Application of Prefabricated Public Buildings in Rural Areas with Extreme Hot–Humid Climate: A Case Study of the Yongtai County Digital Industrial Park, Fuzhou, China †

Abstract

1. Introduction

2. Methodology

2.1. Building Carbon Emissions Measurement and Analysis

2.1.1. Introduction of Building Carbon Emissions Measurement

2.1.2. Selection of Carbon Emission Factors

2.1.3. Carbon Emission Measurement Method

2.2. Analysis of Spatial Accessibility Method

- (1)

- Calculate supply–demand ratios within a radius for each supplier.

- (2)

- Weight ratios using a Gaussian function to determine accessibility for each demand point.

2.3. Supply and Demand Evaluation Grading

2.4. Case Study: Fuzhou Yongtai County Digital Industrial Park

3. Results

3.1. Carbon Emissions Comparison

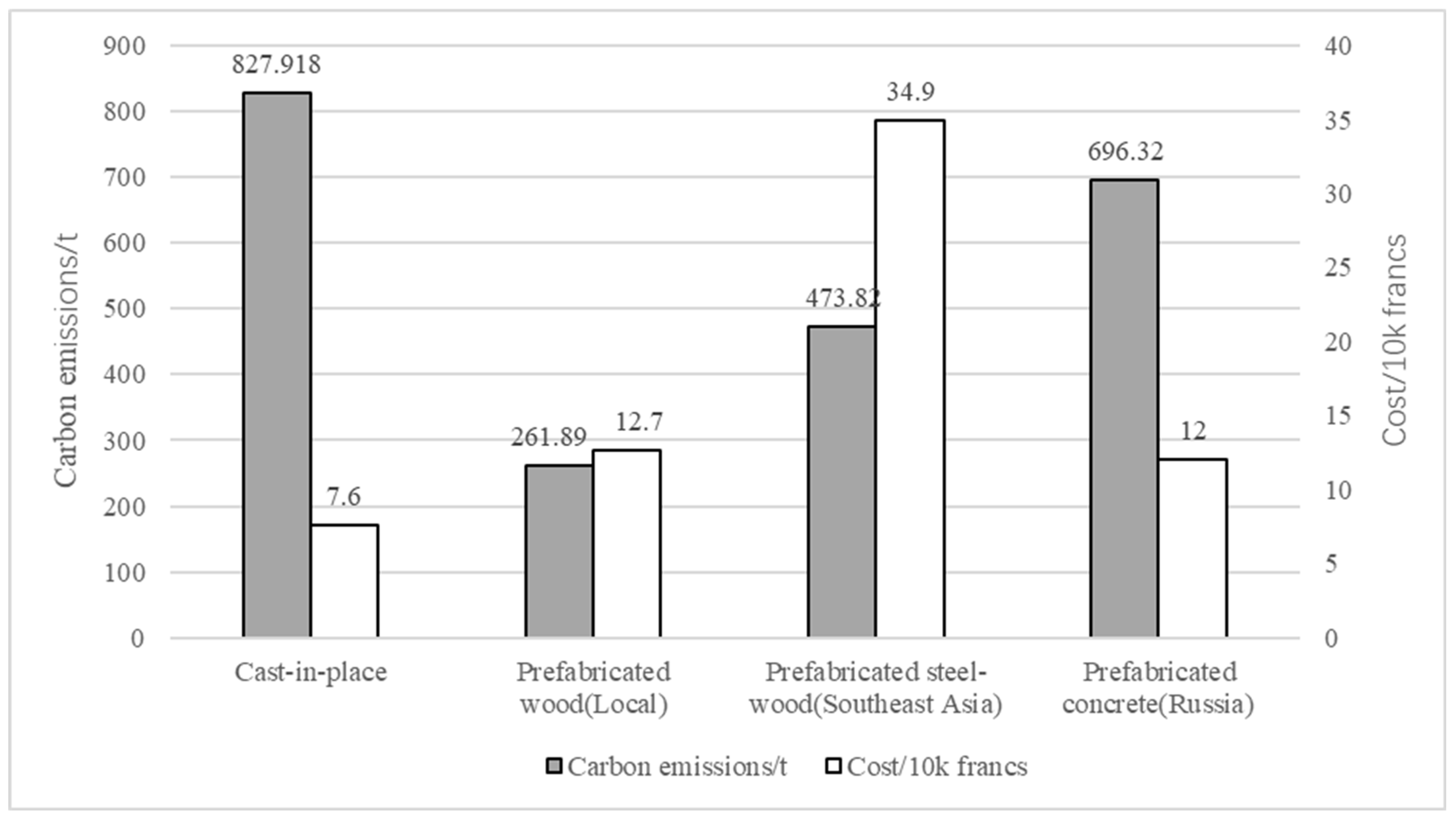

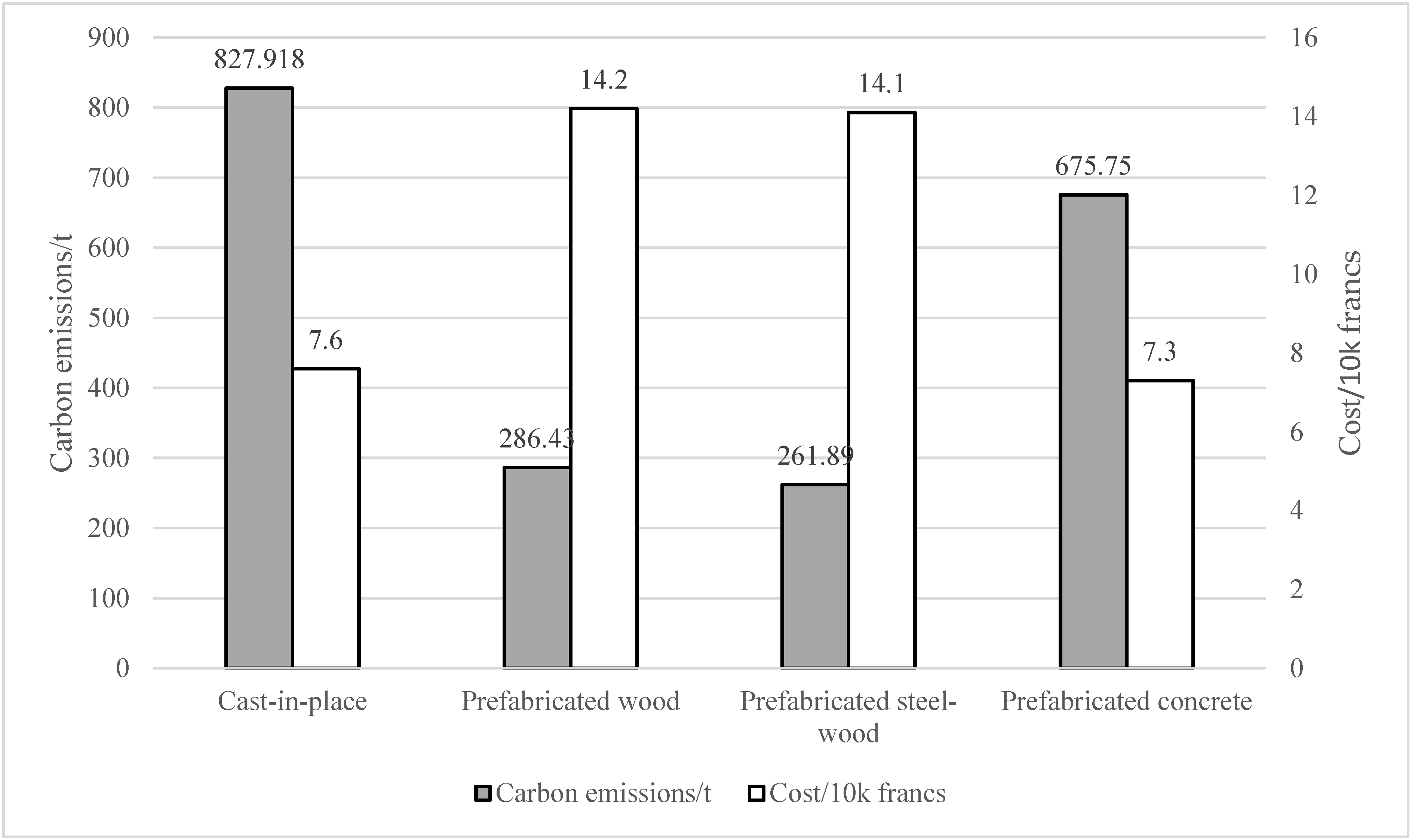

3.1.1. Carbon Emissions Comparison Between Prefabricated and Cast-In-Situ Buildings

3.1.2. Carbon Footprint Comparison Between Prefabricated Timber Structures and Steel–Wood Hybrid Structures

3.1.3. Carbon Emissions Differences Between Local and Imported Timber

3.2. Spatial Accessibility Analysis

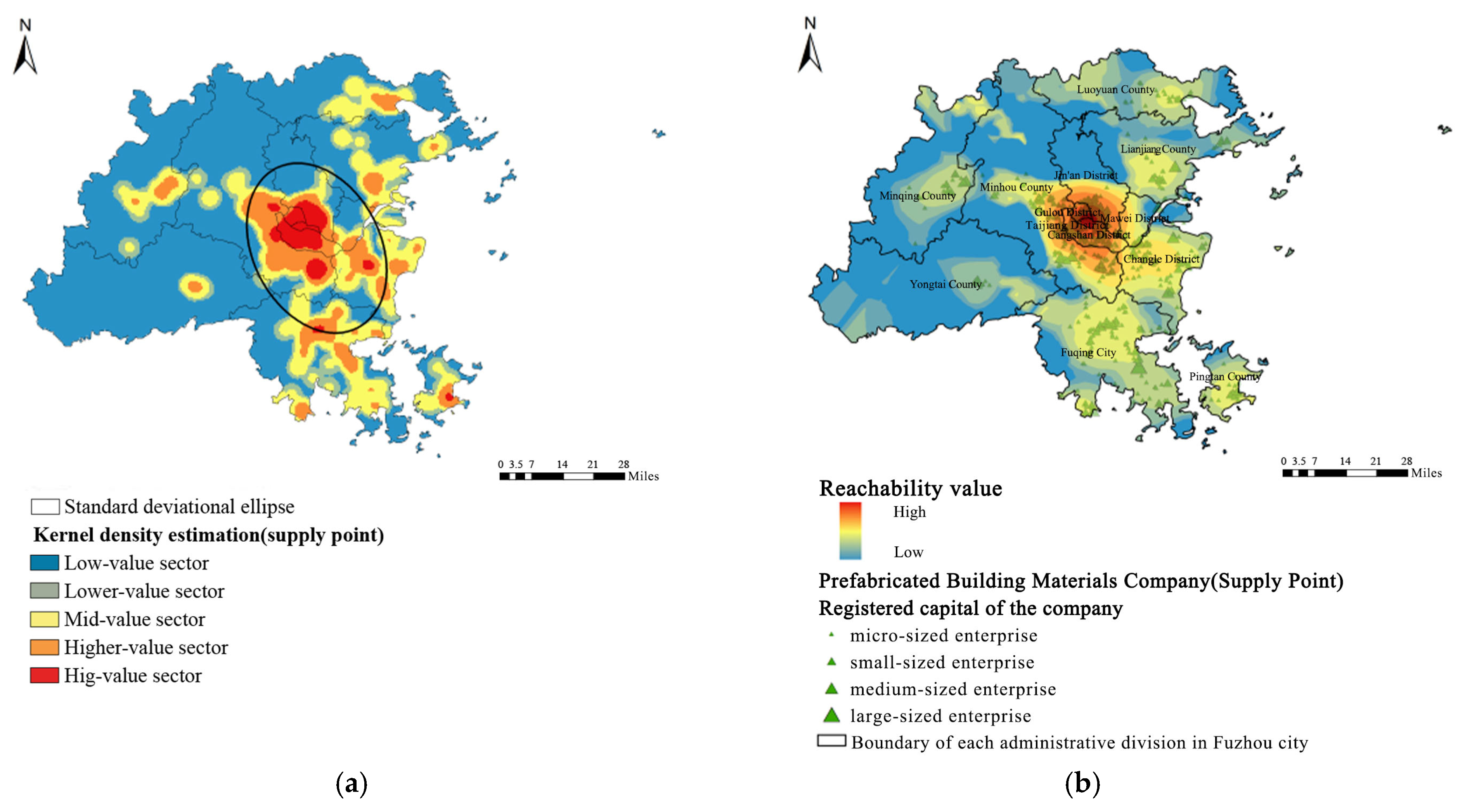

3.2.1. Spatial Accessibility Analysis of Prefabricated Building Materials

- Accessibility Analysis of Prefabricated Building Material Suppliers Across Different Tiers

- 2.

- Spatial Distribution of Prefabricated Building Material Suppliers’ Accessibility

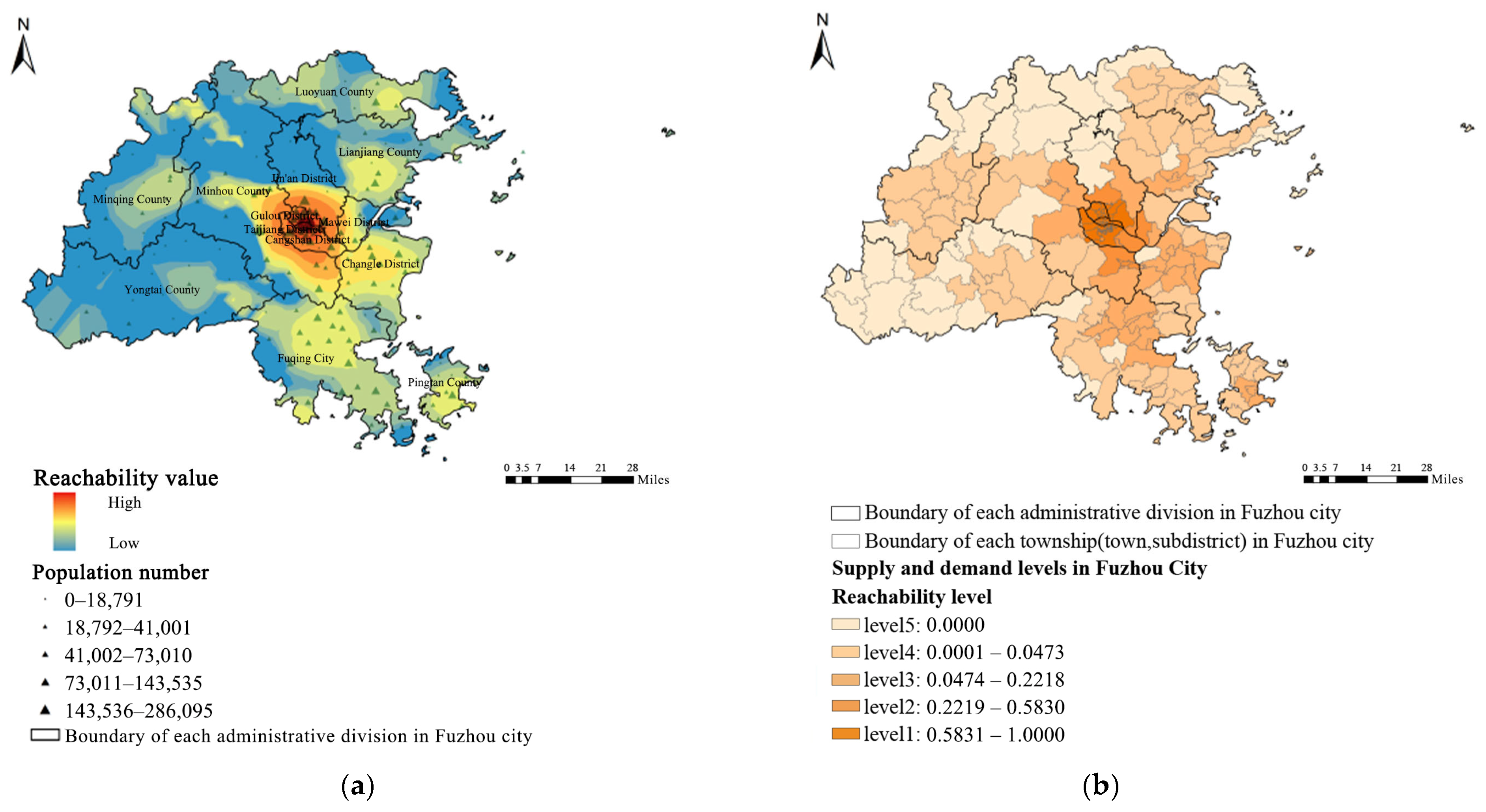

3.2.2. Supply–Demand Relationship Analysis of Prefabricated Building Materials

4. Discussion

4.1. Discussion of Carbon Emissions Comparison

4.2. Discussion of Spatial Accessibility Analysis

4.3. Limitations and Prospects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bonamente, E.; Cotana, F. Carbon and Energy Footprints of Prefabricated Industrial Buildings: A Systematic Life Cycle Assessment Analysis. Energies 2015, 8, 12685–12701. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development. China Building Energy Consumption and Carbon Emissions Report 2024; Architecture & Building Press: Beijing, China, 2025. [Google Scholar]

- Zhu, L.; Yu, W.; Li, W.; Tang, C. Research on countermeasures for the development of rural assembled buildings in the context of rural revitalization. South. Agric. Mach. 2022, 53, 103–105. [Google Scholar]

- Niu, Y. Exploring the Feasibility of Prefabricated Assembled Buildings in Rural Residential Applications in Northern Regions. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2020. [Google Scholar]

- Zhuang, F.; Zhang, Y. Research on the design of rural assembled buildings in the context of rural revitalization. Real Estate World 2022, 358, 56–58. [Google Scholar]

- Zhang, J. Present Situation, Causes and Prospect of Road Traffic Development in Fujian Province. Dev. Res. 2007, 4, 35–36. [Google Scholar]

- Chen, H. Research on the Constraints of the Development of Prefab Building and Its Countermeasures in Fujian Province. Master’s Thesis, Fujian Engineering College, Fujian, China, 2018. [Google Scholar]

- Li, M.; Yang, L.; Wei, Y. Model Research of Gauss Two-step Mobile Search Method: A Case Study of Green Space Accessibility in Shanghai. Prog. Geogr. 2016, 35, 990–996. [Google Scholar]

- Ma, L.; Cao, X. Evaluation Method of Urban Public Green Space Landscape Accessibility Basedon GIS. J. Sun Yat-Sen Univ. (Nat. Sci. Ed.) 2006, 6, 111–115. [Google Scholar]

- Bi, Q.; Pan, J.; Wu, X. Application of Prefabricated Public Buildings in Sustainable Rural Regeneration in the Context of Carbon Neutrality: A Case Study of the Digital Industrial Park in Yongtai County, Fuzhou City. In Proceedings of the 2023 6th International Conference on Civil, Architectural and Environmental Engineering (ICCAEE 2023), Guangzhou, China, 17–19 November 2023. [Google Scholar]

- Pan, J.; Bi, Q.; Wu, X. Spatial accessibility analysis of the prefab building suppliers using Gaussian based 2-step floating catchment area method: A case study of Fuzhou city. In Constructional Engineering and Ecological Environment, 1st ed.; CRC Press: Boca Raton, FL, USA, 2023; ISBN 9781003410843. [Google Scholar]

- Yin, S. Analysis of Carbon Emission Accounting for the Whole Life Cycle of Buildings. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2012. [Google Scholar]

- GB/T 51366-2019; Building Carbon Emission Calculation Standard. China Architecture & Building Press: Beijing, China, 2019.

- Gao, Y.; Li, Z.; Zhang, H.; Yu, B.; Wang, J. Carbon emission analysis of the whole process of assembled building construction based on LCA. J. Eng. Manag. 2018, 32, 30–34. [Google Scholar]

- Mao, R.-C. Research on the Environmental Impact Analysis of Urban Transportation Infrastructure Based on LCA. Master’s Thesis, Shenzhen University, Shenzhen, China, 2017. [Google Scholar]

- Luo, W.; Wang, F. Measures of spatial accessibility to health care in a GIS environment. Int. J. Geogr. Inf. Sci. 2003, 17, 663–666. [Google Scholar]

- Public Draft of the Revision of the Control Control Detailed Planning; Yongtai Smart Town by Yongtai County People’s Government: Fuzhou, China, 2022. Available online: www.yongtai.gov.cn (accessed on 20 April 2022).

- Wei, S. Research on Low Carbon Design of Office Building in High Technology Park Under Ecological Concept. Master’s Thesis, Nanchang Aviation University, Nanchang, China, 2020. [Google Scholar]

- GB/T 30790-2014; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems. Standards Press of China: Beijing, China, 2014.

- Wang, Y.; Xu, M. Revit-based prototype system for building carbon emission prediction. Eng. Constr. Stand. 2022, 2, 73–77. [Google Scholar]

- Liu, Y. Building Carbon Emission Evaluation Model Based on Whole Life Cycle. Master’s Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Li, Q.; Mao, Y.; Zhang, Y.; Ren, H.; Gong, L. The spatial and temporal evolution, development dilemma and trend outlook of China’s log import trade. For. Grass Policy Res. 2022, 2, 56–63. [Google Scholar]

- Liu, C. Optimization of China-Europe Multimodal Transport Path Selection Considering Carbon Emission. Master’s Thesis, Dalian Maritime University, Dalian, China, 2020. [Google Scholar]

| Material | Carbon Emission Factors KgCO2e/m3 |

|---|---|

| Precast Concrete | 295 |

| Fir | 178 |

| Cast-in-situ Concrete | 385 |

| OSB | 358 |

| Welded H-shaped Steel Column | 2137 |

| Reachability Level | Qi | Supply and Demand |

|---|---|---|

| 1 | 0.5831 ≤ Qi ≤ 1.0000 | Sufficient supply |

| 2 | 0.2219 ≤ Qi < 0.5830 | Balanced supply and demand |

| 3 | 0.0474 ≤ Qi < 0.0473 | Insufficient supply |

| 4 | 0.0001 ≤ Qi < 0.5000 | Lack of supply |

| 5 | Qi = 0.0000 | No supply |

| Zone | Leve l1 | Leve l2 | Leve l3 | Leve l4 | Leve l5 | Total |

|---|---|---|---|---|---|---|

| Cangshan District | 78.6% | 21.4% | 0.0% | 0.0% | 0.0% | 100.0% |

| Fuqing City | 0.0% | 0.0% | 38.5% | 50.0% | 11.5% | 100.0% |

| Gulou District | 100.0% | 0.0% | 0.0% | 0.0% | 0.0% | 100.0% |

| Jin’an District | 55.6% | 11.1% | 11.1% | 0.0% | 22.2% | 100.0% |

| Lianjing County | 0.0% | 0.0% | 13.6% | 54.5% | 31.8% | 100.0% |

| Luoyuan County | 0.0% | 0.0% | 0.0% | 58.3% | 41.7% | 100.0% |

| Mawei District | 0.0% | 0.0% | 50.0% | 50.0% | 0.0% | 100.0% |

| Minhou County | 0.0% | 12.5% | 25.0% | 31.3% | 31.1% | 100.0% |

| Minqing County | 0.0% | 0.0% | 0.0% | 68.8% | 31.3% | 100.0% |

| Pingtan County | 0.0% | 0.0% | 20.0% | 53.3% | 26.7% | 100.0% |

| Taijiang District | 100.0% | 0.0% | 0.0% | 0.0% | 0.0% | 100.0% |

| Yongtai County | 0.0% | 0.0% | 0.0% | 38.1% | 61.9% | 100.0% |

| Changle District | 0.0% | 0.0% | 50.0% | 44.4% | 5.6% | 100.0% |

| total | 18.7% | 3.1% | 16.6% | 38.3% | 23.3% | 100.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Wang, J.; Zhang, R.; Bi, Q.; Pan, J. Application of Prefabricated Public Buildings in Rural Areas with Extreme Hot–Humid Climate: A Case Study of the Yongtai County Digital Industrial Park, Fuzhou, China. Buildings 2025, 15, 2767. https://doi.org/10.3390/buildings15152767

Wu X, Wang J, Zhang R, Bi Q, Pan J. Application of Prefabricated Public Buildings in Rural Areas with Extreme Hot–Humid Climate: A Case Study of the Yongtai County Digital Industrial Park, Fuzhou, China. Buildings. 2025; 15(15):2767. https://doi.org/10.3390/buildings15152767

Chicago/Turabian StyleWu, Xin, Jiaying Wang, Ruitao Zhang, Qianru Bi, and Jinghan Pan. 2025. "Application of Prefabricated Public Buildings in Rural Areas with Extreme Hot–Humid Climate: A Case Study of the Yongtai County Digital Industrial Park, Fuzhou, China" Buildings 15, no. 15: 2767. https://doi.org/10.3390/buildings15152767

APA StyleWu, X., Wang, J., Zhang, R., Bi, Q., & Pan, J. (2025). Application of Prefabricated Public Buildings in Rural Areas with Extreme Hot–Humid Climate: A Case Study of the Yongtai County Digital Industrial Park, Fuzhou, China. Buildings, 15(15), 2767. https://doi.org/10.3390/buildings15152767