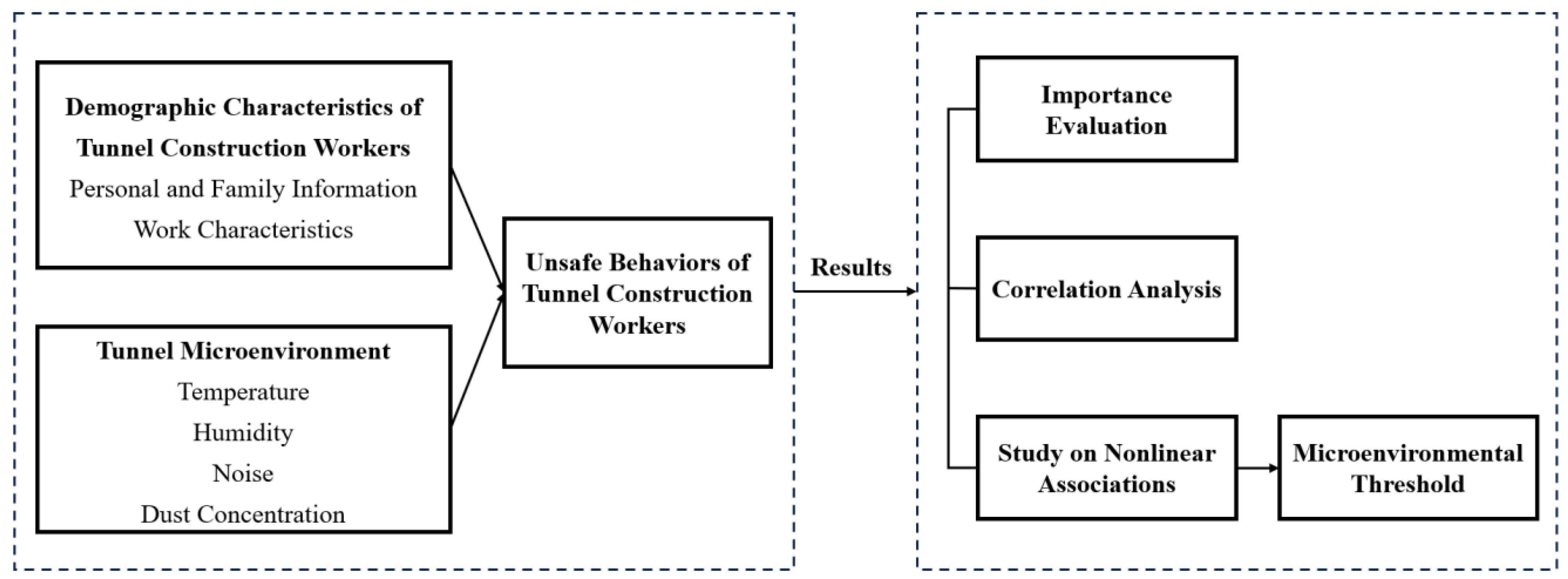

2.1. Study Area

The permafrost distribution in China is characterized by significant geographical extensiveness and environmental diversity, given the extensive coverage of cold regions throughout the country. According to the most recent statistics, the area of permafrost in China (with the exception of glaciers and lakes) is approximately 1.59 million km

2, which constitutes 16.6 percent of the country’s total land area. Specifically, high-latitude permafrost is primarily distributed in Northeast China, covering approximately 240,000 km

2, while high-altitude permafrost is widely found on the Qinghai–Tibet Plateau and in the mountainous regions of Northwest China, with a total area of about 1.35 million km

2. In addition, seasonally frozen ground covers an even larger area, approximately 5.36 million km

2, accounting for 55.8% of the country’s land area. In recent years, as China’s national transportation infrastructure strategy continues to expand into western and remote regions, an increasing number of tunnel projects have traversed areas of permafrost and seasonally frozen ground, facing challenges posed by high altitudes, low temperatures, and intense freeze–thaw cycles under extreme climatic and geological conditions [

28,

29,

30,

31,

32]. This places greater demands on the design, construction, and maintenance technologies of tunnels. Furthermore, it is imperative that a more profound understanding of the characteristics of the cold-region permafrost environment be developed in order to enhance the safety and sustainability of the project.

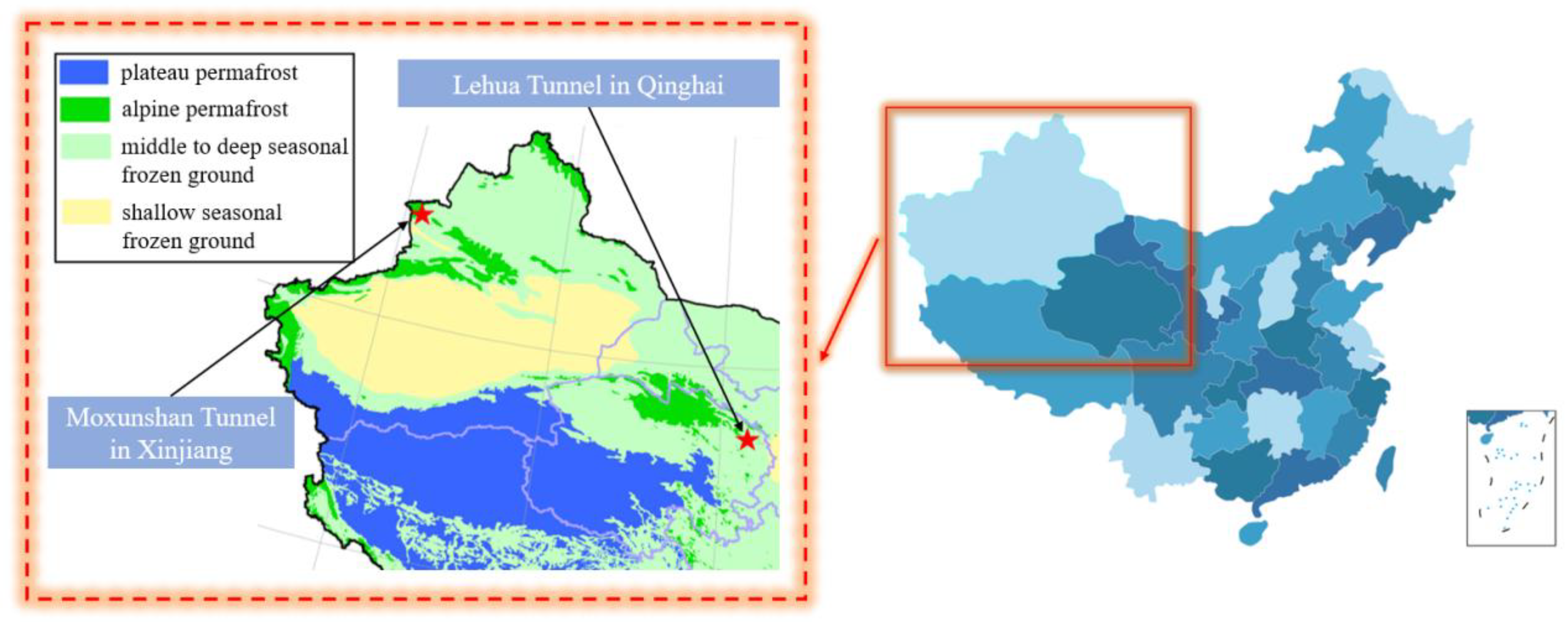

The study focuses on two representative under-construction tunnels in the cold regions of Xinjiang and Qinghai, China. The specific geographic locations of these tunnels are shown in

Figure 2. The tunnels are the Moxunshan Tunnel in Xinjiang and the Lehua Tunnel in Qinghai. Both tunnels are situated in typical cold-region microenvironments characterized by high altitude, low temperatures, and fluctuating humidity. These features make them representative and well-suited for studying the relationship between cold-region tunnel construction environments and worker behavior. Specifically, the Moxunshan Tunnel in Xinjiang has a total length of 942 m, with a clear width of 8.59 m and a clear height of 10.8 m. The Lehua Tunnel in Qinghai is 879 m long, with a clear width of 7.38 m and a clear height of 10.98 m. The tunnels selected for this study are located in typical cold plateau regions of Xinjiang and Qinghai, both characterized by continental arid or semi-arid climates. The frequent freeze–thaw cycles in these areas pose significant challenges to tunnel structural stability and construction safety. The geological strata of the project area are primarily composed of Quaternary loose sediments, including sandy soil, silt, gravel layers, and locally interbedded clay. The soil is loosely structured, highly permeable, exhibits certain collapsibility, and has a pronounced frost heave potential. Field investigation data indicate that the multi-year average permafrost depth generally ranges from 1.4 to 2.0 m, and the soil is typically classified as frost resistance grade II. In some areas, the soil exhibits poor frost resistance, making it prone to generating frost heave pressure during winter.

The selection of these two projects aims to explore the impact mechanisms of unsafe behaviors among construction workers under the complex microenvironmental conditions in cold regions, and to provide regional insights and empirical support for safety management in tunnel construction in cold areas. Both Xinjiang and Qinghai are located in the typical cold plateau regions of Northwest China. Tunnel projects in these areas often face multiple environmental challenges, including low temperatures, large temperature fluctuations, dryness, strong winds, and intense radiation. Additionally, they encounter construction difficulties due to complex geological structures and poor ventilation. These factors not only increase the difficulty of project organization and management but also have a lasting impact on the physiological load, psychological state, and decision-making ability of construction workers. Compared to tunnel projects in Central and East China, the construction environment in the northwestern cold regions is more severe, and the working conditions are more representative. As a result, it serves as an important experimental field for studying the relationship between tunnel microenvironments and unsafe behaviors. The Moxunshan Tunnel is an important ongoing transportation project in the Ili region of Xinjiang. Located in a high-altitude mountainous area, it experiences low temperatures for most of the year, with significant humidity fluctuations inside the tunnel. The construction process is often accompanied by persistent high noise levels and dust disturbances, making it a typical example of a cold, enclosed working space. The Lehua Tunnel in Qinghai is located in the plateau–hill region, with a fractured geological structure. Inside the tunnel, there are large diurnal temperature variations and poor ventilation. Particularly during the winter construction period, the tunnel environment significantly affects the human body in terms of thermal stress, sensory fatigue, and psychological pressure. These two tunnels not only represent typical characteristics of construction in cold regions in terms of geographic and climatic features but also employ the same mining method construction technique, making it easier to compare data across projects and establish models.

The research team conducted a series of field studies in the vicinity of the two tunnels in late 2023 and early 2024. They entered the construction sites and systematically collected microenvironmental exposure information, as well as data on the psychological health status and safety behavior of the frontline construction workers. The focus of the survey was on frontline workers with long exposure times and higher risk levels. A stratified sampling approach was used, targeting different job types, work areas, and teams. A total of 540 questionnaires were distributed, with 498 valid responses collected, covering typical positions such as ventilation workers, blasting workers, shotcrete workers, and haulage workers. Additionally, semi-structured interviews were conducted to supplement the data with frontline workers’ subjective experiences and behavioral feedback in extreme microenvironments. This paper conducts an in-depth empirical study of two typical tunnels in the cold regions of Xinjiang and Qinghai, with the objective of revealing the key factors influencing the safety behavior of construction personnel under alpine and complex conditions from the microenvironmental dimension. The paper’s findings provide both theoretical support and practical paths for the safety control of tunnel construction in cold regions.

2.2. Research Data

To systematically evaluate the potential impact of the tunnel microenvironment on construction workers’ unsafe behavior, this study selects four representative physical environmental factors—temperature, relative humidity, noise, and dust concentration—as key microenvironmental indicators. These factors not only represent the most common environmental exposure sources during tunnel construction but also serve as core variables influencing workers’ physiological health, psychological state, and behavioral performance [

33].

The selection of indicators is based on three main criteria: First, numerous studies have shown that the above environmental factors are commonly present in tunnel and underground construction and are highly correlated with workers’ health and safety behavior; second, these factors exhibit significant fluctuations in typical cold-region tunnels, being influenced by climate conditions, construction stages, and types of work; and third, the relevant indicators are measurable on-site and quantifiable, facilitating comparative analysis across multiple work types and scenarios.

During the on-site data acquisition process, several limitations and challenges were encountered. First, the tunnels are located in high-altitude cold regions with harsh climatic conditions, and extremely low winter temperatures occasionally caused sensor malfunctions or data interruptions. Second, due to the complex and dynamic construction environment, the placement of some monitoring points was constrained by ongoing excavation activities, safety requirements, and ventilation layouts, resulting in partial data gaps or reduced sampling frequency. Additionally, for parameters such as instantaneous dust concentration and high-frequency noise fluctuations, repeated measurements using portable high-sensitivity instruments were necessary, which increased the difficulty of calibration and verification. Although these challenges imposed certain limitations on data completeness and acquisition efficiency, supplementary measurements, cross-validation, and careful preprocessing were adopted to ensure data reliability as much as possible.

With regard to the collection of data, the present study employs a multi-source fusion data acquisition strategy in conjunction with field research on the Moxunshan Tunnel in Xinjiang and the Lehua Tunnel in Qinghai. On the one hand, portable environmental monitoring instruments (such as temperature and humidity loggers, sound-level meters, and dust concentration monitors) were deployed in typical work areas classified by job type and construction phase to conduct real-time dynamic monitoring of temperature, humidity, noise, and dust levels. The monitoring period covered multiple critical construction phases to ensure the representativeness and timeliness of the data. On the other hand, information on workers’ job types, working hours, and operational areas was collected through questionnaires and precisely matched with the monitoring data in terms of space and time, thereby estimating the actual environmental exposure levels of individual workers.

In this study, all tunnel microenvironment data were obtained through systematic on-site measurements to ensure the authenticity and representativeness of the data. Microenvironmental variables were obtained through discrete observations using portable devices to record key indicators—such as temperature, humidity, dust concentration, and noise levels—at different time points. Although the data were not collected continuously, this approach effectively captured the typical variations in the tunnel microenvironment during construction. Based on a systematic review of existing literature on tunnel engineering and environmental monitoring, this study selected drilling, mucking, and shotcreting as representative construction operations with significant environmental impact. Combined with key spatial nodes such as the tunnel entrance, tunnel midpoint, secondary lining, air outlet, and tunnel face, a multi-condition and multi-point microenvironment monitoring framework was established. Specifically, each tunnel is systematically tested under 15 different combinations of working conditions and measurement points, with three independent measurements in each group, and the average value is taken as the final reference data. This process reduces chance errors and deviations caused by instrument fluctuations, and enhances the robustness and repeatability of the data. This study utilizes a multi-dimensional and standardized sampling design, enabling the capture of the spatial–temporal variability characteristics of the tunnel microenvironment. This provides a solid data foundation for subsequent correlation analysis and mechanism exploration.

To systematically assess the variation characteristics of the temperature environment within the tunnel workspace, this study employed the SMART Sensor AR847+ handheld industrial-grade high-precision temperature and humidity detector (Shenzhen Smart Sensor Co., Ltd., Shenzhen, China) for continuous on-site monitoring. The device has an environmental temperature measurement range of −10 °C to 50 °C, with a resolution of 0.1 °C. It features rapid response and real-time display capabilities. During the measurement process, data were collected every 5 s and averaged on an hourly basis to capture the dynamic temperature variation characteristics across different construction phases. Regarding sensor placement, five representative monitoring points were arranged along the longitudinal central axis of each tunnel, located at (1) the tunnel face, (2) the air outlet, (3) the secondary lining, (4) the tunnel midpoint, and (5) the tunnel entrance. All monitoring points were positioned at a height of 1.5 m above the ground to approximate the breathing zone of the construction workers. Monitoring was conducted daily between 9:00 a.m. and 6:00 p.m., covering three typical construction activities: drilling, mucking, and shotcreting. This sensor placement strategy ensured the representativeness, comparability, and spatial coverage of the measurement data [

34,

35,

36].

To comprehensively characterize the thermal and humidity variations within the tunnel workspace, this study conducted synchronous and continuous humidity measurements using the same SMART Sensor AR847+ handheld temperature and humidity detector (Shenzhen Smart Sensor Co., Ltd., Shenzhen, China) employed for temperature monitoring. The device has a humidity measurement range of 5.0% to 98.0% relative humidity (RH), with a resolution of 0.1%, and is capable of stable operation in high-humidity and high-dust environments. Humidity monitoring points were consistent with those for temperature, located at five positions: the tunnel face, air outlet, secondary lining, tunnel midpoint, and tunnel entrance. All sensors were installed at a height of 1.5 m above the tunnel floor to simulate the actual working environment of construction personnel. Monitoring was conducted during typical construction working hours (9:00–18:00), with a data sampling frequency of once every 5 s. By comparing humidity variations across different construction conditions and spatial locations, the study reveals the dynamic characteristics of the thermal–humidity environment within enclosed workspaces [

37,

38,

39].

Tunnel construction noise primarily originates from the operation of high-intensity machinery, such as drilling rigs, transport vehicles, and shotcreting equipment, which can have potential impacts on workers’ hearing and psychological health. This study employed a SMART Sensor AS844+ handheld industrial-grade sound-level meter (Shenzhen Smart Sensor Co., Ltd., Shenzhen, China) for high-precision on-site measurements. The device has a measurement range of 30 dB to 130 dB, with a resolution of 0.1 dB, and is equipped with A-weighting and Leq (equivalent continuous sound level) measurement modes. Five noise monitoring points were set up in each tunnel, located at the following positions: the tunnel face, air outlet, secondary lining, tunnel midpoint, and tunnel entrance. The testing equipment was mounted on a tripod at a height of 1.3 m, maintaining the same spatial position as the other environmental parameters being monitored. The measurement duration at each location was 10 min, with typical working conditions selected for recording. Ultimately, this study used the “A-weighted equivalent continuous sound level” (Leq) to characterize noise intensity. This parameter reflects the average noise energy level over a specific period and is a widely used noise exposure indicator in occupational and environmental health research. All instruments were calibrated for sound before measurement to ensure data accuracy and repeatability [

40,

41].

Dust exposure is one of the key factors affecting the health of tunnel workers. To obtain the spatiotemporal distribution characteristics of dust concentration at the construction site, this study employed a CCZ-1000 direct-reading dust concentration meter (Suzhou Yilian Electromechanical Technology Co., Ltd., Suzhou, China) for continuous sampling. The instrument has a measurement range of 0.01 mg/m

3 to 1000 mg/m

3, with a resolution of 0.01 mg/m

3. It features a real-time display, data storage, and USB export functions, making it suitable for the complex and variable tunnel construction environment. The dust monitoring points were arranged in accordance with the noise monitoring points, positioned at five representative locations. All sensors were uniformly mounted on tripods at a height of 1.3 m above the ground to ensure consistency and comparability of data across different spatial samples. The measurement period covered three major construction phases. Instruments were activated 30 min prior to the start of each construction phase to ensure the capture of the entire dust generation process. The data collection duration was five minutes per session, and the data were subsequently analyzed by time intervals [

42,

43,

44].

By integrating on-site monitoring data with questionnaire responses, this study developed microenvironmental exposure profiles for workers of different trades under specific working conditions. This approach helped to reveal the interactive effects among microenvironmental factors in tunnel construction, laying a data-driven foundation for exploring their influence pathways on unsafe behaviors and providing scientific support for targeted improvements to the working environment.

2.3. Research Results

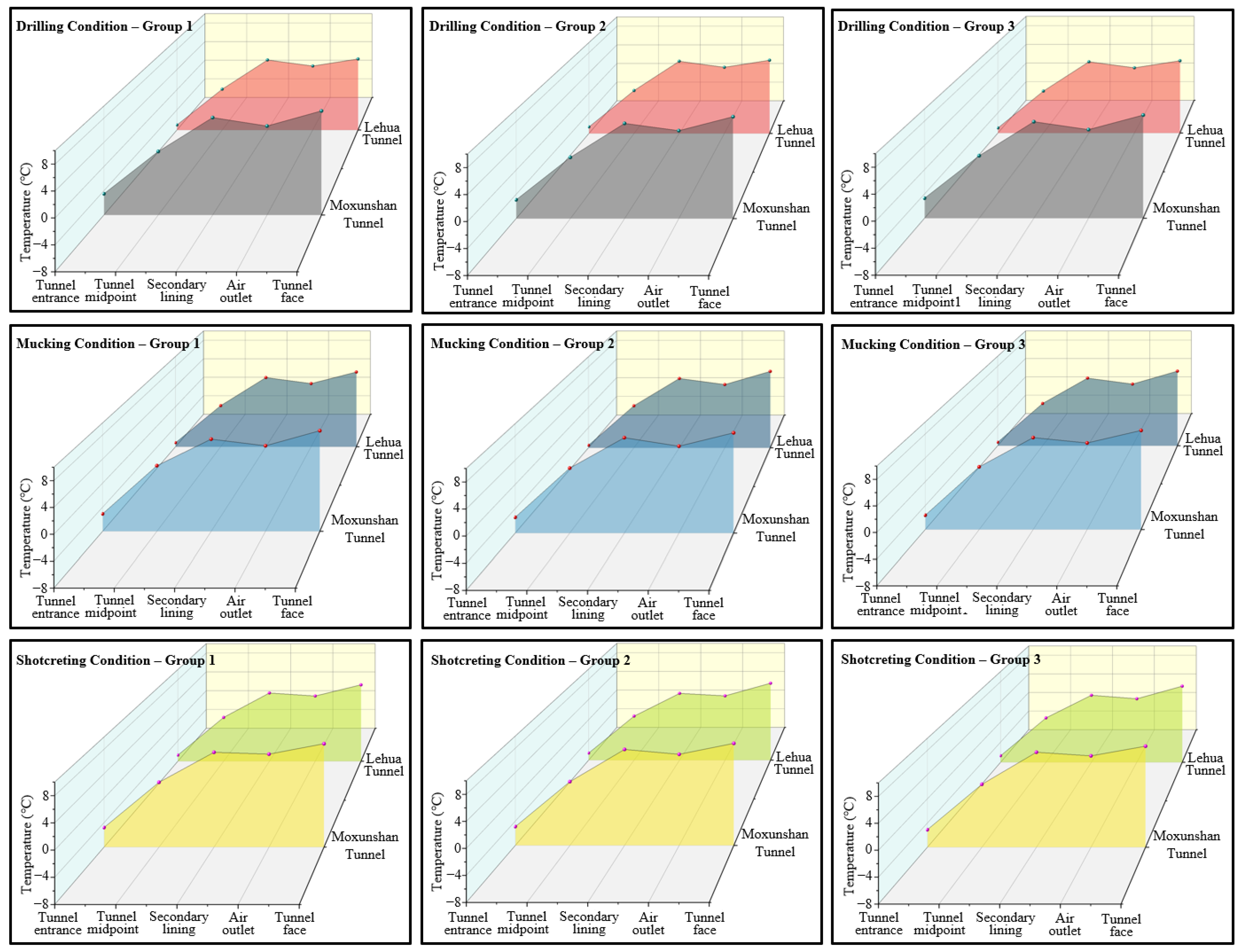

As shown in

Figure 3, the analysis of 18 sets of measured data reveals that the temperature in the tunnel face area is consistently the highest. This reflects the combined effects of concentrated heat sources from construction machinery, limited local ventilation, and high work intensity. The temperature in the secondary lining construction area is also notably elevated, possibly due to the heat released from concrete hydration and the enclosed construction conditions. In contrast, the temperatures in areas such as the tunnel entrance, tunnel midpoint, and air outlet are significantly lower, being more influenced by external temperature and ventilation conditions. In terms of working condition comparison, the temperature distribution trends under the three typical operation conditions—drilling, mucking, and shotcreting—are generally consistent, with no significant differences observed between the conditions. Therefore, no separate distinction is made in subsequent analyses.

Monitoring results indicate that temperatures at the tunnel face are consistently higher than those in other sections, showing a distinct spatial variation. This pattern can be attributed to several interacting mechanisms: As the foremost working zone, the tunnel face hosts concentrated operations of heavy machinery such as drills and loaders, which continuously generate heat. Additionally, the high density of workers and their physically intensive activities contribute metabolic heat to the microenvironment. Moreover, limited or unidirectional ventilation in this area hinders effective heat dissipation, leading to a “thermal accumulation effect” within the relatively enclosed space. These factors collectively result in the persistently elevated temperatures observed at the tunnel face.

Table 1 presents the statistical indicators of operational temperature at different measurement locations in the Moxunshan and Lehua tunnels, including the mean, standard deviation, minimum, maximum, range, and median values.

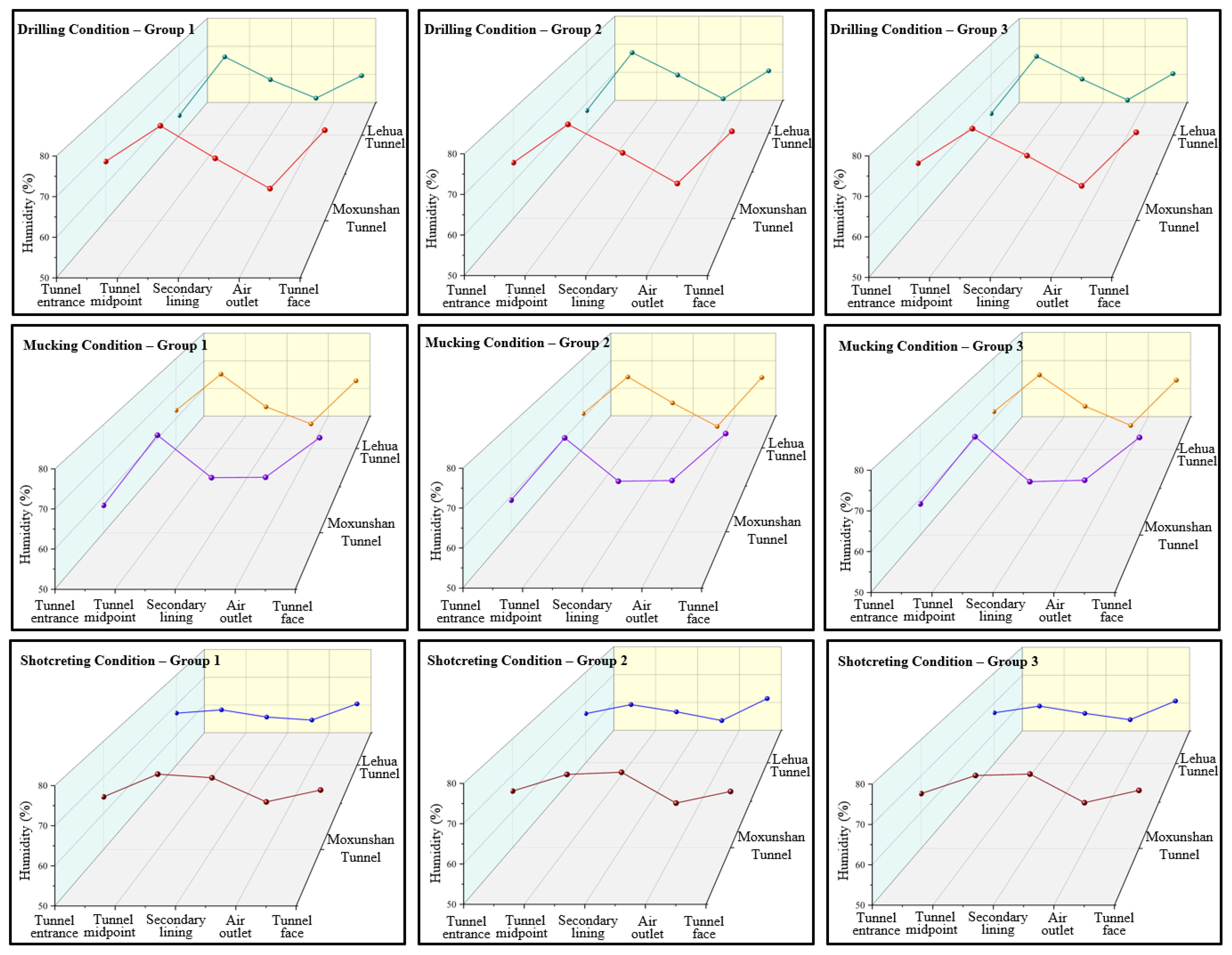

As shown in

Figure 4, under drilling and mucking conditions, the humidity levels in the tunnel midpoint are generally higher, likely due to limited ventilation and the accumulation of moisture. In contrast, the air outlet exhibits the lowest humidity, influenced by the inflow of dry external air, reflecting a clear spatial gradient. Humidity variations in other areas are relatively stable, with minimal fluctuations. Notably, under shotcreting conditions, the extensive use of water during construction, combined with deliberate humidity control measures, leads to a convergence in humidity levels across tunnel locations. This results in significantly reduced overall fluctuation and exhibits a high degree of spatial homogeneity. This result not only reveals the dynamic variation patterns of humidity under different working conditions but also indicates that humidity distribution during specific construction phases may potentially affect workers’ comfort, physiological load, and operational efficiency. It provides essential data support for the optimization of thermal–humidity environments and the enhancement of construction safety management.

Table 2 present the statistical indicators of operational humidity at different measurement locations in the Moxunshan and Lehua tunnels, including the mean, standard deviation, minimum, maximum, range, and median values.

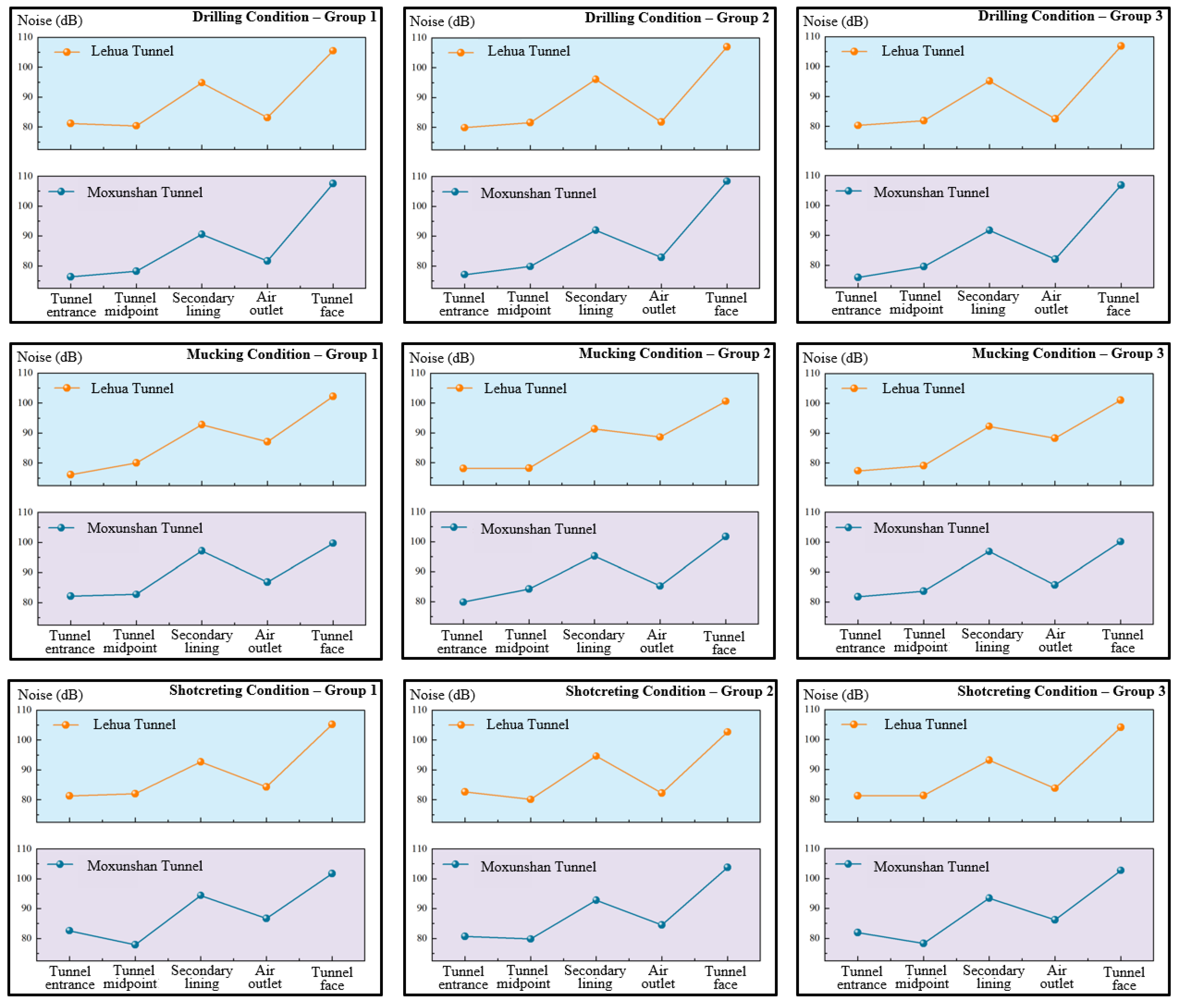

As shown in

Figure 5, the noise variation trends under the three typical working conditions—drilling, mucking, and shotcreting—are generally consistent; therefore, no separate comparison between these conditions was conducted. In terms of spatial distribution, the noise level at the tunnel face is the highest, with multiple measurements exceeding 100 dB(A). This significantly surpasses the occupational noise exposure limits set by the International Labor Organization (ILO) and the World Health Organization (WHO)—typically 85 dB(A) for an 8 h workday—as well as the mandatory protection threshold of 90 dB(A) for 8 h of exposure established by the U.S. Occupational Safety and Health Administration (OSHA). Furthermore, noise levels are consistently above 80 dB(A) at the majority of the measurement points, indicating that the tunnel construction environment is generally exposed to high levels of noise. Prolonged exposure to such high-intensity noise can lead to hearing damage (e.g., noise-induced hearing loss), neurological fatigue, reduced attention, and slower reaction times, thereby significantly increasing the risk of operational errors and workplace accidents. This result highlights the urgent need for effective noise control and personal protection measures in tunnel construction.

Table 3 presents the statistical indicators of operational noise at different measurement locations in the Moxunshan and Lehua tunnels, including the mean, standard deviation, minimum, maximum, range, and median values.

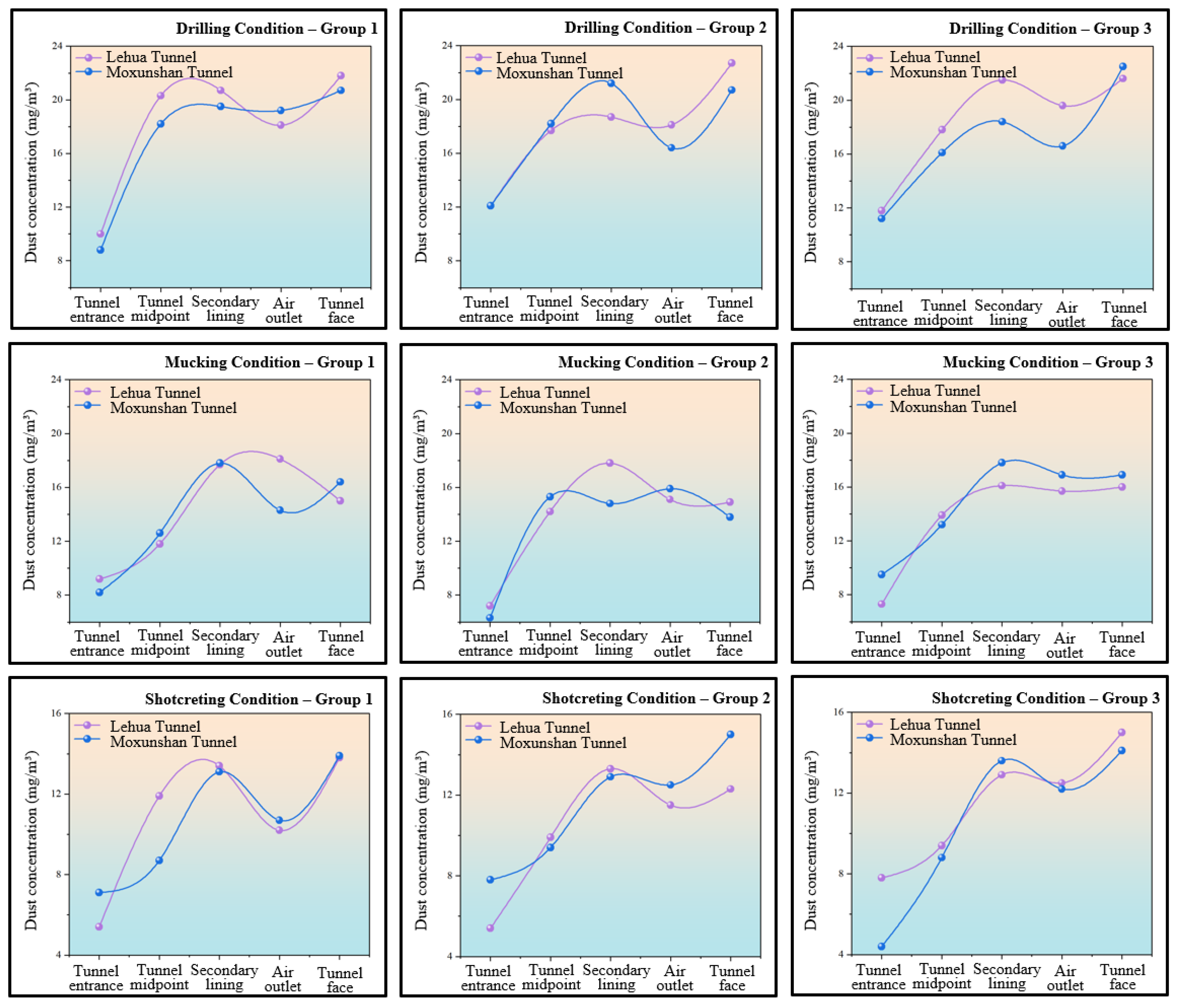

As shown in

Figure 6, in terms of spatial distribution, dust concentration is highest at the tunnel face, reaching or exceeding 20 mg/m

3. This level significantly exceeds the World Health Organization (WHO) recommended occupational exposure limit for dust (typically 10 mg/m

3), posing a serious threat to workers’ respiratory health and overall well-being. In addition, the dust concentration in the secondary lining construction area remains relatively high. Although lower than that at the tunnel face, it still reaches levels considered harmful to human health. By contrast, dust concentrations at other monitoring points are relatively low, particularly near tunnel air outlets and in areas with effective airflow, where air quality shows noticeable improvement. Notably, the dust concentration trends under all three working conditions are generally consistent, characterized by localized high concentrations and overall fluctuations. Therefore, this study did not conduct a separate analysis of inter-condition differences. Prolonged exposure to such high concentrations of dust may pose risks to construction workers, including respiratory diseases (such as pneumoconiosis), impaired lung function, and even early-onset cardiovascular diseases. Furthermore, the impact of dust on task accuracy, attention, and reaction speed may also indirectly increase the incidence of operational accidents.

Table 4 presents the statistical indicators of operational dust concentration at different measurement locations in the Moxunshan and Lehua tunnels, including the mean, standard deviation, minimum, maximum, range, and median values.

2.4. Research Methods

To investigate the relationship between tunnel microenvironmental factors and construction workers’ unsafe behaviors in depth, multiple analytical methods were employed to examine the data. Statistical analysis and machine learning algorithms were integrated to enhance the scientific rigor and explanatory power of the research.

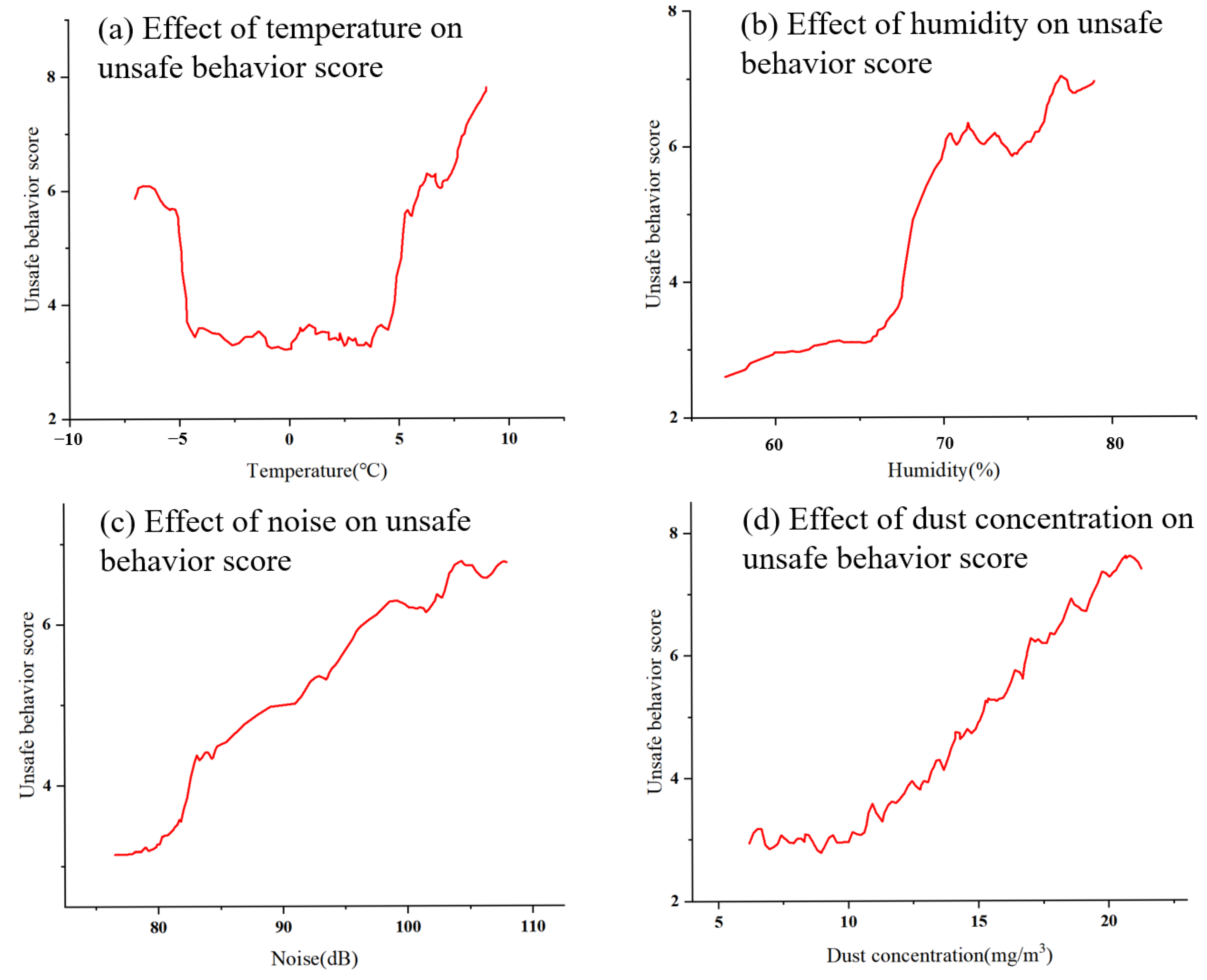

Initially, preliminary statistical analyses and cleaning processes were executed on the collected variable data using SPSS 27.0 software. These processes included missing value processing, outlier identification, and variable normality testing. On this basis, Pearson correlation coefficients were calculated to examine the bivariate associations between tunnel microenvironmental factors (such as temperature, humidity, noise, and dust concentration) and unsafe behaviors among construction workers.

Secondly, to identify the most influential microenvironmental variables affecting unsafe behavior, a random forest algorithm was employed for variable importance analysis. The model was implemented in a Python 3.10 environment using the Scikit-learn library, constructing multiple decision trees and incorporating out-of-bag (OOB) samples to estimate model accuracy. Variable importance was measured using the mean decrease in the Gini index, with factors ranked based on their influence. The reasons for selecting the random forest model are as follows: Firstly, random forest can effectively handle complex nonlinear relationships and higher-order interactions between variables, while also being robust to noisy data and outliers. Secondly, the model does not require extensive assumptions, allowing it to reveal potentially important variables. Finally, random forest improves model stability and generalization ability through cross-validation. Therefore, random forest was chosen as the primary modeling tool for this study to ensure the reliability and interpretability of the results.

After identifying the key variables, a nonlinear regression model was further developed to characterize the complex relationship between critical microenvironmental factors and unsafe behaviors. Considering the potential nonlinearity and interaction effects among variables, polynomial regression and support vector regression were primarily used for fitting, with cross-validation employed to assess the model’s stability and generalizability. Model performance was comprehensively evaluated using the coefficient of determination, root mean square error, and mean absolute error. The model with the best performance was ultimately selected for interpretation and prediction.