Study on Impact Resistance of All-Lightweight Concrete Columns Based on Reinforcement Ratio and Stirrup Ratio

Abstract

1. Introduction

2. Experiment Program

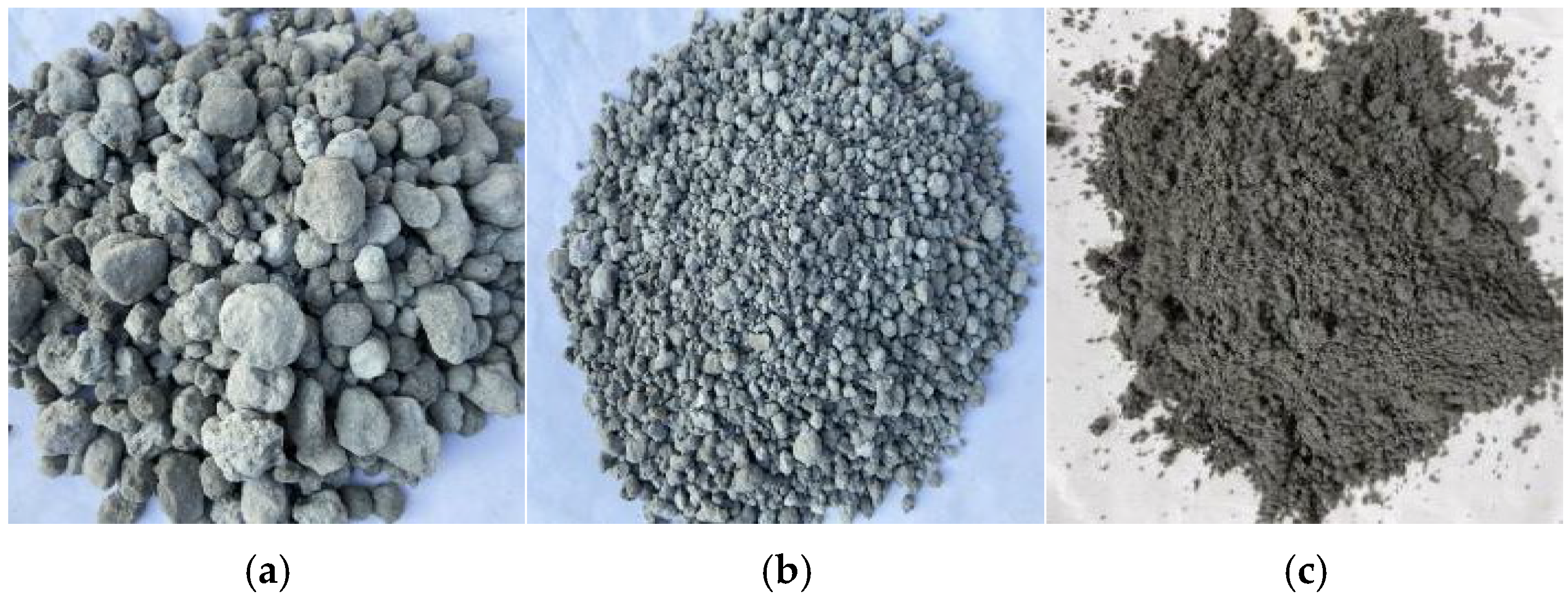

2.1. Materials

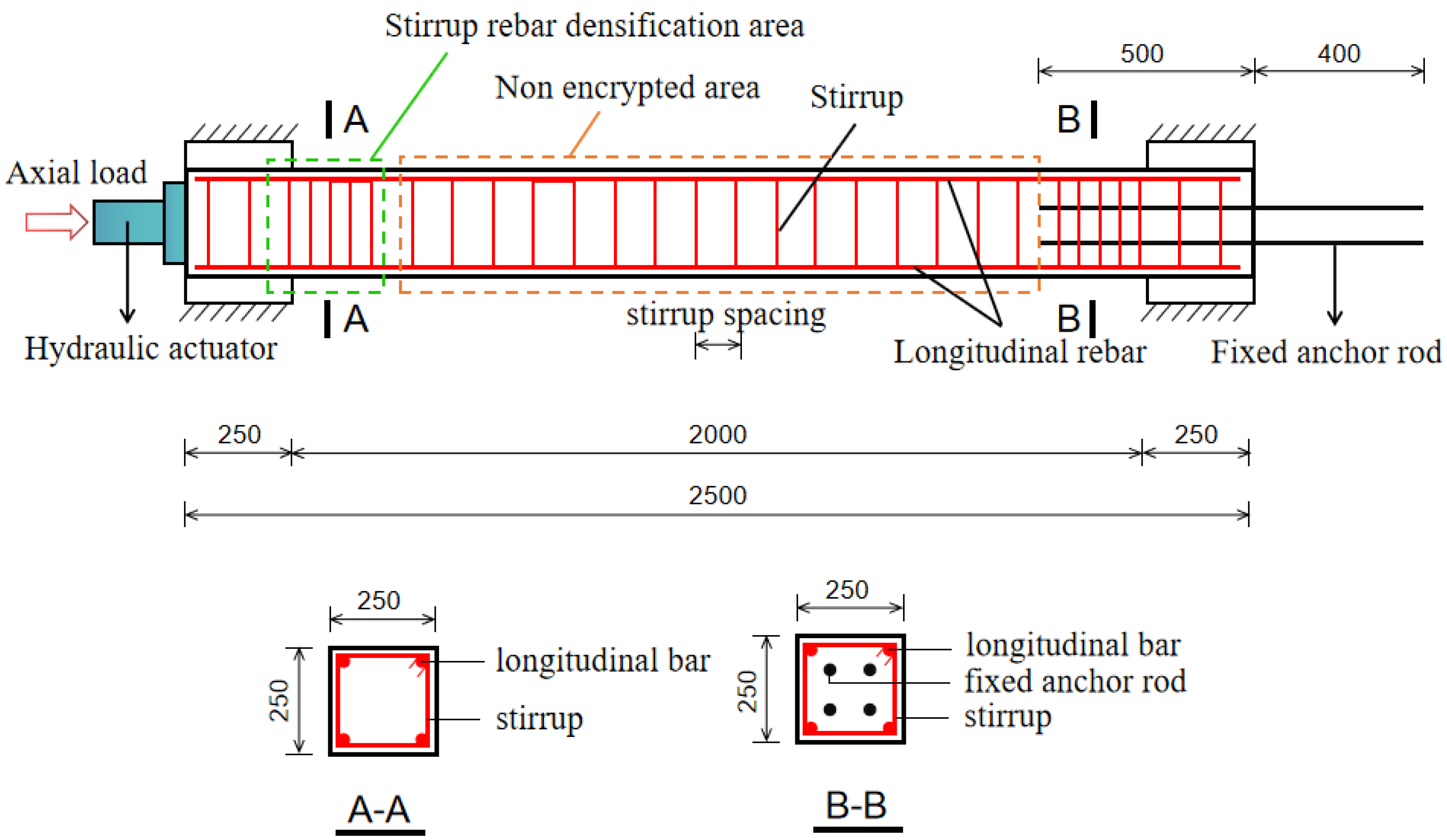

2.2. Specimen Design

2.3. Drop Hammer Impact Test Procedure

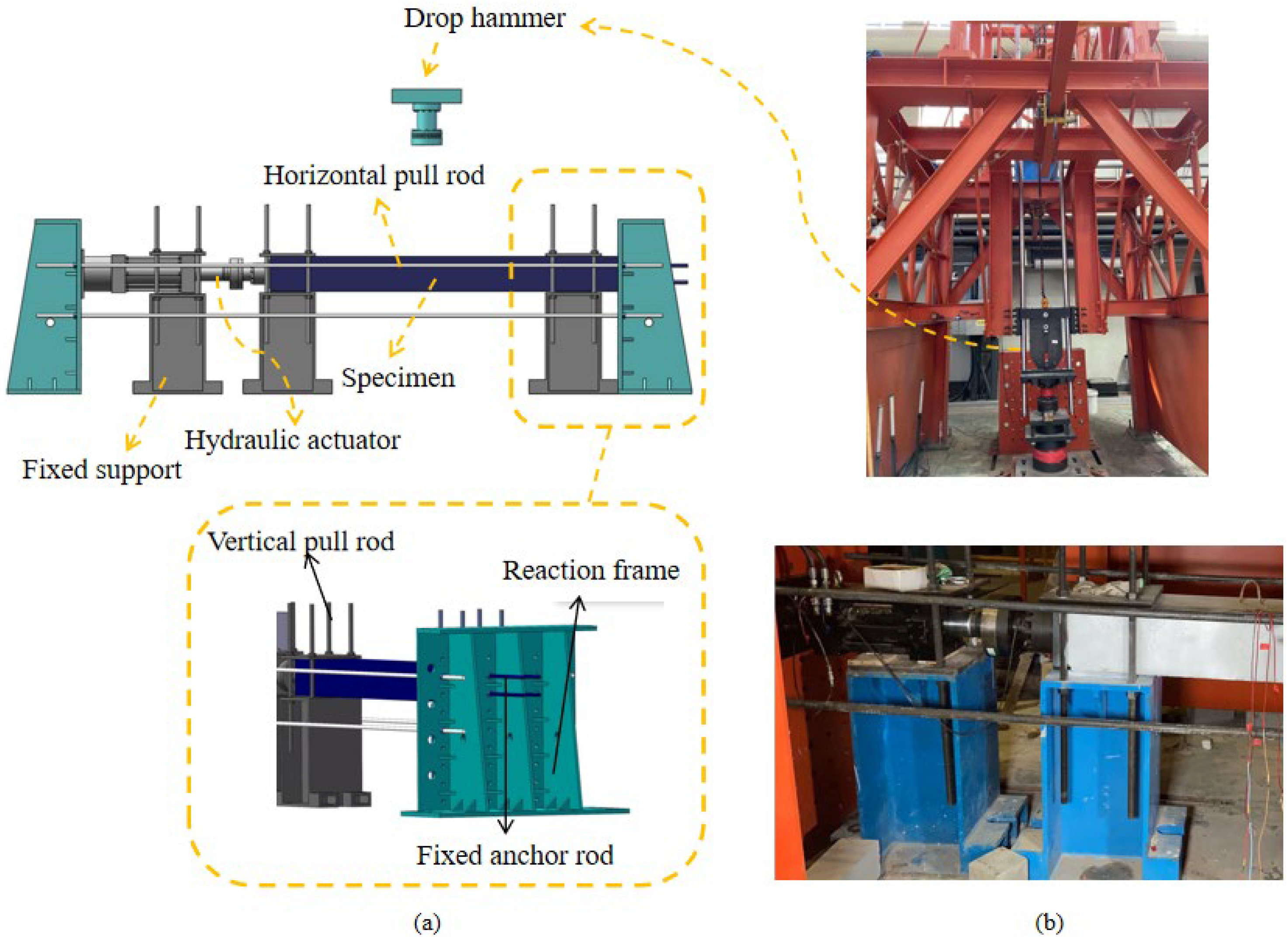

2.3.1. Test Loading Setup

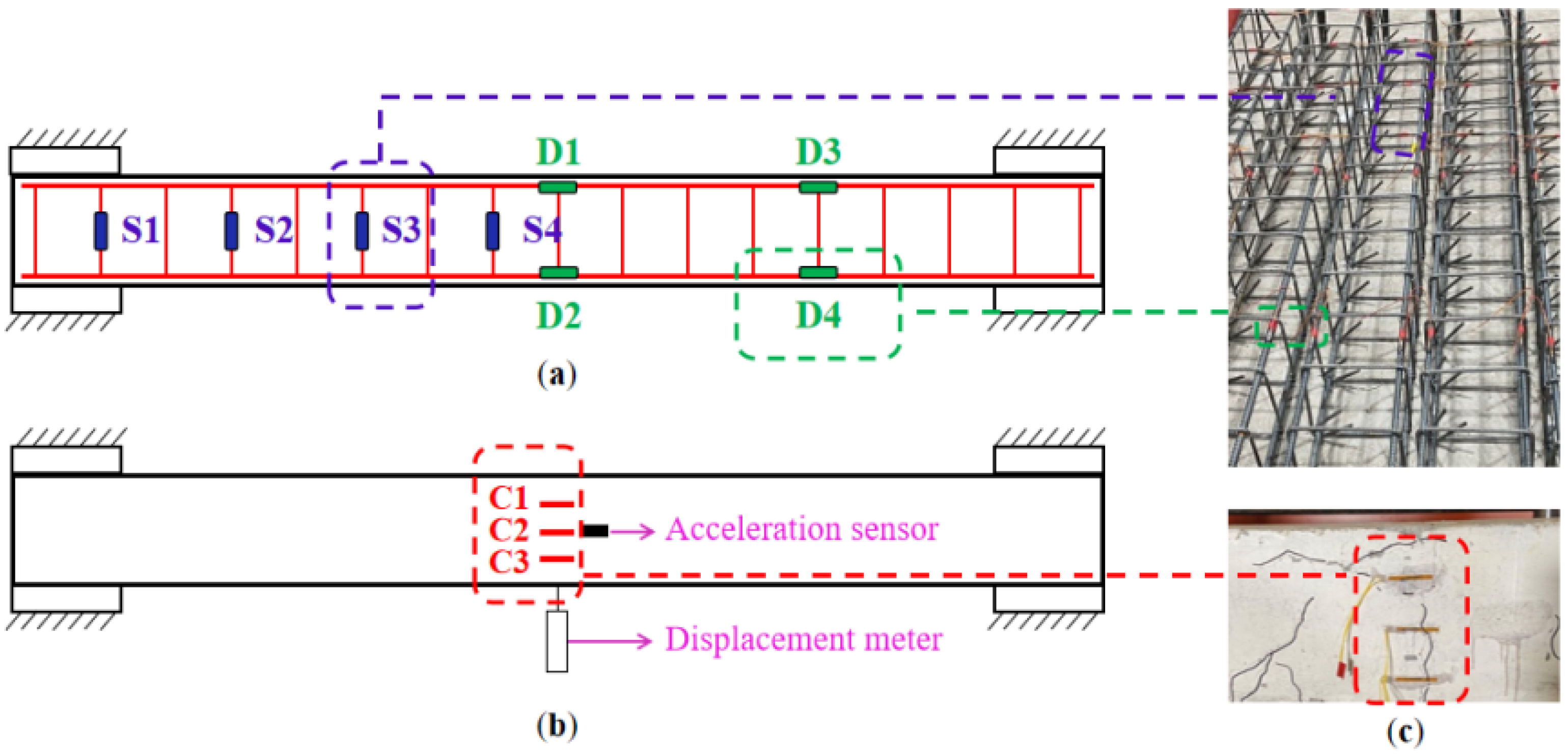

2.3.2. Measurement Plan

3. Results and Discussion

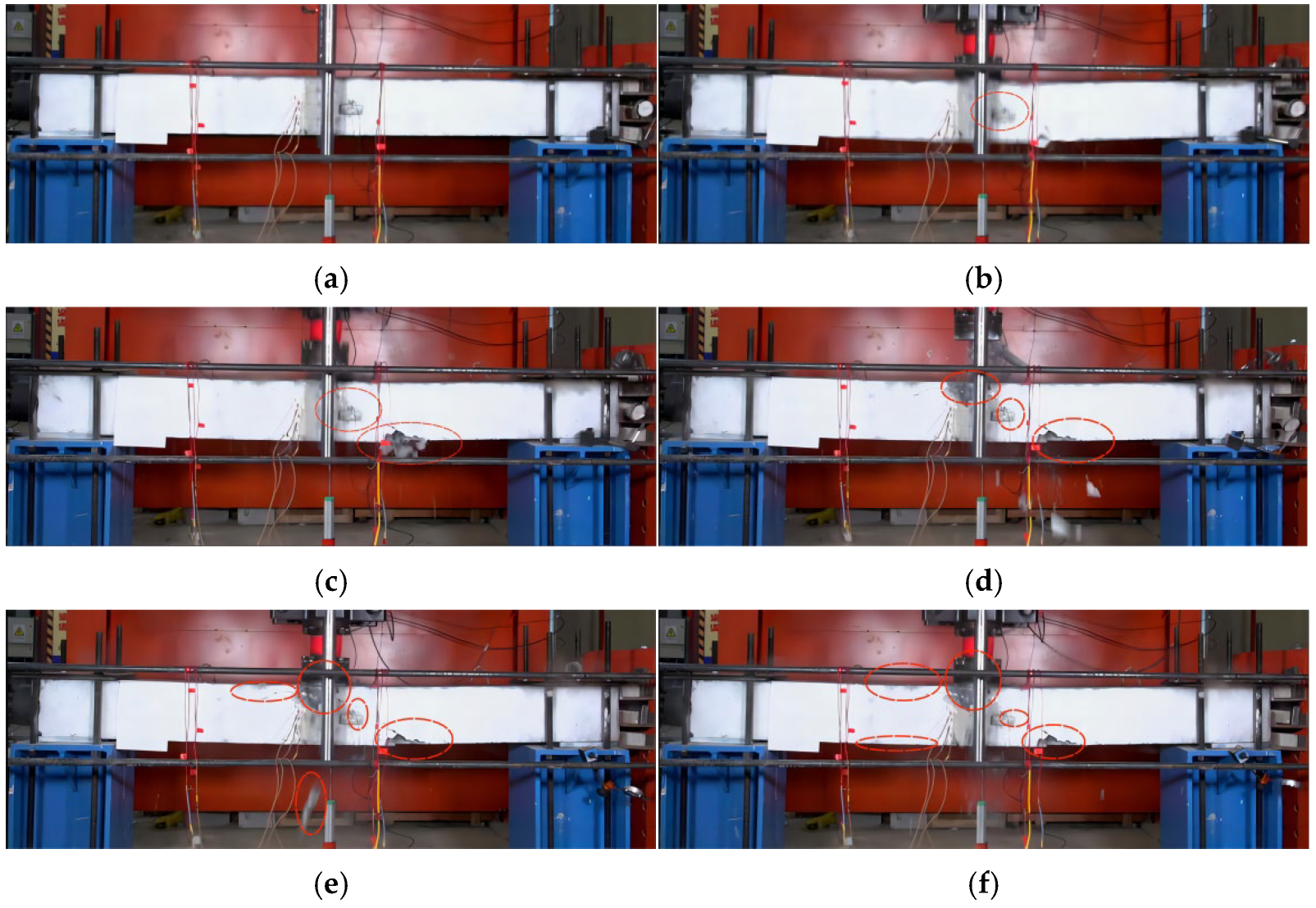

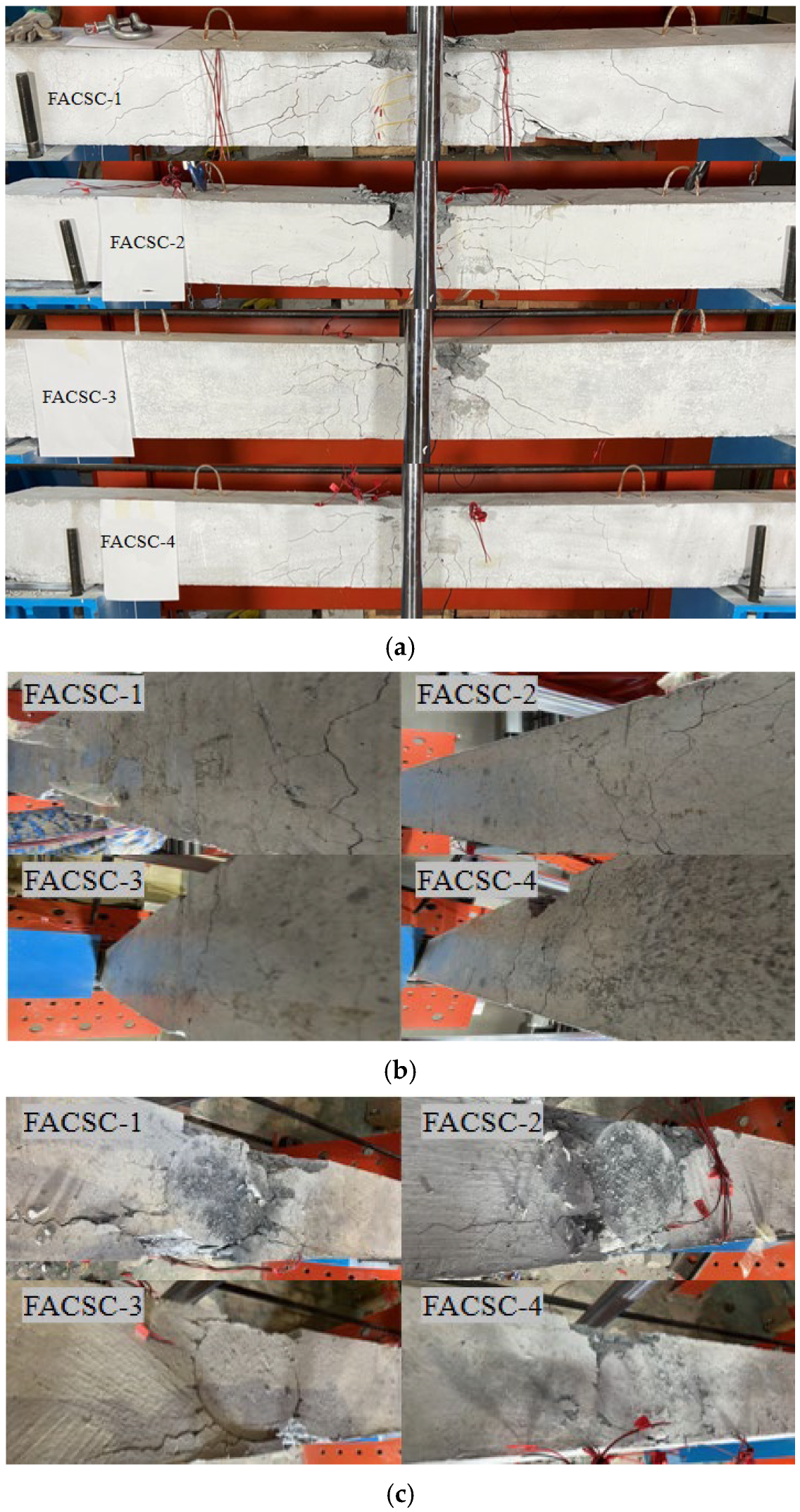

3.1. Impact Failure Process

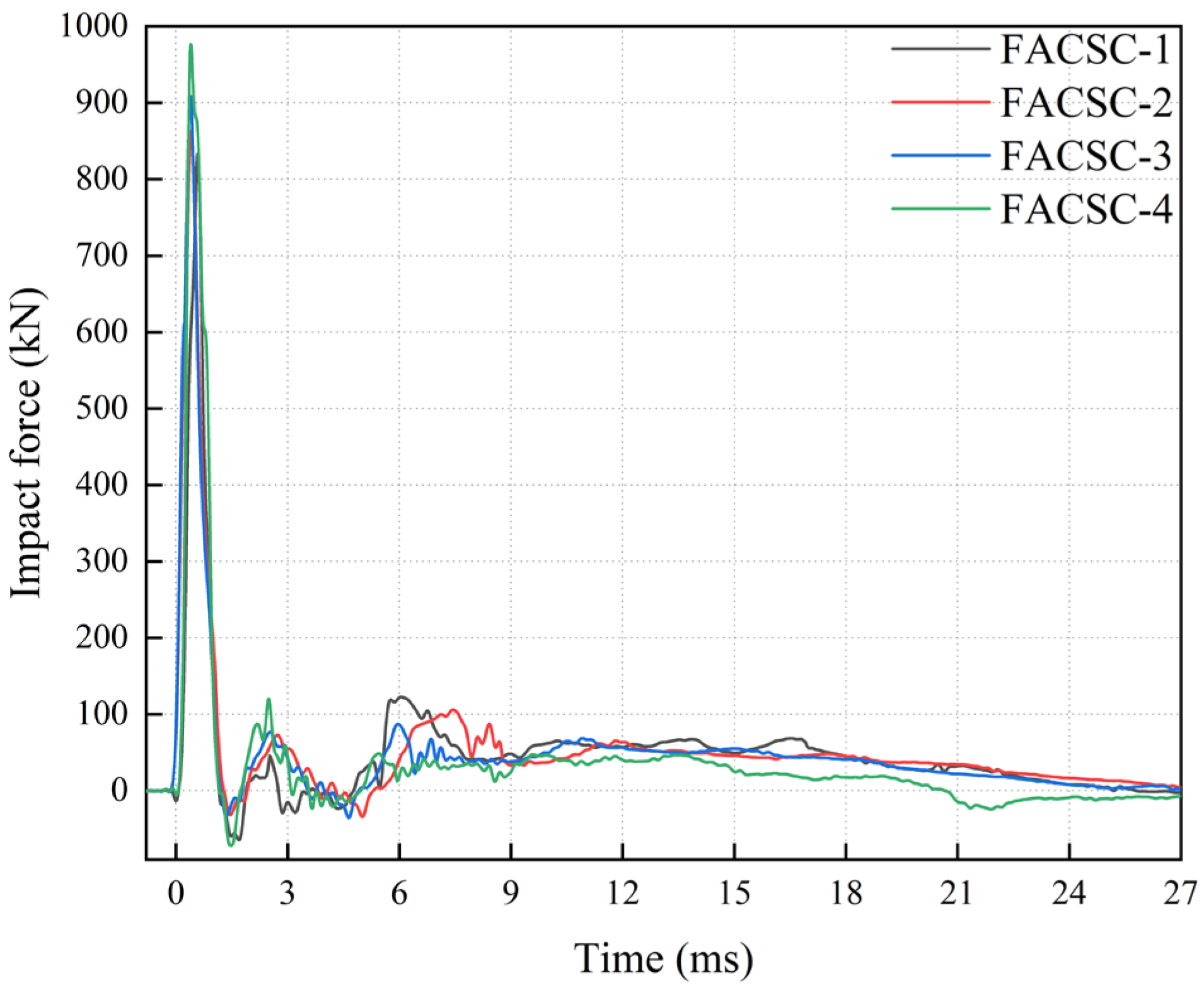

3.2. Impact Force Time History Analysis

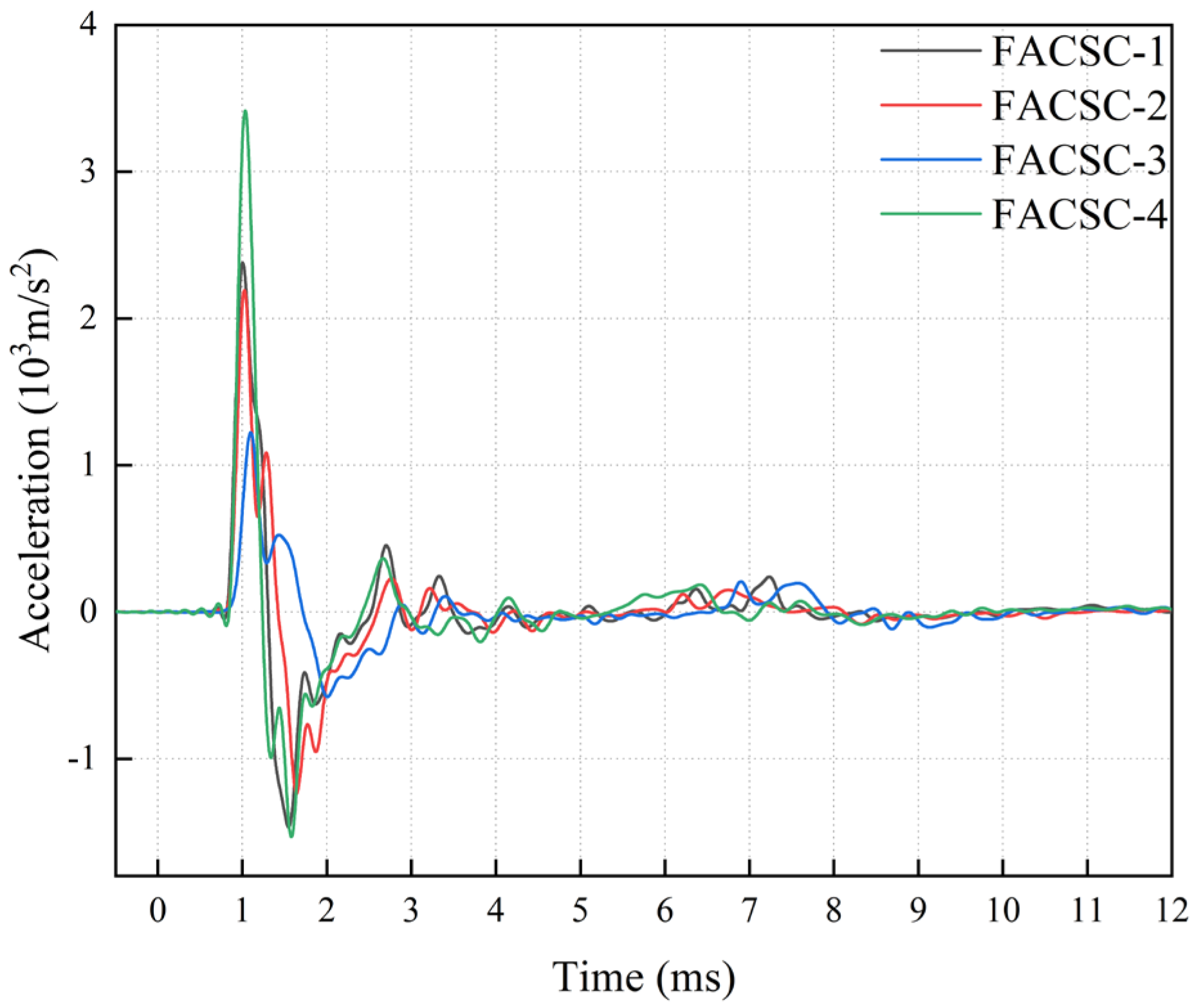

3.3. Acceleration Time History Analysis

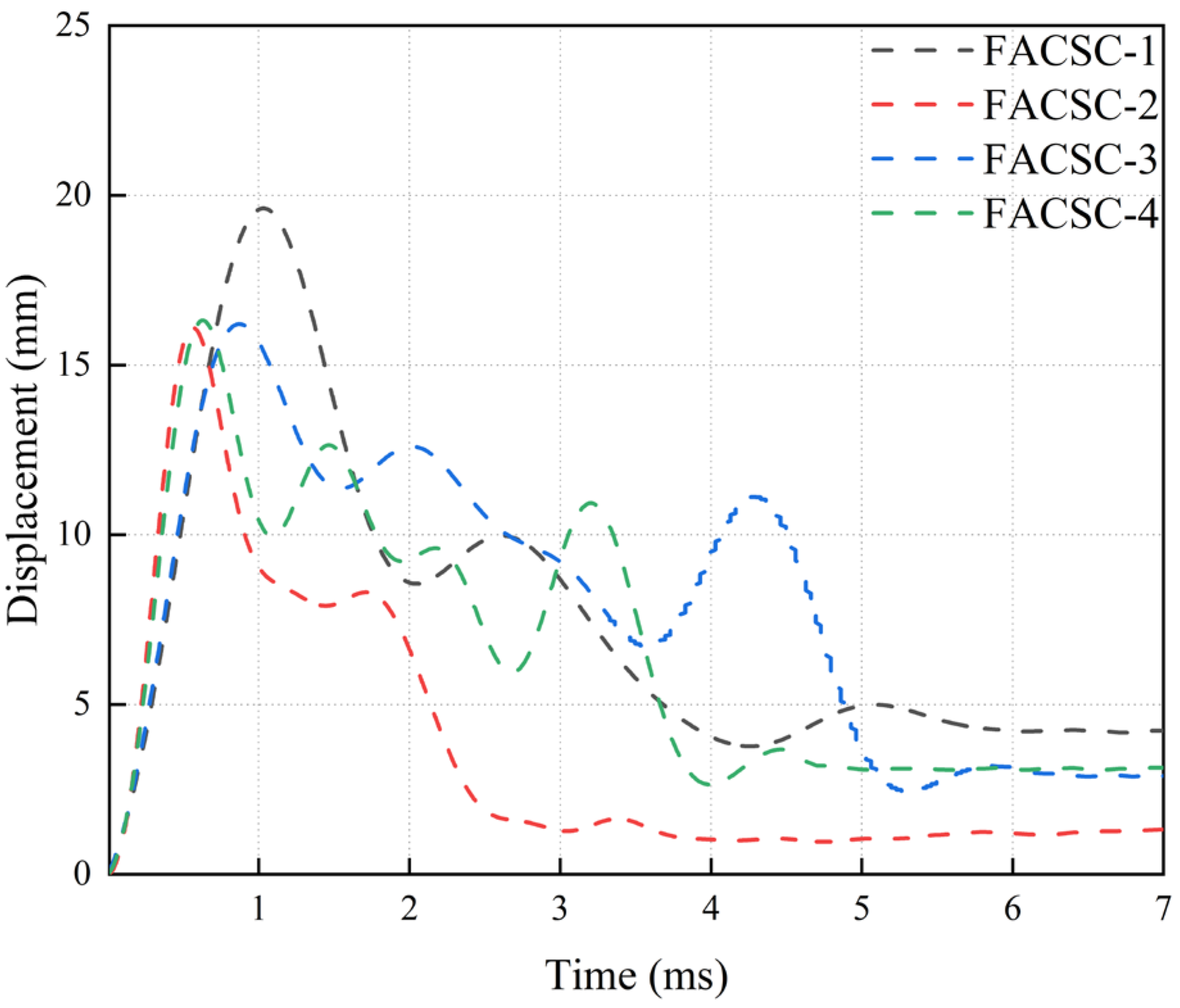

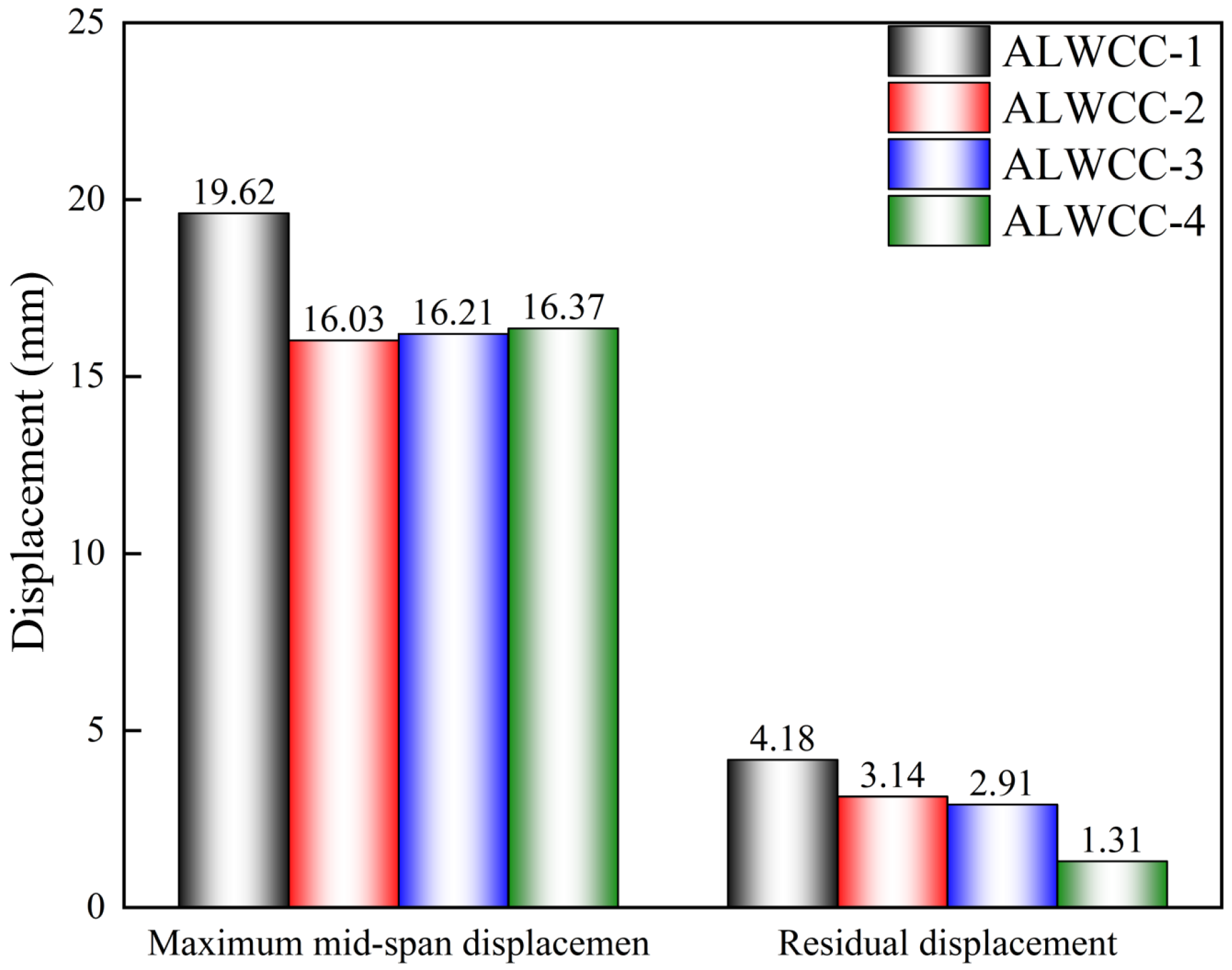

3.4. Midspan Displacement Time History Analysis

4. Finite Element Modeling

4.1. Finite Element Analysis of FSJ Concrete Columns Under Impact Loading

4.1.1. Material Model and Parameters

- —FSJ peak strain of single-axis compression of concrete;

- —FSJ concrete axial compressive strength, (MPa);

- —FSJ apparent density of concrete;

- —FSJ concrete cube compressive strength, (MPa).

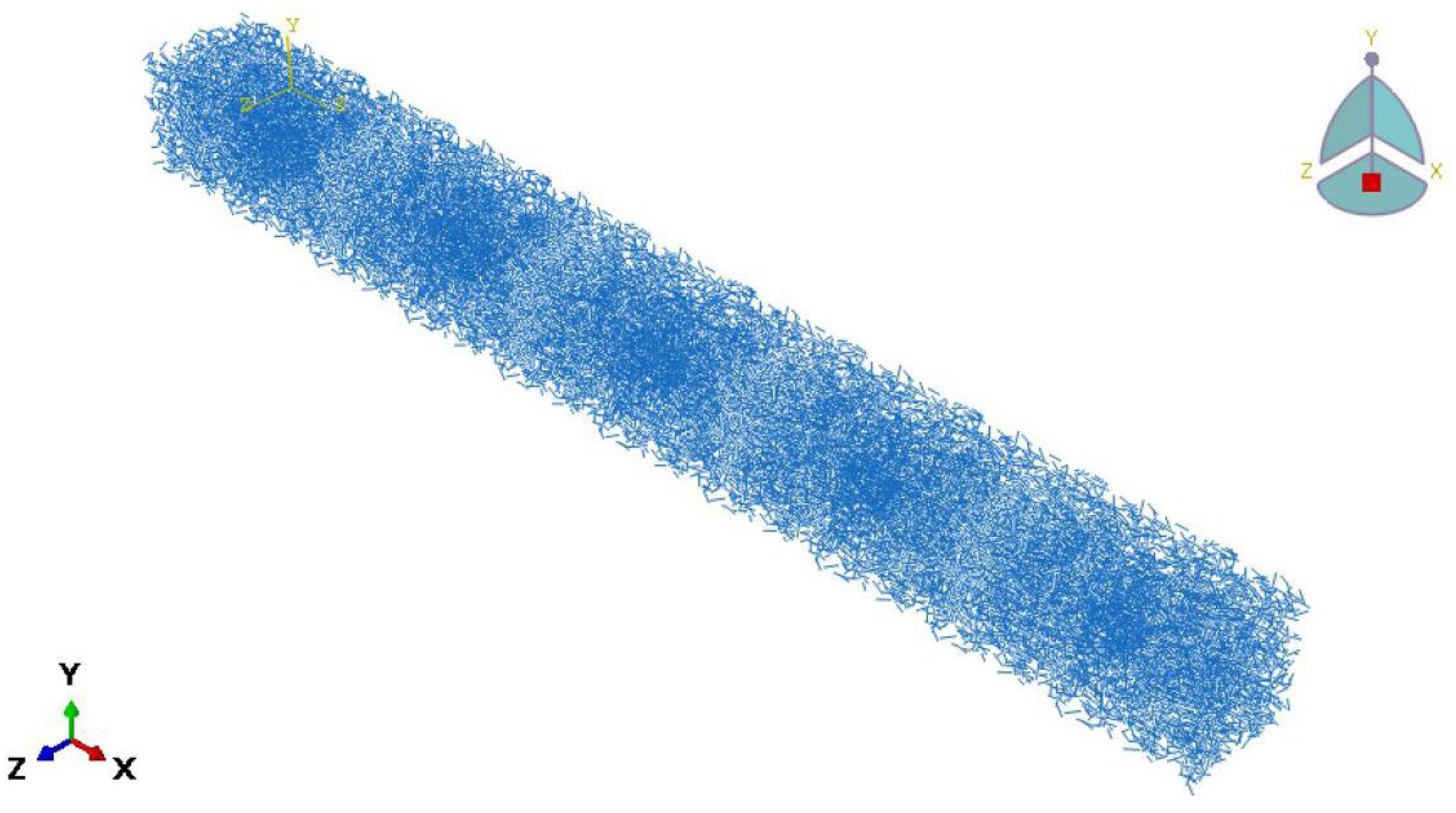

4.1.2. Geometric Model Establishment

4.1.3. Strain Rate Effect

4.2. Analysis of Injury Morphology

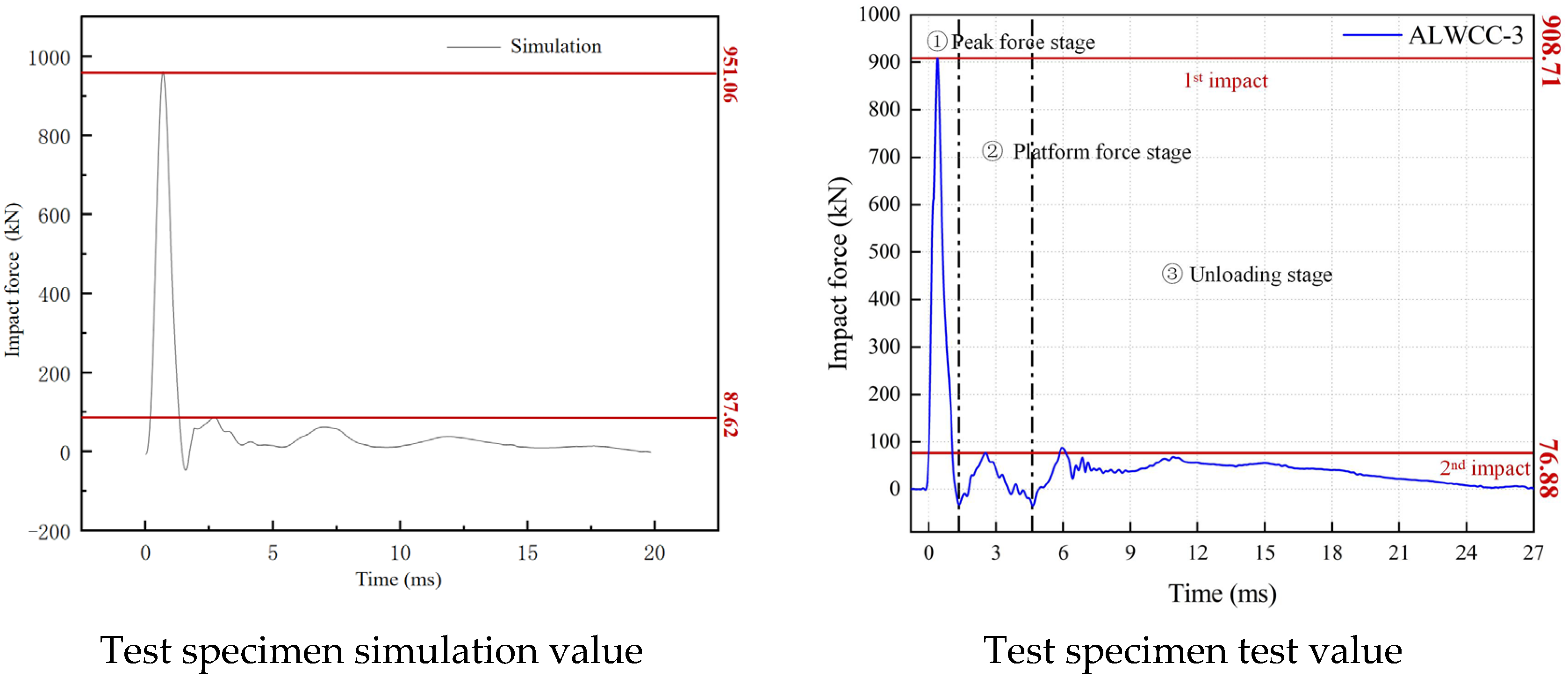

4.3. Comparison Analysis of Impact Force Time History Curves

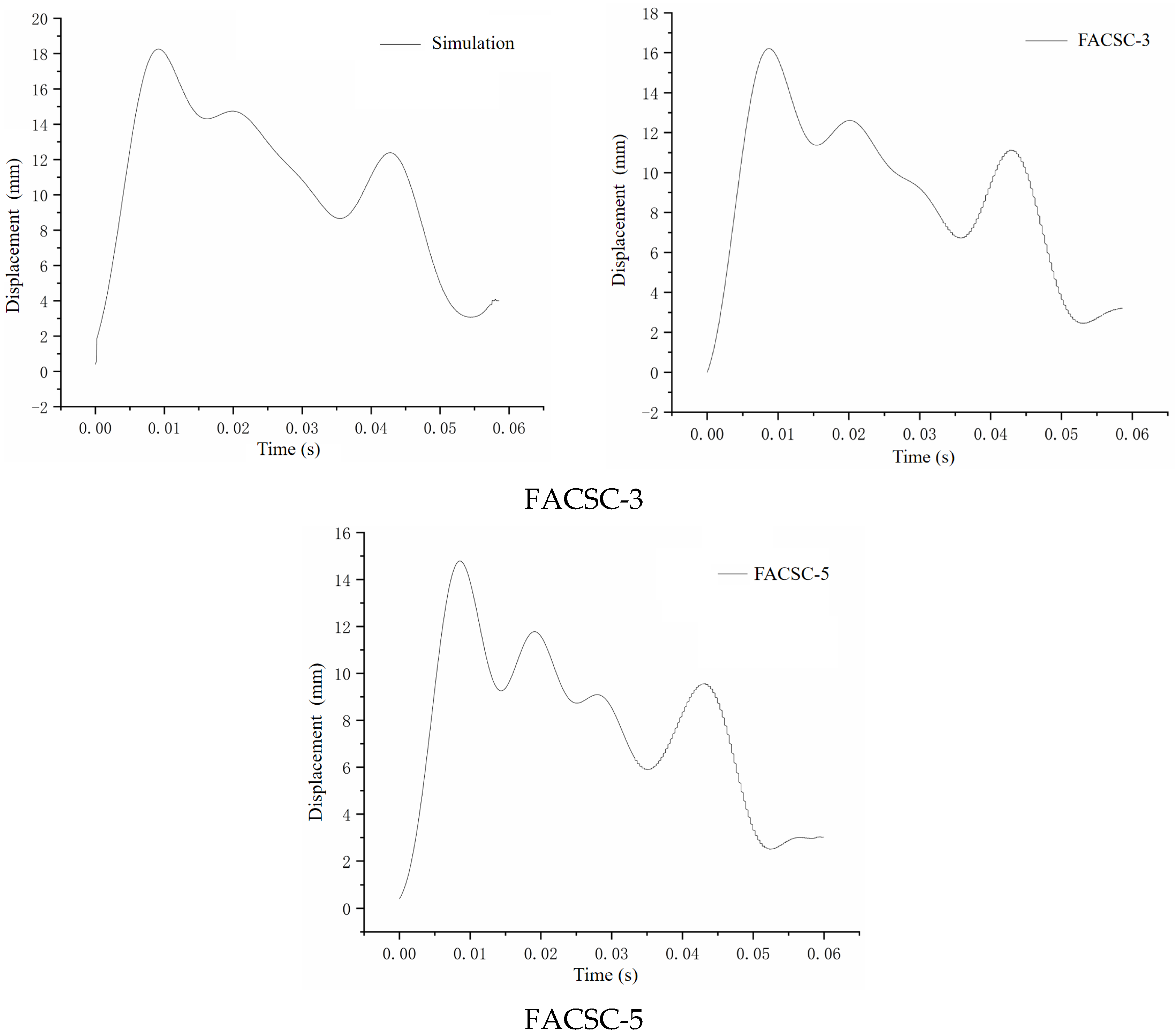

4.4. Comparison Analysis of Midspan Displacement Time History Curves

5. Conclusions

- (1)

- From the main failure modes of the columns, it was observed that increasing the reinforcement and stirrup ratios gradually changed the failure mode from shear to flexural failure, and the degree of punching failure decreased. With densified stirrups at both ends, the columns experienced only localized flexural failure, significantly enhancing impact resistance.

- (2)

- When the reinforcement ratio increased from 0.72% to 0.98%, the first peak impact force increased by 3.43%, and the second peak increased by 60.47%. When the stirrup ratio increased from 0.27% to 0.40%, the first and second peak impact forces increased by 8.98% and 70.35%, respectively. For FACSC-4, with densified stirrups at both ends compared to FACSC-3, the first peak increased by 7.43%, and the second peak increased by 55.98%. The experimental results indicate that increasing the reinforcement and stirrup ratios and densifying stirrups at both ends improved the stiffness and damping of the specimens, reducing the amplitude of structural vibrations and enhancing the energy absorption capacity under impact loading.

- (3)

- Under impact loading, increasing the reinforcement and stirrup ratios effectively improved the impact toughness of the specimens. In particular, increasing the reinforcement ratio enhanced the lateral compressive capacity and impact resistance, effectively suppressing the downward impact acceleration caused by the hammer and reducing both midspan and residual displacements.

- (4)

- Densifying stirrups at both ends of the columns led to an increase in peak acceleration, with midspan displacement remaining almost the same as that of FACSC-3, while residual displacement was improved. The results suggest that densifying stirrups at both ends can enhance the impact resistance of the columns to some extent, and expanding the densified stirrup region could further improve the overall impact resistance of the columns.

- (5)

- For ALWC columns used in high seismic intensity zones, a minimum stirrup ratio of ≥0.4% is recommended to shift the failure mode to flexural failure and prevent sudden shear collapse. In areas subject to explosion or impact risks, a confined stirrup zone of 500 mm at both ends with a spacing of 50 mm should be employed, which can enhance the secondary peak load by 55.98% and significantly reduce progressive impact damage. The lightweight concrete columns reduce self-weight by 30%, making them suitable for seismic isolation floors in high-rise buildings.

- (6)

- The simulation results of the impact resistance performance of FSJ concrete columns conducted by ABAQUS show that in building structures, when designing FSJ concrete components, by increasing the longitudinal reinforcement ratio and hoop reinforcement ratio and adding 1% of wave-shaped steel fibers, the impact resistance performance can be significantly improved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Zhang, R.; Jin, L.; Lan, D.; Du, X. A unified impact displacement prediction model for geometrically similar RC beams: From test specimen to prototype component. Int. J. Impact Eng. 2023, 181, 104731. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, H.K. Impact resistance and mechanical properties of UHPFRC. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 371–380. [Google Scholar] [CrossRef]

- Kishi, N.; Mikami, H. Empirical formulas for designing reinforced concrete beams under impact loading. ACI Struct. J. 2012, 109, 509–520. [Google Scholar] [CrossRef]

- Pham, T.M.; Hao, H. Effect of the plastic hinge and boundary conditions on the impact behavior of reinforced concrete beams. Int. J. Impact Eng. 2017, 102, 74–85. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Liang, Q.; Zhao, J.; Pan, D.; Ma, J. Resource utilization of solid waste in the field of phase change thermal energy storage. J. Energy Storage 2023, 58, 106362. [Google Scholar] [CrossRef]

- Meneguin, J.G.; Bruns, P.H.G.; da Silva, C.T.P.; Moise, M.P.; Roge, M.; Radovanovic, E.; Rinaldi, A.W. An optimized process for recycling silicon chemical compounds from agro-industry solid waste. Ind. Eng. Chem. Res. 2019, 58, 4511–4517. [Google Scholar] [CrossRef]

- Lee, C.; Kim, S.; Park, M.H.; Lee, Y.S.; Lee, C.; Lee, S.; Yang, J.; Kim, J.Y. Valorization of petroleum refinery oil sludges via anaerobic co-digestion with food waste and swine manure. J. Environ. Manag. 2022, 307, 114562. [Google Scholar] [CrossRef]

- Xue, K.; Su, M.; Yang, X.; Qi, J.; Liu, M.; Ju, C.; Peng, X.; Wu, Y. Investigation of the water resistance of non-sintered wrap-shell lightweight aggregates with high content solid waste and its application in water permeable bricks. Constr. Build. Mater. 2023, 400, 132612. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Q.; Gao, Z.; Sha, L. Study on Impact Resistance of All-Lightweight Concrete Columns Based on Steel Fiber Reinforced and Various Axial Compression Ratio. Buildings 2023, 13, 2076. [Google Scholar] [CrossRef]

- Thilakarathna, H.M.I.; Thambiratnam, D.P.; Dhanasekar, M.; Perera, N. Numerical simulation of axially loaded concrete columns under transverse impact and vulnerability assessment. Int. J. Impact Eng. 2010, 37, 1100–1112. [Google Scholar] [CrossRef]

- Huang, Z.; Khan, M.Z.N.; Chen, W.; Hao, H.; Elchalakani, M.; Pham, T.M. Effectiveness of reinforcing methods in enhancing the lateral impact performance of geopolymer concrete column reinforced with BFRP bars. Int. J. Impact Eng. 2023, 175, 104544. [Google Scholar] [CrossRef]

- Meng, L.; Ding, Y.; Li, L.; Wei, J.; Li, M.; Wang, J.; Cao, S.; Liu, J. Study on dynamic properties of lightweight ultra-high performance concrete (L-UHPC). Constr. Build. Mater. 2023, 399, 132526. [Google Scholar] [CrossRef]

- Wei, F.; Shen, D.; Yang, T.; Shao, X. Experimental and numerical study on low-velocity lateral impact behaviors of RC, UHPFRC and UHPFRC-strengthened columns. Eng. Struct. 2019, 191, 509–525. [Google Scholar]

- Esaker, M.; Thermou, G.E.; Neves, L. Impact resistance of concrete and fibre-reinforced concrete: A review. Int. J. Impact Eng. 2023, 180, 104722. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Elchalakani, M.; Do, T.V.; Hao, H. Sensitivity of lateral impact response of RC columns reinforced with GFRP bars and stirrups to concrete strength and reinforcement ratio. Eng. Struct. 2021, 242, 112512. [Google Scholar] [CrossRef]

- Othman, H.; Marzouk, H. An experimental investigation on the effect of steel reinforcement on impact response of reinforced concrete plates. Int. J. Impact Eng. 2016, 88, 12–21. [Google Scholar] [CrossRef]

- Zhong, J.; Song, C.; Xu, J.; Cheng, Y.; Liu, F. Experimental and numerical simulation study on failure mode transformation law of reinforced concrete beam under impact load. Int. J. Impact Eng. 2023, 179, 104645. [Google Scholar] [CrossRef]

- JGJ/T12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. Standards Press of China: Beijing, China, 2019.

- GB/T17431.2-2010; Lightweight Aggregates and Their Testing Methods. Standards Press of China: Beijing, China, 2010.

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standards Press of China: Beijing, China, 2019.

- GB/T 228.1-2010; Metallic Materials—Tensile Testing at Ambient Temperature. Standards Press of China: Beijing, China, 2010.

- Fujikake, K.; Li, B.; Soeun, S. Impact response of reinforced concrete beam and its analytical evaluation. J. Struct. Eng. 2009, 135, 938–950. [Google Scholar] [CrossRef]

- Jafari, A.; Shahmansouri, A.A.; Bengar, H.A.; Zhou, Y. Flexural rigidity of SFRC columns at the onset of buckling failure: Analytical and numerical study. Steel Compos. Struct. 2025, 55, 533. [Google Scholar]

- Bentur, A.; Mindess, S.; Banthia, N. The behaviour of concrete under impact loading: Experimental procedures and method of analysis. Mater. Struct. 1986, 19, 371–378. [Google Scholar] [CrossRef]

- Hibbitt, Karlsson & Sorensen, Inc. ABAQUS/Standard User Subroutines Reference Manual; The Pennsylvania State University: University Park, PA, USA, 1998; pp. 1–200. [Google Scholar]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Hibbitt, Karlsson & Sorensen, Inc. ABAQUS Version 6.5 Theory Manual, Users Manual; Hibbitt, Karlsson & Sorensen, Inc.: Pawtucket, RI, USA, 2005; Available online: https://classes.engineering.wustl.edu/2009/spring/mase5513/abaqus/docs/v6.5/books/stm/default.htm?startat (accessed on 22 July 2025).

- Ding, Y. Unified Calculation Method for Uniaxial Mechanical Properties of Lightweight Aggregate Concrete. J. Cent. South Univ. 2010, 41, 1974–1979. [Google Scholar]

- Li, X.; Chen, Q.; Chen, J.; Liao, J.; Lu, Y. Dynamic increase factor (DIF) for concrete in compression and tension in FE modelling with a local concrete model. Int. J. Impact Eng. 2021, 163, 104079. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E. Dynamic increase factor for concrete. In Proceedings of the 28th Department of Defense Explosives Safety Seminar, Orlando, FL, USA, 18–20 August 1998. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

| Cement (kg/m3) | Fly Ash Ceramic Pellets (kg/m3) | Pottery Sand (kg/m3) | Fly Ash (kg/m3) | Water (kg/m3) | W/C | Water Reducing Admixture % |

|---|---|---|---|---|---|---|

| 450 | 693 | 531 | 50 | 200 | 0.4 | 3.6 |

| Strength | Cube Compressive Strength MPa | Axial Compressive Strength MPa | Elastic Modulus MPa |

|---|---|---|---|

| LC25 | 26.3 | 20.8 | 3.02 × 104 |

| Reinforcement Diameter mm | Yield Strength MPa | Ultimate Tensile Strength Mpa | Elongation % | Elastic Modulus GPa |

|---|---|---|---|---|

| 14 | 492 | 679 | 17.6 | 201 |

| 12 | 489 | 661 | 18.9 | 204 |

| 8 | 462 | 647 | 20.7 | 195 |

| No. | Longitudinal Reinforcement Ratio | Stirrup Ratio | Longitudinal Reinforcement | Stirrup Spacing in Non-Densified Region |

|---|---|---|---|---|

| FACSC-1 | 0.72% | 0.27% | 4C12 | C8@150 |

| FACSC-2 | 0.98% | 0.27% | 4C14 | C8@150 |

| FACSC-3 | 0.72% | 0.40% | 4C12 | C8@100 |

| FACSC-4 | 0.72% | 0.42% | 4C12 | C8@100 |

| No. | First Peak Forces | Second Peak Forces |

|---|---|---|

| FACSC-1 | 833.83 | 45.13 |

| FACSC-2 | 862.51 | 72.42 |

| FACSC-3 | 908.71 | 76.88 |

| FACSC-4 | 976.21 | 119.92 |

| Name | Properties |

|---|---|

| Hammer head | ρ = 7800 kg/m3, E = 210 GPa, fy = 1000 MPa |

| FSJ concrete | ρ = 1674 kg/m3, E = 30.2 GPa, fc = 26.3 MPa |

| Rebar | ρ = 7800 kg/m3, E = 210 Gpa, fy = 428 MPa, 410 MPa (upper longitudinal reinforcement and lower) 335 MPa (stirrups) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zheng, A.; Hou, Y. Study on Impact Resistance of All-Lightweight Concrete Columns Based on Reinforcement Ratio and Stirrup Ratio. Buildings 2025, 15, 3028. https://doi.org/10.3390/buildings15173028

Wang X, Zheng A, Hou Y. Study on Impact Resistance of All-Lightweight Concrete Columns Based on Reinforcement Ratio and Stirrup Ratio. Buildings. 2025; 15(17):3028. https://doi.org/10.3390/buildings15173028

Chicago/Turabian StyleWang, Xiuli, Ao Zheng, and Yongqi Hou. 2025. "Study on Impact Resistance of All-Lightweight Concrete Columns Based on Reinforcement Ratio and Stirrup Ratio" Buildings 15, no. 17: 3028. https://doi.org/10.3390/buildings15173028

APA StyleWang, X., Zheng, A., & Hou, Y. (2025). Study on Impact Resistance of All-Lightweight Concrete Columns Based on Reinforcement Ratio and Stirrup Ratio. Buildings, 15(17), 3028. https://doi.org/10.3390/buildings15173028