Investigation of Borehole Network Parameters for Rock Breaking via High-Pressure Gas Expansion in Subway Safety Passages of Environmentally Sensitive Zones

Abstract

1. Introduction

2. Principles and Feasibility of High-Pressure Gas Expansion Rock-Fracturing Technology

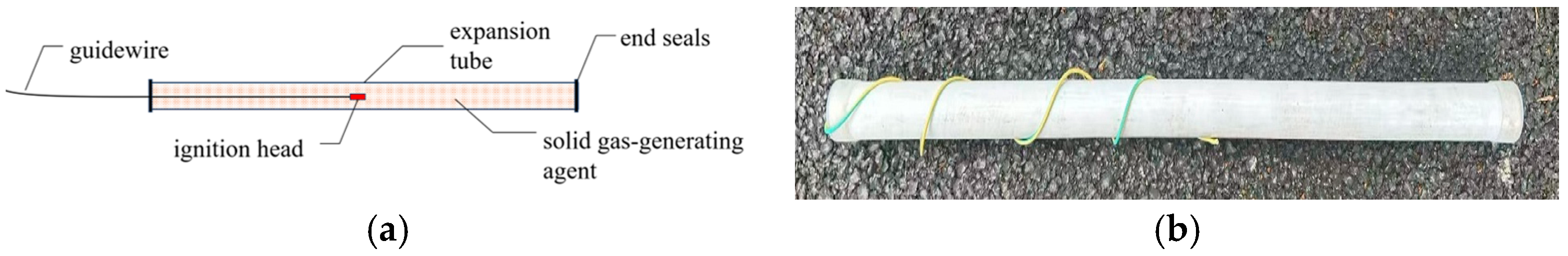

2.1. Rock-Fracturing Equipment and Process

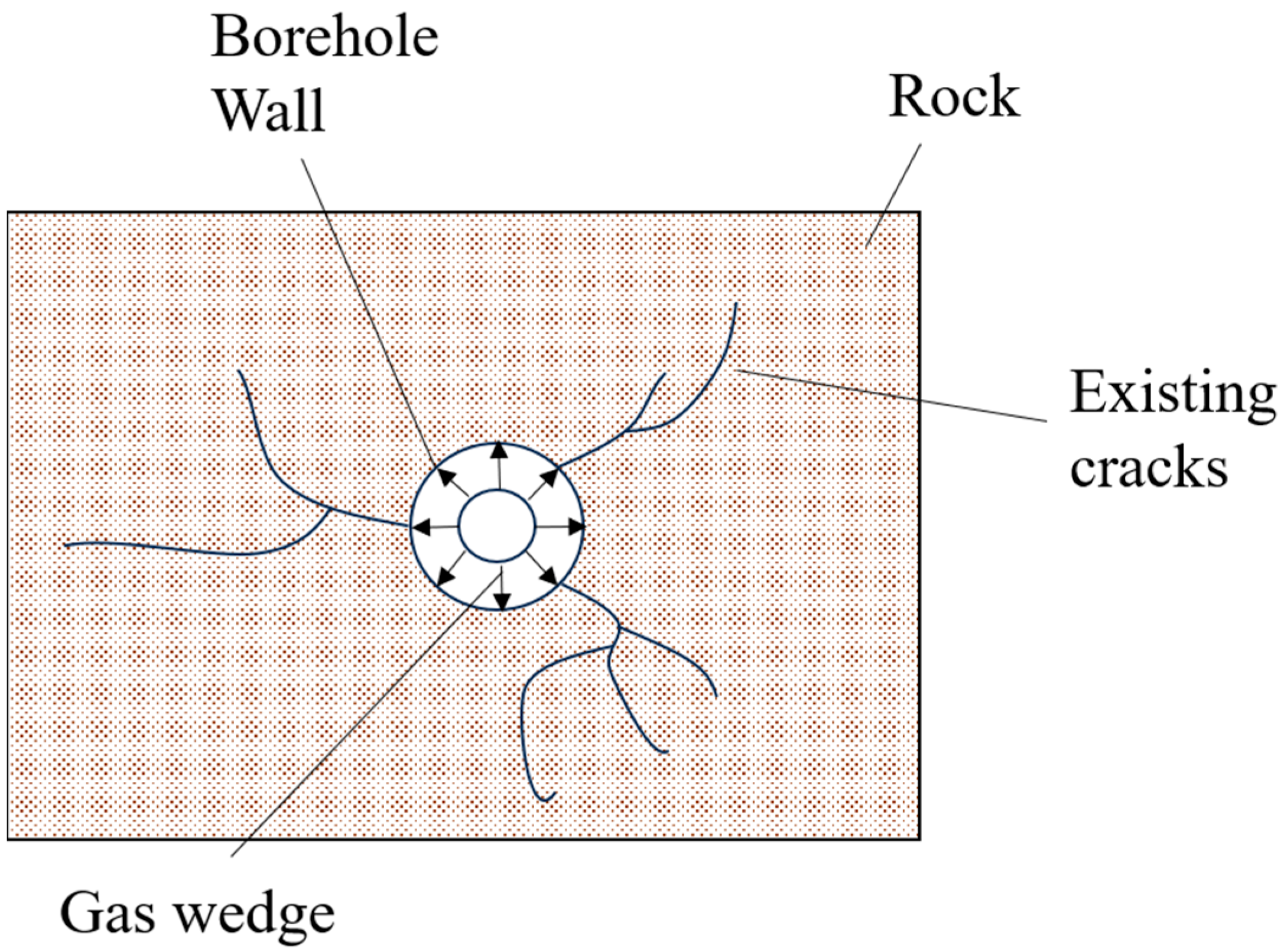

2.2. Theoretical Analysis of High-Pressure Gas Expansion Rock Fracturing

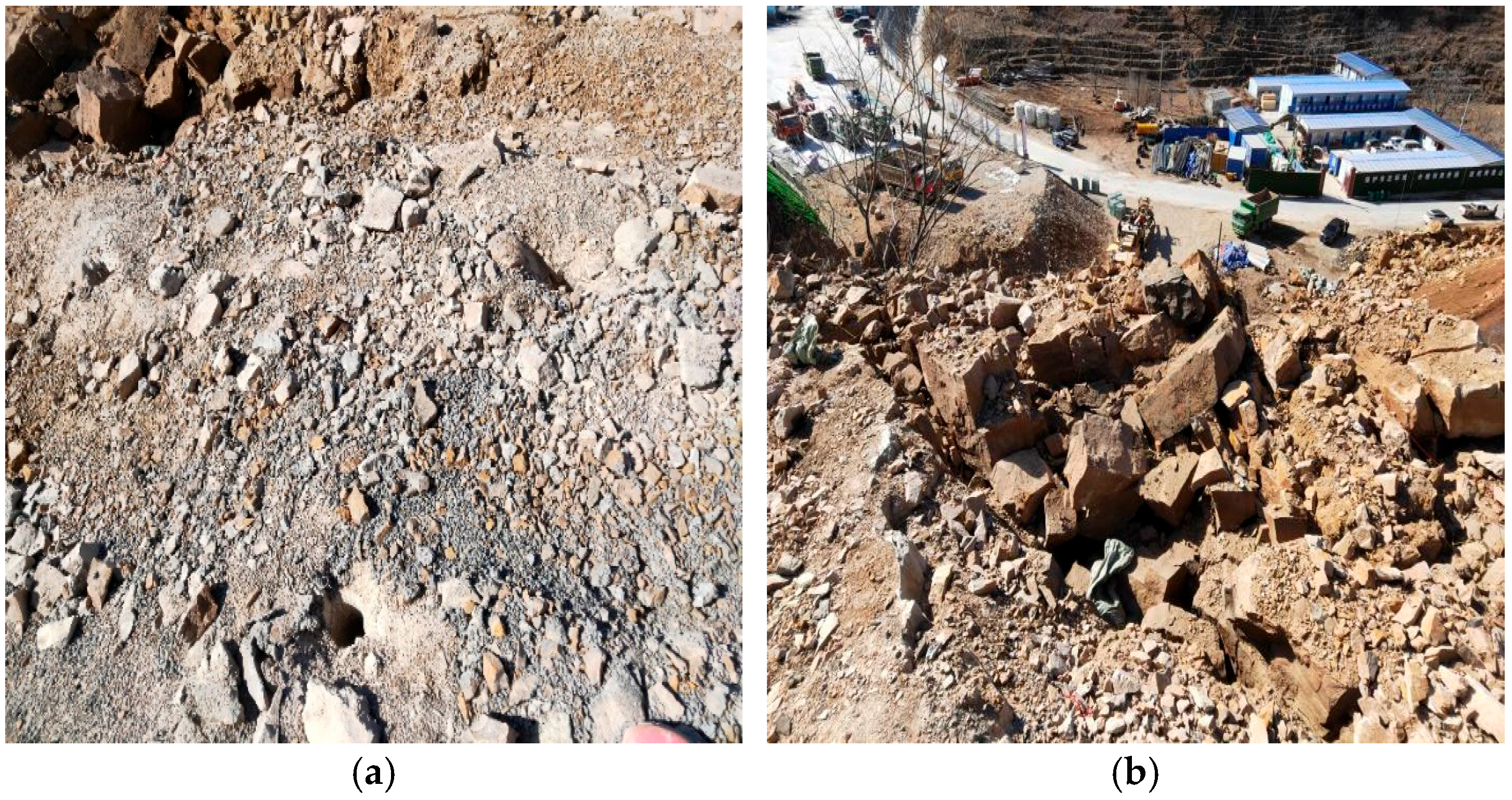

2.3. Feasibility Analysis

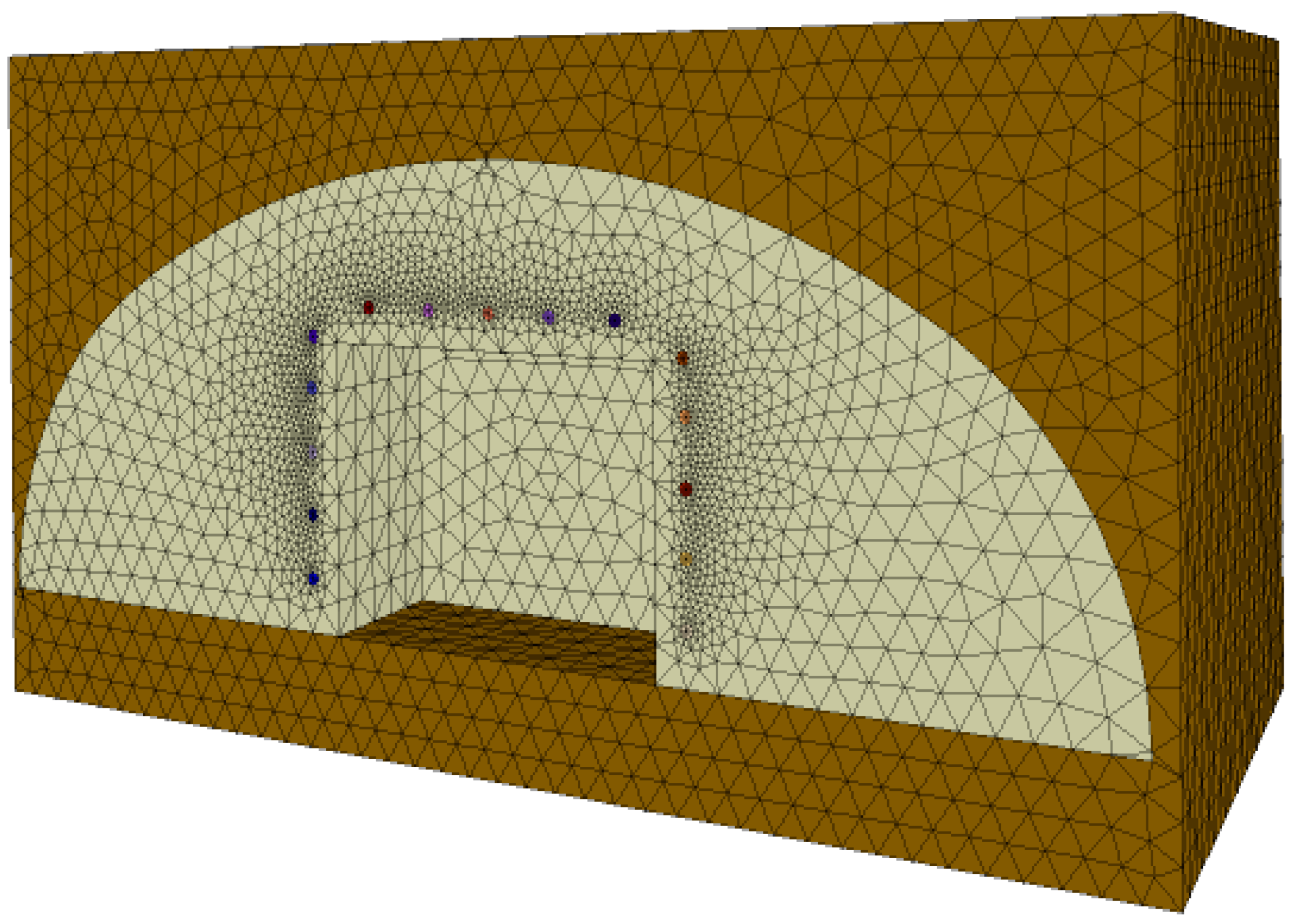

3. Finite Element Analysis

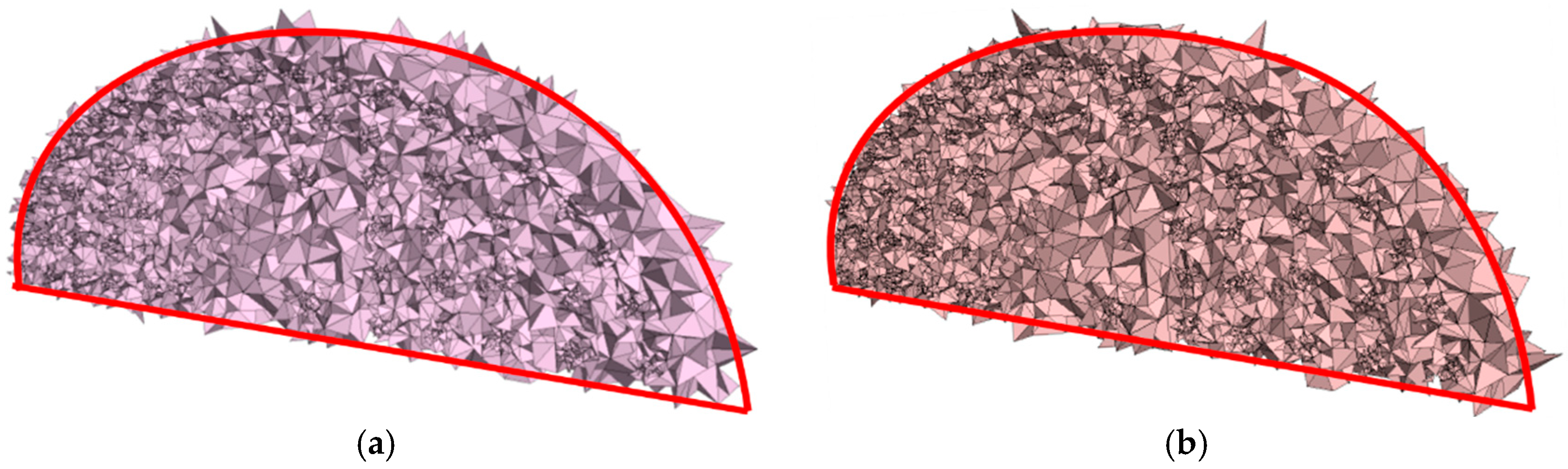

3.1. Model Parameters

3.1.1. Geological Parameters

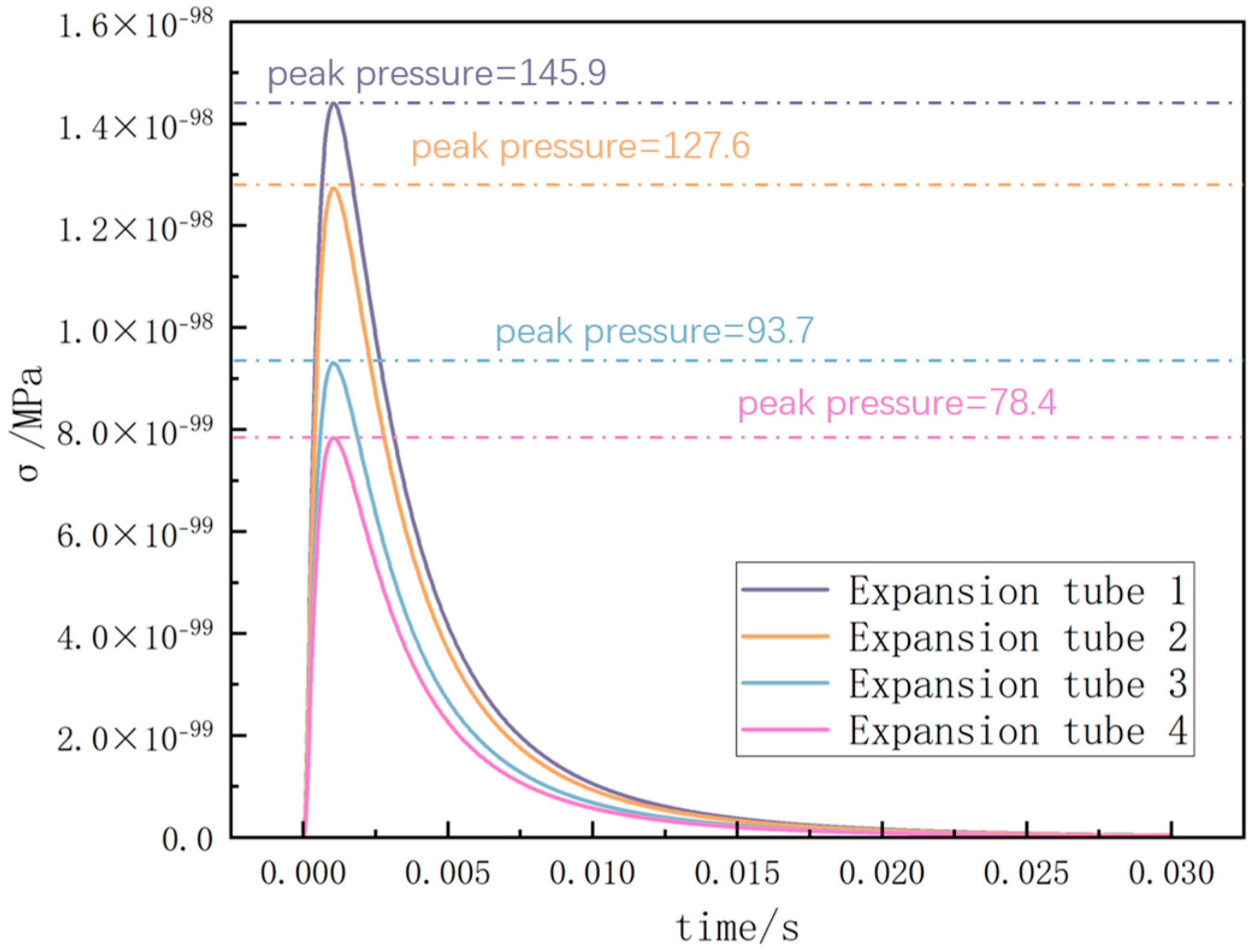

3.1.2. Expansion Tube Action Parameters

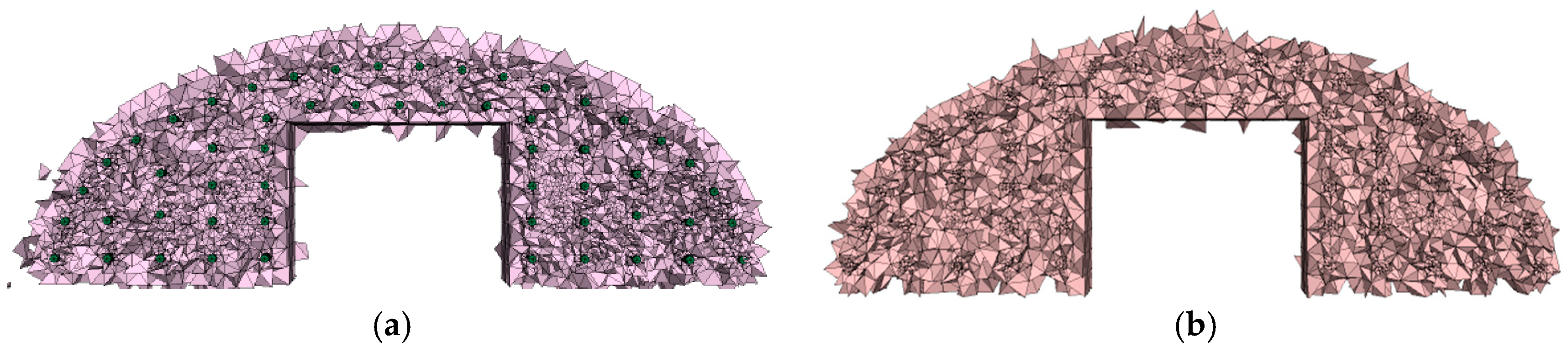

3.2. Study on Borehole Network Parameters in the Cut Area

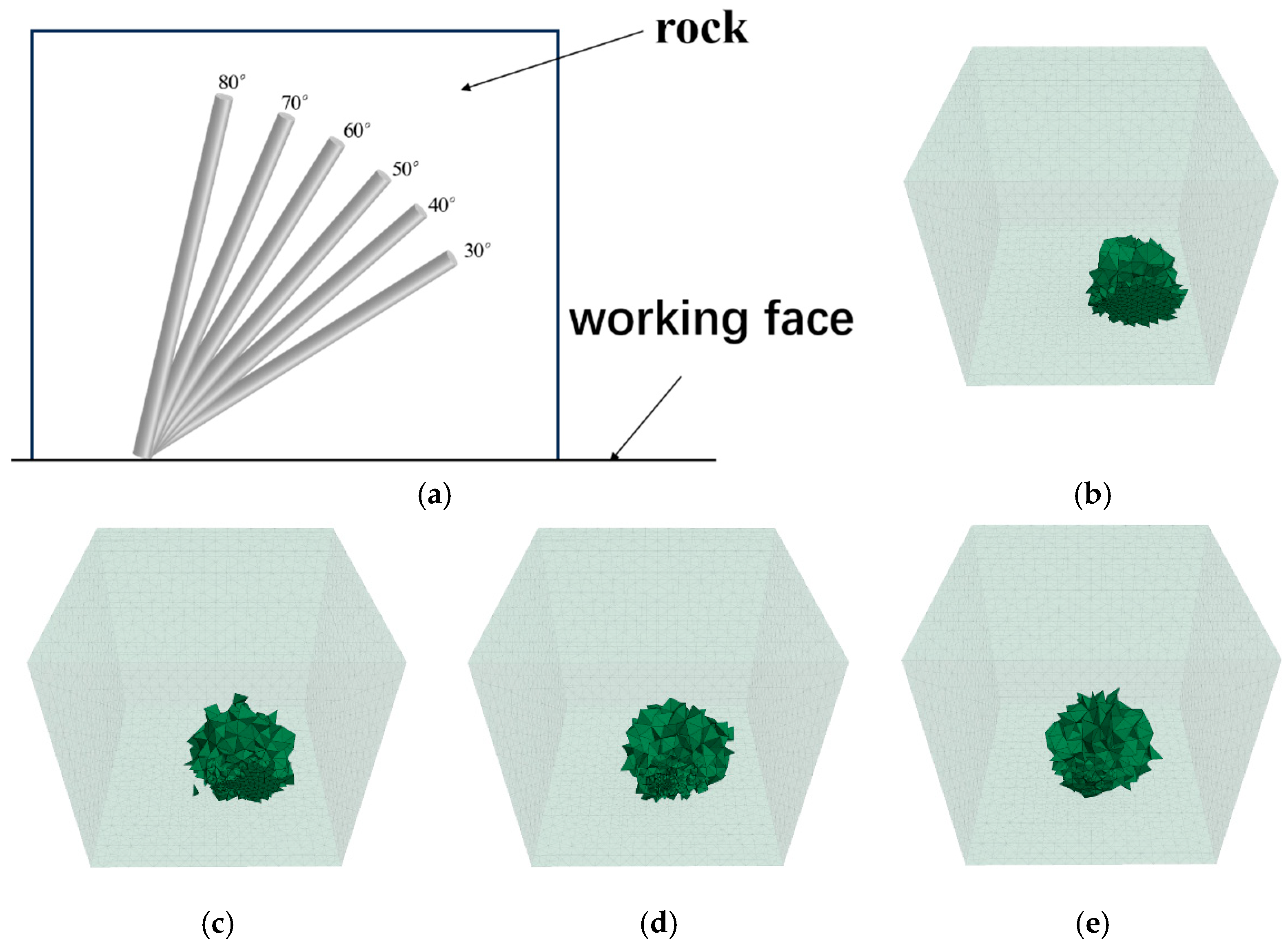

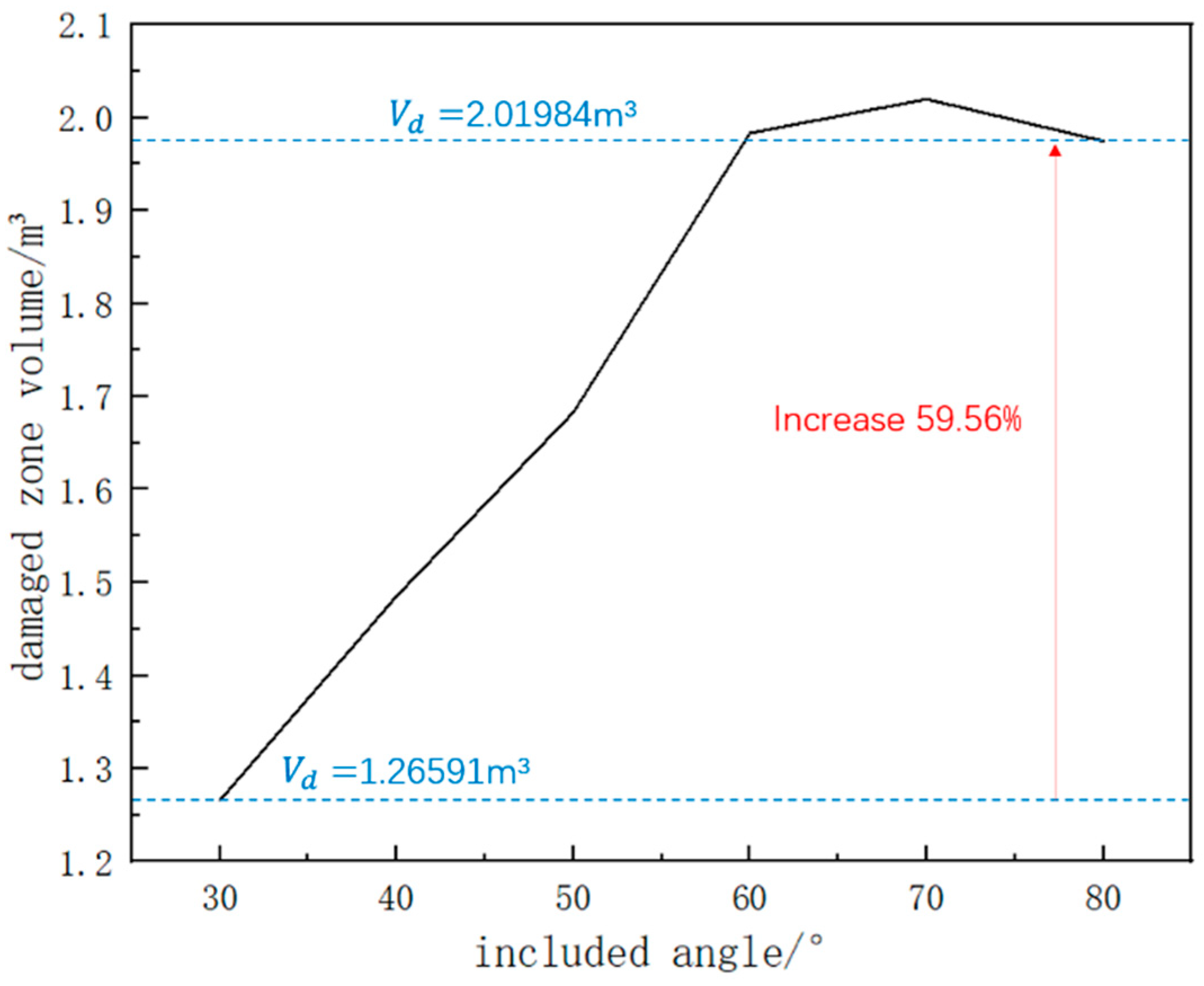

3.2.1. Research on the Optimization of Hole Angle Spacing

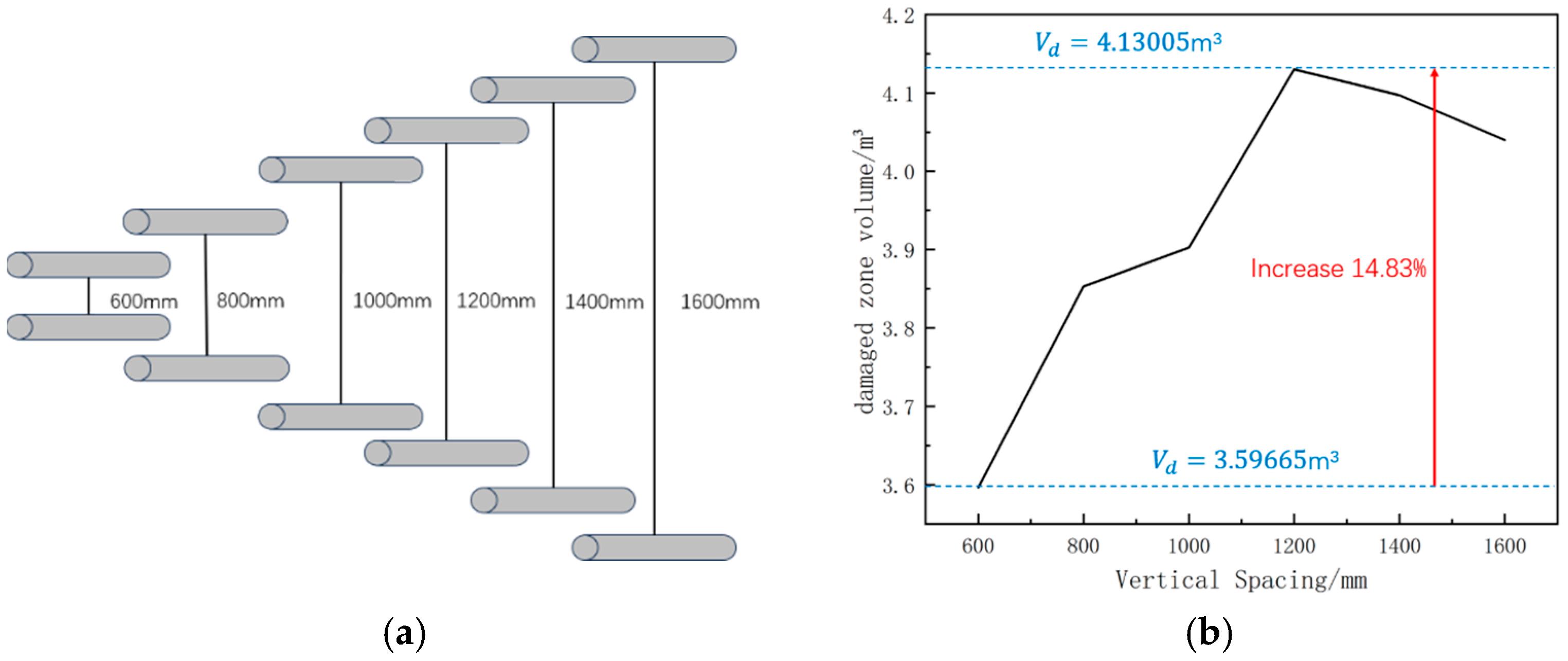

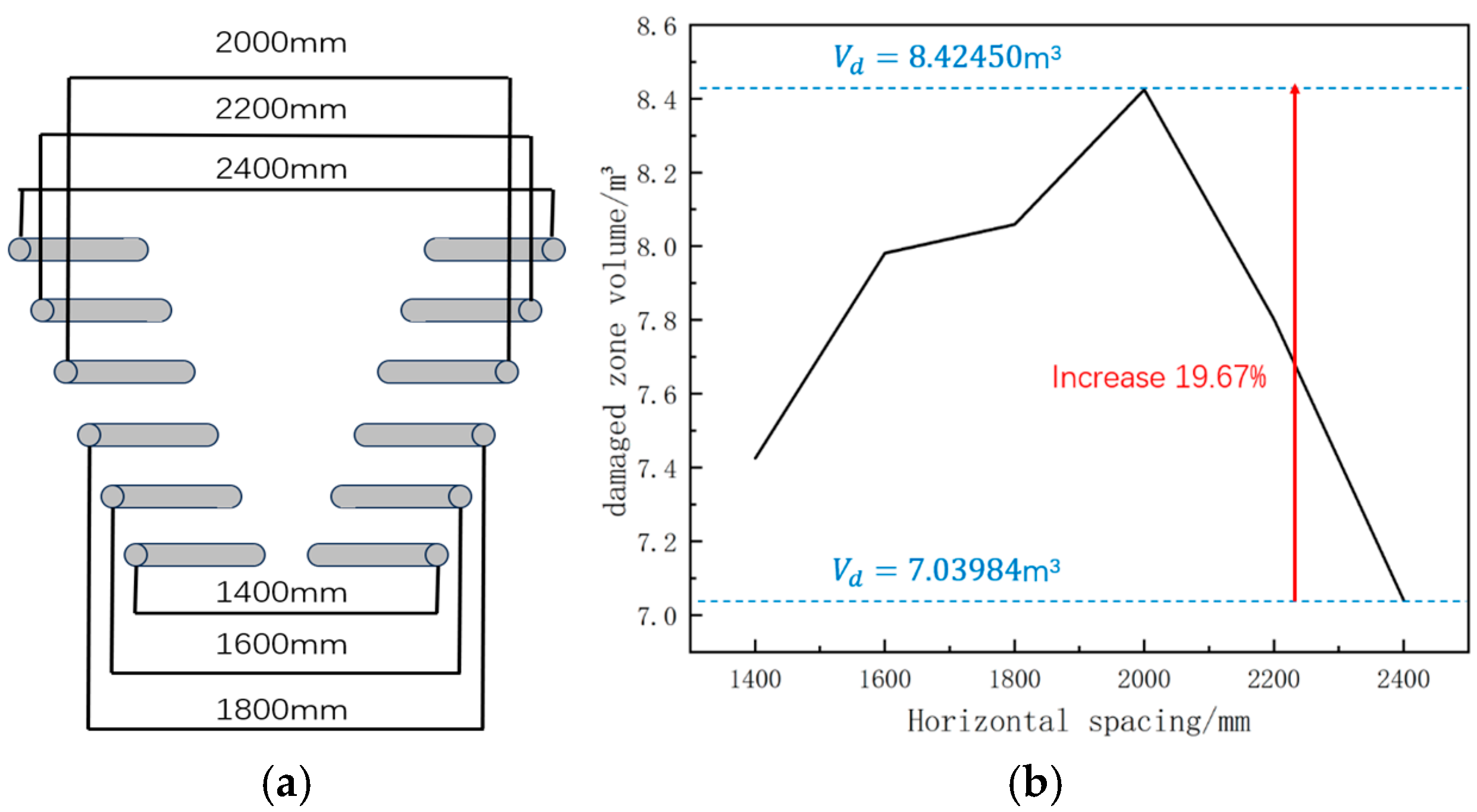

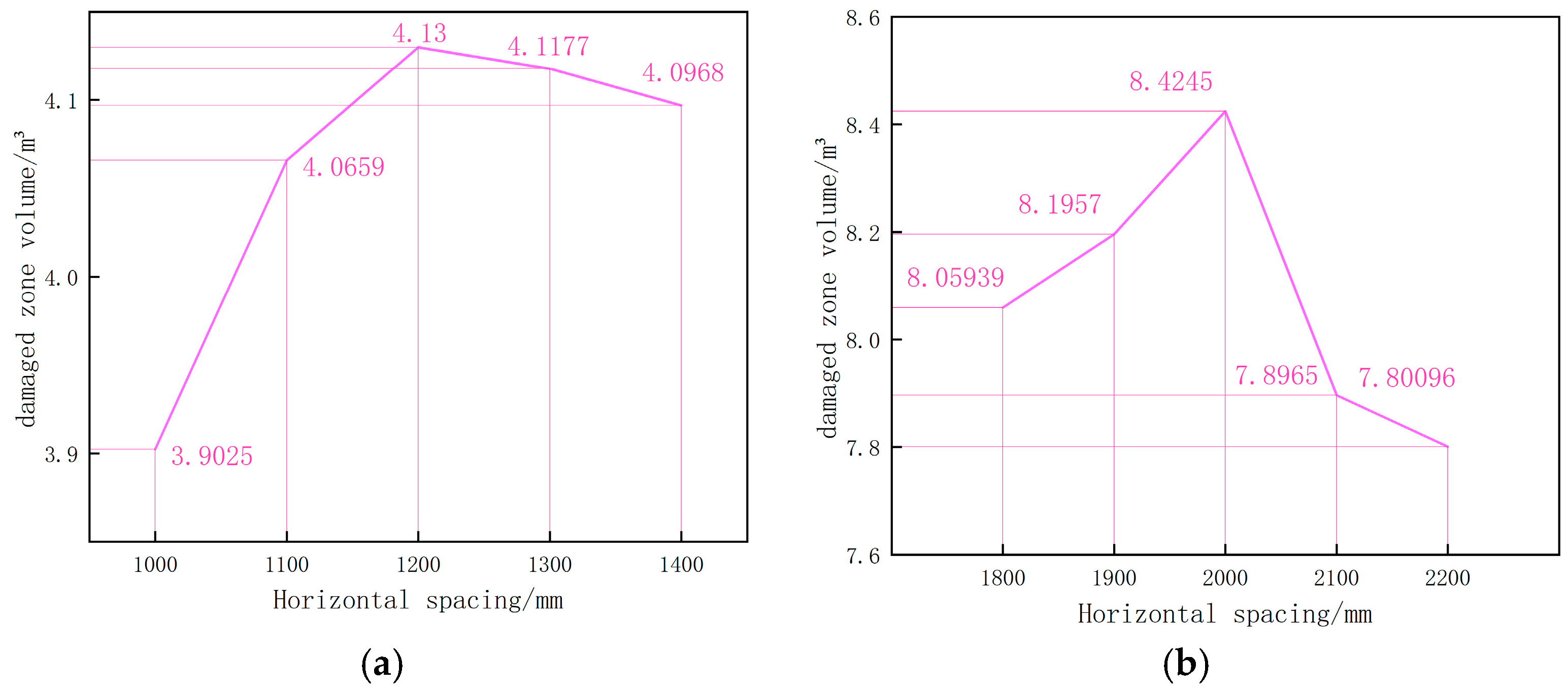

3.2.2. Optimization Study on Borehole Spacing Arrangement

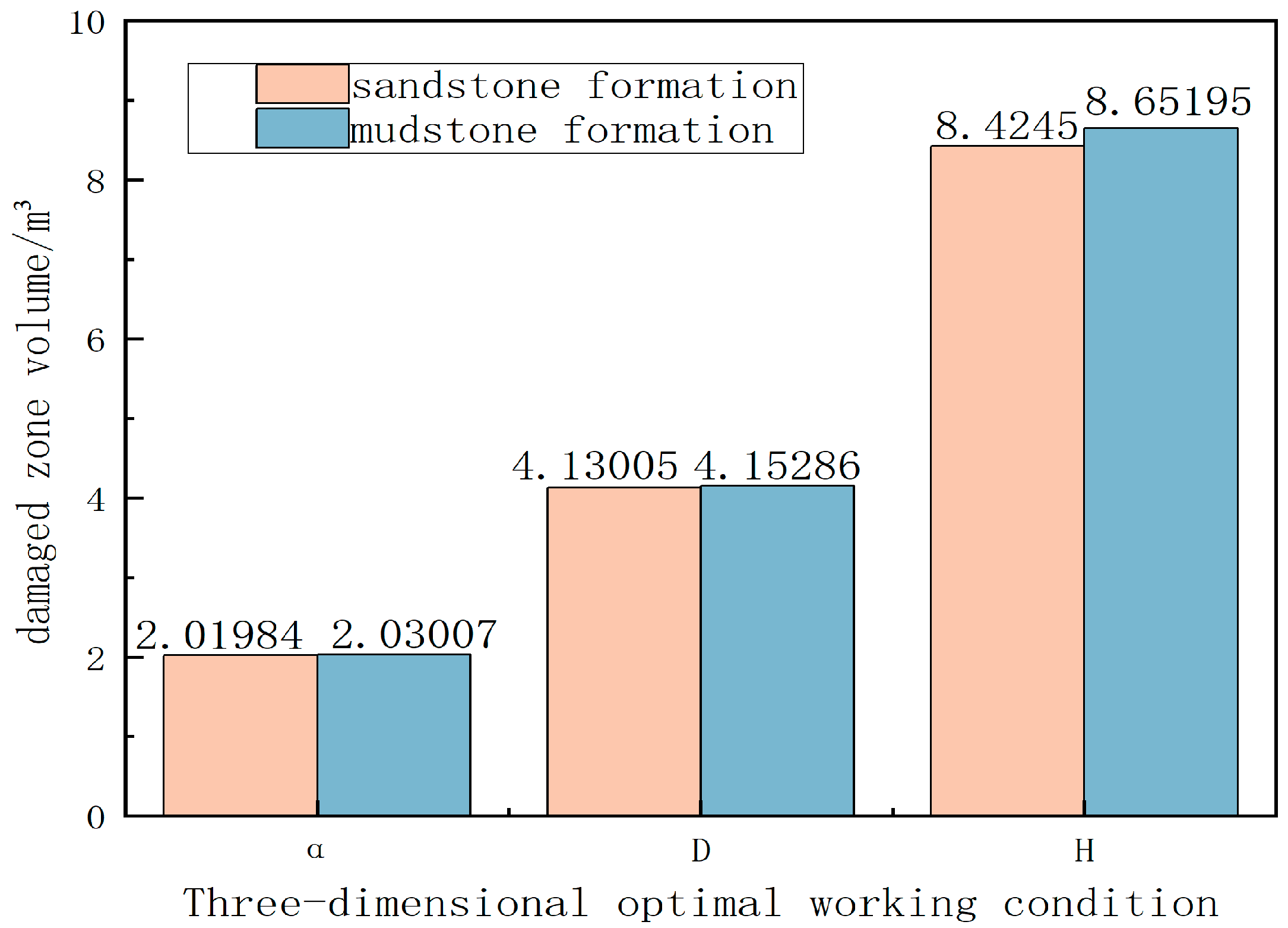

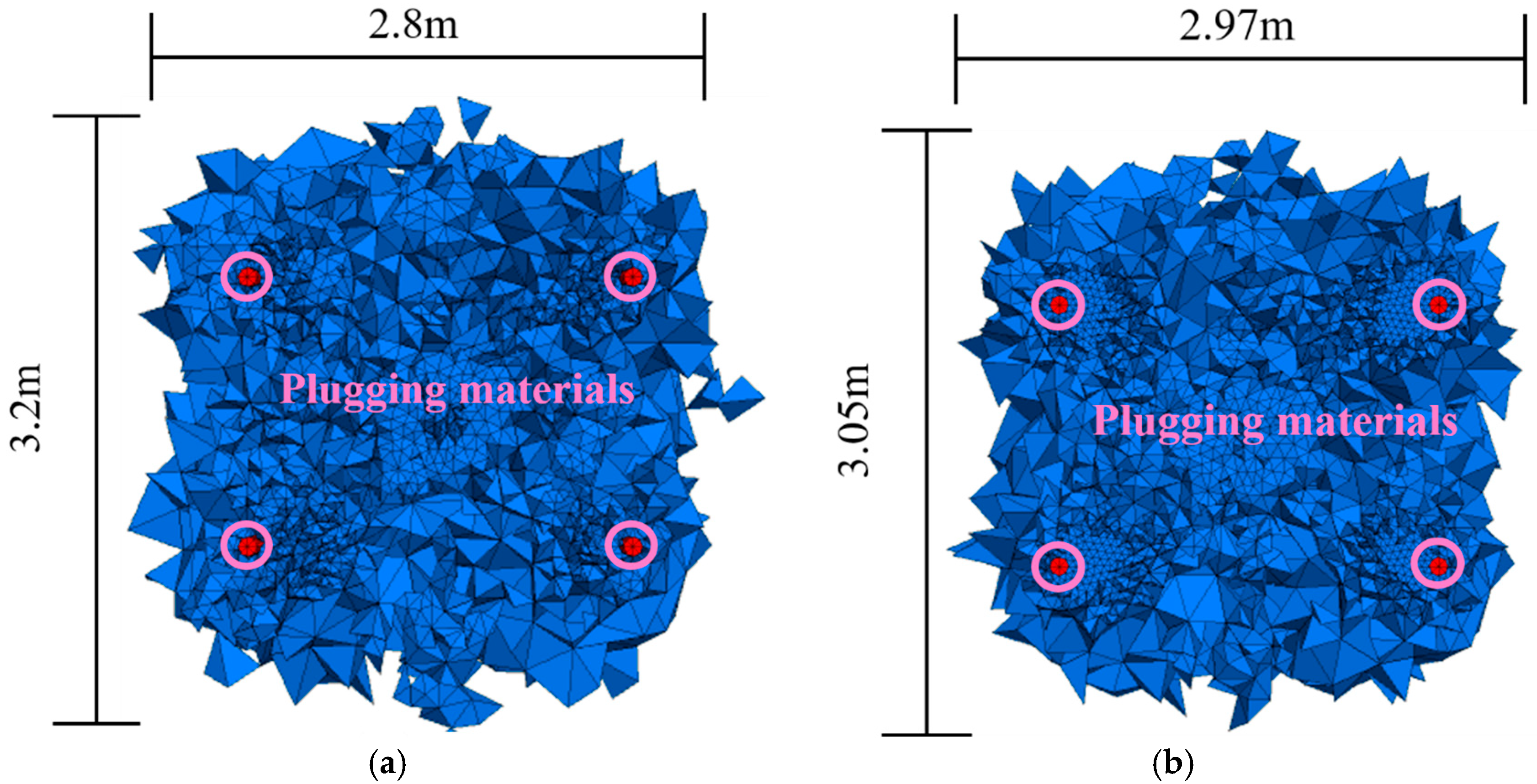

3.3. Study on Auxiliary Borehole Parameters

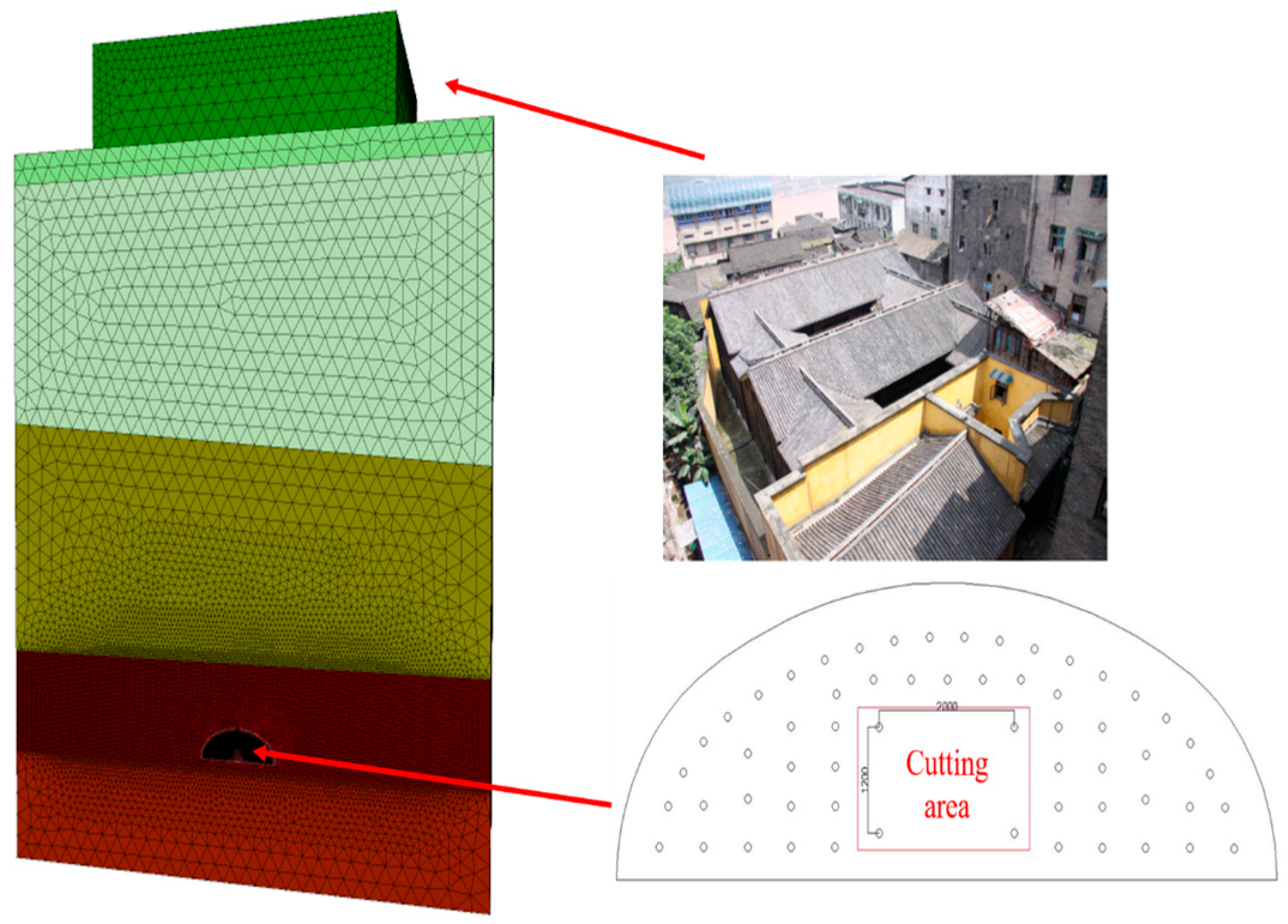

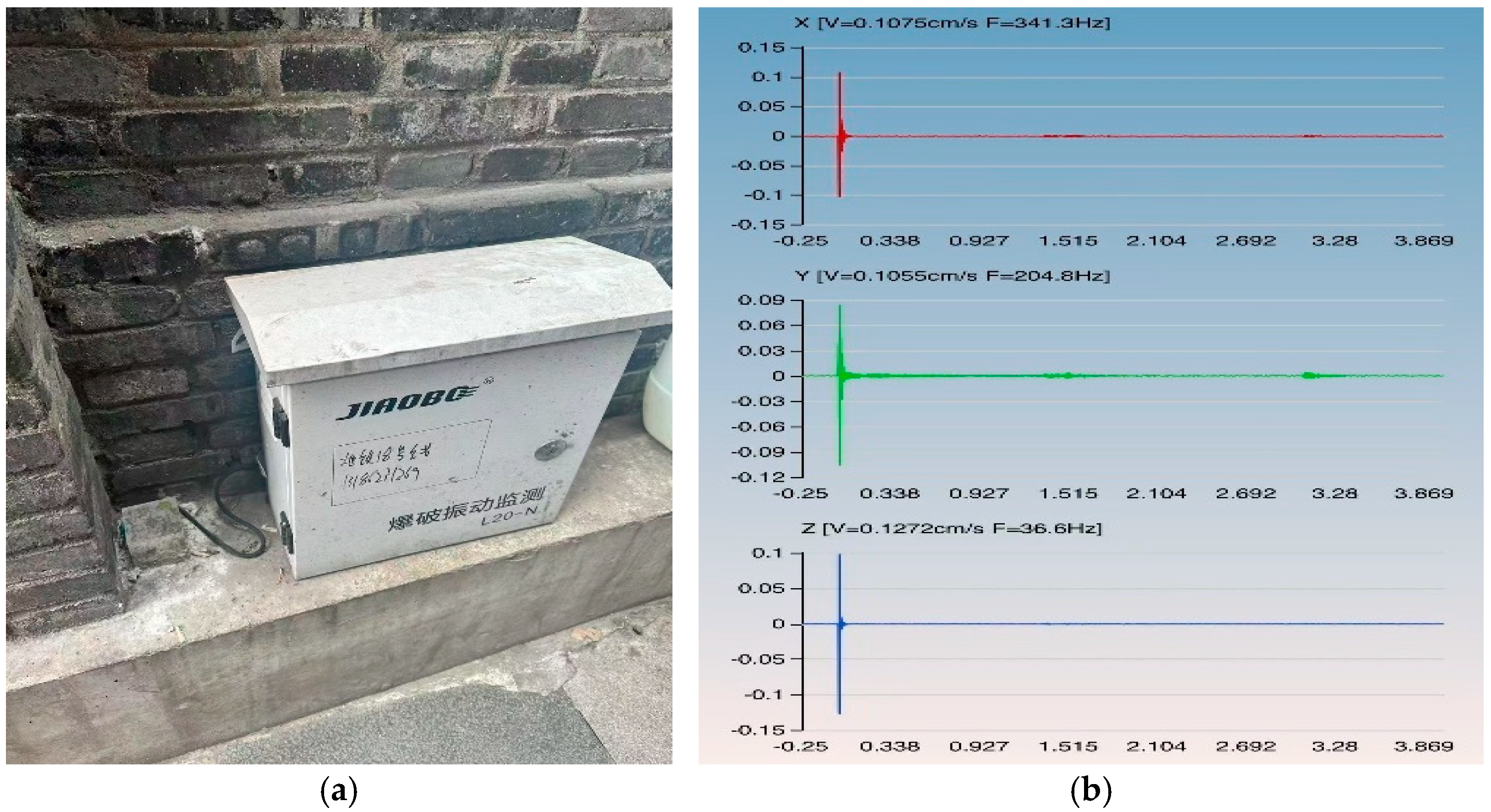

4. Vibration Safety Analysis

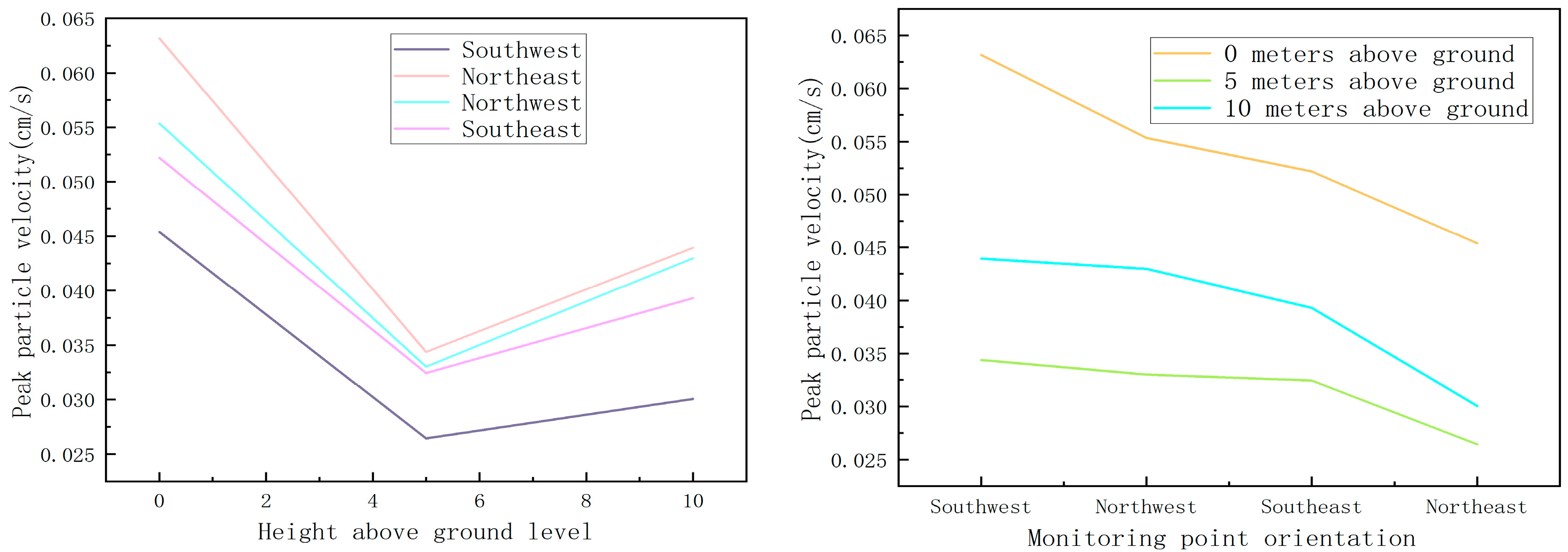

4.1. Vibration Analysis in Building Areas

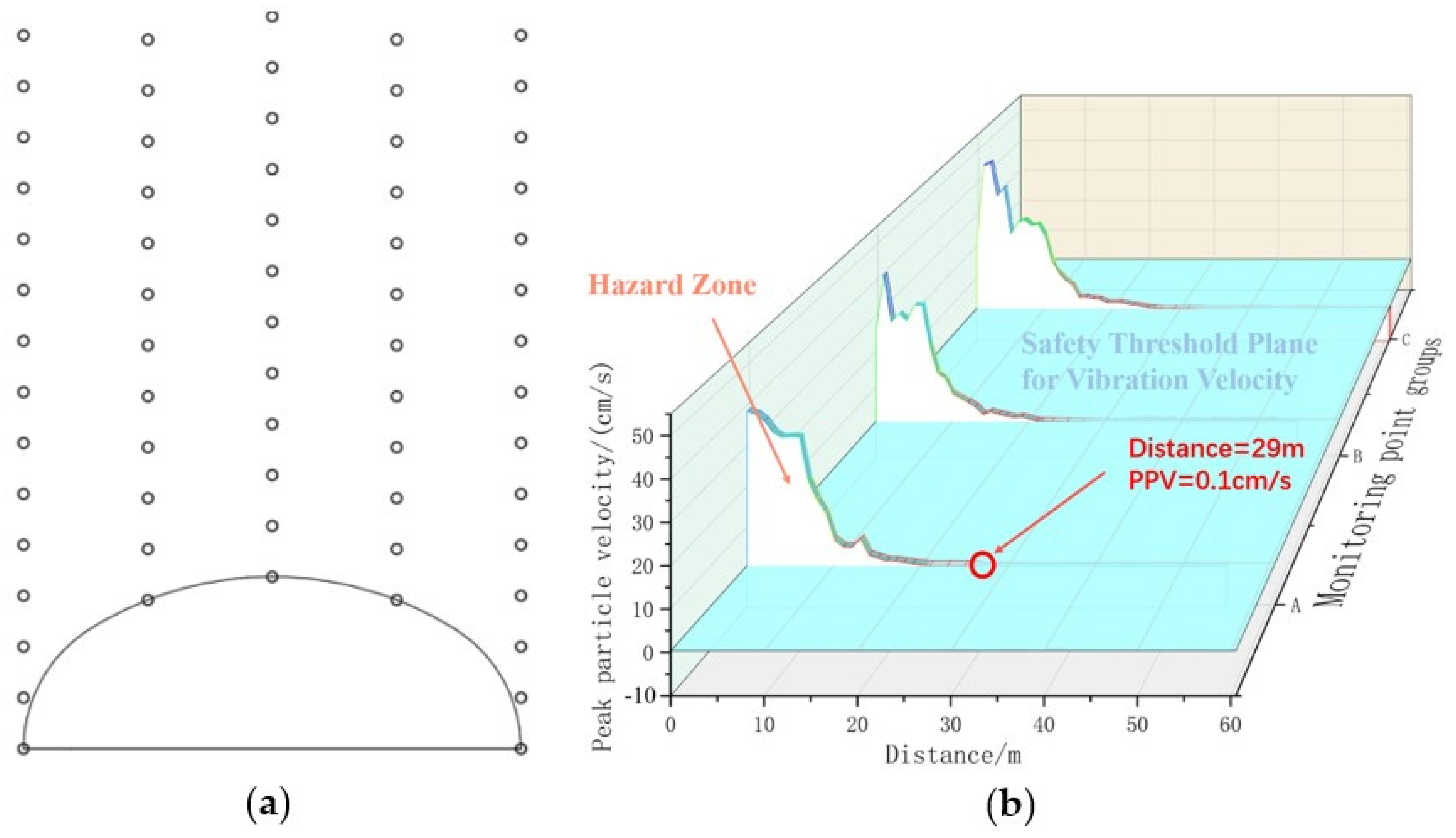

4.2. Vibration Analysis in the Tunnel Face Area

5. Discussion

5.1. Research Significance

5.2. Research Limitations

5.3. Future Research Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Zhou, D.; Zhou, X.; Xiao, N.; Guo, C. Rock Breaking Performance of TBM Disc Cutter Assisted by High-Pressure Water Jet. Appl. Sci. 2020, 10, 6294. [Google Scholar] [CrossRef]

- Shangguan, J.; Ge, Z.; Zhou, Z.; Zhang, X.; Liu, L.; Li, Z. Experimental study on dynamic deformation and breaking mechanism of high-temperature hard rock cutting by abrasive water jet. Int. J. Rock Mech. Min. Sci. 2024, 180, 105797. [Google Scholar] [CrossRef]

- Gao, Y.; Han, P.; Wang, F.; Cao, J.; Zhang, S. Study on the Characteristics of Water Jet Breaking Coal Rock in a Drilling Hole. Sustainability 2022, 14, 8258. [Google Scholar] [CrossRef]

- Liu, S.; Li, H.; Chang, H. Drilling Performance of Rock Drill by High-Pressure Water Jet under Different Configuration Modes. Shock. Vib. 2017, 2017, 5413823. [Google Scholar] [CrossRef]

- Reinsch, T.; Paap, B.; Hahn, S.; Wittig, V.; Berg, S.v.D. Insights into the radial water jet drilling technology-Application in a quarry. J. Rock Mech. Geotech. Eng. 2018, 10, 236–248. [Google Scholar] [CrossRef]

- Zhang, K.; Xiao, S.; Liu, W.; Wang, D.; Zhang, G. Feasibility study of an adjustable-power laser cutting head for TBM applications: Focus on rock fragmentation efficiency and energy consumption. Tunn. Undergr. Space Technol. 2025, 155, 106155. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, C.; Li, C.; Wei, W.; Dong, J. Laser rock-breaking mechanism considering rock inhomogeneity and the temperature effect. Comput. Geotech. 2025, 179, 107029. [Google Scholar] [CrossRef]

- Jamali, S.; Wittig, V.; Börner, J.; Bracke, R.; Ostendorf, A. Application of high powered Laser Technology to alter hard rock properties towards lower strength materials for more efficient drilling, mining, and Geothermal Energy production(Article). Geomech. Energy Environ. 2019, 20, 100112. [Google Scholar] [CrossRef]

- Guo, C.; Sun, Y.; Yue, H.; Li, Q.; He, S.; Zhang, J.; Zhang, Y. Experimental research on laser thermal rock breaking and optimization of the process parameters. Int. J. Rock Mech. Min. Sci. 2022, 160, 105251. [Google Scholar] [CrossRef]

- Yu, B.; Niu, S.; Zhou, S.; Lei, Y.; He, Z.; Luo, X. Impact Pressure Characteristics of Carbon Dioxide Phase Transition Fracturing Technique. ACS Omega 2024, 9, 23927–23939. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Nie, B.; Guo, K.; Zhang, C.; Wang, Z.; Wang, L. Permeability enhancement and porosity change of coal by liquid carbon dioxide phase change fracturing. Eng. Geol. 2021, 287, 106106. [Google Scholar] [CrossRef]

- Zhou, S.; Luo, X.; Jiang, N.; Zhang, S.; Lei, Y. Ground vibration characteristics of carbon dioxide phase transition fracturing: An in situ test. Bull. Eng. Geol. Environ. 2021, 80, 9029–9047. [Google Scholar] [CrossRef]

- Xia, J.; Dou, B.; Tian, H.; Zheng, J.; Cui, G.; Kashif, M. Research on Initiation of Carbon Dioxide Fracturing Pipe Using the Liquid Carbon Dioxide Phase-Transition Blasting Technology. Energies 2021, 14, 521. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Shi, F.; Zhou, Y.; Sun, M.; Wu, S.; Zhou, X.; Li, S. Rock breaking using liquid nitrogen and water jet: A case of granite. Arch. Civ. Mech. Eng. 2025, 25, 1–21. [Google Scholar] [CrossRef]

- Zou, Z.; Cai, C.; Wang, B.; Gao, Y.; Tao, Z.; Feng, Y. Complex Flow Mechanism and Pressurization Effect of Liquid Nitrogen Jet Fracturing Formation Perforation Tunnel. Processes 2023, 11, 2878. [Google Scholar] [CrossRef]

- Xue, Y.; Yao, L.; Li, J.; Ding, L.; Luo, W.; Zhou, X.; Wang, S.; Zhao, Y. Temporal and spatial evolution laws of temperature effects in high-velocity liquid nitrogen jet rock breaking. Appl. Therm. Eng. 2024, 255, 124060. [Google Scholar] [CrossRef]

- Cai, C.; Yang, Y.; Liu, J.; Gao, F.; Gao, Y.; Zhang, Z. Downhole Transient Flow Field and Heat Transfer Characteristics During Drilling With Liquid Nitrogen Jet. J. Energy Resour. Technol. 2018, 140, 122902. [Google Scholar] [CrossRef]

- Ren, F.; Fang, T.; Cheng, X. Theoretical modeling and experimental study of rock-breaking depth in particle jet impact drilling process(Article). J. Pet. Sci. Eng. 2019, 183, 106419. [Google Scholar] [CrossRef]

- Fang, T.; Wang, B.; Cheng, T.; Ren, F. Stress Modeling and Simulation Analysis of Particle Impact Rock-Breaking. In Proceedings of the International Forum on Electrical Engineering and Automation, Hefei, China, 25–27 September 2020. [Google Scholar]

- Huang, S.; Mohanty, B.; Xia, K. A multi-particle crushing apparatus for studying rock fragmentation due to repeated impacts. Rev. Sci. Instrum. 2017, 88, 125114. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; He, L.; Dai, L.; Shen, K.; Ba, Q. Analysis of Rock Breaking Parameters and Simulation of Mechanical Characteristics of Multi-Nozzle Jet Impact. Sustainability 2023, 15, 12414. [Google Scholar] [CrossRef]

- Wei, H.; Wang, C.; Zhu, J.; Yang, X.; Chu, H. Propagation characteristics of stress wave in layered rock mass under the impact of high-pressure gas. Proc. Inst. Civ. Eng.-Geotech. Eng. 2023, 177, 303–322. [Google Scholar] [CrossRef]

- Peng, H.; Sheng, J.; Da, Q.; Dai, B.; Zhang, L.; Tan, L. The Vibration Response to the High-Pressure Gas Expansion Method: A Case Study of a Hard Rock Tunnel in China. Appl. Sci. 2024, 14, 6645. [Google Scholar] [CrossRef]

- Liu, D.W.; Zhang, Z.L.; Chu, F.J.; Jian, Y.H.; Zhang, S.; Huang, Z. Experimental study on rock-breaking by slotting using high-pressure gas expansion method in urban small cross-section hard rock tunnels. Blasting 2019, 36, 104–111. [Google Scholar]

- Peng, H.-D.; Liu, D.-W.; Chu, F.-J.; Jian, Y.-H. Test on high pressure gas expansion rock fragmentation in hard rock tunnel. Rock Soil Mech. 2018, 39, 242–248. [Google Scholar]

- Pan, Q.; Zhang, J.C.; Shi, H.C.; Zou, X.K.; Deng, X.F.; Xu, H. Study on damage distribution characteristics of rock mass under single-hole non-coupled charge blasting. J. Vib. Shock. 2019, 38, 264–269. [Google Scholar]

- Wang, S.; Gong, M.; Wu, H.; Wu, X.; Liu, X. Optimization Study of Water Interval Charge Structure Based on the Evaluation of Rock Damage Effect in Smooth Blasting. Appl. Sci. 2024, 14, 2868. [Google Scholar] [CrossRef]

- Tang, W.; You, Y.; Hu, F.; Bian, Y.; Xiao, C.; Zhu, Y.; Meng, T. Experimental Study on SHPB Dynamic Mechanical Response in Different Damaged zones of Rock under Blast Load. Shock. Vib. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiu, X.; Shi, X.; Luo, Z.; Chen, H.; Zong, C. Burden effects on rock fragmentation and damage, and stress wave attenuation in cut blasting of large-diameter long-hole stopes. Rock Mech. Rock Eng. 2023, 56, 8657–8675. [Google Scholar] [CrossRef]

- Liu, D.; Wang, C.; Yang, C.; Zhang, W.; Cao, K. Model experimental study on high-pressure gas expansion directional rock-cracking based on directional expansion pipe. Results Eng. 2024, 24, 103568. [Google Scholar] [CrossRef]

- Liu, D.; Wang, C.; Tang, Y.; Chen, H. Application of High-Pressure Gas Expansion Rock-Cracking Technology in Hard Rock Tunnel near Historic Sites. Appl. Sci. 2023, 13, 1017. [Google Scholar] [CrossRef]

| Type of Expansion Tube | Charge Density/ (g·cm−3) | Gas Yield per Unit Mass/ (L·kg−1) | Reaction Temperature/ K | Peak Pressure of High Pressure/ MPa |

|---|---|---|---|---|

| Expansion tube 1 | 0.273 | 626.16 | 1986 | 145.9 |

| Expansion tube 2 | 0.247 | 626.16 | 1986 | 127.6 |

| Expansion tube 3 | 0.184 | 626.16 | 1986 | 93.7 |

| Expansion tube4 | 0.160 | 626.16 | 1986 | 78.4 |

| Material Type | Density/g·cm−3 | Elastic Modulus/GPa | Tensile Strength/MPa | Internal Friction Angle/° | Cohesion/MPa | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| Sandstone | 2.7 | 45 | 8.5 | 41.5 | 23.8 | 0.28 |

| Material Type | Density/g·cm−3 | Elastic Modulus/GPa | Tensile Strength/MPa | Internal Friction Angle/° | Cohesion/MPa | Poisson’s Ratio | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sandstone | 2.7 | 6 | 5.17 | 37 | 6.13 | 0.26 | ||||

| (Sandy) Mudstone | 2.446 | 2 | 0.75 | 25 | 1.68 | 0.34 | ||||

| Artificial fill | 1.95 | 0.2 | 30 | 0.21 | 0.3 | |||||

| Structure (Nanmu timber) | 7 | 10 | ||||||||

| Single-Hole Deflection Angle (°) | Vertical Spacing (mm) | Horizontal Spacing (mm) | Auxiliary Hole Spacing (mm) |

|---|---|---|---|

| 70 | 1200 | 2000 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Zhong, J.; Zhang, Y.; Jin, Y. Investigation of Borehole Network Parameters for Rock Breaking via High-Pressure Gas Expansion in Subway Safety Passages of Environmentally Sensitive Zones. Buildings 2025, 15, 3158. https://doi.org/10.3390/buildings15173158

Liu D, Zhong J, Zhang Y, Jin Y. Investigation of Borehole Network Parameters for Rock Breaking via High-Pressure Gas Expansion in Subway Safety Passages of Environmentally Sensitive Zones. Buildings. 2025; 15(17):3158. https://doi.org/10.3390/buildings15173158

Chicago/Turabian StyleLiu, Dunwen, Jimin Zhong, Yupeng Zhang, and Yuhui Jin. 2025. "Investigation of Borehole Network Parameters for Rock Breaking via High-Pressure Gas Expansion in Subway Safety Passages of Environmentally Sensitive Zones" Buildings 15, no. 17: 3158. https://doi.org/10.3390/buildings15173158

APA StyleLiu, D., Zhong, J., Zhang, Y., & Jin, Y. (2025). Investigation of Borehole Network Parameters for Rock Breaking via High-Pressure Gas Expansion in Subway Safety Passages of Environmentally Sensitive Zones. Buildings, 15(17), 3158. https://doi.org/10.3390/buildings15173158