Risk Assessment of Prefabricated Building Projects Based on the G1-CRITIC Method and Cloud Model: A Case Study from China

Abstract

1. Introduction

2. Literature Review

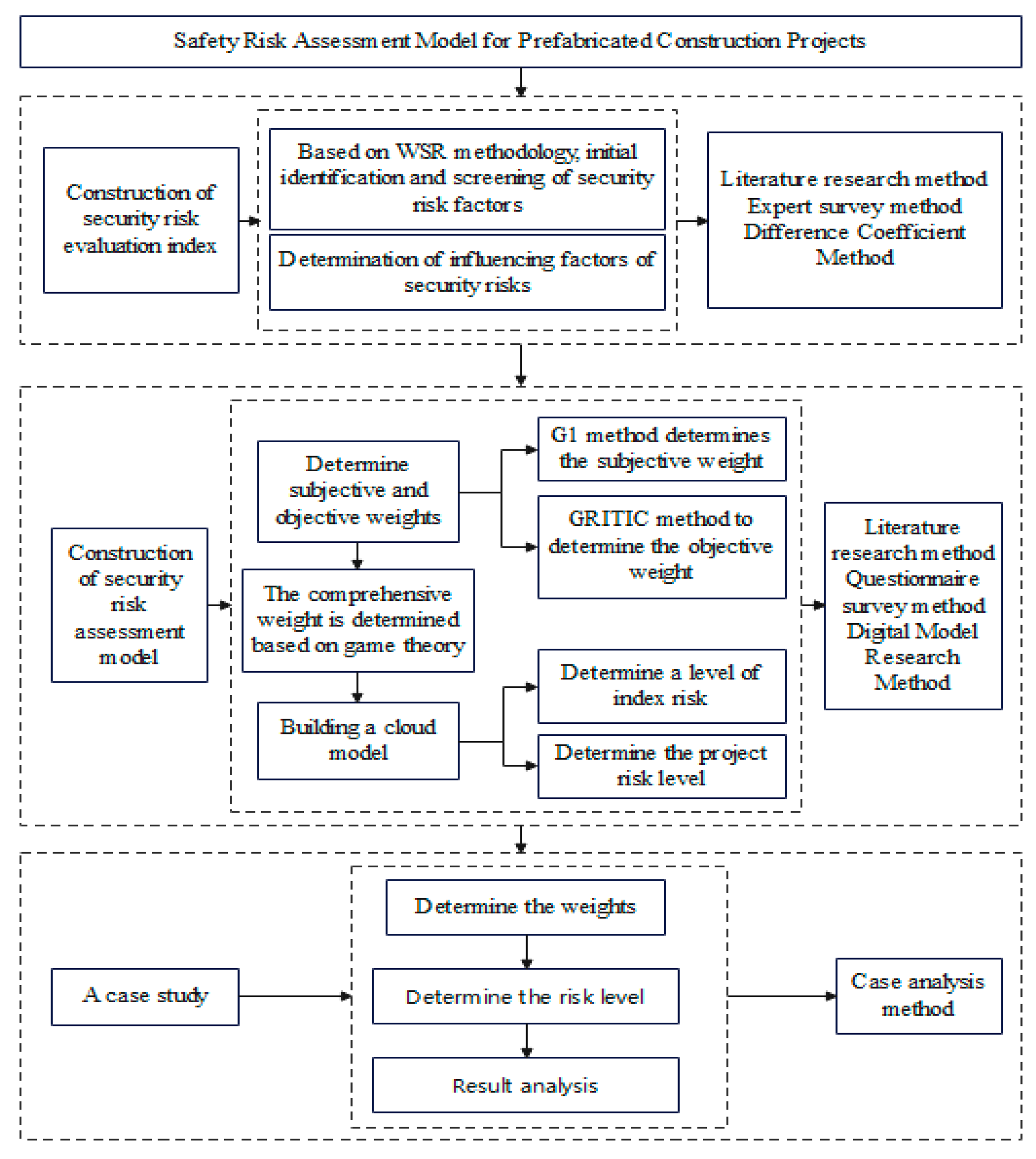

3. Research Method

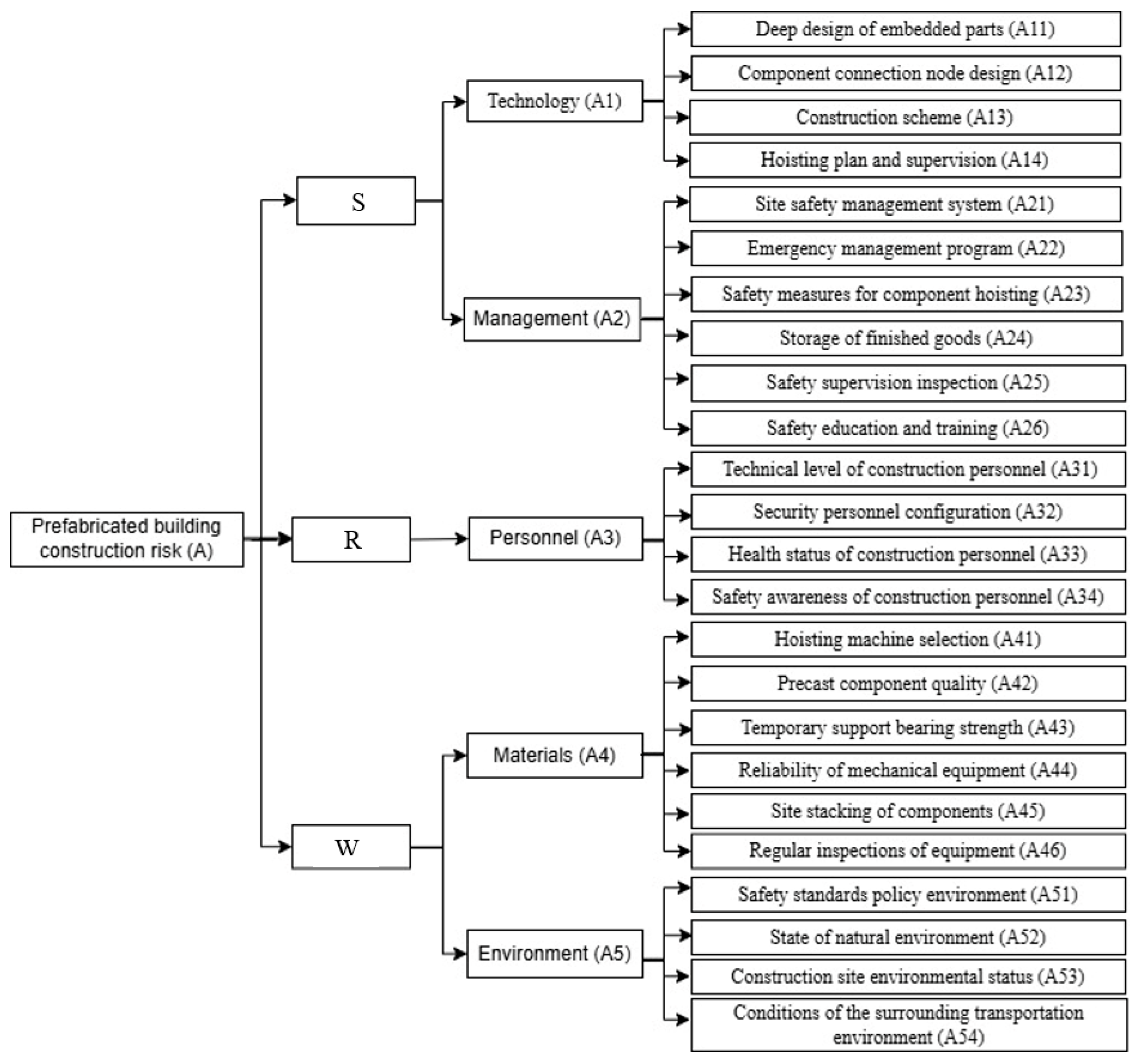

3.1. Identification and Determination of Safety Risk Factors in Prefabricated Construction Projects

3.2. The Evaluation System Based on the Combined Weighting of Game Theory and Cloud Model

3.2.1. Indicator Weighting Based on the G1-CRITIC Method

3.2.2. The Game Combination Weighting Method Determines the Comprehensive Weight

3.2.3. The Basic Theory of Cloud Models

- (1)

- Standard cloud

- (2)

- Index comment cloud

- (3)

- Comprehensive comment cloud

- (4)

- Determine the level of safety risk assessment

4. Case Analysis

4.1. Project Overview

4.2. Weights Calculation

4.3. Build the Project Standard Cloud

4.4. Build the Project Comment Cloud

4.5. Determine the Project Construction Safety Risk Level

5. Discussion

5.1. Model Validation

5.2. Management Suggestions

6. Conclusions

- (1)

- Compared with previous construction risk assessment models, the construction risk assessment model proposed in this paper is based on the integration of the G1-CRITIC method and the cloud model. By focusing on a specific category of risk, the model systematically incorporates the ambiguity and stochastic characteristics of risk factors, thereby enhancing the objectivity and accuracy of dynamic risk characterization. Meanwhile, this evaluation model provides new ideas for other similar studies and offers experience to risk managers of similar projects, which is of significant guiding value.

- (2)

- Based on the research results of this article, from the perspective of the first-level indicators, technical factors and material factors have a greater impact on the safety risk management of this project, while personnel factors, management factors and environmental factors have a relatively smaller influence on the construction risks. From the perspective of the secondary indicators, the key points of risk management include the proper stacking and protection of materials at the construction site, the optimization of embedded part design, and the upgrading of hoisting plans. By implementing effective management measures, the incidence of engineering safety accidents has decreased by approximately 30%, and the efficiency of hazard identification has also significantly improved. Strengthened management of the above key factors supports risk control and enhances construction safety.

- (3)

- To rigorously validate the effectiveness of the established evaluation model, this paper applies the conventional fuzzy comprehensive evaluation methodology to systematically analyze and quantitatively assess the membership degrees of key risk indicators in prefabricated building construction. The final determination is that the construction risk level of this project is low risk, further confirming the effectiveness of the G1-CRITIC method and cloud model in risk assessment. Moreover, the model’s evaluation results align with the actual construction conditions of the project, further validating the objectivity and accuracy of the model.

- (4)

- Based on the existing research, future studies will subsequently consider the dynamic changes of risks. We intend to incorporate Internet of Things technologies and introduce a real-time data acquisition system, such as real-time monitoring of environmental temperature and humidity, wind speed during high-altitude operations, and using sensors to monitor the lifting load capacity of components. In the course of prefabricated building construction, the probability of construction risks can be quantified by means of machine learning algorithms. Moreover, the incidence of construction risks can be mitigated through proactive intervention strategies. To address the dynamic nature of risks related to environmental conditions, material properties, management practices, and personnel performance during the construction process, a comprehensive strategy incorporating monitoring, prediction, and intervention mechanisms will be implemented.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tran, H.; Nguyen, T.N.; Christopher, P.; Bui, D.K.; Khoshelham, K.; Ngo, T.D. A digital twin approach for geometric quality assessment of as-built prefabricated façades. J. Build. Eng. 2021, 41, 102377. [Google Scholar] [CrossRef]

- Liu, J.; Gong, E.; Wang, D.; Teng, Y. Cloud model-based safety performance evaluation of prefabricated building project in China. Wirel. Pers. Commun. 2018, 102, 3021–3039. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Li, X.; Wu, G. A review of global lean construction during the past two decades: Analysis and visualization. Eng. Constr. Archit. Manag. 2019, 26, 1192–1216. [Google Scholar] [CrossRef]

- Li, Y.; Pu, X.; Qin, F. Construction and Application of Maturity Model of Prefabricated Construction Industry Development. Constr. Econ. 2023, 44, 478–483. [Google Scholar]

- Du, H.; Han, Q.; Sun, J.; Wang, C.C. Adoptions of prefabrication in residential sector in China: Agent-based policy option exploration. Eng. Constr. Archit. Manag. 2023, 30, 1697–1725. [Google Scholar] [CrossRef]

- Hang, S. Prefabricated buildings are coming to us. Econ. Dly. 2024. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M.; Wang, F.; Li, R. Safety performance assessment of fabricated building project based on cloud model. China Saf. Sci. J. 2017, 27, 115. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2022, 22, 133–147. [Google Scholar] [CrossRef]

- Bavafa, A.; Mahdiyar, A.; Marsono, A.K. Identifying and assessing the critical factors for effective implementation of safety programs in construction projects. Saf. Sci. 2018, 106, 47–56. [Google Scholar] [CrossRef]

- Yang, M. Risk management of prefabricated building construction based on fuzzy neural network. Sci. Program. 2022, 2022, 2420936. [Google Scholar] [CrossRef]

- Amiri, M.; Ardeshir, A.; Zarandi, M.H.F. Fuzzy probabilistic expert system for occupational hazard assessment in construction. Saf. Sci. 2017, 93, 16–28. [Google Scholar] [CrossRef]

- Shojaei, P.; Haeri, S.A.S. Development of supply chain risk management approaches for construction projects: A grounded theory approach. Comput. Ind. Eng. 2019, 128, 837–850. [Google Scholar] [CrossRef]

- Fard, M.M.; Terouhid, S.A.; Kibert, C.J.; Hakim, H. Safety concerns related to modular/prefabricated building construction. Int. J. Inj. Control. Saf. Promot. 2017, 24, 10–23. [Google Scholar] [CrossRef]

- Liao, J.; Jiang, X.; Liu, J. Risk assessment of prefabricated buildings based on combination weighting and interval approximation construction. J. Railw. Sci. Eng. 2024, 21, 4311–4320. [Google Scholar]

- Cao, P.; Lei, X. Evaluating Risk in Prefabricated Building Construction under EPC Contracting Using Structural Equation Modeling: A Case Study of Shaanxi Province, China. Buildings 2023, 13, 1465. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, J.; Feng, L. Safety risk assessment of the hoisting construction of prefabricated buildings based on improved cloud model. J. Qingdao Univ. Technol. 2023, 44, 30–38. [Google Scholar]

- Dang, P.; Niu, Z.W.; Gao, S.; Hou, L.; Zhang, G.M. Critical Factors Influencing the Sustainable Construction Capability in Prefabrication of Chinese Construction Enterprises. Sustainability 2020, 12, 8996. [Google Scholar] [CrossRef]

- Wang, X.W.; Sun, Y.C.; Liu, Y. Research on Influencing Factors of Unsafe Behavior of Prefabricated Building. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 546. [Google Scholar]

- Torkayesh, A.E.; Malmir, B.; Asadabadi, M.R. Sustainable waste disposal technology selection: The stratified best-worst multi-criteria decision-making method. Waste Manag. 2021, 122, 100–112. [Google Scholar] [CrossRef]

- Zhao, X. Construction risk management research: Intellectual structure and emerging themes. Int. J. Constr. Manag. 2024, 24, 540–550. [Google Scholar] [CrossRef]

- Liu, Z.; Li, A.; Sun, Z.; Shi, G.; Meng, X. Digital twin-based risk control during prefabricated building hoisting operations. Sensors 2022, 22, 2522. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, G. A novel hybrid methodology to study the risk management of prefabricated building supply chains: An outlook for sustainability. Sustainability 2022, 15, 361. [Google Scholar] [CrossRef]

- Gu, Z. Risk analysis of construction safety level of prefabricated buildings based on multi-level fuzzy comprehensive evaluation. EDP Sci. 2024, 565, 01002. [Google Scholar] [CrossRef]

- Zhang, Q.; Xue, H. An analytical model for environmental safety based on WSR methodology. China Soft Sci. 2010, 165–174. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W. Safety evaluation of prefabricated building construction based on entropy correction BWM. J. Saf. Environ. 2023, 23, 2580–2588. [Google Scholar]

- Yang, W.; Li, J. Safety risk analysis of hoisting construction of prefabricated buildings based on Dynamic Bayesian Network. J. Saf. Environ. 2024, 24, 1328–1336. [Google Scholar]

- Wang, L.; Yan, L. Safety evaluation of prefabricated building construction based on combination weighting and variable fuzzy sets. J. Saf. Sci. Technol. 2023, 16, 103–109. [Google Scholar]

- Yan, S.; Zhang, J. Safety Evaluation of Prefabricated Building Construction Based on ICUOWGA-RBF Neural Network. Saf. Environ. Eng. 2019, 26, 121–126. [Google Scholar]

- Li, S.; Ma, B.; Wang, C. Research on risk assessment of prefabricated building construction based on Cov-AHP and cloud model. J. Xi’an Univ. Technol. 2024, 40, 429–437. [Google Scholar]

- Lu, W.; Fang, L.; Ai, L. A novel risk assessment model for prefabricated building construction based on combination weight and catastrophe progression method. Teh. Vjesn. 2023, 30, 1959–1967. [Google Scholar]

- Xia, M.; Zhao, L.; Zhao, L. A comprehensive risk-assessment method for prefabricated buildings using EPC: A case study from China. Sustainability 2022, 14, 1910. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, Y. Safety risk assessment of assembly building component hoisting based on combined weighted two-dimensional cloud model. J. Nat. Disasters 2022, 31, 167–174. [Google Scholar]

- Yu, Z.; Lu, H.; Wu, S. Safety risk evaluation method for assembly building construction based on improved tractable cloud. J. Shihezi Univ. Nat. Sci. 2024, 42, 322–331. [Google Scholar]

- Xun, Z.Y.; Zhang, L.M.; Xu, Y.L.; Zhao, Z.Y. Evaluation of Prefabricated Buildings Safety Risk Based on Combination Weighting and Cloud Model. Math. Pract. Theory 2020, 50, 302–310. [Google Scholar]

- Wang, J.; Guo, F.; Song, Y.; Liu, Y.; Hu, X.; Yuan, C. Safety risk assessment of prefabricated buildings hoisting construction: Based on IHFACS-ISAM-BN. Buildings 2022, 12, 811. [Google Scholar] [CrossRef]

- Wan, P.; Wang, J.; Liu, Y.; Lu, Q.; Yuan, C. On risk probability of prefabricated building hoisting construction based on multiple correlations. Sustainability 2022, 14, 4430. [Google Scholar] [CrossRef]

- Xiao, W.; Tian, W.P. Hazard assessment and zoning of collapse along highways in China based on backward cloud algorithm. Geomatics. Nat. Hazards Risk 2019, 10, 1227–1241. [Google Scholar] [CrossRef]

- Krishnan, A.R.; Kasim, M.M.; Hamid, R.; Ghazali, M.F. A modified CRITIC method to estimate the objective weights of decision criteria. Symmetry 2021, 13, 973. [Google Scholar] [CrossRef]

- Mesmer, B.L.; Bloebaum, C.L. Modeling decision and game theory based pedestrian velocity vector decisions with interacting individuals. Saf. Sci. 2016, 87, 116–130. [Google Scholar] [CrossRef]

- Ju, W.; Wu, J.; Kang, Q.; Jiang, J.; Xing, Z. Fire risk assessment of subway stations based on combination weighting of game theory and topsis method. Sustainability 2022, 14, 7275. [Google Scholar] [CrossRef]

- Li, D. Membership clouds and membership cloud generators. Comput. Res. Dev. 1995, 32, 15–20. [Google Scholar]

- Liu, W.; Han, M.; Meng, X.; Qin, Y. Mine water inrush risk assessment evaluation based on the GIS and combination weight-cloud model: A case study. ACS Omega 2021, 6, 32671–32681. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Cheung, D.; Shi, X.; Ng, V. Uncertainty reasoning based on cloud models in controllers. Comput. Math. Appl. 1998, 35, 99–123. [Google Scholar] [CrossRef]

- Liu, J.Q.; Wei, Q.; Wang, P. Risk assessment based on combined weighting-cloud model of tunnel construction. Teh. Vjesn. 2021, 28, 203–210. [Google Scholar]

- Liu, J.; Zheng, W.; Li, H.; Chen, J. Evaluation of flooding disaster risks for subway stations based on the PSR Cloud model. Sustainability 2023, 15, 15552. [Google Scholar] [CrossRef]

| Classification | Number | Influence Factors | Reference | Frequency |

|---|---|---|---|---|

| Personnel | 1 | Technical level of construction personnel | [25,26,27,28,29,30,31,32,33,34] | 10 |

| 2 | Security personnel configuration | [25,26,27,28,29,32] | 6 | |

| 3 | Health status of construction personnel | [27,28,30,34,35] | 5 | |

| 4 | Safety awareness of construction personnel | [25,26,27,28,29,30,32,33,34,35] | 10 | |

| 5 | Degree of coordination between jobs | [26] | 1 | |

| Management | 6 | Site safety management system | [26,27,29,30,33,34] | 6 |

| 7 | Emergency management program | [25,26,29,30,32,33,34] | 7 | |

| 8 | Safety measures for component hoisting | [25,27,28,35] | 4 | |

| 9 | Implementation of security measures | [29,35] | 2 | |

| 10 | Storage of finished goods | [27,28,32,34] | 4 | |

| 11 | Safety supervision inspection | [25,30,33,35] | 4 | |

| 12 | Protective measures for working at heights | [32] | 1 | |

| 13 | Safety education and training | [29,30,33,34,35] | 5 | |

| 14 | Coordination management level | [34] | 1 | |

| 15 | Layout of temporary facilities | [32] | 1 | |

| Technology | 16 | Deep design of embedded parts | [25,27,28] | 3 |

| 17 | Component connection node design | [27,28,30,31,33,36] | 6 | |

| 18 | Component connection positioning technology | [25,27,28,30,34,36] | 6 | |

| 19 | Construction scheme | [25,26,29,30,33,34] | 7 | |

| 20 | Hoisting plan and supervision | [26,32,33] | 3 | |

| 21 | Hoisting technology | [29,31,34,35] | 4 | |

| 22 | Tower crane cross-operation | [35] | 1 | |

| 23 | Other technical recovery degree | [35] | 1 | |

| 24 | Exterior wall connection technology | [27] | 1 | |

| Environment | 25 | Temporary hole protection | [28] | 1 |

| 26 | State of the natural environment | [27,30,33,34] | 4 | |

| 27 | Construction site environmental status | [25,27,28,30,33,34,36] | 6 | |

| 28 | Surrounding environment of hoisting process | [26,29,31,32] | 4 | |

| 29 | Conditions of the surrounding transportation environment | [25,27,28,32] | 4 | |

| 30 | Safety standards policy environment | [25,27,28,29,34] | 5 | |

| Materials | 31 | Reliability of mechanical equipment | [29,30] | 2 |

| 32 | Hoisting machine selection | [25,26,27,28,32,33,34] | 7 | |

| 33 | Precast component quality | [25,26,28,29,30,32,33,34] | 8 | |

| 34 | Regular inspections of equipment | [25,27,28,33,34] | 5 | |

| 35 | Equipment maintenance | [26,29,30,36] | 4 | |

| 36 | Temporary support bearing strength | [25,26,27,28,29,30,34] | 7 | |

| 37 | Site stacking of components | [25,29,30,32,35] | 5 | |

| 38 | The carrying capacity of lifting equipment | [30] | 1 |

| Classification | Number | Influence Factors | Index Attribute Grade Score | ||||

|---|---|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | |||

| Technology | 1 | Deep design of embedded parts | 6 | 3 | 1 | 0 | 0 |

| 2 | Component connection node design | 4 | 2 | 2 | 2 | 0 | |

| 3 | Component connection positioning technology | 4 | 2 | 2 | 1 | 1 | |

| 4 | Construction scheme | 5 | 2 | 2 | 0 | 1 | |

| 5 | Hoisting plan and supervision | 3 | 2 | 2 | 3 | 0 | |

| 6 | Hoisting technology | 2 | 3 | 2 | 3 | 0 | |

| Classification | Number | Influence Factors | Index Attribute Grade Score | ||||

|---|---|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | |||

| Technology | 1 | Deep design of embedded parts | 0.6 | 0.3 | 0.1 | 0.0 | 0.0 |

| 2 | Component connection node design | 0.4 | 0.2 | 0.2 | 0.2 | 0.0 | |

| 3 | Component connection positioning technology | 0.4 | 0.2 | 0.2 | 0.1 | 0.1 | |

| 4 | Construction scheme | 0.5 | 0.2 | 0.2 | 0.0 | 0.1 | |

| 5 | Hoisting plan and supervision | 0.3 | 0.2 | 0.2 | 0.3 | 0.0 | |

| 6 | Hoisting technology | 0.2 | 0.3 | 0.2 | 0.3 | 0.0 | |

| Value Description | |

|---|---|

| 1.0 | |

| 1.2 | |

| 1.4 | |

| 1.6 | |

| 1.8 | |

| 1.1,1.3,1.5,1.7 | The mid-value between the aforementioned two adjacent judgments |

| First-Level Indexes | Second-Level Indexes | G1 Method Subjective Weight | CRITIC Method Objective Weight |

|---|---|---|---|

| A1 | A11 | 0.0838 | 0.0681 |

| A12 | 0.0430 | 0.0466 | |

| A13 | 0.0762 | 0.0666 | |

| A14 | 0.0247 | 0.0373 | |

| A2 | A21 | 0.0296 | 0.0382 |

| A22 | 0.0326 | 0.0493 | |

| A23 | 0.0520 | 0.0423 | |

| A24 | 0.0326 | 0.0381 | |

| A25 | 0.0572 | 0.0456 | |

| A26 | 0.0206 | 0.0377 | |

| A3 | A31 | 0.0629 | 0.0495 |

| A32 | 0.0326 | 0.0377 | |

| A33 | 0.0247 | 0.0501 | |

| A34 | 0.0572 | 0.0484 | |

| A4 | A41 | 0.0358 | 0.0398 |

| A42 | 0.0430 | 0.0344 | |

| A43 | 0.0473 | 0.0377 | |

| A44 | 0.0692 | 0.0431 | |

| A45 | 0.0247 | 0.0422 | |

| A46 | 0.0296 | 0.0414 | |

| A5 | A51 | 0.0296 | 0.0437 |

| A52 | 0.0187 | 0.0348 | |

| A53 | 0.0520 | 0.0368 | |

| A54 | 0.0206 | 0.0405 |

| First-Level Indexes | Second-Level Indexes | Comprehensive Weights (Game Theory) | Comprehensive Weights (Average Value Method) | ||

|---|---|---|---|---|---|

| Weight Value | Ranking | Weight Value | Ranking | ||

| A1 | A11 | 0.0806 | 1 | 0.0760 | 1 |

| A12 | 0.0450 | 10 | 0.0448 | 8 | |

| A13 | 0.0748 | 2 | 0.0714 | 2 | |

| A14 | 0.0291 | 21 | 0.0310 | 21 | |

| A2 | A21 | 0.0329 | 19 | 0.0339 | 19 |

| A22 | 0.0385 | 12 | 0.0410 | 11 | |

| A23 | 0.0501 | 7 | 0.0472 | 7 | |

| A24 | 0.0350 | 14 | 0.0354 | 17 | |

| A25 | 0.0548 | 6 | 0.0514 | 6 | |

| A26 | 0.0263 | 23 | 0.0292 | 23 | |

| A3 | A31 | 0.0601 | 4 | 0.0562 | 3 |

| A32 | 0.0349 | 15 | 0.0352 | 18 | |

| A33 | 0.0331 | 18 | 0.0374 | 14 | |

| A34 | 0.0557 | 5 | 0.0528 | 5 | |

| A4 | A41 | 0.0378 | 13 | 0.0378 | 13 |

| A42 | 0.0412 | 11 | 0.0387 | 12 | |

| A43 | 0.0453 | 9 | 0.0425 | 10 | |

| A44 | 0.0625 | 3 | 0.0562 | 4 | |

| A45 | 0.0307 | 20 | 0.0335 | 20 | |

| A46 | 0.0339 | 17 | 0.0355 | 16 | |

| A5 | A51 | 0.0346 | 16 | 0.0367 | 15 |

| A52 | 0.0241 | 24 | 0.0268 | 24 | |

| A53 | 0.0484 | 8 | 0.0444 | 9 | |

| A54 | 0.0272 | 22 | 0.0306 | 22 | |

| Risk Level | Score Interval | Standard Features |

|---|---|---|

| Very low risk | [90,100] | (95.0,1.667,0.5) |

| Low risk | [75,90) | (82.5,2.500,0.5) |

| Medium risk | [50,75) | (62.5,4.167,0.5) |

| High risk | [25,50) | (37.5,4.167,0.5) |

| Very high risk | [0,25) | (12.5,4.167,0.5) |

| First-Level Indexes | Comment Cloud | Second-Level Indexes | Comment Cloud |

|---|---|---|---|

| A1 | (82.3,3.2531,0.6769) | A11 | (77.0,3.7599,0.5995) |

| A12 | (87.0,3.5093,0.3579) | ||

| A13 | (80.3,2.4565,0.6839) | ||

| A14 | (72.2,2.6069,1.1755) | ||

| A2 | (84.6,2.7117,0.7932) | A21 | (89.6,2.6069,0.5997) |

| A22 | (87.0,2.7573,0.2170) | ||

| A23 | (71.2,2.0554,0.5189) | ||

| A24 | (87.3,3.1333,1.6912) | ||

| A25 | (77.5,2.8826,1.0690) | ||

| A26 | (84.2,2.4565,0.3787) | ||

| A3 | (88.1,3.3724,0.5597) | A31 | (84.3,3.8853,0.4420) |

| A32 | (87.2,3.0080,0.1374) | ||

| A33 | (80.5,3.5093,0.5202) | ||

| A34 | (86.9,2.6320,0.9095) | ||

| A4 | (82.9,2.8063,0.6379) | A41 | (80.9,1.8800,0.3177) |

| A42 | (80.6,1.7546,0.7220) | ||

| A43 | (80.4,1.9552,0.6663) | ||

| A44 | (81.6,3.0080,0.8838) | ||

| A45 | (73.4,4.0106,0.2013) | ||

| A46 | (80.6,3.5093,0.6293) | ||

| A5 | (90.2,4.1774,0.9961) | A51 | (87.1,5.1637,0.8863) |

| A52 | (87.9,3.4090,0.7953) | ||

| A53 | (90.0,2.5066,1.1280) | ||

| A54 | (80.9,5.2639,0.9055) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Duan, L.; Du, X. Risk Assessment of Prefabricated Building Projects Based on the G1-CRITIC Method and Cloud Model: A Case Study from China. Buildings 2025, 15, 2787. https://doi.org/10.3390/buildings15152787

Zhang Z, Duan L, Du X. Risk Assessment of Prefabricated Building Projects Based on the G1-CRITIC Method and Cloud Model: A Case Study from China. Buildings. 2025; 15(15):2787. https://doi.org/10.3390/buildings15152787

Chicago/Turabian StyleZhang, Zhipeng, Lini Duan, and Xinran Du. 2025. "Risk Assessment of Prefabricated Building Projects Based on the G1-CRITIC Method and Cloud Model: A Case Study from China" Buildings 15, no. 15: 2787. https://doi.org/10.3390/buildings15152787

APA StyleZhang, Z., Duan, L., & Du, X. (2025). Risk Assessment of Prefabricated Building Projects Based on the G1-CRITIC Method and Cloud Model: A Case Study from China. Buildings, 15(15), 2787. https://doi.org/10.3390/buildings15152787