Localized Compression Behavior of GFRP Grid Web–Concrete Composite Beams: Experimental, Numerical, and Analytical Studies

Abstract

1. Introduction

2. Experimental Program

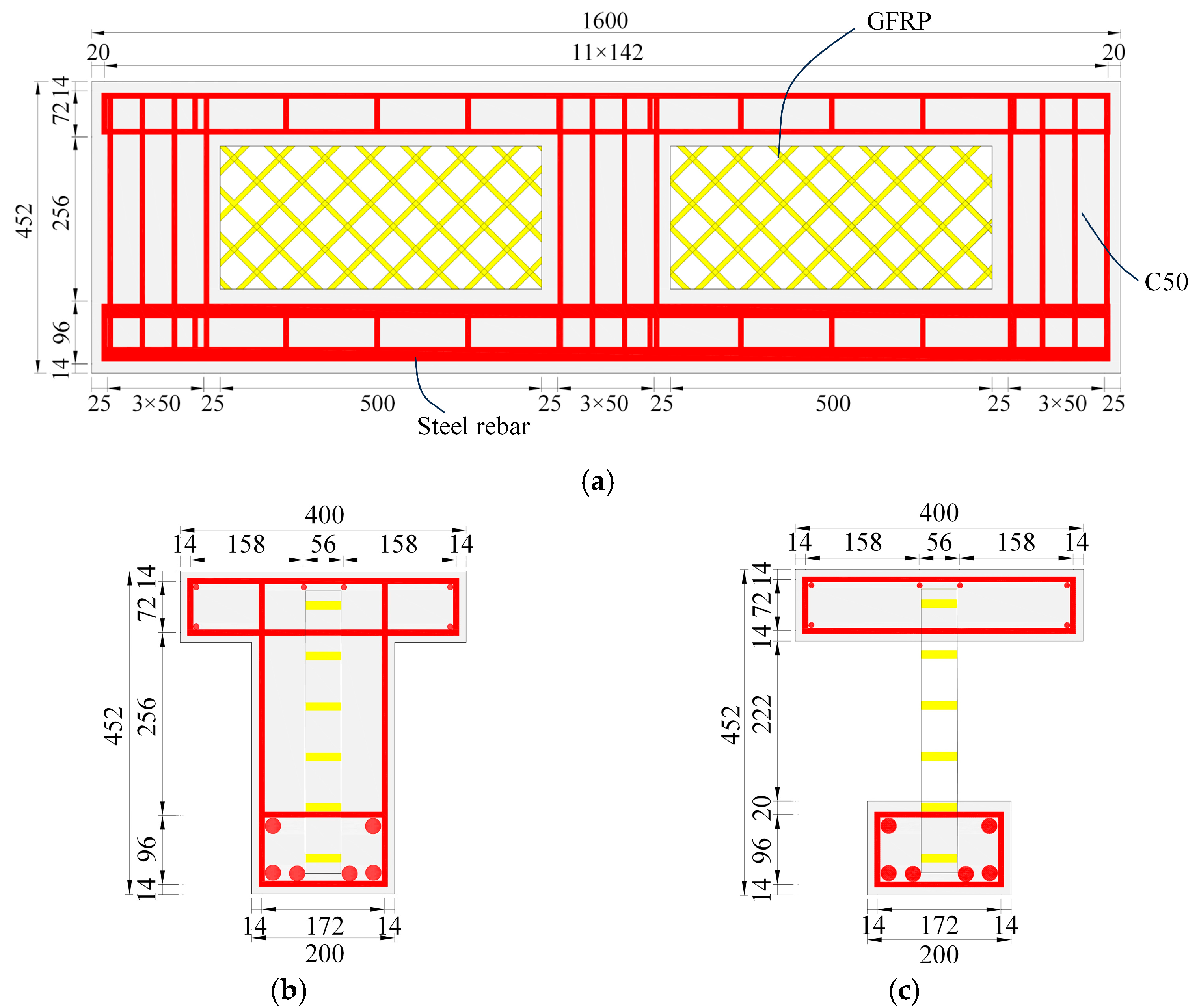

2.1. Specimen Features and Preparation

2.2. Materials

2.3. Test Setup and Instrumentation

3. Experimental Results and Discussion

3.1. Failure Mode

3.2. Load–Displacement Curve

3.3. Section Shear Force and Strain Analysis

4. Numerical Analysis

4.1. Finite Element Model

4.2. Numerical Verification

4.3. Localized Compressive Transfer Mechanism of GFRP Grid

4.4. Parametric Study of GFRP Grid Web

- (1)

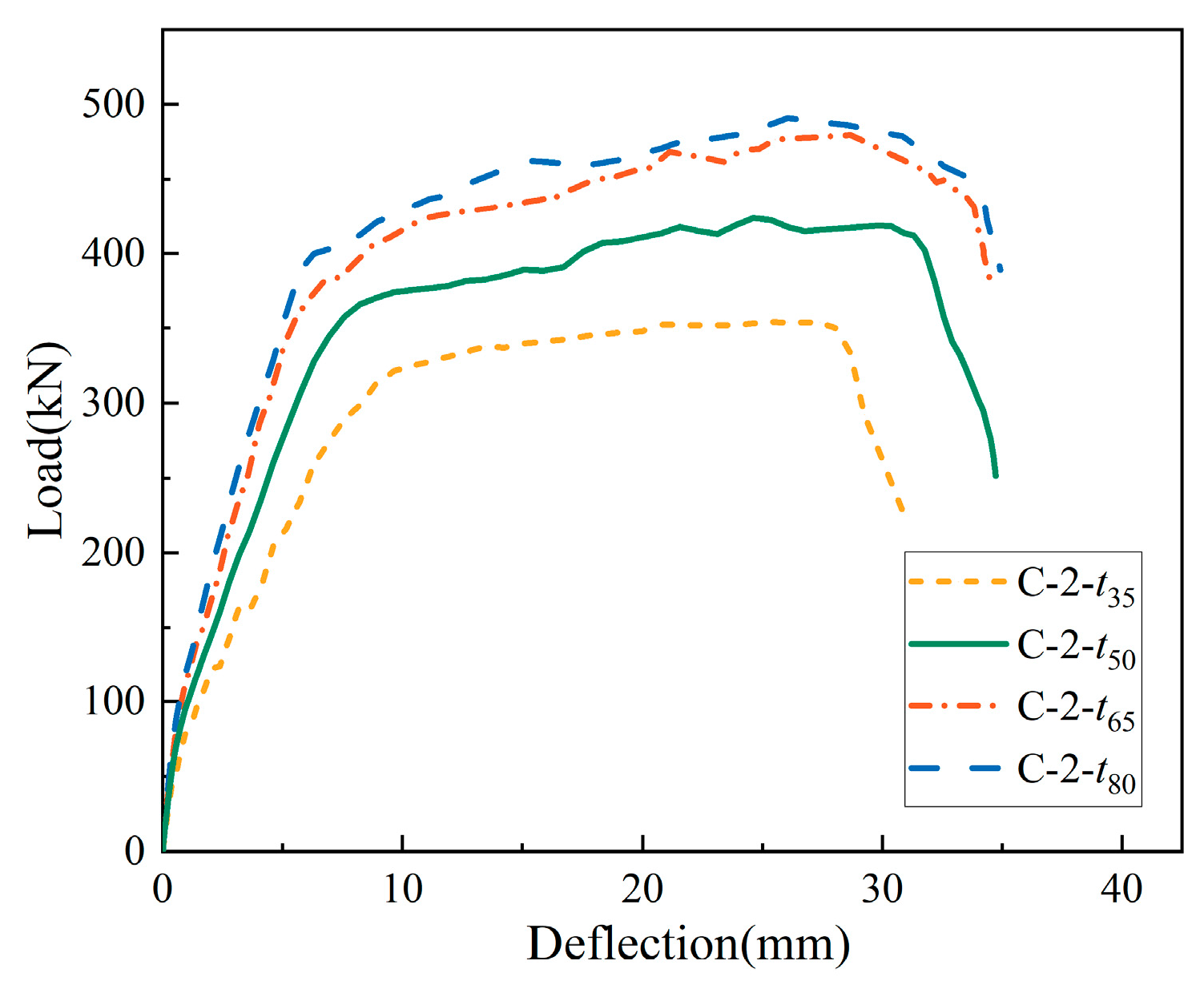

- Grid thickness

- (2)

- Grid spacing

5. Analytical Model

- (1)

- The interface between the concrete and the GFRP grid web is assumed to form a reliable bond, with no relative slippage considered.

- (2)

- Given that the localized compression failure in the composite beam is predominantly governed by the GFRP grid web, and experimental observations indicate that damage in the upper flange occurs after web failure while the lower flange contributes minimally due to tensile cracking, the contribution of the reinforced concrete flanges to the bearing capacity is conservatively neglected to simplify the calculation model.

- (3)

- The stiffness of the GFRP grid web is assumed to be constant and uniformly distributed along the axial direction of the beam.

6. Conclusions

- (1)

- The failure process of the novel GFRP grid web–concrete composite beam under localized compression can be categorized into three stages: the linear elastic phase, the post-cracking stiffening phase, and the failure phase. The localized failure of the composite beam is primarily governed by the GFRP grid web. At the ultimate state, the localized crushing of the grid web results in a rapid loss of load-bearing capacity in the structure.

- (2)

- Experimental results show that a 19.2% reduction in the shear-span ratio (from 1.77 to 1.43) leads to an approximate 22.93% increase in ultimate capacity and a 66.85% improvement in stiffness. Furthermore, the addition of local stiffener further enhances the ultimate capacity and stiffness by 77.53% and 94.29%, respectively. These findings indicate that optimizing the shear-span ratio and reinforcing local stiffener can significantly improve load distribution and overall structural performance.

- (3)

- The finite element model developed using ABAQUS successfully reproduced the load–displacement relationship, strain distribution, and failure modes observed in the experiments. The predicted ultimate bearing capacity had a deviation of less than 5% from the experimental results, demonstrating the accuracy of the numerical simulation and supporting its applicability for subsequent parametric analyses.

- (4)

- Parametric studies using the validated finite element model indicate that increasing the grid thickness within a range of 35–65 mm and reducing the grid spacing to between 30 and 40 mm can significantly enhance localized compression performance. This improvement is attributed to the fact that a thicker grid increases the load-bearing capacity, while a smaller spacing promotes more uniform stress distribution across the web. However, the influence of the grid parameters on localized compression performance necessitates further experimental and numerical validation to achieve an optimal balance between material efficiency and structural performance.

- (5)

- The analytical model derived from the Winkler elastic foundation theory can effectively predict the ultimate load. Comprehensive analysis of the experimental, numerical, and theoretical results shows that the calculation deviation remains within 10%, providing a practical and reliable theoretical basis for engineering design. However, the grid strength adjustment factor βg introduced still requires further refinement through further experimental and numerical validations.

- (6)

- For the same cross-sectional design, the localized bearing capacity of composite beams is generally higher than their flexural failure capacity. In practical engineering applications, although the localized compression performance meets the required standards after proper design, the rational optimization of the GFRP grid web parameters remains crucial.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xin, H.; Liu, Y.; Mosallam, A.S.; He, J.; Du, A. Evaluation on material behaviors of pultruded glass fiber reinforced polymer (GFRP) laminates. Compos. Struct. 2017, 182, 283–300. [Google Scholar] [CrossRef]

- Liu, T.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Feng, P.; Wang, J.; Wang, Y.; Loughery, D.; Niu, D. Effects of corrosive environments on properties of pultruded GFRP plates. Compos. Part B Eng. 2014, 67, 427–433. [Google Scholar] [CrossRef]

- Yang, C.; Nan, Z.; Huo, Y.; Yang, Y.; Xu, P.; Xiao, Y.; Meng, K. Design, characterisation, and crushing performance of hexagonal-quadrilateral lattice-filled steel/CFRP hybrid structures. Compos. Part B Eng. 2025, 304, 112631. [Google Scholar] [CrossRef]

- Bazli, M.; Li, Y.-L.; Zhao, X.-L.; Raman, R.K.S.; Bai, Y.; Al-Saadi, S.; Haque, A. Durability of seawater and sea sand concrete filled filament wound FRP tubes under seawater environments. Compos. Part B Eng. 2020, 202, 108409. [Google Scholar] [CrossRef]

- Siwowski, T.; Kulpa, M.; Rajchel, M.; Poneta, P. Design, manufacturing and structural testing of all-composite FRP bridge girder. Compos. Struct. 2018, 206, 814–827. [Google Scholar] [CrossRef]

- Pang, K.; Zhou, H.; Wu, C.; Jiang, H.; Zhang, Z.; Yu, Y.; Zhang, J. Study on behavior of waffle-type UHPC-GFRP composite slab under three-point loading. Case Stud. Constr. Mater. 2023, 19, e02457. [Google Scholar] [CrossRef]

- Wu, C.; Wang, X.; Zhang, Z.; Zou, Y.; Yang, J.; Jin, M.; Lun, X. Flexural behavior of embedded GFRP grid framework-UHPC composite plate without steel rebar. Case Stud. Constr. Mater. 2024, 20, e02900. [Google Scholar] [CrossRef]

- Yang, J.Q.; Smith, S.T.; Feng, P. Effect of FRP-to-steel bonded joint configuration on interfacial stresses: Finite element investigation. Thin-Walled Struct. 2013, 62, 215–228. [Google Scholar] [CrossRef]

- Liu, T.; Vieira, J.D.; Harries, K.A. Lateral torsional buckling and section distortion of pultruded GFRP I-sections subject to flexure. Compos. Struct. 2019, 225, 111151. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Ababneh, A.; Alhassan, M. Hybrid CFRP-steel for enhancing the flexural behavior of reinforced concrete beams. J. King Saud Univ. Eng. Sci. 2021, 33, 459–470. [Google Scholar] [CrossRef]

- Jiang, Z.; Wan, S.; Fang, Z.; Song, A. Experimental investigation of fatigue behavior for adhesively-bonded GFRP/steel joints. Eng. Struct. 2020, 213, 110580. [Google Scholar] [CrossRef]

- Sylaj, V.; Jawdhari, A.; Fam, A. Sandwich concrete beams with GFRP side faces tested and modeled in flexure. Thin-Walled Struct. 2022, 179, 109703. [Google Scholar] [CrossRef]

- Liu, T.; Feng, P.; Lu, X.; Yang, J.-Q.; Wu, Y. Flexural behavior of novel hybrid multicell GFRP-concrete beam. Compos. Struct. 2020, 250, 112606. [Google Scholar] [CrossRef]

- Chen, D.; El-Hacha, R. Damage tolerance and residual strength of hybrid FRP–UHPC beam. Eng. Struct. 2013, 49, 275–283. [Google Scholar] [CrossRef]

- Muc, A.; Stawiarski, A.; Chwał, M. Design of the hybrid FRP/concrete structures for bridge constructions. Compos. Struct. 2020, 247, 112490. [Google Scholar] [CrossRef]

- Zou, X.; Lin, H.; Feng, P.; Bao, Y.; Wang, J. A review on FRP-concrete hybrid sections for bridge applications. Compos. Struct. 2021, 262, 113336. [Google Scholar] [CrossRef]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Safonov, A. The Effects of Eccentric Web Openings on the Compressive Performance of Pultruded GFRP Boxes Wrapped with GFRP and CFRP Sheets. Polymers 2022, 14, 4567. [Google Scholar] [CrossRef]

- Iskander, M.; El-Hacha, R.; Shrive, N. Governing failure criterion of short-span hybrid FRP-UHPC beams subjected to high shear forces. Compos. Struct. 2018, 185, 123–131. [Google Scholar] [CrossRef]

- Alizadeh, E.; Dehestani, M.; Navayi Neya, B.; Nematzadeh, M. Efficient composite bridge deck consisting of GFRP. J. Sandw. Struct. Mater. 2019, 21, 154–174. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, J.; Qian, X.; Yan, J.-B. Interfacial shear behaviour of GFRP box-concrete composite girders under low temperature. Eng. Struct. 2024, 312, 118242. [Google Scholar] [CrossRef]

- Wang, W.-W.; Harries, K.; Tian, J. Bonding Behavior of Wet-Bonded GFRP-Concrete Interface. J. Compos. Constr. 2015, 19, 04015001. [Google Scholar] [CrossRef]

- Zou, X.; Feng, P.; Wang, J. Bolted Shear Connection of FRP-Concrete Hybrid Beams. J. Compos. Constr. 2018, 22, 04018012. [Google Scholar] [CrossRef]

- Zou, X.; Feng, P.; Wang, J. Perforated FRP ribs for shear connecting of FRP-concrete hybrid beams/decks. Compos. Struct. 2016, 152, 267–276. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, Y.; Pang, Y.; Feng, H.; Gao, D.; Zhao, J.; Sheikh, S.A. Influence factors analysis of the interfacial bond behavior between GFRP plates, concrete. Structures 2020, 26, 79–91. [Google Scholar] [CrossRef]

- Csillag, F.; Pavlović, M. Push-out behaviour of demountable injected vs. blind-bolted connectors in FRP decks. Compos. Struct. 2021, 270, 114043. [Google Scholar] [CrossRef]

- Kong, S.Y.; Yang, X.; Lee, Z.Y. Mechanical performance and numerical simulation of GFRP-concrete composite panel with circular hollow connectors and epoxy adhesion. Constr. Build. Mater. 2018, 184, 643–654. [Google Scholar] [CrossRef]

- Zou, Y.; Yu, K.; Heng, J.; Zhang, Z.; Peng, H.; Wu, C.; Wang, X. Feasibility study of new GFRP grid web—Concrete composite beam. Compos. Struct. 2023, 305, 116527. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Zeng, W.-B.; Ye, Y.-Y.; Liao, J.; Zhuge, Y.; Fan, T.-H. Flexural behavior of FRP grid reinforced ultra-high-performance concrete composite plates with different types of fibers. Eng. Struct. 2022, 272, 115020. [Google Scholar] [CrossRef]

- Li, G.-Q.; Jiang, J.; Zhu, Q. Local buckling of compression flanges of H-beams with corrugated webs. J. Constr. Steel Res. 2015, 112, 69–79. [Google Scholar] [CrossRef]

- Jáger, B.; Dunai, L.; Kövesdi, B. Flange buckling behavior of girders with corrugated web Part II: Numerical study and design method development. Thin-Walled Struct. 2017, 118, 238–252. [Google Scholar] [CrossRef]

- ACI 318-19(22); Building Code Requirements for Structural Concrete and Commentary (Reapproved 2022). American Concrete Institute: Farmington Hills, MI, USA, 2019.

- Zou, Y.; Wu, C.; Zhang, Z.; Jiang, J.; Yu, K.; Wang, X. Investigation on flexural behavior of novel GFRP grid web-concrete hybrid beam. Eng. Struct. 2023, 278, 115489. [Google Scholar] [CrossRef]

- GB/T 50448-2015; Technical Code for Application of Cementitious Grout. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2015. (In Chinese)

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. State Administration for Market Regulation, Standardization Administration: Beijing, China, 2019. (In Chinese)

- 36. GB/T 228.1-2010; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2010. (In Chinese)

- GB 50010-2010; Code for Design of Concrete Structures. General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2010. (In Chinese)

- ABAQUS 6.14 User Manual. Available online: http://62.108.178.35:2080/v6.14/index.html (accessed on 28 July 2025).

- Al-Hosani, K.; Fadhil, S.; El-Zafrany, A. Fundamental solution and boundary element analysis of thick plates on Winkler foundation. Comput. Struct. 1999, 70, 325–336. [Google Scholar] [CrossRef]

- Eisenberger, M.; Yankelevsky, D.Z. Exact stiffness matrix for beams on elastic foundation. Comput. Struct. 1985, 21, 1355–1359. [Google Scholar] [CrossRef]

- Wstawska, I.; Magnucki, K.; Kędzia, P. Stability of three-layered beam on elastic foundation. Thin-Walled Struct. 2022, 175, 109208. [Google Scholar] [CrossRef]

- Nguyen, N.-D.; Vo, T.P.; Nguyen, T.-K. An improved shear deformable theory for bending and buckling response of thin-walled FG sandwich I-beams resting on the elastic foundation. Compos. Struct. 2020, 254, 112823. [Google Scholar] [CrossRef]

- Gao, K.; Gao, W.; Wu, D.; Song, C. Nonlinear dynamic characteristics and stability of composite orthotropic plate on elastic foundation under thermal environment. Compos. Struct. 2017, 168, 619–632. [Google Scholar] [CrossRef]

| Material | Compressive Strength of Concrete fc (MPa) | Young’s Modulus of Concrete Ec (GPa) | Yield Stress of Steel Rebar fv (MPa) | Ultimate Stress of Steel Rebar fu (MPa) | Young’s Modulus of Steel Rebar Es (GPa) |

|---|---|---|---|---|---|

| C50 | 46.7 | 35.1 | - | - | - |

| HRB400 | - | - | 459.3 | 577.1 | 203.7 |

| Performance | Compression Modulus | Compressive Strength | Tensile Modulus | Tensile Strength | Interlaminar Shear Strength |

|---|---|---|---|---|---|

| Result (MPa) | 20,000.0 | 320.0 | 15,000.0 | 238.7 | 33.2 |

| Test Number | a (mm) | b (mm) | L (mm) | Shear Span Ratio | Notes |

|---|---|---|---|---|---|

| C-1 | 775 | 75 | 2300 | 1.77 | Unribbed |

| C-2 | 625 | 175 | 2300 | 1.43 | Unribbed |

| C-3 | 625 | 175 | 1600 | 1.43 | Local ribbed |

| Test Number | Pu (kN) | Su (mm) | Pu/Su (kN/mm) | Su,0.5 (mm) | Kel (kN/mm) | Energy Absorption (J) | Stiffness Degradation Rate (%) | Failure Mode |

|---|---|---|---|---|---|---|---|---|

| C-1 | 362.65 | 39.20 | 9.23 | 4.14 | 45.27 | 11,337.58 | 79.61 | Bending failure |

| C-2 | 445.32 | 28.90 | 15.40 | 4.12 | 53.65 | 9007.47 | 71.29 | Local collapse |

| C-3 | 790.75 | 26.40 | 29.92 | 6.02 | 55.65 | 13,030.96 | 46.23 | Flexural-shear failure |

| Test Number | C-1 | C-2 | C-3 | |||

|---|---|---|---|---|---|---|

| FEM | EXP | FEM | EXP | FEM | EXP | |

| Pu (kN) | 351.1 | 362.0 | 425.6 | 445.0 | 757.1 | 790.0 |

| Deviation | 3.01% | 4.36% | 4.16% | |||

| Number | Grid Thickness (mm) | Grid Spacing (mm) | Pu (kN) | Su (mm) | Pu/Su (kN/mm) |

|---|---|---|---|---|---|

| C-2-t35 | 35 | 50 | 348.0 | 25.3 | 13.7 |

| C-2-t50 | 50 | 50 | 425.6 | 30.3 | 14.1 |

| C-2-t65 | 65 | 50 | 479.6 | 28.7 | 17.1 |

| C-2-t80 | 80 | 50 | 491.5 | 26.0 | 17.6 |

| C-2-s60 | 50 | 60 | 398.5 | 21.6 | 16.1 |

| C-2-s50 | 50 | 50 | 425.6 | 30.3 | 14.1 |

| C-2-s40 | 50 | 40 | 479.9 | 25.3 | 19.0 |

| C-2-s30 | 50 | 30 | 544.4 | 30.8 | 17.7 |

| Number | Pn (kN) | Pn,c (kN) | Deviation |

|---|---|---|---|

| C-2 | 445.0 | 420.5 | 5.49% |

| C-2FEM | 425.6 | 420.5 | 1.19% |

| C-2-t35 | 348.0 | 318.6 | 8.45% |

| C-2-t65 | 479.6 | 524.4 | 9.35% |

| C-2-t80 | 491.5 | 625.7 | 27.30% |

| C-2-s60 | 398.5 | 361.2 | 9.36% |

| C-2-s40 | 479.9 | 507.3 | 5.72% |

| C-2-s30 | 544.4 | 647.8 | 19.09% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Cao, H.; Zhou, Y.; Kong, W.; Yu, K.; Jiang, H.; Zhang, Z. Localized Compression Behavior of GFRP Grid Web–Concrete Composite Beams: Experimental, Numerical, and Analytical Studies. Buildings 2025, 15, 2693. https://doi.org/10.3390/buildings15152693

Li Y, Cao H, Zhou Y, Kong W, Yu K, Jiang H, Zhang Z. Localized Compression Behavior of GFRP Grid Web–Concrete Composite Beams: Experimental, Numerical, and Analytical Studies. Buildings. 2025; 15(15):2693. https://doi.org/10.3390/buildings15152693

Chicago/Turabian StyleLi, Yunde, Hai Cao, Yang Zhou, Weibo Kong, Kun Yu, Haoting Jiang, and Zhongya Zhang. 2025. "Localized Compression Behavior of GFRP Grid Web–Concrete Composite Beams: Experimental, Numerical, and Analytical Studies" Buildings 15, no. 15: 2693. https://doi.org/10.3390/buildings15152693

APA StyleLi, Y., Cao, H., Zhou, Y., Kong, W., Yu, K., Jiang, H., & Zhang, Z. (2025). Localized Compression Behavior of GFRP Grid Web–Concrete Composite Beams: Experimental, Numerical, and Analytical Studies. Buildings, 15(15), 2693. https://doi.org/10.3390/buildings15152693