1. Introduction

The construction industry is a key driver of national development, especially in rapidly urbanizing regions like the Gulf states. While it contributes to infrastructure growth and job creation, this sector faces persistent challenges, including project delays, cost overruns, labor inefficiencies, and safety risks. To address these persistent issues, there is growing interest in integrating advanced technologies that can improve construction outcomes and asset longevity. One such innovation is Structural Health Monitoring (SHM), which enables real-time assessment of infrastructure through data-driven insights, supporting timely maintenance and structural safety. Moreover, SHM ensures the safety and serviceability of critical structures like bridges, high-rise buildings, and industrial facilities through continuous monitoring and condition assessment. Optimizing SHM system configurations, including the arrangements and types of sensors, is a crucial step in ensuring effective monitoring outcomes, as highlighted in recent decision-making frameworks [

1].

For better and more efficient SHM applications, it was found that the transition from traditional manual inspection methods to automated, intelligent systems powered by robotics offers significant advantages in terms of efficiency, coverage, and reliability [

2,

3]. Robotic technologies are emerging as key enablers of SHM. They can access hard-to-reach or dangerous areas, perform repetitive tasks with precision, and transmit real-time data to support predictive maintenance decisions [

4,

5]. Moreover, robotics and automation offer a safer, more accurate, and more efficient alternative to manual inspections. These technologies enable high-precision monitoring in hazardous or hard-to-reach areas and, when combined with artificial intelligence (AI), facilitate predictive diagnostics for proactive infrastructure management. Therefore, research has increasingly recognized robotics as a transformative approach in the field of SHM and infrastructure management. A recent study demonstrated the potential for deep learning-based modal parameter identification techniques to further improve diagnostic accuracy in SHM [

6].

Given the growing interest in this emerging field, a preliminary literature review is essential to guide future research and establish a solid foundation for scholarly exploration. While several reviews have addressed SHM and robotics independently, a focused synthesis that specifically addresses the integration of robotic technologies in SHM, particularly within the context of Saudi Arabia’s infrastructure development, has not been published, underscoring a significant gap in the literature. Therefore, this paper addresses that gap by providing a basic overview of the integration of robotics in SHM, with a particular emphasis on the Saudi Arabian construction sector. It examines the key technological, institutional, and contextual factors influencing adoption, thereby laying the groundwork for this study’s subsequent empirical investigation. This paper concludes with a set of well-informed recommendations for future research, offering potential research directions to support and inspire scholars and practitioners interested in advancing this critical area of study.

A key research gap became evident in the reviewed literature: while there is a growing volume of publications addressing robotics and automation in SHM, very few studies offer a systematic synthesis that integrates technical developments with contextual factors such as geographic, institutional, and industry-specific constraints.

Accordingly, the primary objective of this review is to critically examine the integration of robotics into SHM, with a particular focus on the Saudi Arabian construction sector. This includes the following:

Synthesizing recent advancements in robotic platforms and their applications in SHM;

Identifying key challenges and enablers associated with robotics adoption;

Drawing transferable insights from other industries such as healthcare, energy, and law;

Offering evidence-based recommendations to inform future research, industry practices, and policy development in Saudi Arabia and beyond.

2. Review Methodology

This review was conducted using a structured, thematic approach to synthesize current knowledge on the integration of robotics into SHM, with a particular focus on the Saudi Arabian construction sector. The process involved three main phases: research identification, screening and selection, and thematic analysis.

This review does not follow a PRISMA protocol but is instead structured as a narrative review with a thematic focus, aiming to synthesize current developments in robotics for SHM, especially as applied to the Saudi construction sector.

2.1. Research Identification

Relevant research was identified through electronic searches in academic databases, e.g., Scopus, Web of Science, Google Scholar, and ScienceDirect. Keywords used in the searches included combinations of “robotics”, “structural health monitoring”, “construction robotics”, “automation in SHM”, “AI in infrastructure monitoring”, and “Saudi Arabia infrastructure technology”. The searches covered publications from 2012 to 2025, with an emphasis on recent studies published between 2021 and 2025 to ensure currency and relevance.

2.2. Screening and Selection

Articles were included based on the following criteria:

Peer-reviewed journal articles, conference papers, or authoritative technical reports;

A clear focus on robotics applications in SHM or related sectors;

Relevance to technological, institutional, or contextual aspects of SHM adoption;

Studies offering transferable insights from other sectors such as healthcare, energy, and law.

Duplicates, irrelevant studies, and those without accessible full texts were excluded. A total of 38 core references were selected for focused review.

2.3. Thematic Analysis

The selected literature was analyzed and categorized into thematic domains aligned with the study objectives:

Technological developments in robotic SHM platforms;

Challenges and enablers of adoption in construction;

Cross-sectoral insights from related fields;

Policy and future research recommendations.

This process helped structure the review into coherent sections and helped identify emerging patterns and knowledge gaps.

3. Overview of SHM in Building Structures

3.1. Concept and Components of SHM

SHM refers to the systematic observation and interpretation of sensor-based data to evaluate the condition and performance of civil structures over time. It plays a central role in ensuring infrastructure integrity by enabling continuous or periodic assessment through integrated sensor networks and intelligent data-processing systems. These components typically include data acquisition units, communication systems, and computational models that support maintenance decisions and safety evaluations.

Recent advancements have improved SHM systems with advanced sensors and wireless communication. SHM applications now use a variety of sensors, including piezoelectric transducers, fiber optics, and vibration sensors, with data management platforms for real-time diagnostics and monitoring. As Wang and Ke [

3] mentioned, this integration can facilitate early fault detection and automated decision-making. The overall architecture supports predictive maintenance, with no need for manual inspection, and extends the life and functionality of infrastructure. Contemporary reviews highlight how these developments are consolidating into coherent SHM workflows and best practices, offering readers an updated map of this field [

7].

3.2. Importance of Early Defect Detection in Structures

Early detection of structural defects is key to the long-term performance and safety of infrastructure systems. Undetected issues like cracks, delamination, or corrosion can escalate into critical failures, pose safety risks, and cost a lot to repair. SHM systems provide a proactive monitoring framework that allows stakeholders to track performance indicators and structural anomalies at an early stage.

Scuro et al. [

8] said that combining SHM with real-time data acquisition and wireless communication allows for timely intervention strategies. This minimizes unexpected downtime and allows for better maintenance planning. As infrastructure ages and gets more loaded, early detection of defects is key to serviceability and public safety. Advanced signal-processing techniques, such as wavelet transforms and Fourier analyses, have also been increasingly applied to enhance SHM data interpretation, particularly in post-disaster assessments [

9].

3.3. Benefits of SHM Related to Infrastructure Durability and Safety

SHM contributes to infrastructure durability by giving insight into the evolving physical states of materials and load-bearing components. Through continuous feedback, engineers can monitor stress distributions, fatigue accumulation, and material degradation and can make precise interventions to reinforce or retrofit vulnerable areas.

Yue et al. [

10] showed how SHM systems support performance-based maintenance and reduce unnecessary repairs by providing data that reflects actual structural conditions. From a safety perspective, SHM systems are essential in areas prone to dynamic stressors such as seismic zones and heavy traffic corridors. Real-time monitoring facilitates rapid decision-making and emergency responses, thereby reducing risks to human life and property.

3.4. Applications of SHM in Structures

SHM is widely applied across various sectors, including transportation, energy, and public infrastructure. In bridge engineering, it is used to monitor load effects, displacement, and fatigue. In high-rise buildings and sports arenas, it ensures dynamic stability under operational conditions. These applications enhance the reliability, value, and risk management of critical assets.

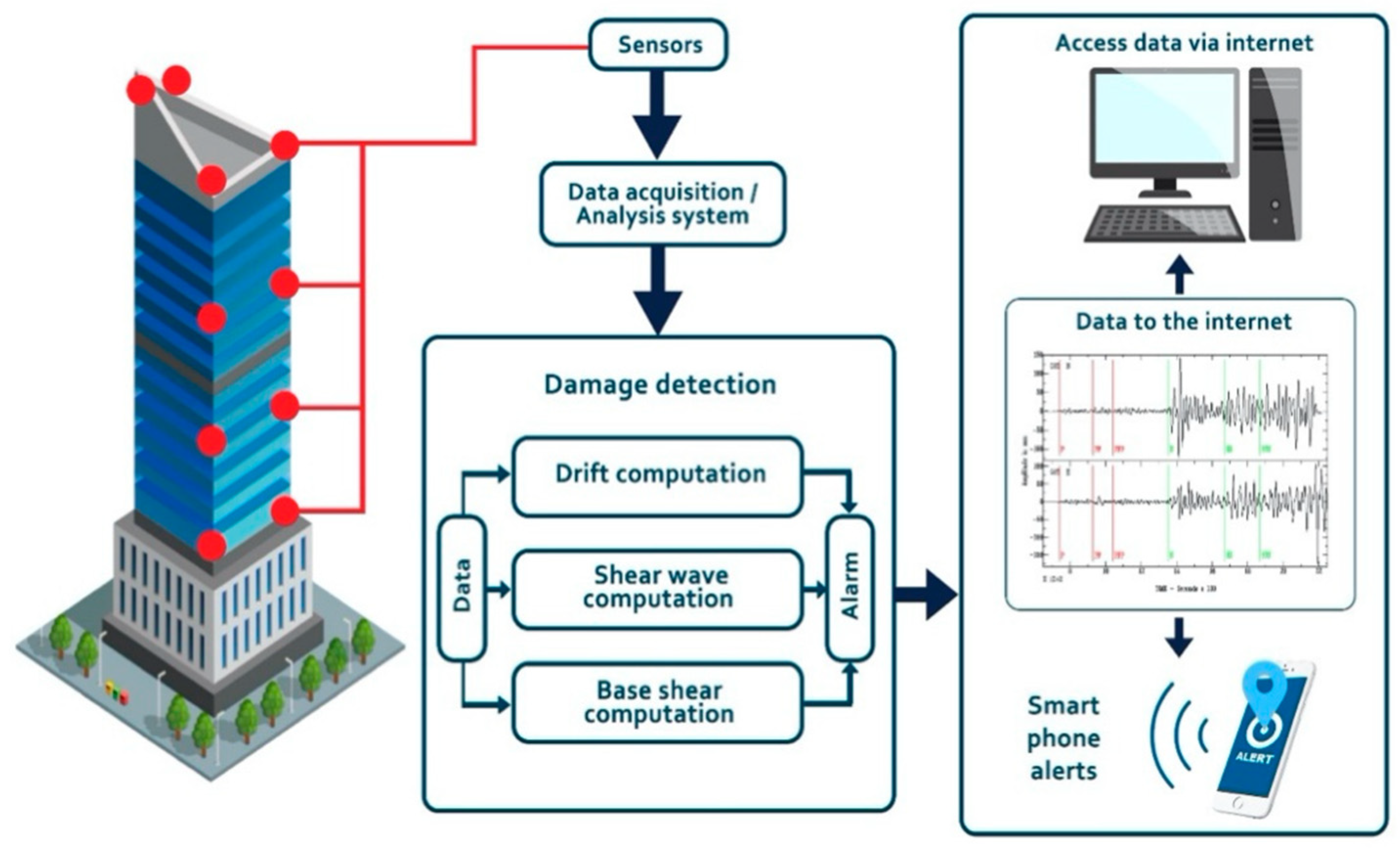

Figure 1 illustrates how SHM functions in high-rise buildings.

Additionally, SHM is being adopted in smart cities and sustainable construction practices, where digital technologies are used to model and optimize infrastructure systems. Figueiredo and Brownjohn [

12] highlighted the evolution of SHM in bridge systems using statistical pattern recognition, underscoring its role in managing aging infrastructure and optimizing long-term investment. The ability to adapt SHM solutions to diverse materials and structural forms further enhances their applicability across infrastructure types.

3.5. Limitations of Conventional Inspection Methods

Traditional inspection approaches, such as visual checks and periodic manual testing, are constrained by their dependence on human judgment, limited access to structural components, and lack of continuous monitoring. These methods are less effective when detecting hidden or progressive damage and often require service interruptions to conduct thorough inspections.

As noted in the literature, these limitations have led to increased adoption of SHM systems, which offer more objective, efficient, and data-driven assessments. SHM not only enhances detection accuracy but also reduces labor and safety risks associated with inspections in hazardous or elevated areas. These advantages make sensor-based SHM a superior alternative for modern infrastructure monitoring and asset management.

4. Robotics in Structural Health Monitoring: Technologies and Applications

The integration of robotic technologies with SHM systems marks a pivotal advancement in the inspection, assessment, and maintenance of civil infrastructure. Robotic platforms provide access to hard-to-reach, hazardous, or expansive areas and enable high-precision data acquisition using a wide array of sensors and communication technologies. These systems enhance diagnostic accuracy, improve safety, and support predictive maintenance through real-time monitoring and AI integration. In this context, AI-enabled reconstruction and imputation methods can enhance the utility of robotic inspections by filling sensing gaps and stabilizing time-series streams for downstream diagnostics [

13].

Tian et al. [

4] highlighted how intelligent robotic systems have increasingly been adapted to support various SHM tasks, including autonomous data collection, real-time structural assessment, and predictive diagnostics, especially in environments requiring precision and adaptability.

In contrast to conventional robotic systems, which are typically limited to remote-controlled data acquisition, AI-enhanced platforms can autonomously interpret complex datasets, detect structural anomalies in real time, and support predictive decision-making, thereby significantly improving operational efficiency and safety outcomes.

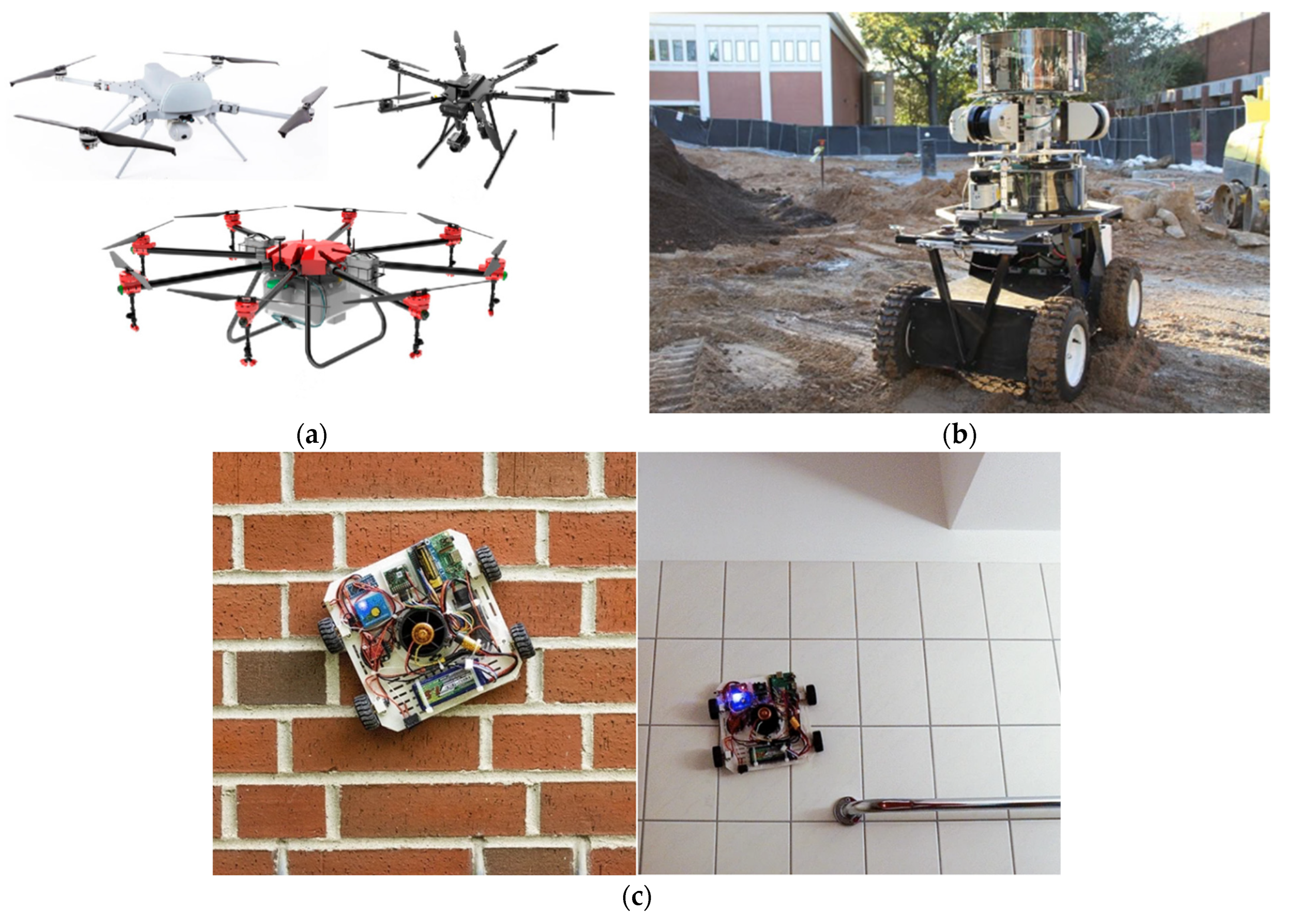

Robotic systems for SHM typically include aerial, wall-climbing, ground, and cable-climbing platforms (

Figure 2). These platforms are equipped with visual, infrared, ultrasonic, or electromagnetic sensors and can perform both surface-level and internal inspections across diverse infrastructure types. For example, unmanned aerial vehicles (UAVs) enable rapid and non-contact inspection of façades, bridge decks, and wind turbine blades. Their mobility, combined with advanced imaging tools, facilitates efficient detection of defects such as cracks, corrosion, and delamination in otherwise inaccessible areas. Integrating multiple sensing modalities into robotic platforms, such as combining visual, ultrasonic, and electromagnetic sensors, can provide a more holistic structural assessment, as shown by recent multi-sensor SHM frameworks [

14].

Gupta [

18] emphasizes the growing role of UAVs in marine structure inspection, where guided wave sensors and imaging systems mounted on drones can detect defects in harsh coastal environments. Wall-climbing robots, using suction, magnets, or biomimetic adhesion, can perform close-up assessments on vertical or curved surfaces in dense urban areas or confined industrial settings. Cable-climbing and ground robots are particularly useful for inspecting cables, tunnels, and pipelines, often integrating nondestructive evaluation (NDE) tools such as acoustic emission sensors, ultrasonic transducers, or electromagnetic scanners.

Mazzeschi [

19] highlighted the use of electromagnetic testing in aerospace structures. It is now increasingly applied in civil contexts via robotic deployment. These tools allow for subsurface inspection to detect hidden flaws such as voids, delamination, or rebar corrosion. These systems are typically remotely operated or semi-autonomous, minimizing human exposure to dangerous environments such as underwater piers, aged tunnels, or earthquake-affected structures.

By streamlining data collection and improving diagnostic precision, robotic SHM technologies reduce reliance on manual inspections, support real-time decision-making, and enhance proactive infrastructure management. Their role is particularly critical at large-scale, complex, or remote installations where conventional inspection methods are infeasible or unsafe.

Górski et al. [

20] further emphasized that robotic systems have become indispensable in modern SHM strategies by enabling both autonomous and assisted inspections. Their review highlighted the ability of robotic devices to enhance operational safety, minimize inspection time, and extend monitoring capabilities across a range of structures, including high-rise buildings, bridges, and industrial installations.

5. Robotics and Automated Systems for SHM

5.1. Mobile Robots, Climbing Robots, and Drones for Dynamic Response Measurement

Robotic platforms are being used not only for visual inspections but also to capture the dynamic responses of structures under operational or environmental loads. Ground-based mobile robots can navigate indoor and outdoor structural environments autonomously with sensors such as accelerometers, gyroscopes, and strain gauges. These systems collect data on displacement, modal frequencies, damping ratios, and other vibrational properties so engineers can see real-time structural behavior and detect anomalies such as resonance or fatigue. Advanced signal-processing methods, such as wavelet transforms and Fourier-based analyses, continue to play a central role in interpreting vibration data, including post-disaster assessments where transient and non-stationary behaviors are prominent [

21]. Building on these measurements, AI-assisted estimators can infer unmeasured states and impute missing sensor streams with high fidelity, improving the continuity and quality of vibration-based diagnostics [

22]. Recent deep learning frameworks for automated modal parameter identification further enhance the reliability of frequency and damping estimation under operational conditions [

23].

Atencio et al. [

24] introduced robotic process automation (RPA) in SHM to automate data workflows in dynamic environments. These technologies, when integrated with mobile robots, enable continuous vibration monitoring and automated data preprocessing, significantly reducing the time and expertise required for data interpretation. Complementary reconstruction techniques, e.g., state-space learning and compressed-sensing-based formulations, can recover full acceleration fields from sparse sensor grids, enabling more complete modal and damage indicators without dense instrumentation [

25].

Flying drones and climbing robots can be deployed in environments that are challenging for mobile ground robots, such as tall towers, bridge pylons, or narrow shafts. According to Hu and Assaad [

26], drones equipped with inertial measurement units (IMUs) and real-time kinematic (RTK) GPS systems offer precise positioning and vibration-sensing capabilities. These systems can be deployed immediately after extreme events, such as earthquakes or storms, to assess structural responses, making them valuable tools for rapid post-disaster evaluation.

Johann et al. [

27] discussed the validation of robot-enabled embedded sensors in civil structures, demonstrating that robotic platforms can not only collect dynamic data but can also interact with embedded systems to trigger alarms or adjust monitoring parameters. This integration enables dynamic SHM with enhanced adaptability and real-time diagnostic capabilities, supporting both short-term incident responses and long-term performance monitoring.

5.2. Multimodal Rigid Robots and Soft Wall-Climbing Robots

Recent technological advances have led to the emergence of multimodal robotic systems capable of switching between locomotion types, such as flying, rolling, crawling, or climbing, depending on the inspection environment. These robots are designed to navigate a wide range of structural contexts and can carry diverse sensor arrays, including visual, thermal, acoustic, and electromagnetic devices. This adaptability makes them particularly effective for inspecting hybrid structures or infrastructure composed of different materials and geometries.

Tian et al. [

4] emphasized the modular architecture of intelligent robotic systems, which allows users to customize sensor payloads based on specific inspection requirements. This flexibility reduces the need for multiple separate devices, enabling more comprehensive evaluations in a single deployment. Such robots are also beneficial for inspecting inaccessible or hazardous areas, enhancing worker safety and reducing inspection costs.

In parallel, soft robotics has introduced new possibilities for inspecting sensitive or historically significant structures. Soft wall-climbing robots, as examined by Hu and Assaad [

26], use flexible bodies and biomimetic adhesion mechanisms, such as suction cups, electro-adhesion pads, or gecko-inspired feet, to traverse delicate or irregular surfaces. Their lightweight and compliant designs reduce the risk of damaging fragile surfaces, making them ideal for use in heritage buildings, curved façades, or prestressed concrete elements.

These soft robots are also inherently safer for human interaction and can conform to complex surface geometries that are challenging for rigid systems. Their integration with real-time sensing and AI-driven defect recognition enables them to operate autonomously, map structural anomalies with high precision, and contribute to long-term preservation strategies.

5.3. Future Outlook: Toward Intelligent and Cooperative SHM Robotics

The future of robotics in SHM lies in the development of intelligent, cooperative, and autonomous systems that can operate collaboratively in multi-agent frameworks. As discussed by Gkoumas et al. [

28], the integration of connected vehicles, Internet of Things (IoT) technologies, and cloud-based analytics will allow SHM robots to share information across systems and adapt their operations based on collective intelligence. This indirect SHM (iSHM) approach expands their monitoring capabilities beyond single infrastructure assets, enabling large-scale, network-wide health assessments.

Through cloud-connected platforms, real-time decision-making, and robotic swarming techniques, SHM systems are expected to become more predictive, self-organizing, and capable of continuous infrastructure surveillance across urban environments. These capabilities will play a vital role in the context of smart cities, infrastructure digital twins, and sustainable development planning.

6. Application of Robotics for SHM

6.1. Robots for Defect Inspection

Robotic systems have become indispensable in detecting both surface-level and internal defects in civil and specialized infrastructure. These systems facilitate safe, efficient, and non-intrusive assessments across a range of environments, including bridges, high-rise buildings, tunnels, and offshore structures. Surface inspections commonly utilize unmanned aerial vehicles (UAVs) and wall-climbing robots equipped with high-resolution visual, infrared, or multispectral imaging systems. These robots enable rapid, non-contact inspection of large and complex surfaces, such as façades, bridge decks, and wind turbine blades.

Gupta [

18] emphasizes the growing role of UAVs in marine structure inspection, where guided wave sensors and advanced imaging tools are mounted on drones to detect corrosion, cracking, and delamination in environments that are otherwise difficult or dangerous to access. Wall-climbing robots, often employing suction-based, magnetic, or biomimetic adhesion systems, can conduct close-up inspections on vertical and curved surfaces. These platforms are especially valuable in urban settings and confined locations where scaffolding or human access is limited.

For internal and subsurface defect detection, cable-climbing and mobile ground robots equipped with nondestructive evaluation (NDE) tools, such as ultrasonic transducers, acoustic emission sensors, or electromagnetic-based scanners, have proven effective. Mazzeschi [

19] highlights the role of electromagnetic testing in aerospace structures. It is increasingly being adapted for civil applications through robotic deployment. These systems can identify hidden anomalies such as delamination, internal voids, and rebar corrosion with high precision. Operated remotely or semi-autonomously, these robots also enhance worker safety by operating in hazardous zones, such as aging tunnels, underwater piers, and assets with seismic damage.

Their sensor integration and high data acquisition rates not only enhance diagnostic accuracy but also support real-time decision-making. By reducing reliance on manual inspection, robotic systems used for defect detection streamline maintenance workflows and contribute significantly to proactive infrastructure management.

6.2. Robots for Vibration Measurement (e.g., Acceleration and Displacement)

Measuring vibration responses is a cornerstone of SHM, providing essential insights into the dynamic behavior and integrity of structural systems under operational or environmental loads. Robotic platforms have emerged as highly effective tools in this domain, as they are capable of collecting data related to acceleration, displacement, velocity, and modal frequency from locations that are often inaccessible or unsafe for manual instrumentation.

Unlike static sensor networks, which are fixed in place, mobile robotic systems offer spatial flexibility and targeted measurements across different parts of a structure. Mahairi [

29] demonstrated the use of semi-active vibration suppression in manufacturing robots, highlighting the potential for such robotic systems to monitor and even modulate vibrations in complex environments. These principles are now being extended to civil infrastructure, where mobile robots are deployed to scan structural elements using inertial measurement units (IMUs), accelerometers, and displacement sensors.

Ground-based robots are often utilized to measure vibrations on flat decks, floors, and interior structural components. For vertical or inclined surfaces, wall-climbing robots provide direct access, capturing high-resolution dynamic data critical for fatigue monitoring or damage localization. UAVs, on the other hand, are suited for high-elevation inspections of structures such as bridge cables, wind towers, and façade-mounted components, where they can hover and capture vibration data during ambient or controlled excitations.

Deng [

30] introduced magnetorheological dampers with variable stiffness and damping characteristics, which were integrated into robotic arms to enhance their responses to dynamic loads. This technology exemplifies how vibration-adaptive robotics can be leveraged not only for monitoring but also for interactive control during SHM tasks. Additionally, displacement sensors integrated into drones and climbing robots enable modal identification and structural resonance evaluation, thereby enhancing diagnostic depth.

Cable-climbing robots, which are specifically designed for suspension elements, can move along bridge cables or hangers to assess dynamic behavior and tension-related properties. These platforms offer a safer and more scalable alternative to manual rope access or scaffolding.

Robotic platforms for vibration monitoring differ in mobility, sensor capabilities, and suitability for specific structural conditions.

Table 1 compares these systems, highlighting how ground, aerial, wall-climbing, and cable-climbing robots serve complementary roles in SHM based on application environments and measured parameters.

7. Challenges in Adopting Robotics for SHM

7.1. Technological Readiness

Technological readiness refers to a nation or industry’s capacity to adopt and integrate advanced robotics into its infrastructure monitoring practices. This includes not only access to robotic technologies and intelligent sensors but also the availability of skilled personnel, data integration platforms, and standardized operational protocols. In regions like Saudi Arabia, this readiness is influenced by disparities in digital maturity across firms, the limited local manufacturing of robotic components, and the novelty of SHM-focused innovation ecosystems.

Tian et al. [

4] emphasized that although intelligent robotic systems are becoming increasingly available for SHM globally, their deployment in emerging markets is often hindered by challenges related to integration with legacy infrastructure and limited sensor-robot interoperability. Similarly, Johann et al. [

27] noted that embedding sensors into existing structures via robotics requires technical know-how, stable communication networks, and standardized calibration procedures, capabilities that are still evolving in many local contexts.

In the Saudi construction sector, small and medium-sized enterprises often lack the in-house technical expertise required for robotic operation and maintenance, thereby slowing the adoption of robotics. As Górski et al. [

20] noted, the sophistication of climbing and mobile robotic systems necessitates a digitally skilled workforce and supportive training infrastructure, elements still under development in many regions. Without coordinated investments in research, development, and education, the gap between technological availability and practical implementation will persist as a significant barrier.

7.2. Regulatory and Governmental Support

The successful integration of robotics into SHM practices depends heavily on the presence of a supportive regulatory environment. Clear regulations are needed to define operational boundaries, safety standards, inspection procedures, and data governance for autonomous systems operating in public or critical infrastructure spaces.

According to Gkoumas et al. [

28], the absence of harmonized standards for robotic SHM has slowed the deployment of such systems in Europe, despite technological maturity. This concern is mirrored in regions like the Gulf, where comprehensive robotic regulations, particularly in high-risk sectors such as bridges, tunnels, and airports, are still being developed. Particularly, issues such as UAV licensing, robotic autonomy levels, and liability in the case of failure remain undefined in many jurisdictions.

Atencio et al. [

24] stressed the importance of institutional alignment between regulatory bodies, technology providers, and infrastructure managers to facilitate SHM deployment at scale. Without clear inspection mandates and enforcement protocols, project owners and contractors often hesitate to invest in robotic systems, fearing non-compliance or legal uncertainty. Moreover, data protection concerns related to real-time video feeds, vibration signatures, and inspection logs require legislative clarity, mainly when data is transmitted across borders or cloud platforms.

For countries seeking to accelerate the adoption of robotics in SHM, such as Saudi Arabia under Vision 2030, embedding robotics into national construction codes and developing localized standards based on global best practices will be essential to unlocking large-scale implementation.

7.3. Cost and Maintenance

While robotic systems offer long-term efficiencies, the initial investments required to deploy them in SHM applications are often substantial. These costs encompass hardware procurement, software licenses, system integration, and personnel training. Deng [

20] and Mahairi [

30] both highlight that robotic platforms with dynamic sensing and vibration suppression technologies tend to involve complex electronics and control systems, making them more expensive to purchase and operate.

Gupta [

18] also noted that UAV-based SHM solutions used in marine environments must be robust, waterproof, and equipped with advanced sensor fusion, all of which contribute to high development and operational costs. This can be prohibitive for smaller infrastructure projects or firms with limited capital.

In addition to acquisition costs, robotic platforms require ongoing maintenance, sensor recalibration, and regular software updates to ensure optimal performance. Highly specialized personnel are also needed to interpret the collected data, especially when utilizing AI-driven analytics or autonomous navigation systems. Mazzeschi [

19] observed that maintaining electromagnetic-based NDE tools requires regular checks to ensure signal integrity and precision, further increasing lifecycle costs.

Although Hu and Assaad [

26] argue that mobile robots and UAVs can reduce long-term inspection expenditures by decreasing labor and minimizing disruptions, these benefits may not be realized without adequate funding models. Public–private partnerships and national incentive schemes may therefore be necessary to support early adoption and reduce cost-related resistance in emerging economies.

7.4. Power Supply and Battery Limitations

Energy limitations represent a critical technical challenge in robotic SHM, particularly for systems operating autonomously in remote, vertical, or high-demand environments. As SHM robots rely on batteries to power their mobility, sensors, communication modules, and onboard processors, energy constraints can significantly restrict mission duration and inspection coverage.

Hu and Assaad [

26] emphasize that energy consumption is particularly high during wall climbing and drone flights, which limits operational cycles and requires frequent recharging or battery replacement. Similarly, Górski et al. [

13] report that many field-deployed robots suffer from insufficient battery capacity, especially when conducting prolonged inspections of tall or inaccessible structures.

Environmental conditions, such as the extreme heat and dust found in many parts of Saudi Arabia, also impair battery efficiency and lifespan. These conditions require specialized thermal control mechanisms and power-hardened components. Deng [

20] and Mahairi [

30] both emphasize the importance of intelligent power management systems within robotic architectures, particularly when robots perform vibration monitoring or dynamic load assessments, which are energy-intensive tasks.

Innovative solutions are emerging to address these constraints. Solar-assisted charging stations, tethered power supplies, and wireless inductive charging technologies are being trialed in experimental SHM applications. For example, Johann et al. [

27] describe the use of hybrid energy systems in robot-enabled sensor platforms, which combine battery power with renewable sources to extend operational endurance. Adapting such solutions for Saudi infrastructure, particularly in coastal and rural areas, could significantly improve the feasibility of continuous robotic monitoring in energy-scarce zones.

7.5. Cross-Sector Insights on Robotics Adoption

To deepen the understanding of robotics adoption challenges in SHM, particularly within the Saudi Arabian construction context, this subsection draws on lessons from other sectors where similar technologies have been implemented. Industries such as healthcare, energy, and public administration offer valuable parallels, highlighting the issues of technological readiness, regulatory alignment, stakeholder engagement, and integration complexity. These cross-sectoral insights provide a broader framework for informing future SHM strategies and adoption models. The inclusion of cross-sector insights in this section is intended to enhance the SHM-specific analysis by drawing on established adoption experiences from analogous sectors.

Table 2 synthesizes cross-sectoral lessons that inform the adoption of robotics in SHM. Drawing from healthcare, energy, and public governance, the themes presented offer critical insights into overcoming barriers related to technological readiness, workforce adaptation, legal regulation, and operational resilience in the Saudi construction context.

7.5.1. Technological Readiness vs. Real-World Adoption

One common finding across sectors is that high levels of technological maturity, often described using the Technology Readiness Level (TRL) scale, do not automatically translate into widespread adoption. For instance, Östlund et al. [

35] found that despite the advanced TRLs of healthcare robots in Europe, their uptake was hindered by insufficient user engagement, misaligned policies, and a lack of institutional preparedness. This suggests that even when robotics systems are technically viable for SHM applications, as in Saudi Arabia’s smart infrastructure projects, adoption will remain limited unless stakeholders, from operators to regulators, are actively involved and well trained.

7.5.2. Institutional Capacity and Workforce Alignment

A recurring theme in robotics integration is the importance of institutional and workforce readiness. Mahbub [

36] highlighted that in the context of Malaysia’s construction industry limited awareness, inadequate training, and weak policy support significantly slowed automation uptake. These findings align closely with the Saudi context, where Vision 2030 outlines digital transformation goals, but operationalizing those goals in the construction sector is often constrained by gaps in digital literacy and workforce skill sets. Hence, the adoption of SHM robotics must be matched by targeted capacity-building and professional development.

7.5.3. Legal Frameworks and Regulatory Preparedness

The legal and regulatory infrastructure remains a critical enabler or barrier to robotics deployment. Holder et al. [

37] and Villaronga [

38] emphasized that the absence of clear accountability frameworks, data governance rules, and safety standards can stall implementation across both public and commercial domains. These insights underscore a key challenge for SHM in Saudi Arabia: robust legal mechanisms are needed to clarify responsibilities in cases of system failure; to regulate autonomous inspections; and to manage data privacy, particularly when real-time structural data is transmitted to cloud platforms or third-party vendors.

7.5.4. Adaptation to Sector-Specific Needs

Lessons from the healthcare sector, as reported by Javaid et al. [

39], reveal that successful integration of robotics depends not just on the robot’s capabilities but also on its contextual fit. In SHM, robotic platforms must be adapted to the structural typologies, environmental stresses, and inspection needs of different civil infrastructure systems. This finding supports the argument for designing domain-specific robotic solutions, such as cable-climbing robots for suspension bridges or heat-resistant UAVs for desert installations, rather than attempting to retrofit generalized systems.

7.5.5. Operational Resilience and Energy Management

Energy supply and durability remain universal concerns for mobile robotic systems, especially in field applications. Mikołajczyk et al. [

40,

41] reviewed battery technologies and found that operational longevity is a significant limitation in both indoor and outdoor robotic deployment. These findings are directly applicable to SHM in Saudi Arabia, where robots are expected to operate in large, remote, and often high-temperature environments. Power management solutions such as hybrid batteries, solar-assisted charging, and wireless inductive systems should therefore be prioritized to ensure uninterrupted inspections and data transmission.

7.5.6. AI Integration and Real-Time Decision Support

Soori et al. [

42] and Kakolu and Faheem [

43] emphasize the value of AI-driven decision-making in robotic applications. These technologies enhance autonomy, perception, and real-time responsiveness, capabilities that are especially critical in SHM, where early warnings and rapid diagnostics can prevent structural failures. In Saudi Arabia, where infrastructure spans seismic zones, coastal regions, and mega-urban developments, integrating AI into SHM robotics can enable predictive maintenance and improve long-term asset performance. However, this also requires robust digital infrastructure, from cloud analytics to edge computing at the sensor level. In addition, AI-based state estimators, such as neural extended Kalman filters, have shown strong performance in reconstructing structural responses and recovering missing measurements from sparse or incomplete sensing layouts [

22].

7.5.7. Human–Robot Interaction and Change Management

Finally, workforce perception and human–robot collaboration are often-overlooked but essential aspects of technology adoption. Campbell et al. [

45] and Kamisetty [

46] discussed how frontline technicians and engineers must accept and trust robotic systems, especially in high-stakes environments like surgical rooms or renewable energy plants. This parallels the construction sector, where site engineers must feel confident in robotic data and must be able to interpret outputs and adapt workflows accordingly. Without this cultural and behavioral alignment, even well-designed SHM systems may remain underutilized.

8. Benefits and Opportunities Associated with Adopting Robotics for SHM

This section outlines both the benefits realized and the emerging opportunities associated with the adoption of robotics in SHM, highlighting practical improvements already achieved in this field as well as areas with high future potential.

8.1. Accessibility and Safety

One of the most transformative opportunities provided by robotics in SHM is the significant enhancement of accessibility in hard-to-reach, confined, or hazardous environments. Traditional inspection methods often involve human entry into elevated, submerged, or narrow structural zones, which present considerable safety risks and logistical challenges. Robotic systems such as UAVs, cable-climbing platforms, and wall-climbing robots can remotely perform these tasks, drastically reducing the need for physical presence in high-risk areas.

Hu and Assaad [

26] found that ground and aerial robots perform effectively in confined environments like pipelines and high-voltage towers. These systems eliminate the need for scaffolding, rope access, or mechanical lifts, thereby reducing the risk of accidents and the time required for inspections. Gupta [

18] similarly demonstrated that UAVs equipped with guided wave sensors could safely inspect marine and offshore structures in high-tide zones, where human access is restricted.

The use of robotics also ensures that inspections cover structurally complex geometries, such as curved surfaces, vertical ducts, and submerged assets, with minimal blind spots. Górski et al. [

20] emphasized that robotic tools designed for concrete structures can maneuver with precision and safety in environments that were previously inaccessible. This capability not only enhances safety standards but also ensures comprehensive inspections, minimizes emergency repairs, and fosters a proactive maintenance culture.

8.2. Efficiency and Accuracy

Robotic systems dramatically improve the efficiency and accuracy of SHM operations. Autonomous platforms can be programmed to follow optimized inspection paths, reducing operational time, eliminating redundancy, and lowering labor costs. These systems can collect continuous, high-resolution data without the inconsistencies associated with manual inspection practices.

Johann et al. [

27] demonstrated how robot-enabled embedded sensor platforms significantly streamline SHM workflows by automating data capture and transmission. This eliminates the delays associated with manual inspections, enabling faster diagnostic cycles. Atencio et al. [

24] further illustrated how robotic process automation (RPA) in dynamic SHM applications reduces inspection times while maintaining consistent data quality across repeated assessments.

In terms of defect detection accuracy, Mazzeschi [

19] developed electromagnetic-based robotic systems that achieved high detection precision in locating subsurface defects, particularly in structural joints. These platforms outperform traditional tools due to their ability to filter noise and detect anomalies at the micro level. Moreover, Tian et al. [

19] found that robotic systems integrated with AI-powered image processing can detect small cracks and corrosion with accuracies exceeding those of manual assessments, particularly in repetitive or long structures.

The repeatability and objectivity of robotic systems eliminate human error and fatigue-related inconsistencies, making them ideal for long-duration or high-frequency inspections of critical infrastructure assets such as high-speed rail, tunnels, and offshore platforms.

8.3. Data-Driven Decision-Making

Robotic SHM systems serve as powerful enablers of data-driven decision-making by continuously collecting and transmitting real-time structural data to central monitoring systems. These systems integrate sensor data with AI, big data analytics, and Internet of Things (IoT) frameworks to derive actionable insights.

Tian et al. [

4] emphasized that intelligent robotic systems can support predictive maintenance models by analyzing stress, strain, displacement, and other physical metrics. These inputs feed into advanced decision-making platforms and can be used to create digital twins, virtual representations of real-world structures that respond dynamically to monitoring data. Gkoumas et al. [

28] further highlighted the rise of indirect SHM systems, where data from robotic inspections supports large-scale infrastructure modeling and investment planning.

This level of insight enables early identification of failure trends, targeted interventions, and more effective resource allocation. Mahairi [

29] noted that integrating vibration data into centralized systems allows engineers to refine modal analysis models and preempt potential structural failures in robotic environments. Similarly, Deng [

21] emphasized how robotics, integrated with adaptive damping and stiffness models, contributes not only to sensing but also to simulating structural behavior under dynamic loads.

Overall, the use of robotics accelerates SHM transitions from reactive to predictive paradigms, aligning with long-term objectives of infrastructure sustainability and operational efficiency.

8.4. Adaptability to Extreme Conditions

Another significant advantage of robotics in SHM is the ability to operate in extreme and challenging environmental conditions, such as those found in the deserts, coastlines, and industrial zones of Saudi Arabia. Harsh environments characterized by high temperatures, dust exposure, and mechanical vibration pose severe limitations for conventional inspection tools.

Hu and Assaad [

26] demonstrated how UAVs and ground robots designed with heat-resistant coatings, sealed enclosures, and autonomous obstacle-avoidance systems have been successfully deployed in oil refineries and arid pipeline corridors. These design modifications allow robotic platforms to operate continuously in high-temperature environments without overheating or sensor failure.

Johann et al. [

27] also noted the use of robotic systems with embedded thermal management features and protective casings for long-term monitoring in structurally exposed regions. These systems show strong resilience when monitoring long bridges, desert-based wind farms, and offshore rigs, even under severe thermal or weather-induced stresses.

Furthermore, solar-assisted energy systems and modular battery packs are increasingly used to enhance robotic endurance in power-constrained environments. Deng [

30] proposed vibration-sensitive energy recovery systems that could be adapted to recharge robotic SHM units during movement, further increasing sustainability and reducing the reliance on external power infrastructure.

These innovations confirm the growing adaptability of robotic SHM technologies in diverse and difficult field conditions. Their deployment ensures continuous monitoring in places where manual methods would be impractical or unsafe, positioning robotics as a cornerstone of resilient infrastructure asset management.

8.5. Robotic SHM in Saudi Arabia: National Initiatives, Opportunities, and Implementation Barriers

Adoption of SHM technologies is accelerating in Saudi Arabia in tandem with the nation’s push toward digital transformation and Construction 4.0 under Vision 2030. Flagship infrastructure initiatives, including smart cities, transportation networks, and coastal developments, are beginning to integrate SHM frameworks that combine AI, robotics, and data-driven diagnostics. As observed by Alsharo et al. [

47], these technologies are being utilized to enable real-time insights into structural performance, optimize maintenance strategies, and align them with broader sustainability goals.

Despite promising developments, the application of robotic SHM systems remains limited to select megaprojects and pilot initiatives. According to Masri et al. [

48], while global SHM technologies, such as cable-climbing robots, UAV-based defect inspection, and AI-powered analytics, are rapidly evolving, the Saudi construction sector continues to face challenges in large-scale integration due to gaps in skilled labor, digital readiness, and infrastructure compatibility. These limitations are particularly apparent in legacy structures that lack embedded sensor networks or designs that are retrofit-friendly.

Nevertheless, government-led reforms and strategic investments are laying the groundwork for more widespread adoption. As noted by Khahro and Khahro [

49], national policy frameworks are increasingly recognizing the role of intelligent monitoring technologies in occupational safety and infrastructure resilience. The integration of SHM into safety governance models and smart project planning aligns directly with Saudi Arabia’s aim to reduce workplace risks, improve compliance, and enhance asset lifecycle performance.

The Saudi Vision 2030 initiative identifies SHM as a key enabler of infrastructure modernization, particularly through the development of AI-enhanced and autonomous systems. Alsharo et al. [

47] describe the emergence of AI-based digital twin frameworks that connect sensor networks to cloud-based platforms for live structural simulation, risk prediction, and resource optimization. These advancements are directly contributing to the country’s goal of establishing smart cities and sustainable construction ecosystems.

Several high-profile Saudi projects serve as national benchmarks for SHM innovation:

NEOM, a futuristic USD 500 billion smart city under development, is integrating robotics, digital twins, and autonomous UAVs for continuous monitoring of structural assets. According to Al Masri et al. [

48], NEOM is leveraging Construction 4.0 tools to support predictive maintenance and autonomous inspections, setting a global precedent for robotics in infrastructure development.

The Red Sea Project demonstrates how SHM can be used to meet environmental and regulatory standards. Alsharo et al. [

47] note that this project employs AI-powered sensors and robotic inspection platforms to monitor marine infrastructure such as piers, bridges, and jetties. These systems not only assess structural health but also ensure ecological preservation in sensitive coastal environments.

The Riyadh Metro provides a prominent example of SHM integration in urban transit. Robotic systems and fixed sensors continuously monitor tunnel deformation, vibration levels, and thermal expansion in real time. Data collected through these platforms feeds into centralized operational dashboards, enabling predictive maintenance and enhancing passenger safety. This approach aligns with research by Johann et al. [

27], who emphasize the role of embedded robotics and sensor fusion in optimizing infrastructure performance in high-density environments.

Collaborative initiatives with academic institutions, public–private partnerships, and digital infrastructure funds also reinforce Saudi Arabia’s investment in SHM. Alsharo et al. [

47] highlight how research grants are now being directed toward localizing SHM technologies, customizing robotics for desert and coastal conditions, and aligning national standards with global safety and sustainability benchmarks.

SHM’s contribution extends beyond technical efficiency; it supports broader objectives such as climate adaptation, material optimization, and circular construction. By reducing unplanned repairs, extending asset lifecycles, and minimizing material waste, SHM is directly aligned with the United Nations Sustainable Development Goals (SDGs), particularly those concerning resilient infrastructure and sustainable cities. Advanced signal-processing techniques, such as wavelet transforms and Fourier analyses, have also been increasingly applied to enhance SHM data interpretation, particularly in post-disaster assessments [

8], thereby enabling rapid recovery and minimizing resource use, key aspects of sustainable infrastructure management.

In summary, Saudi Arabia is moving from exploratory SHM applications toward strategic implementation in high-value projects. Robotics, AI, and smart data platforms are no longer viewed as futuristic options but as critical tools for realizing Vision 2030’s infrastructure modernization and sustainability ambitions. Continued investment in localized innovation, regulation, and workforce training will be essential to scaling these technologies across the construction sector.

9. Conclusions

This review synthesized recent developments in the integration of robotics into Structural Health Monitoring (SHM), with a particular focus on the Saudi Arabian construction sector. While the benefits of robotics related to improving inspection accuracy, operational safety, and predictive maintenance are well established, the analysis underscores that these advantages are not being fully realized in practice, primarily due to unresolved challenges related to technological readiness, institutional capacity, regulatory clarity, and operational costs.

A key outcome of this review is the recognition that technological maturity alone is insufficient to ensure effective deployment. Even with advanced robotic systems and artificial intelligence (AI)-enabled inspection tools available, their adoption in SHM will remain limited without supportive legal frameworks, digitally literate workforces, and clear implementation roadmaps, issues that are especially pronounced in emerging economies. This misalignment between innovation and integration is one of the most pressing barriers to progress.

By incorporating cross-sectoral insights from healthcare, energy, and law, this review provides a broader lens to understand systemic adoption challenges. These examples demonstrate that robotics uptake is often hindered by institutional inertia, a lack of standardization, and user resistance, even in technologically advanced contexts. In the SHM domain, this calls for a shift in focus from solely developing better tools to designing more inclusive, adaptable, and regulation-ready systems.

In Saudi Arabia, national initiatives under Vision 2030 and projects like NEOM and the Riyadh Metro signal promising advances in digital infrastructure and smart construction. However, critical gaps persist in local Research and Development (R&D) capabilities, skills training, and policy enforcement. Without coordinated action across academia, industry, and government, the scalability of robotic SHM solutions may remain limited.

Overall, this paper contributes a structured foundation for understanding the robotics–SHM nexus while also highlighting the contextual nuances that shape technology adoption in the Gulf region. Future work should prioritize empirical validation, AI integration strategies, development of context-specific robotic platforms, and alignment with institutional and regulatory readiness. A more inclusive, interdisciplinary, and adaptive research agenda will be essential for realizing the full potential of robotics in advancing resilient, intelligent infrastructure.

10. Recommendations for Future Work

Based on the literature reviewed in this paper, it is evident that there are still numerous research gaps that need to be addressed to further advance the understanding and application of robotics for SHM in construction in Saudi Arabia. The following are some recommendations for researchers interested in addressing these gaps and expanding this field of research:

Conduct longitudinal studies to track robotics adoption over time and assess how organizational readiness, technology performance, and policy changes influence long-term integration and impact SHM operations.

Differentiate between different types of robotic systems, such as UAVs (drones), ground-based robots, and fixed sensor networks, to explore how adoption dynamics vary by functionality, complexity, and use case.

Assess external macro-environmental factors, such as global supply chain disruptions, vendor availability, and international technology transfer policies, which may affect the accessibility and sustainability of robotics in the Saudi Arabian construction sector.

Study the economic and environmental impacts of robotics integration in SHM by examining cost–benefit ratios, returns on investment, and carbon footprint reductions over project lifecycles.

Explore workforce implications, including skill shifts, job redesigns, and the acceptance of robotics among site engineers and technicians in Saudi Arabia, to gain a deeper understanding of the dynamics of human–robot collaboration.

Future research should also explore the role of robotics in SHM across a broader range of infrastructure systems, including bridges, tunnels, and pipelines, where complex geometries, harsh environments, and accessibility challenges present unique opportunities for robotic innovation.

Finally, insights from recent structural engineering studies on the behavior of steel and concrete elements [

50,

51] may inspire interdisciplinary approaches to improving robotic data interpretation and structural assessment models. Such cross-domain integration could enhance the accuracy, adaptability, and reliability of robotic SHM systems in future applications.