Stress and Deformation Control of Active Pile Foundation of Tunnel Underpass Bridge Based on Field Monitoring

Abstract

1. Introduction

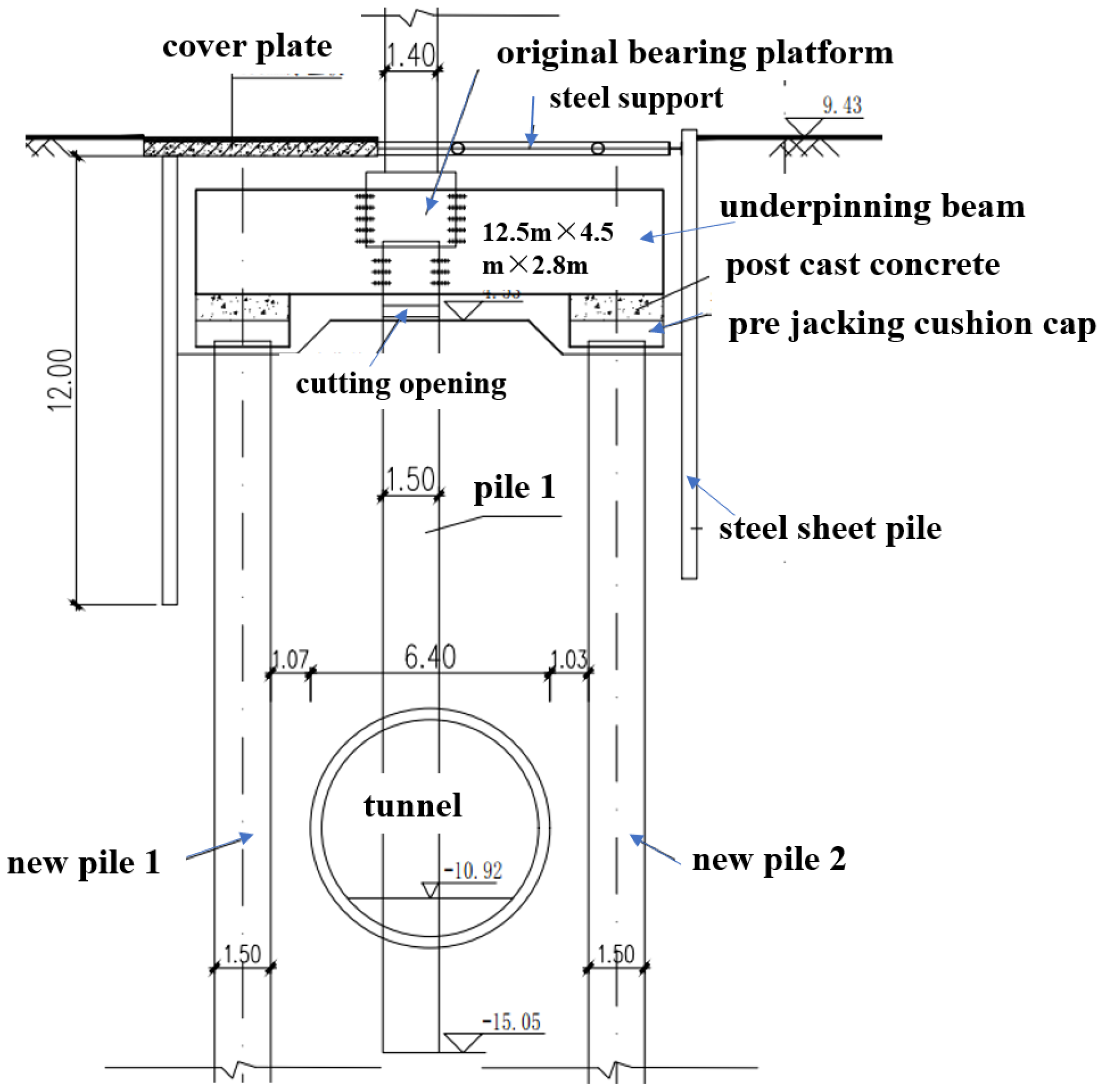

2. Project Overview

3. Scheme and Construction of Tunnel Underpass Bridge Pile

3.1. Design Scheme of Underpass Bridge Pile

- (1)

- The underpinning foundation pit is supported by Larsen IV steel sheet piles with ∅325 × 10 steel pipe struts; local concrete slabs are installed to maintain traffic flow during construction.

- (2)

- The underpinning beams and caps are constructed using C40 concrete, the post-cast closure segment uses C40 micro-expansion concrete, and a 200 mm-thick C20 concrete cushion is placed beneath the underpinning elements.

- (3)

- The underpinning piles are cast using C35 underwater concrete, with lengths determined by site conditions. If karst features are encountered, piles shall be embedded 1.0 m into slightly weathered bedrock below the cave, ensuring a minimum of 5 m of intact rock beneath the pile tip.

- (4)

- During shield tunneling, strict control of face pressure, enhanced synchronous and secondary grouting, and continuous structural monitoring are required to ensure bridge safety.

3.2. Underpinning Construction

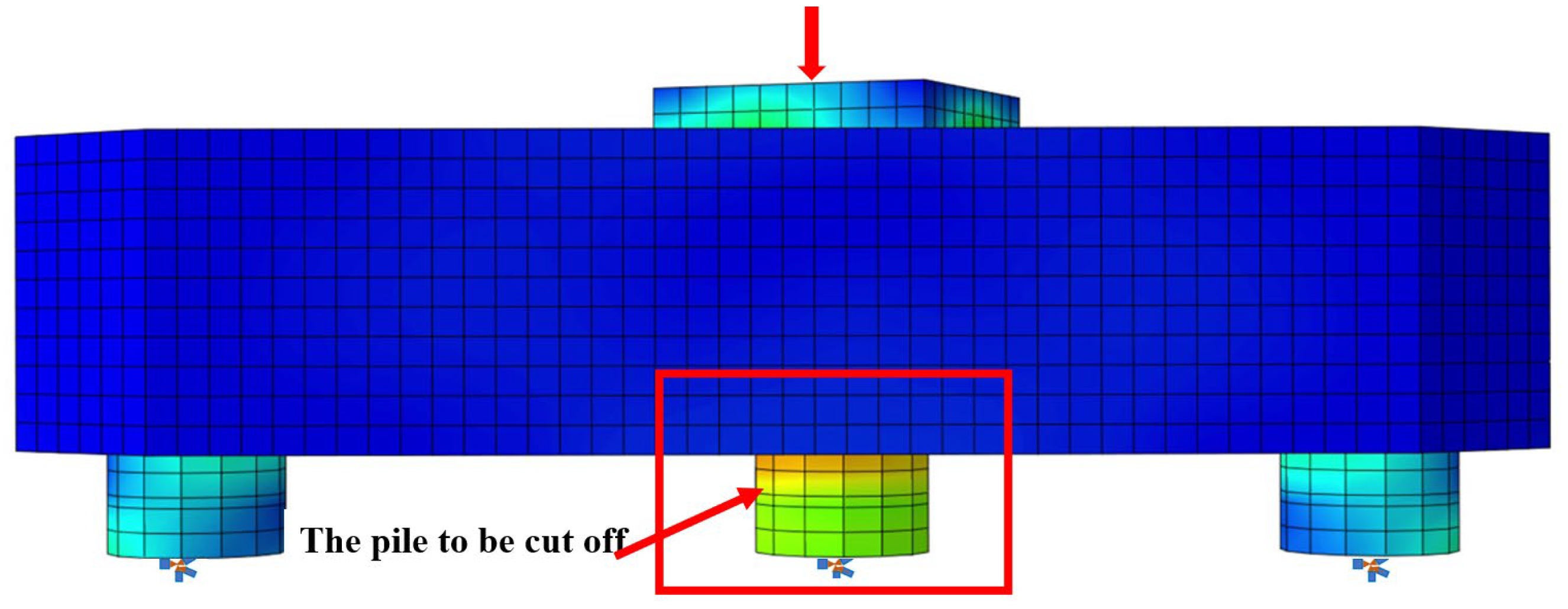

4. Establishment of Numerical Simulation Model

5. Comparison of Calculation Results with Monitoring Data

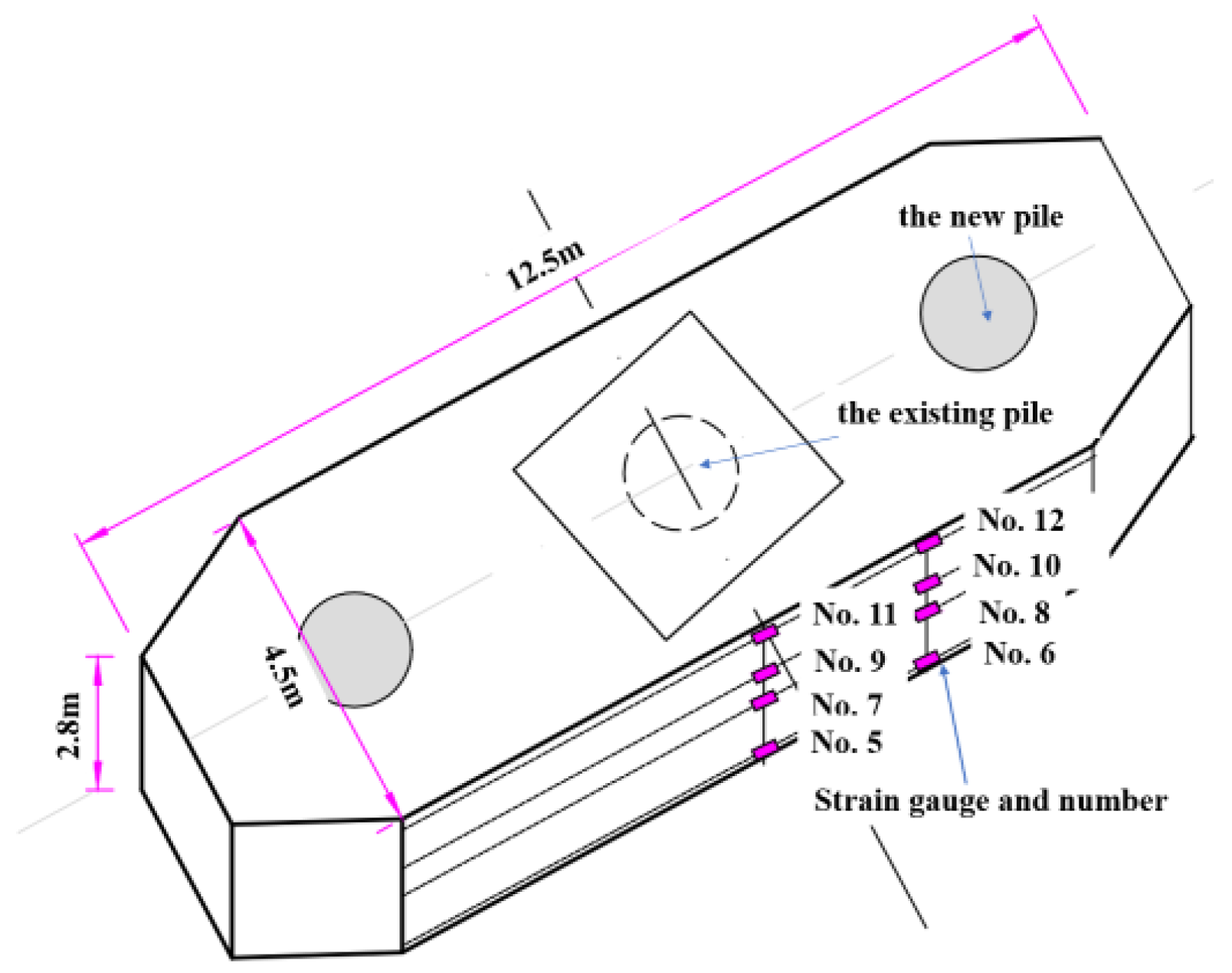

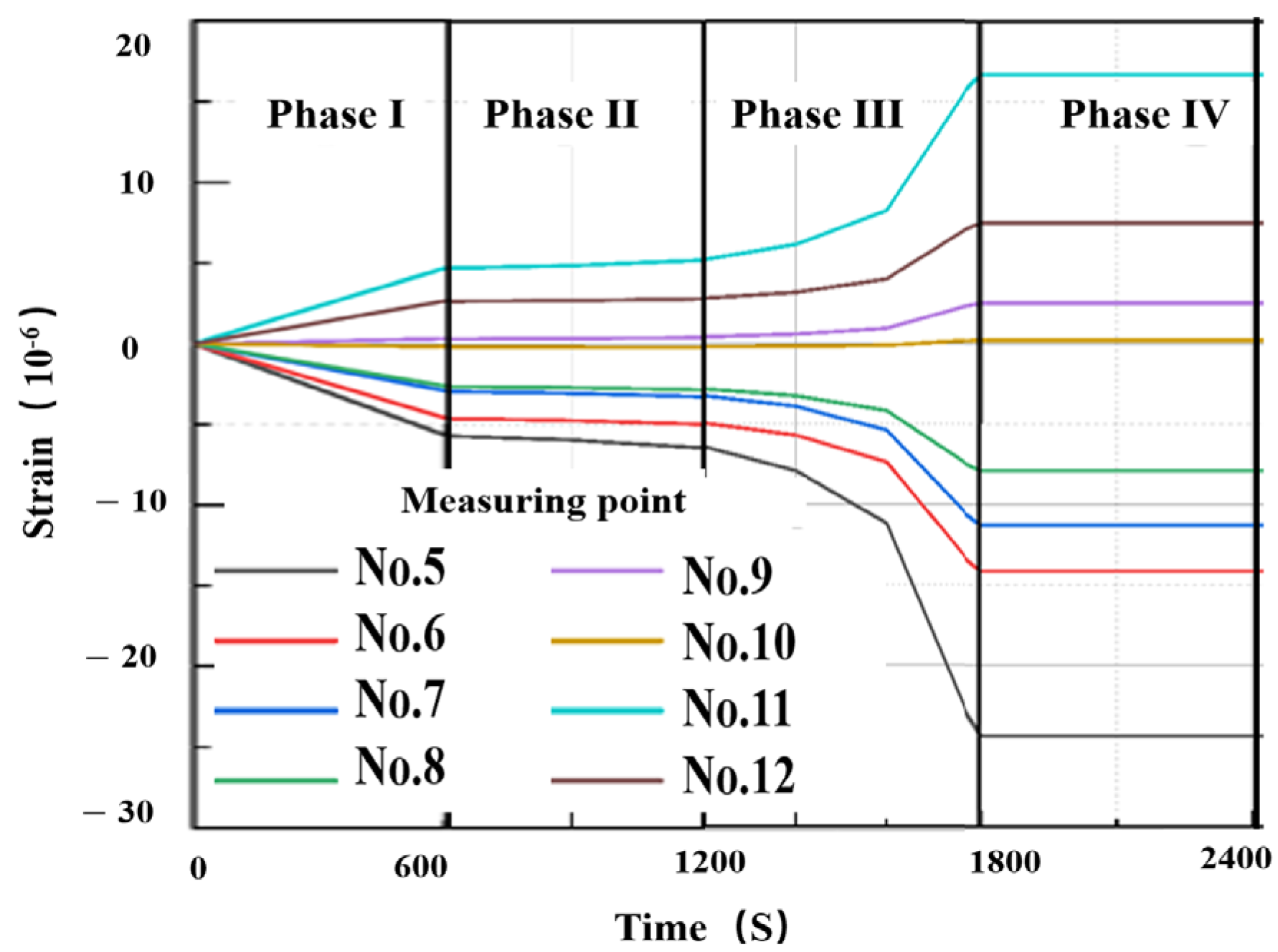

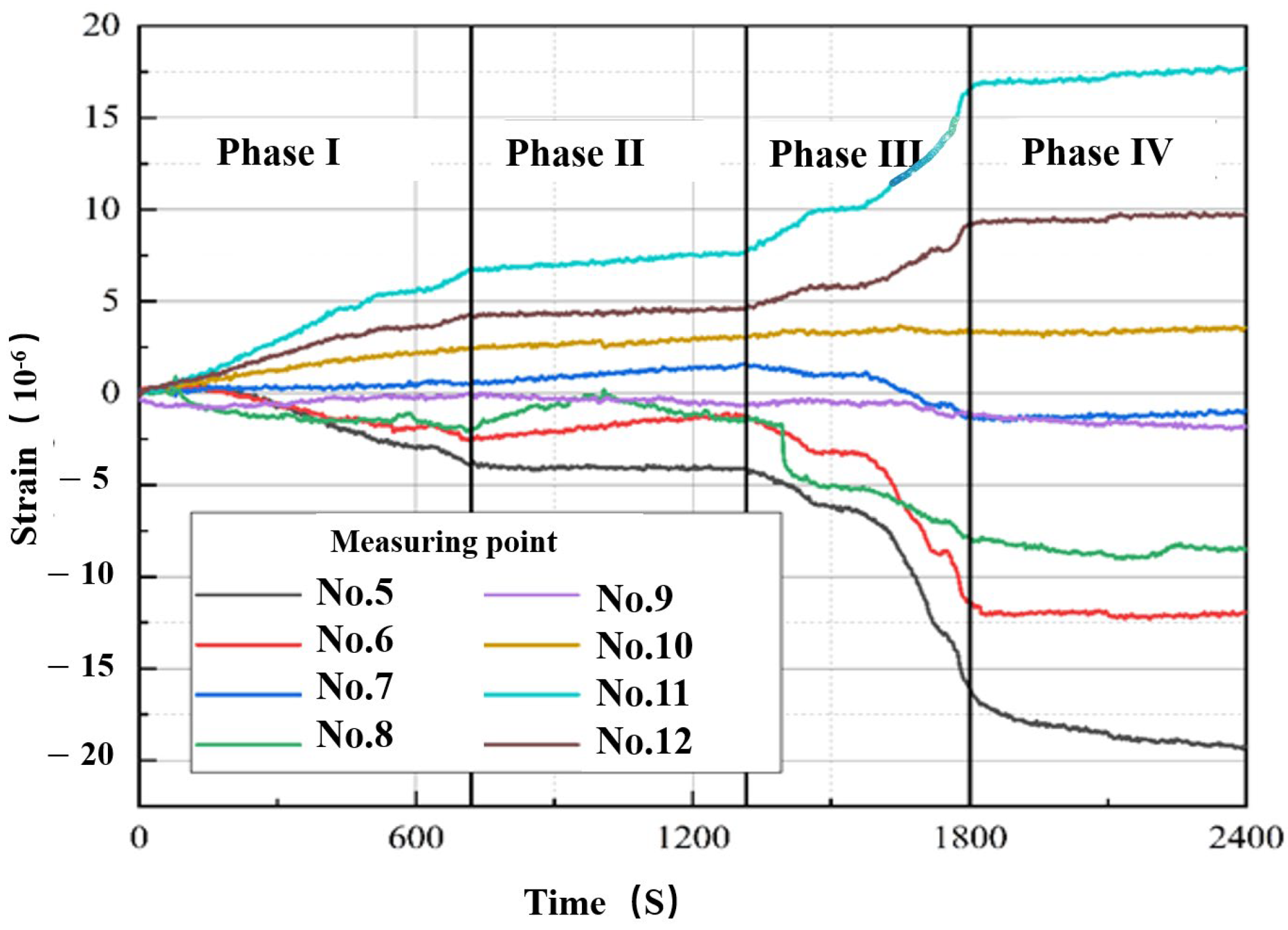

5.1. Strain Analysis

5.1.1. Finite Element Calculation

5.1.2. Comparison of Calculated and Measured Data

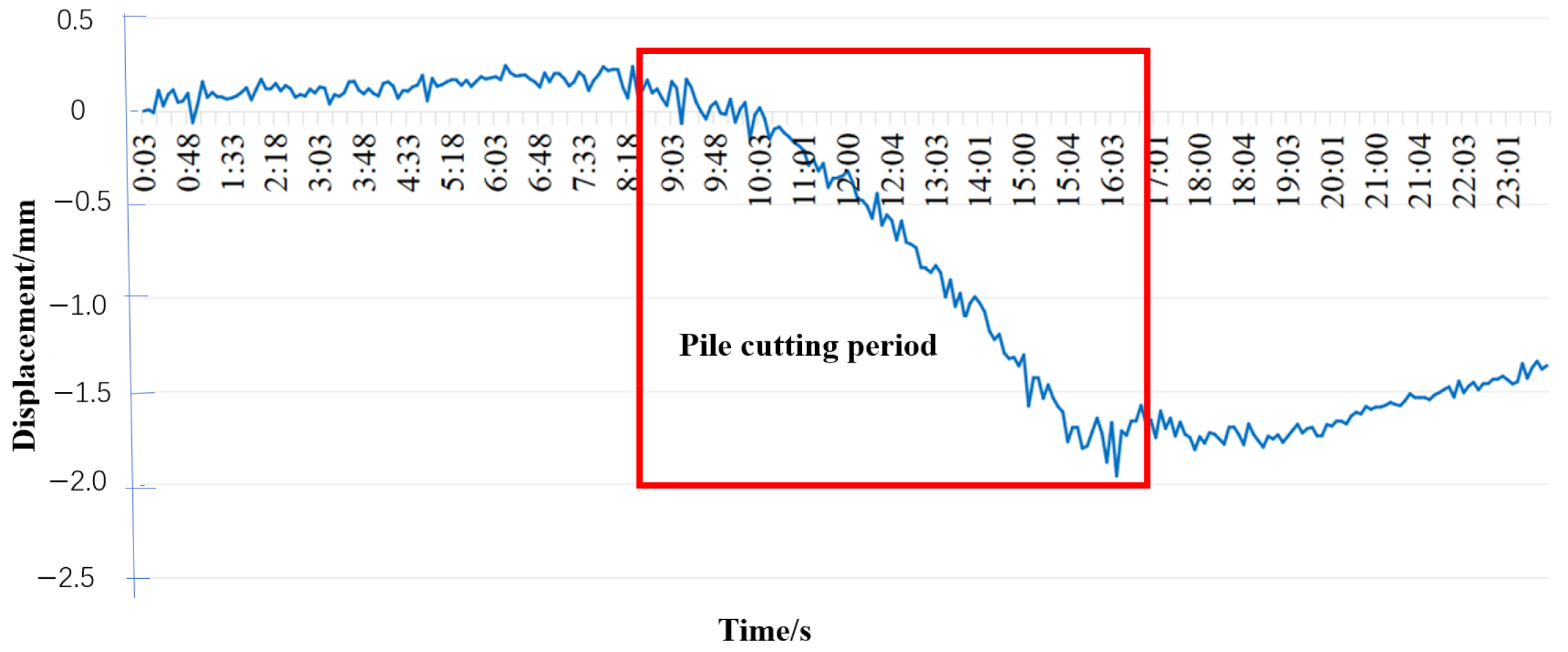

5.2. Settlement Analysis

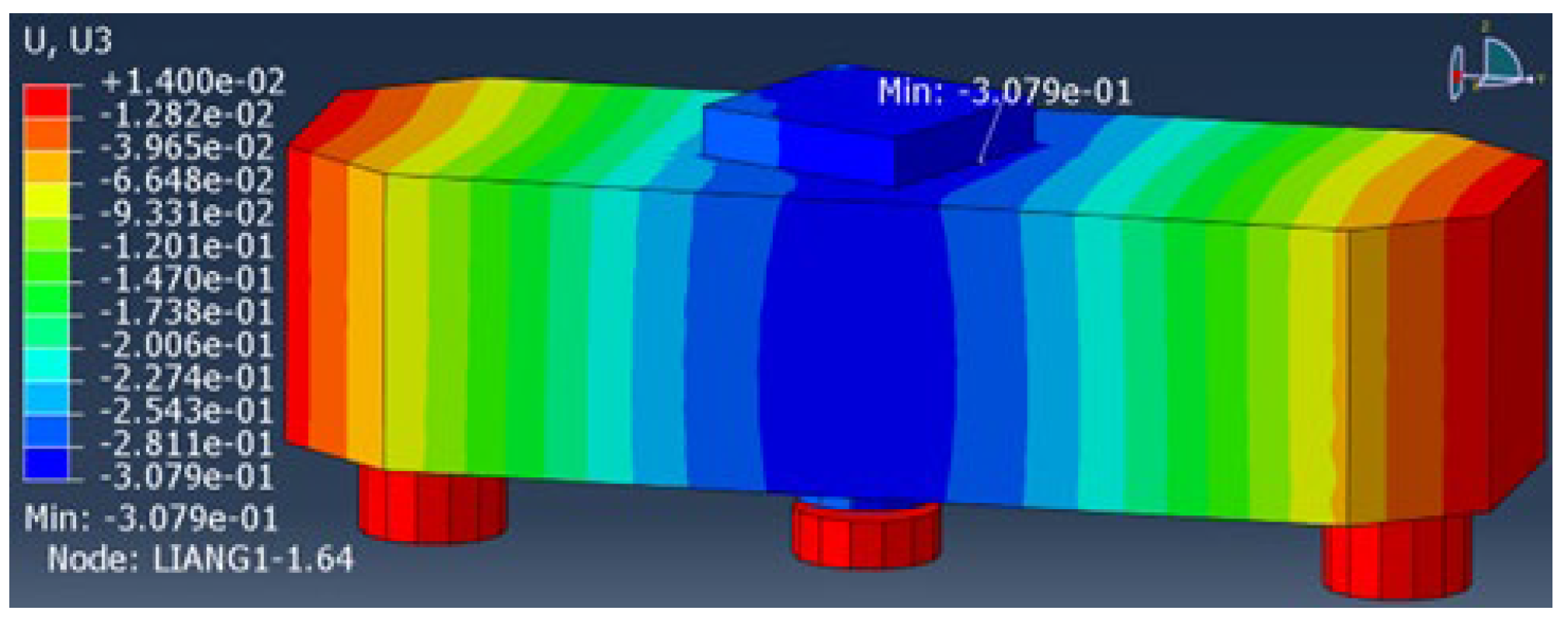

5.2.1. Vertical Deformation Calculation

5.2.2. Calculation and Measurement Comparison

6. Discussion

6.1. Displacement Control Value of Superstructure

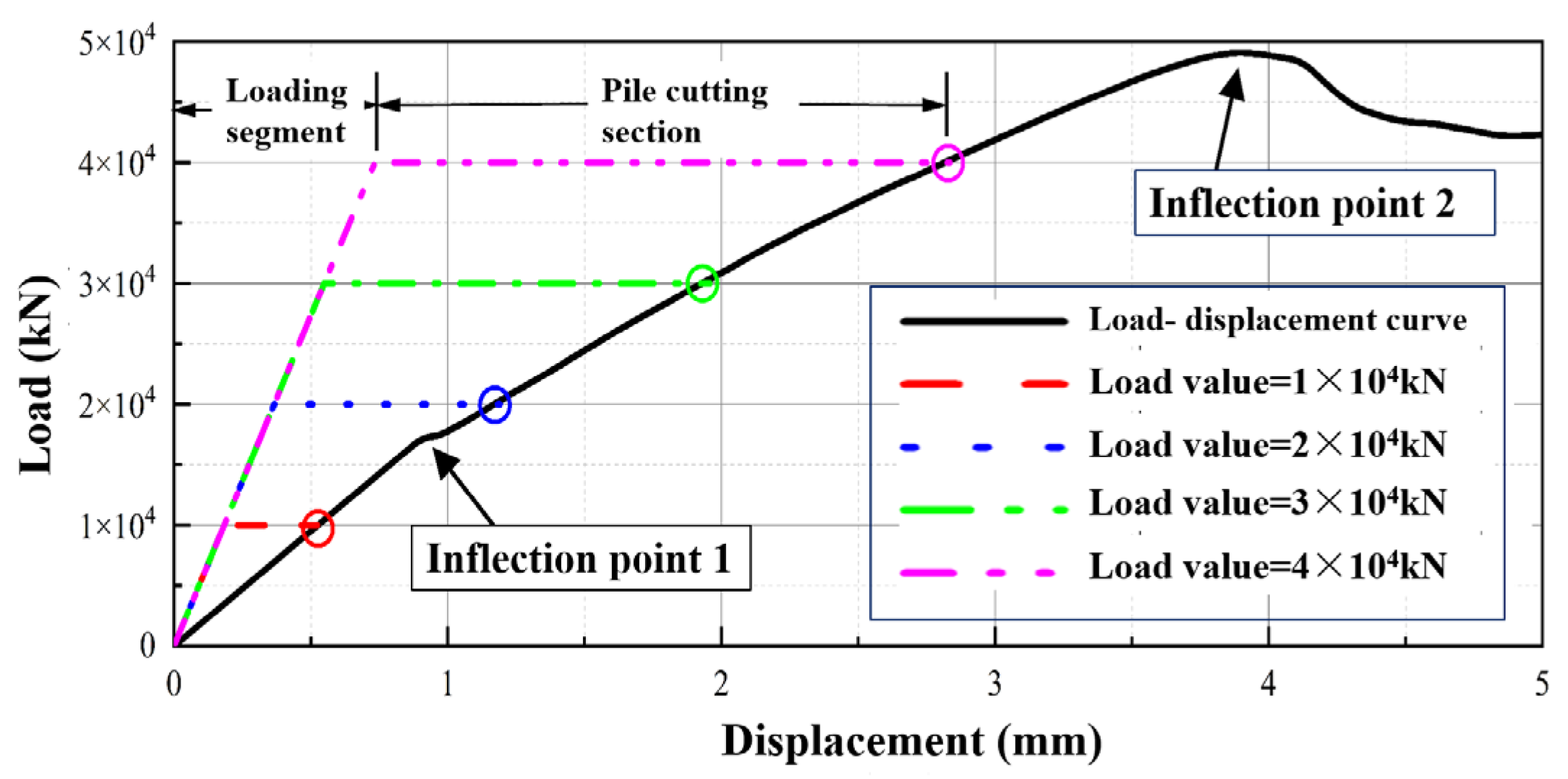

6.2. Determination of Jacking Force

7. Conclusions

- (1)

- Aiming at the technical challenge of tunnel undercrossing bridges in complex geological conditions, a reasonable active pile foundation underpinning design scheme was proposed, considering terrain constraints and the requirement of uninterrupted bridge operation. The fundamental construction process was established. A three-dimensional numerical model simulating the active underpinning process was developed, and its validity was verified by comparing the computational results with experimental data.

- (2)

- Comparative analysis of strain data between numerical simulations and field measurements reveals a high degree of consistency. The strain evolution during pile cutting exhibits a characteristic pattern: “rapid initial change, followed by deceleration, then acceleration, and finally rapid stabilization”. Notably, after the fourth stage, the measured strain at No. 5 monitoring point (19.5 × 10−6) deviates from the computed value (24.3 × 10−6), with the measured value being approximately 80% of the numerical prediction.

- (3)

- Comparison between numerical predictions and static leveling measurements indicates that the maximum relative settlement at the pier base is less than 1 mm, which is consistent with the finite element calculation results. The pile cutting leads to inconsistency between the deformation of the underpinning beam and the settlement of the bridge, with the settlement variation of the bridge being relatively slow.

- (4)

- Taking into account the traffic conditions of the bridge and the requirements for additional stress, it is reasonable to recommend that the actual settlement of the active pile foundation underpinning of the bridge be 2–3 mm. The jacking force should generally be determined with two criteria. It should be greater than the load transferred from the pier column to the underpinning beam. It should also be less than 75% of the maximum bearing capacity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peng, F.; Qiao, Y.; Dong, Y.; Run, Z.; Zhu, H. Development Strategy for Urban Underground Space in the New Development Stage. China Eng. Sci. 2024, 26, 176–185. [Google Scholar]

- Wang, W.; Yao, J.; Yue, J.; Lan, W. Key techniques and application of underground space development under neath heritage buildings in soft soil. J. Build. Struct. 2023, 44, 92–99. [Google Scholar]

- Chen, J.; Shang, H.; Xu, S. Comparative Analysis and Research on the Construction Scheme of the Entrance and Exit line of Yuzhu Depot Passing under Building Complex. Mod. Tunneling Technol. 2022, 59 (Suppl. S1), 776–782. [Google Scholar]

- Zhang, T.; Hu, C.; Zhou, S.; Wei, J.; Wang, Q. Key technology of pile foundation underpinning design for BRT bridge under tunnel. Highway 2022, 67, 43–50. [Google Scholar]

- Liang, Y.; Zhai, L.; Shi, H. Research and Application of Arch-shaped Pile Foundation Underpinning in Tunnel with Large Axial Force and Span of Metro Construction. Tunn. Constr. 2020, 40, 1765. [Google Scholar]

- Huang, S.; Liu, J.; Tian, W. Research on Underpinning and Deformation Control of Pile Foundation in Tunnel under Bridge. J. Railw. Eng. Soc. 2023, 40, 9–14. [Google Scholar]

- Sheng, H.; Li, H.; Gu, X.; Jin, W. Researches on the mechanical properties and deformation characteristics of the temporary support system of pile foundation underpinning. Build. Struct. 2021, 51 (Suppl. S2), 1545–1550. [Google Scholar]

- Chen, X.; Zhang, X.; Zhao, Y.; Liu, J.; Yu, W.; Zhou, X.; Dong, Z. Study on the influence of the in-tunnel underpinning construction of the subway tunnel in the soft ground on the pile foundation. J. Railw. Sci. Eng. 2021, 18, 3294–3302. [Google Scholar]

- Zhang, P.; Sun, G.; Liu, H.; Yuan, W. Research on mechanical behavior and deformation law of pile foundation underpinning of special shaped slab bridge. Chin. J. Appl. Mech. 2024, 41, 843–852. [Google Scholar]

- Lv, W. Model test and numerical simulation of under pinning pile foundation in saturated loess arca. Railw. Eng. 2022, 62, 94–97. [Google Scholar]

- Li, H.; Wang, C. Simulation Evaluation Method for Reinforcement Effect of Active Underpinning of Tunnel Pile Foundation. Comput. Simul. 2021, 38, 188–192. [Google Scholar]

- Yang, Z.; Duan, J.; Guo, Q.; Yan, Y. Deformation Monitoring Analysis of Pile Foundation Underpinning of Irregular Widening Continuous Beam. Urban Mass Transit 2022, 25, 106–111. [Google Scholar]

- Zang, Y.; Liu, C.; Yan, J.; Yu, J.; Yu, T.; Zhu, H.; Ding, P.; Zhu, J.; Xu, R. Study on the influence and control methods of shield tunneling through the existing buildings. Build. Struct. 2023, 53 (Suppl. S1), 2960–2964. [Google Scholar]

- Lin, L. Stress System Transform of Operational BRT Viaduct Piles Underpinned by Cast-in-Situ Tunnel Structure of Xiamen 2nd East Passage. Tunn. Constr. 2023, 43, 1896. [Google Scholar]

- Li, S. Abaqus Finite Element Analysis: From Entry to Mastery (2022 Edition); China Machine Press: Beijing, China, 2022. [Google Scholar]

- Liu, L.; Xiao, X. Research on deformation control technology of shield tunnel penetrating existing railway. Low Temp. Build. Technol. 2023, 45, 109–112. [Google Scholar]

- JTG 3363—2019; The Ministry of Transport of the People’s Republic of China. Specifications for Design of Foundation of Highway Bridges and Culverts. China Communications Press: Beijing, China, 2019.

- Lin, G.; Ke, W.; Guo, S.; Lin, Z.; Xu, C.; Chi, M.; Xiao, Y. Influence of Pile Foundation Construction on Existing Tunnels in a Metro Protection Area: Field Test and Numerical Simulation. Buildings 2024, 14, 2280. [Google Scholar] [CrossRef]

| Material Name | Material Grade | Modulus of Elasticity E/GPa | Poisson’s Ratio μ | Density γ/(kN∗m−3) |

|---|---|---|---|---|

| Main tendon | HRB400 | 210 | 0.3 | 78.0 |

| Stirrup | HPB300 | 210 | 0.3 | 78.0 |

| Foundation pit cushion | C20 | 25.5 | 0.2 | 24.0 |

| Existing piers, caps and piles | C30 | 30.0 | 0.2 | 24.0 |

| Underpinning pile | C35 | 31.5 | 0.2 | 24.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Liu, L.; Tang, X.; Yang, B. Stress and Deformation Control of Active Pile Foundation of Tunnel Underpass Bridge Based on Field Monitoring. Buildings 2025, 15, 3034. https://doi.org/10.3390/buildings15173034

Xu Z, Liu L, Tang X, Yang B. Stress and Deformation Control of Active Pile Foundation of Tunnel Underpass Bridge Based on Field Monitoring. Buildings. 2025; 15(17):3034. https://doi.org/10.3390/buildings15173034

Chicago/Turabian StyleXu, Zhenhua, Lian Liu, Xianyuan Tang, and Bai Yang. 2025. "Stress and Deformation Control of Active Pile Foundation of Tunnel Underpass Bridge Based on Field Monitoring" Buildings 15, no. 17: 3034. https://doi.org/10.3390/buildings15173034

APA StyleXu, Z., Liu, L., Tang, X., & Yang, B. (2025). Stress and Deformation Control of Active Pile Foundation of Tunnel Underpass Bridge Based on Field Monitoring. Buildings, 15(17), 3034. https://doi.org/10.3390/buildings15173034