1. Introduction

With the rapid development of the global economy and the continuous advancement of urbanization, the construction industry’s demand for concrete has been increasing [

1]. Concrete, as one of the most widely used building materials, involves the extraction of a large amount of natural resources and calcination processing, including sand, gravel, and cement. This not only leads to the rapid depletion of resources but also causes environmental damage, such as increased carbon emissions, soil erosion, and loss of biodiversity [

2,

3,

4,

5]. To address this challenge, the civil engineering field is actively exploring environmentally friendly alternative materials, which include two main approaches: recycling and development of new materials [

6,

7,

8]. Following this concept, one approach is to use recycled aggregates, where waste building materials are processed and used as aggregates in new concrete. This not only reduces the extraction of natural resources but also effectively deals with construction waste and lowers environmental burdens. The other approach is to develop industrial by-products, such as fly ash, slag, and coal gangue [

9,

10], as partial replacements for cement. These materials have significantly lower carbon emissions during calcination compared to traditional cement and possess good mechanical properties. By optimizing the concrete mix design, cement consumption can be further reduced, thereby decreasing energy consumption and carbon emissions during the production process [

11].

The continuous growth of the global construction industry, particularly in China, has led to extensive exploitation and use of natural resources such as river sand and limestone gravel, resulting in significant environmental concerns. In the summer of 2018, the price of sand and gravel in the Pearl River Delta region surged to 300 RMB per cubic meter [

12,

13], driving the cost of C30 ready-mixed concrete to 700 RMB per cubic meter and causing market instability in the construction industry [

14,

15]. Consequently, finding alternatives to natural aggregates in concrete production has become a critical research focus, with recycled aggregates, industrial waste, and tailings emerging as promising solutions [

16,

17,

18]. Coal, a key energy source relied upon by many countries, plays a vital role in the global energy landscape. According to proven reserves, the top five countries with the largest coal reserves are the United States (27.6%), Russia (18.2%), China (13.3%), Australia (8.9%), and India (7.0%). As a coal-dependent nation, China generates hundreds of millions of tons of coal gangue solid waste annually, with an annual increase of 40 to 50 million tons. Long-term stockpiling of coal gangue occupies land resources, hinders land utilization, and generates dust pollution. Spontaneous combustion of coal gangue releases harmful gases such as SO

2, CO, CO

2, H

2S, and NOx, causing severe environmental pollution [

19,

20,

21]. Despite the variability in coal gangue types and properties, mineralogical analysis reveals that it primarily consists of silicate minerals such as quartz, kaolinite, and illite, which align with the composition of natural aggregates. The chemical bonding energy (ΔE < 5%) and surface roughness (Ra = 15–25 μm) of coal gangue exhibit topological similarity to natural aggregates. In terms of physical properties, coal gangue’s bulk density (1.4–1.8 g/cm

3), apparent density (2.4–2.8 g/cm

3), and crushing value (15–25%) meet the technical requirements of GB/T 14685-2011 [

22] “Pebble and Crushed Stone for Construction,” demonstrating its high potential as a substitute for natural aggregates [

23].

Simultaneously, as one of the major contributors to global carbon emissions, the cement production industry accounts for 8% of total CO

2 emissions from human activities. Driven by the dual-carbon strategy, reducing the use of Portland cement and developing low-carbon cementitious material systems has become imperative. Coal gangue (CG), with its pozzolanic components (SiO

2 40–65%, Al

2O

3 15–28% [

23]) similar to Portland cement and superior carbon footprint characteristics (production energy consumption < 0.3 t CO

2/t vs. cement 0.8 t CO

2/t), has emerged as a highly promising alternative to cement [

24,

25]. Thermal activation (calcination at 750–850 °C) can transform its kaolinite phase into reactive metakaolin (Al

2O

3·2SiO

2) while releasing amorphous SiO

2/Al

2O

3 networks. These components undergo secondary hydration reactions with cement hydration products like Ca(OH)

2, forming C-S-H and C-A-S-H gels, which densify the internal structure and enhance the compressive strength of concrete [

26]. Additionally, in alkaline environments, pozzolanic reactions generate C-(A)-S-H gels and calcium sulfoaluminate hydrates (AFt), with a cementitious efficiency coefficient (k = 0.7–0.9) comparable to Class II fly ash. Thus, properly treated coal gangue can serve as a potentially active supplementary cementitious material, partially replacing cement [

27,

28]. Evidently, the use of coal gangue in concrete production can reduce the exploitation of natural sand and gravel, significantly lower carbon emissions, and promote green industrial transformation. An increasing number of scholars are now focusing on applying coal gangue in concrete materials.

Qian et al. [

29] summarized research progress since 2014 on improving the performance of coal gangue as a coarse aggregate in concrete. Their review analyzed the basic physical and chemical properties of coal gangue, key factors affecting its application in concrete, and methods to enhance the performance of coal gangue concrete at that time. Deng et al. [

30] comprehensively discussed advancements since 2011 in the mechanical and durability properties of coal gangue concrete (CGC) using coal gangue as a substitute for fine and coarse aggregates. They reviewed the influence of regional variations in the chemical and mineralogical characteristics of coal gangue on CGC performance and explored its resource utilization prospects in civil engineering. Zhang et al. [

31] provided a comprehensive review of activation methods for coal gangue and their effects on cement-based materials since 2010, analyzing how different activation techniques enhance the reactivity of coal gangue and improve the performance of cement-based materials. Despite extensive research and reviews on CG and CGC, significant progress has been made since 2014 in the study of physical and durability indicators of coal gangue and its powder in concrete (CGC). These advancements have not been comprehensively reflected in the aforementioned studies, and the performance, applications, and physical and durability results of CGC incorporating various mineral admixtures have yet to be systematically reviewed.

Therefore, this study aims to provide a more comprehensive summary of the current state of research on coal gangue-based concrete, including new research techniques and indicators. It explores the development of environmentally friendly concrete with higher coal gangue substitution rates or even “all-solid-waste” compositions. By collecting and analyzing published data on the mechanical and durability properties of CGC using coal gangue as a substitute for aggregates and cementitious materials, this review thoroughly discusses the performance of CGC, from single coal gangue incorporation to CGC with multiple mineral admixtures. The overall findings will help identify the most suitable mineral admixture combinations for developing CGC and their independent or synergistic effects on specific properties, supporting future research on novel coal gangue-based concrete and providing the construction industry with a highly sustainable and eco-friendly material choice.

2. Coal Gangue as Aggregate

Coal gangue aggregates exhibit a rough, porous, and angular fractured morphology, containing abundant microcracks and dissolution pores (with porosity three to five times higher than natural aggregates), resulting in high water absorption (5–9%) and weak concrete interfaces. In contrast, coal gangue powder demonstrates three characteristic morphologies: flaky structures, porous aggregates, and amorphous reactive fragments. The calcined honeycomb-like porous structure significantly increases specific surface area (300–500 m2/kg), enhancing pozzolanic activity, though its flaky particles may reduce paste compactness. Both the porous aggregates and powder morphology critically influence concrete performance, necessitating geometric optimization through improved grinding processes or surface modification. Moreover, it is evident that coal gangue is a heterogeneous mixture of various rock fragments, and its chemical composition varies with rock type and mineralogy. For example, gangue derived from clay rocks is primarily composed of SiO2 (30–60%) and Al2O3 (15–40%).

Coal gangue can be directly used as a fine or coarse aggregate to partially replace traditional sand and gravel in concrete production, which helps reduce reliance on natural aggregates and, to some extent, improves concrete performance [

32]. This approach not only facilitates the reuse of waste materials but also opens new possibilities for innovation in construction materials, demonstrating the potential and value of coal gangue in the field of building materials.

2.1. Mechanical Properties

2.1.1. Compressive Strength

Table 1 lists the relevant references consulted for the study on compressive strength. Previous studies indicate that the compressive strength of CGC decreases as the percentage of coal gangue substitution increases, as shown in

Table 2. This effect is more pronounced at early ages (up to 7 days), but strength gains can be observed over time.

Figure 1 illustrates the compressive strength values and their averages at 3, 7, and 28 days for CGC with coal gangue replacement rates of CG-10/20/30/50/100, based on the existing literature. A clear trend is observed over time and with increasing coal gangue percentages. Notably, most CGC mixes in

Table 2 exhibit rapid strength development, with the 3-day compressive strength averaging 70% of the 28-day strength and reaching 81% at 7 days, largely due to the effective use of water-reducing agents.

Compressive strength, which measures a material’s ability to withstand compressive loads without failure, is a critical parameter for evaluating the suitability of coal gangue as a coarse aggregate in concrete [

30]. It is one of the most important indicators of the mechanical performance of concrete materials. Studies have shown that the compressive strength of non-self-combustible coal gangue coarse aggregate concrete increases with curing time but decreases with higher coal gangue replacement rates and water-to-binder ratios. Optimizing compressive strength requires balancing the proportions of coal gangue, fly ash, and the water-to-binder ratio [

33]. When the coal gangue content is low (<20%), the compressive strength of concrete tends to improve or remain stable. However, as the content increases (>20%), especially beyond 40%, the compressive strength significantly declines [

33,

34,

35,

36]. For instance, research by Sun and Wang demonstrated that CGC with 20% coal gangue fine aggregate showed a 1.28% increase in compressive strength for C30-grade concrete, while slight decreases were observed for C40 and C50 grades (1.28% and 2.59%, respectively). However, when the replacement rate exceeded 20%, the compressive strength dropped significantly. For example, at a 50% replacement rate, the compressive strength of C30, C40, and C50 concrete decreased by 17.09%, 19.87%, and 22.97%, respectively [

37,

38]. Furthermore, summarized research findings indicate that coal gangue can fully replace crushed stone in concrete with strength grades of C30 and below. However, for C40 and C50 concrete, the replacement rate should be limited to 50% to ensure strength compliance [

39,

40]. Yan [

41] found that the water-to-binder ratio affects coal gangue coarse aggregate concrete similarly to ordinary concrete, with increased ratios leading to reduced compressive strength. At low water-to-cement ratios (e.g., 0.35), the compressive strength of coal gangue aggregate concrete is relatively high, even exceeding 45 MPa. However, as the water-to-cement ratio increases (e.g., 0.45), the negative impact of coal gangue on strength diminishes [

42,

43,

44,

45].

The compressive strength of coal gangue-admixed concrete improves with curing age, showing better strength development at later stages. At 28 days, the axial compressive strength of coal gangue aggregate concrete slightly increases with higher replacement rates (e.g., from 32.6 MPa to 36.0 MPa), but the strength gain is more pronounced at 90 days [

46]. The incorporation of fly ash improves the interfacial properties of the cement matrix, reduces Ca(OH)

2 content, and mitigates alkali corrosion of basalt fibers. Fly ash’s secondary hydration reaction also enhances the structure of the cement matrix, resulting in a denser internal concrete structure and improved long-term strength and frost resistance [

47,

48]. Some studies have shown that the strength growth rate of coal gangue concrete between 28 and 56 days is higher than that of ordinary concrete, indicating superior long-term strength development [

49]. The effects of coal gangue coarse and fine aggregates on concrete strength differ. Zuo [

50] found that a 100% replacement rate of coal gangue coarse aggregate, combined with calcination strengthening, increased the 28-day compressive strength by 11.7% to 20.3%. Additionally, low replacement rates of coal gangue fine aggregate (<20%) slightly improve strength, while high replacement rates (>20%) lead to strength reduction due to the low strength and high water absorption of coal gangue [

34,

35]. Strengthening treatments, such as calcination and cement reinforcement, significantly enhance the compressive strength of coal gangue aggregate concrete [

51,

52]. The physicochemical properties of coal gangue, such as water absorption, crushing index, and chemical composition, also significantly affect compressive strength. Ma [

53] observed that CGC with a 100% replacement rate of coal gangue coarse aggregate exhibited significantly enhanced compressive strength in low-temperature environments due to pore-filling by frozen water. However, strength decreased with higher replacement rates or lower design strengths. Coal gangue with high SiO

2, CaO, and Al

2O

3 content and low Fe

2O

3 content is more suitable as a coarse aggregate [

54]. Furthermore, curing conditions, such as low-temperature environments, significantly influence the strength performance of coal gangue concrete [

55]. In summary, CGC exhibits better compressive strength under low replacement rates (<20%) and low water-to-cement ratios (<0.45). However, high replacement rates and water-to-cement ratios lead to strength reduction. Strengthening treatments and optimizing the physicochemical properties of coal gangue can significantly improve its performance in concrete [

56].

Table 1.

Relevant literature on the compressive strength of coal gangue aggregate concrete.

Table 1.

Relevant literature on the compressive strength of coal gangue aggregate concrete.

| Author(s) | Research Focus | Key Result | Reference |

|---|

| — | Non-self-ignited CG coarse-aggregate concrete at various curing ages | Compressive strength grows with age but decreases with higher CG replacement ratio and w/b ratio | [33] |

| Sun and Wang | C30/C40/C50 concretes with coal-gangue fine aggregate | At 20% replacement C30 strength climbed 1.28%; above 20 % strength drops sharply; at 50% replacement C30 slid 17.09% | [38,39] |

| Yan | Influence of w/b ratio on CG coarse-aggregate concrete | Higher w/b ratio results lower strength; with w/c = 0.35 strength exceeds 45 MPa | [42] |

| — | Fly-ash–CG composite concrete | Strength gain between 28–56 d exceeds that of ordinary concrete, showing superior later-age strength | [50] |

| Zuo | 100% CG coarse aggregate with calcination strengthening | Calcination increases 28-d compressive strength by 11.7–20.3% | [51] |

| Ma | Low-temperature performance of 100% CG coarse-aggregate concrete | Strength rises notably at low temperature due to ice filling pores; high SiO2, CaO, Al2O3 and low Fe2O3 favor strength | [54] |

Table 2.

Compressive strength of concrete with coal gangue as a substitute for aggregate. Unit: kg/m3.

Table 2.

Compressive strength of concrete with coal gangue as a substitute for aggregate. Unit: kg/m3.

| Reference | Citation | Coal Gangue (Coarse) | Crushed Stone | Coal Gangue (Fine) | Cement | Sand | Water | Water Reducer (%) | Sand Ratio | Water-to-Cement Ratio | Compressive Strength (MPa) |

|---|

| 3 d | 7 d | 28 d | 56 d |

|---|

| CG-10 | [35] | 0 | 1190 | 64.2 | 376 | 577.8 | 169 | 1.2 | 0.30 | 0.4 | 44.7 | 46.3 | 48.6 | - |

| | | 0 | 1182 | 60.8 | 422 | 547.2 | 164 | 2.3 | 0.30 | 0.4 | 55.2 | 57.6 | 59.8 | - |

| | [49] | 0 | 1190 | 69.5 | 325 | 625.5 | 180 | 1.6 | 0.30 | 0.4 | - | 28.3 | 39.6 | 45.1 |

| | | 0 | 1210 | 59.0 | 406 | 531.0 | 185 | 1.5 | 0.30 | 0.4 | - | 36.7 | 48.8 | 54.3 |

| | | 0 | 1200 | 51.5 | 487 | 463.5 | 180 | 1.6 | 0.30 | 0.4 | - | 42.2 | 59.3 | 67.7 |

| | [40] | 114.1 | 1026.9 | 0 | 347 | 700 | 190 | 1.8 | 0.40 | 0.3 | 12.0 | 23.4 | 27.6 | - |

| | | 107.9 | 971.1 | 0 | 396 | 662 | 190 | 1.8 | 0.40 | 0.3 | 19.5 | 25.1 | 34.7 | - |

| CG-15 | [46] | 139.7 | 897.0 | 0 | 380 | 791.4 | 499.6 | 3.75 | 0.40 | 0.4 | 28.6 | 30.6 | 32.8 | - |

| CG-20 | [53] | 218 | 871 | 0 | 384 | 728 | 154 | - | 0.40 | 0.4 | 28.3 | 31.7 | 33.6 | - |

| | [35] | 0 | 1190 | 128.4 | 376 | 513.6 | 169 | 1.2 | 0.30 | 0.4 | 42.4 | 44.6 | 47.6 | - |

| | | 0 | 1182 | 121.6 | 422 | 486.4 | 164 | 2.3 | 0.30 | 0.4 | 53.2 | 55.6 | 57.9 | - |

| | [49] | 0 | 1190 | 139.0 | 325 | 556 | 180 | 1.6 | 0.30 | 0.4 | - | 27.6 | 41.4 | 48.3 |

| | | 0 | 1210 | 118.0 | 406 | 472 | 185 | 1.5 | 0.30 | 0.4 | - | 35.4 | 50.5 | 57.4 |

| | | 0 | 1200 | 103.0 | 487 | 412 | 180 | 1.6 | 0.20 | 0.4 | - | 41.7 | 60.7 | 71.8 |

| | [40] | 228.2 | 912.8 | 0 | 347 | 700 | 190 | 1.8 | 0.40 | 0.3 | 12.2 | 18.4 | 26.1 | - |

| | | 215.8 | 863.2 | 0 | 396 | 662 | 190 | 1.8 | 0.40 | 0.3 | 18.4 | 24.3 | 33.1 | - |

| CG-30 | [57] | 334.0 | 676.0 | 0 | 368 | 628.0 | 195 | 1.30 | 0.40 | 0.2 | 38.9 | 40.6 | 43.9 | - |

| | [33] | 338.5 | 789.9 | 0 | 450 | 634.7 | 200 | 3.60 | 0.40 | 0.4 | 19.7 | 21 | 33.2 | - |

| | [58] | 315.0 | 732.5 | 0 | 352 | 855.0 | 145 | 1.76 | 0.45 | 0.41 | 16.6 | 26.5 | 35.8 | - |

| | [54] | 286.0 | 857.0 | 0 | 356 | 660.0 | 160 | 2.00 | 0.35 | 0.45 | 28.6 | 39.3 | 42.2 | - |

| | [46] | 279.3 | 954 | 0 | 380 | 651.7 | 499.6 | 3.75 | 0.30 | 0.4 | 28.7 | 31.8 | 33.6 | - |

| | [49] | 0 | 1190 | 208.5 | 325 | 486.5 | 180 | 1.6 | 0.30 | 0.4 | - | 26.4 | 38.1 | 43.4 |

| | | 0 | 1210 | 177.0 | 406 | 413 | 185 | 1.5 | 0.20 | 0.4 | - | 34.7 | 47.2 | 51.9 |

| | | 0 | 1200 | 154.5 | 487 | 360.5 | 180 | 1.6 | 0.20 | 0.4 | - | 40.1 | 57.5 | 65.6 |

| | [40] | 342.3 | 798.7 | 0 | 347 | 700 | 190 | 1.8 | 0.40 | 0.3 | 11.7 | 17.4 | 24.6 | - |

| | | 323.7 | 755.3 | 0 | 396 | 662 | 190 | 1.8 | 0.40 | 0.3 | 17.4 | 22.9 | 29.1 | - |

| CG-50 | [57] | 552.0 | 749 | 0 | 368 | 621.0 | 195 | 1.30 | 0.30 | 0.2 | 33.8 | 36.4 | 38.5 | - |

| | | 552.0 | 749 | 0 | 390 | 621 | 195 | 1.3 | 0.30 | 0.2 | 30.6 | 33.5 | 35.9 | - |

| | | 552.0 | 749 | 0 | 346 | 621 | 195 | 1.3 | 0.30 | 0.2 | 30.5 | 32.9 | 34.1 | - |

| | | 518.0 | 679 | 0 | 557 | 583 | 195 | 1.7 | 0.30 | 0.2 | 42.3 | 44.8 | 46.1 | - |

| | | 573.0 | 769 | 0 | 354 | 645 | 195 | 1.1 | 0.30 | 0.2 | 22.6 | 26.7 | 28.1 | - |

| | [33] | 556.7 | 556.7 | 0 | 450 | 626.2 | 210 | 3.60 | 0.40 | 0.40 | 22.9 | 24 | 33.4 | - |

| | [58] | 510.0 | 510.0 | 0 | 395 | 835.0 | 150 | 2.37 | 0.45 | 0.38 | 15.4 | 24.5 | 29.3 | - |

| | | 485.0 | 485.0 | 0 | 500 | 792.5 | 140 | 5.00 | 0.45 | 0.28 | 22.4 | 30.4 | 35.0 | - |

| | [35] | 0 | 1190 | 321 | 376 | 321 | 169 | 1.2 | 0.20 | 0.4 | 34.2 | 36.6 | 38.2 | - |

| | | 0 | 1182 | 304 | 422 | 304 | 164 | 2.3 | 0.20 | 0.4 | 43.8 | 46.4 | 48.1 | - |

| | [49] | 0 | 1190 | 347.5 | 325 | 347.5 | 180 | 1.6 | 0.20 | 0.4 | - | 21.6 | 32.0 | 37.2 |

| | | 0 | 1210 | 295 | 406 | 295 | 185 | 1.5 | 0.20 | 0.4 | - | 26.9 | 36.3 | 42.1 |

| | | 0 | 1200 | 257.5 | 487 | 257.5 | 180 | 1.6 | 0.20 | 0.4 | - | 31.4 | 43.0 | 51.7 |

| CG-100 | [55] | 875.0 | 875.0 | 0 | 457 | 608.0 | 160 | 3.80 | 0.40 | 0.3 | 16.3 | 18.1 | 23.8 | - |

| | | 875.0 | 875.0 | 0 | 457 | 608.0 | 160 | 3.80 | 0.40 | 0.3 | 17.4 | 19.2 | 29.2 | - |

| | [54] | 953.0 | 953.0 | 0 | 356 | 660.0 | 160 | 2.00 | 0.35 | 0.45 | 29.3 | 32.6 | 36.4 | - |

Figure 1.

Compressive strength values of coal gangue aggregate concrete with different replacement amounts at 3 days (

a), 7 days (

b), and 28 days (

c) [

33,

35,

40,

46,

49,

53,

54,

55,

57,

58].

Figure 1.

Compressive strength values of coal gangue aggregate concrete with different replacement amounts at 3 days (

a), 7 days (

b), and 28 days (

c) [

33,

35,

40,

46,

49,

53,

54,

55,

57,

58].

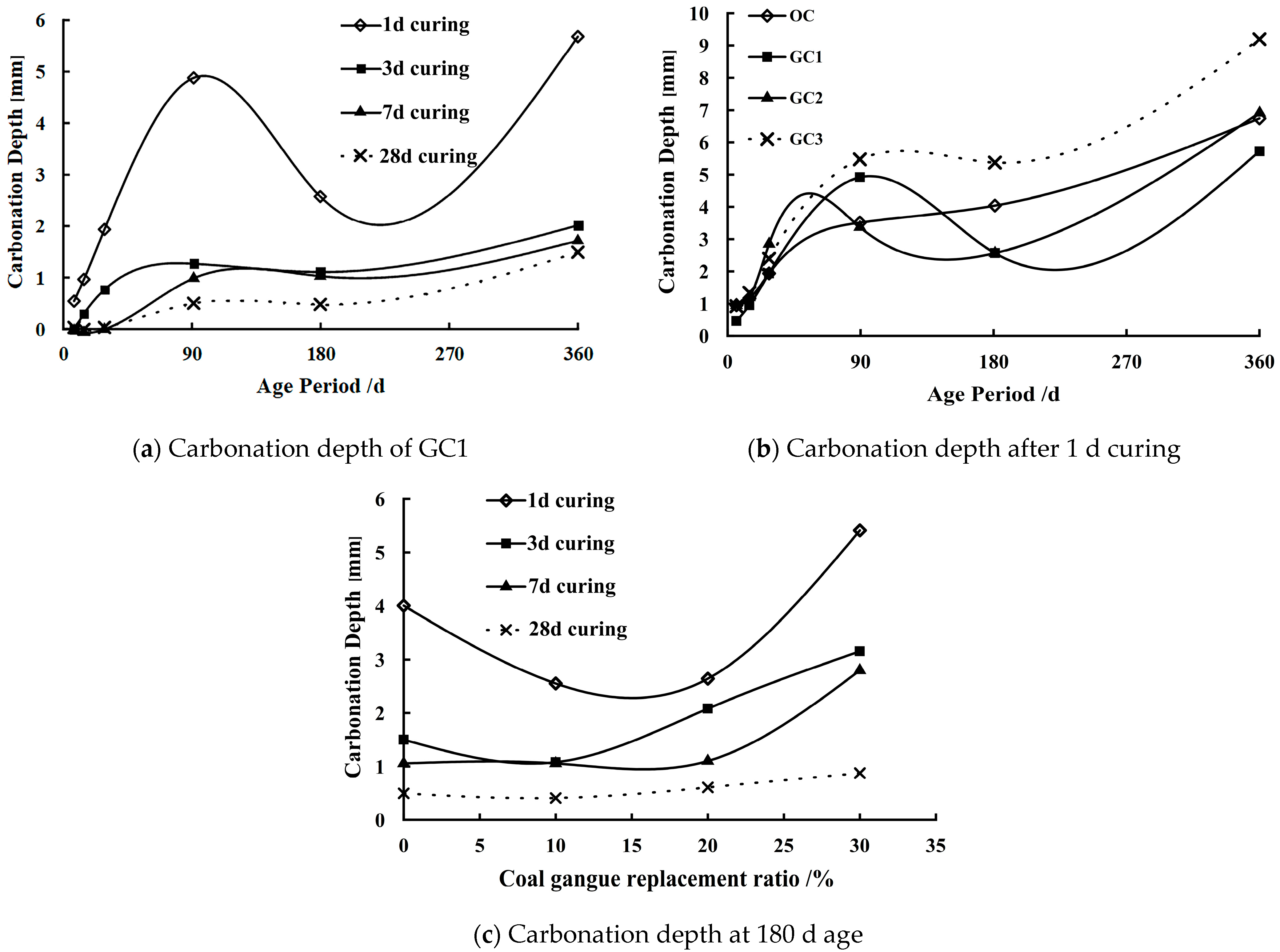

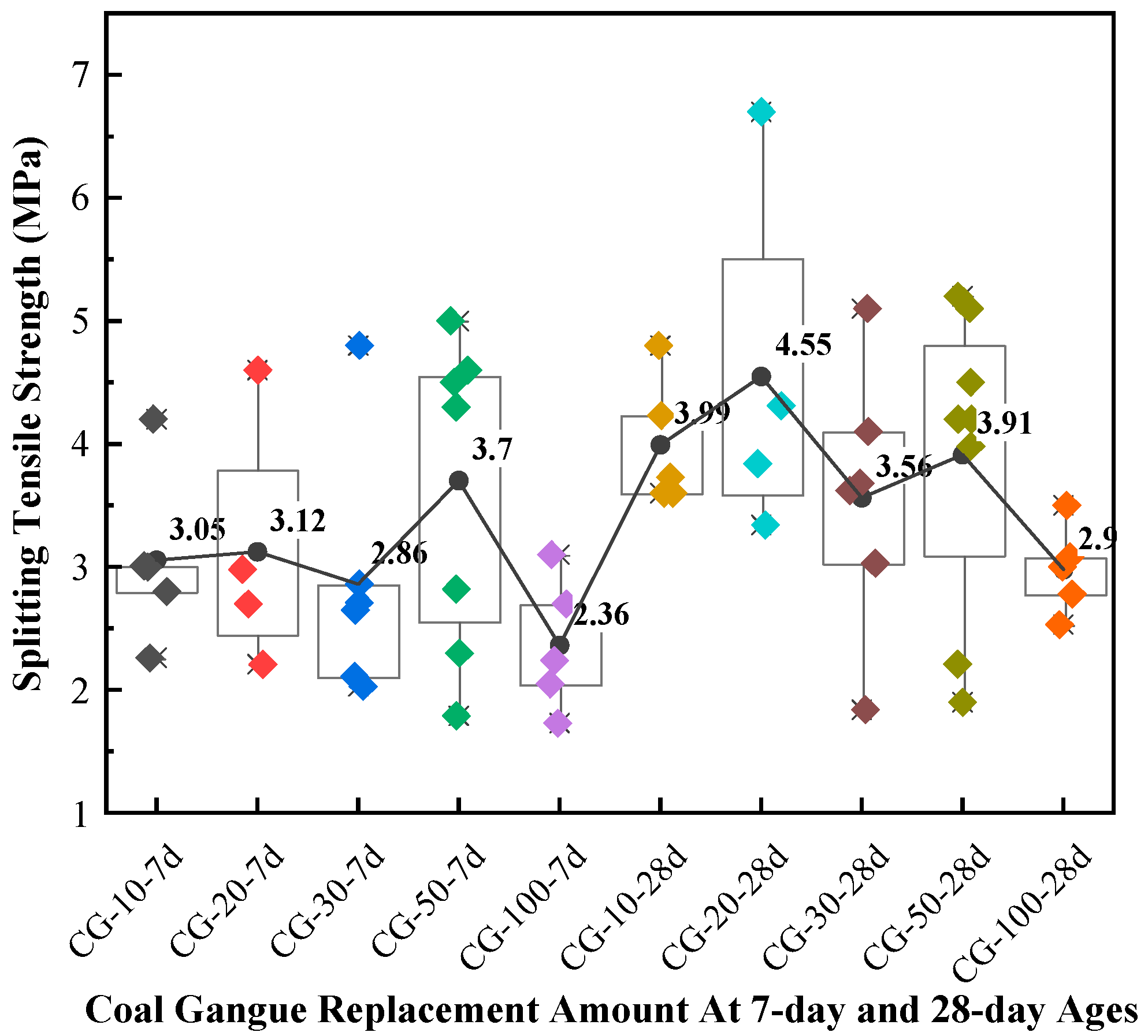

2.1.2. Splitting Tensile Strength

Table 3 lists the relevant references consulted for the study on splitting tensile strength. Similar to the development of compressive strength, the splitting tensile strength of coal gangue aggregate concrete generally decreases with increasing coal gangue content, although the rate of decrease varies over time. As observed in

Table 4, reducing the water-to-binder ratio helps improve the splitting tensile strength of coal gangue concrete. For example, in the CG-30 group, the 28-day splitting tensile strength was 5.1 MPa at a water-to-cement ratio of 0.2, but decreased to 3.03 MPa at a water-to-cement ratio of 0.4. The water-to-binder ratio significantly affects the splitting tensile strength of coal gangue concrete, and this effect interacts with the coal gangue replacement rate. Studies show that when the water-to-binder ratio is between 0.4 and 0.5, the splitting tensile strength initially increases and then decreases with higher coal gangue content, indicating an optimal replacement range. However, when the water-to-binder ratio is between 0.5 and 0.6, the strength continuously decreases with increasing coal gangue content [

33]. Wang [

57] further demonstrated that at a 50% replacement rate of non-self-combustible coal gangue, the splitting tensile strength decreased from 4.93 MPa to 4.3 MPa, and when the water-to-binder ratio increased to 0.55, the strength further dropped to 3.5 MPa [

45]. This suggests that higher water-to-binder ratios weaken the tensile performance of coal gangue concrete, and this weakening effect becomes more pronounced with higher coal gangue content. He [

45] continued to investigate the differences in strength growth rates with curing age, noting that at water-to-cement ratios of 0.40 and 0.45, the 7-day strength of coal gangue concrete was close to that of ordinary concrete. However, as the curing age increased, the strength growth rate of coal gangue concrete was significantly lower than that of ordinary concrete. Additionally, higher coal gangue content reduced the strength growth rate, and this difference was more pronounced at higher water-to-cement ratios.

Table 3.

Relevant literature on the splitting tensile strength of coal-gangue aggregate concrete.

Table 3.

Relevant literature on the splitting tensile strength of coal-gangue aggregate concrete.

| Author(s) | Research Focus | Key Result | Reference |

|---|

| Wang | Non-self-ignited CG aggregate concrete (50% replacement) | Splitting tensile strength drops from 4.93 MPa to 4.3 MPa at 50% CG; further falls to 3.5 MPa when w/b rises to 0.55 | [33,46] |

| — | Interaction of w/b ratio (0.4–0.6) and CG dosage on splitting strength | Strength first rises then falls with CG content at w/b 0.4–0.5, whereas it decreases continuously at w/b 0.5–0.6 | [34] |

| He | CG concrete under w/c = 0.40 and 0.45, curing age effect | 7 d strength similar to normal concrete, but later-age growth rate markedly lower; higher CG content and w/c amplify the deficit | [46] |

| — | Slag–fly-ash ternary blend in CG concrete (slag:FA = 1:2) | 28 d splitting tensile strength increases by 43% compared with control | [7,59,60] |

The use of water-reducing agents has lowered the water–cement ratio, significantly improving the splitting tensile strength, while an increase in sand ratio leads to a reduction in strength. In the CG-10 group, when the dosage of water-reducing agent was increased from 1.2% to 2.3%, the 28-day strength improved from 3.6 MPa to 4.8 MPa, representing a 33% increase. The specific strength values are shown in

Figure 2. In contrast, in the CG-30 group, increasing the sand ratio from 0.4 to 0.45 caused the 28-day strength to drop sharply from 5.1 MPa to 1.84 MPa, a 64% decrease. Thus, the effects of water reducers and sand ratio on splitting tensile strength are opposite, with the sand ratio having a more significant negative impact. Therefore, mix design should optimize water reducer dosage and strictly control the sand ratio. The pozzolanic activity of blast furnace slag enhances hydration reactions, increasing the density of concrete and thereby improving both compressive and splitting tensile strength. When the slag-to-fly ash ratio is 1:2, the 28-day compressive and splitting tensile strengths increase by 72.27% and 43%, respectively [

7,

59,

60]. Studies also indicate that low-temperature environments help improve the tensile performance of coal gangue concrete, and the splitting tensile strength decreases with higher replacement rates of non-self-combustible coal gangue coarse aggregate, following a trend similar to compressive strength. The splitting tensile strength of both uncalcined and calcined coal gangue concrete generally meets the requirements of GB50010-2010 “Code for Design of Concrete Structures” [

61], except at water-to-cement ratios of 0.35 and 0.40 with a 100% coal gangue replacement rate, where the tensile strength falls below the specified values [

37,

38,

44,

53]. However, the splitting tensile strength of coal gangue concrete from different sources is relatively low, approximately 1/13 to 1/12 of the cube compressive strength, and variations in carbon content have no significant effect. This suggests that the source characteristics of coal gangue significantly influence tensile performance, and coal gangue from different sources requires optimization based on its properties [

55].

Figure 2.

Splitting tensile strength values of coal gangue aggregate concrete with different replacement amounts at 7 days and 28 days [

33,

35,

49,

53,

57,

58].

Figure 2.

Splitting tensile strength values of coal gangue aggregate concrete with different replacement amounts at 7 days and 28 days [

33,

35,

49,

53,

57,

58].

2.1.3. Flexural Strength

In the CG-50 and CG-100 groups, the flexural strength decreases with increasing coal gangue content. For example, in the CG-100 group with a water reducer dosage of 1.2%, the 7-day and 28-day flexural strengths were 5.46 MPa and 6.23 MPa, respectively, lower than other groups. This may be due to the high coal gangue content affecting the density and strength development of the concrete. The flexural strength of coal gangue-admixed concrete significantly decreases with higher replacement rates, especially at high rates (e.g., 100%), where the reduction can reach 45.3%. Additionally, increasing the water-to-cement ratio further weakens the flexural strength. For instance, when the water-to-cement ratio increases from 0.15 to 0.35, the flexural strength decreases by 42.3% [

58]. Low-temperature environments (e.g., −10 °C) exacerbate this trend, with high replacement rates leading to a 32.4% reduction in flexural strength [

53]. However, Dong [

44] found that in the CG-30 group, with a coal gangue content of 315 kg/m

3, a water-to-cement ratio of 0.41, and a water reducer dosage of 1.76%, the 7-day and 28-day flexural strengths were 6.12 MPa and 7.01 MPa, respectively. This indicates that optimizing the water-to-cement ratio and water reducer dosage can improve the flexural strength of coal gangue concrete.

2.1.4. Elastic Modulus

The elastic modulus of coal gangue concrete is significantly influenced by coal gangue content, water-to-binder ratio, and aggregate type. As shown in

Table 4, in the CG-30 group, with a coal gangue content of 334 kg/m

3, a water-to-cement ratio of 0.2, and a water reducer dosage of 1.3%, the 28-day elastic modulus was 34.4 GPa. Under the same conditions, increasing the water reducer dosage to 3.6% reduced the elastic modulus to 21.9 GPa, indicating that higher water reducer dosages may lower the elastic modulus. In the CG-50 group, the elastic modulus varied between 26.3 GPa and 28.6 GPa, showing that changes in water-to-cement ratio and water reducer dosage had a limited impact on the elastic modulus. Research indicates that the elastic modulus decreases significantly with increasing coal gangue content. For instance, when the replacement ratio increases from 0% to 100%, the elastic modulus can decrease by up to 51%. This demonstrates that high-volume coal gangue incorporation has a markedly negative effect on the elastic modulus. Higher coal-gangue contents intensify internal defects and weaken the interfacial transition zone, causing both the static and dynamic elastic moduli to decline in tandem. The dynamic modulus is derived from ultrasonic pulse velocity, and because a theoretical positive correlation exists between the two moduli (E

s ≈ k·E

d) and the dynamic test is free of plastic deformation, porosity and cracking affect both values in the same direction. Consequently, the non-destructive measurement of the dynamic modulus can rapidly and reliably track the overall trend of the elastic modulus, as illustrated in

Figure 3 and

Figure 4 [

33,

35,

37,

57]. When both fine and coarse coal gangue aggregates are used, the reduction can reach 39.9%, nearly five times that of using fine aggregate alone [

56]. Increasing the water-to-binder ratio and the low-strength characteristics of self-combustible coal gangue also weaken the elastic modulus, likely due to increased porosity in the concrete at higher water-to-binder ratios, reducing overall rigidity [

36]. However, controlling aggregate water absorption and saturation can mitigate this trend to some extent [

33,

62]. Additionally, Dong [

44] noted that the elastic modulus of coal gangue coarse aggregate concrete is generally lower than the calculated values specified in standards, and it decreases with higher coal gangue content. In summary, coal gangue-admixed concrete exhibits better elastic modulus performance at low replacement rates (<50%) and low water-to-cement ratios (<0.4), while high replacement rates and water-to-cement ratios lead to significant reductions.

Figure 3.

Elastic modulus of non-spontaneous combustion coal gangue concrete [

57].

Figure 3.

Elastic modulus of non-spontaneous combustion coal gangue concrete [

57].

Figure 4.

The impact of coal gangue fine aggregate replacement rate on elastic modulus [

35].

Figure 4.

The impact of coal gangue fine aggregate replacement rate on elastic modulus [

35].

Table 4.

The mechanical properties of concrete with coal gangue as a replacement for aggregate. Unit: kg/m3.

Table 4.

The mechanical properties of concrete with coal gangue as a replacement for aggregate. Unit: kg/m3.

| Reference | Citation | Coal Gangue (Coarse) | Crushed Stone | Coal Gangue (Fine) | Cement | Sand | Water | Water Reducer (%) | Sand Ratio | Water-to-Cement Ratio | Flexural Strength (MPa) | Splitting Tensile Strength (MPa) | Elastic Modulus |

|---|

| 7 d | 28 d | 3 d | 7 d | 28 d | 28 d |

|---|

| CG-10 | [35] | 0 | 1190 | 64.2 | 376 | 577.8 | 169 | 1.2 | 0.3 | 0.4 | - | - | 2.6 | 3.0 | 3.6 | - |

| | | 0 | 1182 | 60.8 | 422 | 547.2 | 164 | 2.3 | 0.3 | 0.4 | - | - | 4.3 | 4.2 | 4.8 | - |

| | [49] | 0 | 1190 | 69.5 | 325 | 625.5 | 180 | 1.6 | 0.3 | 0.4 | 7.3 | 8.4 | - | 2.26 | 3.60 | - |

| | | 0 | 1210 | 59.0 | 406 | 531.0 | 185 | 1.5 | 0.3 | 0.4 | - | - | - | 2.80 | 3.73 | - |

| | | 0 | 1200 | 51.5 | 487 | 463.5 | 180 | 1.6 | 0.3 | 0.4 | - | - | - | 3.01 | 4.23 | - |

| CG-20 | [53] | 218.0 | 871 | 0 | 384 | 728 | 154 | - | 0.4 | 0.4 | 6.27 | 7.12 | 3.3 | 4.6 | 6.7 | - |

| | [49] | 0 | 1190 | 139 | 325 | 556 | 180 | 1.6 | 0.3 | 0.4 | - | - | - | 2.21 | 3.34 | - |

| | | 0 | 1210 | 118 | 406 | 472 | 185 | 1.5 | 0.3 | 0.4 | - | - | - | 2.70 | 3.84 | - |

| | | 0 | 1200 | 103 | 487 | 412 | 180 | 1.6 | 0.2 | 0.4 | - | - | - | 2.98 | 4.31 | - |

| CG-30 | [57] | 334.0 | 676.0 | 0 | 368 | 628.0 | 195 | 1.30 | 0.4 | 0.2 | - | - | 4.9 | 4.8 | 5.1 | 34.4 |

| | [33] | 338.5 | 789.9 | 0 | 450 | 634.7 | 200 | 3.60 | 0.40 | 0.40 | - | - | - | 2.71 | 3.68 | 21.9 |

| | [58] | 315.0 | 732.5 | 0 | 352 | 855.0 | 145 | 1.76 | 0.45 | 0.41 | 6.12 | 7.01 | 1.62 | 2.03 | 1.84 | - |

| | [49] | 0 | 1190 | 208.5 | 325 | 486.5 | 180 | 1.6 | 0.3 | 0.4 | - | - | - | 2.11 | 3.03 | - |

| | | 0 | 1210 | 177 | 406 | 413 | 185 | 1.5 | 0.2 | 0.4 | - | - | - | 2.65 | 3.62 | - |

| | | 0 | 1200 | 154.5 | 487 | 360.5 | 180 | 1.6 | 0.2 | 0.4 | - | - | - | 2.86 | 4.10 | - |

| CG-50 | [57] | 552.0 | 749 | 0 | 368 | 621.0 | 195 | 1.30 | 0.30 | 0.2 | - | - | 4.3 | 4.3 | 4.2 | 26.3 |

| | | 552.0 | 749 | 0 | 390 | 621 | 195 | 1.3 | 0.3 | 0.2 | - | - | 4.9 | 5.0 | 5.1 | 26.8 |

| | | 552.0 | 749 | 0 | 346 | 621 | 195 | 1.3 | 0.3 | 0.2 | - | - | 4.4 | 4.3 | 4.2 | 25.4 |

| | | 518.0 | 679 | 0 | 557 | 583 | 195 | 1.7 | 0.3 | 0.2 | - | - | 4.6 | 4.5 | 4.5 | 26.7 |

| | | 573.0 | 769 | 0 | 354 | 645 | 195 | 1.1 | 0.3 | 0.2 | - | - | 4.6 | 4.6 | 5.2 | 28.6 |

| | [33] | 556.7 | 556.7 | 0 | 450 | 626.2 | 210 | 3.60 | 0.40 | 0.40 | 5.93 | 6.65 | - | 2.82 | 3.98 | 22.4 |

| | [58] | 510.0 | 510.0 | 0 | 395 | 835.0 | 150 | 2.37 | 0.45 | 0.38 | - | - | 1.91 | 1.79 | 1.90 | - |

| | | 485.0 | 485.0 | 0 | 500 | 792.5 | 140 | 5.00 | 0.45 | 0.28 | - | - | 1.45 | 2.30 | 2.21 | - |

| CG-100 | [35] | 0 | 1190 | 321 | 376 | 321 | 169 | 1.2 | 0.2 | 0.4 | 5.46 | 6.23 | 2.4 | 2.7 | 3.0 | - |

| | | 0 | 1182 | 304 | 422 | 304 | 164 | 2.3 | 0.2 | 0.4 | 5.78 | 6.55 | 2.7 | 3.1 | 3.5 | - |

| | [49] | 0 | 1190 | 347.5 | 325 | 347.5 | 180 | 1.6 | 0.2 | 0.4 | - | - | 1.62 | 1.73 | 2.53 | - |

| | | 0 | 1210 | 295 | 406 | 295 | 185 | 1.5 | 0.2 | 0.4 | - | - | 1.98 | 2.05 | 2.78 | - |

| | | 0 | 1200 | 257.5 | 487 | 257.5 | 180 | 1.6 | 0.2 | 0.4 | - | - | 2.01 | 2.24 | 3.08 | - |

2.2. Durability Performance

2.2.1. Chloride Ion Penetration Resistance

Studies show that the chloride ion diffusion coefficient of coal gangue aggregate concrete decreases over time. At 28 and 56 days, the chloride ion diffusion coefficient of concrete with 20% coal gangue fine aggregate is lower than that of natural fine aggregate concrete. However, concrete with 30% coal gangue coarse aggregate exhibits a higher chloride ion diffusion coefficient due to its higher porosity [

34]. Research by Ma and Wang et al. [

39,

63] indicates that the chloride ion penetration resistance of coal gangue concrete can be significantly improved by optimizing the replacement rate and mix proportions, as shown in

Figure 5. Specifically, a low water-to-binder ratio and an appropriate replacement rate of calcined coal gangue (45% to 70%) can enhance chloride ion penetration resistance, but excessive replacement rates may weaken this effect. For example, at a water-to-cement ratio of 0.5, a calcined coal gangue replacement rate of less than 45% performs better, while at water-to-cement ratios of 0.35 to 0.45, a replacement rate of less than 70% yields the best performance. Additionally, chloride ion penetration resistance improves with curing age, transitioning from “moderate” to “low” at 90 days.

Figure 5.

Coulomb charge values passed in 6 h for calcined coal gangue-crushed stone coarse aggregate concrete measured by rapid chloride ion penetration test [

39].

Figure 5.

Coulomb charge values passed in 6 h for calcined coal gangue-crushed stone coarse aggregate concrete measured by rapid chloride ion penetration test [

39].

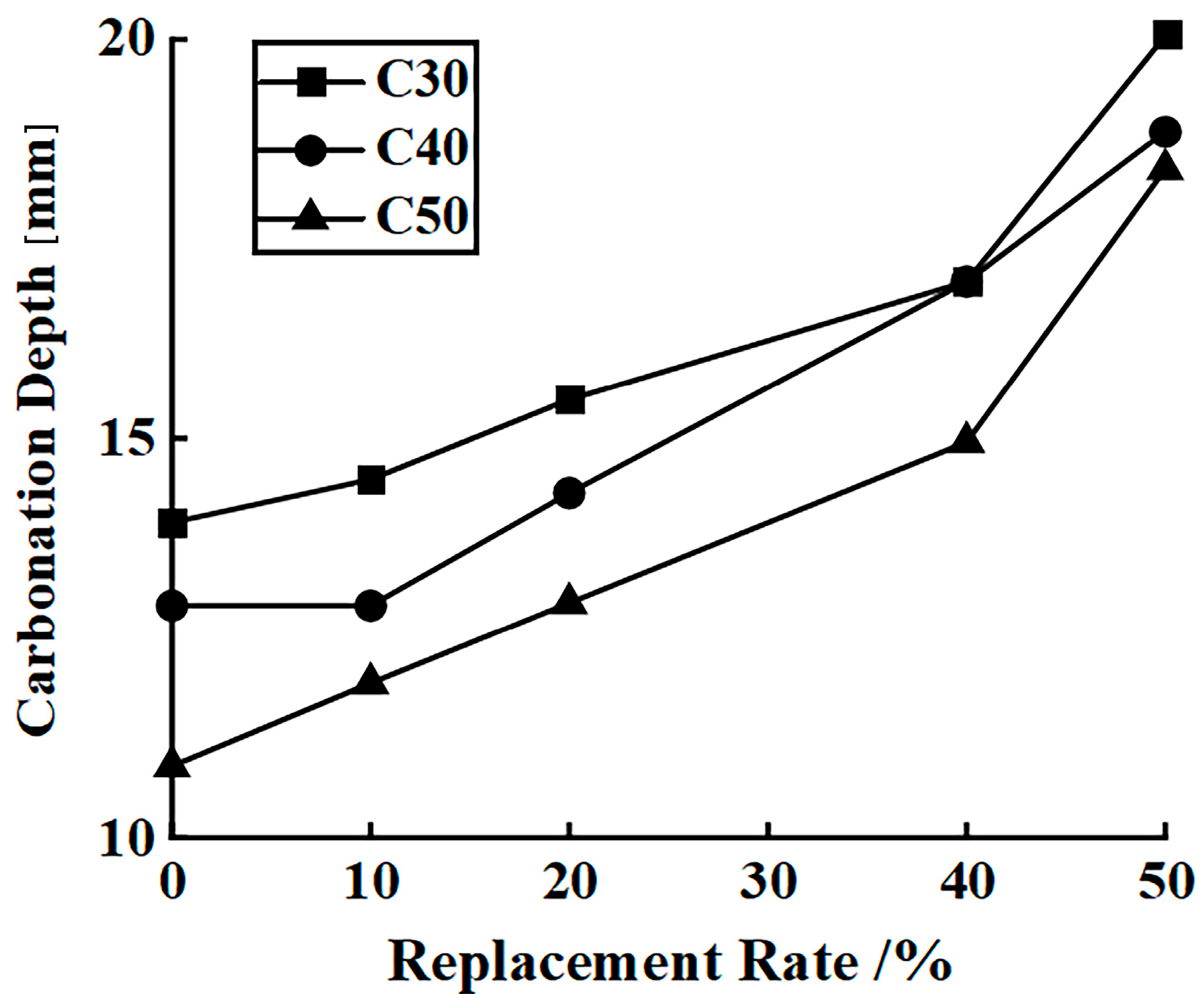

2.2.2. Carbonation Resistance

As a porous material containing interconnected pores of varying sizes [

30], concrete exhibits significantly reduced carbonation resistance when incorporating coal gangue, with carbonation depth showing a linear increase relative to gangue content [

44]. Experimental data demonstrates that at a 0.45 water–cement ratio, concrete containing either raw or calcined coal gangue coarse aggregates develops 1.1–1.37 times greater carbonation depth compared to natural aggregate concrete, with this differential progressively worsening as replacement rates increase from 30% to 100%. While the carbonation depth difference remains negligible (<0.2 mm) between natural fine aggregate concrete and 20% gangue replacement mixtures at 28 days, it becomes substantially more pronounced at 50% replacement [

34]. Wang et al. [

35] further quantified this relationship, showing 10.71–18.18% greater carbonation depth at 20% replacement that further escalates at 50% replacement (

Figure 6). Research consistently indicates that lower water–cement ratios (particularly ≤0.35) enhance carbonation resistance, with calcined gangue demonstrating superior performance to raw gangue at replacement rates below 40%. However, this calcination advantage becomes less significant at higher water–cement ratios (>0.35) [

39,

64,

65]. These findings collectively suggest that optimal carbonation resistance in gangue-modified concrete can be achieved through a combination of low water–cement ratios (≤0.35), moderate replacement rates (<40%), and proper calcination pretreatment of the coal gangue.

Figure 6.

The impact of coal gangue fine aggregate replacement rate on carbonation depth [

35].

Figure 6.

The impact of coal gangue fine aggregate replacement rate on carbonation depth [

35].

2.2.3. Sulfate Attack Resistance

Research indicates that high water-to-binder ratios reduce the compressive strength and corrosion resistance of concrete, and performance loss initially decreases and then increases with prolonged exposure to sulfate attack and the variation in mass loss rate is presented in

Figure 7 [

57], and the test variables were the water-to-binder ratio, the replacement ratio of non-spontaneously-combusted coal-gangue coarse aggregate, and the fly-ash replacement ratio. For example, W0.45H30F15 denotes the reference concrete with a water-to-binder ratio of 0.45, 30% of the coarse aggregate replaced by coal gangue, and 15% fly ash by mass of the binder. Additionally, higher coal gangue content leads to a sharp decline in the corrosion resistance coefficient after 15 wet-dry cycles, followed by a gradual stabilization. Natural crushed stone concrete can withstand 150 wet-dry cycles with a corrosion resistance coefficient greater than 0.75, but this decreases to 100 and 70 cycles at 30% and 50% replacement rates, respectively. Calcination does not significantly improve sulfate attack resistance. At a 45% coal gangue replacement rate, concrete exhibits the lowest electrical charge and strongest chloride ion penetration resistance, with low water-to-binder ratios further enhancing this performance [

39,

46]. Wang et al. [

38] also studied the effects of a 45% coal gangue replacement rate, finding minimal compressive strength loss (12.19%) under sulfate attack, whereas at a 0% replacement rate, compressive strength increased after 240 days of exposure. Furthermore, the addition of slag optimizes freeze–thaw and sulfate attack resistance, but high replacement rates (e.g., over 40%) may increase carbonation depth [

66,

67,

68]. In summary, low water-to-binder ratios and a 45% coal gangue replacement rate are key to improving sulfate attack resistance, while calcination has limited benefits.

Figure 7.

Sulfate erosion days and mass loss rate of concrete under different replacement rates of non-spontaneous combustion coal gangue coarse aggregate [

57].

Figure 7.

Sulfate erosion days and mass loss rate of concrete under different replacement rates of non-spontaneous combustion coal gangue coarse aggregate [

57].

2.2.4. Freeze–Thaw Resistance

High water-to-cement ratios (e.g., 65%) significantly reduce the freeze–thaw resistance of coal gangue concrete, with durability indices and mass loss rates being inferior to those of concrete with low water-to-cement ratios (e.g., 45%) [

69]. Higher coal gangue content worsens freeze–thaw resistance, with greater mass loss rates and reductions in dynamic elastic modulus, especially at replacement rates exceeding 60% [

43,

46]. Additionally, replacing crushed stone with coal gangue ceramsite weakens freeze–thaw resistance, but at replacement rates below 60%, the dynamic elastic modulus remains stable. Moreover, the influence of coal gangue fine aggregate replacement ratio on the relative dynamic elastic modulus of concrete after freeze–thaw cycles is illustrated in

Figure 8. Sand ratio also affects freeze–thaw resistance, with excessively high or low sand ratios reducing performance [

38,

45,

70,

71]. In contrast, calcined coal gangue (SCGA) exhibits better freeze–thaw resistance than uncalcined coal gangue (RCGA), and surface modification further enhances this advantage [

52,

72,

73,

74]. Therefore, low water-to-cement ratios, moderate coal gangue replacement rates (<60%), and optimized sand ratios are critical for improving freeze–thaw resistance, while calcination and surface modification effectively enhance performance.

Figure 8.

The impact of coal gangue fine aggregate replacement rate on relative dynamic modulus of elasticity of concrete after freeze–thaw cycles [

35].

Figure 8.

The impact of coal gangue fine aggregate replacement rate on relative dynamic modulus of elasticity of concrete after freeze–thaw cycles [

35].

5. Discussion

In summary, concrete incorporating calcined coal gangue exhibits higher compressive strength. However, its long-term freeze–thaw resistance is inferior to that of concrete containing natural coal gangue. This is primarily due to the higher water absorption of calcined coal gangue compared to natural coal gangue. As the content of calcined coal gangue increases, the cumulative water absorption of concrete rises, leading to greater frost pressure in the same volume of concrete specimens. In salt-freeze environments, the water and chloride salt absorption characteristics of calcined coal gangue expand the concentration gradient of the solution in concrete capillaries, increasing water saturation. The pressure generated by frost formation is more damaging than that caused by water freezing [

113].

The addition of calcined coal gangue densifies the interfacial transition zone (ITZ) between coarse aggregates and mortar. However, because calcined coal gangue is more porous than raw coal gangue, its increased content raises the chloride ion diffusion coefficient, as shown in the SEM images below. Among the hydration products, calcium hydroxide (CH) and aluminates (Al) are most susceptible to sulfate attack, forming gypsum or ettringite, which causes expansion and cracking [

140]. Alkali-activated coal gangue-slag cementitious concrete (AACGS) immersed in 5% Na

2SO

4 solution for 90 days shows a compressive strength change rate of less than 5%, with most specimens exhibiting strength gain. In contrast, Rodríguez et al. [

141] found that ordinary Portland cement (OPC) concrete under the same conditions experiences a 43% strength loss and six times the volume expansion of alkali-activated slag concrete.

Additionally, the effects of sodium sulfate solution on alkali-activated coal gangue-slag cementitious material concrete are manifested in four aspects: Firstly, sodium sulfate can act as an alkali activator for coal gangue and slag. During soaking, the unreacted solid particles in coal gangue and slag are further alkali-activated. Moreover, sulfates accelerate the transformation of N-A-S-H gel into zeolite and promote the crystallization of zeolite [

142]. Then, in alkali-activated coal gangue-slag cementitious material concrete, Na

2SO

4 crystallizes and expands, generating crystallization pressure. Thirdly, the N-A-S-H gel and C-(A)-S-H gel in alkali-activated coal gangue-slag cementitious material paste undergo disintegration and recombination during solidification, leading to the formation of microcracks within the concrete. Sulfates react with the reactive Al

2O

3 in coal gangue to form ettringite, which expands upon hydration and fills the microcracks [

143]. Lastly, the expansion of ettringite or the generation of crystallization pressure can create new microcracks, exacerbating internal damage. In summary, as slag content increases, the amount of unreacted powder particles in AACGS decreases, and the Ca content in the system rises, leading to increased ettringite formation and additional adverse effects. As shown in

Figure 19, after 90 days of immersion in Na

2SO

4 solution, the C-(A)-S-H and N-A-S-H structures in AACGS remain largely intact, with minimal harmful ettringite and gypsum. SEM images show only a small amount of needle-like calcium sulfate (AFt). The low-calcium environment effectively inhibits AFt formation, enhancing the resistance of AACGS to Na

2SO

4 [

113].

Figure 19.

SEM photos of sulfate attack 90 d AACGS concrete [

113].

Figure 19.

SEM photos of sulfate attack 90 d AACGS concrete [

113].

As the water-to-binder ratio (W/B) increases, the compressive strength growth rate of concrete under 120 days of sulfate attack rises. Higher W/B ratios facilitate Na

2SO

4 penetration, promoting the formation of ettringite and gypsum, which significantly increases compressive strength. However, after 120 or 180 days of sulfate attack, compressive strength begins to decline due to the expansion of ettringite hydration products [

144]. When the content of non-self-combustible coal gangue (NCCG) coarse aggregate increases, the compressive strength of concrete after 240 days of sulfate attack shows an “initial increase followed by a decrease,” peaking at 30% replacement. This is primarily due to the high crushing value, strong water absorption, and high internal porosity of coal gangue, which reduce density and allow easier Na

2SO

4 penetration, leading to rapid compressive strength loss from extensive ettringite formation. Single incorporation of fly ash or slag exhibits poor sulfate attack resistance, with compressive strength losses of 2.18% and 0.06%, respectively, after 240 days of sulfate attack. Composite fly ash-slag concrete shows improved sulfate attack resistance, as the different surface areas and morphologies of fly ash and slag fill internal voids, enhancing density.

Figure 20 shows SEM images of high-performance coal gangue coarse aggregate concrete after sulfate attack. After 240 days, needle-like and granular calcium sulfoaluminate hydrates are observed, with

Figure 20d,f clearly showing extensive calcium sulfoaluminate hydrates on the surface of coal gangue coarse aggregates [

38].

Figure 20.

SEM photo of NCCG coarse-aggregate high-performance concrete after sulfate attack [

38].

Figure 20.

SEM photo of NCCG coarse-aggregate high-performance concrete after sulfate attack [

38].

The study concludes that the water-to-binder ratio (W/B) has the greatest impact on concrete carbonation. Higher W/B ratios increase the number of internal pores in coal gangue high-performance concrete, providing more channels for CO

2 diffusion. As carbonation age increases, the internal density of coal gangue coarse aggregate concrete improves, and the reaction of CO

2 with surface Ca(OH)

2 forms calcium carbonate, further hindering CO

2 penetration [

145]. Wang et al. [

38] found that during the initial carbonation stage, the surface cement mortar layers of all samples were similar, allowing CO

2 to penetrate at the same rate. In later stages, the layered structure of coal gangue aggregates, with numerous microcracks and pores, facilitates CO

2 diffusion and reaction with hydration products, leading to greater carbonation depth with higher coal gangue replacement rates. Adding fly ash alone reduces the Ca(OH)

2 content in mortar, which is detrimental to resisting CO

2 ingress and leads to increased carbonation depth. Composite incorporation of slag reduces carbonation depth, related to Ca(OH)

2 content in mortar. Coating coal gangue coarse aggregates with silica fume reduces carbonation depth, with lower water-to-silica ratios resulting in smaller carbonation depths.