.79 × 1.47 = 23,252.15 h. The USD 1.3/h labor rate generates a benefit of 23,252.15 × 1.3 = USD 30,227.8.

- Savings from legal permission: Refurbishing reduces the use of landfills. The legal permission for land use and impacts to the community costs about USD 74/m2. Refurbishing 15,817.79 kg of ACPs saves landfill space by 23.1 m2 and brings the savings to 74 × 23.1 = USD 1709.4

4.4. CBA Results of Scenario 4 (Landfilling)

- Land purchase: Based on the interviews, the company must purchase land for ACP waste disposal. With 22,596.84 kg of ACPs at a density of 5.4 kg/m2, the area required is 22,596.84/5.4 = 4184.6 m2. A panel thickness of 4 mm results in a landfill volume of 4184.6 × 0.004 = 16.74 m3. With an average stacking height of 2.5 m, the area needed is 16.74/2.5 = 6.67 m2. In addition, a 200% additional area is required to accommodate road access, safety zones, and handling operations, increasing the required area to 6.67 × 3 = 20.01 m2 [95,96]. The land cost is 20.01 × 675.79 = USD 13,522.56.

- Labor: Laborers are required to load ACPs onto trucks for transportation from the demolition site to the designated landfill. They must also extract ACPs from old buildings (manual dismantling) and load them onto trucks for transportation. They are also required at the repurposing facility.

- o

- Manual dismantling takes three months and three laborers, costing 3 × 349 × 3 = USD 3141.

- o

- Five laborers are required for landfill operations. The landfilling process takes three months, costing 5 × 349 × 3 = USD 5235.

- o

- The total labor cost is 3141 + 5235 = USD 8376.

- Transportation: ACP waste is transported to landfills, and the cost comprises truck rental and fuel consumption.

- o

- The truck rental cost is calculated from the number of trips and the truck rental fee: 4 × 152 = USD 608.

- o

- The fuel cost is calculated from the distance between the demolition site and landfill, the fuel consumption rate, the fuel price, and the number of trips: 47.2/4.5 × 1 × 4 = USD 41.96.

- o

- This yields a total transportation cost of USD 649.96.

- Material handling: ACPs are dismantled using a crane. Forklifts and bulldozers transport ACP waste to landfills.

- o

- The crane is rented for USD 485/month for three months, or USD 485 × 3 = USD 1455.

- o

- The forklift is rented for USD 463/month for three months, costing USD 606 × 3 = USD 1818.

- o

- The bulldozer is rented at USD 3399/month for three months, costing 3399 × 3 = USD 10,197.

- o

- This yields a total material handling cost of 1455 + 1818 + 10,197 = USD 13,470.

- Carbon tax: CO2eq emissions occur during diesel combustion.

- o

- Truck transportation to landfills requires 41.96 L.

- o

- A crane requires 10 L/h, with a maximum of 160 working hours/month for three months; the diesel consumption is then 10 × 160 × 3 = 4800 L.

- o

- A forklift requires 2 L/h, with a maximum of 160 h/month for three months; the diesel consumption is then 2 × 160 × 3 = 960 L.

- o

- A bulldozer requires 12 L/h, with a maximum of 160 h/month for three months, yielding diesel consumption of 12 × 160 × 3 = 5760 L.

- o

- The carbon tax is then (41.96 + 4800 + 960 + 5760) × 2.68 × 0.0052 = USD 161.13.

- PM generation: PM is generated from demolition activities, diesel fuel combustion, and landfill preparation.

- o

- PM is generated at 22,596.84 × 0.00214 = 48.36 kg for ACP dismantling.

- o

- Diesel combustion generates PM at (41.96 + 4800 + 960 + 5760) × 0.0013 = 15.03 kg.

- o

- For landfill development, landfill preparation releases approximately 1.5 kg of PM/m2. With the required space of 20.01 m2, this becomes 20.01 × 1.5 = 30.01 kg of PM.

- o

- This incurs a PM-related cost of (48.36 + 15.03 + 30.01) × 0.45 = USD 42.03.

- Fuel depletion: The fuel depletion is calculated by converting diesel consumption to oil equivalents.

- o

- Using 41.96 L of diesel in truck transportation causes fuel depletion of 41.96 × 0.85 = 35.66 kg oileq.

- o

- The fuel depletion of a crane is 10 × 160 × 3 × 0.85 = 4080 kg oileq.

- o

- The fuel depletion of forklifts is 2 × 160 × 3 × 0.85 = 816 kg oileq.

- o

- The fuel depletion of bulldozers is 12 × 160 × 3 × 0.85 = 4896 kg oileq.

- o

- The total fuel depletion cost is (35.66 + 4080 + 816 + 4896) × 0.26 = USD 2555.19.

- Reimbursement and medical bills: ACP dismantling causes a reimbursement cost of USD 3643.2.

- CSR: This cost, approximately USD 9164, covers a community health check, dust mitigation, and tree planting activities.

- Legal permission: Landfill operations require official approval from relevant government authorities, such as the Department of Industrial Works, Office of Natural Resources and Environmental Policy and Planning, and Pollution Control Department [99]. The permits cover land use, environmental compliance, and pollution control to protect nearby communities. The legal cost for obtaining such permissions is USD 74/m2. The total legal permission cost is 33.48 × 74 = USD 2477.52.

5. Discussion

5.1. CBA Result Discussion

5.2. Sensitivity Analysis of the Repurposing Scenario

5.3. The Use of KM to Integrate the Repurposing Scenario with LEED Certification

- The group meetings summarize details of the selected repurposing scenario to pinpoint key cost- and benefit-related activities.

- Data from this scenario are shared between team members using Google Docs and updated regularly.

- Meetings with contractors are organized to finalize the selected scenario. Team members share experiences from past projects regarding LEED certification to set action plans for certification. Tentative action plans are checked with the LEED criteria to ensure their integrity and the possibility of implementation.

- The analysis steps and results are shared between stakeholders and stored in the project’s files for future reference.

6. Conclusions

- This study contributes to the body of knowledge as follows:

- The study integrates the use of KM into C&D waste management, making it effective for sustainable planning and development.

- Several scenarios are proposed for waste management. The results are presented by C/B ratios, making them easy to understand and facilitating planning for implementation.

- This study’s cost and benefit data cover the economic, environmental, and social perspectives, representing a complete sustainability concept.

- The selected end-of-life management scenario is mapped with the LEED criteria—specifically the MR credits—guiding the preliminary steps toward green certification.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Summary of Costs Used in the Analysis

| Scenario | Element | Information | Definition | Detail | Reference | Country/Year |

| Reselling (As-is) | ACP | ACP waste from demolition | ACPs are extracted using cranes from the demolished building to be sold to a second-hand shop |

| [74,75], interviews, observations | Thailand/2025 |

| Cost | Investment | Equipment and tools, specifically pressure washers and edge trimming machines |

| [105] | Thailand/2019 | |

| Labor | Laborers for reselling process |

| [106], observations | Thailand/2025 | ||

| Transportation | Truck transportation to the second-hand shop |

| [6,107], interviews, observations | UK/2020, USA/2016, Thailand/2025 | ||

| Material handling | Cranes used for ACP extraction |

| [106], observations | Thailand/2019, Thailand/2025 | ||

| Environmental-related costs | CO2eq cost is calculated using carbon tax PM cost refers to expected health issues from PM generation Water costs are incurred in the cleaning process Fuel cost comes from the use of machinery and transportation |

| [82,91,104,105,107,108,109] | USA/2016, Guinea/2019, Thailand/2019, South Asia/2019, EU/2024, Brazil/2025, Thailand/2025 | ||

| Social-related costs | Reimbursement cost comes from injuries related to ACP extraction and activities CSR costs come from community campaigns, such as regular health checks and tree planting |

| [94,110,111], interviews | Thailand/2011, China/2020, Thailand/2025 | ||

| Refurbishing | ACPs | ACP waste from demolition | ACPs are manually extracted and refurbished as new ACP facades |

| [74,75], interviews, observations | - |

| Cost | Investment | Equipment and tools, specifically pressure washers, orbital sanders, saw cutters, and spray guns |

| [105] | Thailand/2019 | |

| Labor | Laborers for refurbishing and reselling processes |

| [106,111] | China/2020, Thailand/2025 | ||

| Electricity | Electricity consumption for equipment and tools |

| [38,105] | Thailand/2019, Thailand/2024 | ||

| Transportation | Truck transportation to the refurbishing plant and second-hand shop |

| [6,107], interviews, observations | USA/2016, UK/2020, Thailand/2025 | ||

| Material handling | Forklifts used in the refurbishing process |

| [105,111], observations | Thailand/2019, China/2020, Thailand/2025 | ||

| Material | Material needed for new ACP facade production |

| [92,111] | China/2020, Thailand/2023 | ||

| Storage | Storage for the refurbishing process |

| [105], interviews, observations | Thailand/2019, Thailand/2025 | ||

| Environmental-related costs | CO2eq cost is calculated using carbon tax PM cost refers to expected health issues from PM generation Water costs are incurred in the cleaning process Fuel cost comes from the use of machinery and transportation |

| [82,91,104,105,107,108,109] | USA/2016, Guinea/2019, Thailand/2019, South Asia/2019, EU/2024, Brazil/2025, Thailand/2025 | ||

| Social-related costs | Reimbursement cost comes from injuries related to ACP extraction and activities CSR costs come from community campaigns, such as regular health checks and tree planting |

| [94,112] | Thailand/2011, USA/2017 | ||

| Repurposing | ACP | ACP waste from demolition | ACPs are manually extracted and repurposed as LED signboards |

| [74,75], interviews, observations | Thailand/2025 |

| Cost | Investment | Equipment and tools, specifically pressure washers, saw cutters, spray guns, hole saws, hot glue guns, mounting equipment, and sticker-format printers |

| [105] | Thailand/2019 | |

| Cost | Labor | Laborers for the repurposing and reselling processes |

| [106,111] | China/2020, Thailand/2025 | |

| Electricity | Electricity consumption for equipment and tools |

| [38,105] | Thailand/2019, Thailand/2024 | ||

| Transportation | Truck transportation to the repurposing plant and second-hand shop |

| [6,107], interviews, observations | USA/2016, UK/2020, Thailand/2025 | ||

| Material handling | Forklifts used in the repurposing process |

| [105,111], observations | Thailand/2019, China/2020, Thailand/2025 | ||

| Material | Materials needed for LED signboards |

| [92] | Thailand/2023 | ||

| Storage | Storge for the repurposing process |

| [105], interviews, observations | Thailand/2019, Thailand/2025 | ||

| Environmental-related costs | CO2eq cost is calculated using carbon tax PM cost refers to expected health issues from PM generation Water costs are incurred in the cleaning process Fuel cost comes from the use of machinery and transportation |

| [82,91,104,105,107,108,109] | USA/2016, Guinea/2019, Thailand/2019, South Asia/2019, Brazil/2025, Thailand/2025 | ||

| Social-related costs | Reimbursement cost comes from injuries related to ACP extraction and activities CSR costs come from community campaigns, such as regular health checks and tree planting |

| [94,112] | Thailand/2011, USA/2017 | ||

| Landfilling | ACP | ACPs from the demolition site | Landfilled ACPs |

| [74,75], interviews, observations | - |

| Cost | Landfill | Landfill preparation |

| [38,91,94,95,96,109] | Thailand/2024, Thailand/2025 | |

| Labor | Laborers for the landfilling process |

| [106], observations | Thailand/2025 | ||

| Transportation | Truck transportation to landfills |

| [6,107], interviews, observations | USA/2016, UK/2020, Thailand/2025 | ||

| Material handling | Cranes used for ACP extraction Forklifts and bulldozers used in the landfilling process |

| [105], interviews, observations | Thailand/2019, Thailand/2025 | ||

| Environmental-related costs | CO2eq cost is calculated using carbon tax PM cost refers to expected health issues from PM generation Water costs are incurred in the cleaning process Fuel cost comes from the use of machinery and transportation |

| [82,91,105,107,108,109,113,114] | USA/2016, Guinea/2019, Thailand/2019, South Asia/2019, EU/2024, Brazil/2025, Thailand/2025 | ||

| Social-related costs | Reimbursement cost comes from injuries related to ACP extraction and activities CSR costs come from community campaigns, such as regular health checks and tree planting |

| [94,110,112], interviews | Thailand/2011, USA/2017, Thailand/2025 |

Appendix B. Summary of Benefits Used in the Analysis

| Scenario | Information | Definition | Detail | Reference | Country/Year |

| Reselling (as is) | Sales of ACP waste | Revenue earned by selling ACP waste |

| [92,112] | USA/2017, Thailand/2023 |

| Refurbishing | Savings from refurbishing ACPs as new facades | Savings by using refurbished ACPs for new facade materials |

| [74,75,111] | China/2020 |

| Savings from environmental impact avoidance | Savings achieved from reduced emissions and pollutions |

| [38,82,91,101] | USA/2015, Guinea/2019, Thailand/2024 | |

| Savings from social-related activities | Savings achieved from reduced legal issues and job opportunities |

| [91,94,106] | Thailand/2011, Thailand/2025 | |

| Repurposing | Savings from repurposing ACPs as signboards | Savings by using ACPs as signboards |

| [74,75,111] | China/2020 |

| Savings from environmental impact avoidance | Savings achieved from reduced emissions and pollution |

| [38,82,91,101] | USA/2015, Guinea/2019, Thailand/2024 | |

| Savings from social-related activities | Savings achieved from reduced legal issues and job opportunities |

| [91,94,106] | Thailand/2011, Thailand/2025 |

References

- Ajayi, B.O.; Bamisaye, M.E.; Macedo, H.M.M.; Sereewatthanawut, I. Integrating system dynamics and machine learning for environmental impact analysis of building materials in the demolition process. Sci. Rep. 2025, 15, 27114. [Google Scholar] [CrossRef]

- Mayowa, B.; Chinda, T. Environmental assessment of demolition tools used in townhouse demolition: System dynamics modeling. Sustainability 2023, 15, 14382. [Google Scholar] [CrossRef]

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Ferronato, N.; Moresco, L.; Lizarazu, G.E.G.; Portillo, M.A.G.; Conti, F.; Torretta, V. Comparison of environmental impacts related to municipal solid waste and construction and demolition waste management and recycling in a Latin American developing city. Environ. Sci. Pollut. Res. 2021, 30, 8548–8562. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2019, 244, 118710. [Google Scholar] [CrossRef]

- Doan, D.T.; Chinda, T. Modeling Construction and Demolition Waste Recycling Program in Bangkok: Benefit and cost analysis. J. Constr. Eng. Manag. 2016, 142, 12. [Google Scholar] [CrossRef]

- Rinsatitnon, N.; Dijaroen, W.; Limpiwun, T.; Suktavee, G.; Chinda, T. Reverse logistics implementation in the construction industry: Paper waste focus. Songklanakarin J. Sci. Technol. (SJST) 2018, 40, 798–805. [Google Scholar] [CrossRef]

- Ubolsook, P.; Podong, C.; Sedpho, S.; Jansanthea, P. Assessing the environmental impact of construction waste management in northern Thailand: An approach to estimate greenhouse gas emissions and cumulative energy demand. J. Clean. Prod. 2024, 467, 142961. [Google Scholar] [CrossRef]

- Phuwanan, C. The situation of using aluminum composite walls in Thailand. NAJUA: Architecture, Design and Built Environment 2016, 21, 103. Available online: https://so04.tci-thaijo.org/index.php/NAJUA-Arch/article/view/45347 (accessed on 1 September 2025).

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Yamada, M.; Kawamoto, K. A review of construction and demolition waste management in Southeast Asia. J. Mater. Cycles Waste Manag. 2019, 22, 315–325. [Google Scholar] [CrossRef]

- Boonkanit, P.; Suthiluck, K. Developing a Decision-Making support System for a smart construction and demolition waste transition to a circular economy. Sustainability 2023, 15, 9672. [Google Scholar] [CrossRef]

- Ngieng, H.Y.; Hadibarata, T.; Rubiyatno, N. Utilization of construction and demolition waster and environmental management practice in Southeast Asian countries. Trop. Aquat. Soil Pollut. 2021, 1, 46–61. [Google Scholar] [CrossRef]

- Tanthanawiwat, K.; Gheewala, S.H.; Nilsalab, P.; Schoch, M.; Silalertruksa, T. Environmental sustainability and cost performances of construction and demolition waste management scenarios: A case study of timber and concrete houses in Thailand. J. Clean. Prod. 2024, 436, 140652. [Google Scholar] [CrossRef]

- USGBC, LEED v4 BD+C: New Construction—MR Credit: Construction and Demolition Waste Management. Available online: https://www.usgbc.org/leed (accessed on 28 June 2025).

- Haapalainen, P.; Pusa, K. Knowledge Management Processes. Int. J. Inf. Syst. Serv. Sect. 2012, 4, 29–39. [Google Scholar] [CrossRef]

- Korkmaz, K.A. Implementation of knowledge management in construction projects. Adv. Civ. Eng. Technol. 2018, 2, 539. [Google Scholar] [CrossRef]

- Fuentes-Ardeo, L.; Otegi-Olaso, J.R.; Aguilar-Fernandez, M.E. How the project knowledge management and the sustainability in project management affect the project success. In Proceedings of the 2027 9th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Bucharest, Romania, 21–23 September 2017; pp. 884–887. [Google Scholar] [CrossRef]

- Khoa, V.D.; Chinda, T. Assessment of Construction Competitiveness through Knowledge Management Process Implementation. Sustainability 2023, 15, 15897. [Google Scholar] [CrossRef]

- Wang, L.; Lv, Y.; Wang, T.; Wan, S.; Ye, Y. Assessment of the impacts of the life cycle of construction waste on human health: Lessons from developing countries. Eng. Constr. Archit. Manag. 2023, 32, 1348–1369. [Google Scholar] [CrossRef]

- Magrini, C.; Pozzo, A.D.; Bonoli, A. Assessing the externalities of a waste management system via life cycle costing: The case study of the Emilia-Romagna Region (Italy). Waste Manag. 2021, 138, 285–297. [Google Scholar] [CrossRef]

- Martinez-Sanchez, V.; Levis, J.W.; Damgaard, A.; DeCarolis, J.F.; Barlaz, M.A.; Astrup, T.F. Evaluation of externality costs in Life-Cycle Optimization of municipal solid waste Management Systems. Environ. Sci. Technol. 2017, 51, 3119–3127. [Google Scholar] [CrossRef]

- Taelman, S.; Sanjuan-Delmás, D.; Tonini, D.; Dewulf, J. An operational framework for sustainability assessment including local to global impacts: Focus on waste management systems. Resour. Conserv. Recycl. 2020, 162, 104964. [Google Scholar] [CrossRef]

- What Are Demolition Waste Recycling Compliance Laws? Available online: https://www.okonrecycling.com/construction-and-demolition-waste/mixed-construction-waste/demolition-waste-recycling-compliance-laws/ (accessed on 1 September 2025).

- Caro, D.; Lodato, C.; Damgaard, A.; Cristóbal, J.; Foster, G.; Flachenecker, F.; Tonini, D. Environmental and socio-economic effects of construction and demolition waste recycling in the European Union. Sci. Total Environ. 2023, 908, 168295. [Google Scholar] [CrossRef]

- Jutidamrongphan, W. Sustainable waste management and waste to energy recovery in Thailand. In InTech eBooks; IntechOpen Limited: London, UK, 2018. [Google Scholar] [CrossRef]

- Biek, S.K.; Khudur, L.S.; Ball, A.S. Challenges and remediation strategies for per- and polyfluoroalkyl substances (PFAS) contamination in composting. Sustainability 2024, 16, 4745. [Google Scholar] [CrossRef]

- Almusaed, A.; Yitmen, I.; Myhren, J.A.; Almssad, A. Assessing the impact of recycled building materials on environmental sustainability and energy efficiency: A comprehensive framework for reducing greenhouse gas emissions. Buildings 2024, 14, 1566. [Google Scholar] [CrossRef]

- Chinda, T. Examination of factors influencing the successful implementation of reverse logistics in the construction industry: Pilot study. Procedia Eng. 2017, 182, 99–105. [Google Scholar] [CrossRef]

- Paktiawal, A.; Alam, M. An experimental study on effect of aluminum composite panel waste on performance of cement concrete. Ain Shams Eng. J. 2020, 12, 83–98. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic building materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Tan, H.C.; Carrillo, P.M.; Anumba, C.J. Case Study of Knowledge Management Implementation in a Medium-Sized Construction Sector Firm. J. Manag. Eng. 2011, 28, 338–347. [Google Scholar] [CrossRef]

- Kokkaew, N.; Jokkaw, N.; Peansupap, V.; Wipulanusat, W. Impacts of human resource management and knowledge management on non-financial organizational performance: Evidence of Thai infrastructure construction firms. Ain Shams Eng. J. 2022, 13, 101750. [Google Scholar] [CrossRef]

- Cerezo-Narváez, A.; Pastor-Fernández, A.; Otero-Mateo, M.; Ballesteros-Pérez, P. The influence of knowledge on managing risk for the success in complex construction projects: The IPMA approach. Sustainability 2022, 14, 9711. [Google Scholar] [CrossRef]

- Ferrada, X.; Serpell, A.; Skibniewski, M. Selection of Construction Methods: A Knowledge-Based Approach. Sci. World J. 2013, 2013, 938503. [Google Scholar] [CrossRef]

- Khoa, V.D.; Chinda, T. Dynamic Effects of Management Support on Knowledge-Based Competitiveness in construction Companies. Buildings 2025, 15, 2015. [Google Scholar] [CrossRef]

- USGBC, LEED v4 Rating System Review (BD+C and ID+C) Materials and Resources v4. Available online: https://www.usgbc.org/education/sessions/materials-resources-v4-12845794 (accessed on 26 June 2025).

- Chayutthanabun, A.; Chinda, T. Circular Economy Implications in Aluminum Composite Panel Reuse: A Case Study in Thailand; School of Management Technology, Sirindhorn International Institute of Technology, Thammasat University: Pathum Thani, Thailand, 2025; manuscript in preparation. [Google Scholar]

- Materials and Resources in LEED v. 4.1. Building Green Webinar. Available online: https://leeduser.buildinggreen.com/sites/default/files/USGBC_LEEDv4.1_MR_Webinar_1.28.19.pdf (accessed on 26 June 2025).

- Ari, I.; Yikmaz, R.F. Greening of industry in a resource- and environment-constrained world. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2019; pp. 53–68. [Google Scholar] [CrossRef]

- Diabat, A.; Kannan, D.; Mathiyazhagan, K. Analysis of enablers for implementation of sustainable supply chain management—A textile case. J. Clean. Prod. 2014, 83, 391–403. [Google Scholar] [CrossRef]

- Zhang, B.; Larsson, J.; Reim, W. Circular Business Models for Construction Companies: A Literature Review and Future Research Directions. Sustainability 2025, 17, 4688. [Google Scholar] [CrossRef]

- Markatos, D.N.; Katsiropoulos, C.V.; Tserpes, K.I.; Pantelakis, S.G. A holistic End-of-Life (EoL) Index for the quantitative impact assessment of CFRP waste recycling techniques. Manuf. Rev. 2021, 8, 18. [Google Scholar] [CrossRef]

- Yuzvovich, L.; Lvova, M.; Isakova, N. Waste management: Environmental strategies and practices. E3S Web Conf. 2024, 541, 04004. [Google Scholar] [CrossRef]

- Bauer, T.; Brissaud, D.; Zwolinski, P. Design for High Added-Value End-of-Life strategies. In Sustainable Production, Life Cycle Engineering and Management; Springer: Berlin/Heidelberg, Germany, 2017; pp. 113–128. [Google Scholar] [CrossRef]

- Marello, M.; Helwege, A. Solid waste management and social inclusion of waste pickers: Opportunities and challenges. Lat. Am. Perspect. 2017, 45, 108–129. [Google Scholar] [CrossRef]

- Hosseini, S.; Shrivastava, M.; Qi, L.; Weise, D.R.; Cocker, D.R.; Miller, J.W.; Jung, H.S. Effect of low-density polyethylene on smoke emissions from burning of simulated debris piles. J. Air Waste Manag. Assoc. 2014, 64, 690–703. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- Charlotte, L.; Eberhardt, M.; Birgisdottir, H. Building the future using the existing building stock: The environmental potential of reuse. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012020. [Google Scholar] [CrossRef]

- Boyd, A.J.; Banthia, N.; Mindess, S. Retrofit of shear strength deficient RC beams with sprayed GFRP. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2009; pp. 1–10. [Google Scholar] [CrossRef]

- Jayakody, S.; Gallage, C.; Ramanujam, J. Performance characteristics of recycled concrete aggregate as an unbound pavement material. Heliyon 2019, 5, e02494. [Google Scholar] [CrossRef] [PubMed]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Exploring environmental benefits of reuse and recycle practices: A circular economy case study of a modular building. Resour. Conserv. Recycl. 2020, 160, 104855. [Google Scholar] [CrossRef]

- Milad, A. Recycled and upcycled materials in contemporary architecture and civil engineering: Their applications, benefits, and challenges. Clean. Waste Syst. 2025, 10, 100203. [Google Scholar] [CrossRef]

- Brough, D.; Jouhara, H. The aluminium industry: A review on state-of-the-art technologies, environmental impacts and possibilities for waste heat recovery. Int. J. Thermofluids 2020, 1–2, 100007. [Google Scholar] [CrossRef]

- Khan, M.W.A.; Ting, N.H.; Kuang, L.C.; Darun, M.R.; Mehfooz, U.; Khamidi, M.F. Green Procurement in Construction industry: A theoretical perspective of enablers and Barriers. MATEC Web Conf. 2018, 203, 02012. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Metin, B.; Tavil, A. Environmental assessment of external wall cladding construction. Archit. Sci. Rev. 2014, 57, 215–226. [Google Scholar] [CrossRef]

- ASKIN Performance Panels. Available online: https://www.askin.net.au/media-resources/case-studies/exteriors/ (accessed on 26 June 2025).

- Chen, C. A study on the renewal construction of office building exterior. Procedia Eng. 2011, 21, 155–162. [Google Scholar] [CrossRef]

- Novotný, M. FacadeFacade renovation—Replacement and restoration of the panels in a monument protected object. Sel. Sci. Pap. 2017, 12, 87–94. [Google Scholar] [CrossRef]

- Mavriqi, L.; Valente, F.; Sinjari, B.; Trubiani, O.; Caputi, S.; Traini, T. Water-Airborne-Particle Abrasion as a Pre-Treatment to improve bioadhesion and bond strength of Glass–Ceramic restorations: From In Vitro Study to 15-Year Survival Rate. Materials 2021, 14, 4966. [Google Scholar] [CrossRef]

- Rose, C. Systems for Reuse, Repurposing and Upcycling of Existing Building Components. Doctoral Thesis, University College London, London, UK, April 2019. [Google Scholar]

- Borges, C.; Chícharo, A.; Araújo, A.; Silva, J.; Santos, R.M. Designing of carbon fiber-reinforced polymer (CFRP) composites for a second life in the aeronautic industry: Strategies towards a more sustainable future. Front. Mater. 2023, 10, 1179270. [Google Scholar] [CrossRef]

- Nadoushani, Z.S.M.; Akbarnezhad, A.; Jornet, J.F.; Xiao, J. Multi-criteria selection of facade systems based on sustainability criteria. Build. Environ. 2017, 121, 67–78. [Google Scholar] [CrossRef]

- Manelius, A.-M.; Nielsen, S.; Kauschen, J.S. ReBeauty—Artistic Strategies for repurposing material components. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012023. [Google Scholar] [CrossRef]

- Thushari, I.; Vicheanteab, J.; Janjaroen, D. Material flow analysis and life cycle assessment of solid waste management in urban green areas, Thailand. Sustain. Environ. Res. 2020, 30, 21. [Google Scholar] [CrossRef]

- Ali, N.E.; Sion, H.C. Solid waste management in Asian countries: A review of solid waste minimization (3’r) towards low carbon. IOP Conf. Ser. Earth Environ. Sci. 2014, 18, 012152. [Google Scholar] [CrossRef]

- Kooduvalli, K.; Unser, J.; Ozcan, S.; Vaidya, U.K. Embodied energy in pyrolysis and solvolysis approaches to recycling for carbon Fiber-Epoxy reinforced composite waste streams. Recycling 2022, 7, 6. [Google Scholar] [CrossRef]

- Samreen, S.; Agarwal, M.K.; Gautam, A.K.; Khajanchi, Y. Comprehensive review of solid waste management strategies and disposal approaches. Multidiscip. Rev. 2024, 6, 2023ss076. [Google Scholar] [CrossRef]

- Ortega, B. Cost-Benefit analysis. In Springer eBooks; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1316–1319. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, F.; Yong, Y. CN111086126A-Recycling and Circulating Preparation Method for Aluminum-Plastic Composite Board-Patents. Available online: https://patents.google.com/patent/CN111086126A/en (accessed on 1 September 2025).

- Casado, U.M.; Altuna, F.I.; Miccio, L.A. A review on the Role of Crosslinked Polymers in Renewable Energy: Complex Network Analysis of Innovations in Sustainability. Sustainability 2025, 17, 4736. [Google Scholar] [CrossRef]

- Tastet, C.; Alsayyed, B. Solar recycling of aluminum cans. ASME Int. Mech. Eng. Congr. Expo. 2024, 88605, V002T03A041. [Google Scholar] [CrossRef]

- Laminators Inc. Available online: https://www.laminatorsinc.com/adaptaclad-rs/ (accessed on 26 June 2025).

- Alucobond. Available online: https://3acompositesusa.com/downloads/Alucobond-How-To-Fabrication-Guide.pdf (accessed on 26 June 2025).

- Cornelio, A.; Zanoletti, A.; Braga, R.; Depero, L.E.; Bontempi, E. The Reuse of Industrial By-Products for the Synthesis of Innovative Porous Materials, with the Aim to Improve Urban Air Quality. Appl. Sci. 2021, 11, 6798. [Google Scholar] [CrossRef]

- International Aluminum Institute. Available online: https://alustory.international-aluminium.org/mining-refining/process-mining/ (accessed on 26 June 2025).

- Johnson, N.M.; Hoffmann, A.R.; Behlen, J.C.; Lau, C.; Pendleton, D.; Harvey, N.; Shore, R.; Li, Y.; Chen, J.; Tian, Y.; et al. Air pollution and children’s health—A review of adverse effects associated with prenatal exposure from fine to ultrafine particulate matter. Environ. Health Prev. Med. 2021, 26, 72. [Google Scholar] [CrossRef]

- De Caro, D.; Tedesco, M.M.; Pujante, J.; Bongiovanni, A.; Sbrega, G.; Baricco, M.; Rizzi, P. Effect of recycling on the mechanical properties of 6000 series Aluminum-Alloy Sheet. Materials 2023, 16, 6778. [Google Scholar] [CrossRef] [PubMed]

- Traoré, S.; Diarra, A.; Kourouma, O.; Traoré, D.L. Survey of Bauxite Resources, Alumina Industry and the Prospects of the Production of Geopolymer Composites from the Resulting by-product. In IntechOpen eBooks; IntechOpen Limited: London, UK, 2019. [Google Scholar] [CrossRef]

- Wesdock, J.C.; Arnold, I.M.F. Occupational and environmental health in the aluminum industry. J. Occup. Environ. Med. 2014, 56 (Suppl. 5), S5–S11. [Google Scholar] [CrossRef]

- Widder, L.; Pacioni, T.D.; Bocoum, O. Sustainably growing Guinea’s Bauxite-Aluminum industry. In IntechOpen eBooks; IntechOpen Limited: London, UK, 2019. [Google Scholar] [CrossRef]

- Zhu, J.; Fei, X.; Yiin, X. Assessment of waste-to-energy conversion technologies for biomass waste under different shared socioeconomic pathways. Energy Environ. Sustain. 2025, 2, 100021. [Google Scholar] [CrossRef]

- Singh, S.; Malyan, S.K.; Maithani, C.; Kashyap, S.; Tyagi, V.K.; Singh, R.; Malhotra, S.; Sharma, M.; Kumar, A.; Panday, B.K.; et al. Microplastics in landfill leachate: Occurrence, health concerns, and removal strategies. J. Environ. Manag. 2023, 342, 118220. [Google Scholar] [CrossRef] [PubMed]

- Angmo, S.; Shah, S. Impact of Okhla, Bhalswa and Ghazipur Municipal Waste Dumpsites (Landfill) on groundwater quality in Delhi. Curr. World Environ. 2021, 16, 210–220. [Google Scholar] [CrossRef]

- Van Rooij, B.; Wainwright, A.L.; Wu, Y.; Zhang, Y. The compensation trap: The limits of Community-Based Pollution regulation in China. Pace Environ. Law Rev. 2012, 29, 701. [Google Scholar] [CrossRef]

- Howard, M.; Hopkinson, P.; Miemczyk, J. The regenerative supply chain: A framework for developing circular economy indicators. Int. J. Prod. Res. 2018, 57, 7300–7318. [Google Scholar] [CrossRef]

- Wassénius, E.; Crona, B.; Quahe, S. Essential environmental impact variables: A means for transparent corporate sustainability reporting aligned with planetary boundaries. One Earth. 2024, 7, 211–225. [Google Scholar] [CrossRef]

- Thailand Green Building Institute. Available online: https://tgbi.or.th/en/trees/ (accessed on 26 June 2025).

- Petcharat, N.; Srinammuang, P. Can environmental and social performance of Thai-listed companies create sustainable value? Res. J. Financ. Account. 2019, 10, 10. [Google Scholar] [CrossRef]

- The Complete Guide to Business Signs Cost: What to Expect and How to Budget. Available online: https://www.megasigninc.com/blog/guide-to-business-signs-cost (accessed on 18 June 2025).

- Octopus Media Solutions. Signboard Pricing and Material Cost Guidelines. Internal Market Survey. Available online: https://www.octopus.co.th/products/association-signage?srsltid=AfmBOor4gV1uDpwWJ0ZBdxTGfnL7ZML05AJnan0hoUaoQgrnaoafNVfQ (accessed on 24 April 2025).

- Jobs and Employment Multipliers in the Construction Sector in ASEAN. Available online: https://www.ilo.org (accessed on 18 June 2025).

- Law and Regulation on Solid Wate Management in Thailand. Available online: https://storage.sbg.cloud.ovh.net/v1/AUTH_e8fb231d58fc40ed9af2a222b6ee4c49/KONTENA-PRODUCTION-HOOU/c8abadf4-3aee-4139-8eae-280ac5e67509/original.pdf (accessed on 1 September 2025).

- Integrated Solid Waste Management for Local Governments: A Practical Guide; Asian Development Bank (ABD). Available online: https://www.adb.org/documents/solid-waste-mgt-local-gov (accessed on 1 September 2025).

- Land for Sale in Bang Na, Bangkok. Available online: http://fazwaz.com/land-for-sale/thailand/bangkok/bang-na#:~:text=Land%20for%20sale%20in%20Bang%20Na%2C%20Bangkok&text=This%20property%20is%20a%20968,(%E0%B8%BF28%2C900/SqM).&text=This%20property%20is%20a%20800,(%E0%B8%BF21%2C900/SqM).&text=This%20property%20is%20a%201%2C088,(%E0%B8%BF32%2C500/SqM) (accessed on 1 September 2025).

- Workmen’s Compensation and Reimbursement Report for Occupational Injuries. Available online: https://www.sso.go.th (accessed on 18 June 2025).

- Abubakar, I.R.; Maniruzzaman, K.M.; Dano, U.L.; AlShihri, F.S.; AlShammari, M.S.; Ahmed, S.M.S.; Al-Gehlani, W.A.G.; Alrawaf, T.I. Environmental sustainability Impacts of solid waste management practices in the global South. Int. J. Environ. Res. Public Health 2022, 19, 12717. [Google Scholar] [CrossRef]

- Energy Policy and Planning Office. Available online: http://eppo.go.th/index.php/en/energy-information-services/report-2015 (accessed on 26 June 2025).

- Carlos-Rivera, F.; Aguilar-Madrid, G.; Gómez-Montenegro, P.A.; Juárez-Pérez, C.A.; Sánchez-Román, F.R.; Montandon, J.E.A.D.; Borja-Aburto, V.H. Estimation of health-care costs for work-related injuries in the Mexican Institute of social security. Am. J. Ind. Med. 2008, 52, 195–201. [Google Scholar] [CrossRef]

- Fontcha, D.S.; Spooner, K.; Salemi, J.L.; Naik, E.; Aliyu, M.H.; Mogos, M.F.; Zoorob, R.; Salihu, H.M. Industry-Related injuries in the United States from 1998 to 2011. J. Occup. Environ. Med. 2015, 57, 814–826. [Google Scholar] [CrossRef]

- What Are Aluminum Composite Panels Used for? Applications and Benefits. Available online: https://stacbond.com/en/blog/aluminum-composite-panel-applications-uses-and-advantages-in-architecture/ (accessed on 1 September 2025).

- Aluminum Composite Panel. Much More Than Visual Appeal for Your Facade. Available online: https://alubuild.com/en/what-is-aluminium-composite-panel/#:~:text=many%20more%20buildings.-,Aluminium%20composite%20panel%20applications,For%20interior%20spaces (accessed on 1 September 2025).

- Luo, B.; Su, Y.; Ding, X.; Chen, Y.; Liu, C. Modulation of initial CaO/Al2O3 and SiO2/Al2O3 ratios on the properties of slag/fly ash-based geopolymer stabilized clay: Synergistic effects and stabilization mechanism. Mater. Today Commun. 2025, 47, 113295. [Google Scholar] [CrossRef]

- Chaiyat, N.; Chaongew, S.; Ondokmai, P.; Makarkard, P. Levelized energy and exergy costings per life cycle assessment of a combined cooling, heating, power and tourism system of the San Kamphaeng hot spring, Thailand. Renew. Energy 2019, 146, 828–842. [Google Scholar] [CrossRef]

- Labour Force Survey Quarterly Report. Available online: http://www.nso.go.th (accessed on 20 June 2025).

- Sullivan, B.; Allawatt, G.; Emery, A.; Means, P.; Kramlich, J.; Posner, J. Time-Resolved particulate emissions monitoring of cookstove biomass combustion using a tapered element oscillating microbalance. Combust. Sci. Technol. 2016, 189, 923–936. [Google Scholar] [CrossRef]

- Jesus, S.D.; Dantas, J.A.F.; Peixoto, M.L.; Cavalcante, H.S.; Manta, R.C.; Coutinho, Y.; Lima, N.B.; Nascimento, H.C.B.; Carneiro, A.M.P.; Fucale, S.; et al. Waste of aluminum composite material applied to cement-based mortars and their chemical, microstructural, and mechanical properties. Next Mater. 2024, 7, 100393. [Google Scholar] [CrossRef]

- Corporate Social Responsibility Disclosure Trends. Available online: https://www.set.or.th (accessed on 21 June 2025).

- Review of the Valuation of Environmental Costs and Benefits in World Bank Projects. Available online: https://documents1.worldbank.org/curated/en/573091468781786486/pdf/293490EDP010940Valuation01Public1.pdf (accessed on 26 June 2025).

- Cheng, K.; Zhang, J.; Yi, P.; Zhu, G.; Hao, W.; Ji, W.; Tian, H.; Wang, Y. Exploring the emission characteristics and reduction potential of air pollutants from Chinese aluminum industry: 2005–2025. Earth S Future 2020, 8, e2019EF001440. [Google Scholar] [CrossRef]

- Ertaş, H.; Erdoğan, A.S. An analysis of occupational accidents in demolition work. Civ. Eng. Archit. 2017, 5, 37–51. [Google Scholar] [CrossRef]

- Jabbar, S.A.; Qadar, L.T.; Ghafoor, S.; Rasheed, L.; Sarfraz, Z.; Sarfraz, A.; Sarfraz, M.; Felix, M.; Cherrez-Ojeda, I. Air Quality, Pollution and Sustainability Trends in South Asia: A Population-Based Study. Int. J. Environ. Res. Public Health 2022, 19, 7534. [Google Scholar] [CrossRef]

- Stodt, F.; Maisch, N.; Ruf, P.; Lechler, A.; Riedel, O.; Reich, C. Collaborative Smart Production Supply Chains with Blockchain Based Digital Product Passports. Preprints 2024, 2024021194. [Google Scholar] [CrossRef]

| Building | Area (m2) | Unit Weight (kg/m2) | Total Weight (kg) |

|---|---|---|---|

| Parking | 353 | 5.49 | 1937.97 |

| Main | 3763 | 5.49 | 20,658.87 |

| Net weight | 22,596.84 |

| Scenario | Total Cost (USD) | Total Benefit (USD) | C/B Ratio | Rank |

|---|---|---|---|---|

| Repurposing | 158,856.76 | 168,166.39 | 0.94 | 1 |

| Refurbishing | 101,715.84 | 89,156.52 | 1.14 | 2 |

| Reselling | 23,969.83 | 7005.05 | 3.42 | 3 |

| Landfilling | 54,061.35 | - | - | 4 |

| Reusable Percentage (%) | Cost | Benefit | C/B Ratio |

|---|---|---|---|

| 50 | 168,499.36 | 124,654.27 | 1.35 |

| 70 | 158,856.74 | 168,166.39 | 0.94 |

| 90 | 145,954.7 | 211,678.47 | 0.69 |

| Credit | Detail | Explanation | Supported by the Repurposing Scenario? |

|---|---|---|---|

| 1 | Building lifecycle impact reduction | Up to 5 points could be earned through one of four options—reuse of building elements, renovation, historic building preservation, or whole-building LCA—with ≥ 20% reduction in global warming potential and ≥ 10% reduction in two other impact categories. | No (only 1 point could be earned from reusing 70% of ACPs as signboards in renovations). |

| 2 | Environmental product declarations (EPDs) | Up to 2 points could be earned: 1 point for using at least 20 products with EPDs and one additional point for optimization. | No: ACPs do not come with EPDs unless newly purchased. |

| 3 | Sourcing of raw materials | Up to 2 points could be earned: 1 point for using at least 20 products with recycled, reused, or certified content; 1 additional point for optimization. | Yes: Repurposed ACPs are counted as reused materials. If their cost is documented, they could contribute toward the 25% threshold by cost. |

| 4 | Material ingredients | Up to 2 points could be earned: 1 point for using at least 20 different permanently installed products from at least five manufacturers; 1 additional point for material ingredient optimization. | No: Repurposed ACPs lack ingredient disclosure documentation. |

| 5 | C&D waste management | Up to 2 points could be earned by diverting ≥ 50% or ≥75% of C&D waste from landfills, with no material stream minimum required. | Yes: ACP waste used as signboards diverts up to 70% of C&D waste from landfills through repurposing. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sereewatthanawut, I.; Ajayi, B.O.; Emmanuel, B.M.; Bunphot, A.; Chayutthanabun, A.; Niyomukiza, J.B.; Chinda, T. Sustainable Material Recovery from Demolition Waste: Knowledge Management and Insights from a Public Sector Building Renovation. Buildings 2025, 15, 3167. https://doi.org/10.3390/buildings15173167

Sereewatthanawut I, Ajayi BO, Emmanuel BM, Bunphot A, Chayutthanabun A, Niyomukiza JB, Chinda T. Sustainable Material Recovery from Demolition Waste: Knowledge Management and Insights from a Public Sector Building Renovation. Buildings. 2025; 15(17):3167. https://doi.org/10.3390/buildings15173167

Chicago/Turabian StyleSereewatthanawut, Issara, Babatunde Oluwaseun Ajayi, Bamisaye Mayowa Emmanuel, Adithep Bunphot, Anatawat Chayutthanabun, John Bosco Niyomukiza, and Thanwadee Chinda. 2025. "Sustainable Material Recovery from Demolition Waste: Knowledge Management and Insights from a Public Sector Building Renovation" Buildings 15, no. 17: 3167. https://doi.org/10.3390/buildings15173167

APA StyleSereewatthanawut, I., Ajayi, B. O., Emmanuel, B. M., Bunphot, A., Chayutthanabun, A., Niyomukiza, J. B., & Chinda, T. (2025). Sustainable Material Recovery from Demolition Waste: Knowledge Management and Insights from a Public Sector Building Renovation. Buildings, 15(17), 3167. https://doi.org/10.3390/buildings15173167