Design Theory and Experimental Study of Strengthening Reinforced Concrete Beams Using Prestressed Carbon Fiber Sheets

Abstract

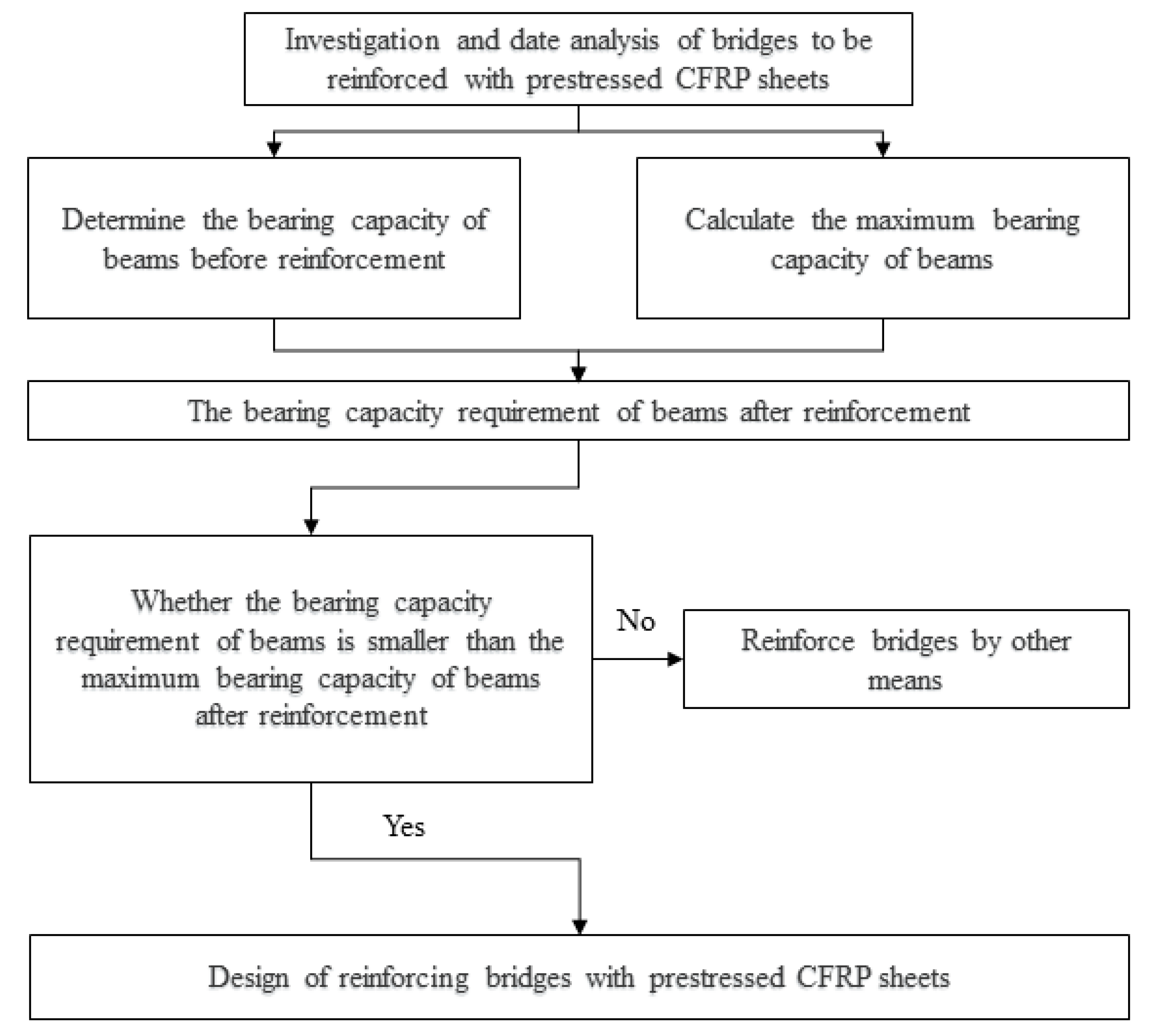

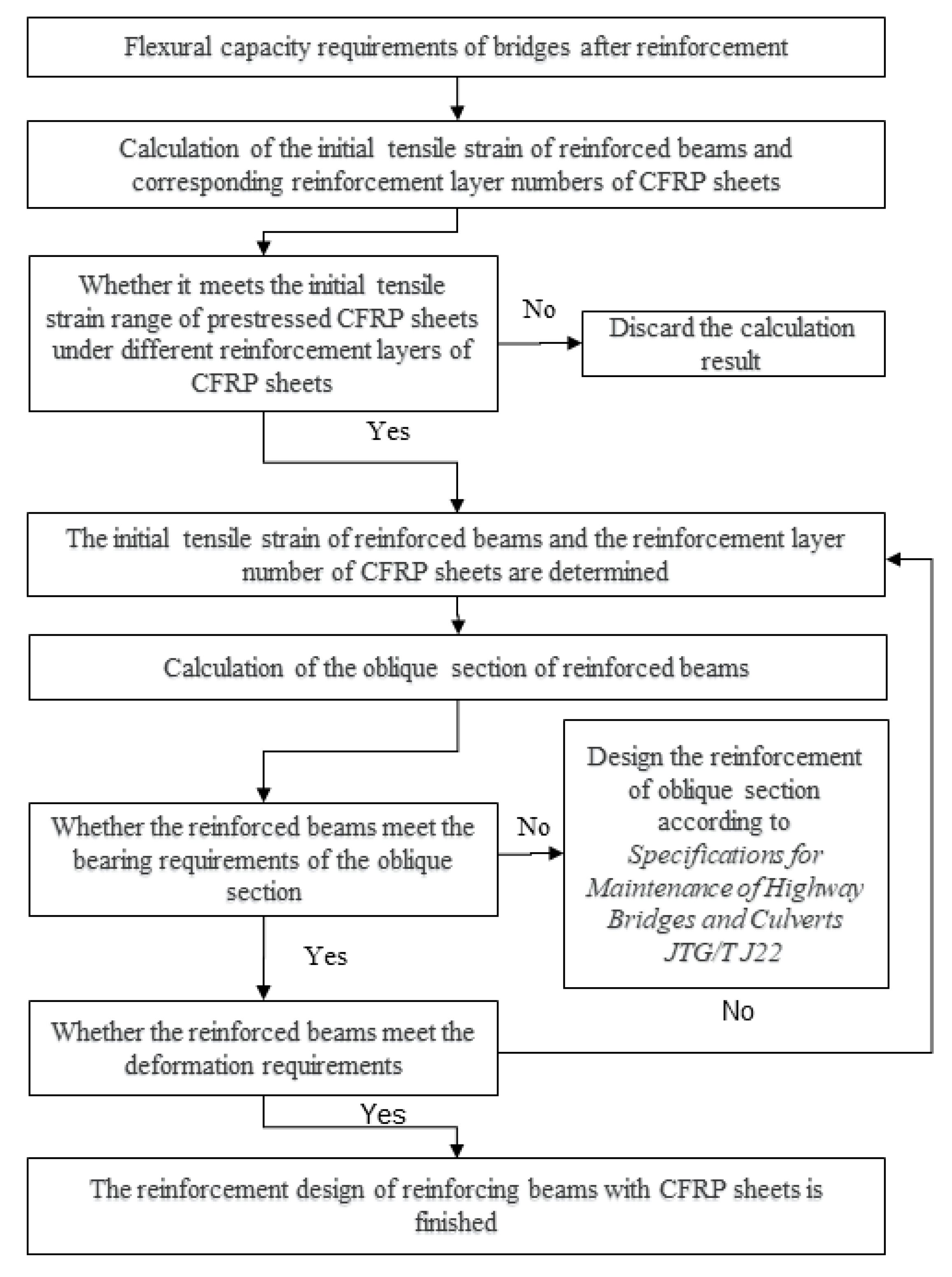

1. Introduction

2. Design Theory for RC Beams Strengthened by Prestressed Carbon Fiber Sheets

2.1. Basic Assumptions

- (1)

- Section deformation conforms to the plane section assumption;

- (2)

- The tensile resistance of concrete is neglected after cracking;

- (3)

- CFRP is an ideal linear–elastic material;

- (4)

- A perfect bond exists between the CFRP sheet and concrete.

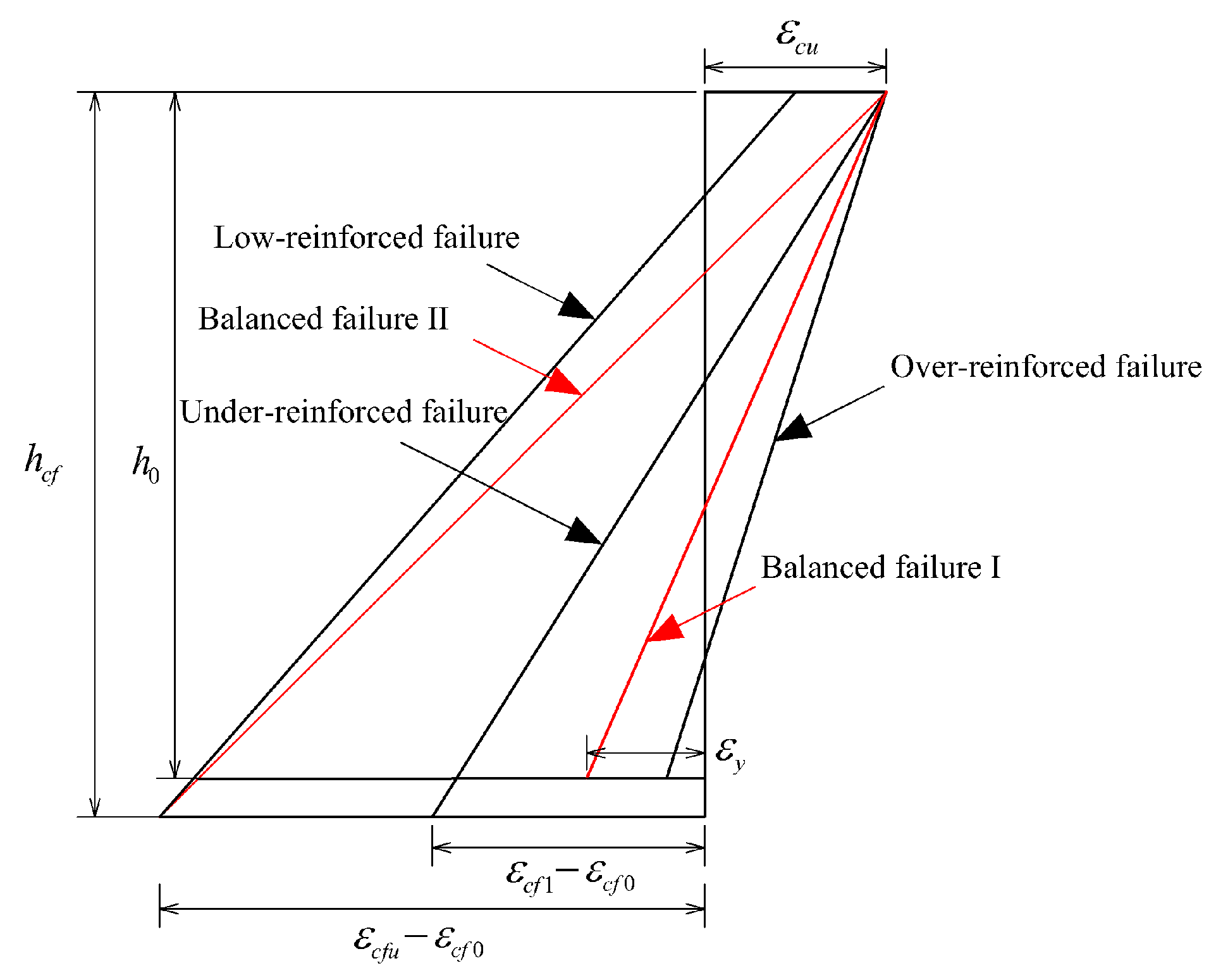

2.2. Analysis of the Tensile Strain Range for CFRP Sheets Based on the Under-Reinforced Failure Mode

- (1)

- Yielding of the tensile steel reinforcement;

- (2)

- The CFRP sheet not being fully ruptured;

- (3)

- Crushing of the concrete in the compression zone.

- –

- is the ultimate compressive strain of concrete at the extreme compression fiber of the cross-section;

- –

- is the yield strain of the tensile steel reinforcement;

- –

- is the section height;

- –

- is the section height;

- –

- is the effective section depth;

- –

- is the strain in the CFRP sheet;

- –

- is the initial tensile strain in the CFRP sheet (pre-tensioning strain);

- –

- is the ultimate tensile strain of the tensile steel reinforcement.

- –

- and are coefficients whose values are determined according to the GB50010-2010 Code for the Design of Concrete Structures [28];

- –

- is the axial compressive strength of concrete;

- –

- is the section width;

- –

- is the tensile strength of the ordinary steel reinforcement;

- –

- is the cross-sectional area of the longitudinal ordinary steel reinforcement in the tension zone;

- –

- is the elastic modulus of the CFRP sheet;

- –

- is the number of layers of the CFRP sheet;

- –

- is the width of the CFRP sheet;

- –

- is the thickness of the CFRP sheet.

- –

- corresponds to the allowable strain of the CFRP sheet.

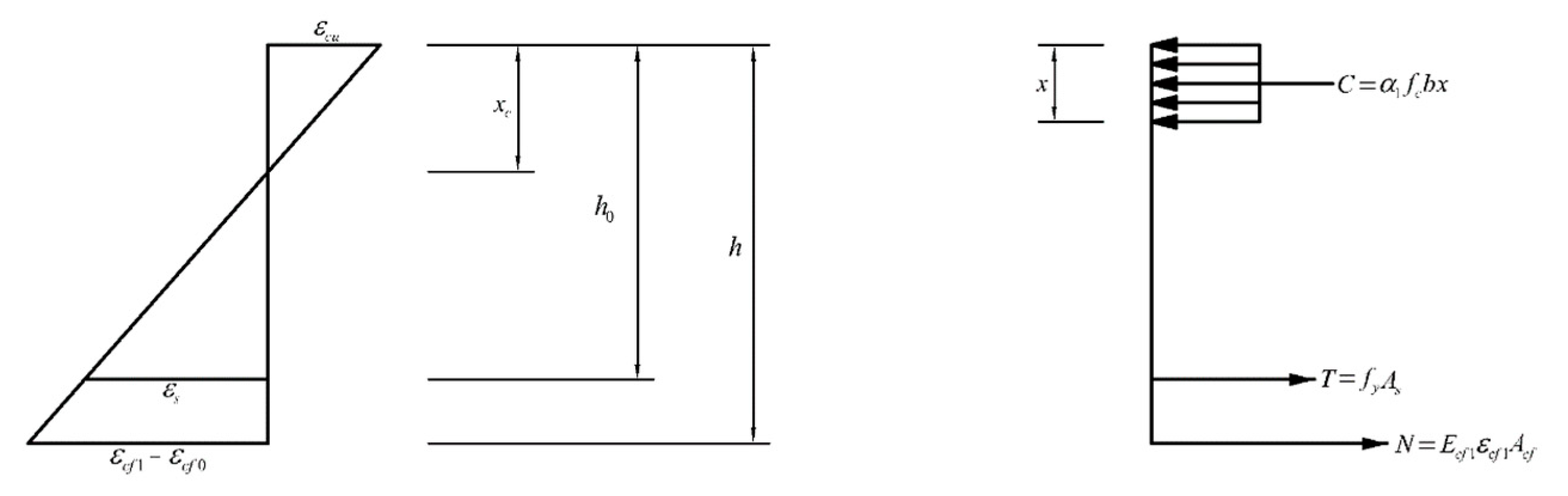

2.3. Determination of CFRP Sheet Strengthening Layers and the Minimum Initial Tensile Strain

- –

- denotes the design flexural capacity of the strengthened RC beam;

- –

- x denotes the depth of the compression zone;

- –

- n denotes the number of CFRP sheet strengthening layers.

2.4. Design Procedure for Prestressed CFRP-Strengthened RC Beams

3. Experimental Study on Prestressed CFRP-Strengthened RC Beams

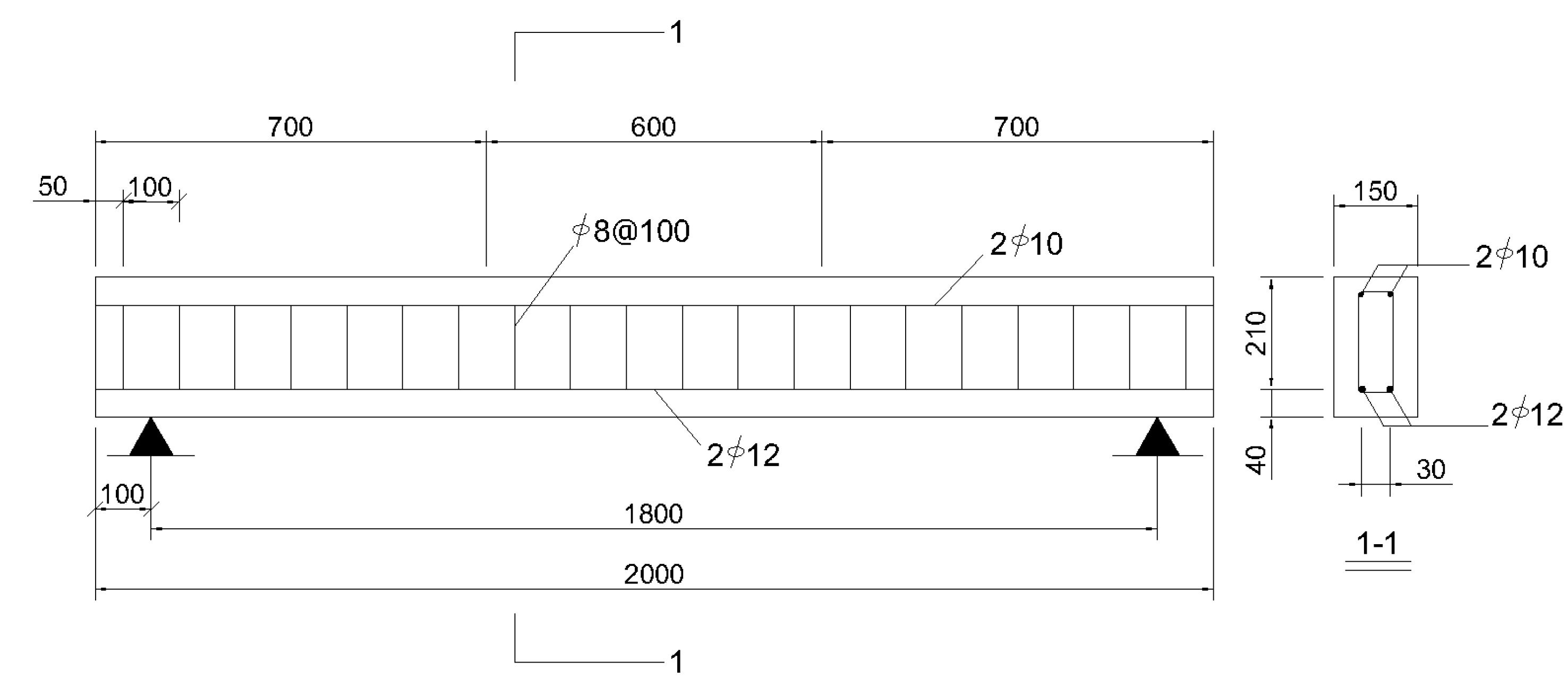

3.1. Test Beam Design

3.2. Strengthening Design Calculation

3.3. Strengthened Beam Design and Performance Prediction

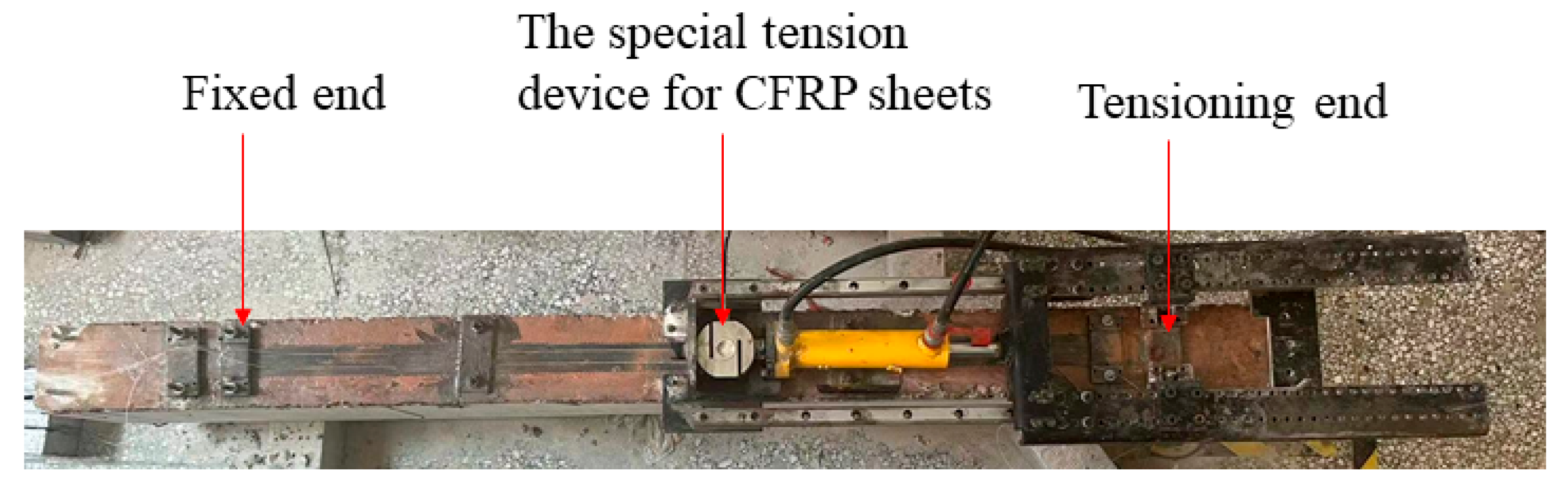

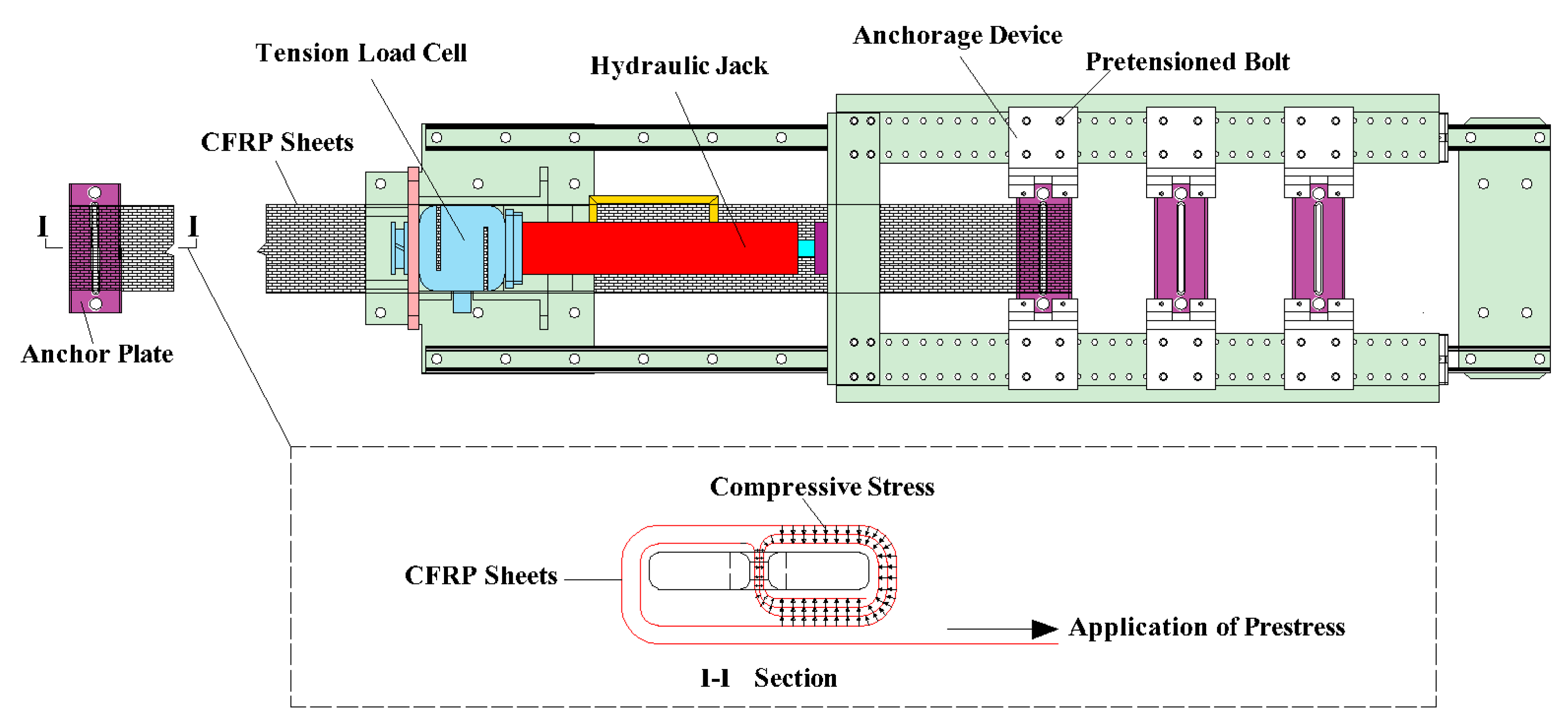

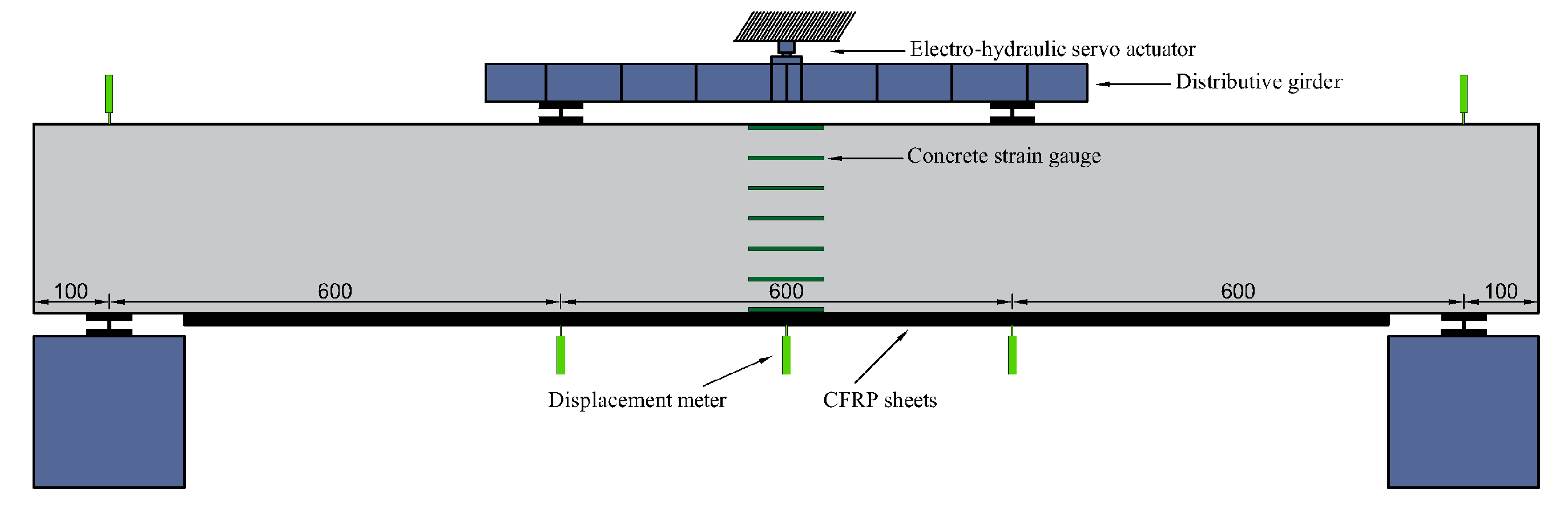

3.4. Experimental Program for Strengthened RC Beams

4. Results and Discussion

4.1. Failure Mode

- (1)

- Test beam WN0

- (2)

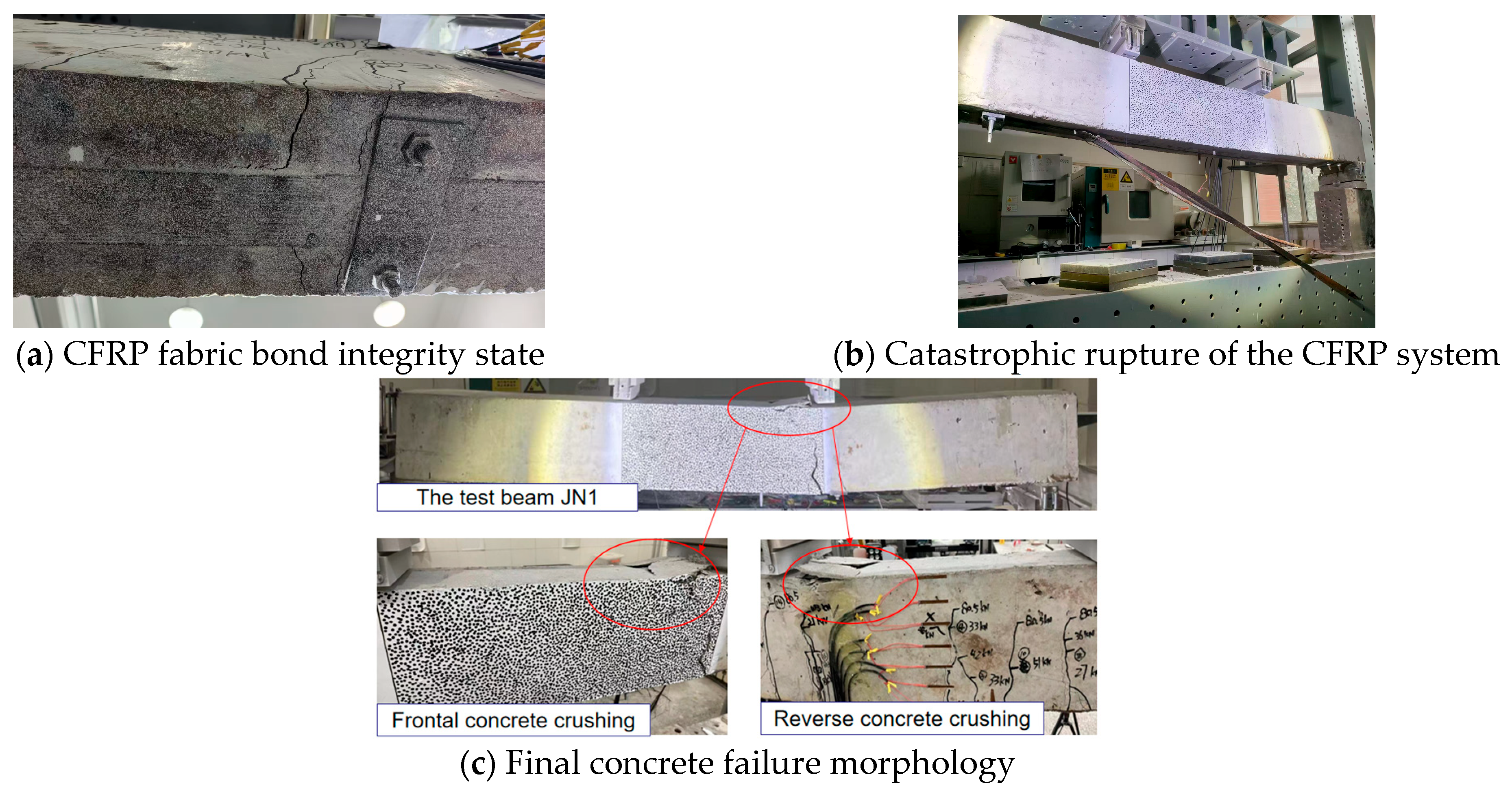

- Test beam JN1

- (3)

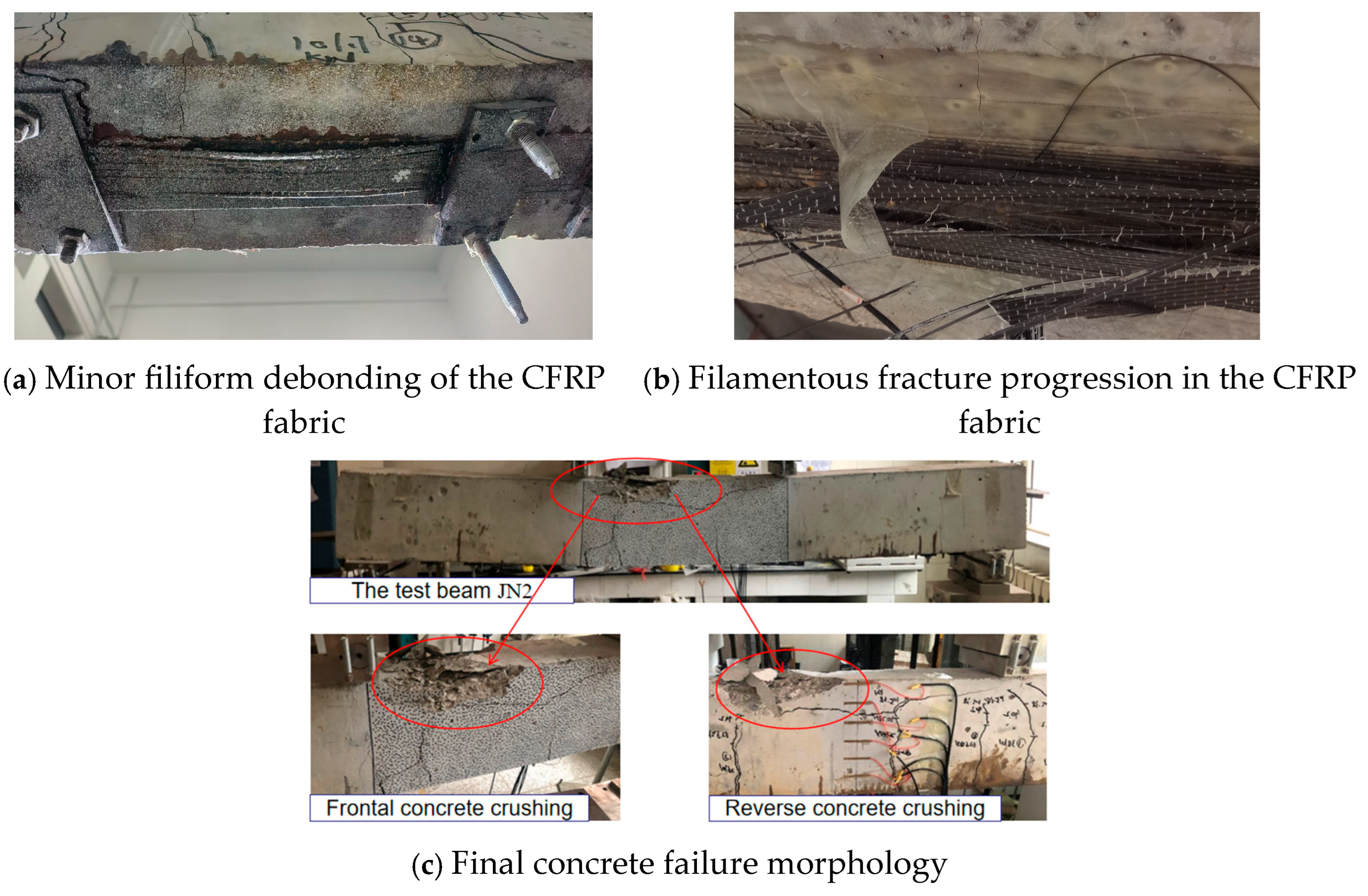

- Test beam JN2

- (4)

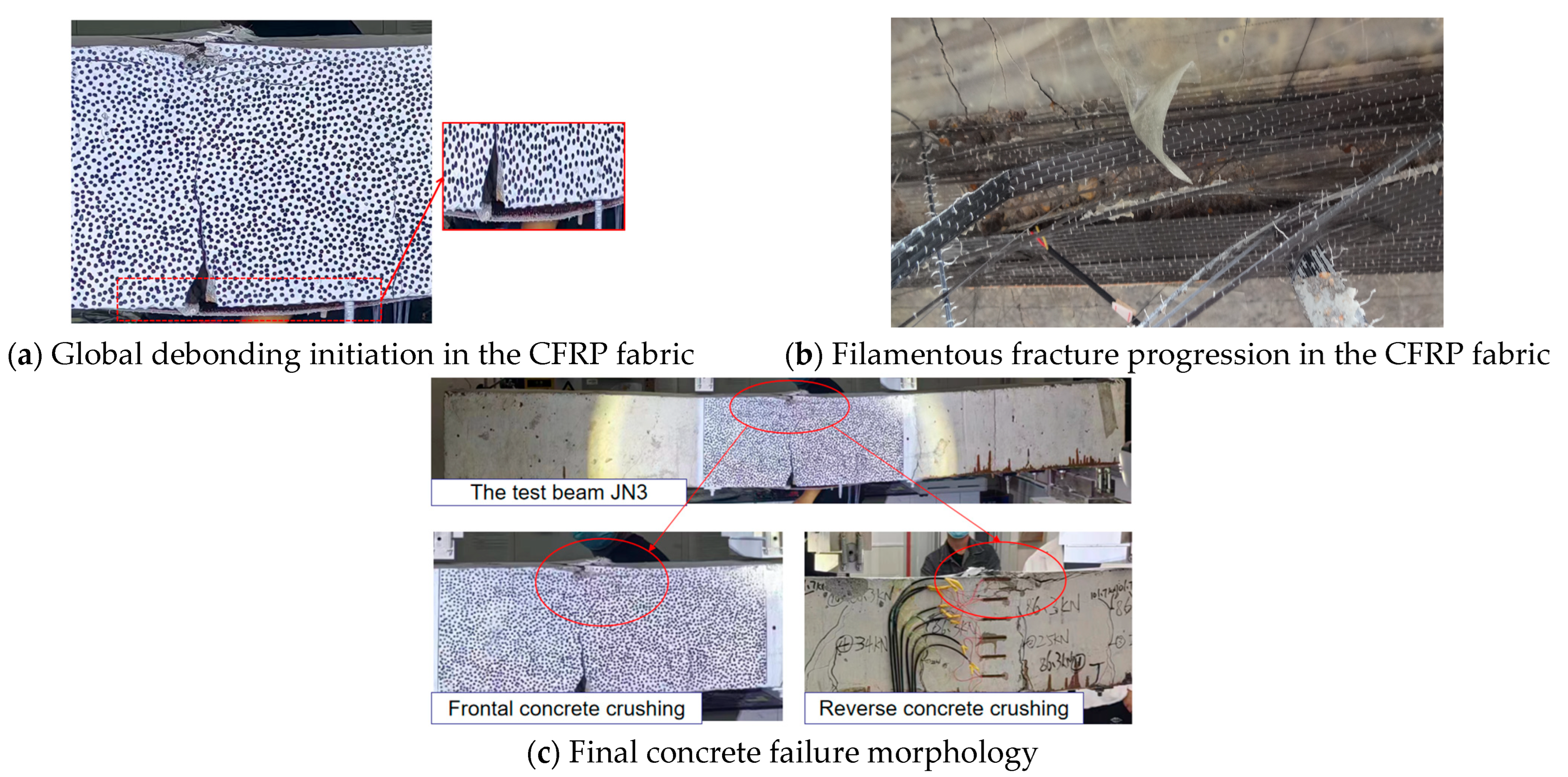

- Test beam JN3

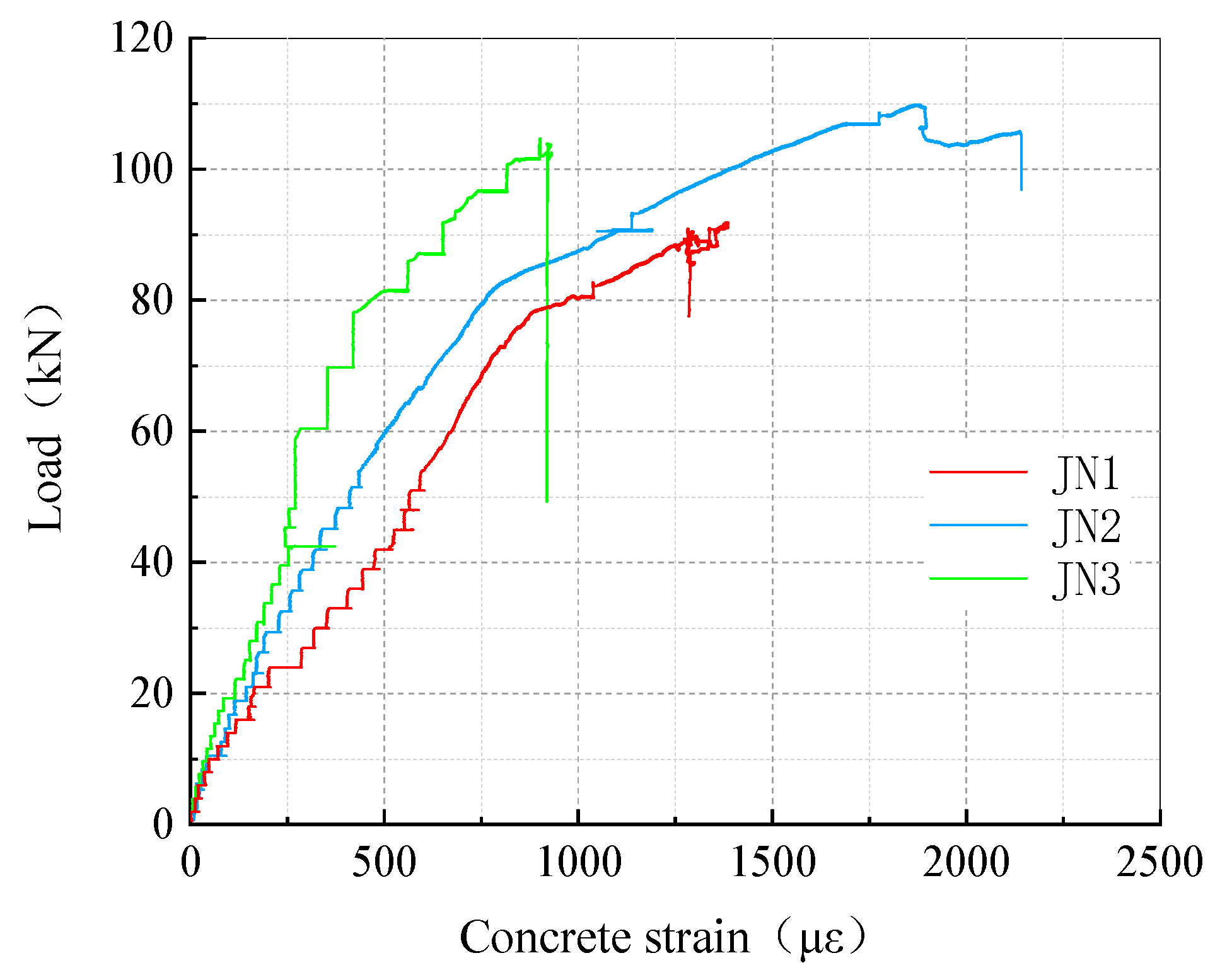

4.2. Concrete Strain Analysis

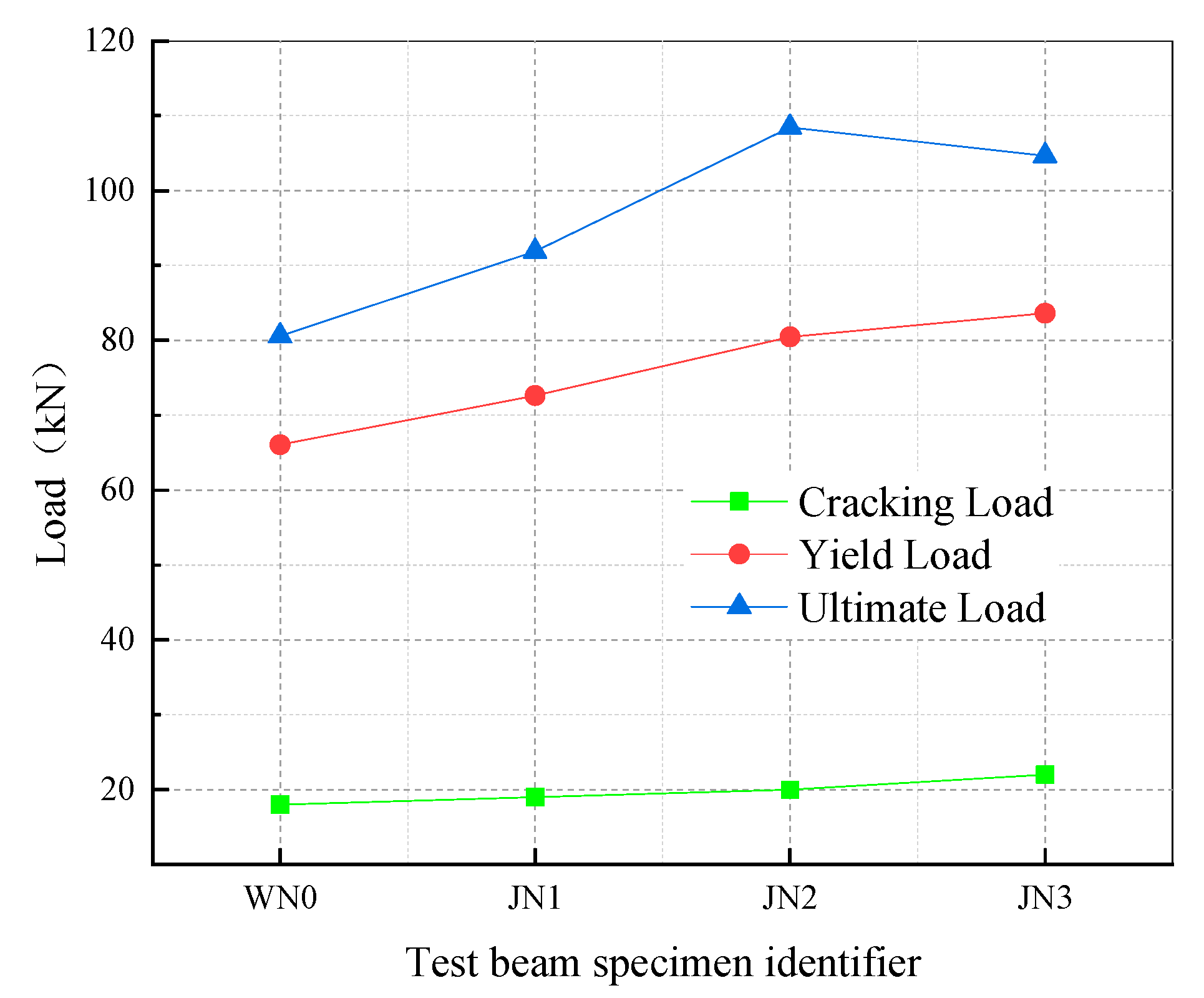

4.3. Load-Carrying Capacity Analysis

5. Conclusions and Future Work

5.1. Conclusions

- (1)

- This study established a design theory for prestressed CFRP-strengthened RC beams. By strictly limiting the initial prestressing strain range, the theory effectively prevents brittle failure due to over-strengthening. The experimental results demonstrated strong agreement with the theoretical predictions, confirming the proposed theory’s reliability and practical applicability for typical strengthening scenarios.

- (2)

- An increase in CFRP layers can effectively enhance the overall stiffness of strengthened beams; however, employing more than two layers may exacerbate CFRP delamination, consequently leading to a reduction in the load-bearing capacity along with diminished strengthening effectiveness.

- (3)

- The proposed optimized schemes—self-locking winding and pre-tightened bolt anchorage—effectively mitigated prestress loss and ensured high tensioning efficiency. Nevertheless, the quality of the bond at the CFRP–concrete interface is the critical factor limiting the effectiveness of the strengthening, particularly for multi-layer applications.

5.2. Future Work

- (1)

- Given that this study has not yet fully revealed the microscopic mechanisms of interfacial failure in multi-layer CFRP strengthening, future work should incorporate micro-characterization techniques such as SEM/XCT [37,38]. This will enable the quantitative analysis of interfacial shear stress distribution, crack propagation, and bond degradation laws. A predictive model for the “layer number–stiffness–delamination threshold” should be established to achieve a breakthrough beyond the current layer limitation.

- (2)

- To facilitate the translation of laboratory findings into engineering practice, validation via full-scale beam-strengthening tests (TRL 6), in-service monitoring of environmental durability, and research on standardized construction methodologies are required.

- (3)

- The scope should be extended to scenarios such as continuous beams and beams with variable cross-sections. Furthermore, long-term performance tests of strengthened beams under fatigue and impact loads should be conducted.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Mosawe, D.; Neves, L.; Owen, J. Reliability analysis of deteriorated post-tensioned concrete bridges: The case study of Ynys-y-Gwas bridge in UK. Structures 2022, 41, 242–259. [Google Scholar] [CrossRef]

- Jiang, X.; Cao, D.; Qiang, X.; Xu, C. Study on fatigue performance of steel bridge welded joints considering initial defects. J. Constr. Steel Res. 2024, 212, 108309. [Google Scholar] [CrossRef]

- Borrie, D.; Al-Saadi, S.; Zhao, X.-L.; Raman, R.S.; Bai, Y. Bonded CFRP/Steel Systems, Remedies of Bond Degradation and Behaviour of CFRP Repaired Steel: An Overview. Polymers 2021, 13, 1533. [Google Scholar] [CrossRef] [PubMed]

- United States. Department of Transportation. University Transportation Centers (UTC) Program, United States. Department of Transportation. Federal Highway Administration, Haifang Wen, Pizhong Qiao, Ayumi K Manawadu, Washington State University. Department of Civil and Environmental Engineering, and Washington State University. National Center for Transportation Infrastructure Durability & Life Extension (TriDurLE) UTC.Test Methods and Bond Performance Characterization of Shotcrete-Concrete Interface. Available online: https://research.ebsco.com/linkprocessor/plink?id=de2e7ea4-1160-3185-a3ce-aef5b0d3c93c (accessed on 14 August 2025).

- Chalot, A.; Michel, L.; Ferrier, E. Experimental study of external bonded CFRP-concrete interface under low cycle fatigue loading. Compos. Part B Eng. 2019, 177, 107255. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, S.; Woo, U.; Choi, H.; Jung, D. Experimental Evaluation of Shape Memory Alloy Retrofitting Effect for Circular Concrete Column Using Ultrasonic Pulse Velocity. Int. J. Concr. Struct. Mater. 2023, 17, 13. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Shah, S. Strengthening of RC beams using prestressed fiber reinforced polymers–A review. Constr. Build. Mater. 2015, 82, 235–256. [Google Scholar] [CrossRef]

- Li, D.; Zhu, R.; Li, F. Flexural Behavior of GFRP–Aluminum Space Truss Strengthened with Prestressed CFRP Tendons: Experimental and Theoretical Study. J. Compos. Constr. 2024, 28, 04024036. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Bergil, E.; Erdal, E. Estimation of the FRP-concrete bond strength with code formulations and machine learning algorithms. Compos. Struct. 2021, 268, 113972.1–113972.16. [Google Scholar] [CrossRef]

- Slaitas, J.; Valivonis, J. Technological peculiarities of strengthening RC members with prestressed FRP laminates. Compos. Struct. 2022, 290, 115526. [Google Scholar] [CrossRef]

- Tang, Y.; Yao, Y.; Cang, J. Structural and Sensing Performance of RC Beams Strengthened with Prestressed Near-Surface Mounted Self-Sensing Basalt FRP Bar. Compos. Struct. 2020, 259, 113474. [Google Scholar] [CrossRef]

- Jiang, F.; Ding, Y.; Song, Y.; Yang, K. Fatigue enhancement in complex U-rib to diaphragm welds via rib-surface-bonded CFRP plates: Performance evaluation and configuration design. Adv. Struct. Eng. 2025, 28, 488–512. [Google Scholar] [CrossRef]

- Cho, S.; Lee, H.; Chung, W. Strengthening effect of prestressed near-surface mounted CFRP bar system according to material properties of aged reinforced concrete beams. Compos. Struct. 2020, 282, 115121. [Google Scholar] [CrossRef]

- Belarbi, A.; Reda, M.; Poudel, P.; Tahsiri, H.; Dawood, M.; Gencturk, B. Prestressing Concrete with CFRP Composites for Sustainability and Corrosion-Free Applications. MATEC Web Conf. 2018, 149, 01010. [Google Scholar] [CrossRef][Green Version]

- Alsuhaibani, E. Optimization of Carbon Fiber-Reinforced Polymer (CFRP) Configuration for Enhanced Flexural Performance in Strengthened Concrete Beams. Buildings 2024, 14, 3953. [Google Scholar] [CrossRef]

- Bensaid, C.; Tbatou, T. Numerical studies on the seismic behavior of reinforced concrete structures Strengthened with CFRP. J. Build. Pathol. Rehabil. 2024, 9, 148. [Google Scholar] [CrossRef]

- Lu, C.; Chen, J.; Gan, X.; Wang, Q.; Zhu, W.X. Experimental study on the prestress loss of double-end prestressing of carbon-fiber reinforced polymer fabric for strengthening large-diameter reinforced concrete circular columns. Polym. Compos. 2023, 44, 1772–1788. [Google Scholar] [CrossRef]

- LI, A.; Diagana, C.; Delmas, Y.; Gedalia, B. Shear performance with externally bonded carbon fibre fabrics. In Fibre-Reinforced Polymer Reinforcement for Concrete Structures; World Scientific: Singapore, 2015. [Google Scholar]

- Liu, J.; Fan, X.; Zou, L.; Shi, C. Effect of different CFRP strengthening methods on fracture parameters of concrete beam. Eng. Fract. Mech. 2025, 314, 110748. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Al-Saraireh, S. Impact of Anchored Holes Technique on Behavior of Reinforced Concrete Beams Strengthened with Different CFRP Sheet lengths and Widths. Case Stud. Constr. Mater. 2020, 13, e00405. [Google Scholar] [CrossRef]

- Hanoon, A.N.; Jaafar, M.; Al Zaidee, S.R.; Hejazi, F.; Abd Aziz, F. Effectiveness factor of the strut-and-tie model for reinforced concrete deep beams strengthened with CFRP sheet. J. Build. Eng. 2017, 12, 8–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Zhen, J.; Li, B.; Cai, D.; Du, Y. Entire mechanical analysis of prestressed CFRP strengthened RC beams under different prestressed introduced methods. Adv. Bridge Eng. 2024, 5, 13. [Google Scholar] [CrossRef]

- Fowai, I.; Noël, M.; Esmaili, M.; Martín-Pérez, B.; Sanchez, L. Bond performance of deteriorated CFRP-concrete interface under different shear lap configurations: A Champlain Bridge case study. Constr. Build. Mater. 2025, 487, 142002. [Google Scholar] [CrossRef]

- Lu, Z.; Li, J.; Xie, J.; Huang, P.; Xue, L. Durability of flexurally strengthened RC beams with prestressed CFRP sheet under wet–dry cycling in a chloride-containing environment. Compos. Struct. 2020, 255, 112869. [Google Scholar] [CrossRef]

- Shang, S.; Peng, H.; Tong, H.; Wei, D.; Zeng, L. Study of strengthening reinforced concrete beam using prestressed carbon fiber sheet. J. Build. Struct. 2003, 24, 24–30. [Google Scholar]

- GB 50367-2013; Code for Design of Strengthening Concrete Structure. Chinese Standard: Beijing, China, 2013.

- Wang, W. FRP Strengthened Concrete Structures: Techniques and Applications; Architecture & Building Press: Beijing, China, 2007. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structure. Chinese Standard: Beijing, China, 2010.

- CECS 146-2003(2007); Technical Code for Strengthening Concrete Structures with Carbon Fiber Reinforced Sheets. Chinese Standard: Beijing, China, 2003.

- Ye, J. Principles of Structural Design, 4th ed.; Communications Press: Beijing, China, 2018; pp. 68–69. [Google Scholar]

- Zheng, X.; Huang, P.; Huang, J. Experimental study on prestress loss of reinforced concrete beams strengthened with prestressed carbon fiber laminates. J. Build. Struct. 2015, 36, 7. [Google Scholar]

- Kazemi, F.; Asgarkhani, N.; Shafighfard, T.; Jankowski, R.; Yoo, D.-Y. Machine-Learning Methods for Estimating Performance of Structural Concrete Members Reinforced with Fiber-Reinforced Polymers. Arch. Comput. Methods Eng. 2025, 32, 571–603. [Google Scholar] [CrossRef]

- Guan, Y.; Miao, H.; Song, X. Study of the anchoring parameter for the hybrid bonding of FRP. J. Shandong Univ. (Eng. Sci.) 2010, 40, 128–132. [Google Scholar]

- Wu, F.; Wu, J.; Bian, Z.; Ma, Y.; Li, Z.; Lei, H. Experimental study on flexural behavior of ECC-NC composite beams. China J. Highw. Transp. 2025, 38, 158–172. [Google Scholar]

- Abdulrahman, B.Q. Precise finite element verification of the unreliability of using multi-layers of FRP on CFRP-debonding in RC beams. Eng. Res. Express 2022, 4, 025048. [Google Scholar] [CrossRef]

- Thamrin, R.; Zaidir, Z.; Desharma, S. Debonding failure analysis of reinforced concrete beams strengthened with CFRP plates. Polymers 2021, 13, 2738. [Google Scholar] [CrossRef]

- Chou, H.Y.; Bunsell, A.R.; Thionnet, A. Visual indicator for the detection of end-of-life criterion for composite high pressure vessels for hydrogen storage. Int. J. Hydrog. Energy 2012, 37, 16247–16255. [Google Scholar] [CrossRef]

- Sakr, M.A. Finite element modeling of debonding mechanisms in carbon fiber reinforced polymer-strengthened reinforced concrete continuous beams. Struct. Concr. J. FIB 2018, 19, 1002–1012. [Google Scholar] [CrossRef]

| Reinforcement Type | Diameter (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|

| HRB400 | 12 | 429.88 | 594.08 | 308,000 |

| Material | Tensile Strength (MPa) | Elastic Modulus (MPa) | Percentage Elongation (%) |

|---|---|---|---|

| CFRP | 4255 | 2.4 × 105 | 1.9 |

| Experimental Beam Type | Midspan Flexural Capacity of Normal Section (kN·m) | Maximum Flexural Capacity of Singly Reinforced Section (kN·m) |

|---|---|---|

| Control beam | 25.2 | 47.94 |

| CFRP Layer Count | Initial Tensile Strain Range | |

|---|---|---|

| 1 | 0.0116 | |

| 2 | 0.0020 | |

| 3 | −0.0012 |

| Specimen ID | Number of CFRP Layers | Initial Prestressing Force Per CFRP Layer (kN) | Calculated Mid-Span Flexural Capacity (kN·m) | |

|---|---|---|---|---|

| WN0 | 0 | - | - | 25.20 |

| JN1 | 1 | 0.0020 | 4 | 29.61 |

| JN2 | 2 | 0.0020 | 4 | 32.76 |

| JN3 | 3 | 0.0020 | 4 | 35.46 |

| Specimen ID | Calculated Mid-Span Flexural Capacity (kN·m) | Tested Mid-Span Flexural Capacity (kN·m) |

|---|---|---|

| WN0 | 25.20 | 24.14 |

| JN1 | 29.61 | 27.56 |

| JN2 | 32.76 | 32.54 |

| JN3 | 35.46 | 31.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Qin, Y.; Long, G.; Ran, Y.; Guan, Y.; Wang, Y.; Sun, R.; Qian, Y. Design Theory and Experimental Study of Strengthening Reinforced Concrete Beams Using Prestressed Carbon Fiber Sheets. Buildings 2025, 15, 3126. https://doi.org/10.3390/buildings15173126

Zhang Z, Qin Y, Long G, Ran Y, Guan Y, Wang Y, Sun R, Qian Y. Design Theory and Experimental Study of Strengthening Reinforced Concrete Beams Using Prestressed Carbon Fiber Sheets. Buildings. 2025; 15(17):3126. https://doi.org/10.3390/buildings15173126

Chicago/Turabian StyleZhang, Zejun, Yu Qin, Guanxu Long, Yao Ran, Yanhua Guan, Yan Wang, Renjuan Sun, and Yuanshun Qian. 2025. "Design Theory and Experimental Study of Strengthening Reinforced Concrete Beams Using Prestressed Carbon Fiber Sheets" Buildings 15, no. 17: 3126. https://doi.org/10.3390/buildings15173126

APA StyleZhang, Z., Qin, Y., Long, G., Ran, Y., Guan, Y., Wang, Y., Sun, R., & Qian, Y. (2025). Design Theory and Experimental Study of Strengthening Reinforced Concrete Beams Using Prestressed Carbon Fiber Sheets. Buildings, 15(17), 3126. https://doi.org/10.3390/buildings15173126