Mechanical Behavior of Paving Stones Made from Construction and Demolition Waste (CDW)

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Collection and Characterization

2.2. Recycled Aggregate Processing

2.3. Material Properties

2.3.1. Natural Aggregate Properties

2.3.2. Recycled Aggregate Properties

2.4. Concrete Mix Design and Manufacturing

- Target compressive strength of 31.37 MPa (320 kg/cm2).

- Slump range between 2.5 cm and 5 cm.

- Nominal maximum size (NMS) of ¾” (19.4 mm) for both natural and recycled aggregates.

- Non-air-entrained concrete.

- Water–cement ratio of 0.42. The slight variations in water content shown in Table 3 (ranging from 5.45 to 5.88 kg) account for adjustments made to compensate for the higher absorption capacity of recycled aggregates, ensuring a consistent effective water-to-cement ratio of 0.42 across all mixtures.

2.5. Testing Procedures

2.5.1. Compression Strength

- : Aspect ratio.

- : Average specimen thickness in mm.

- : Average specimen width in mm.

- : Aspect ratio factor.

- : Compressive strength in MPa.

- : Maximum applied load in N.

- : Average net area of the specimen in mm2.

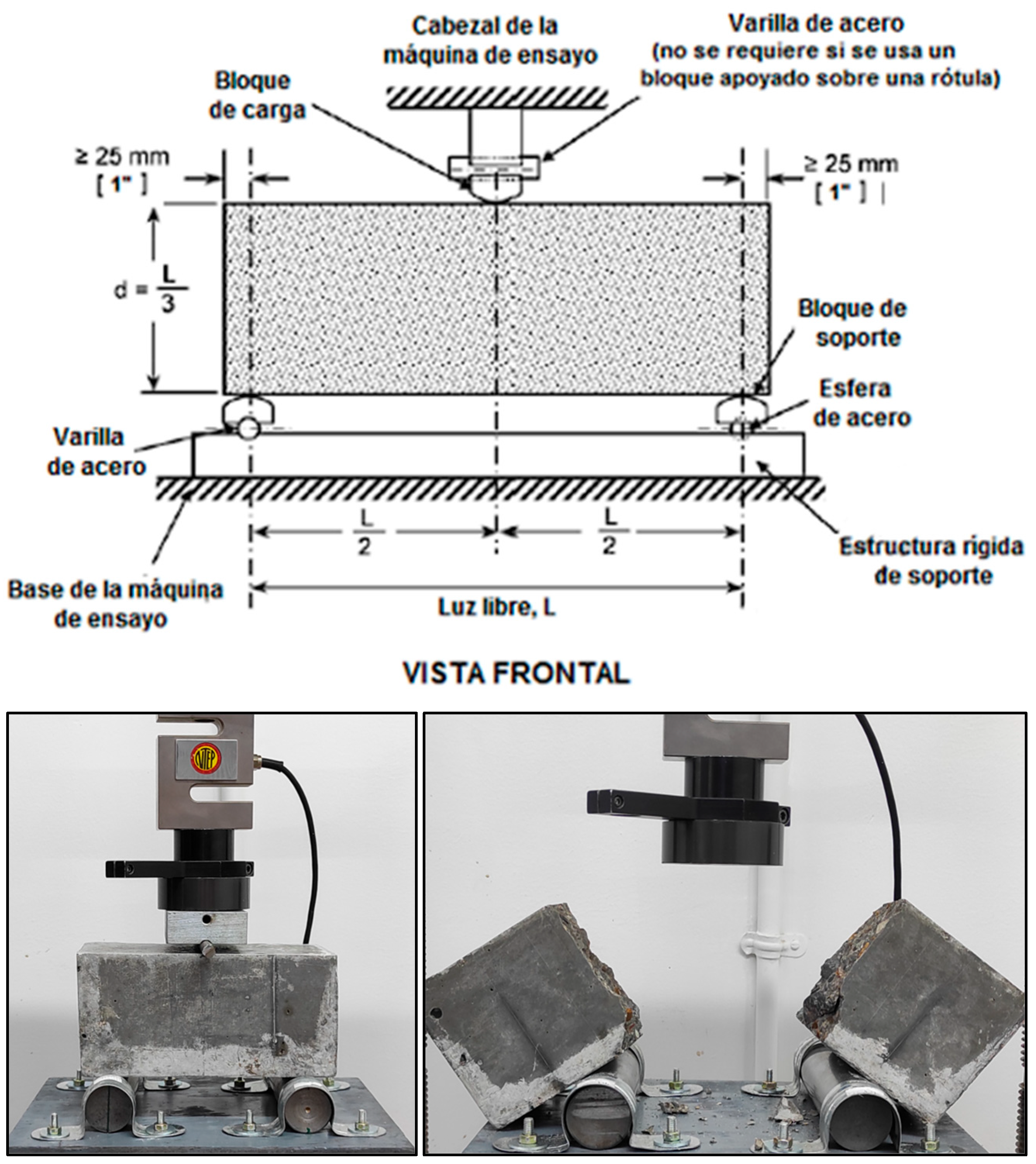

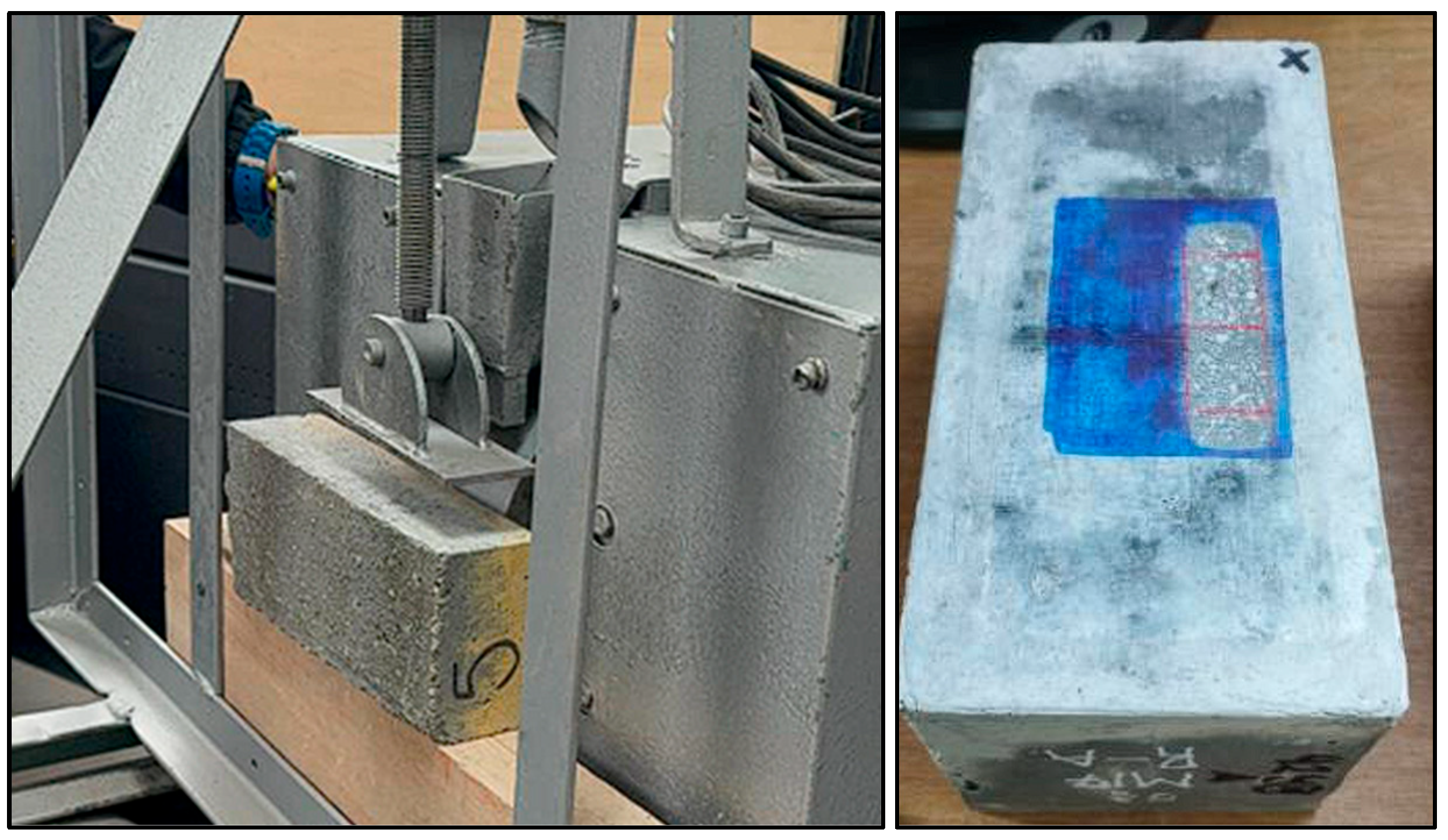

2.5.2. Flexural Strength

- : Modulus of rupture in MPa.

- : Maximum applied load in N.

- : Spacing between supports in mm.

- : Average specimen width at the fracture site in mm.

- : Average specimen height at the fracture site in mm.

2.5.3. Water Absorption

- : Water absorption of the specimen %.

- : Saturated surface-dry mass in kg.

- : Oven-dry mass of the specimen in kg.

2.5.4. Abrasion Resistance

- : Resulting wear track length in mm.

- : Calibration factor in mm.

- Wear track length in the zone in mm.

2.6. Performance Verification

2.7. Microstructural Characterization

3. Results and Discussion

3.1. Compression Strength Performance

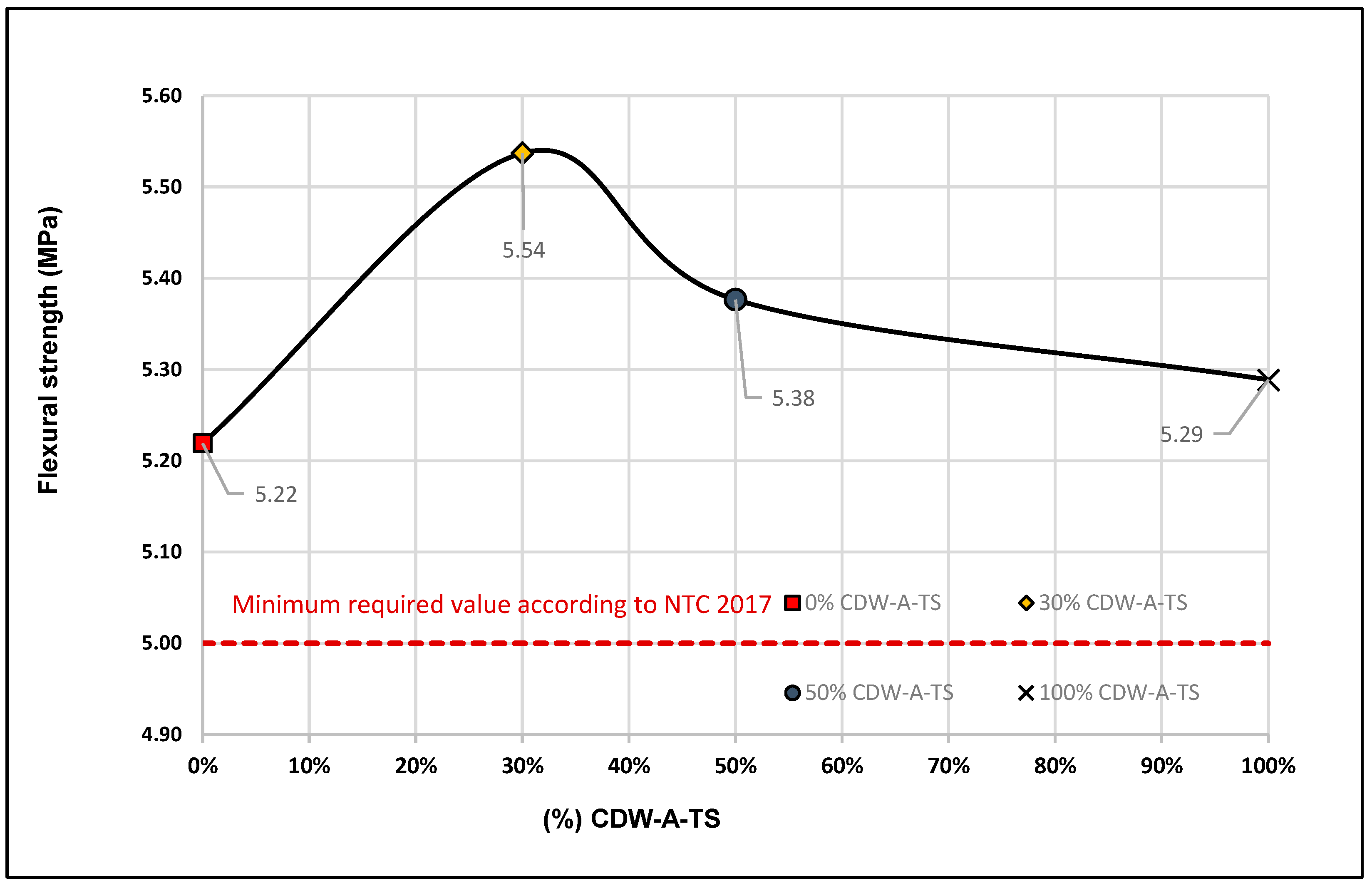

3.2. Flexural Strength Analysis

3.3. Water Absorption Characteristics

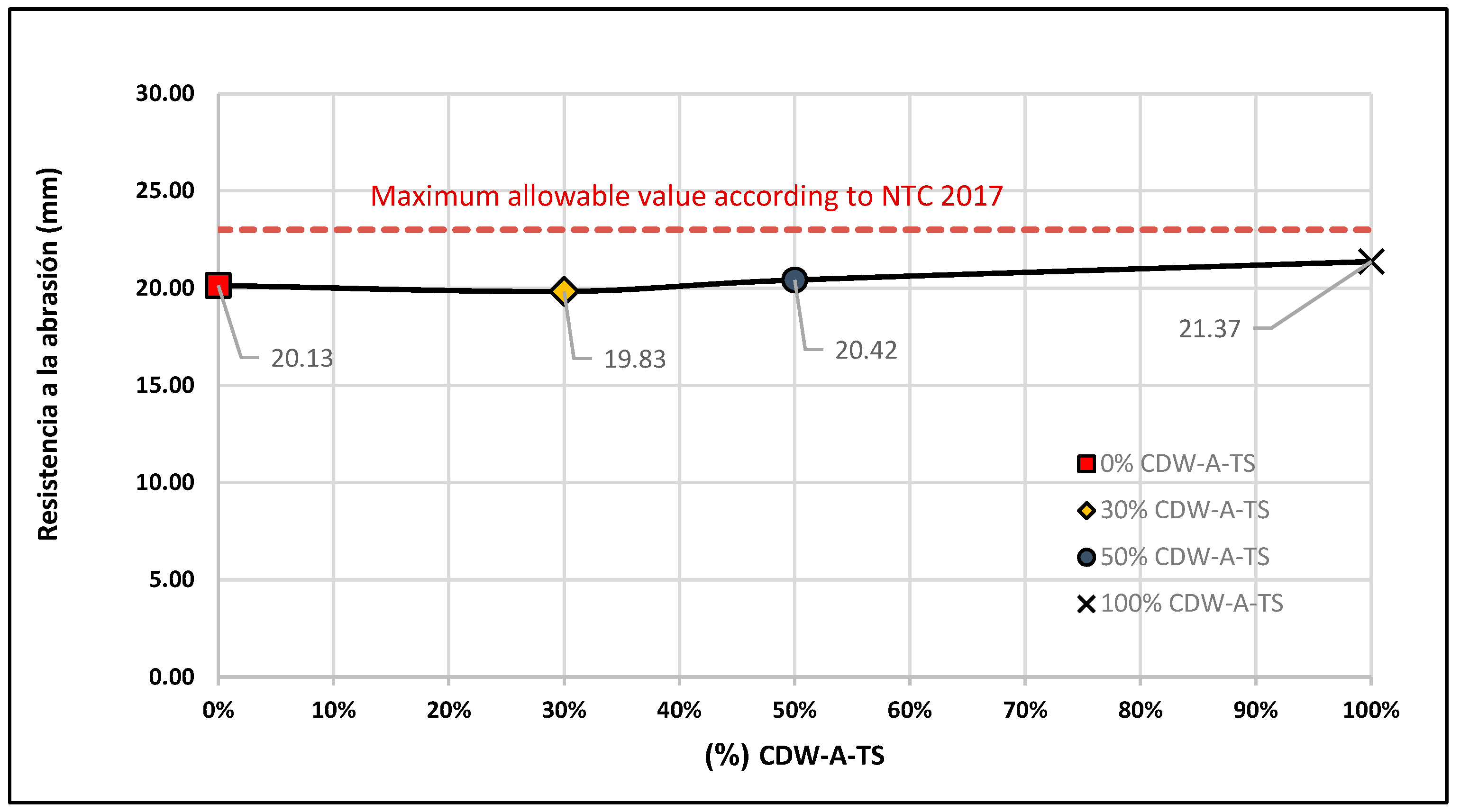

3.4. Absorption Resistance Evolution

3.5. Microstructural Analysis Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gaitán, M.A. Lineamientos para la Gestión Ambiental de Residuos de Construcción y Demolición (RCD) en Bogotá D.C. Master’s Thesis, Pontificia Universidad Javeriana, Bogotá, Colombia, 2013. [Google Scholar]

- Latorre, L.J. Gestión Integral de los Residuos Susceptibles de Aprovechamiento, 49 Generados en las Actividades de Construcción de Vías en Colombia. Master’s Thesis, Universidad Militar nueva Granada, Bogotá, Colombia, 2017. [Google Scholar]

- Lasso, A.L.; Misle, R. Evaluación Técnica, Económica e Institucional de la Gestión de Residuos de Construcción y Demolición en Bogotá D.C. Master’s Thesis, Pontificia Universidad Javeriana, Bogotá, Colombia, 2012. [Google Scholar]

- Sierra, N. Residuos de Construcción y Demolición (RCD), Construcción en la Ciudad de Bogotá y la Metodología PMBOK; Universidad Militar Nueva Granada: Bogotá, Colombia, 2009. [Google Scholar]

- TransMilenio, S.A. Informe de Gestión 2020; TransMilenio S.A.: Bogotá, Colombia, 2020. [Google Scholar]

- Sánchez, X.A. Diseño de Pavimento Articulados para Tráfico Medio y Alto. Bogotá D.C. Bachelor’s Thesis, Universidad de los Andes, Bogotá, Colombia, 2003. [Google Scholar]

- Quintero, A.P.; Trujillo, K.L. Análisis del Manejo de Residuos de Construcción y Demolición (RCD) y Sostenibilidad en la Construcción en Bogotá D.C. Bachelor’s Thesis, Universidad de la Salle, Bogotá, Colombia, 2021. [Google Scholar]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Bermudez, R.D. Evaluación de la Resistencia a la Compresión de un Concreto con la Sustitución de Residuos de Construcción y Demolición Como Agregado Grueso. Bachelor’s Thesis, Universidad de la Costa, Barranquilla, Colombia, 2021. [Google Scholar]

- Nixon, P.J. Recycled concrete as an aggregate for concrete—A review. Matériaux Constr. 1978, 11, 371–378. [Google Scholar] [CrossRef]

- Padilla, M.; Stalim, D. Escombros de Construcción y su Influencia en el Comportamiento Físico–Mecánicas en Adoquines de Tránsito Ligero, Lima–2021. Bachelor’s Thesis, Universidad Cesar Vallejo, Víctor Larco, Peru, 2021. [Google Scholar]

- Cuenca, K.A.; Sepúlveda, X.A. Elaboración de Probetas a Base de RCD de Laboratorio de Concreto para Adoquines Peatonales en el Municipio de Girardot, Cundinamarca. Bachelor’s Thesis, Corporación Universitaria Minuto de Dios, Bogotá, Colombia, 2021. [Google Scholar]

- Silva, J.M.; Brito, J.d.; Correia, J.R.; Almeida, J.M.d. Properties of recycled aggregates from different composition and its influence on concrete strength. Rev. IBRACON Estrut. E Mater. 2019, 12, 1195–1207. [Google Scholar]

- Su, Y.; Yao, Y.; Wang, Y.; Zhao, X.; Li, L.; Zhang, J. Modification of Recycled Concrete Aggregate, and Its Use in Concrete: An Overview of Research Progress. Materials 2023, 16, 7144. [Google Scholar] [CrossRef] [PubMed]

- González-Taboada, I.; González-Fonteboa, B.; Martínez-Abella, F.; Castro-Fresno, D. Study of recycled concrete aggregate quality and its relationship with recycled concrete compressive strength using database analysis. Mater. Construcción 2016, 66, 323. [Google Scholar] [CrossRef]

- Valdés, A.J. Re-use of construction and demolition residues and industrial wastes for the elaboration or recycled eco-efficient concretes. Univ. León 2010, 8, 25–34. [Google Scholar] [CrossRef]

- Elías, J.W.; Flores, J.E.; Barrera, R.E.; Reyna, C.A. Effect of the use of recycled concrete aggregates on the environment and housing construction in Huamachuco city. Puriq 2020, 2, 16–27. [Google Scholar]

- INV E-213; Análisis Granulométrico de los Agregados Grueso y Fino. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-230; Índice de Aplanamiento y de Alargamiento de los Agregados para Carreteras. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-217; Densidad Bulk (Peso Unitario) y Porcentaje de Vacío de los Agregados en Estado Suelto y Compactado. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-218; Resistencia a la Degradación de los Agregados de Tamaños Menores de 37.5 mm (1 ½″) por Medio de la Máquina de los Ángeles. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-222; Densidad, Densidad Relativa (Gravedad Especifica) y Absorción del Agregado Fino. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-223; Densidad, Densidad Relativa (Gravedad Especifica) y Absorción del Agregado Grueso. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- EN 206 2013+A2:2021; Concrete-Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2021.

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- INV E-426; Resistencia a la Compresión de Adoquines de Concreto. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-415; Resistencia a la Flexión del Concreto Usando una Viga Simple Apoyada y Cargada en el Punto Central. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- INV E-427; Absorción de Agua por los Adoquines de Concreto. Normas de Ensayo para Materiales para Carreteras. Instituto Nacional de Vías: Bogotá, Colombia, 2013.

- NTC 5147; Método de Ensayo para Determinar la Resistencia a la Abrasión de Materiales para Pisos y Pavimentos, Mediante Arena y Disco Metálico Ancho. Metroblock S.A.: Barranquilla, Colombia, 2002.

- NTC 2017; Adoquines de Concreto para Pavimentos. Metroblock S.A.: Barranquilla, Colombia, 2004.

- Ministerio de Ambiente y Desarrollo Sostenible. Resolución 472 de 2017, por la cual se Reglamenta la Gestión Integral de los Residuos Generados en las Actividades de Construcción y Demolición (RCD) y se Dictan Otras Disposiciones. Diario Oficial No. 50.166. 28 February 2017. Available online: https://normas.cra.gov.co/gestor/docs/resolucion_minambienteds_0472_2017.htm (accessed on 15 March 2025).

- Lozano, F.M.; Castro, C.L. Formulación de un Plan de Gestión para el uso de Agregados de Concreto Reciclado en Concretos Hidráulicos para una Empresa Constructora en la Ciudad de Bogotá. Master’s Thesis, Universidad Católica de Colombia, Bogotá, Colombia, 2018. [Google Scholar]

- Xargay, H.; Ripani, M.; Caggiano, A.; Folino, P.; Martinelli, E. Uso de materiales reciclados en compuestos cementicios. Tecnura 2019, 23, 38–51. [Google Scholar] [CrossRef]

- Xiao, J.-Z.; Li, J.-B.; Zhang, C. Mechanical properties of recycled aggregate concrete under unaxial loading. Mater. Struct. 2004, 35, 1187–1194. [Google Scholar]

- Xiao, J.Z.; Li, J.B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2006, 39, 655–664. [Google Scholar] [CrossRef]

- Jian, S.-M.; Wu, B. Compressive behavior of compound concrete containing demolished concrete lumps and recycled aggregate concrete. Constr. Build. Mater. 2020, 272, 121624. [Google Scholar] [CrossRef]

- Aneiros, L.M. Gestión de RCD y su repercusión en el desarrollo sostenible. Residuos Rev. Técnica Medio Ambiente 2008, 102, 48–60. [Google Scholar]

- Montalvo, E.; Nathaly, K. Reaprovechamiento de los Residuos de Construcción y Demolición, Como Agregado Reciclado para la Elaboración de Adoquines, 2018. Master’s Thesis, Universidad Cesar Vallejo, Víctor Larco, Peru, 2018. [Google Scholar]

- Martínez, Y.R.; Poveda, J.E. Fabricación de Adoquín a Partir de un Sistema de Aprovechamiento de Escombros en Obra. Master’s Thesis, Universidad la Gran Colombia, Bogotá, Colombia, 2015. [Google Scholar]

- Montiel, L.M. Uso de Agregaos Reciclados para la Fabricación de Adoquines que se Puedan Utilizar en la Pavimentación de Calles, Avenidas y Pasos Peatonales. Master’s Thesis, Universidad Nacional Autónoma de México, Mexico City, Mexico, 2017. [Google Scholar]

- Agreda, G.A.; Moncada, L.G. Viabilidad en la Elaboración de Prefabricados en Concreto Usando Agregados Gruesos Recilados. Bachelor’s Thesis, Universidad Católica de Colombia, Bogotá, Colombia, 2015. [Google Scholar]

- Hedriks, C.F.; Janssen, G.T. Application of contruction and demolition waste. Univ. Tecnológica Delft 2001, 45, 95–108. [Google Scholar]

- González, B. Hormigones con Áridos Reciclados Procedentes de Demoliciones: Dosificaciones, Propiedades Mecánicas y Comportamiento Estructural al Cortante. Ph.D. Thesis, Universidade da Coruña, Coruña, Spain, 2002. [Google Scholar]

| Parameters | Value | |

|---|---|---|

| Coarse (C-NA) | Fine (F-NA) | |

| Fineness Modulus | 7.30 | 3.10 |

| 30.26 | - | |

| 1397.80 | 1344.8 | |

| 1540.70 | 1514.6 | |

| 0.21 | 0.86 | |

| 2550.00 | 2350.00 | |

| 1.94 | 4.01 | |

| Parameters | Value | |

|---|---|---|

| Coarse (CDW-CA-TS) | Fine (CDW-FA-TS) | |

| Fineness Modulus | 7.30 | 3.10 |

| 31.54 | - | |

| 1143.90 | 1098.40 | |

| 1266.70 | 1199.30 | |

| 4.17 | 4.57 | |

| 2150.00 | 2080.00 | |

| 6.96 | 9.15 | |

| (%) | Water (kg) | Cement (kg) | Natural Aggregate | Aggregate CDW-A-TS | ||

|---|---|---|---|---|---|---|

| CDW-A-TS | Coarse (kg) | Fine (kg) | Coarse (kg) | Fine (kg) | ||

| 0 | 5.88 | 17.61 | 32.88 | 27.99 | 0.00 | 0.00 |

| 30 | 5.75 | 17.61 | 23.01 | 19.59 | 8.80 | 7.60 |

| 50 | 5.66 | 17.61 | 16.44 | 14.00 | 14.67 | 12.67 |

| 100 | 5.45 | 17.61 | 0.00 | 0.00 | 29.35 | 25.34 |

| Modulus of Rupture (Mr) at 28 Days Minimum (MPa) | Track Length (lh) Maximum (mm) | Absorption (Aa) After 24 h (% Max) | |

|---|---|---|---|

| Average of 5 paving stones | Individual | Average of 5 paving stones | Average of 5 paving stones |

| 5.0 | 4.2 | - | 7 |

| 4.2 | 3.8 | 23 | 7 |

| Notation | Rca (MPa) | Average Rca (MPa) | (−) Decrease, (+) Increase Compression Strength (%) |

|---|---|---|---|

| 0% CDW-A-TS M1 C-A | 37.64 | 39.17 | − |

| 0% CDW-A-TS M2 C-A | 41.26 | ||

| 0% CDW-A-TS M3 C-A | 35.72 | ||

| 0% CDW-A-TS M4 C-A | 38.55 | ||

| 0% CDW-A-TS M5 C-A | 42.68 | ||

| 30% CDW-A-TS M1 C-A | 48.68 | 52.03 | (+) 32.82 |

| 30% CDW-A-TS M2 C-A | 62.01 | ||

| 30% A-RCD-LT M3 C-A | 53.50 | ||

| 30% CDW-A-TS M4 C-A | 43.87 | ||

| 30% CDW-A-TS M5 C-A | 52.07 | ||

| 50% CDW-A-TS M1 C-A | 49.16 | 48.37 | (+) 23.50 |

| 50% CDW-A-TS M2 C-A | 44.88 | ||

| 50% CDW-A-TS M3 C-A | 45.91 | ||

| 50% CDW-A-TS M4 C-A | 41.14 | ||

| 50% CDW-A-TS M5 C-A | 60.78 | ||

| 100% CDW-A-TS M1 C-A | 44.96 | 44.93 | (+) 14.71 |

| 100% CDW-A-TS M2 C-A | 40.09 | ||

| 100% CDW-A-TS M3 C-A | 50.54 | ||

| 100% CDW-A-TS M4 C-A | 40.17 | ||

| 100% CDW-A-TS M5 C-A | 48.89 |

| Notation | Mr (MPa) | Average Mr (MPa) | (−) Decrease, (+) Increase Flexural Strength (%) |

|---|---|---|---|

| 0% CDW-A-TS M6 F-T | 5.26 | 5.52 | − |

| 0% CDW-A-TS M7 F-T | 5.42 | ||

| 0% CDW-A-TS M8 F-T | 5.13 | ||

| 0% CDW-A-TS M9 F-T | 4.80 | ||

| 0% CDW-A-TS M10 F-T | 5.49 | ||

| 30% CDW-A-TS M6 F-T | 5.57 | 5.54 | (+) 6.13 |

| 30% CDW-A-TS M7 F-T | 5.69 | ||

| 30% CDW-A-TS M8 F-T | 5.40 | ||

| 30% CDW-A-TS M9 F-T | 5.66 | ||

| 30% CDW-A-TS M10 F-T | 5.37 | ||

| 50% CDW-A-TS M6 F-T | 5.25 | 5.38 | (+) 3.07 |

| 50% CDW-A-TS M7 F-T | 5.21 | ||

| 50% CDW-A-TS M8 F-T | 5.36 | ||

| 50% CDW-A-TS M9 F-T | 5.58 | ||

| 50% CDW-A-TS M10 F-T | 5.49 | ||

| 100% CDW-A-TS M6 F-T | 5.88 | 5.29 | (+) 1.34 |

| 100% CDW-A-TS M7 F-T | 5.70 | ||

| 100% CDW-A-TS M8 F-T | 5.19 | ||

| 100% CDW-A-TS M9 F-T | 4.26 | ||

| 100% CDW-A-TS M10 F-T | 5.41 |

| Notation | Aa (%) | Average Aa (%) | (−) Decrease, (+) Increase Absorption (%) |

|---|---|---|---|

| 0% CDW-A-TS M11 A-B | 6.23 | 6.38 | − |

| 0% CDW-A-TS M12 A-B | 6.86 | ||

| 0% CDW-A-TS M13 A-B | 6.70 | ||

| 0% CDW-A-TS M14 A-B | 6.47 | ||

| 0% CDW-A-TS M15 A-B | 5.64 | ||

| 30% CDW-A-TS M11 A-B | 7.30 | 7.06 | (+) 10.66 |

| 30% CDW-A-TS M12 A-B | 7.44 | ||

| 30% CDW-A-TS M13 A-B | 7.06 | ||

| 30% CDW-A-TS M14 A-B | 6.86 | ||

| 30% CDW-A-TS M15 A-B | 6.62 | ||

| 50% CDW-A-TS M11 A-B | 6.96 | 7.45 | (+) 16.77 |

| 50% CDW-A-TS M12 A-B | 7.49 | ||

| 50% CDW-A-TS M13 A-B | 7.32 | ||

| 50% CDW-A-TS M14 A-B | 7.55 | ||

| 50% CDW-A-TS M15 A-B | 7.92 | ||

| 100% CDW-A-TS M11 A-B | 8.48 | 7.99 | (+) 25.24 |

| 100% CDW-A-TS M12 A-B | 7.49 | ||

| 100% CDW-A-TS M13 A-B | 8.43 | ||

| 100% CDW-A-TS M14 A-B | 7.08 | ||

| 100% CDW-A-TS M15 A-B | 8.47 |

| Notation | Lh (mm) | Average Lh (mm) | (−) Decrease, (+) Increase Longitud De La Huella (%) |

|---|---|---|---|

| 0% CDW-A-TS M16 R-A | 19.80 | 20.13 | − |

| 0% CDW-A-TS M17 R-A | 19.20 | ||

| 0% CDW-A-TS M18 R-A | 21.40 | ||

| 30% CDW-A-TS M16 R-A | 20.10 | 19.83 | (−) 1.49 |

| 30% CDW-A-TS M17 R-A | 19.60 | ||

| 30% CDW-A-TS M18 R-A | 19.80 | ||

| 50% CDW-A-TS M16 R-A | 19.30 | 20.42 | (+) 1.44 |

| 50% CDW-A-TS M17 R-A | 21.90 | ||

| 50% CDW-A-TS M18 R-A | 20.00 | ||

| 100% CDW-A-TS M16 R-A | 20.30 | 21.37 | (+) 6.16 |

| 100% CDW-A-TS M17 R-A | 20.10 | ||

| 100% CDW-A-TS M18 R-A | 23.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murillo, C.; Calvache, D.; Gómez, C. Mechanical Behavior of Paving Stones Made from Construction and Demolition Waste (CDW). Buildings 2025, 15, 2986. https://doi.org/10.3390/buildings15172986

Murillo C, Calvache D, Gómez C. Mechanical Behavior of Paving Stones Made from Construction and Demolition Waste (CDW). Buildings. 2025; 15(17):2986. https://doi.org/10.3390/buildings15172986

Chicago/Turabian StyleMurillo, Carol, Deyvid Calvache, and Carlos Gómez. 2025. "Mechanical Behavior of Paving Stones Made from Construction and Demolition Waste (CDW)" Buildings 15, no. 17: 2986. https://doi.org/10.3390/buildings15172986

APA StyleMurillo, C., Calvache, D., & Gómez, C. (2025). Mechanical Behavior of Paving Stones Made from Construction and Demolition Waste (CDW). Buildings, 15(17), 2986. https://doi.org/10.3390/buildings15172986