Influence of Friction on Pre-Stressing Construction of Suspen-Dome Structures

Abstract

1. Introduction

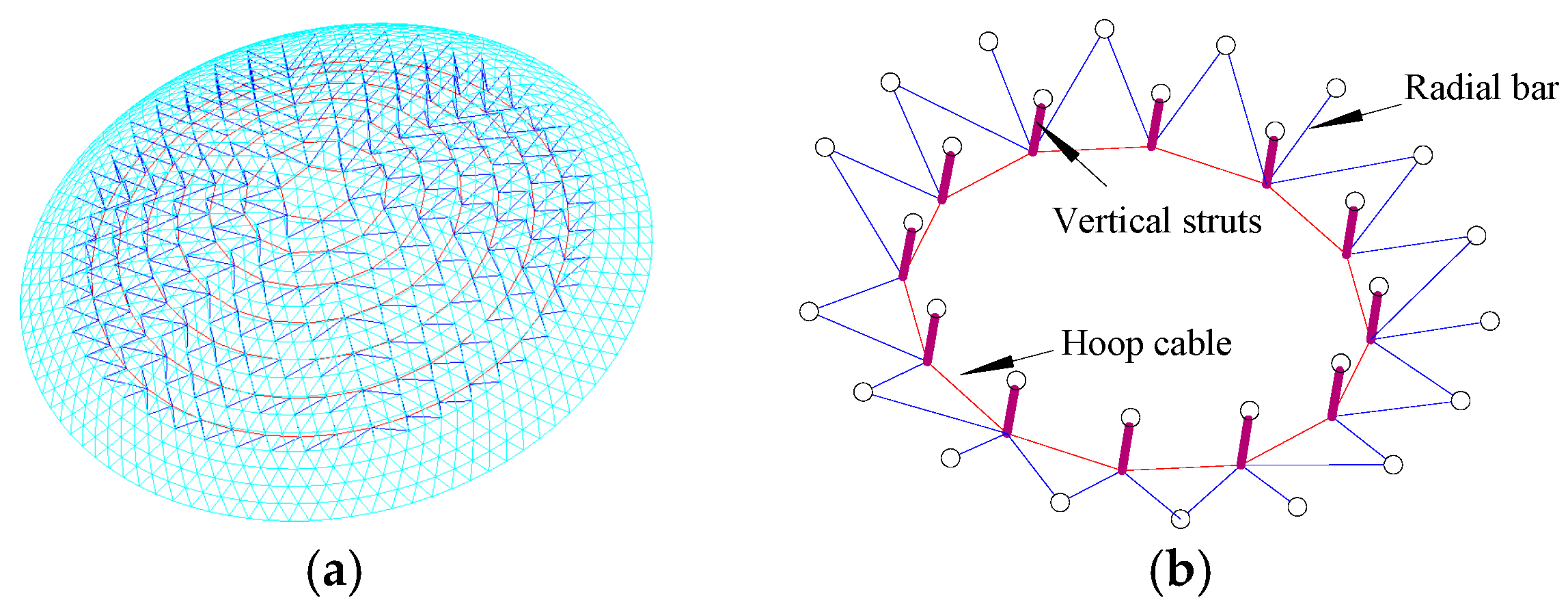

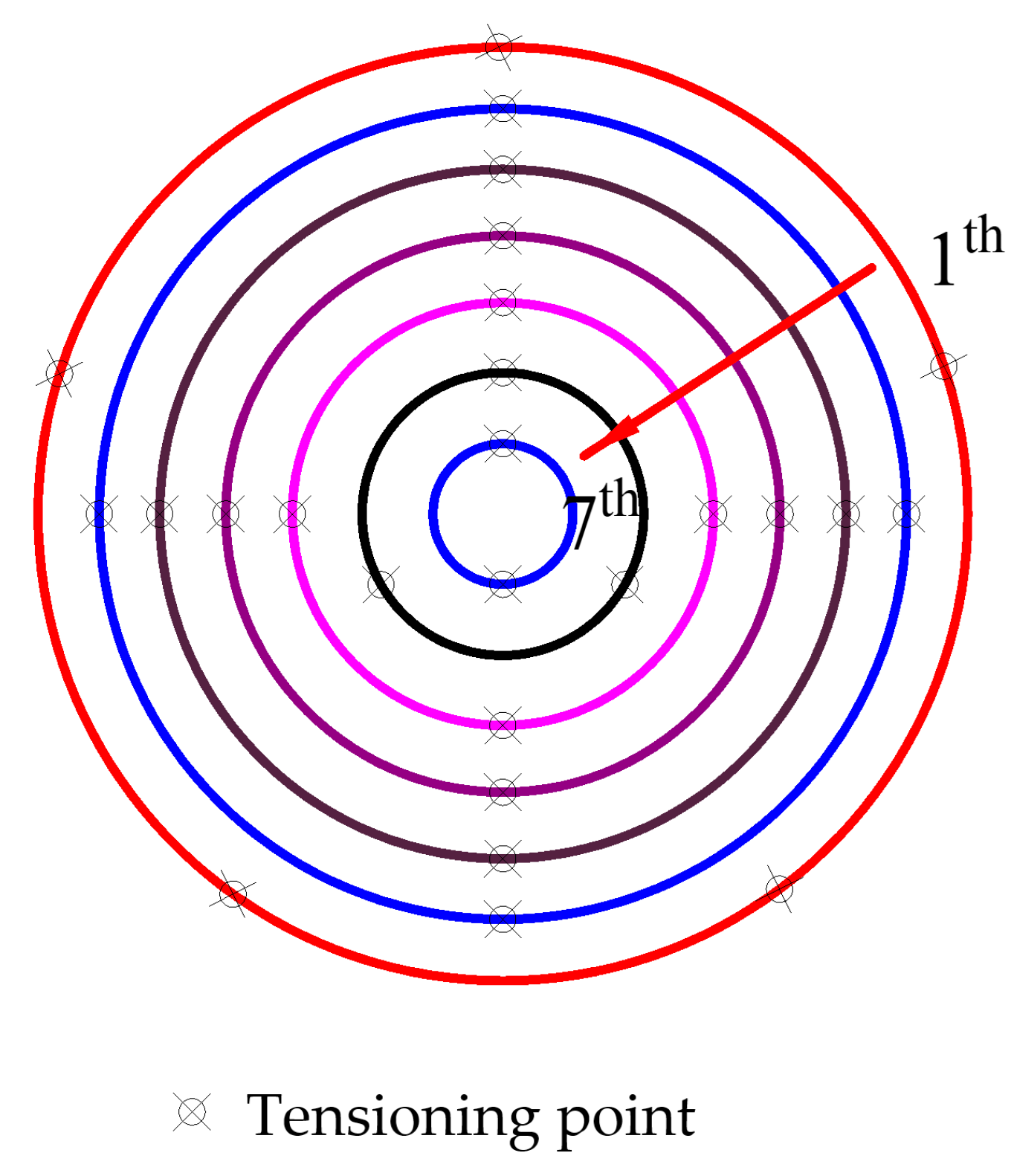

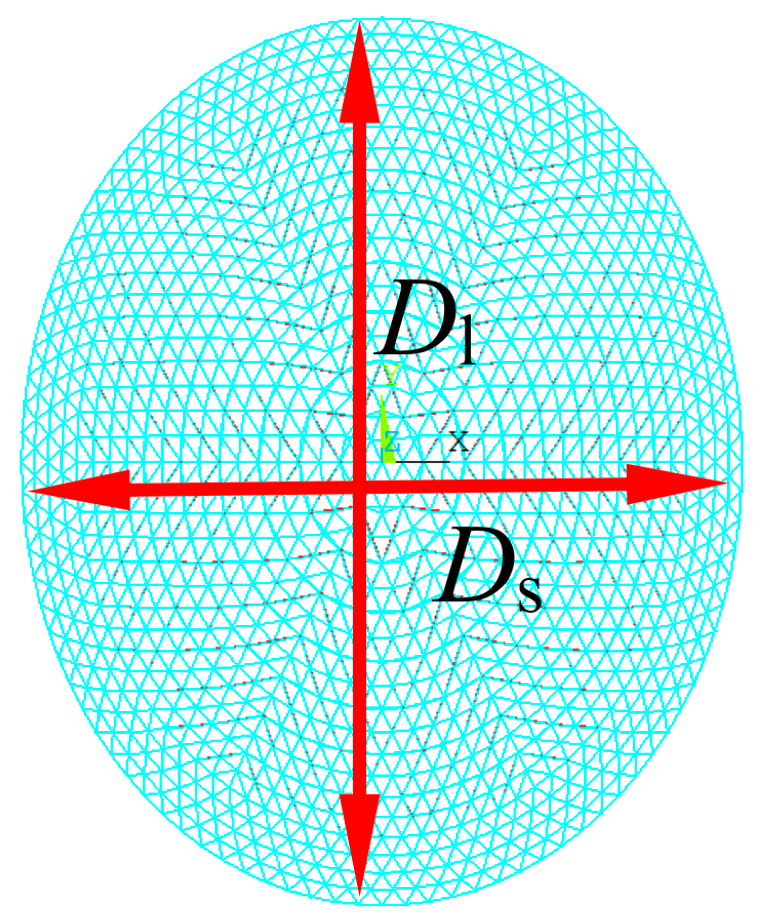

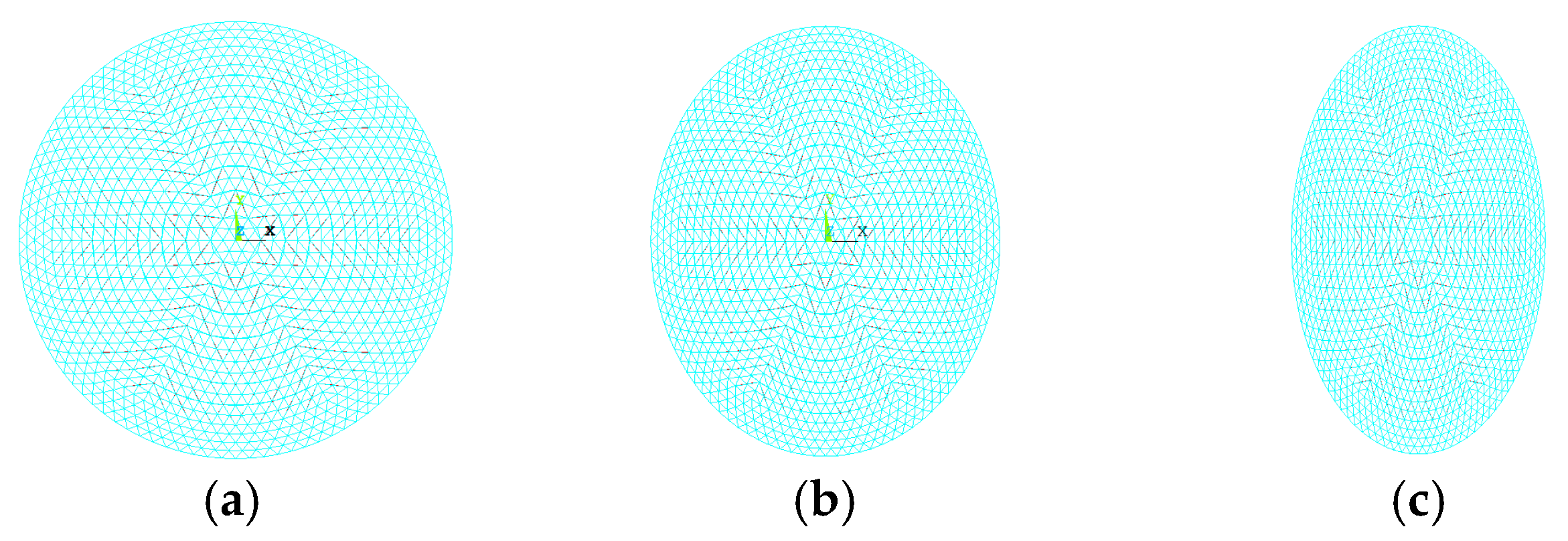

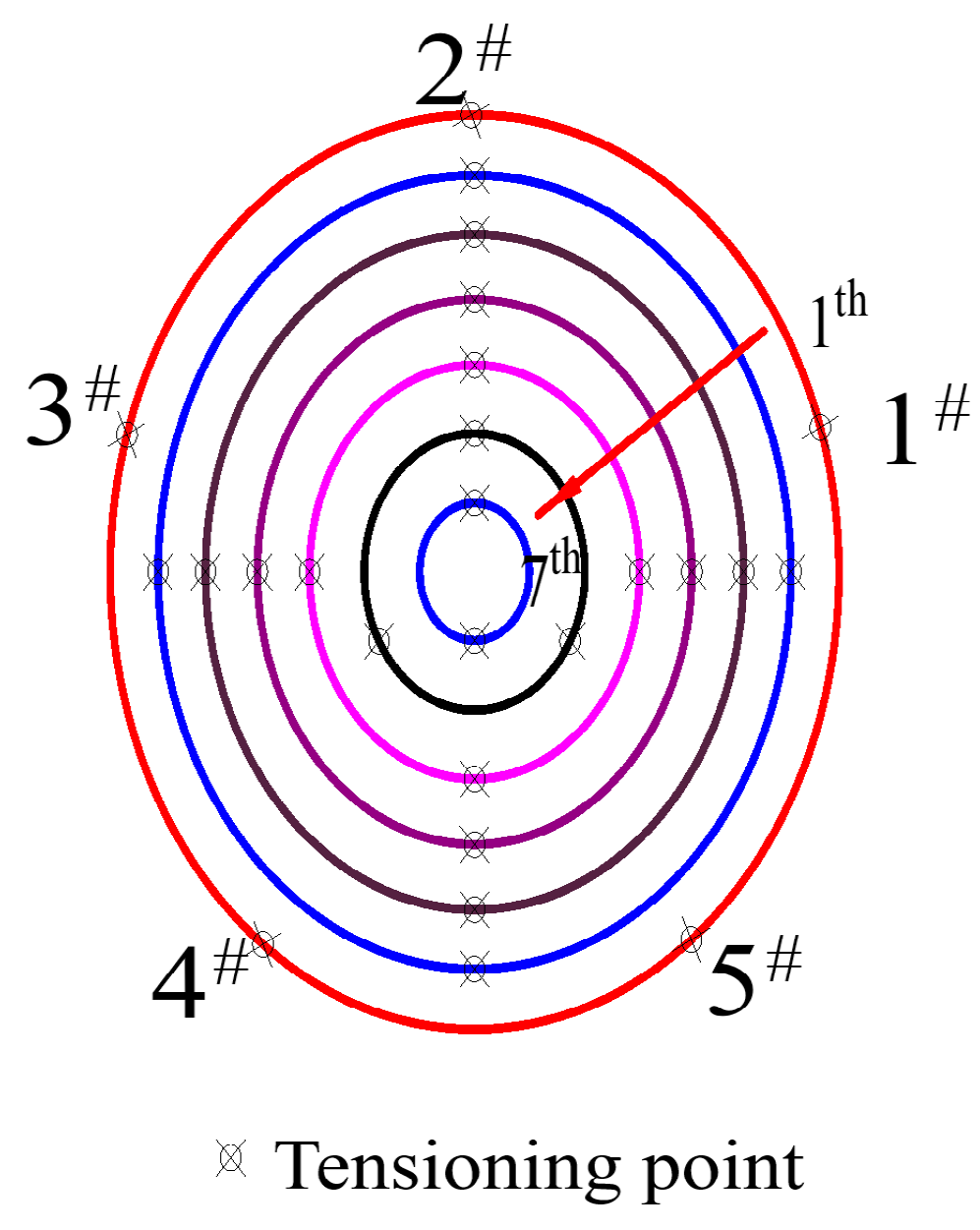

2. The Studied Model

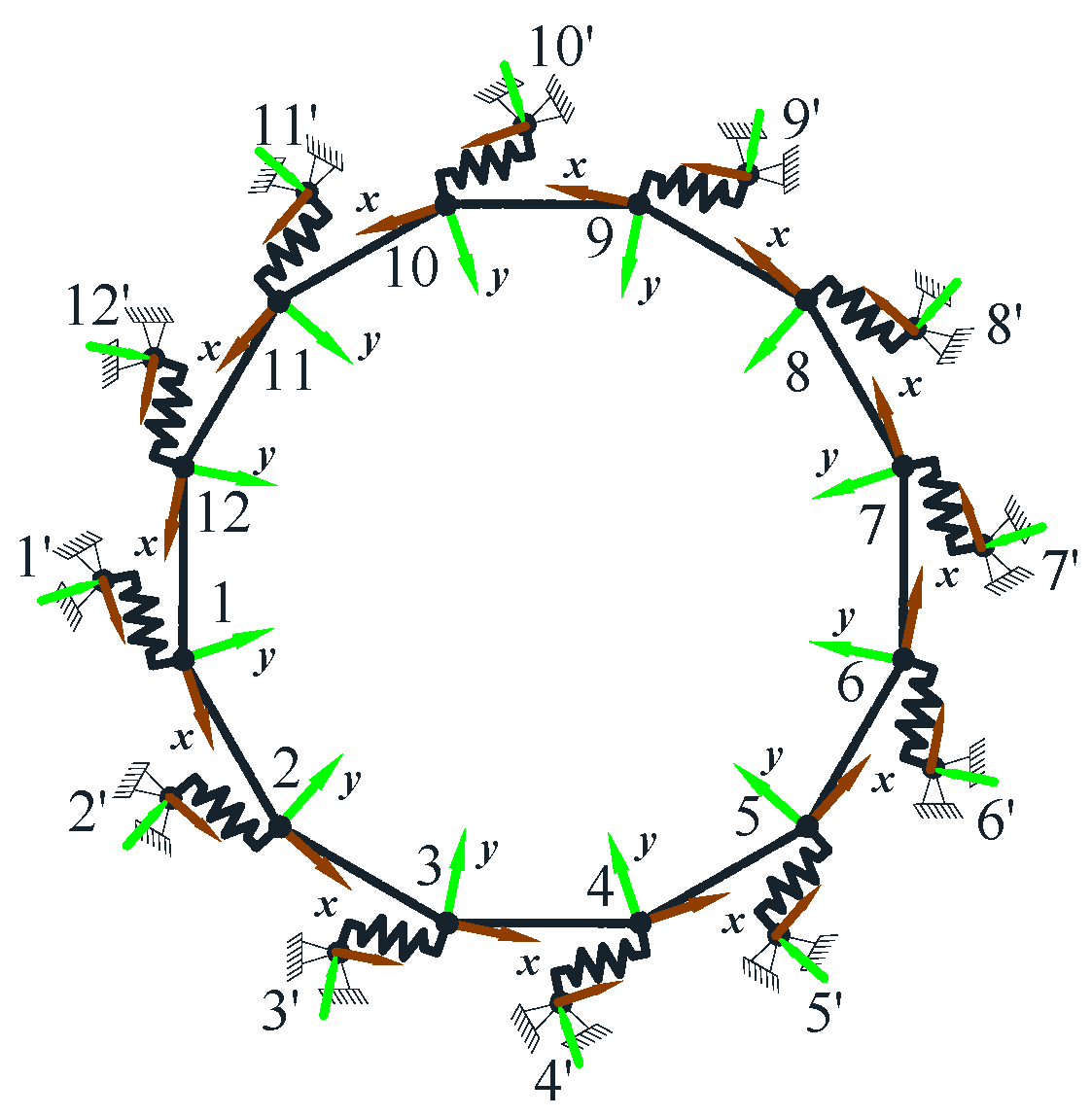

2.1. The Establishment of Numerical Model

2.2. Verification of Friction Element

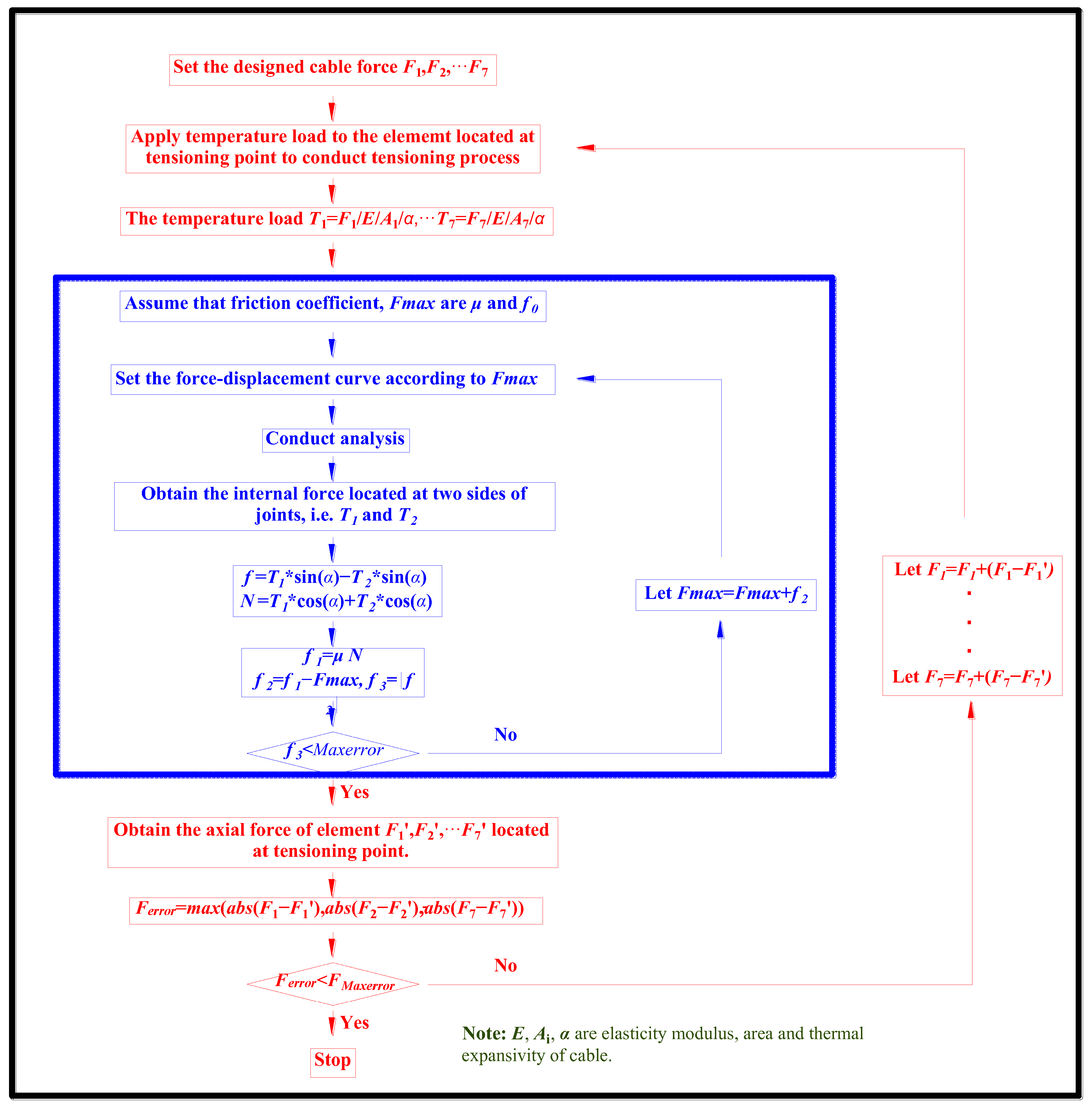

3. Flow Chart of Numerical Simulation

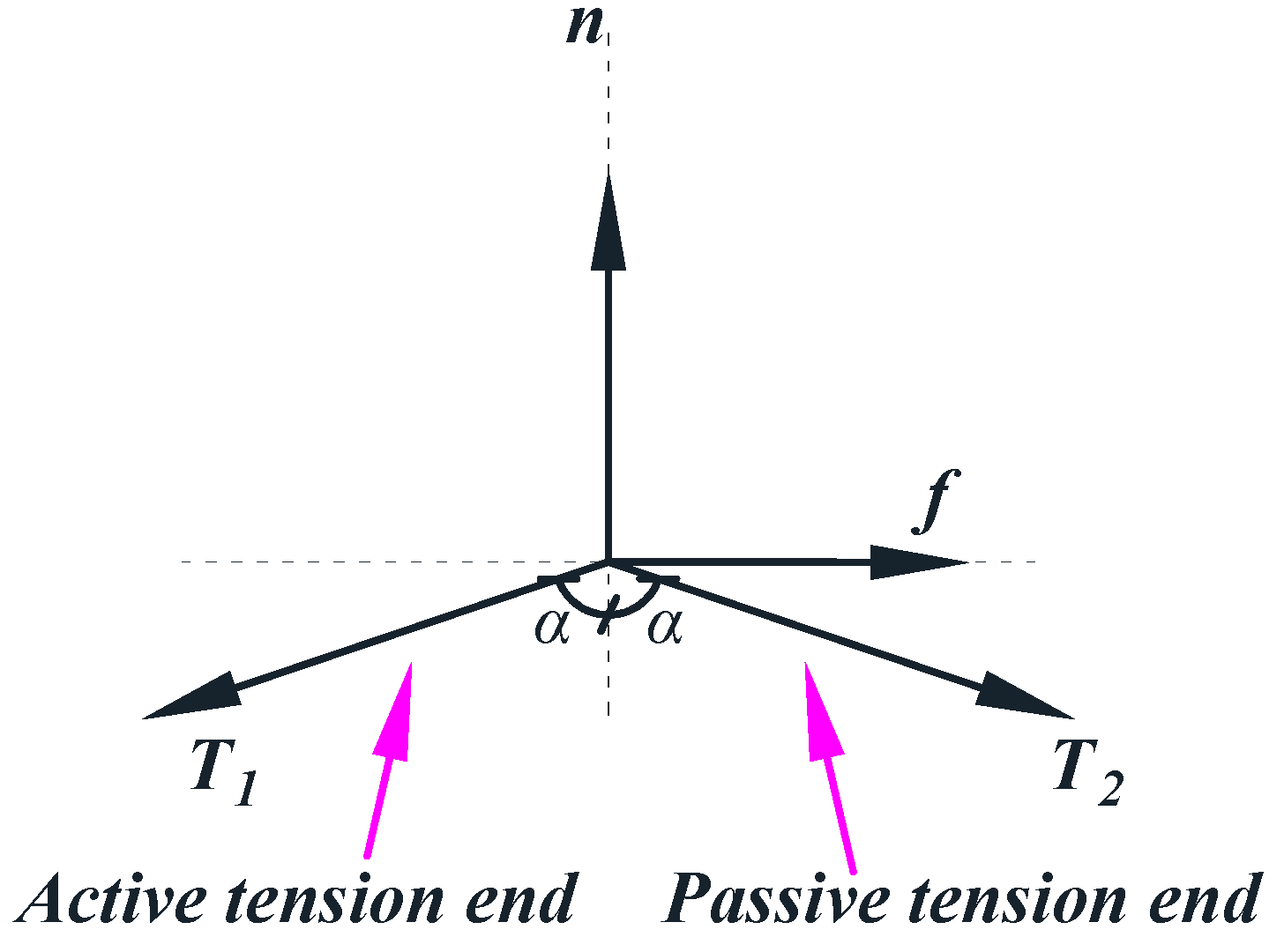

3.1. Calculation of the Friction

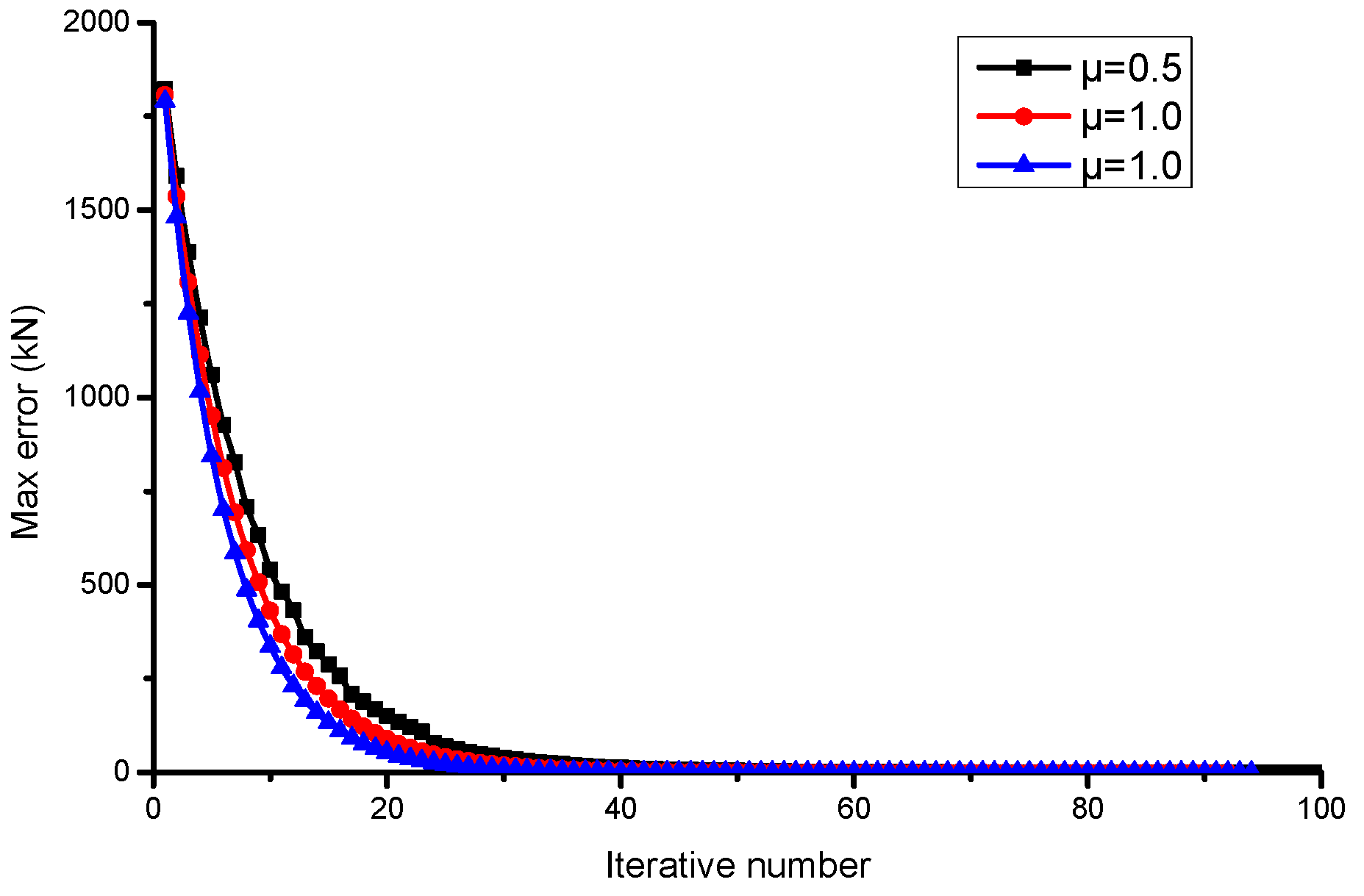

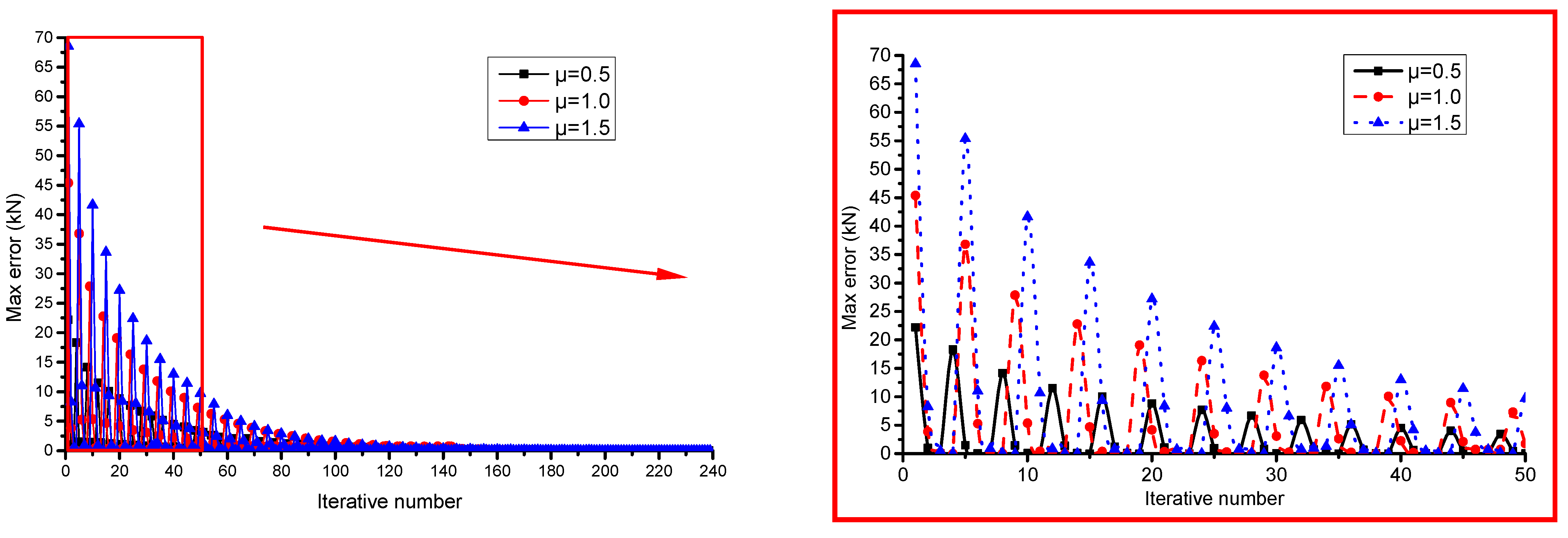

3.2. Tension-Compensation Method

4. Results and Discussions

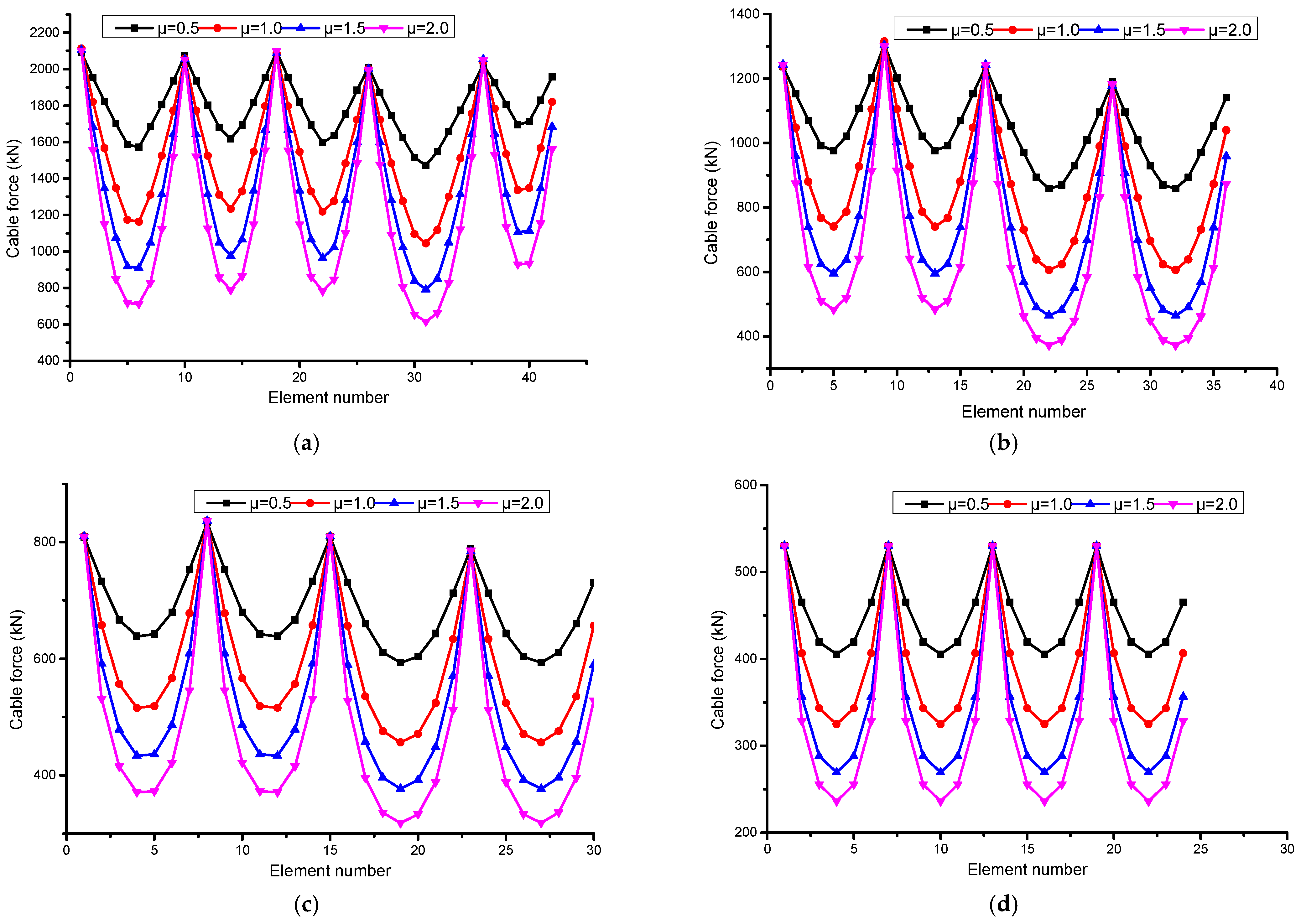

4.1. Influence of Friction on Cable Force Distribution

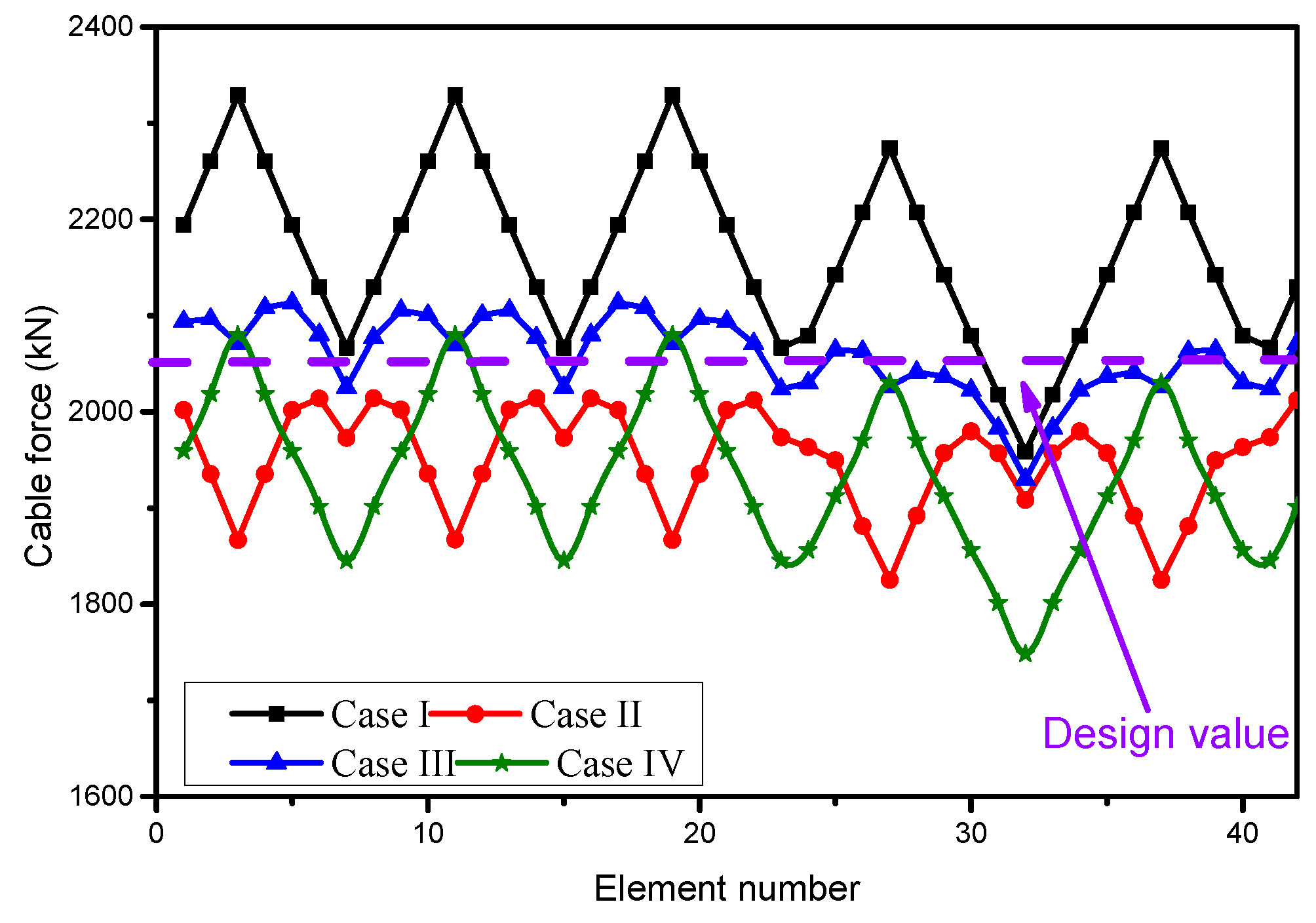

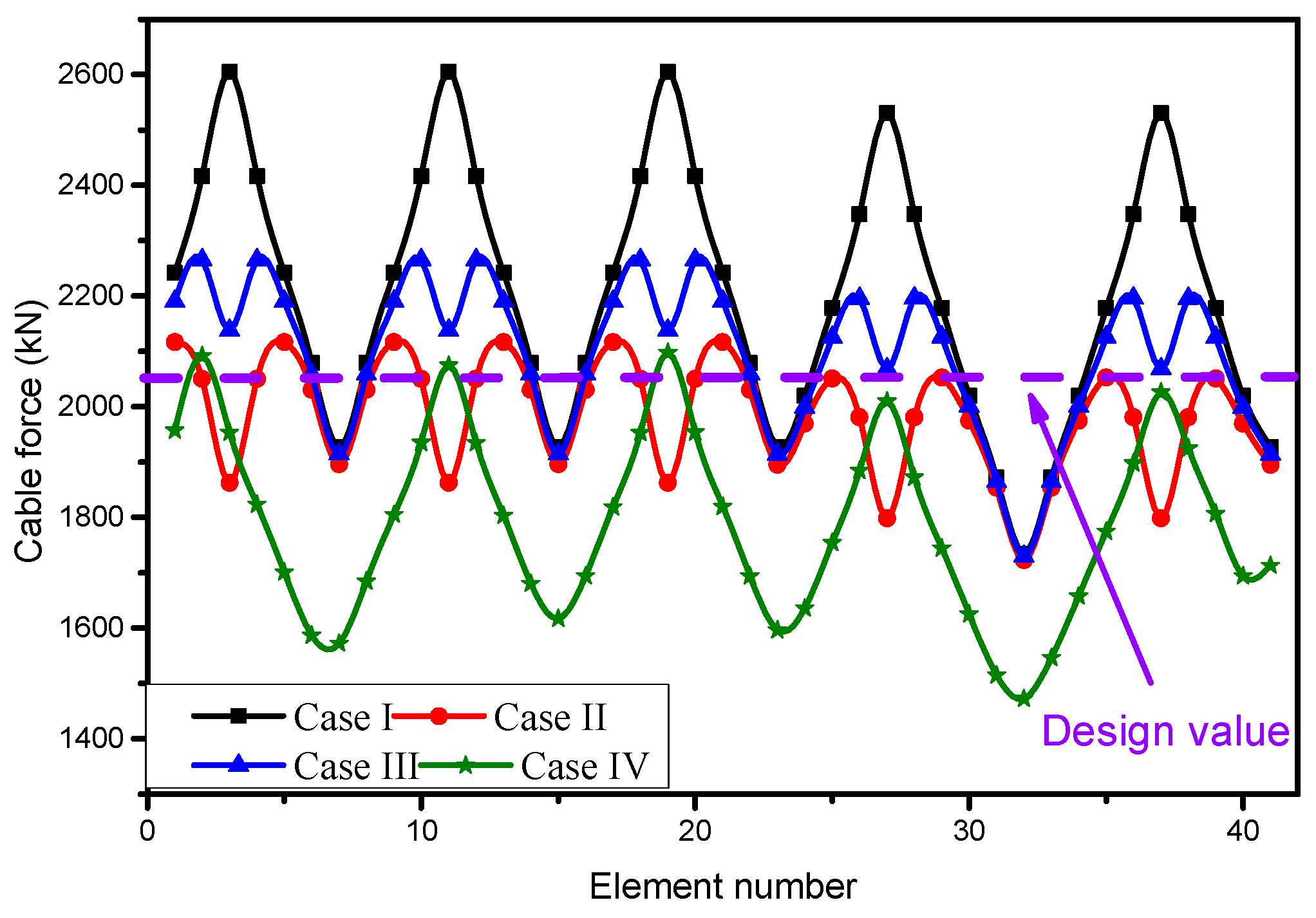

4.2. Influence of Over-Tensioning

- Case I:

- The cables were tensioned 12% and 25% higher than the design value (2060 kN) when μ was set as 0.2 and 0.5, respectively.

- Case II:

- The cables were tensioned 12% and 25% higher than the design value, and then the cable force was reduced to 95% of the design value.

- Case III:

- The cables were tensioned 12% and 25% higher than the design value, and then the cable force was reduced to 90% of the design value.

- Case IV:

- The cables were tensioned directly to the design value.

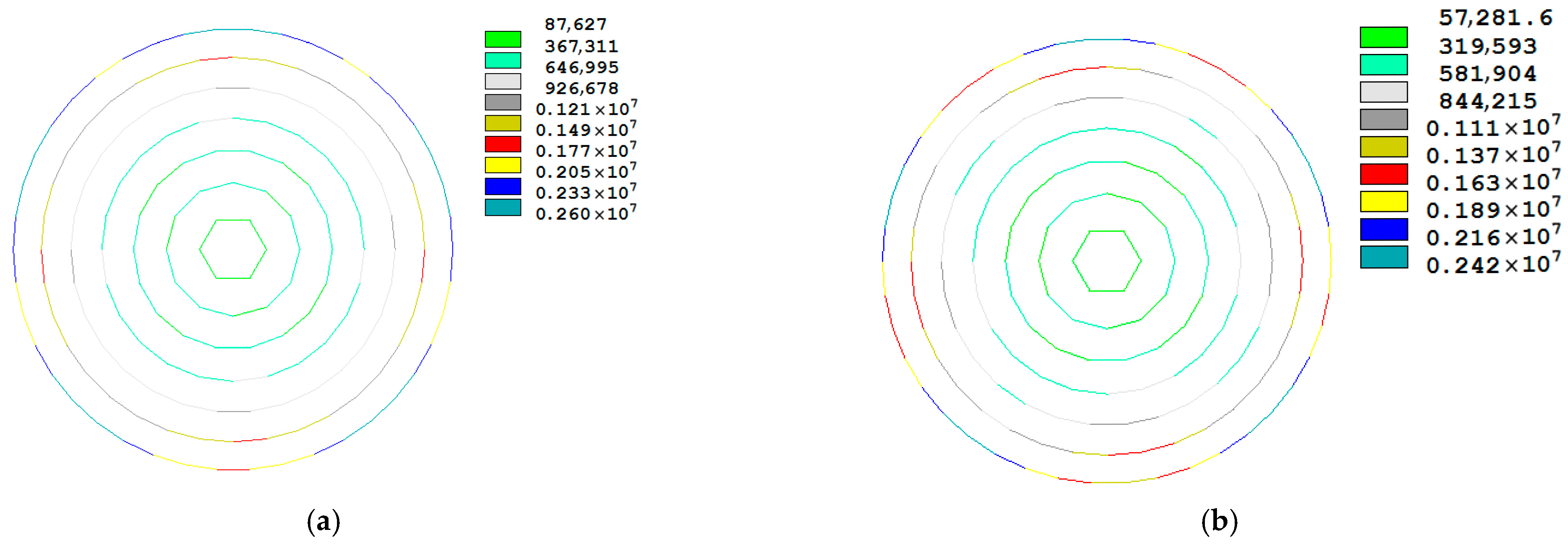

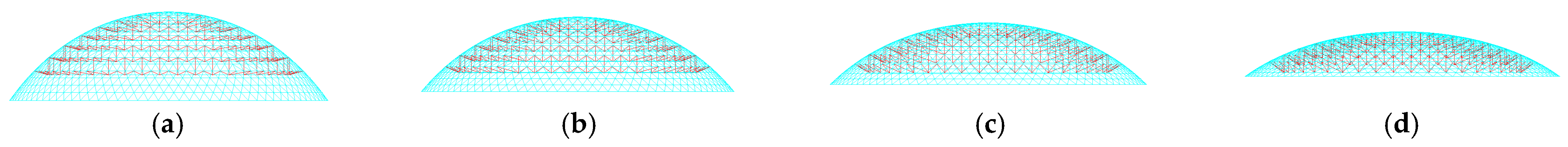

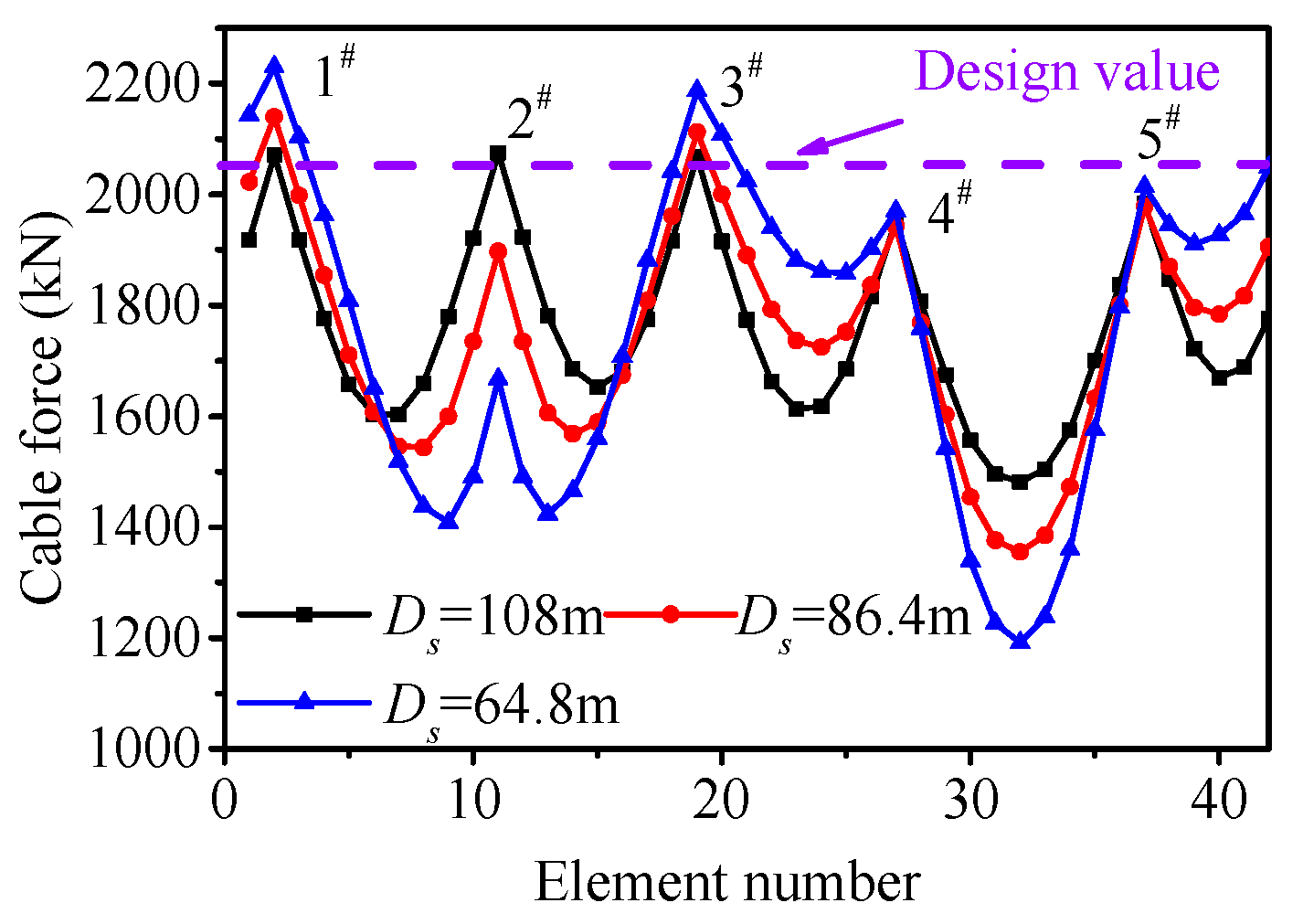

4.3. Influence of Geometrical Size of Dome

5. Conclusions

- (a)

- The loss ratio of cable force was about 20% when the friction coefficient was 0.5 and almost linearly changed with the variation in friction coefficient.

- (b)

- The maximal displacement was reduced by 10 mm due to loss of cable force.

- (c)

- Friction has almost no influence on the stress distribution of vertical struts, but friction has a large influence on the stress of diagonal members. The axial stress of diagonal members increased by about 18 MPa.

- (d)

- The over-tensioning method can be effectively utilized to weaken the influence of friction, but the optimal value of improved cable force is relevant to the frictional coefficient.

- (e)

- The spherical reticulated shell has little influence on the cable force loss ratio; however, ellipsoidal reticulated shell structures have significant influence on the cable force loss ratio.

- (f)

- In practical design applications, the adoption of a friction coefficient range of 0.2–0.5 is recommended for preliminary calculations. Note that this model is limited to static conditions and does not account for time-dependent effects (e.g., creep, stress relaxation), which should be considered in long-term structural analysis. Furthermore, ellipsoidal dome geometries demonstrate advantages in minimizing force loss variations and should be preferentially considered in structural configurations. The proposed method is currently implemented as an ANSYS script and will be developed into a plugin for engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Z.; Wu, J.; Meng, S. Influence of member geometric imperfection on geometrically nonlinear buckling and seismic performance of suspen-dome structures. Int. J. Struct. Stab. Dyn. 2014, 14, 1350070. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, A.; Fu, W. Cable tension preslack method construction simulation and engineering application for a prestressed suspended dome. Adv. Mater. Sci. Eng. 2015, 2015, 651041. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, W.; Yan, R.; Zhao, B. Tensile capacity degradation of randomly corroded strands based on a refined numerical model. Reliab. Eng. Syst. Saf. 2025, 253, 110512. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, Y.; Yin, Y.; Shan, C. Formulation and application of multi-node sliding cable element for the analysis of suspen-dome structures. Finite Elem. Anal. Des. 2010, 46, 743–750. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, H.; Wang, X.; Zhou, T. Establishment and application of cable-sliding criterion equation. Adv. Steel Constr. 2011, 7, 131–143. [Google Scholar]

- Liu, H.; Chen, Z. Research on effect of sliding between hoop cable and cable-strut joint on behavior of suspen-dome structures. Adv. Steel Constr. 2012, 8, 359–365. [Google Scholar]

- Liu, H.; Chen, Z. Influence of cable sliding on the stability of suspen-dome with stacked arches structures. Adv. Steel Constr. 2012, 8, 54–70. [Google Scholar]

- Liu, H.; Han, Q.; Chen, Z.; Wang, X.; Yan, R.Z.; Zhao, B. Precision control method for pre-stressing construction of suspen-dome structures. Adv. Steel Constr. 2014, 10, 404–425. [Google Scholar]

- Ali, N.B.H.; Sychterz, A.C.; Smith, I.F.C. A dynamic-relaxation formulation for analysis of cable structures with sliding-induced friction. Int. J. Solids Struct. 2017, 126, 240–251. [Google Scholar]

- Ni, Y.Q.; Ko, J.M.; Zheng, G. Dynamic analysis of large-diameter sagged cables taking into account flexural rigidity. J. Sound Vib. 2002, 257, 301–319. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Wu, L.L.; Shi, Y.J.; Sun, F.; Luo, K.Y.; Xu, Y. FEM analysis and experimental study on monolayer cable net for glass facades: Static performance. Adv. Struct. Eng. 2007, 10, 371–382. [Google Scholar] [CrossRef]

- Zhu, M.L.; Dong, S.L.; Yuan, X.F. Failure analysis of a cable dome due to cable slack or rupture. Adv. Struct. Eng. 2013, 16, 259–271. [Google Scholar] [CrossRef]

- Thai, H.T.; Kim, S.E. Nonlinear static and dynamic analysis of cable structures. Finite Elem. Anal. Des. 2011, 47, 237–246. [Google Scholar] [CrossRef]

- Li, J.J.; Chan, S.L. An integrated analysis of membrane structures with flexible supporting frames. Finite Elem. Anal. Des. 2004, 40, 529–540. [Google Scholar] [CrossRef]

- Tang, J.M.; Dong, M.; Qian, R.J. A finite element method with five isoparametric elements for nonlinear analysis of tension structures. Chin. J. Comput. Mech. 1997, 14, 108–113. [Google Scholar]

- Tang, J.M.; Shen, Z.Y. A nonlinear analysis method with sliding cable elements for cable structures. Chin. J. Comput. Mech. 1999, 16, 143–149. [Google Scholar]

- Zhang, Z.H.; Dong, S.L. Slippage analysis of continuous cables in tension structures. Spat. Struct. 2001, 7, 26–32. [Google Scholar]

- Wei, J.D. Sliding cable elements for the analysis of cable structures. Eng. Mech. 2004, 21, 172–177. [Google Scholar]

- Fan, X.; Zhao, Z.; Xu, H.; Liu, H.; Zhang, N.; Wu, X. The tensioning process of ellipsoidal suspen-dome structures considering the friction of cable-strut joints. Structures 2021, 34, 3757–3775. [Google Scholar] [CrossRef]

- Liu, H.B.; Chen, Z.H.; Zhou, T. Prestress loss induced by friction in suspendome construction. J. Tianjin Univ. 2009, 42, 1055–1060. [Google Scholar]

- Wei, J.D. Friction gliding cable elements in the analysis of gliding cable structures. Eng. Mech. 2006, 23, 66–70. [Google Scholar]

- Yan, R.Z.; Chen, Z.H.; Wang, X.D.; Liu, H.B.; Xiao, X. A new equivalent friction element for analysis of cable-supported structures. Steel Compos. Struct. 2015, 18, 947–970. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, J.; Liu, H.; Liang, B. Influence of friction on buckling and dynamic behavior of suspen-dome structures. Struct. Eng. Int. 2020, 30, 262–269. [Google Scholar] [CrossRef]

- Zhao, Z.; Liang, B.; Yan, R. A novel numerical method for considering friction during pre-stressing construction of cable-supported structures. Int. J. Steel Struct. 2021, 18, 1699–1709. [Google Scholar] [CrossRef]

- Ansys Inc. ANSYS Multiphysics, version 10.0; Ansys Inc.: Canonsburg, PA, USA, 2003. [Google Scholar]

| Condition | Tensioning Force T1 (kN) | Tensioning Force at Fixed End T2 (kN) | Friction Coefficient μ | T2 (kN) (Computational Value in This Paper) |

|---|---|---|---|---|

| Condition I | 40.00 | 33.35 | 0.1675 | 33.07 |

| Condition II | 40.00 | 35.66 | 0.1060 | 35.62 |

| Condition III | 40.00 | 31.34 | 0.2243 | 31.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Li, P.; Zhang, N.; Lao, Z. Influence of Friction on Pre-Stressing Construction of Suspen-Dome Structures. Buildings 2025, 15, 2697. https://doi.org/10.3390/buildings15152697

Liu M, Li P, Zhang N, Lao Z. Influence of Friction on Pre-Stressing Construction of Suspen-Dome Structures. Buildings. 2025; 15(15):2697. https://doi.org/10.3390/buildings15152697

Chicago/Turabian StyleLiu, Miao, Pengyuan Li, Ni Zhang, and Zhancai Lao. 2025. "Influence of Friction on Pre-Stressing Construction of Suspen-Dome Structures" Buildings 15, no. 15: 2697. https://doi.org/10.3390/buildings15152697

APA StyleLiu, M., Li, P., Zhang, N., & Lao, Z. (2025). Influence of Friction on Pre-Stressing Construction of Suspen-Dome Structures. Buildings, 15(15), 2697. https://doi.org/10.3390/buildings15152697