Assessment of Phase Change Materials Incorporation into Construction Commodities for Sustainable and Energy-Efficient Building Applications

Abstract

1. Introduction

2. Fundamentals of Phase Change Materials

2.1. Thermal Energy Storage in Buildings

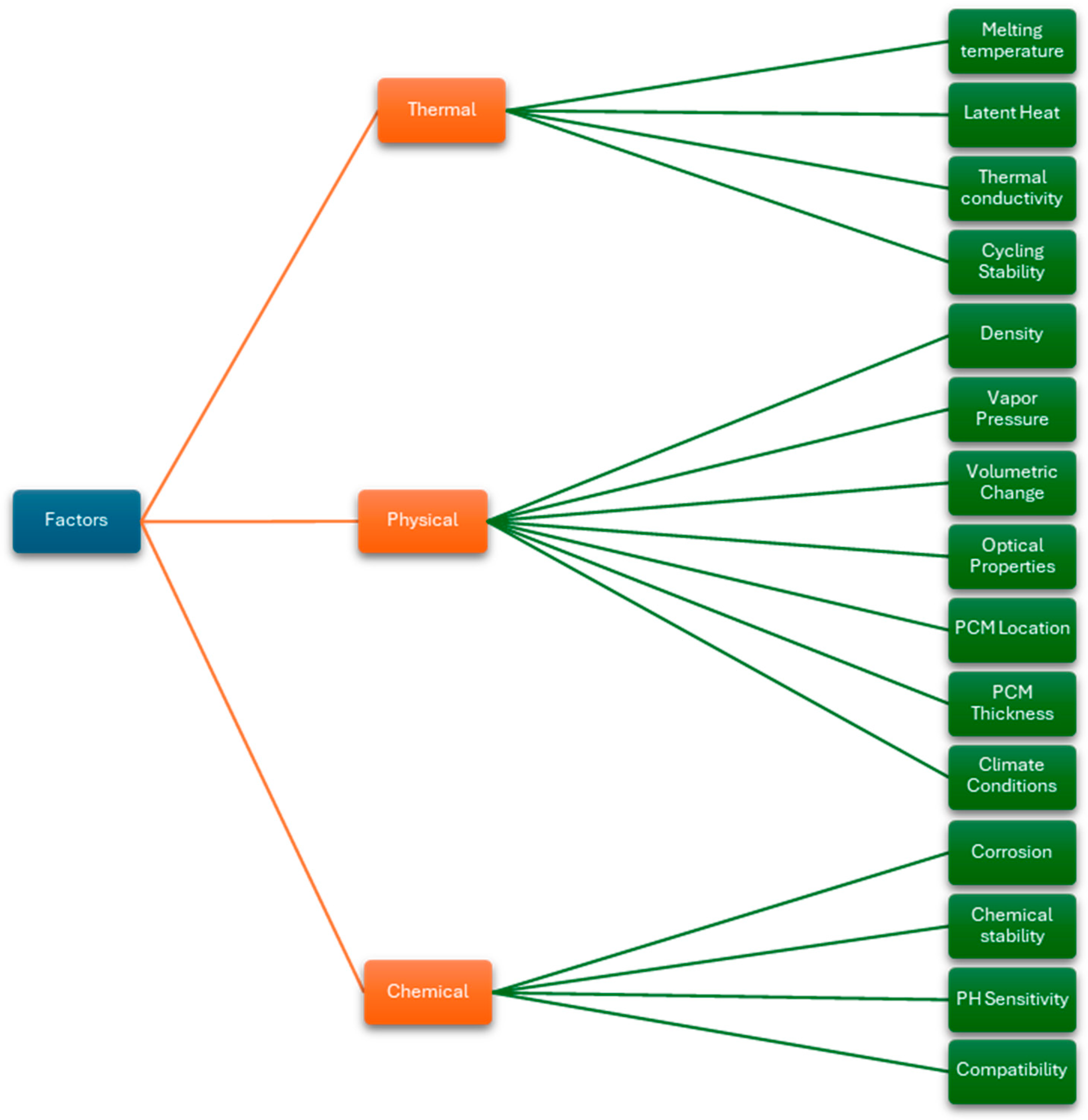

2.2. Evaluation Criteria for Phase Change Materials Selection

2.3. PCM Interaction with Construction Commodities

2.3.1. Impact on Mechanical Properties

2.3.2. Impacts on Durability

2.3.3. Building Materials Response

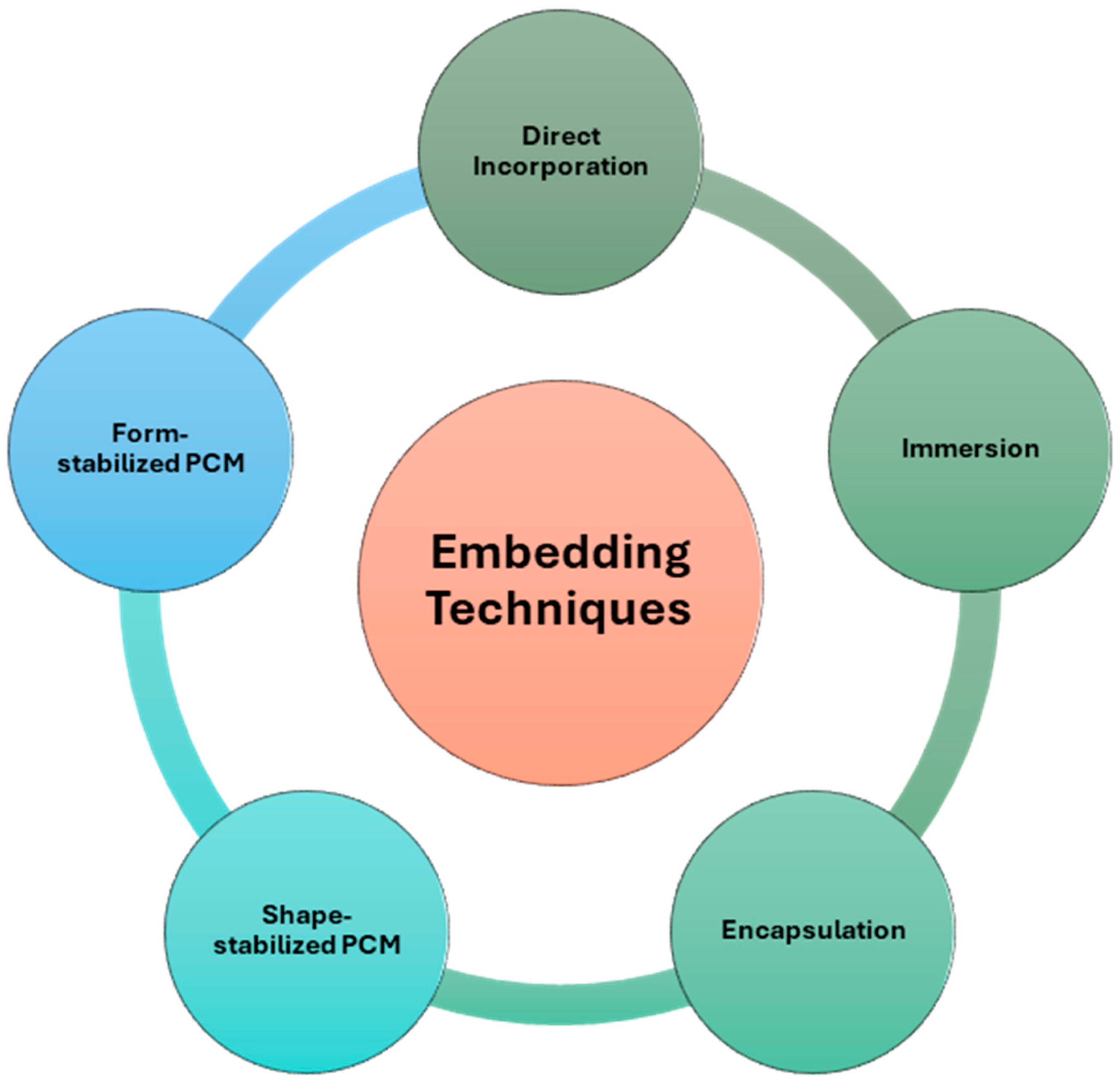

2.4. Embedding Techniques

2.4.1. Direct Incorporation

2.4.2. Immersion

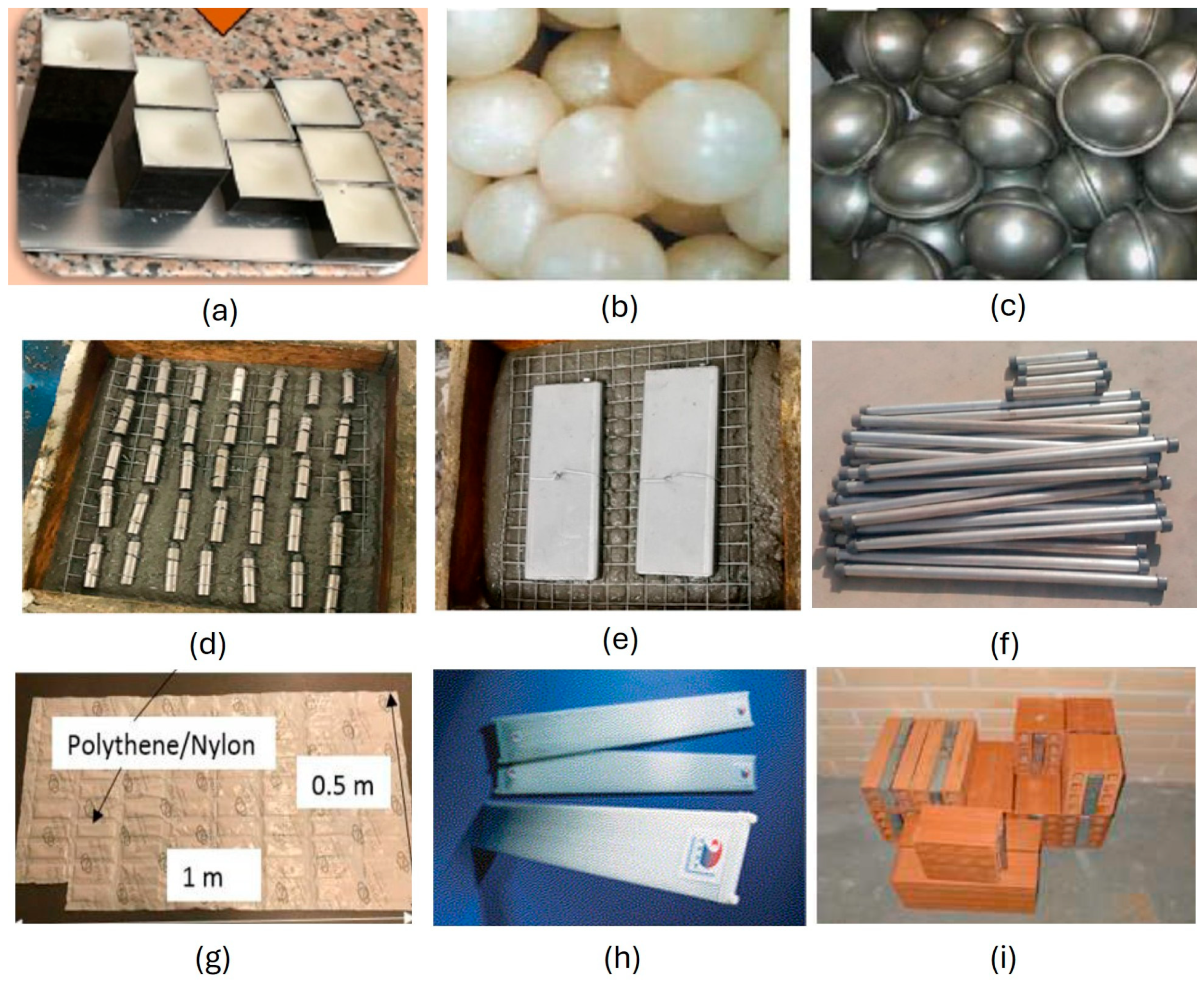

2.4.3. Encapsulation

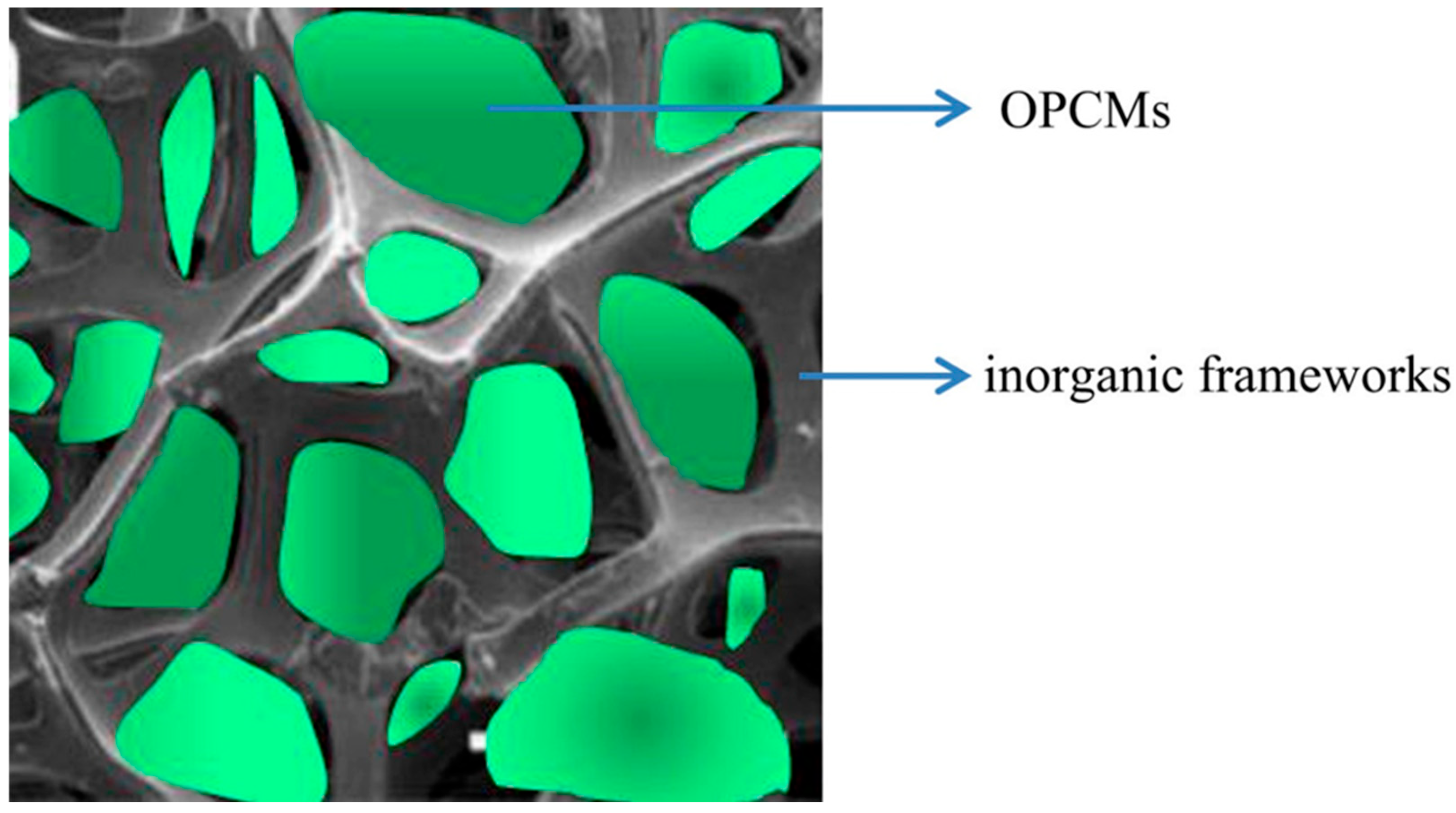

2.4.4. Shape-Stable PCM

2.4.5. Form-Stable PCM

2.4.6. Comparative Analysis of Embedding Techniques

2.5. Environmental Considerations

3. Incorporation of PCMs into Building Commodities

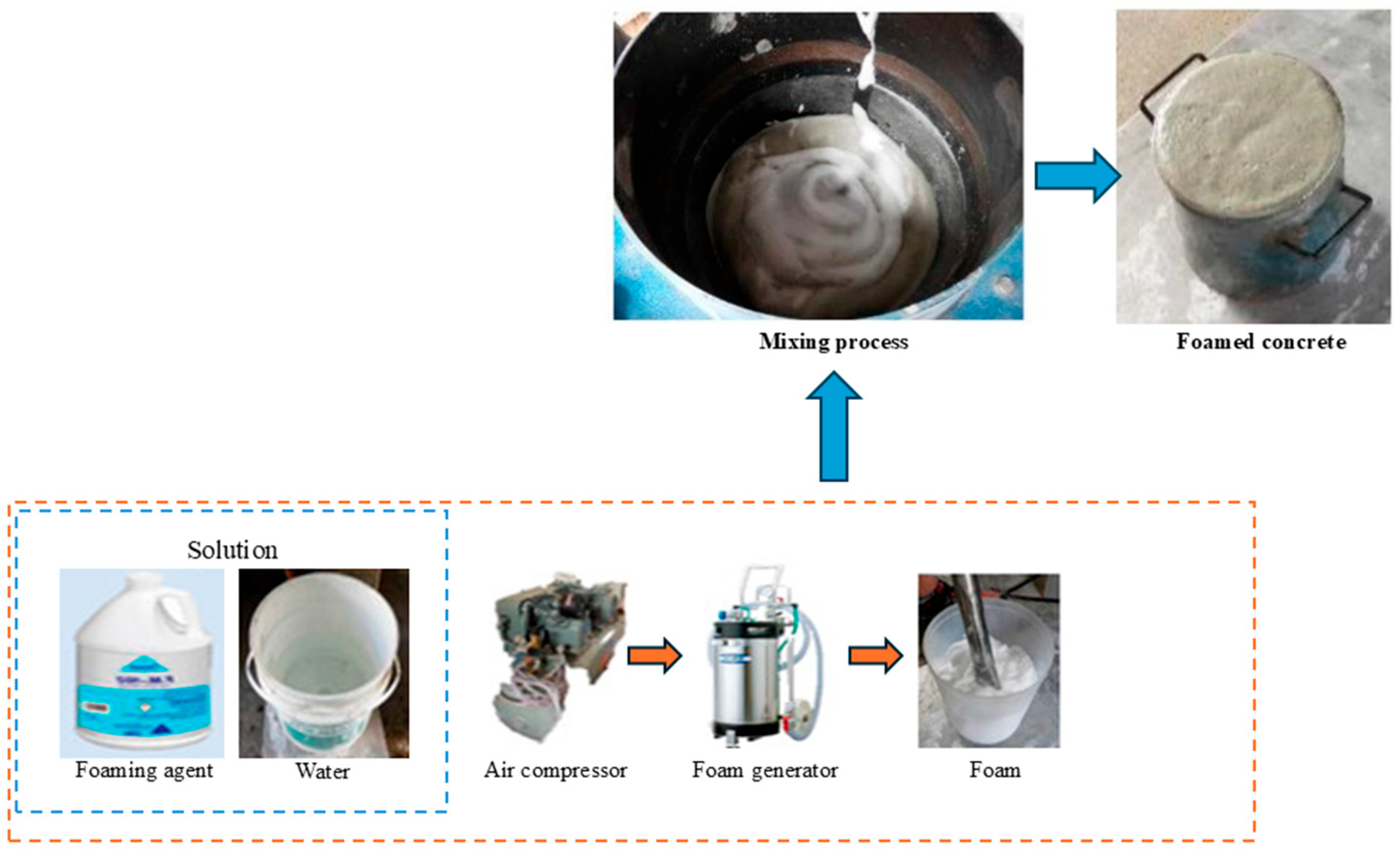

3.1. Concrete, Cementitious, or Other Building Materials

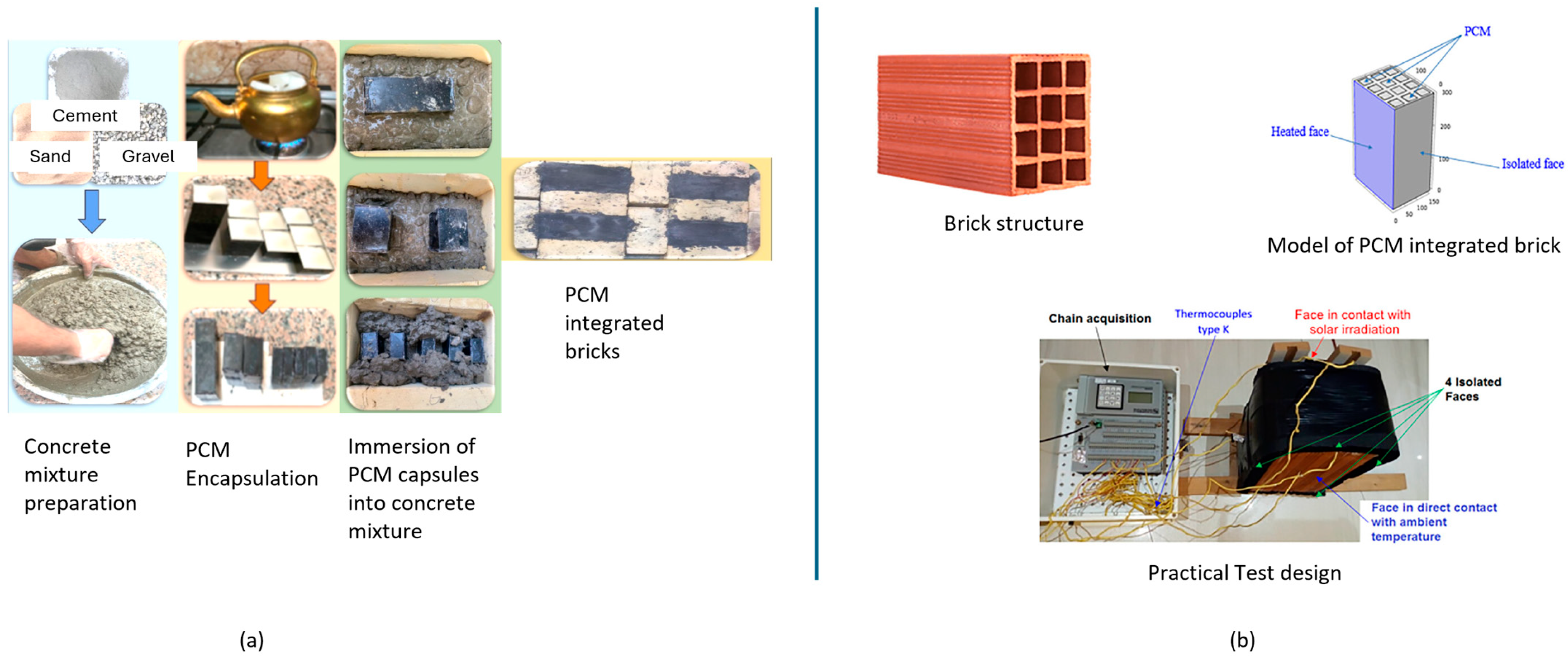

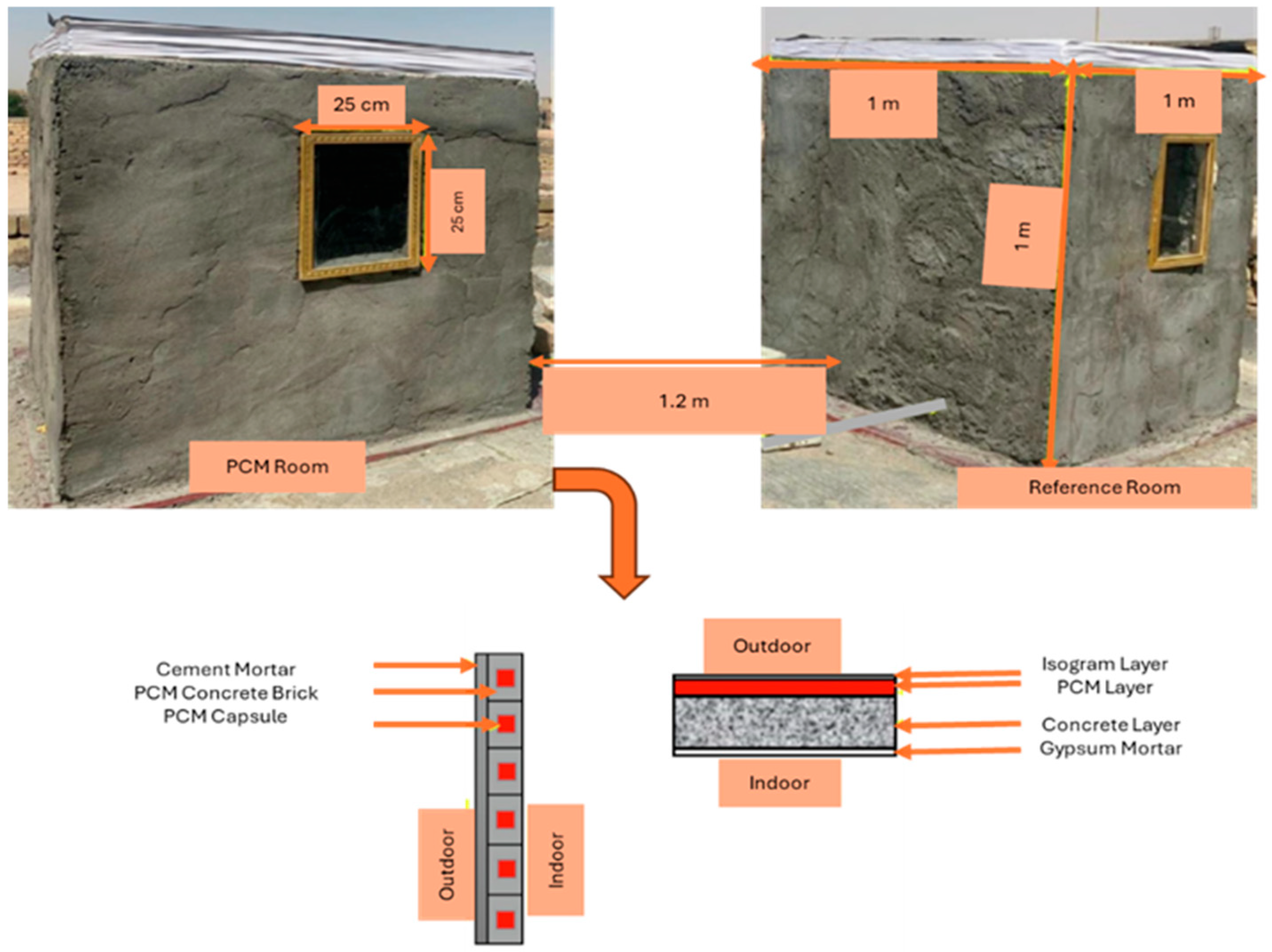

3.1.1. Bricks and Masonry

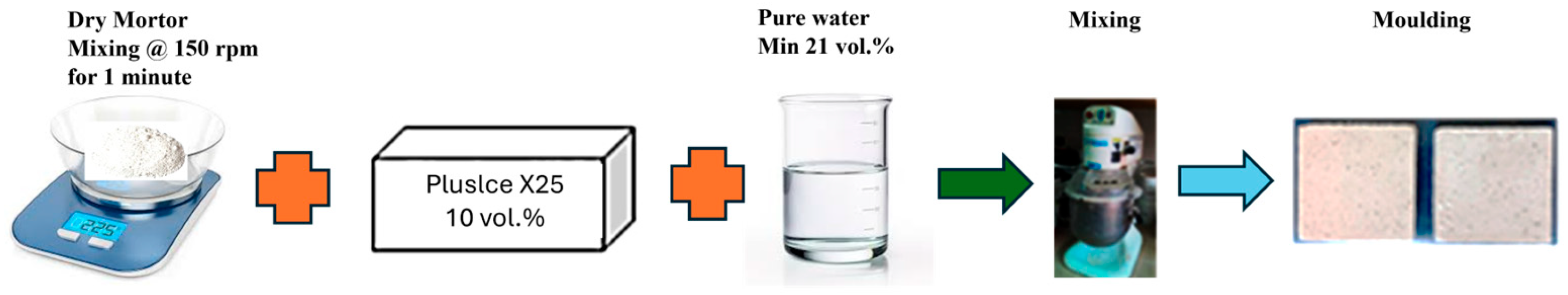

3.1.2. Plasters and Coatings

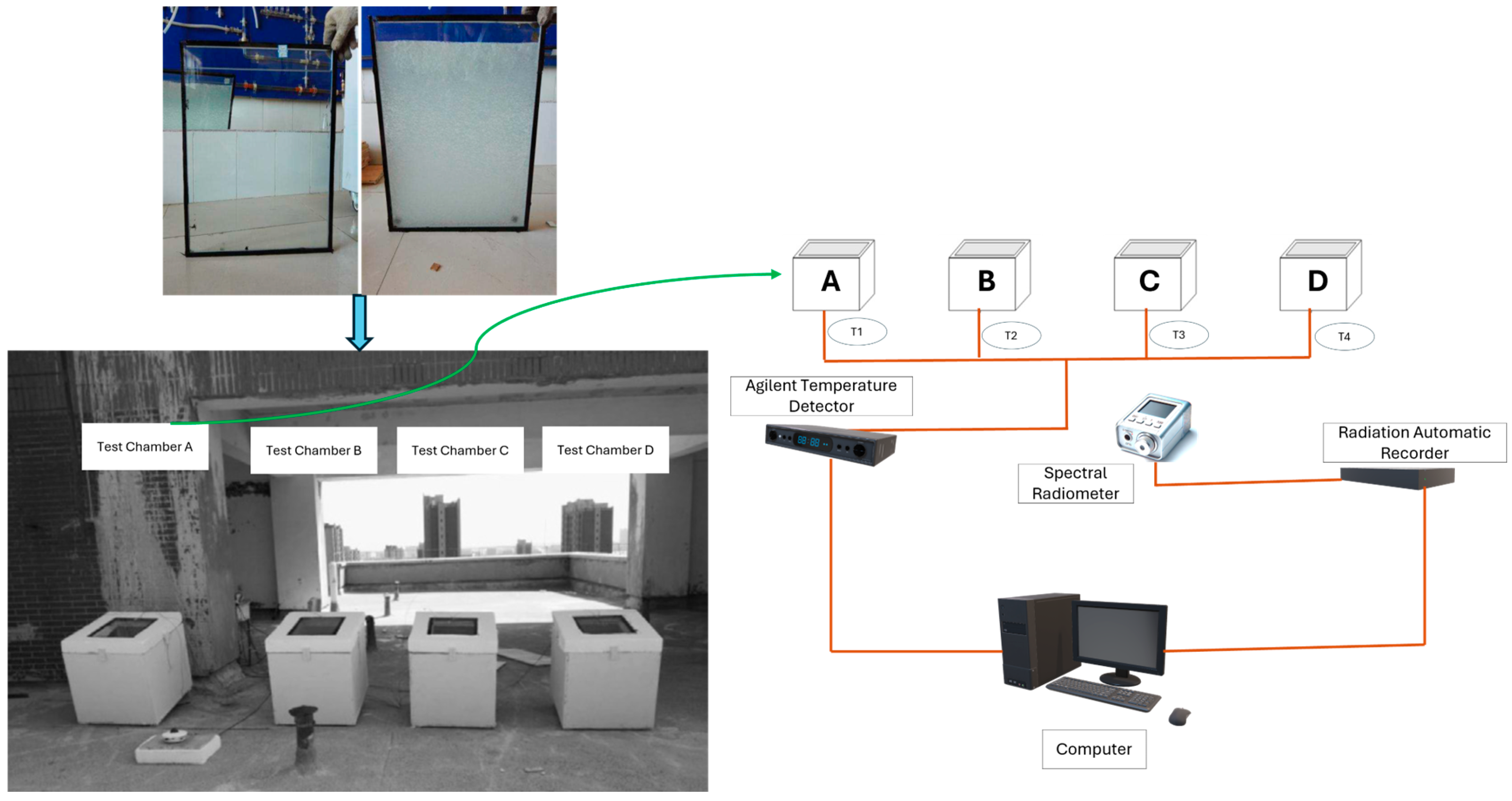

3.1.3. Glasses and Windows Glazing

PCM Behavior in Severe Climates

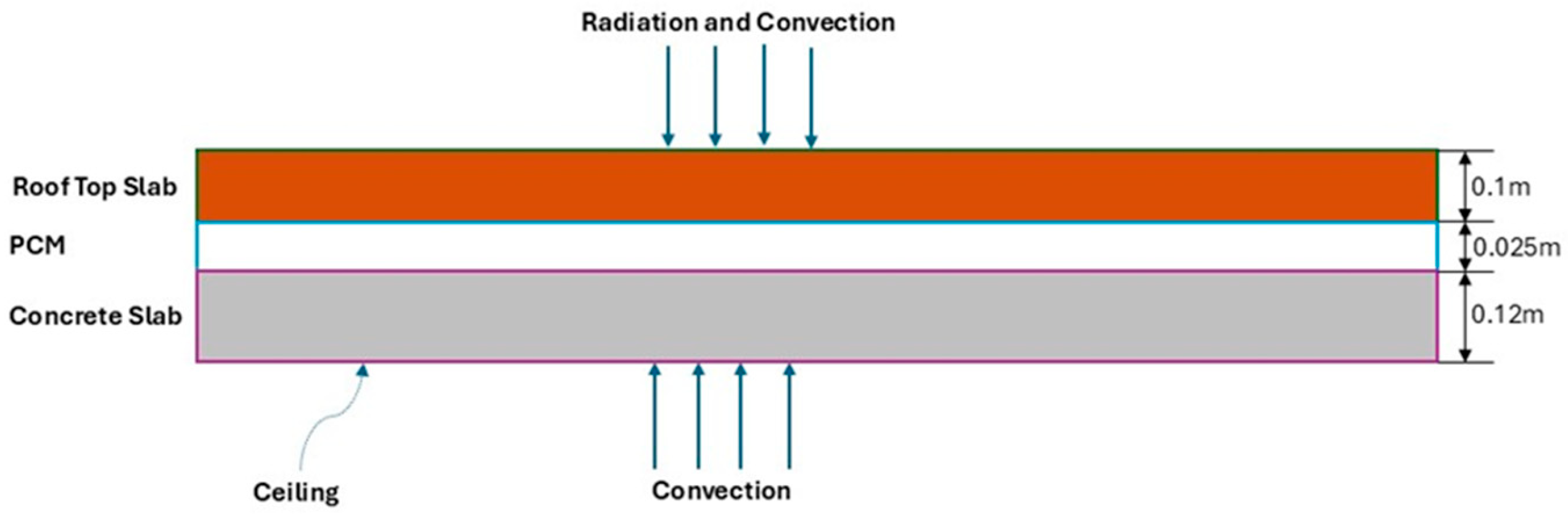

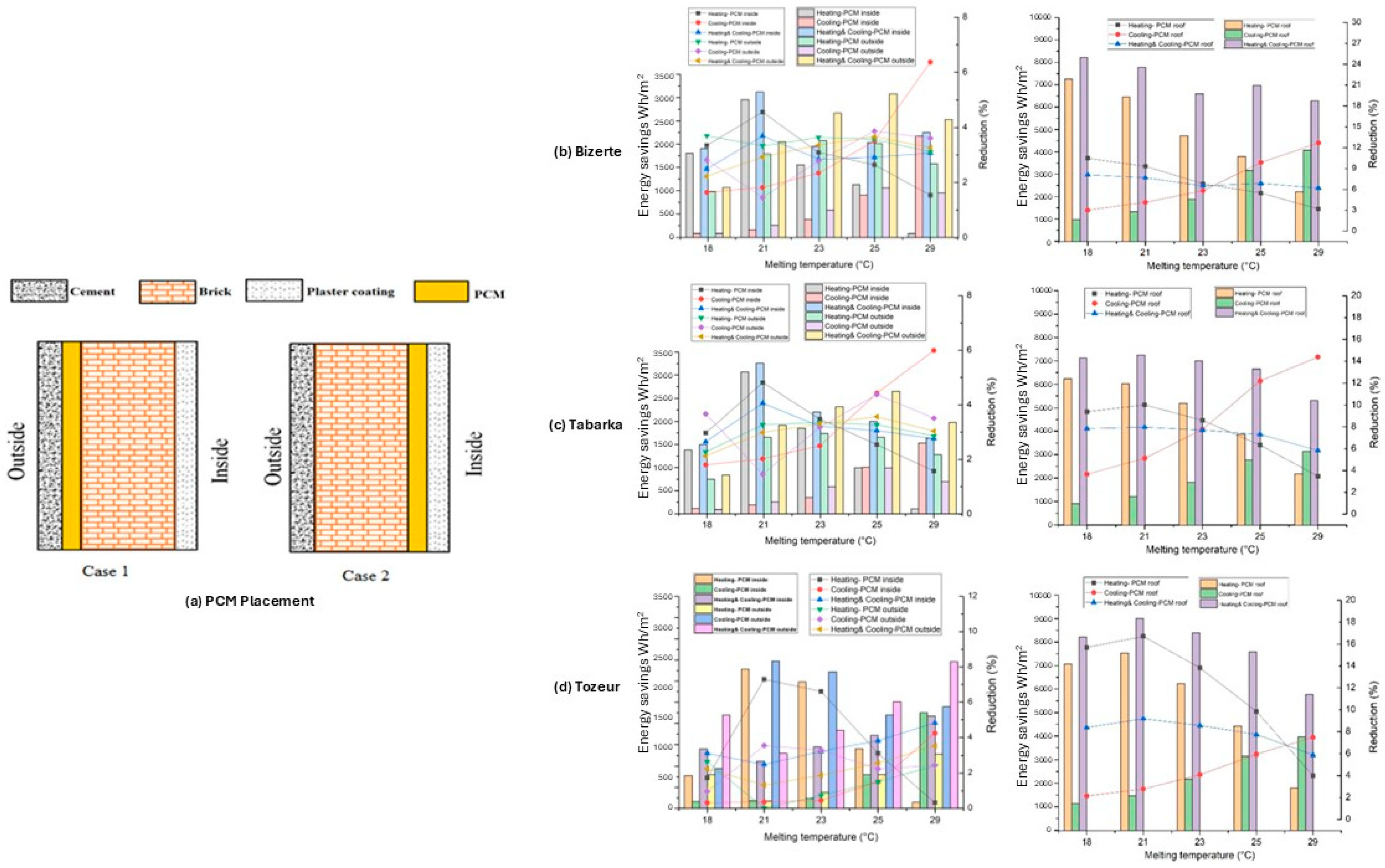

3.1.4. Roofing and Wall Materials

3.1.5. Floor, Chilled Ceiling, and HVAC Tanks

Inter-Floor Void Formers

4. Factors Affecting Thermal Performance

5. Assessment of PCM-Added Construction Commodities

5.1. Experimental Assessment Techniques

| Research Study | Experimental Characterization Technique | Type of PCM Used | Purpose of the Technique |

|---|---|---|---|

| Berthou et al. [289] | DSC | Eutectic PCM | To investigate the thermophysical properties of eutectic PCMs. |

| Cellat et al. [118] | DSC | Strontium-based powder (Sr(OH)2.8H2O) | To test the desired properties of the PCM, like melting temperature and enthalpies. |

| Chelliah et al. [197] | Viscometer with cooling and heating elements | OM18, HS22, OM29, OM32, and OM37 | To measure thermal conductivity in solid and liquid states. |

| KD2 Pro-thermal property analyzer | To measure the thermal conductivity of PCMs. | ||

| DSC | To measure the phase transition temperature of PCMs. | ||

| Ren et al. [38] | DSC (NETZSCH DSC 200 F3) | Microencapsulated PCM (MPCM) | To quantify the melting point and latent heat of MPCM. |

| Laser thermal conductance instrument (LFA467) | For characterization of thermal properties of MPCM in paste samples. | ||

| FT-IR (FT-IR 650) | To analyze chemical compatibility between MPCM and the cement matrix. | ||

| SEM (S-570 SEM, Hitachi in Japan) | To examine the microstructure of MPCM in the cement. | ||

| TGA (TGA, SDT650 TA) | To observe the impact of MPCM on hydration products and thermal stability. | ||

| Mercury intrusion porosimetry (MIP, AutoPore IV 9500, Micromeritics Instrument Corp, Norcross, GA, USA) | To evaluate the pore parameters of ultra-high-performance concrete. | ||

| Farulla et al. [218] | DSC | Pluslce X25 (pristine PCM) | To check the stability of the material and assess the main parameters, like phase change enthalpy and specific heat. |

| Pisello et al. [302] | CC-TPS method (through HOT Disk TPS 2500S unit and ATT DM 340 SR climatic chamber, Gothenburg, Sweden) | Paraffin-based MPCM | To check the dynamic thermal behavior of the PCM-integrated concrete walls by determining volumetric specific heat and thermal diffusivity. |

| Boussaba et al. [297] | TGA | Bio-based PCM | To analyze the thermal stability of bio-based PCM in natural clay, cellulose fibers, and graphite. |

| SEM | To examine the uniform distribution in the matrix. | ||

| FT-IR | To analyze the Chemical stability of bio-based PCM in natural clay, cellulose fibers, and graphite. | ||

| DSC | For the characterization of thermal properties. | ||

| Yinping et al. [284] | T-history | Various PCMs, including salt hydrates and paraffin-based | To determine the heat of fusion, thermal conductivity, and specific heat of various PCMs. |

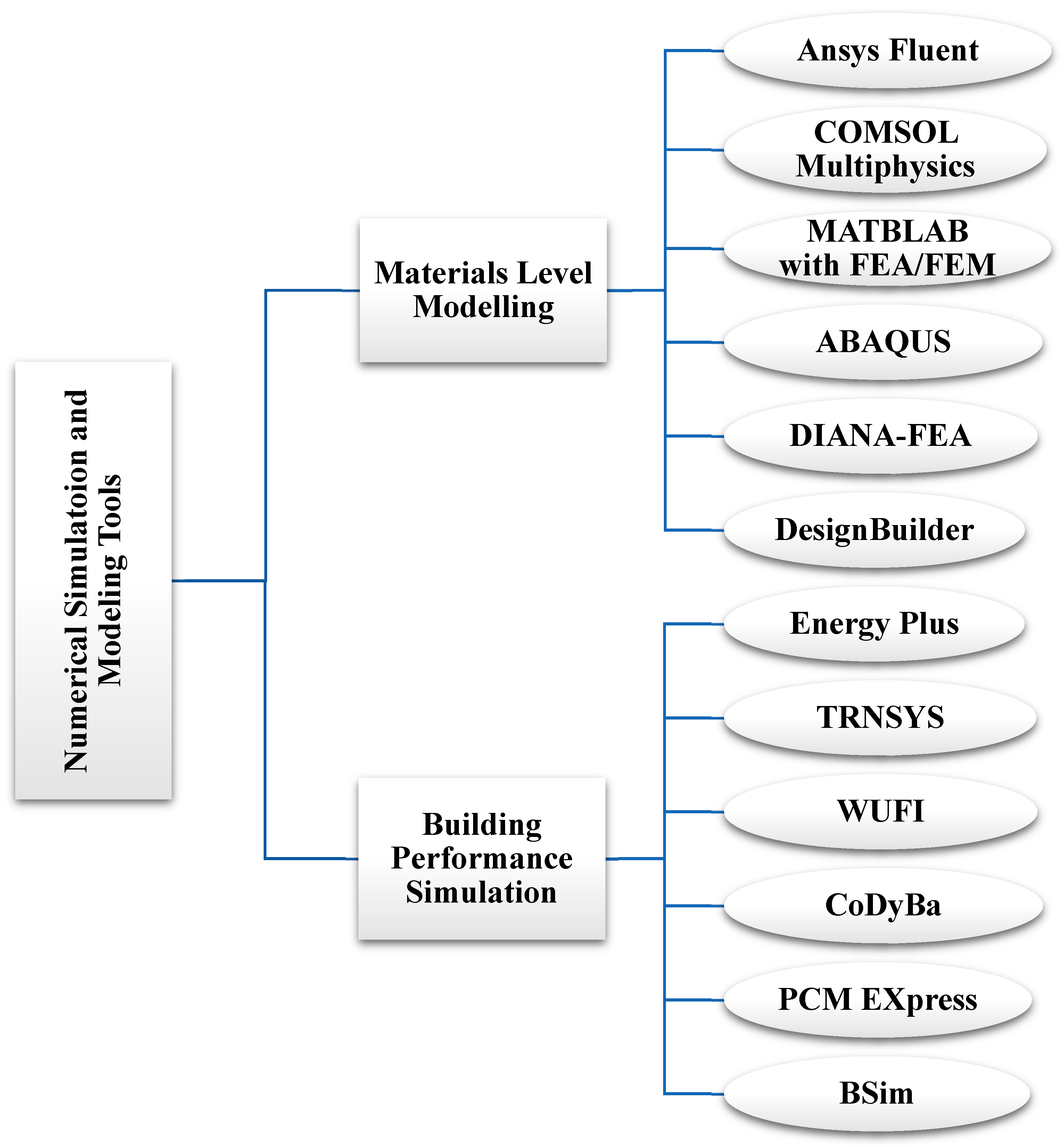

5.2. Numerical Simulation and Modeling Techniques

5.2.1. Material Level Modeling

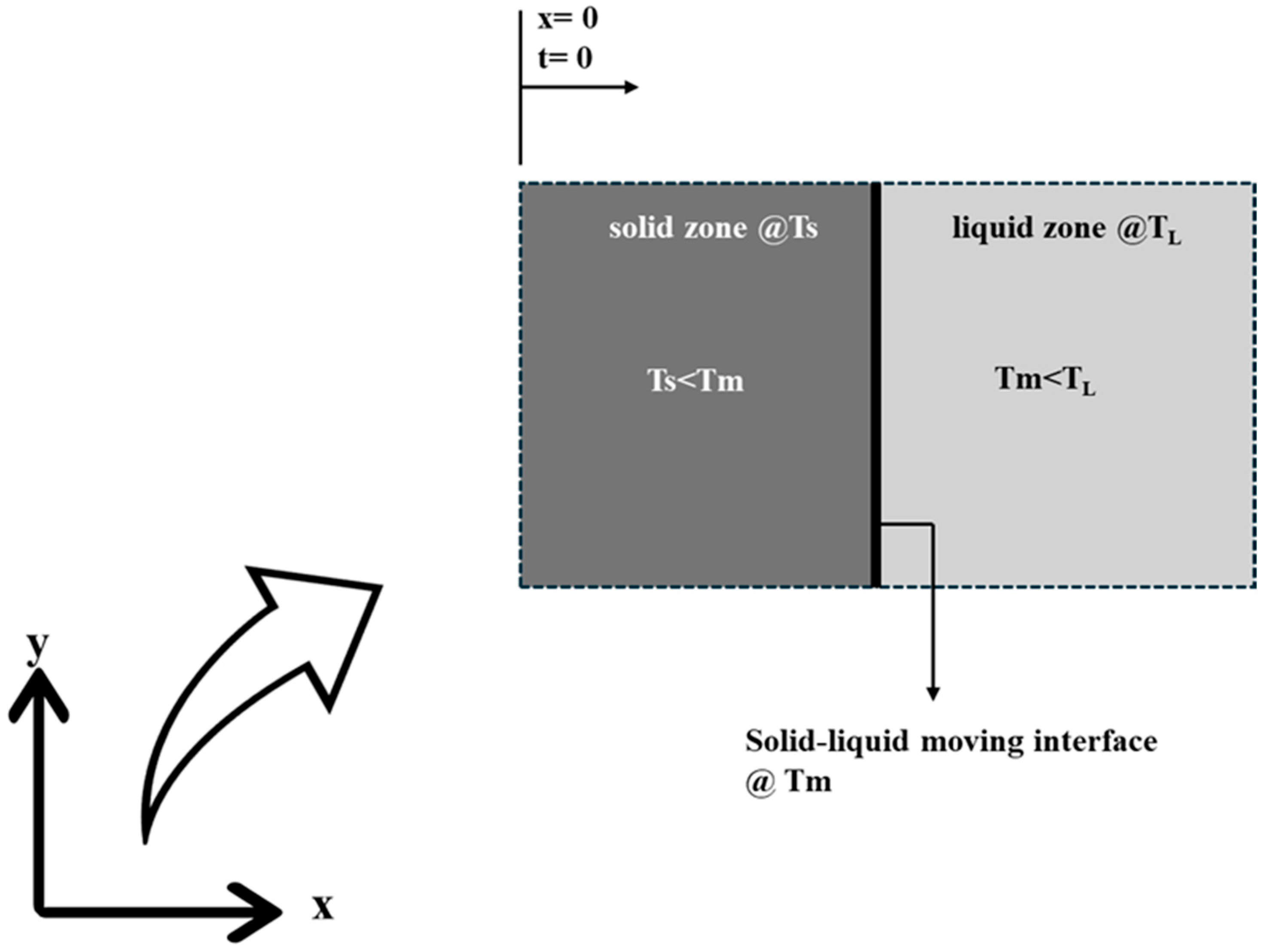

Stefan Problem and Modeling Methods

Conduction-Only vs. CFD Modeling

5.2.2. Building Performance Simulation

Key Elements in BPS

- HVAC systems: These systems are deeply integrated with PCM layers in various configurations, such as walls and ceilings, to improve energy efficiency [332]. PCMs can be part of active TES systems, like PAHX, coupled with air conditioning (AC) units. This integration aims to mitigate the peak load demands of heating and cooling systems, thereby boosting operational efficiency. For instance, cool outdoor air at night can charge the PCM, and during the day, ventilation fans help discharge cooling energy into the interior space [49]. Studies have explored the functionality of PCMs beyond passive regulation, extending to direct contact with heating and cooling cycles within HVAC components like ducts, evaporator coils, and heat exchangers [322,353,354,355].

- Occupancy schedules: The building type must be identified to establish the predominant occupancy throughout the daytime, which directly influences internal gains and energy loads. The varying occupancy periods for different building types (e.g., offices, schools, and residences) determine their specific cooling demands. Occupant behavior is a crucial factor influencing building performance [49,352].

- Transparent components (e.g., windows): These components significantly influence solar gains and play a role in the PCM charging process. Highly insulated buildings, particularly passive houses with substantial window areas (e.g., approximately 20% of the floor area for daylight), can experience elevated indoor temperatures during summer due to solar gain. Incorporating PCMs into large window areas can help reduce indoor temperatures. However, current commercially available PCMs may have low solar transmittance during their melting phase, potentially reducing the daylight factor in double-glazed windows [356].

- Lighting systems: These systems contribute to the internal heat loads within a building. While the direct heat contribution from lighting systems is part of the overall internal gains, which also include equipment and people, models focusing on cooling demand often simplify or exclude detailed accounting of these specific heat sources when prioritizing occupant-related loads [325].

- Typical Meteorological Year (TMY) data: This provides essential local climate inputs for an accurate BPS. Daily temperature profiles are critical for designing free cooling applications. BPS studies often utilize real climate data, such as variable daily temperature profiles, for the numerical investigation of PCM units. Comprehensive climatic databases, like those supporting energy certification, provide meteorological reference data for specific cooling seasons, enabling long-term simulations that cover entire cooling periods and diverse climatic conditions. The effectiveness of PCM integration is highly dependent on climate conditions [180,352,357,358,359,360,361,362].

- Internal loads: These encompass heat contributions from equipment, people, and appliances within the building. For cooling demand analysis, the internal load associated with occupants is a primary focus, while contributions from equipment and appliances may sometimes be simplified or excluded in specific analyses. Overall, internal loads are a key factor influencing the performance of buildings [363].

Building Performance Simulation Tools

| BPS Tool | Context/Study Description | Conjunction with Materials-Level Modeling | Key Findings |

|---|---|---|---|

| EnergyPlus [49,371,372] | Wooden Building with Latent Heat TES Unit (Bordeaux, France): Evaluated the thermal performance of a lightweight wooden building with integrated latent heat TES units. | A dynamic simulation model of the TES unit was first developed in MATLAB and validated with experimental data at the component/material level. This validated MATLAB model was subsequently integrated into EnergyPlus via a co-simulation framework for comprehensive building-scale evaluation. | Enabled a comprehensive evaluation of the building’s performance with integrated TES units. |

| Swedish Passive House with PCM Air-Heat Exchanger (Stockholm, Sweden): Assessed a comfort cooling strategy to achieve a good indoor climate during summer. | MATLAB code was used to analyze the thermodynamic properties of the PCM storage prior to simulation in EnergyPlus. This involved detailed material property characterization informing the BPS model. | The PCM could remove a substantial amount of excessive temperatures (degree hours), contributing to a good indoor climate during summer. | |

| TRNSYS [49,315,373,374,375,376] | Passive Buildings with Latent Heat TES Units (Stockholm): Conducted a comprehensive techno-economic assessment of passive buildings incorporating latent heat TES units under specific climatic conditions. | TRNSYS was used to model both the TES unit and the building, implying the development or use of detailed, user-defined components or modules to precisely represent PCM behavior and its interaction with building systems within the TRNSYS environment. | A multi-objective optimization algorithm identified cost-effective solutions that simultaneously reduced cooling demand and life cycle costs. |

| Building with Phase Change Humidity Controlling Material (PCHCM) Wallboards (Wuhan, China): Studied the effects of PCHCM wallboards on building energy consumption and indoor hygrothermal environment. | The PCM effect was integrated using the effective heat capacity method, a common material-level modeling approach for phase change, which accounts for the relationship between specific heat capacity and temperature. Kunzel’s model was additionally used to describe hygrothermal behavior at the material level. | The PCHCM wallboard significantly reduced energy consumption and improved the indoor hygrothermal environment. | |

| Development of New TRNSYS Modules for PCM Walls: Focused on enhancing TRNSYS’s capability to simulate PCM-integrated building components. | Involved the establishment and experimental verification of new, user-defined TRNSYS modules designed to accurately represent the heat transfer model of PCM rooms or latent heat storage walls, based on material-level characteristics like latent heat utilization ratio. | Improved the accuracy and capability of TRNSYS for modeling PCM-enhanced walls and rooms. | |

| WUFI [377] | Wood-Frame Walls with Macro-Packed PCM (MPPCM): Assessed the hygrothermal performance of building components containing PCM (n-octadecane). | WUFI PRO 5.3 was utilized, a BPS tool particularly known for its focus on coupled heat and moisture transfer in materials and its integration of a full moisture model. This indicates a direct application of material-level hygrothermal modeling within the software. | Demonstrated improved hygrothermal performance and the potential to mitigate mold growth risk when MPPCM was used as a vapor retarder replacement. |

5.3. Practical Applications via Case Studies

6. Advantages and Shortcomings of PCM Integration

6.1. Advantages

6.1.1. Energy Savings

6.1.2. Reduction in Peak Load

6.1.3. Enhanced Indoor Comfort

6.1.4. Reduced HVAC Dependence

6.2. Shortcomings

6.2.1. Leakage Issue

6.2.2. Thermal Degradation

6.2.3. High Cost

6.2.4. Compatibility with Building Materials

6.2.5. Fire Safety Concern

6.3. Building Code Provision for PCM Integration

7. Recent Progression and Future Potential

7.1. Innovation in Approaches

7.2. Advancement in Policy Support

8. Conclusions

- The selection of an adequate type of PCM and its long-term durability, cost-effectiveness, and effectiveness for specific applications.

- The compatibility of PCMs with construction materials and their optimization for integration.

- Optimization of PCM encapsulation to prevent leakage and further deterioration of building materials.

- Lack of incentivizing policies for the implementation of PCM integration into building materials.

- Utilization of PCM in severe weather conditions, specifically in the case of glazed units.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gas |

| PCMs | Phase change materials |

| OPCMs | Organic PCMs |

| MPCMs | Microencapsulated PCMs |

| NePCMs | Nano-enhanced PCMs |

| BPCMs | Bio-based PCMs |

| HVAC | Heating, ventilation, and air conditioning |

| SDGs | Sustainable development goals |

| IEA | International Energy Agency |

| TES | Thermal energy storage |

| LHS | Latent heat storage |

| SHTES | Sensible heat thermal energy storage |

| LHTES | Latent heat thermal energy storage |

| EIA | Environmental Impact Assessment |

| LCA | Life cycle assessment |

| CNTs | Carbon nanotubes |

| DSC | Differential scanning calorimetry |

| DTA | Differential thermal analysis |

| SEM | Scanning electron microscopy |

| TGA | Thermal gravimetric analysis |

| EM | Enthalpy method |

| EHCM | Effective heat capacity method |

| HSM | Heat source method |

| FVM | Finite volume method |

| FEM | Finite element method |

| BPS | Building simulation performance |

| PAHX | PCM to air heat exchangers |

| TMY | Typical meteorological year |

| ATFR | Average temperature fluctuation reduction |

| BEES | Building energy efficiency standards |

| TABS | Thermally activated building systems |

References

- OECD. Key World Energy Statistics 2016; OECD: Paris, France, 2016; Available online: https://www.oecd.org/en/publications/key-world-energy-statistics-2016_key_energ_stat-2016-en.html (accessed on 11 March 2025).

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Lahoud, C.; Chahwan, A.; Rishmany, J.; Yehia, C.; Daaboul, M. Enhancing Energy Efficiency in Mediterranean Coastal Buildings Through PCM Integration. Buildings 2024, 14, 4023. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- Said, Z.; Pandey, A.K. Nano Enhanced Phase Change Materials; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Memon, S.A. Phase change materials integrated in building walls: A state of the art review. Renew. Sustain. Energy Rev. 2014, 31, 870–906. [Google Scholar] [CrossRef]

- 2019 Global Status Report for Buildings and Construction Sector. UN Environment Program. Available online: https://www.unep.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 20 February 2025).

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 11 December 2024).

- Abed, F.M.; Al-Douri, Y.; Al-Shahery, G.M. Review on the energy and renewable energy status in Iraq: The outlooks. Renew. Sustain. Energy Rev. 2014, 39, 816–827. [Google Scholar] [CrossRef]

- IEA. Tracking Buildings. Available online: https://www.iea.org/energy-system/buildings?utm (accessed on 19 August 2025).

- IEA. Buildings. Available online: https://www.iea.org/reports/energy-efficiency-policy-toolkit-2025/buildings (accessed on 19 August 2025).

- IEA. Global Status Report for Buildings and Construction 2019; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/global-status-report-for-buildings-and-construction-2019 (accessed on 11 January 2023).

- Haselbach, L. The Engineering Guide to LEED-New Construction: Sustainable Construction for Engineers; McGraw-Hill: Columbus, OH, USA, 2010. [Google Scholar]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Naili, B.; Háber, I.; Kistelegdi, I. Façade typology development in high-rise office building envelope. Pollack Period. 2023, 18, 151–156. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Dulaimi, A.; Mahmood, D.M.; Sopian, K. A review of recent improvements, developments, and effects of using phase-change materials in buildings to store thermal energy. Designs 2023, 7, 90. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2024; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 13 January 2025).

- Brozzesi, Z.; Li, D.; Lee, A. Exploring the potential of phase change material for thermal energy storage in building envelopes. J. Energy Power Technol. 2023, 5, 1–21. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Enhanced thermophysical properties of organic PCM through shape stabilization for thermal energy storage in buildings: A state of the art review. Energy Build. 2021, 236, 110799. [Google Scholar] [CrossRef]

- Lin, Y.; Alva, G.; Fang, G. Review on thermal performances and applications of thermal energy storage systems with inorganic phase change materials. Energy 2018, 165, 685–708. [Google Scholar] [CrossRef]

- Lamrani, B.; Johannes, K.; Kuznik, F. Phase change materials integrated into building walls: An updated review. Renew. Sustain. Energy Rev. 2021, 140, 110751. [Google Scholar] [CrossRef]

- Tyagi, V.; Pandey, A.; Buddhi, D.; Kothari, R. Thermal performance assessment of encapsulated PCM based thermal management system to reduce peak energy demand in buildings. Energy Build. 2016, 117, 44–52. [Google Scholar] [CrossRef]

- Albdour, M.S.; Baranyai, B.; Shalby, M.M. Overview of whole-building energy engines for investigating energy-related systems. Pollack Period. 2023, 18, 36–41. [Google Scholar] [CrossRef]

- Abdulhussein, M.A.; Hashem, A.L. Experimental study of the thermal behavior of perforated bricks wall integrated with PCM. Int. J. Heat Technol. 2021, 39, 1917–1922. [Google Scholar] [CrossRef]

- Benachir, N.; Farida, B.; Mohib, T. Integration and Validation of a Numerical Pcm Model for Building Energy Programs. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Abdulhussein, M.A.; Hashem, A.L. An experimental study of the thermal behavior of bricks integrated with PCM-capsules in building walls. Al-Qadisiyah J. Eng. Sci. 2021, 14, 160–165. [Google Scholar] [CrossRef]

- Saliby, A.; Kovács, B. Enhancing thermal performance of phase change materials in building envelopes. Pollack Period. 2024, 20, 87–94. [Google Scholar] [CrossRef]

- Kosny, J. PCM-Enhanced Building Components: An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Hu, J.; Yu, X.B. Adaptive building roof by coupling thermochromic material and phase change material: Energy performance under different climate conditions. Constr. Build. Mater. 2020, 262, 120481. [Google Scholar] [CrossRef]

- Zalba, B.; Marín, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Salem, T.; Kazma, M.; Bitar, J.; Moussa, J.; Falah, D. Mechanical characterization of a concrete masonry block enhanced with micro-encapsulated phase changing materials. J. Phys. Conf. Ser. 2021, 2042, 012184. [Google Scholar] [CrossRef]

- Silva, S.M.; Almeida, M.G.d. Using PCM to Improve Building’s Thermal Performance. 2013. Available online: https://repositorium.uminho.pt/bitstream/1822/25781/3/SESBConference-Dublin_SMS.pdf (accessed on 20 April 2025).

- Shukla, N.; Fallahi, A.; Kosny, J. Performance characterization of PCM impregnated gypsum board for building applications. Energy Procedia 2012, 30, 370–379. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Energetic and thermal comfort assessment of phase change material passively incorporated building envelope in severe hot Climate: An experimental study. Appl. Energy 2022, 314, 118957. [Google Scholar] [CrossRef]

- Ministry of Energy and Mineral Resources. Energy 2019—Facts and Figures; Ministry of Energy and Mineral Resources: Amman, Jordan, 2019.

- Jaradat, M.; Al Majali, H.; Bendea, C.; Bungau, C.C.; Bungau, T. Enhancing energy efficiency in buildings through PCM integration: A study across different climatic regions. Buildings 2023, 14, 40. [Google Scholar] [CrossRef]

- Ren, M.; Wen, X.; Gao, X.; Liu, Y. Thermal and mechanical properties of ultra-high performance concrete incorporated with microencapsulated phase change material. Constr. Build. Mater. 2021, 273, 121714. [Google Scholar] [CrossRef]

- Jiao, K.; Lu, L.; Zhao, L.; Wang, G. Towards Passive Building Thermal Regulation: A State-of-the-Art Review on Recent Progress of PCM-Integrated Building Envelopes. Sustainability 2024, 16, 6482. [Google Scholar] [CrossRef]

- Elhamy, A.A.; Mokhtar, M. Phase change materials integrated into the building envelope to improve energy efficiency and thermal comfort. Future Cities Environ. 2024, 10, 1–16. [Google Scholar] [CrossRef]

- Yun, B.Y.; Park, J.H.; Yang, S.; Wi, S.; Kim, S. Integrated analysis of the energy and economic efficiency of PCM as an indoor decoration element: Application to an apartment building. Sol. Energy 2020, 196, 437–447. [Google Scholar] [CrossRef]

- Alizadeh, M.; Sadrameli, S. Indoor thermal comfort assessment using PCM based storage system integrated with ceiling fan ventilation: Experimental design and response surface approach. Energy Build. 2019, 188, 297–313. [Google Scholar] [CrossRef]

- Ortega Del Rosario, M.D.L.Á.; Chen Austin, M.; Bruneau, D.; Nadeau, J.-P.; Sébastian, P.; Jaupard, D. Operation assessment of an air-PCM unit for summer thermal comfort in a naturally ventilated building. Archit. Sci. Rev. 2021, 64, 37–46. [Google Scholar] [CrossRef]

- Afolabi, L.O.; Ariff, Z.M.; Megat-Yusoff, P.S.M.; Al-Kayiem, H.H.; Arogundade, A.I.; Afolabi-Owolabi, O.T. Red-mud geopolymer composite encapsulated phase change material for thermal comfort in built-sector. Sol. Energy 2019, 181, 464–474. [Google Scholar] [CrossRef]

- Paroutoglou, E.; Afshari, A.; Bergsøe, N.C.; Fojan, P.; Hultmark, G. A PCM based cooling system for office buildings: A state of the art review. In Proceedings of the CLIMA 2019: REHVA 13th HVAC World Congress, Bucharest, Romania, 26–29 May 2019; EDP Sciences: Les Ulis, France, 2019; pp. 1–8. [Google Scholar]

- Teng, T.-P. Thermal conductivity and phase-change properties of aqueous alumina nanofluid. Energy Convers. Manag. 2013, 67, 369–375. [Google Scholar] [CrossRef]

- Tyagi, P.K.; Kumar, R.; Said, Z.; Rathore, P.K.S. Application of Nano-enhanced PCMs in Buildings. In Nano Enhanced Phase Change Materials: Preparation, Properties and Applications; Springer: Berlin/Heidelberg, Germany, 2023; pp. 151–166. [Google Scholar]

- Pop, O.G.; Fechete Tutunaru, L.; Bode, F.; Abrudan, A.C.; Balan, M.C. Energy efficiency of PCM integrated in fresh air cooling systems in different climatic conditions. Appl. Energy 2018, 212, 976–996. [Google Scholar] [CrossRef]

- Zhang, Q.; Sazon, T.A.S.; Fadnes, F.S.; Peng, X.; Ahmed, N.; Nikpey, H.; Mansouri, M.; Assadi, M. Design optimization of the cooling systems with PCM-to-air heat exchanger for the energy saving of the residential buildings. Energy Convers. Manag. X 2024, 23, 100630. [Google Scholar] [CrossRef]

- Rahman, I.U.; Nardini, S.; Buonomo, B.; Manca, O.; Khan, H.; Siviero, B. Thermal interface materials: A promising solution for passive heat dissipation in electronic appliances. Therm. Sci. Eng. Prog. 2025, 62, 103673. [Google Scholar] [CrossRef]

- Chandel, S.; Agarwal, T. Review of current state of research on energy storage, toxicity, health hazards and commercialization of phase changing materials. Renew. Sustain. Energy Rev. 2017, 67, 581–596. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.-G.; Hu, J.-W. Phase-change materials in concrete: Opportunities and challenges for sustainable construction and building materials. Materials 2022, 15, 335. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, Z.J.; Yang, T.; Qin, D.; Li, S.; Zhang, G.; Haghighat, F.; Joybari, M.M. A review on macro-encapsulated phase change material for building envelope applications. Build. Environ. 2018, 144, 281–294. [Google Scholar] [CrossRef]

- Malode, S.J.; Shetti, N.P. Thermal energy storage systems using bio-based phase change materials: A comprehensive review for building energy efficiency. J. Energy Storage 2025, 105, 114709. [Google Scholar] [CrossRef]

- Caggiano, A.; Mankel, C.; Koenders, E. Reviewing Theoretical and Numerical Models for PCM-embedded Cementitious Composites. Buildings 2019, 9, 3. [Google Scholar] [CrossRef]

- Al-Absi, Z.A.A.S.; Isa, M.H.M.; Ismail, M. Application of phase change materials (PCMs) in building walls: A review. In Proceedings of the The Advances in Civil Engineering Materials, Proceedings of the ICACE 2018, Batu Ferringhi, Penang, Malaysia, 9–10 May 2018; Springer: Cham, Switzerland; pp. 73–82. [Google Scholar]

- Kenisarin, M.M. Thermophysical properties of some organic phase change materials for latent heat storage. A review. Sol. Energy 2014, 107, 553–575. [Google Scholar] [CrossRef]

- Al-Saadi, S.N.; Zhai, Z.J. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renew. Sustain. Energy Rev. 2020, 119, 109579. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.d.; De Gracia, A.; Fernández, A. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Kasaeian, A.; Pourfayaz, F.; Khodabandeh, E.; Yan, W.-M. Experimental studies on the applications of PCMs and nano-PCMs in buildings: A critical review. Energy Build. 2017, 154, 96–112. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Y.; Weng, M.; Yu, J.; Sun, L.; Zeng, H.; Liu, Y.; Zeng, W.; Min, Y.; Guo, Z. Advances and applications of phase change materials (PCMs) and PCMs-based technologies. ES Mater. Manuf. 2021, 13, 23–39. [Google Scholar] [CrossRef]

- Lee, K.O.; Medina, M.A.; Sun, X.; Jin, X. Thermal performance of phase change materials (PCM)-enhanced cellulose insulation in passive solar residential building walls. Sol. Energy 2018, 163, 113–121. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. On the placement of a phase change material thermal shield within the cavity of buildings walls for heat transfer rate reduction. Energy 2014, 73, 780–786. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R.; Seeniraj, R. Phase change material-based building architecture for thermal management in residential and commercial establishments. Renew. Sustain. Energy Rev. 2008, 12, 39–64. [Google Scholar] [CrossRef]

- Harikrishnan, S.; Imran Hussain, S.; Devaraju, A.; Sivasamy, P.; Kalaiselvam, S. Improved performance of a newly prepared nano-enhanced phase change material for solar energy storage. J. Mech. Sci. Technol. 2017, 31, 4903–4910. [Google Scholar] [CrossRef]

- Rahman, I.U.; Nardini, S.; Buonomo, B.; Mohammed, H.J.; Khan, H.; Rehman, S.U.; Manca, O. Graphene-Enhanced Composite Phase Change Materials for Battery Thermal Management; IntechOpen: London, UK, 2025. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Prakash, S.A.; Kumaran, P.; Sankar, S.; Loganathan, G.B.; Arivarasan, A. Performance analysis of concrete block integrated with PCM for thermal management. Mater. Today Proc. 2020, 22, 370–374. [Google Scholar] [CrossRef]

- Jha, S.K.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of phase change materials in buildings. Constr. Mater. 2024, 4, 676–703. [Google Scholar] [CrossRef]

- Devaux, P.; Farid, M.M. Benefits of PCM underfloor heating with PCM wallboards for space heating in winter. Appl. Energy 2017, 191, 593–602. [Google Scholar] [CrossRef]

- Wang, J.; Liu, F. Low-cost, robust microcapsules of phase change materials for thermal active concrete structures. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 2016; pp. 7–11. [Google Scholar]

- Bueno, A.M.; de Paula Xavier, A.A.; Broday, E.E. Evaluating the connection between thermal comfort and productivity in buildings: A systematic literature review. Buildings 2021, 11, 244. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. An experimental evaluation of thermal behavior of the building envelope using macroencapsulated PCM for energy savings. Renew. Energy 2020, 149, 1300–1313. [Google Scholar] [CrossRef]

- Jelle, B.; Kalnæs, S. Phase change materials for application in energy-efficient buildings. Cost-Eff. Energy Effic. Build. Retrofit. 2017, 57–118. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Therm. Energy Storage Phase Change Mater. 2021, 162–175. [Google Scholar]

- Kenisarin, M.M.; Mahkamov, K.; Costa, S.C.; Makhkamova, I. Melting and solidification of PCMs inside a spherical capsule: A critical review. J. Energy Storage 2020, 27, 101082. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, S.; Shukla, A. Adaptability research on phase change materials based technologies in China. Renew. Sustain. Energy Rev. 2017, 73, 145–158. [Google Scholar] [CrossRef]

- Zakaria, N.M.; Omar, M.A.; Mukhtar, A. Numerical study on the thermal insulation of smart windows embedded with low thermal conductivity materials to improve the energy efficiency of buildings. CFD Lett. 2023, 15, 41–52. [Google Scholar] [CrossRef]

- Vitorino, N.; Abrantes, J.C.; Frade, J.R. Quality criteria for phase change materials selection. Energy Convers. Manag. 2016, 124, 598–606. [Google Scholar] [CrossRef]

- Kumar, A.; Tiwari, A.K.; Said, Z. A comprehensive review analysis on advances of evacuated tube solar collector using nanofluids and PCM. Sustain. Energy Technol. Assess. 2021, 47, 101417. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A review on phase change material application in building. Adv. Mech. Eng. 2017, 9, 1687814017700828. [Google Scholar] [CrossRef]

- Laghari, I.A.; Samykano, M.; Pandey, A.; Kadirgama, K.; Tyagi, V. Advancements in PV-thermal systems with and without phase change materials as a sustainable energy solution: Energy, exergy and exergoeconomic (3E) analytic approach. Sustain. Energy Fuels 2020, 4, 4956–4987. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Alam, M.; Sanjayan, J.; Wilson, J. Parametric analysis for performance enhancement of phase change materials in naturally ventilated buildings. Energy Build. 2016, 124, 35–45. [Google Scholar] [CrossRef]

- Du, K.; Calautit, J.; Wang, Z.; Wu, Y.; Liu, H. A review of the applications of phase change materials in cooling, heating and power generation in different temperature ranges. Appl. Energy 2018, 220, 242–273. [Google Scholar] [CrossRef]

- Zahir, M.H.; Irshad, K.; Shafiullah, M.; Ibrahim, N.I.; Islam, A.K.; Mohaisen, K.O.; Sulaiman, F.A.A. Challenges of the application of PCMs to achieve zero energy buildings under hot weather conditions: A review. J. Energy Storage 2023, 64, 107156. [Google Scholar] [CrossRef]

- Kitagawa, H.; Asawa, T.; Del Rio, M.A.; Kubota, T.; Trihamdani, A.R. Thermal energy simulation of PCM-based radiant floor cooling systems for naturally ventilated buildings in a hot and humid climate. Build. Environ. 2023, 238, 110351. [Google Scholar] [CrossRef]

- Nurlybekova, G.; Memon, S.A.; Adilkhanova, I. Quantitative evaluation of the thermal and energy performance of the PCM integrated building in the subtropical climate zone for current and future climate scenario. Energy 2021, 219, 119587. [Google Scholar] [CrossRef]

- IEA. The Future of Cooling; IEA: Paris, France, 2018; Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 12 February 2025).

- Sun, X.; Jovanovic, J.; Zhang, Y.; Fan, S.; Chu, Y.; Mo, Y.; Liao, S. Use of encapsulated phase change materials in lightweight building walls for annual thermal regulation. Energy 2019, 180, 858–872. [Google Scholar] [CrossRef]

- Hasan, M.I.; Basher, H.O.; Shdhan, A.O. Experimental investigation of phase change materials for insulation of residential buildings. Sustain. Cities Soc. 2018, 36, 42–58. [Google Scholar] [CrossRef]

- Navarro, L.; Solé, A.; Martín, M.; Barreneche, C.; Olivieri, L.; Tenorio, J.A.; Cabeza, L.F. Benchmarking of useful phase change materials for a building application. Energy Build. 2019, 182, 45–50. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Appl. Therm. Eng. 2019, 147, 841–855. [Google Scholar] [CrossRef]

- Jebasingh, B.E.; Arasu, A.V. A detailed review on heat transfer rate, supercooling, thermal stability and reliability of nanoparticle dispersed organic phase change material for low-temperature applications. Mater. Today Energy 2020, 16, 100408. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Luo, Z.; Wang, K.; Shah, S.P. A critical review on phase change materials (PCM) for sustainable and energy efficient building: Design, characteristic, performance and application. Energy Build. 2022, 260, 111923. [Google Scholar] [CrossRef]

- Aftab, W.; Usman, A.; Shi, J.; Yuan, K.; Qin, M.; Zou, R. Phase change material-integrated latent heat storage systems for sustainable energy solutions. Energy Environ. Sci. 2021, 14, 4268–4291. [Google Scholar] [CrossRef]

- Rathod, M.K.; Banerjee, J. Thermal stability of phase change materials used in latent heat energy storage systems: A review. Renew. Sustain. Energy Rev. 2013, 18, 246–258. [Google Scholar] [CrossRef]

- Nie, B.; Palacios, A.; Zou, B.; Liu, J.; Zhang, T.; Li, Y. Review on phase change materials for cold thermal energy storage applications. Renew. Sustain. Energy Rev. 2020, 134, 110340. [Google Scholar] [CrossRef]

- Jayalath, A.; San Nicolas, R.; Sofi, M.; Shanks, R.; Ngo, T.; Aye, L.; Mendis, P. Properties of cementitious mortar and concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 2016, 120, 408–417. [Google Scholar] [CrossRef]

- Zhao, R.; Gu, J.; Liu, J. Optimization of a phase change material based internal cooling system for cylindrical Li-ion battery pack and a hybrid cooling design. Energy 2017, 135, 811–822. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Bentz, D.P. Incorporation of phase change materials in cementitious systems via fine lightweight aggregate. Constr. Build. Mater. 2012, 35, 483–490. [Google Scholar] [CrossRef]

- Snehal, K.; Das, B.B. Effect of phase-change materials on the hydration and mineralogy of cement mortar. Proc. Inst. Civ. Eng. -Constr. Mater. 2020, 176, 117–127. [Google Scholar] [CrossRef]

- Marani, A.; Nehdi, M.L. Integrating phase change materials in construction materials: Critical review. Constr. Build. Mater. 2019, 217, 36–49. [Google Scholar] [CrossRef]

- Djamai, Z.I.; Salvatore, F.; Larbi, A.S.; Cai, G.; El Mankibi, M. Multiphysics analysis of effects of encapsulated phase change materials (PCMs) in cement mortars. Cem. Concr. Res. 2019, 119, 51–63. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Rodriguez, J.F.; Carmona, M.; Al-Manasir, N.; Kjøniksen, A.-L. Microencapsulated phase change materials for enhancing the thermal performance of Portland cement concrete and geopolymer concrete for passive building applications. Energy Convers. Manag. 2017, 133, 56–66. [Google Scholar] [CrossRef]

- Memon, S.A.; Cui, H.; Zhang, H.; Xing, F. Utilization of macro encapsulated phase change materials for the development of thermal energy storage and structural lightweight aggregate concrete. Appl. Energy 2015, 139, 43–55. [Google Scholar] [CrossRef]

- Hunger, M.; Entrop, A.G.; Mandilaras, I.; Brouwers, H.J.H.; Founti, M. The behavior of self-compacting concrete containing micro-encapsulated Phase Change Materials. Cem. Concr. Compos. 2009, 31, 731–743. [Google Scholar] [CrossRef]

- Sharma, R.; Pei, J.J.; Jang, J.G. Methods of phase change material deposits in concrete to attain the minimal negative effect on mechanical properties. Proc. Korea Concr. Inst. Conf. 2021, 33, 563–564. [Google Scholar]

- Giro-Paloma, J.; Martínez, M.; Cabeza, L.F.; Fernández, A.I. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef]

- Orsini, F.; Marrone, P.; Santini, S.; Sguerri, L.; Asdrubali, F.; Baldinelli, G.; Bianchi, F.; Presciutti, A. Smart Materials: Cementitious Mortars and PCM Mechanical and Thermal Characterization. Materials 2021, 14, 4163. [Google Scholar] [CrossRef]

- Paksoy, H.; Kardas, G.; Konuklu, Y.; Cellat, K.; Tezcan, F. Characterization of concrete mixes containing phase change materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 3rd International Conference on Innovative Materials, Structures and Technologies (IMST 2017), Riga, Latvia, 27–29 September 2017; p. 012118. [Google Scholar]

- Hawes, D.W.; Banu, D.; Feldman, D. Latent heat storage in concrete. Sol. Energy Mater. 1989, 19, 335–348. [Google Scholar] [CrossRef]

- Da Cunha, J.P.; Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl. Energy 2016, 177, 227–238. [Google Scholar] [CrossRef]

- Yun, H.-D.; Ahn, K.-L.; Jang, S.-J.; Khil, B.-S.; Park, W.-S.; Kim, S.-W. Thermal and mechanical behaviors of concrete with incorporation of strontium-based phase change material (PCM). Int. J. Concr. Struct. Mater. 2019, 13, 18. [Google Scholar] [CrossRef]

- Adesina, A. Use of phase change materials in concrete: Current challenges. Renew. Energy Environ. Sustain. 2019, 4, 9. [Google Scholar] [CrossRef]

- Cellat, K.; Tezcan, F.; Beyhan, B.; Kardaş, G.; Paksoy, H. A comparative study on corrosion behavior of rebar in concrete with fatty acid additive as phase change material. Constr. Build. Mater. 2017, 143, 490–500. [Google Scholar] [CrossRef]

- Kim, Y.-R.; Khil, B.-S.; Jang, S.-J.; Choi, W.-C.; Yun, H.-D. Effect of barium-based phase change material (PCM) to control the heat of hydration on the mechanical properties of mass concrete. Thermochim. Acta 2015, 613, 100–107. [Google Scholar] [CrossRef]

- Porisini, F.C. Salt hydrates used for latent heat storage: Corrosion of metals and reliability of thermal performance. Sol. Energy 1988, 41, 193–197. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Ferreira, V.; Tadeu, A. Argamassas com incorporação de Materiais de Mudança de Fase (PCM): Caracterização física, mecânica e durabilidade. Matéria 2015, 20, 245–261. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.; Ferreira, V.; Tadeu, A. Mortars based in different binders with incorporation of phase-change materials: Physical and mechanical properties. Eur. J. Environ. Civ. Eng. 2015, 19, 1216–1233. [Google Scholar] [CrossRef]

- Cunha, S.R.L.; Aguiar, J.; Ferreira, V. Durability of mortars with incorporation of phase change materials microcapsules. Rom. J. Mater./Rev. Romana De Mater. 2017, 47, 166. [Google Scholar]

- Necib, H. Enhancing Building Thermal Inertia: Impact of Surface-to-Volume Ratio on Multi-Layered PCM-Integrated Brick Walls. Ann. West Univ. Timis. Phys. Ser. 2024, 66, 172–190. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Li, L.; Zhao, M. Experimental assessment on a kind of composite wall incorporated with shape-stabilized phase change materials (SSPCMs). Energy Build. 2016, 128, 567–574. [Google Scholar] [CrossRef]

- Shi, Z.; Ren, J.; Zhang, T.; Shen, Y. The Effects of Thickness and Location of PCM on the Building’s Passive Temperature-Control--A Numerical Study. Energy Eng. 2024, 121, 681. [Google Scholar] [CrossRef]

- Bat-Erdene, P.-E.; Pareek, S. Experimental Study on the Development of Fly Ash Foam Concrete Containing Phase Change Materials (PCMs). Materials 2022, 15, 8428. [Google Scholar] [CrossRef]

- Cunha, S.; Lima, M.; Aguiar, J.B. Influence of adding phase change materials on the physical and mechanical properties of cement mortars. Constr. Build. Mater. 2016, 127, 1–10. [Google Scholar] [CrossRef]

- Rakkappan, S.R.; Sivan, S.; Pethurajan, V.; Aditya, A.; Mittal, H. Preparation and thermal properties of encapsulated 1-Decanol for low-temperature heat transfer fluid application. Colloids Surf. A Physicochem. Eng. Asp. 2021, 614, 126167. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, G.; Lin, K.; Zhang, Q.; Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 2007, 42, 2197–2209. [Google Scholar] [CrossRef]

- Chung, W.J.; Park, S.H.; Yeo, M.S.; Kim, K.W. Control of thermally activated building system considering zone load characteristics. Sustainability 2017, 9, 586. [Google Scholar] [CrossRef]

- Guardia, C.; Barluenga, G.; Palomar, I.; Diarce, G. Thermal enhanced cement-lime mortars with phase change materials (PCM), lightweight aggregate and cellulose fibers. Constr. Build. Mater. 2019, 221, 586–594. [Google Scholar] [CrossRef]

- Regin, A.F.; Solanki, S.; Saini, J. Heat transfer characteristics of thermal energy storage system using PCM capsules: A review. Renew. Sustain. Energy Rev. 2008, 12, 2438–2458. [Google Scholar] [CrossRef]

- Tyagi, V.; Kaushik, S.; Tyagi, S.; Akiyama, T. Development of phase change materials based microencapsulated technology for buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1373–1391. [Google Scholar] [CrossRef]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-mortar based construction materials for energy efficient buildings: A review on research trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Jensen, R.L.; Cheng, R.; Zhang, Y. A new experimental method to determine specific heat capacity of inhomogeneous concrete material with incorporated microencapsulated-PCM. Cem. Concr. Res. 2014, 55, 22–34. [Google Scholar] [CrossRef]

- Lecompte, T.; Le Bideau, P.; Glouannec, P.; Nortershauser, D.; Le Masson, S. Mechanical and thermo-physical behaviour of concretes and mortars containing phase change material. Energy Build. 2015, 94, 52–60. [Google Scholar] [CrossRef]

- Aguayo, M.; Das, S.; Maroli, A.; Kabay, N.; Mertens, J.C.; Rajan, S.D.; Sant, G.; Chawla, N.; Neithalath, N. The influence of microencapsulated phase change material (PCM) characteristics on the microstructure and strength of cementitious composites: Experiments and finite element simulations. Cem. Concr. Compos. 2016, 73, 29–41. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Barreneche, C.; Martínez, M.; Šumiga, B.; Cabeza, L.F.; Fernández, A.I. Comparison of phase change slurries: Physicochemical and thermal properties. Energy 2015, 87, 223–227. [Google Scholar] [CrossRef]

- Milián, Y.E.; Gutiérrez, A.; Grageda, M.; Ushak, S. A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew. Sustain. Energy Rev. 2017, 73, 983–999. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Potential of macroencapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabo, M. Effect of encapsulation area on the thermal performance of PCM incorporated concrete bricks: A case study under Iraq summer conditions. Case Stud. Constr. Mater. 2021, 15, e00686. [Google Scholar] [CrossRef]

- Sepehri, A. Introduction and Literature Review of Building Components with Passive Thermal Energy Storage Systems. Renew. Energy Build. Technol. Control Oper. Tech. 2022, 1–18. [Google Scholar] [CrossRef]

- Ying Kong, S.; Yang, X.; Chandra Paul, S.; Sing Wong, L.; Šavija, B. Thermal response of mortar panels with different forms of macro-encapsulated phase change materials: A finite element study. Energies 2019, 12, 2636. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Bland, A.; Khzouz, M.; Statheros, T.; Gkanas, E.I. PCMs for residential building applications: A short review focused on disadvantages and proposals for future development. Buildings 2017, 7, 78. [Google Scholar] [CrossRef]

- Zukowski, M. Experimental study of short term thermal energy storage unit based on enclosed phase change material in polyethylene film bag. Energy Convers. Manag. 2007, 48, 166–173. [Google Scholar] [CrossRef]

- Wei, J.; Kawaguchi, Y.; Hirano, S.; Takeuchi, H. Study on a PCM heat storage system for rapid heat supply. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; pp. 267–274. [Google Scholar]

- Cheng, W.; Xie, B.; Zhang, R.; Xu, Z.; Xia, Y. Effect of thermal conductivities of shape stabilized PCM on under-floor heating system. Appl. Energy 2015, 144, 10–18. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A. Phase change materials for energy efficiency in buildings and their use in mortars. Materials 2019, 12, 1260. [Google Scholar] [CrossRef]

- Gandhi, M.; Kumar, A.; Elangovan, R.; Meena, C.S.; Kulkarni, K.S.; Kumar, A.; Bhanot, G.; Kapoor, N.R. A review on shape-stabilized phase change materials for latent energy storage in buildings. Sustainability 2020, 12, 9481. [Google Scholar] [CrossRef]

- Wu, M.; Wu, S.; Cai, Y.; Wang, R.; Li, T. Form-stable phase change composites: Preparation, performance, and applications for thermal energy conversion, storage and management. Energy Storage Mater. 2021, 42, 380–417. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, K.; Yang, R.; Di, H.; Jiang, Y. Preparation, thermal performance and application of shape-stabilized PCM in energy efficient buildings. Energy Build. 2006, 38, 1262–1269. [Google Scholar] [CrossRef]

- Sarrafha, H.; Kasaeian, A.; Jahangir, M.H.; Taylor, R.A. Transient thermal response of multi-walled carbon nanotube phase change materials in building walls. Energy 2021, 224, 120120. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Khoshaim, A.; Alzahrani, M.A.; Hatamleh, R.I. Study of the flat plate solar collector’s efficiency for sustainable and renewable energy management in a building by a phase change material: Containing paraffin-wax/Graphene and Paraffin-wax/graphene oxide carbon-based fluids. J. Build. Eng. 2022, 57, 104804. [Google Scholar] [CrossRef]

- Mishra, A.K.; Lahiri, B.; Philip, J. Carbon black nano particle loaded lauric acid-based form-stable phase change material with enhanced thermal conductivity and photo-thermal conversion for thermal energy storage. Energy 2020, 191, 116572. [Google Scholar] [CrossRef]

- Fallahi, A.; Guldentops, G.; Tao, M.; Granados-Focil, S.; Van Dessel, S. Review on solid-solid phase change materials for thermal energy storage: Molecular structure and thermal properties. Appl. Therm. Eng. 2017, 127, 1427–1441. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Pan, S. Review of phase change materials integrated in building walls for energy saving. Procedia Eng. 2015, 121, 763–770. [Google Scholar] [CrossRef]

- Tariq, S.L.; Ali, H.M.; Akram, M.A.; Janjua, M.M.; Ahmadlouydarab, M. Nanoparticles enhanced phase change materials (NePCMs)-A recent review. Appl. Therm. Eng. 2020, 176, 115305. [Google Scholar] [CrossRef]

- Khadiran, T.; Hussein, M.Z.; Zainal, Z.; Rusli, R. Encapsulation techniques for organic phase change materials as thermal energy storage medium: A review. Sol. Energy Mater. Sol. Cells 2015, 143, 78–98. [Google Scholar] [CrossRef]

- Sawadogo, M.; Duquesne, M.; Belarbi, R.; Hamami, A.E.A.; Godin, A. Review on the integration of phase change materials in building envelopes for passive latent heat storage. Appl. Sci. 2021, 11, 9305. [Google Scholar] [CrossRef]

- Saffari, M.; De Gracia, A.; Ushak, S.; Cabeza, L.F. Economic impact of integrating PCM as passive system in buildings using Fanger comfort model. Energy Build. 2016, 112, 159–172. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Gupta, N.K.; Yadav, D.; Shukla, S.K.; Kaul, S. Thermal performance of the building envelope integrated with phase change material for thermal energy storage: An updated review. Sustain. Cities Soc. 2022, 79, 103690. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Lu, Z.; Li, Z. Paraffin/expanded vermiculite composite phase change material as aggregate for developing lightweight thermal energy storage cement-based composites. Appl. Energy 2015, 160, 358–367. [Google Scholar] [CrossRef]

- Suttaphakdee, P.; Dulsang, N.; Lorwanishpaisarn, N.; Kasemsiri, P.; Posi, P.; Chindaprasirt, P. Optimizing mix proportion and properties of lightweight concrete incorporated phase change material paraffin/recycled concrete block composite. Constr. Build. Mater. 2016, 127, 475–483. [Google Scholar] [CrossRef]

- Cui, H.; Memon, S.A.; Liu, R. Development, mechanical properties and numerical simulation of macro encapsulated thermal energy storage concrete. Energy Build. 2015, 96, 162–174. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K.; Gupta, N.K. Potential of microencapsulated PCM for energy savings in buildings: A critical review. Sustain. Cities Soc. 2020, 53, 101884. [Google Scholar] [CrossRef]

- Liu, F.; Wang, J.; Qian, X. Integrating phase change materials into concrete through microencapsulation using cenospheres. Cem. Concr. Compos. 2017, 80, 317–325. [Google Scholar] [CrossRef]

- Konuklu, Y.; Ostry, M.; Paksoy, H.O.; Charvat, P. Review on using microencapsulated phase change materials (PCM) in building applications. Energy Build. 2015, 106, 134–155. [Google Scholar] [CrossRef]

- Cunha, S.; Aguiar, J.B.; Ferreira, V.M.; Tadeu, A. Influence of the Type of Phase Change Materials Microcapsules on the Properties of Lime-G ypsum Thermal Mortars. Adv. Eng. Mater. 2014, 16, 433–441. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Chang, S.J.; We, S.; Kim, S. Energy efficient thermal storage montmorillonite with phase change material containing exfoliated graphite nanoplatelets. Sol. Energy Mater. Sol. Cells 2015, 139, 65–70. [Google Scholar] [CrossRef]

- Biswas, K.; Lu, J.; Soroushian, P.; Shrestha, S. Combined experimental and numerical evaluation of a prototype nano-PCM enhanced wallboard. Appl. Energy 2014, 131, 517–529. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, W.; Jin, W. Experimental and numerical study on thermal energy storage of polyethylene glycol/expanded graphite composite phase change material. Energy Build. 2016, 111, 242–252. [Google Scholar] [CrossRef]

- Arunachalam, P. 6—Polymer-based nanocomposites for energy and environmental applications. In Polymer-based Nanocomposites for Energy and Environmental Applications; Jawaid, M., Khan, M.M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 185–203. [Google Scholar]

- Li, C.; Wen, X.; Cai, W.; Yu, H.; Liu, D. Phase change material for passive cooling in building envelopes: A comprehensive review. J. Build. Eng. 2023, 65, 105763. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, X.; Hu, M.; Zhang, L.; Fan, J. Adaptive dynamic building envelope integrated with phase change material to enhance the heat storage and release efficiency: A state-of-the-art review. Energy Build. 2023, 286, 112928. [Google Scholar] [CrossRef]

- Sovetova, M.; Memon, S.A.; Kim, J. Thermal performance and energy efficiency of building integrated with PCMs in hot desert climate region. Sol. Energy 2019, 189, 357–371. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Saffari, M.; De Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef]

- Louanate, A.; Otmani, R.E.; Kandoussi, K.; Boutaous, M.H.; Abdelmajid, D. Energy saving potential of phase change materials-enhanced building envelope considering the six Moroccan climate zones. J. Build. Phys. 2022, 45, 482–506. [Google Scholar] [CrossRef]

- Soudian, S.; Berardi, U. Assessing the effect of night ventilation on PCM performance in high-rise residential buildings. J. Build. Phys. 2019, 43, 229–249. [Google Scholar] [CrossRef]

- Yu, J.; Leng, K.; Ye, H.; Xu, X.; Luo, Y.; Wang, J.; Yang, X.; Yang, Q.; Gang, W. Study on thermal insulation characteristics and optimized design of pipe-embedded ventilation roof with outer-layer shape-stabilized PCM in different climate zones. Renew. Energy 2020, 147, 1609–1622. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Numerical analysis of thin building envelope-integrated phase change material towards energy-efficient buildings in severe hot location. Sustain. Cities Soc. 2023, 89, 104365. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Experimental study of PCM-enhanced building envelope towards energy-saving and decarbonisation in a severe hot climate. Energy Build. 2023, 279, 112680. [Google Scholar] [CrossRef]

- De Gracia, A.; Rincón, L.; Castell, A.; Jiménez, M.; Boer, D.; Medrano, M.; Cabeza, L.F. Life Cycle Assessment of the inclusion of phase change materials (PCM) in experimental buildings. Energy Build. 2010, 42, 1517–1523. [Google Scholar] [CrossRef]

- Anika, U.A.; Kibria, M.G.; Kanka, S.D.; Mohtasim, M.S.; Paul, U.K.; Das, B.K. Exergy, exergo-economic, environmental and sustainability analysis of pyramid solar still integrated hybrid nano-PCM, black sand, and sponge. Sol. Energy 2024, 274, 112559. [Google Scholar] [CrossRef]

- Mohseni, E.; Tang, W. Parametric analysis and optimisation of energy efficiency of a lightweight building integrated with different configurations and types of PCM. Renew. Energy 2021, 168, 865–877. [Google Scholar] [CrossRef]

- M’hamdi, Y.; Baba, K.; Tajayouti, M.; Nounah, A. Energy, environmental, and economic analysis of different buildings envelope integrated with phase change materials in different climates. Sol. Energy 2022, 243, 91–102. [Google Scholar] [CrossRef]

- de Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef]

- Min, H.-W.; Kim, S.; Kim, H.S. Investigation on thermal and mechanical characteristics of concrete mixed with shape stabilized phase change material for mix design. Constr. Build. Mater. 2017, 149, 749–762. [Google Scholar] [CrossRef]

- Xue, C.; Li, W.; Li, J.; Tam, V.W.; Ye, G. A review study on encapsulation-based self-healing for cementitious materials. Struct. Concr. 2019, 20, 198–212. [Google Scholar] [CrossRef]

- Figueiredo, A.; Lapa, J.; Vicente, R.; Cardoso, C. Mechanical and thermal characterization of concrete with incorporation of microencapsulated PCM for applications in thermally activated slabs. Constr. Build. Mater. 2016, 112, 639–647. [Google Scholar] [CrossRef]

- Huo, J.-h.; Peng, Z.-g.; Xu, K.; Feng, Q.; Xu, D.-y. Novel micro-encapsulated phase change materials with low melting point slurry: Characterization and cementing application. Energy 2019, 186, 115920. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. Use of phase change materials for thermal energy storage in concrete: An overview. Constr. Build. Mater. 2013, 46, 55–62. [Google Scholar] [CrossRef]

- Gentilini, C.; Franzoni, E.; Graziani, G.; Bandini, S. Mechanical properties of fired-clay brick masonry models in moist and dry conditions. Key Eng. Mater. 2014, 624, 307–312. [Google Scholar] [CrossRef]

- Saxena, R.; Rakshit, D.; Kaushik, S. Phase change material (PCM) incorporated bricks for energy conservation in composite climate: A sustainable building solution. Sol. Energy 2019, 183, 276–284. [Google Scholar] [CrossRef]

- Chelliah, A.; Saboor, S.; Ghosh, A.; Kontoleon, K.J. Thermal Behaviour Analysis and Cost-Saving Opportunities of PCM-Integrated Terracotta Brick Buildings. Adv. Civ. Eng. 2021, 2021, 6670930. [Google Scholar] [CrossRef]

- Dellagi, A.; Ayed, R.; Bouadila, S.; Guizani, A. Computational and experimental analysis of PCM-infused brick for sustainable heat regulation. J. Build. Phys. 2024, 48, 222–243. [Google Scholar] [CrossRef]

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabay, H. PCM integrated to external building walls: An optimization study on maximum activation of latent heat. Appl. Therm. Eng. 2020, 165, 114560. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Lee, J.-H.; Seo, J.; Kim, S. Thermal performance evaluation of Bio-based shape stabilized PCM with boron nitride for energy saving. Int. J. Heat Mass Transf. 2014, 71, 245–250. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A. Heat transfer studies of building brick containing phase change materials. Sol. Energy 2017, 155, 1233–1242. [Google Scholar] [CrossRef]

- Sharma, V.; Rai, A.C. Performance assessment of residential building envelopes enhanced with phase change materials. Energy Build. 2020, 208, 109664. [Google Scholar] [CrossRef]

- Huang, Y.; Alekhin, V.N.; Hu, W.; Pu, J. Adaptability Analysis of Hollow Bricks with Phase-Change Materials Considering Thermal Performance and Cold Climate. Buildings 2025, 15, 590. [Google Scholar] [CrossRef]

- Fahrurrozi, F.; Iwan, M.; Irawan, D.; Gunarto, G.; Fahrezi, D.; Govari, M.K. A Comparative Study of the Effect of Paraffin Phase Change Material Mixture and Ice Bag on Temperature Control in Bricks. Int. J. Ind. Innov. Mech. Eng. 2024, 2, 17–31. [Google Scholar] [CrossRef]

- Ru, C.; Li, G.; Guo, F.; Sun, X.; Yu, D.; Chen, Z. Experimental evaluation of the properties of recycled aggregate pavement brick with a composite shaped phase change material. Materials 2022, 15, 5565. [Google Scholar] [CrossRef]

- Ashok Kumar, J.; Muthuvel, S.; Issac Selvaraj, R.V.; Ramoni, M.; Shanmugam, R.; Pandian, R.S. Mechanical Property Comparison of Geopolymer Brick Dried by Electrical and Passive Solar Devices with Phase Change Material (Paraffin Wax). Processes 2023, 12, 28. [Google Scholar] [CrossRef]

- Chihab, Y. Thermal Performance Improvement of Hollow Fired Clay Bricks Embedding Phase Change Materials. In Proceedings of the International Conference on Civil Engineering, Singapore, 24–26 March 2023; Springer: Berlin/Heidelberg, Germany, 2023; pp. 555–563. [Google Scholar] [CrossRef]

- Erlbeck, L.; Schreiner, P.; Schlachter, K.; Dörnhofer, P.; Fasel, F.; Methner, F.-J.; Rädle, M. Adjustment of thermal behavior by changing the shape of PCM inclusions in concrete blocks. Energy Convers. Manag. 2018, 158, 256–265. [Google Scholar] [CrossRef]

- Hichem, N.; Noureddine, S.; Nadia, S.; Djamila, D. Decrease of Electrical Consumption During Periods of Peak Load Into the National Grid by Improving Thermal Insulation of Buildings. 2008. Available online: https://dspace.univ-ouargla.dz/jspui/bitstream/123456789/3421/1/Necib_Hichem.pdf (accessed on 15 June 2025).

- Tunçbilek, E.; Arıcı, M.; Bouadila, S.; Wonorahardjo, S. Seasonal and annual performance analysis of PCM-integrated building brick under the climatic conditions of Marmara region. J. Therm. Anal. Calorim. 2020, 141, 613–624. [Google Scholar] [CrossRef]

- Hamidi, Y.; Aketouane, Z.; Malha, M.; Bruneau, D.; Bah, A.; Goiffon, R. Integrating PCM into hollow brick walls: Toward energy conservation in Mediterranean regions. Energy Build. 2021, 248, 111214. [Google Scholar] [CrossRef]

- Prakash, D.; Vishore Krishnan, R.; Rizwan Ahamed, S.; Roger Arnold, H. Development of PCM tile for residential buildings in hot and dry climate: Design and optimization. J. Eng. Appl. Sci. 2024, 71, 202. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Pisello, A.L.; Fabiani, C.; Ubertini, F.; Cabeza, L.F.; Cotana, F. Multifunctional smart concretes with novel phase change materials: Mechanical and thermo-energy investigation. Appl. Energy 2018, 212, 1448–1461. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, X.; Ji, J.; Yan, H. Review of research progress on corrosion and anti-corrosion of phase change materials in thermal energy storage systems. J. Energy Storage 2023, 63, 107005. [Google Scholar] [CrossRef]

- Okogeri, O.; Stathopoulos, V.N. What about greener phase change materials? A review on biobased phase change materials for thermal energy storage applications. Int. J. Thermofluids 2021, 10, 100081. [Google Scholar] [CrossRef]

- Raj, V.A.A.; Velraj, R. Review on free cooling of buildings using phase change materials. Renew. Sustain. Energy Rev. 2010, 14, 2819–2829. [Google Scholar] [CrossRef]

- Farulla, G.A.; Brancato, V.; Palomba, V.; Zhang, Y.; Dino, G.E.; Frazzica, A. Experiments and Modeling of Solid–Solid Phase Change Material-Loaded Plaster to Enhance Building Energy Efficiency. Energies 2023, 16, 2384. [Google Scholar] [CrossRef]

- Alizadeh, M.; Sadrameli, S. Development of free cooling based ventilation technology for buildings: Thermal energy storage (TES) unit, performance enhancement techniques and design considerations–A review. Renew. Sustain. Energy Rev. 2016, 58, 619–645. [Google Scholar] [CrossRef]

- Heier, J.; Bales, C.; Martin, V. Combining thermal energy storage with buildings—A review. Renew. Sustain. Energy Rev. 2015, 42, 1305–1325. [Google Scholar] [CrossRef]

- Cárdenas-Ramírez, C.; Gómez, M.A.; Jaramillo, F.; Cardona, A.F.; Fernández, A.G.; Cabeza, L.F. Experimental steady-state and transient thermal performance of materials for thermal energy storage in building applications: From powder SS-PCMs to SS-PCM-based acrylic plaster. Energy 2022, 250, 123768. [Google Scholar] [CrossRef]

- Lakhdari, Y.A.; Chikh, S.; Campo, A. Analysis of the thermal response of a dual phase change material embedded in a multi-layered building envelope. Appl. Therm. Eng. 2020, 179, 115502. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.; Castro-Gomes, J. Experimental and numerical studies of hybrid PCM embedded in plastering mortar for enhanced thermal behaviour of buildings. Energy 2016, 94, 250–261. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Sanjayan, J.G. Retrofitting building envelope using phase change materials and aerogel render for adaptation to extreme heatwave: A multi-objective analysis considering heat stress, energy, environment, and cost. Sustainability 2021, 13, 10716. [Google Scholar] [CrossRef]

- Wu, M.; Liu, C.; Rao, Z. Experimental study on lauryl alcohol/expanded graphite composite phase change materials for thermal regulation in building. Constr. Build. Mater. 2022, 335, 127400. [Google Scholar] [CrossRef]

- Li, C.; Zhang, B.; Liu, Q. N-eicosane/expanded graphite as composite phase change materials for electro-driven thermal energy storage. J. Energy Storage 2020, 29, 101339. [Google Scholar] [CrossRef]

- Meng, Y.; Zhao, Y.; Zhang, Y.; Tang, B. Induced dipole force driven PEG/PPEGMA form-stable phase change energy storage materials with high latent heat. Chem. Eng. J. 2020, 390, 124618. [Google Scholar] [CrossRef]

- Maleki, B.; Khadang, A.; Maddah, H.; Alizadeh, M.; Kazemian, A.; Ali, H.M. Development and thermal performance of nanoencapsulated PCM/plaster wallboard for thermal energy storage in buildings. J. Build. Eng. 2020, 32, 101727. [Google Scholar] [CrossRef]

- Al-Absi, Z.A.; Hafizal, M.I.M.; Ismail, M. Experimental study on the thermal performance of PCM-based panels developed for exterior finishes of building walls. J. Build. Eng. 2022, 52, 104379. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Wang, B.; Liu, C.; Arıcı, M. Optical and thermal performance of glazing units containing PCM in buildings: A review. Constr. Build. Mater. 2020, 233, 117327. [Google Scholar] [CrossRef]

- Gowreesunker, B.; Stankovic, S.; Tassou, S.; Kyriacou, P. Experimental and numerical investigations of the optical and thermal aspects of a PCM-glazed unit. Energy Build. 2013, 61, 239–249. [Google Scholar] [CrossRef]

- Xamán, J.; Olazo-Gómez, Y.; Chávez, Y.; Hinojosa, J.; Hernández-Pérez, I.; Hernández-López, I.; Zavala-Guillén, I. Computational fluid dynamics for thermal evaluation of a room with a double glazing window with a solar control film. Renew. Energy 2016, 94, 237–250. [Google Scholar] [CrossRef]

- Al-mudhafar, A.H.; Hamzah, M.T.; Tarish, A.L. Potential of integrating PCMs in residential building envelope to reduce cooling energy consumption. Case Stud. Therm. Eng. 2021, 27, 101360. [Google Scholar] [CrossRef]

- Derradji, L.; Errebai, F.B.; Amara, M. Effect of PCM in improving the thermal comfort in buildings. Energy Procedia 2017, 107, 157–161. [Google Scholar] [CrossRef]

- Gil-Lopez, T.; Gimenez-Molina, C. Environmental, economic and energy analysis of double glazing with a circulating water chamber in residential buildings. Appl. Energy 2013, 101, 572–581. [Google Scholar] [CrossRef]

- Li, S.; Sun, G.; Zou, K.; Zhang, X. Experimental research on the dynamic thermal performance of a novel triple-pane building window filled with PCM. Sustain. Cities Soc. 2016, 27, 15–22. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Osterman, E.; Tyagi, V.; Butala, V.; Rahim, N.A.; Stritih, U. Review of PCM based cooling technologies for buildings. Energy Build. 2012, 49, 37–49. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F. Literature review on the use of phase change materials in glazing and shading solutions. Renew. Sustain. Energy Rev. 2016, 53, 515–535. [Google Scholar] [CrossRef]

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Cuce, E.; Riffat, S.B. A state-of-the-art review on innovative glazing technologies. Renew. Sustain. Energy Rev. 2015, 41, 695–714. [Google Scholar] [CrossRef]

- Favoino, F.; Overend, M.; Jin, Q. The optimal thermo-optical properties and energy saving potential of adaptive glazing technologies. Appl. Energy 2015, 156, 1–15. [Google Scholar] [CrossRef]

- Carlos, J.S.; Corvacho, H. Evaluation of the performance indices of a ventilated double window through experimental and analytical procedures: SHGC-values. Energy Build. 2015, 86, 886–897. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Liu, C.; Zhang, G.; Arıcı, M. Energy investigation of glazed windows containing Nano-PCM in different seasons. Energy Convers. Manag. 2018, 172, 119–128. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- Ismail, K.; Henríquez, J. Thermally effective windows with moving phase change material curtains. Appl. Therm. Eng. 2001, 21, 1909–1923. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Zheng, Y.; Liu, C.; Hussein, A.K.; Liu, X. Thermal performance of a PCM-filled double-glazing unit with different thermophysical parameters of PCM. Sol. Energy 2016, 133, 207–220. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl. Therm. Eng. 2007, 27, 1271–1277. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, Y.; Li, D.; Meng, F.; Zheng, Y.; Liu, X. Numerical analysis on thermal performance of a PCM-filled double glazing roof. Energy Build. 2016, 125, 267–275. [Google Scholar] [CrossRef]

- World Expo Shanghai. A Green Idea at Alsace Case Pavilion of France in Expo 2010 Shanghai. Available online: http://2010shanghaichina.blogspot.com/2010/09/green-idea-at-alsace-case-pavilion-of.html (accessed on 12 February 2025).

- Li, D.; Wu, Y.; Zhang, G.; Arıcı, M.; Liu, C.; Wang, F. Influence of glazed roof containing phase change material on indoor thermal environment and energy consumption. Appl. Energy 2018, 222, 343–350. [Google Scholar] [CrossRef]

- Alawadhi, E.M. Using phase change materials in window shutter to reduce the solar heat gain. Energy Build. 2012, 47, 421–429. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Zhou, Y.; Wang, Z.; Liu, X. Effect of PCM thickness and melting temperature on thermal performance of double glazing units. J. Build. Eng. 2017, 11, 87–95. [Google Scholar] [CrossRef]

- Nematpour Keshteli, A.; Sheikholeslami, M. Nanoparticle enhanced PCM applications for intensification of thermal performance in building: A review. J. Mol. Liq. 2019, 274, 516–533. [Google Scholar] [CrossRef]

- Yin, H.; Norouziasas, A.; Hamdy, M. PCM-Incorporated Building Envelope for Improving Cost Savings in Residential Buildings Under Cold Climates; Multiphysics and Multiscale Building Physics; Springer Nature: Singapore, 2024; pp. 384–392. [Google Scholar]

- Kumar, D.; Alam, M.; Sanjayan, J.; Haris, M. Comparative analysis of form-stable phase change material integrated concrete panels for building envelopes. Case Stud. Constr. Mater. 2023, 18, e01737. [Google Scholar] [CrossRef]

- Gao, Y.; Meng, X. A comprehensive review of integrating phase change materials in building bricks: Methods, performance and applications. J. Energy Storage 2023, 62, 106913. [Google Scholar] [CrossRef]

- Abass, P.J.; Muthulingam, S. Thermal energy storage performance of biaxial voided RCC roof slab integrated with macroencapsulated PCM for passive cooling of buildings. J. Energy Storage 2024, 88, 111478. [Google Scholar] [CrossRef]

- Kim, H.B.; Mae, M.; Choi, Y. Application of shape-stabilized phase-change material sheets as thermal energy storage to reduce heating load in Japanese climate. Build. Environ. 2017, 125, 1–14. [Google Scholar] [CrossRef]

- Piselli, C.; Castaldo, V.L.; Pisello, A.L. How to enhance thermal energy storage effect of PCM in roofs with varying solar reflectance: Experimental and numerical assessment of a new roof system for passive cooling in different climate conditions. Sol. Energy 2019, 192, 106–119. [Google Scholar] [CrossRef]

- Dardouri, S.; Tunçbilek, E.; Khaldi, O.; Arıcı, M.; Sghaier, J. Optimizing PCM integrated wall and roof for energy saving in building under various climatic conditions of mediterranean region. Buildings 2023, 13, 806. [Google Scholar] [CrossRef]

- Hu, J.; Yu, X. Thermo and light-responsive building envelope: Energy analysis under different climate conditions. Sol. Energy 2019, 193, 866–877. [Google Scholar] [CrossRef]

- Rahimpour, Z.; Verbič, G.; Chapman, A.C. Can phase change materials in building insulation improve self-consumption of residential rooftop solar? An Australian case study. Renew. Energy 2022, 192, 24–34. [Google Scholar] [CrossRef]

- Bolteya, A.M.; Elsayad, M.A.; Belal, A.M. Thermal efficiency of PCM filled double glazing units in Egypt. Ain Shams Eng. J. 2021, 12, 1523–1534. [Google Scholar] [CrossRef]

- Jangeldinov, B.; Memon, S.A.; Kim, J.; Kabdrakhmanova, M. Evaluating the Energy Efficiency of PCM-Integrated Lightweight Steel-Framed Building in Eight Different Cities of Warm Summer Humid Continental Climate. Adv. Mater. Sci. Eng. 2020, 2020, 4381495. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, S.; Aadmi, M.; Wang, Y.; Karkri, M.; Zhang, Z. Numerical analysis on phase change progress and thermal performance of different roofs integrated with phase change material (PCM) in Moroccan semi-arid and Mediterranean climates. Build. Simul. 2023, 16, 69–85. [Google Scholar] [CrossRef]

- Panchabikesan, K.; Vellaisamy, K.; Ramalingam, V. Passive cooling potential in buildings under various climatic conditions in India. Renew. Sustain. Energy Rev. 2017, 78, 1236–1252. [Google Scholar] [CrossRef]

- Nagano, K.; Takeda, S.; Mochida, T.; Shimakura, K.; Nakamura, T. Study of a floor supply air conditioning system using granular phase change material to augment building mass thermal storage—Heat response in small scale experiments. Energy Build. 2006, 38, 436–446. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. On the importance of the location of PCMs in building walls for enhanced thermal performance. Appl. Energy 2013, 106, 72–78. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, X. Thermal analysis of a double layer phase change material floor. Appl. Therm. Eng. 2011, 31, 1576–1581. [Google Scholar] [CrossRef]

- Zhou, G.; He, J. Thermal performance of a radiant floor heating system with different heat storage materials and heating pipes. Appl. Energy 2015, 138, 648–660. [Google Scholar] [CrossRef]

- Wong, R.J.D.; Al-Jethelah, M.; Ebadi, S.; Singh, A.; Mahmud, S. Investigation of phase change materials integrated with fin-tube baseboard convector for space heating. Energy Build. 2019, 187, 241–256. [Google Scholar] [CrossRef]

- Barzin, R.; Chen, J.J.J.; Young, B.R.; Farid, M.M. Application of PCM underfloor heating in combination with PCM wallboards for space heating using price based control system. Appl. Energy 2015, 148, 39–48. [Google Scholar] [CrossRef]

- Koschenz, M.; Lehmann, B. Development of a thermally activated ceiling panel with PCM for application in lightweight and retrofitted buildings. Energy Build. 2004, 36, 567–578. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. Peak load shifting using a price-based control in PCM-enhanced buildings. Sol. Energy 2020, 211, 661–673. [Google Scholar] [CrossRef]

- Mosleh, H.J.; Kavian, S.; Shafii, M.B. Performance analysis and transient simulation of a vapor compression cooling system integrated with phase change material as thermal energy storage for electric peak load shaving. J. Energy Storage 2021, 35, 102316. [Google Scholar] [CrossRef]

- Kheradmand, M.; Castro-Gomes, J.; Azenha, M.; Silva, P.D.; de Aguiar, J.L.B.; Zoorob, S.E. Assessing the feasibility of impregnating phase change materials in lightweight aggregate for development of thermal energy storage systems. Constr. Build. Mater. 2015, 89, 48–59. [Google Scholar] [CrossRef]

- Hanchi, N.; Hamza, H.; Lahjomri, J.; Oubarra, A. Thermal behavior in dynamic regime of a multilayer roof provided with two phase change materials in the case of a local conditioned. Energy Procedia 2017, 139, 92–97. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, G. Investigating the performance of the PCM-integrated building envelope on a seasonal basis. J. Taiwan Inst. Chem. Eng. 2021, 124, 91–97. [Google Scholar] [CrossRef]

- Schossig, P.; Henning, H.-M.; Gschwander, S.; Haussmann, T. Micro-encapsulated phase-change materials integrated into construction materials. Sol. Energy Mater. Sol. Cells 2005, 89, 297–306. [Google Scholar] [CrossRef]

- Yu, J.; Yang, Q.; Ye, H.; Huang, J.; Liu, Y.; Tao, J. The optimum phase transition temperature for building roof with outer layer PCM in different climate regions of China. Energy Procedia 2019, 158, 3045–3051. [Google Scholar] [CrossRef]

- Vukadinović, A.; Radosavljević, J.; Đorđević, A. Energy performance impact of using phase-change materials in thermal storage walls of detached residential buildings with a sunspace. Sol. Energy 2020, 206, 228–244. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. Phase change materials (PCMs) in buildings. In Multifunctional Phase Change Materials; Elsevier: Amsterdam, The Netherlands, 2023; pp. 507–567. [Google Scholar]

- Yinping, Z.; Zhou, G.; Yang, R.; Lin, K. Our research on shape-stabilized PCM in energy-efficient buildings. In Proceedings of the Ecostock 10th International Conference on Thermal Energy Storage, Galloway, NJ, USA, 31 May–2 June 2006; pp. 1–9. [Google Scholar]

- Mourid, A.; El Alami, M.; Kuznik, F. Experimental investigation on thermal behavior and reduction of energy consumption in a real scale building by using phase change materials on its envelope. Sustain. Cities Soc. 2018, 41, 35–43. [Google Scholar] [CrossRef]

- Li, Z.; Al-Rashed, A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]