Effects of Partial Replacement of Cement with Fly Ash on the Mechanical Properties of Fiber-Reinforced Rubberized Concrete Containing Waste Tyre Rubber and Macro-Synthetic Fibers

Abstract

1. Introduction

2. Experimental Program

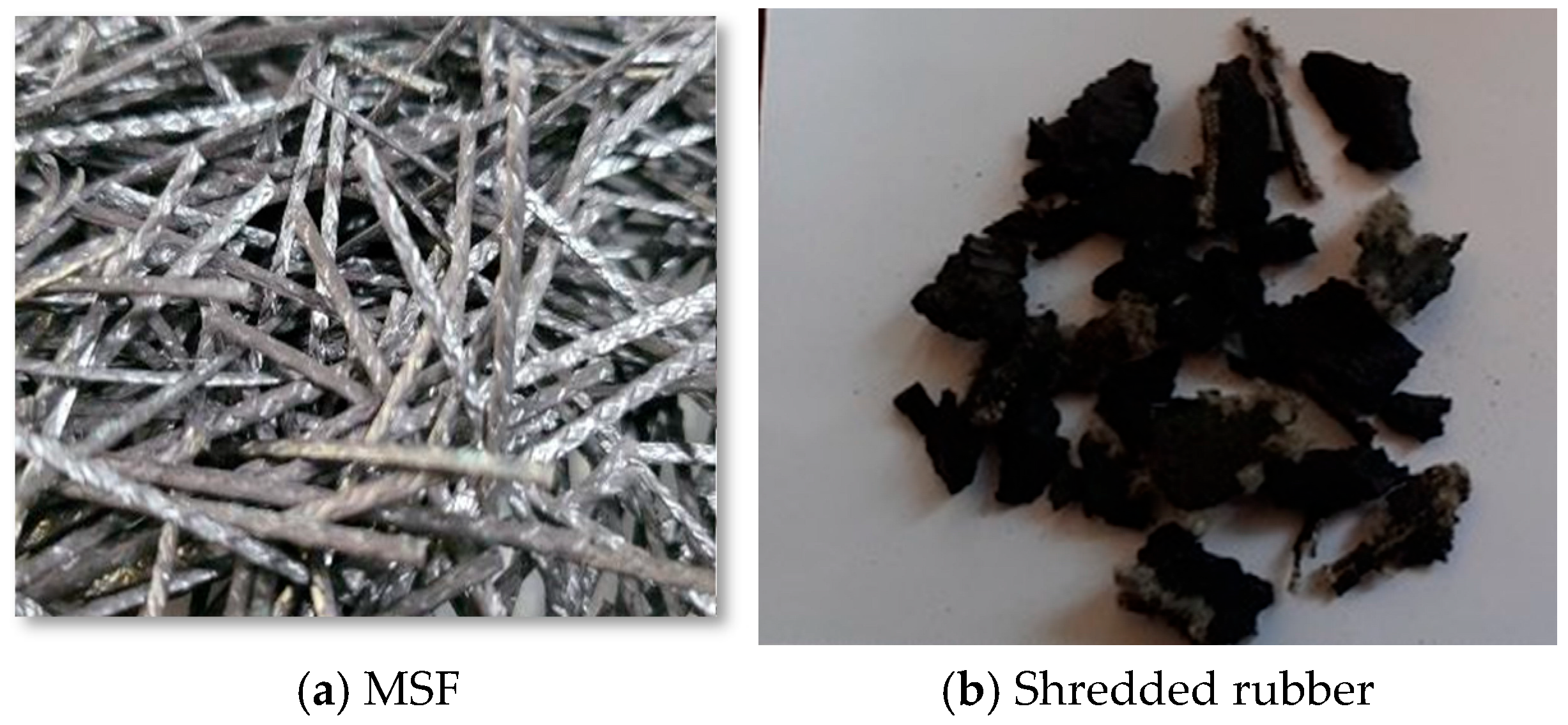

2.1. Materials

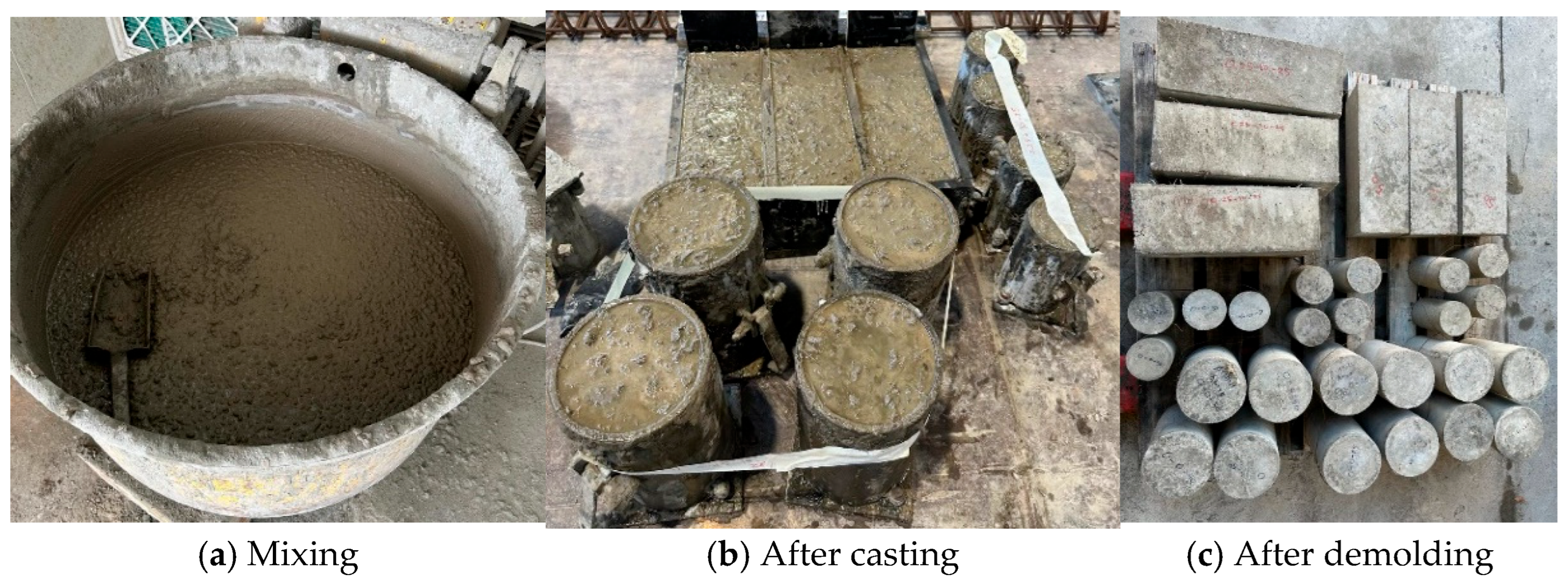

2.2. Mix Design of Concrete and Preparation of Test Specimens

2.3. Testing Setup

3. Test Results and Discussions

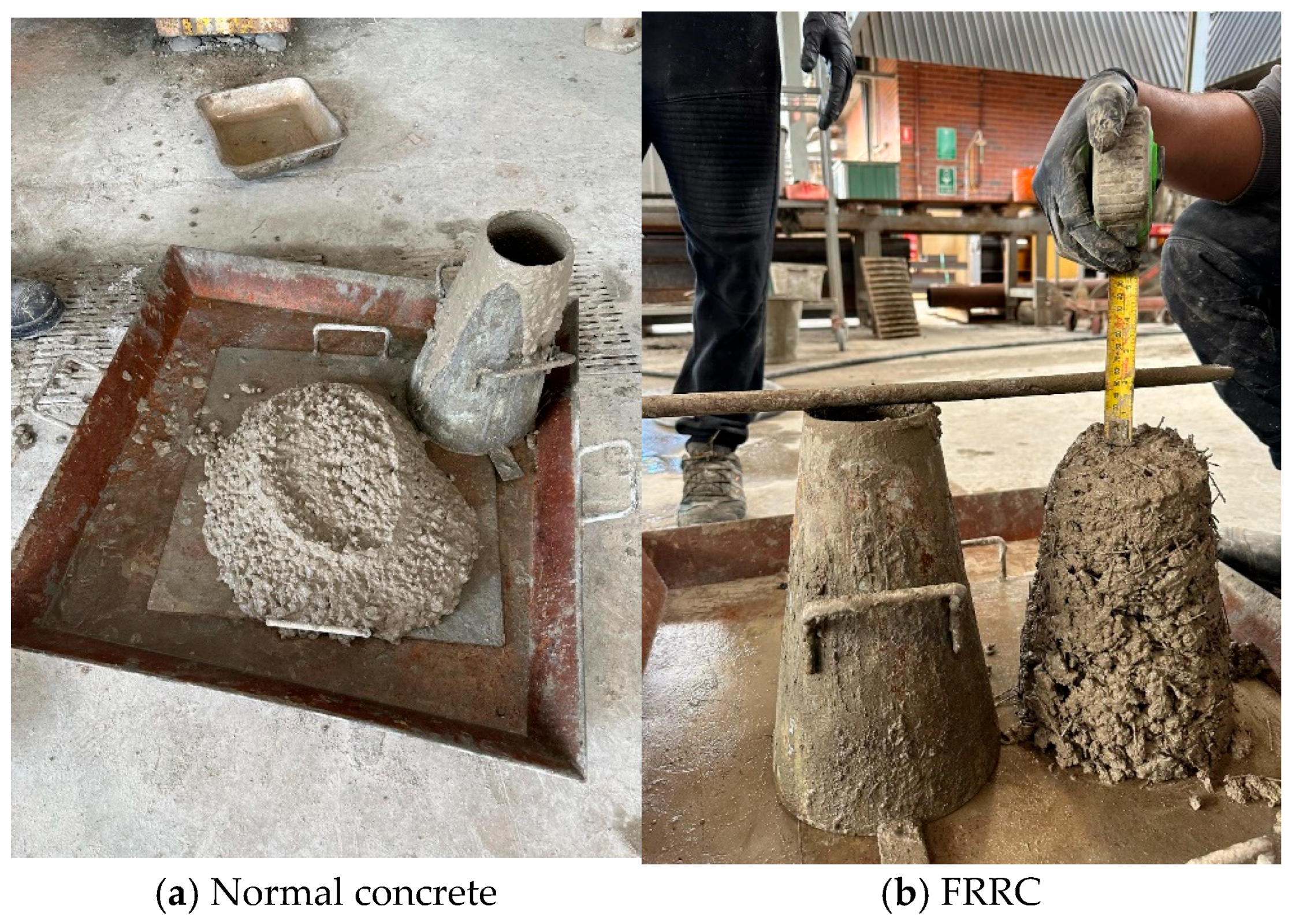

3.1. Effects of Fly Ash on the Slump of FRRC

3.2. Effects of Fly Ash on the Compressive Strength of FRRC

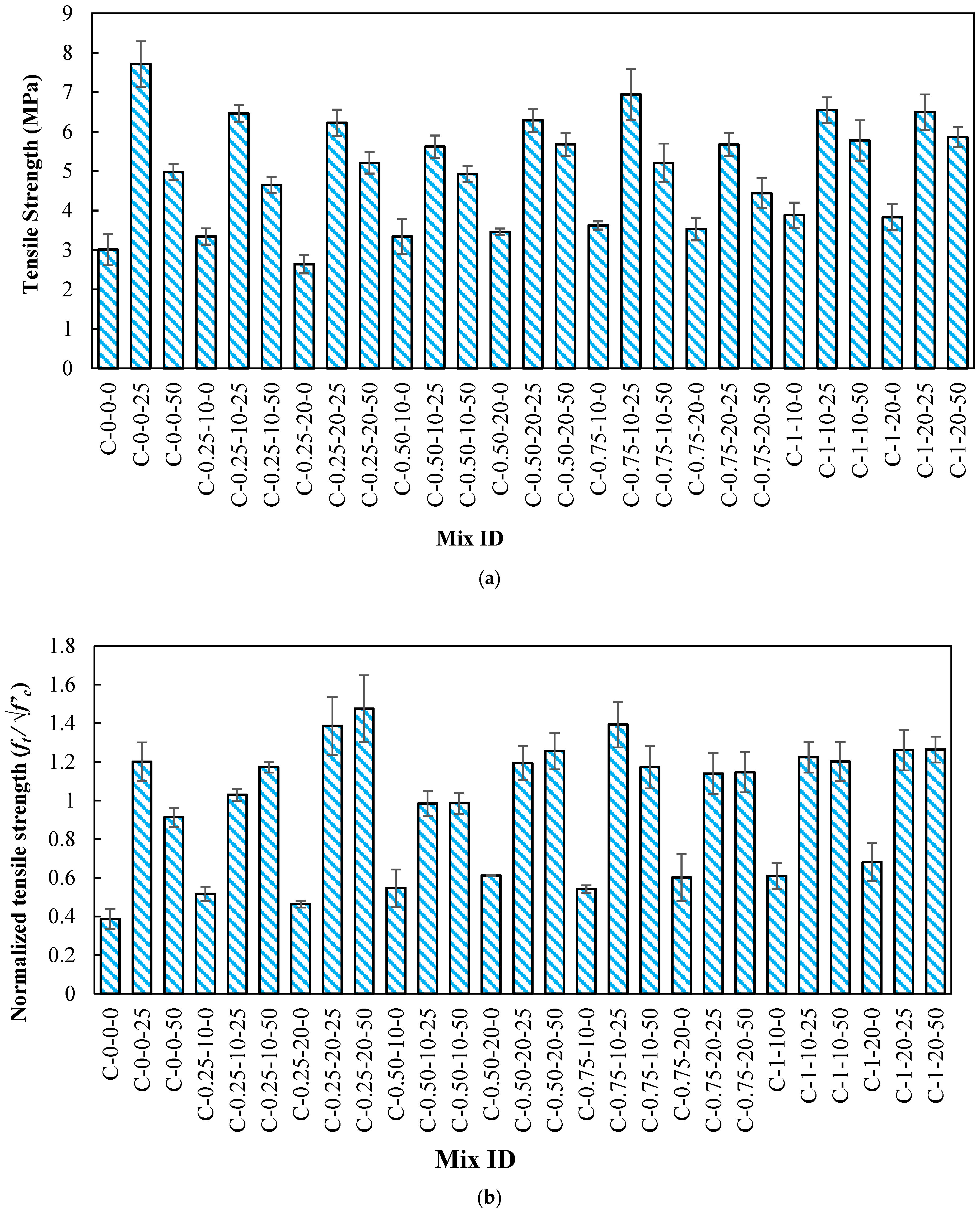

3.3. Effects of Fly Ash on the Splitting Tensile Strength of FRRC

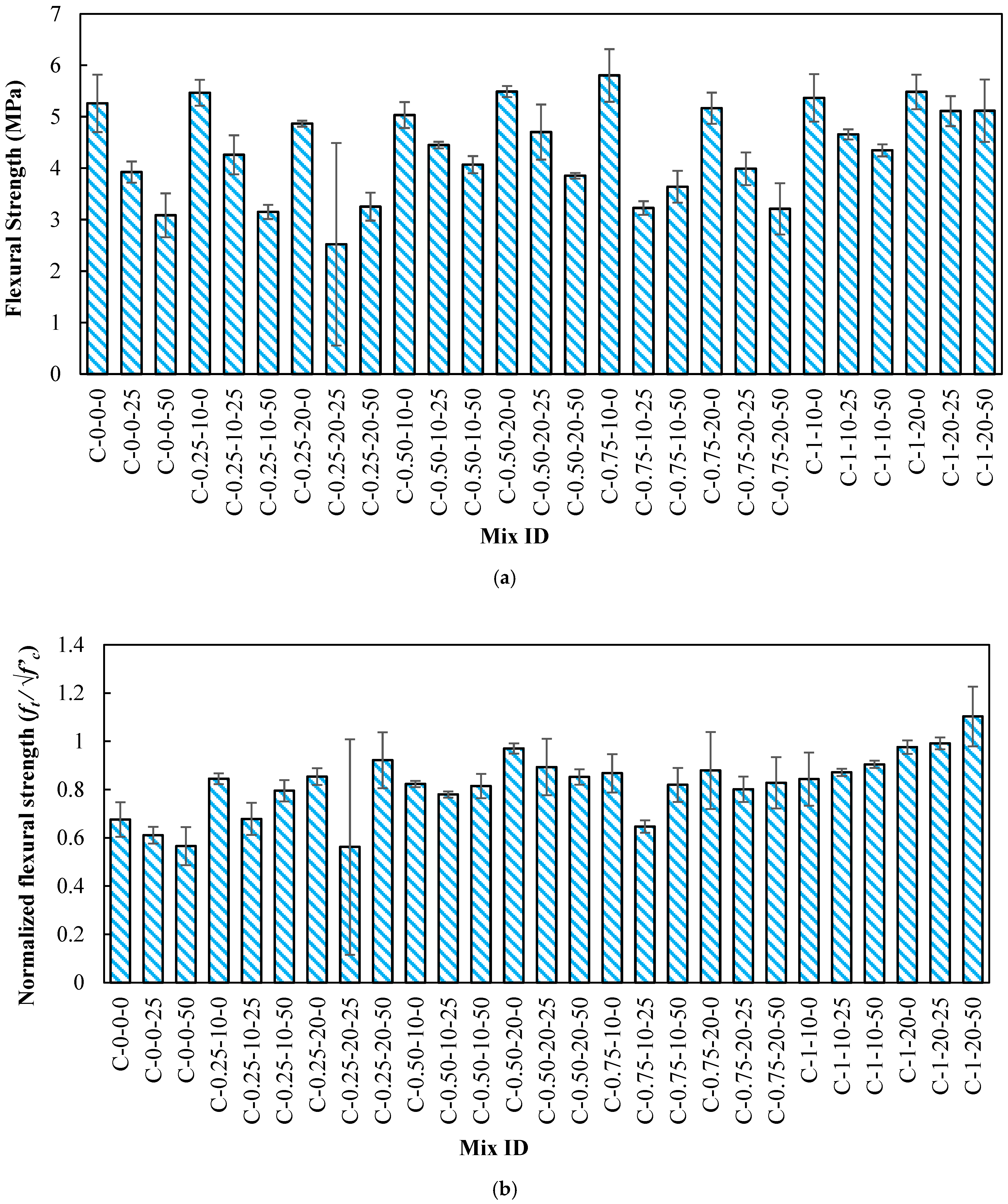

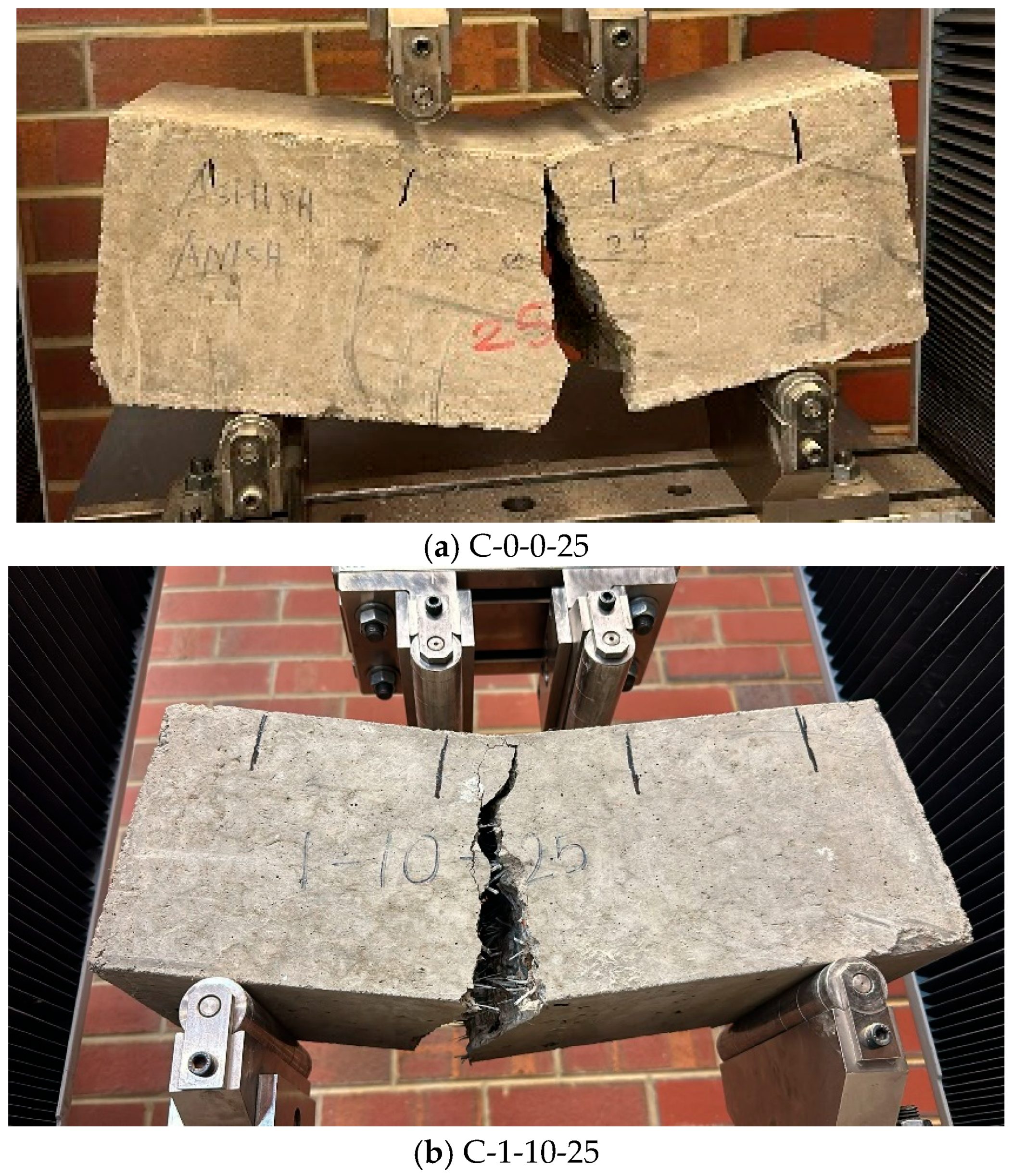

3.4. Effects of Fly Ash on the Flexural Strength of FRRC

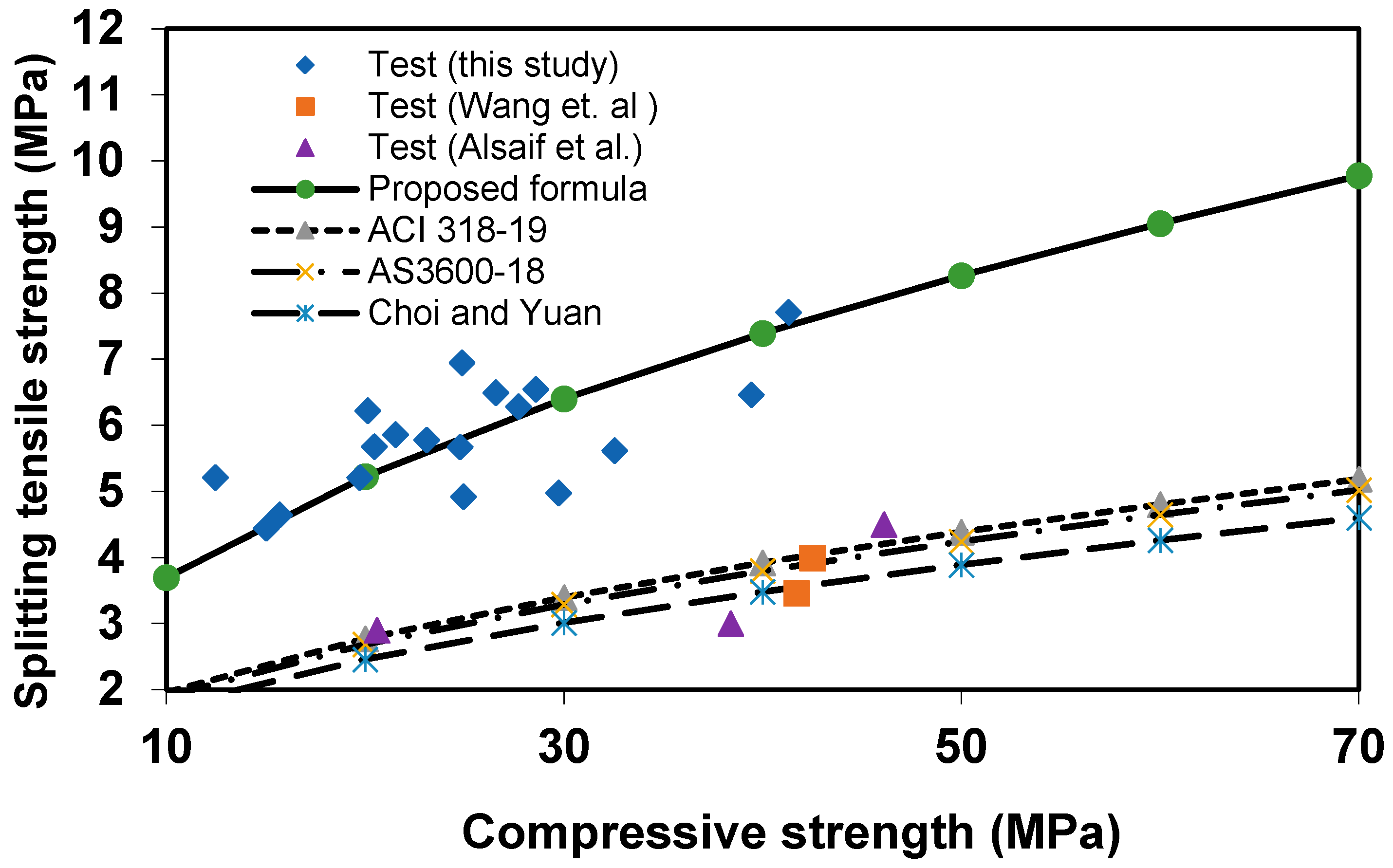

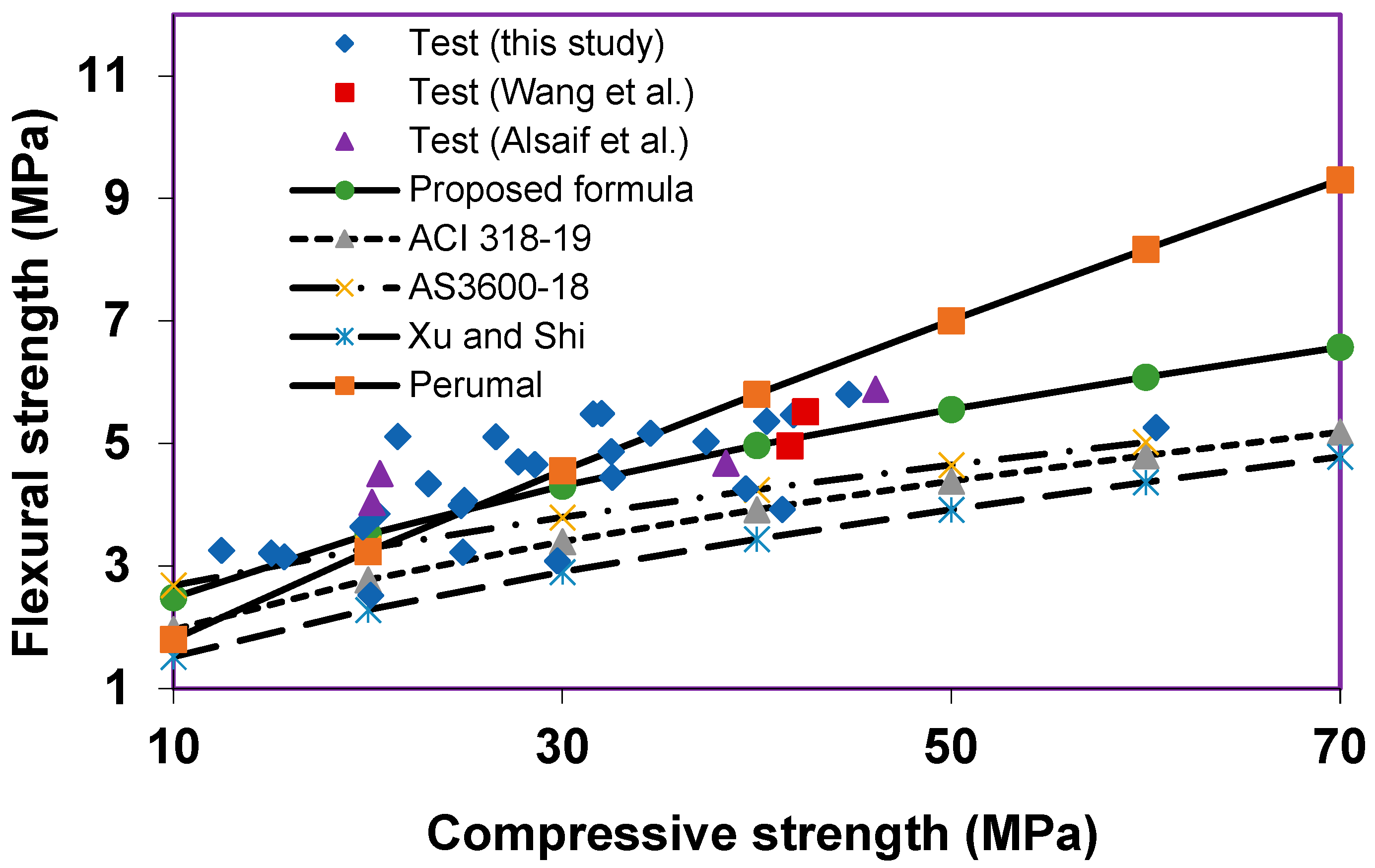

3.5. Comparisons of the Results with the Existing Literature

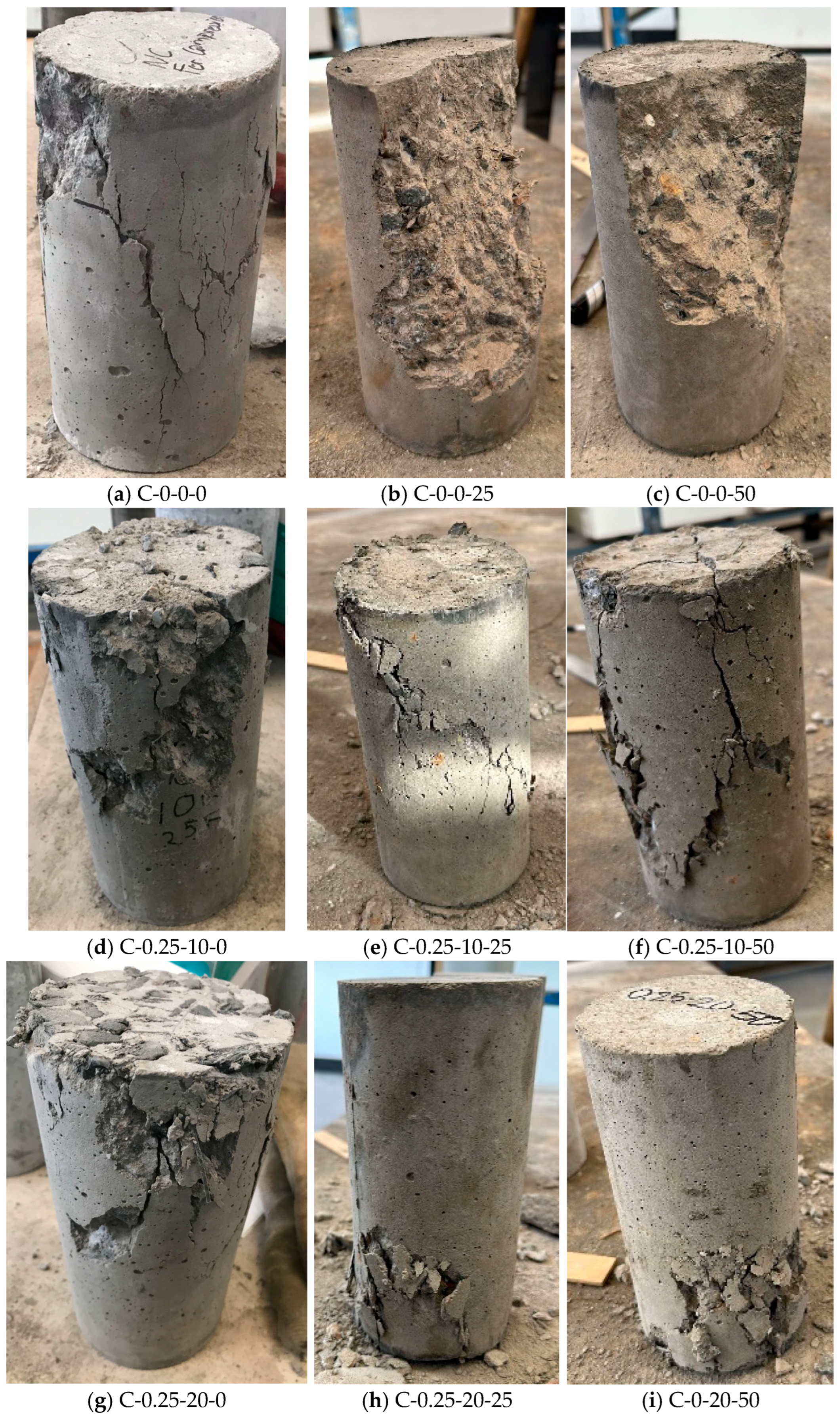

3.6. Failure Modes of the Specimens

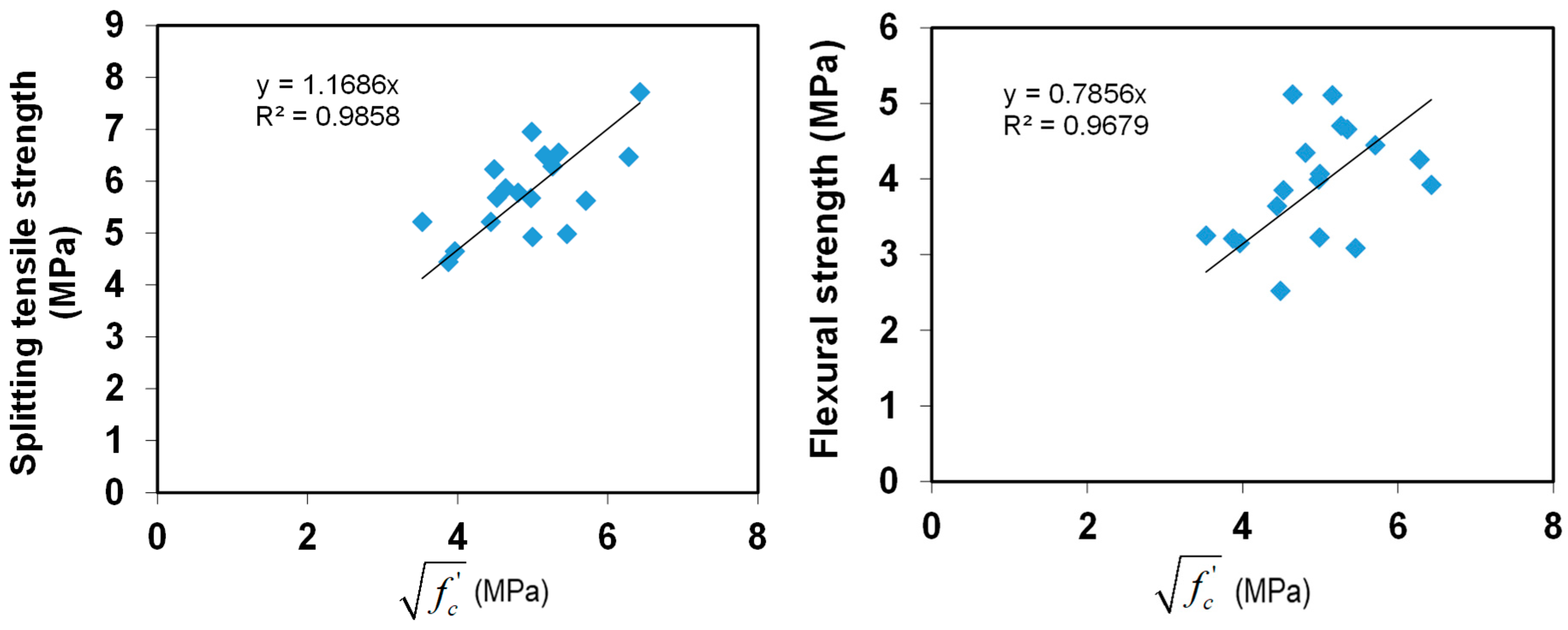

4. Empirical Formulas to Predict the Strength of the FRRC

5. Carbon Footprint and Land-Saving Implications

6. Conclusions

- Fly ash significantly improves workability across all the mixes, increasing slump from 140 mm (control) up to 200 mm at 50% replacement, even mitigating the flowability loss caused by rubber particles. However, increasing fiber content consistently reduced workability due to the physical obstruction of fibers, with the lowest slump recorded at 60 mm in high-rubber, high-fiber mixes.

- Compressive strength was adversely affected by fly ash replacement, showing a decline from 60.53 MPa in the control to 29.73 MPa at 50% fly ash. Rubber further reduced compressive strength by introducing weak interfaces, with high-rubber mixes dropping to 12.46 MPa at 50% fly ash. Although fibers bridged microcracks and enhanced toughness, they could not fully offset strength loss caused by high fly ash and rubber content.

- In contrast, tensile strength improved notably with 25% fly ash replacement, more than doubling from 3.01 MPa (control) to 7.71 MPa, attributed to improved matrix densification and enhanced fiber-matrix bonding. Increasing fly ash beyond 25% reduced tensile gains but still maintained values above the control. Rubber reduced tensile capacity due to poor bonding, yet fly ash partially mitigated this, while fibers consistently improved tensile resistance.

- Flexural strength showed a decreasing trend with increasing FA content, falling from 5.26 MPa in the control to 3.09 MPa at 50% FA due to slower pozzolanic reaction of FA. However, fibers contributed significantly to maintaining flexural performance by enhancing crack bridging, especially at moderate fly ash levels, while rubber content weakened the matrix stiffness and bonding. The combined presence of fly ash and fibers helped offset rubber’s negative influence on flexural strength, highlighting the importance of a balanced mix design.

- The developed empirical formulas for predicting tensile and flexural strengths of FRRC with fly ash showed superior accuracy compared to existing models, closely matching experimental data and enabling reliable performance-based design for sustainable FRRC applications.

- The use of waste tyres in concrete can reduce around 14% of GHG emissions while maintaining structural integrity. This substitution also has a significant bearing in reducing ecological bearings. A gross estimate for Western Australia shows that about 80 hectares of land can be avoided through this recycling activity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Chen, H.; Chow, C.L.; Lau, D. Developing green and sustainable concrete in integrating with different urban wastes. J. Clean. Prod. 2022, 368, 133057. [Google Scholar] [CrossRef]

- Karim, M.; Zain, M.; Jamil, M.; Lai, F. Significance of waste materials in sustainable concrete and sustainable development. Int. J. Biotechnol. Environ. Manag. 2011, 18, 43–47. [Google Scholar]

- Assi, L.; Carter, K.; Deaver, E.E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Li, J.; Roychand, R.; Saberian, M.; Chen, F. A comprehensive review on the application of renewable waste tire rubbers and fibers in sustainable concrete. J. Clean. Prod. 2022, 374, 133998. [Google Scholar] [CrossRef]

- Bu, C.; Zhu, D.; Lu, X.; Liu, L.; Sun, Y.; Yu, L.; Xiao, T.; Zhang, W. Modification of rubberized concrete: A review. Buildings 2022, 12, 999. [Google Scholar] [CrossRef]

- Kist, B.; Kigali, R. A review on construction technologies that enables environmental protection: Rubberized concrete. Am. J. Eng. Appl. Sci. 2008, 1, 40–44. [Google Scholar] [CrossRef]

- Elshazly, F.A.; Mustafa, S.A.; Fawzy, H.M. Rubberized concrete properties and its structural engineering applications–an overview. Egypt. Int. J. Eng. Sci. Technol. 2020, 30, 1–11. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T.; Hassanli, R. Behavior of rubberized concrete under active confinement. Constr. Build. Mater. 2017, 138, 372–382. [Google Scholar] [CrossRef]

- Kandil, U.; Bulut, H.A. Examination of the permeability of rubberized concrete with different water/cement ratios and their resistance against acid and sulfate attack. Prog. Rubber Plast. Recycl. Technol. 2024, 40, 320–339. [Google Scholar] [CrossRef]

- Abbassi, F.; Ahmad, F. Behavior analysis of concrete with recycled tire rubber as aggregate using 3D-digital image correlation. J. Clean. Prod. 2020, 274, 123074. [Google Scholar] [CrossRef]

- Ho, A.C.; Turatsinze, A.; Hameed, R.; Vu, D.C. Effects of rubber aggregates from grinded used tyres on the concrete resistance to cracking. J. Clean. Prod. 2012, 23, 209–215. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Segre, N.; Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 2000, 30, 1421–1425. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- Reda Taha, M.M.; El-Dieb, A.S.; Abd El-Wahab, M.; Abdel-Hameed, M. Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Bu, C.; Zhu, D.; Liu, L.; Lu, X.; Sun, Y.; Yu, L.; OuYang, Y.; Cao, X.; Wang, F. Research progress on rubber concrete properties: A review. J. Rubber Res. 2022, 25, 105–125. [Google Scholar] [CrossRef]

- Raffoul, S.; Garcia, R.; Pilakoutas, K.; Guadagnini, M.; Medina, N.F. Optimisation of rubberised concrete with high rubber content: An experimental investigation. Constr. Build. Mater. 2016, 124, 391–404. [Google Scholar] [CrossRef]

- Anas, M.; Khan, M.; Bilal, H.; Jadoon, S.; Khan, M.N. Fiber reinforced concrete: A review. Eng. Proc. 2022, 22, 3. [Google Scholar]

- Brown, R.; Shukla, A.; Natarajan, K.R. Fiber Reinforcement of Concrete Structures; Report no: URITC FY99-02; University of Rhode Island, Dept. of Chemical Engineering, Crawford Hall: Kingston, RI, USA, 2002. [Google Scholar]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. Steel fiber-reinforced concrete: A systematic review of the research progress and knowledge mapping. Materials 2022, 15, 6155. [Google Scholar] [CrossRef] [PubMed]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Strength, frost resistance, and resistance to acid attacks on fiber-reinforced concrete for industrial floors and road pavements with steel and polypropylene fibers. Materials 2022, 15, 8339. [Google Scholar] [CrossRef]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Azandariani, M.G.; Vajdian, M.; Asghari, K.; Mehrabi, S. Mechanical properties of polyolefin and polypropylene fibers-reinforced concrete–An experimental study. Compos. Part C Open Access 2023, 12, 100410. [Google Scholar] [CrossRef]

- Clarke, T.; Ghiji, M.; Fragomeni, S.; Guerrieri, M. Mechanical properties of macro synthetic fiber reinforced concrete at elevated temperatures: A systematic review and meta-analysis. Struct. Concr. 2023, 24, 1244–1270. [Google Scholar] [CrossRef]

- Nana, W.; Tran, H.; Goubin, T.; Kubisztal, G.; Bennani, A.; Bui, T.; Cardia, G.; Limam, A. Behaviour of macro-synthetic fibers reinforced concrete: Experimental, numerical and design code investigations. Structures 2021, 32, 1271–1286. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Guo, J.; Wu, J.; Zhang, C. Production of sustainable steel fiber-reinforced rubberized concrete with enhanced mechanical properties: A state-of-the-art review. J. Build. Eng. 2024, 91, 109735. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, H.; Pan, Z.; Li, X.; Lu, L.; He, M.; Li, H.; Liu, F.; Feng, P.; Li, L. Fracture properties and mechanisms of steel fiber and glass fiber reinforced rubberized concrete. J. Build. Eng. 2024, 86, 108866. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical properties of natural as well as synthetic fiber reinforced concrete: A review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Chen, L.; Chen, X.; Liu, Z.; Lu, K.; Liu, J.; Wang, Z. Mechanical properties of macro-synthetic fiber reinforced rubber concrete under uniaxial loading. Constr. Build. Mater. 2024, 445, 137821. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical properties of macro polypropylene fibre-reinforced concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Miller, S.A.; Moore, F.C. Climate and health damages from global concrete production. Nat. Clim. Chang. 2020, 10, 439–443. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO 2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Nayak, D.K.; Abhilash, P.; Singh, R.; Kumar, R.; Kumar, V. Fly ash for sustainable construction: A review of fly ash concrete and its beneficial use case studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Tangpagasit, J.; Cheerarot, R.; Jaturapitakkul, C.; Kiattikomol, K. Packing effect and pozzolanic reaction of fly ash in mortar. Cem. Concr. Res. 2005, 35, 1145–1151. [Google Scholar] [CrossRef]

- Bala, A.; Sehgal, V.; Saini, B. Effect of Fly ash and Waste Rubber on Properties of Concrete composite. Concr. Res. Lett. 2014, 5, 842–857. [Google Scholar]

- Nur, O.F.; Albarqi, K.; Melinda, A.P.; Al Jauhari, Z. The effect of waste tyre rubber on mechanical properties of normal concrete and fly ash concrete. GEOMATE J. 2021, 20, 55–61. [Google Scholar]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Compos. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Wilińska, I.; Pacewska, B.; Ostrowski, A. Investigation of different ways of activation of fly ash–cement mixtures: Part 1. Chemical activation by Na2SO4 and Ca(OH)2. J. Therm. Anal. Calorim. 2019, 138, 4203–4213. [Google Scholar] [CrossRef]

- Peng, K.-D.; Zeng, J.-J.; Huang, B.-T.; Huang, J.-Q.; Zhuge, Y.; Dai, J.-G. Bond performance of FRP bars in plain and fiber-reinforced geopolymer under pull-out loading. J. Build. Eng. 2022, 57, 104893. [Google Scholar] [CrossRef]

- C150/C150M—22; Standard Specification for Portland Cement. ASTM: West Conshohocken, PA, USA, 2022.

- Htet, P.; Chen, W.; Hao, H.; Shaikh, F. Physical and mechanical properties of quaternary blended concrete with recycled coarse aggregates and crushed waste glass. Constr. Build. Mater. 2022, 353, 129016. [Google Scholar] [CrossRef]

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- AS1012; Methods of Testing Concrete. Australian/New Zealand Standard: Sydney, NSW, Australia, 2014.

- AS 1012.3.1:2014; Methods of Testing Concrete Determination of Properties Related to the Consistency of Concrete—Slump Test. Australian/New Zealand Standard: Sydney, NSW, Australia, 2014.

- AS 1141.4-2013; Methods for Sampling and Testing Aggregates—Bulk Density of Aggregate. Australian/New Zealand Standard: Sydney, NSW, Australia, 2013.

- AS 1012.9.1:2014; Methods of Testing Concrete Compressive strength Tests—Concrete, Mortar and Grout Specimens. Australian/New Zealand Standard: Sydney, NSW, Australia, 2014.

- AS 1012.11-2000; Methods of Testing Concrete Determination of the Modulus of Rupture. Australian/New Zealand Standard: Sydney, NSW, Australia, 2000.

- AS 1012.10-2000Methods of Testing Concrete Determination of Indirect Tensile Strength of Concrete Cylinders, Australian/New Zealand Standard: Sydney, NSW, Australia, 2000.

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Najmi, A.; Mariyana, A.; Shek, P.; Nurizaty, Z. Hardened properties of concrete with different proportion of crumb rubber and fly ash. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Langkawi, Malaysia, 20–22 August 2019; p. 012038. [Google Scholar]

- Signorini, C.; Nobili, A. Durability of fibre-reinforced cementitious composites (FRCC) including recycled synthetic fibres and rubber aggregates. Appl. Eng. Sci. 2022, 9, 100077. [Google Scholar] [CrossRef]

- Babu, K.G.; Rao, G.S.N. Early strength behaviour of fly ash concretes. Cem. Concr. Res. 1994, 24, 277–284. [Google Scholar] [CrossRef]

- Güneyisi, E. Fresh properties of self-compacting rubberized concrete incorporated with fly ash. Mater. Struct. 2010, 43, 1037–1048. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Reyes, J.; Feliu, J.; Hernández, M. Influence of scrap rubber addition to Portland I concrete composites: Destructive and non-destructive testing. Compos. Struct. 2005, 71, 439–446. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Ravina, D.; Mehta, P. Compressive strength of low cement/high fly ash concrete. Cem. Concr. Res. 1988, 18, 571–583. [Google Scholar] [CrossRef]

- Harison, A.; Srivastava, V.; Herbert, A. Effect of fly ash on compressive strength of Portland pozzolona cement concrete. J. Acad. Ind. Res. 2014, 2, 476–479. [Google Scholar]

- Gu, C.; Yao, J.; Huang, S.; Yang, Y.; Liu, J.; Ni, T.; Yang, Z. Study on early-age tensile properties of high volume fly ash concrete. Mater. Struct. 2022, 55, 135. [Google Scholar] [CrossRef]

- Qureshi, M.; Li, J.; Wu, C.; Sheng, D. Mechanical strength of rubberized concrete: Effects of rubber particle size, content, and waste fibre reinforcement. Constr. Build. Mater. 2024, 444, 137868. [Google Scholar] [CrossRef]

- Ataria, R.B.; Wang, Y.C. Mechanical properties and durability performance of recycled aggregate concrete containing crumb rubber. Materials 2022, 15, 1776. [Google Scholar] [CrossRef]

- Babalu, R.; Anil, A.; Sudarshan, K.; Amol, P. Compressive strength, flexural strength, and durability of high-volume fly ash concrete. Innov. Infrastruct. Solut. 2023, 8, 154. [Google Scholar] [CrossRef]

- Kayali, O. Effect of high volume fly ash on mechanical properties of fiber reinforced concrete. Mater. Struct. 2004, 37, 318–327. [Google Scholar]

- Barbuta, M.; Bucur, R.; Serbanoiu, A.A.; Scutarasu, S.; Burlacu, A. Combined effect of fly ash and fibers on properties of cement concrete. Procedia Eng. 2017, 181, 280–284. [Google Scholar] [CrossRef]

- ACI 318-19; Building Code Requirements for Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2019.

- AS 3600; Concrete Structures. Australian/New Zealand Standard: Sydney, NSW, Australia, 2018.

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Alsaif, A.; Alharbi, Y.R. Strength, durability and shrinkage behaviours of steel fiber reinforced rubberized concrete. Constr. Build. Mater. 2022, 345, 128295. [Google Scholar] [CrossRef]

- Xu, B.; Shi, H. Correlations among mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2009, 23, 3468–3474. [Google Scholar] [CrossRef]

- Perumal, R. Correlation of compressive strength and other engineering properties of high-performance steel fiber–reinforced concrete. J. Mater. Civ. Eng. 2015, 27, 04014114. [Google Scholar] [CrossRef]

- Grant, T. Australian Life Cycle Database Manual; Australian Life Cycle Assessment Society (ALCAS): Gold Coast, Australia, 2016. [Google Scholar]

- Loo, V.H.; Biswas, W.K.; Chin, N.Z. Life Cycle Assessment of Utilization of Shredded Tire for Sustainable Road Embankment. In Proceedings of the International Conference on Emerging Smart Cities, Kuching, Sarawak, Malaysia, 1–2 December 2022; pp. 329–338. [Google Scholar]

- Biswas, W.K.; Zhang, X.; Matters, C.; Maboud, M. Techno-Eco-Efficiency Assessment of Using Recycled Steel Fibre in Concrete. Sustainability 2024, 16, 3717. [Google Scholar] [CrossRef]

- Simms, A.; Hamilton, S.; Biswas, W.K. Carbon footprint assessment of Western Australian groundwater recycling scheme. Environ. Manag. 2017, 59, 557–570. [Google Scholar] [CrossRef]

- Waste Authority 2021. Annual Report 2021–2022. Available online: https://www.wasteauthority.wa.gov.au/images/resources/files/Waste_Authority_annual_report_2020-21.pdf (accessed on 24 June 2025).

- Mistri, A.; Dhami, N.; Bhattacharyya, S.K.; Barai, S.V.; Mukherjee, A.; Biswas, W.K. Environmental implications of the use of bio-cement treated recycled aggregate in concrete. Resour. Conserv. Recycl. 2021, 167, 105436. [Google Scholar] [CrossRef]

- Paul, K.; Dutta, A.; Krishna, A. A comprehensive study on landfill site selection for Kolkata City, India. J. Air Waste Manag. Assoc. 2014, 64, 846–861. [Google Scholar] [CrossRef] [PubMed]

| Component | Portland Cement | Fly Ash |

|---|---|---|

| CaO | 64 | 0.9 |

| SiO2 | 20.2 | 65.1 |

| Al2O3 | 5.3 | 24.5 |

| Fe2O3 | 2.7 | 4 |

| MgO | 1.4 | 0.6 |

| MnO | - | 0.07 |

| K2O | - | 1.17 |

| Na2O | 0.6 | 0.39 |

| P2O5 | - | 0.4 |

| TiO2 | - | 1.1 |

| Cl | 0.01 | - |

| SO3 | 0.1 | |

| Others | 0.25 | 0.37 |

| Loss on ignition (LOI) | 2.3 | 1.3 |

| Properties | Portland Cement | Fly Ash |

|---|---|---|

| Specific Gravity | 2.5–3.2 | 2.35–2.40 |

| Melting Point | >1200 °C | >1400 °C |

| Particle size | 10–30% of Particles are ≤7 µm | 40% of particles are ≤7 µm |

| Odor | Odorless | Odorless |

| Sample | Rubber (%) | Fiber (%) | Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | Rubber | MSF |

|---|---|---|---|---|---|---|---|---|

| C-0-0-0 | 0 | 0 | 1 | 0 | 1.96 | 2.04 | 0.00 | 0 |

| C-0-0-25 | 0.75 | 0.25 | ||||||

| C-0-0-50 | 0.5 | 0.5 | ||||||

| C-0.25-10-0 | 10 | 0.25 | 1 | 0 | 1.96 | 1.86 | 0.07 | 0.0051 |

| C-0.25-10-25 | 0.75 | 0.25 | ||||||

| C-0.25-10-50 | 0.5 | 0.5 | ||||||

| C-0.25-20-0 | 20 | 1 | 0 | 1.96 | 1.66 | 0.15 | ||

| C-0.25-20-25 | 0.75 | 0.25 | ||||||

| C-0.25-20-50 | 0.5 | 0.5 | ||||||

| C-0.50-10-0 | 10 | 0.5 | 1 | 0 | 1.96 | 1.86 | 0.07 | 0.0102 |

| C-0.50-10-25 | 0.75 | 0.25 | ||||||

| C-0.50-10-50 | 0.5 | 0.5 | ||||||

| C-0.50-20-0 | 20 | 1 | 0 | 1.96 | 1.66 | 0.15 | ||

| C-0.50-20-25 | 0.75 | 0.25 | ||||||

| C-0.50-20-50 | 0.5 | 0.5 | ||||||

| C-0.75-10-0 | 10 | 0.75 | 1 | 0 | 1.96 | 1.86 | 0.07 | 0.0153 |

| C-0.75-10-25 | 0.75 | 0.25 | ||||||

| C-0.75-10-50 | 0.5 | 0.5 | ||||||

| C-0.75-20-0 | 20 | 1 | 0 | 1.96 | 1.66 | 0.15 | ||

| C-0.75-20-25 | 0.75 | 0.25 | ||||||

| C-0.75-20-50 | 0.5 | 0.5 | ||||||

| C-1-10-0 | 10 | 1 | 1 | 0 | 1.96 | 1.86 | 0.07 | 0.0204 |

| C-1-10-25 | 0.75 | 0.25 | ||||||

| C-1-10-50 | 0.5 | 0.5 | ||||||

| C-1-20-0 | 20 | 1 | 0 | 1.96 | 1.66 | 0.15 | ||

| C-1-20-25 | 0.75 | 0.25 | ||||||

| C-1-20-50 | 0.5 | 0.5 |

| Fly Ash (%) | Rubber Content (%) | Rubber Content (%) | Rubber Content (%) | Rubber Content (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10–20 | 5–20 | 0–40 | 10–20 | 5–20 | 10–20 | 5–20 | 0–20 | 5–20 | 0–40 | |

| Compressive Strength Range (MPa) | Splitting Tensile Strength Range (MPa) | Splitting Tensile Strength Range (MPa) | Flexural Strength Range (MPa) | Density (kg/m3) | ||||||

| This Study | Study by Najmi et al. [55] | Study by Bala et al. [39] | This Study | Study by Najmi et al. [55] | This Study | Study by Najmi et al. [55] | This Study | Study by Najmi et al. [55] | Study by Bala et al. [39] | |

| 0 | 31.57–41.87 | 10.8–22.5 | 5.33–36.47 | 2.64–3.88 | 1.57–2.46 | 4.87–5.80 | 2.54–3.83 | 2183–2300 | 2030–2217 | 1611–2241 |

| 10 | - | 11.2–25.4 | 2.43–33.09 | - | 1.62–2.72 | - | 2.37–3.87 | - | 2077–2237 | 1696–2265 |

| 20 | - | 10.4–21.8 | 1.42–24.62 | - | 1.41–2.50 | - | 2.52–3.35 | - | 2051–2225 | 1786–2249 |

| 25 | 20.13–39.42 | - | - | 5.67–6.95 | - | 2.52–5.11 | - | 2177–2299 | - | - |

| 30 | - | 9.2–19.4 | 1.20–22.43 | - | 1.18–2.33 | - | 2.09–3.24 | - | 2011–2186 | 1769–2279 |

| 40 | - | - | - | - | - | - | - | - | - | - |

| 50 | 12.46–24.94 | - | - | 4.44–5.86 | - | 3.15–5.12 | - | 2170–2287 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.; Mim, N.J.; Biswas, W.; Shaikh, F.; Zhang, X.; Patel, V.I. Effects of Partial Replacement of Cement with Fly Ash on the Mechanical Properties of Fiber-Reinforced Rubberized Concrete Containing Waste Tyre Rubber and Macro-Synthetic Fibers. Buildings 2025, 15, 2685. https://doi.org/10.3390/buildings15152685

Ahmed M, Mim NJ, Biswas W, Shaikh F, Zhang X, Patel VI. Effects of Partial Replacement of Cement with Fly Ash on the Mechanical Properties of Fiber-Reinforced Rubberized Concrete Containing Waste Tyre Rubber and Macro-Synthetic Fibers. Buildings. 2025; 15(15):2685. https://doi.org/10.3390/buildings15152685

Chicago/Turabian StyleAhmed, Mizan, Nusrat Jahan Mim, Wahidul Biswas, Faiz Shaikh, Xihong Zhang, and Vipulkumar Ishvarbhai Patel. 2025. "Effects of Partial Replacement of Cement with Fly Ash on the Mechanical Properties of Fiber-Reinforced Rubberized Concrete Containing Waste Tyre Rubber and Macro-Synthetic Fibers" Buildings 15, no. 15: 2685. https://doi.org/10.3390/buildings15152685

APA StyleAhmed, M., Mim, N. J., Biswas, W., Shaikh, F., Zhang, X., & Patel, V. I. (2025). Effects of Partial Replacement of Cement with Fly Ash on the Mechanical Properties of Fiber-Reinforced Rubberized Concrete Containing Waste Tyre Rubber and Macro-Synthetic Fibers. Buildings, 15(15), 2685. https://doi.org/10.3390/buildings15152685