Abstract

The research was initiated by the Plečnik House gallery (Ljubljana, Slovenia) and focuses on the 3D architectural reconstruction of the unrealised monument of the Czech military leader Jan Žižka, designed by the Slovenian architect Jože Plečnik. In addition, the experience with the 3D reconstructed monument in the exhibition “Plečnik and the Sacred” was analysed. Using the available references and interpretative approaches, a digital and 3D-printed reconstruction was created that retains Plečnik’s architectural style. The experimental phase included a detailed interpretation of the studied references, 3D modelling, 3D printing, exhibition and experience analysis. The dimensions of the finished 3D-printed model are 52.80 × 55.21 × 44.60 cm. It was produced using stereolithography (SLA) for figurative elements and fused deposition modelling (FDM) for architectural components. The reconstruction was evaluated using participant testing, including semantic differential analysis, comparative studies, and knowledge-based questionnaires. The results showed that architectural elements were reconstructed with an average similarity score of 1.97 out of 5. Statues followed with a score of 1.81, and props, though detailed, met audience expectations, scoring 1.61. Clothing received the lowest score of 1.40. This research emphasises the importance of a hypothetical digital 3D reconstruction of never constructed monument for broader understanding of Plečnik’s legacy.

1. Introduction

Reconstruction in architecture refers to the process of restoring buildings, monuments or structures that no longer exist or whose original form is uncertain. It has its roots in Renaissance archaeology and has always relied on analysis and interpretation to avoid purely speculative results. However, reconstructions remain inherently hypothetical, shaped by the available evidence and cultural or ideological motives. While traditional reconstructions were based on physical replicas or scale models, digital technology has revolutionised the process. Virtual reconstructions enable dynamic visualisation, allowing scientists to explore different phases of an object’s history. Digital reconstructions run in parallel with physical reconstructions, using historical and archaeological evidence to create scientifically sound models. This approach improves research, supports conservation and helps to uncover inconsistencies in historical documentation. Digital reconstructions play a crucial role in preserving and understanding lost architectural heritage while providing flexible, modifiable and interactive representations [1,2,3].

Unrealised monuments hold a distinct position within architectural history, serving as valuable records of visionary concepts that remained unbuilt due to various historical, technical, or economic constraints. These projects provide critical insights into the artistic ambitions and engineering challenges of their respective periods, reflecting both the limitations and aspirations of architectural practice. Despite their lack of physical realisation, such designs continue to influence contemporary discourse, offering inspiration to architects, historians, and preservationists while shaping ongoing debates on historical memory and interpretative methodologies in architectural heritage [4].

An example of an unrealised monument is Jože Plečnik’s design for the monument of the military leader Jan Žižka in Prague, a project that was never realised but demonstrates the architect’s inventiveness in combining monumental form and historical symbolism. Plečnik’s design was characterised by a remarkable integration of functional and aesthetic elements and reflected his deep commitment to the cultural context of his time [5,6,7]. Although the monument was never built, the reconstruction of Plečnik’s design through digital technologies has enabled a new understanding of the project. Jože Plečnik was the most important Slovenian architect and a key figure of European modernism. His work was characterised by an exceptional understanding of space and materials, with original architectural solutions. Plečnik pursued an independent path and revisited his ideas in an innovative way. Although he was inspired by antiquity, especially ancient Egyptian art, he never directly copied historical styles, but blended traditional forms with a deep respect for history and artistic tradition.

The study motivation that formed the starting point of the research was the request of the Plečnik House in Ljubljana (Slovenia) to reconstruct the unrealised monument of the military leader Jan Žižek in 3D as part of the national exhibition Plečnik and the sacred [8,9], the significance of which lies in the interpretation and reconstruction of the architect’s vision and the design of objects, buildings and monuments dedicated to the sacred. Due to the national and European significance of Plečnik’s work in the field of the sacred and because the monument to the military leader Jan Žižek was not realised, the 3D reconstruction of the memorial object reveals the architect’s vision of the glory of the military leader and the Hussite soldiers and presents the sacred in the architectural heritage as it was designed and represented by the architect.

1.1. 3D Technology in Cultural Heritage Preservation

In recent years, the protection of historical and cultural heritage through digitalisation has been increasingly adopted, using a variety of techniques [10,11,12,13,14,15,16,17]. In the field of architectural heritage, various methods can be used for digital 3D reconstruction. Some methods rely primarily on photographs or 2D images from archives, while others are based on photogrammetry, laser scanning, geospatial tools and more recently on AI. Very often, several different methods are used simultaneously for 3D reconstructions. [18,19,20,21,22,23,24]

The use of 3D technologies has revolutionised the preservation and reconstruction of cultural heritage by providing innovative solutions for documenting, restoring and replicating historical artifacts. Digital reconstruction ensures the long-term preservation of monuments and artifacts, safeguarding cultural heritage for future generations. High-quality software enables the creation of detailed three-dimensional representations, allowing virtual exploration from multiple perspectives [25,26,27].

3D technologies offer curators, researchers, and archaeologists powerful tools for capturing and analysing artifacts in three dimensions [28]. Techniques, such as 3D modelling, scanning, photogrammetry and 3D printing, improve documentation, restoration and presentation at historical sites, facilitating research and enhancing public access to museum collections [29,30,31].

3D printing allows for the precise replication of historical objects, enabling visitors to physically interact with artifacts rather than merely observing them. It also supports the repair of damaged artifacts by producing perfectly fitting replacement parts, a practice increasingly adopted in museums and cultural institutions [29,32]. Laser scanning and digital photogrammetry provide non-invasive methods for recording the shape and geometry of artefacts for conservation and study [31,33].

Furthermore, 3D technologies facilitate global collaboration by allowing researchers to share digital models and visualisations online, streamlining research and heritage management workflows [26,32]. The accuracy and effectiveness of 3D reproductions in cultural heritage preservation have been demonstrated in comparative studies assessing different scanning and printing technologies [34].

Arapakopoulos et al. [35] showed the value of 3D reconstruction through a case study on a traditional Greek boat integrated into a digital heritage library. Codarin [36] highlighted the sustainable applications of 3D printing in conservation, emphasizing its role in mitigating damage and loss of heritage. By integrating these technologies, cultural heritage restoration becomes faster, more cost-effective and safer.

3D printing enables precise replicas of historical objects, allowing visitors to physically engage with the artefacts rather than just looking at them. In addition, 3D technologies are invaluable for the preservation of sites and artefacts that exist only in historical records. They also facilitate global collaboration by enabling the sharing of digital models and visualisations, accelerating research and streamlining cultural heritage management workflows worldwide [26,32].

3D printing enables the repair of damaged artefacts by producing perfectly fitting parts, a practise that is becoming increasingly common in museums and cultural institutions around the world. By combining 3D scanning, digital modelling and printing, valuable cultural artefacts can be accurately reproduced and preserved. This approach not only improves our understanding of cultural heritage but also promotes its accessibility and educational value [25].

1.2. User Experience and 3D Technologies

The digitisation of ancient artefacts and the production of 3D-printed replicas improve the accessibility of cultural heritage for viewers with disabilities. The research by Kantaros and others [37,38] describes how 3D-printed tactile replicas made from recycled PLA in the Archaeological Museum of Piraeus create a multisensory experience for visually impaired people. The study highlights the technical challenges of 3D scanning, material production and optimising printing parameters for high-quality replicas. These replicas promote inclusion and accessibility.

Tsipi [39] presented a digital archive service that enables scalable and accessible 3D printing of cultural artefacts, improving access and preservation. This cloud-based platform enables better interaction and dissemination of collections.

Rodriguez-Echavarria [40,41] explored how gamification through 3D artefact puzzles increases visitor engagement in museums. The interactive game with 3D-printed historical artefacts enriches the museum experience. The study presented a digital process for designing and producing 3D puzzles, in which authentic artefacts were digitised through 3D scanning and modelled using 3D software. The results show that interactive engagement with historical artefacts through play enriches visitors’ experiences.

Pollalis and others [42] compared the learning outcomes of students interacting with ancient Egyptian statues using HoloLens AR, SketchFab and 3D-printed models. The study provides insights into the effectiveness of different technologies in the museum environment. Skublewska-Paszkowska [43] explored the use of 3D technologies in the preservation of intangible cultural heritage and highlighted their role in education and documentation, including virtual reconstructions. Tamberino and others [44] studied the multifaceted role of 3D printing in cultural heritage preservation, accessibility and education. The authors explore how 3D printing can produce accurate replicas of artefacts to make them accessible to a wider audience. The study highlights its use in creating tactile models for visually impaired museum visitors to enhance their experience and understanding of cultural heritage.

Building on the user experience insights from 3D technologies, the combination of 3D printing with extended reality (XR) technologies, such as augmented reality (AR) and mixed reality (MR), is improving the way cultural heritage is experienced in museums. These advances offer immersive, interactive experiences that allow visitors to engage with artefacts in dynamic ways that go beyond traditional viewing.

Garro and Sundstedt [45] studied the Ljungaviken dog 8000-year-old skeleton, which was digitised through 3D scanning and presented in a museum exhibition in both AR and 3D-printed formats. The study found positive visitor reactions to both methods, with AR being slightly favoured in terms of realism, satisfaction and ease of use. Mann and Fryazinov [46] investigated the combination of mixed reality (MR) and 3D printing in museum exhibitions. These technologies enable direct interaction with 3D-printed replicas that are durable and suitable for handling. Ramkumar and others [47] investigated user behaviour with physical and virtual archaeological artefacts through AR and 3D printed objects and confirmed consistent visual attention patterns with both formats.

1.3. Semantic Differential

Unlike generic similarity models, semantic similarity has been explored through specialised approaches, including Osgood et al.’s [48] semantic differential. In semantic differential scales, participants rate a topic or subject using a standardised set of bipolar adjectives. This simple approach offers several advantages for both researchers and participants. While this reliance on preselected dimensions is a limitation, the semantic differential remains widely used due to its simplicity in data collection, analysis, and interpretation.

Researchers often adapt bipolar adjective pairs to the specific focus of their study. While some rely on Osgood’s original pairs, others develop their own to better assess the subjects they are studying. To ensure the quality of the data, a structured process is recommended. Researchers first collect adjectives from participants to describe a concept, then use them to create a scale prototype, test it on a separate group and refine it through statistical analyses. Alternatively, some researchers use adjective pairs from previous studies to ensure consistency. The selection of suitable antonyms is also crucial. Often this is a simple negation, such as fair–unfair [49].

The aim of this study was to reconstruct a 3D model of the unrealised Plečnik monument based on the available plans and photographs of the original wooden model, which no longer exists. Since the original scale model has been lost, there was a request from Slovenian experts in the architect’s work to create a 3D-printed reproduction of tangible representation of the monument for the purpose of presenting it to the wider public and exhibiting it in the Plečnik House. This study presents the precise digital and 3D-printed reconstruction of Jože Plečnik’s unbuilt sacral monument in Slovenia and the first to analyse it through user experience and semantic differential analysis. What makes the project particularly unique is the fact that it includes both an architectural and a sculptural reproduction, although it relies on a very limited amount of reference material. It introduces an innovative use of digital tools to reconstruct Plečnik’s architectural language and sculptural vision. It thus provides a basis for future research into his legacy and a model for the reconstruction of other culturally significant works.

A user observation study was conducted to evaluate participants’ comparisons between the 3D-printed model and the reference materials. The semantic differential method was applied to assess participants’ emotional and cognitive responses to the different representations of the monument.

The two research assumptions that were set before the research were the following. H1: A thorough analytical approach, taking into account the existing available reference types, will provide us with sufficient data about the monument and enable 3D modelling. H2: The 3D printed reproduction will improve the user experience of the exhibition visitors and their experience of both the architectural and sculptural elements of the monument of the military leader Jan Žižka.

2. Materials and Methods

In the physical reproduction or reconstruction of any architectural object, especially when we have no physical references, interventions and approaches are required that go beyond the technical aspects of reconstruction and also include an in-depth knowledge of the author, the architectural and design style, the author’s creative method, the influences that shaped both the author’s personality and his/her work in a particular creative approaches, etc. This was also the preliminary analysis before the main experimental framework: 1. preliminary research and analysis, including obtaining references and analysing the author’s style on buildings, figures, and props; 2. the analysis of documentation and references and the determination of interpretive approaches for the reconstruction; 3. 3D modelling and sculpting; 4. preparation for 3D printing; 5. finishing and post-processing of 3D print (sanding, gluing, filling, painting); 6. gallery exhibition; and 7. research and evaluation of the gallery experience.

2.1. Referencing

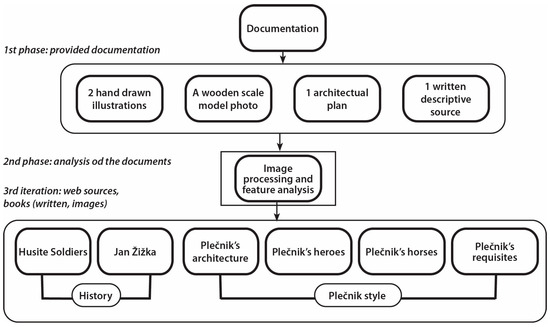

The experimental part began with conversations with representatives of the Plečnik House (https://mgml.si/en/plecnik-house/) (accessed on 15 July 2025), where the architect also lived and worked in Ljubljana (the capital of Slovenia) and with experts on Plečnik’s work, obtaining and studying pictorial references of the monument (hand sketches, an architectural plan and a photograph of a wooden model) and various written and visual sources. Due to the lack of information and references about the sculptural and architectural work, we researched Plečnik’s works and style, looked at the depictions of heroes, clothes and horses, the historical background of the Hussite wars and soldiers, and investigated and researched the life, important events, and character of Jan Žižka, what role he played in the Hussite wars and why he is considered a hero in the Czech Republic. We searched for a variety of depictions of the Hussite soldiers and Žižka to identify important features of their appearance [50,51]. Figure 1 presents the process of acquisition of the references and their analysis before the 3D interpretation and reconstruction.

Figure 1.

The process of acquisition of the references and their analysis.

Plečnik made several sketches and an architectural plan for the monument. The appearance of the monument was allegedly finalised in a wooden scale model that Plečnik made for his application to the competition in Prague. Unfortunately, the wooden scale model was not preserved or was lost, and Plečnik’s proposal was not selected. Only one photo, taken under poor lighting conditions is the actual evidence of the existence of a wooden model of the monument’s plan, which is explained in the next section. The poorly contrasted photo shows the model from the side. The elements and parts of the monument are barely visible and recognizable on it, and it is even impossible to make out the details.

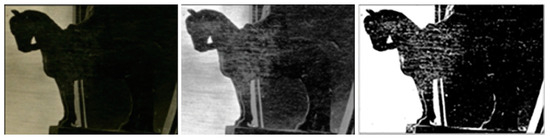

Image processing and analysis were implemented as an approach to recognise and extract details from the features on the reference of the scale wood model. Individual objects of the photo (soldiers, horses, etc.) were extracted from the photo and processed using the procedure of conversion to greyscale and black and white images, contrast enhancement, shape edge detection and detail marker detection on the processed images of objects. The first steps of the process for the horse object are shown in Figure 2. The results of the processing contributed to insights about the volume of the objects and smaller design features (position of the horse’s legs, details of the warriors’ silhouettes), which we then supplemented by visual observation of the wooden model.

Figure 2.

Initial processing procedure on a horse image element.

2.1.1. Analysis of the Documentation and References

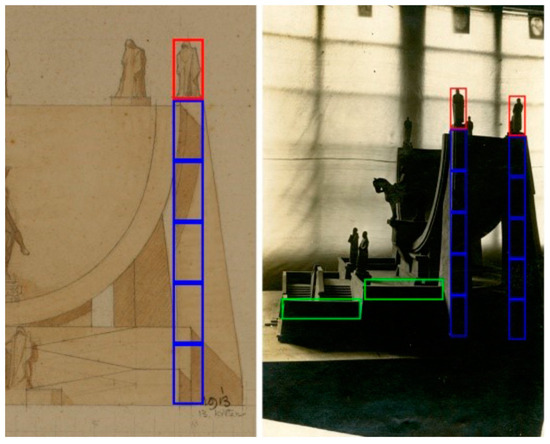

As the main references for the reconstruction of the monument, we have used the only available image references, namely Plečnik’s sketch or competition drawing for the monument (6 May 1913), the architectural plan for the monument (May 1913) and a photograph of the scale model of the monument (November 1913) (Figure 3). After reviewing Plečnik’s references, we divided the monument into two main parts according to the geometry, shape and form of the references, namely the architectural part with architectural elements and the sculptural part.

Figure 3.

References of the Plečnik monument (sketch—left; architectural plan—central; and photograph of the wooden model—right); source: Plečnik House.

The architectural part includes the following elements:

- The lower part with stairs and a plateau to which the columns are attached;

- Five columns;

- Half of a chalice.

The sculptural part contains the following:

- A monk and a guard with a sword in front of him;

- The military leader Žižek, a horse and five soldiers, each standing on his own column.

The pictorial references (Figure 3) of the monument were not coherent, and it was difficult to discern the appearance of the sculptural part of the monument from them, as no details were visible. There were differences in the placement of the lower guardian and the monk, which are placed on the wall at the top of the stairs in the model and at the bottom of the stairs in the architectural plan, whereas in the sketch, it looks like there are three guardians, each on their own level of the stairs. There were also differences in the arrangement of the staircase, which has three tiers in the sketch and the architectural plan, but two in the model. The soldiers at the top of the chalice are active in the sketch, whereas in the photo, they appear calm. In the sketch, it looks as if a soldier has a spear in his hand, whereas in the architectural plan, it can be seen that the soldiers at the front edge of the chalice have their arms outstretched (their hands are not resting against their bodies). Another difference lies in the depiction of the rider and the horse, which assume a calm, passive pose in the sketch, whereas they assume an active pose in the architectural plan: The horse stands on its hind legs. In the sketch, the rider wears a long cloak with a hood on his head and holds a lance or staff in his hand, while in the plan, he has his hands free and floats in the air. In the sketch, the horse’s foot is completely inside the chalice (the edge of the foot is aligned with the edge of the chalice), while in the model, it protrudes from the chalice. With the exception of the horse, each sculptural part was discussed and analysed step by step: Figures (facial features and bodies), clothing, shoes and accessories (shirts, pants, belts, boots, undercaps, blankets) and props (swords, shields, helmets, chalice).

We used a photo of the wooden scale model as the main reference, which is considered Plečnik’s final decision on the appearance of the monument. The architectural part was made according to the architectural plan to facilitate the modelling and placement of the architectural elements, and the final appearance of the architecture was adapted to the photo of the scale model. As details and specific features were not apparent from the main reference of the wooden scale model (Figure 3 right), interpretative solutions were introduced in the 3D reconstruction of the monument, which are presented as follows for the military leader Žižek, his clothing and equipment, the horse, the soldiers and their clothing and equipment, and the props.

2.1.2. Jan Žižka

Jan Žižka’s collected visual references include illustrations, images of various sculptures and other representations [51,52]. From these, it was possible to glean the characteristics of Jan Žižka’s physique and appearance. The illustrations generally show a rugged warrior with pronounced facial features, such as a pronounced, slightly hooked nose, accentuated cheekbones and strong, pronounced laugh lines. The analysed statues’ references show a more classical hero with smoothed facial features.

Based on the references, they could also recognise other features of the figure, such as broad shoulders, bushy moustache, medium-length hair and a bandage over the eye [53]. It was decided that the 3D reconstruction model of the military leader has a beard and moustache as in the references [54,55,56,57,58]. The moustache is depicted in very different ways in the references—from straight, growing downwards, to curled. In some places, the moustache is connected to the hair so that it grows along the lower part of the cheeks. In some references, he also wears a beard. Everywhere, he is depicted with medium-length, slightly wavy hair, the length of which reaches between his ears and shoulders. In most cases, he appears with a bandage over his right eye [54,55,56,57,58], but there are also depictions in which the left eye is covered, as also discovered by a recent detailed study by the authors Moraes et al. [53]. The features observed in the references were compared with a photograph of a wooden scale model for the reconstruction of the military leader, in which the horseman is depicted as a classical hero on horseback. He sits in an upright position and holds the reins with his left hand at the withers (part of the horse) or at the end of the horse’s neck. As the model was photographed from the left side, the right hand is not visible, so it was assumed that the hero might be holding a stick in it, which appears in various references [50,51,52,59,60]. After consulting with an art historian and a historian of the Plečnik House, it was decided that Žižek is holding the reins of his horse with both hands in the reconstruction. According to the photograph of the model, Žižek is sitting on a saddle or on a semi-circular cushion, which could also be part of a coat that falls on the horse. This is not clearly recognisable on the wooden model, only faint outlines can be seen. His legs fall freely beside the horse, so we cannot be sure whether he has a saddle.

In the references [50,51,52,59,60], Žižka appears in different clothes, but almost everywhere he wears a cloak. The cloak usually reaches just above the ankles and can be sleeveless or have short sleeves reaching the elbows. The cloak may have a fur collar and is open. Under the cloak, he wears a two-piece suit separated by a belt. The lower part of the suit can be trousers or a skirt. In some places, he is depicted with a metal suit in the upper part. He wears boots or high shoes that reach his knees [50,51,52,59,60]. Plečnik’s style was adopted in the 3D modelling of the clothes, which the architect depicted in statues and architectural objects, as shown in Figure 4 and Figure 5. He designed simple and not too wrinkled clothes.

Figure 4.

Statue of St. John the Baptist on the Trnovo Bridge in Ljubljana, the work of sculptor Nikolaj Pirnat (Photo: Anja Škerjanc).

Figure 5.

Statue of Moses in front of the National and University Library in Ljubljana, the work of the sculptor Lojze Dolinar (Photo: Anja Škerjanc).

In the wooden scale model reference (Figure 3 right), Žižka wears a simple outfit that looks like a cloak reaching down to the knees. It was assumed that the military leader wears high shoes or boots that peek out from under the coat, so in the reconstruction, an undergarment in the form of a skirt and jumper, separated by a belt [61], and a coat over it was planned [50,61]. The skirt was specified as knee-length, and the footwear consisted of high leather boots that reached under the skirt.

Žižka appears in the depictions with various headgear [50,51,52,53,59,60], such as different hats or a helmet, or without any headgear at all. According to the photo of the wooden model, Žižka wears a hat that does not reach the ears but ends earlier, has a non-furry upper part that fits the head and a rolled-up fur part [56,58].

2.1.3. Horse

Apart from the outline, the position of the ears and the appearance of the mane, the wooden scale model (Figure 3, right) provided hardly any information about the horse. It could be noticed that the horse is standing with all four legs on the ground. Its head is not in a natural position and it is slightly bent because Žižka is holding it by the reins. The ears are pointing forward and slightly upwards. After a thorough examination, we found that it has a long mane that falls over the head and neck and approximately reaches the middle of the neck. Additionally, it has a strong and emphasised chest.

Two important references from Plačnik’s work were used for the 3D modelling, showing how the architect designed the horses. Posture, proportions and physique were modelled using a statue of King Peter by the sculptor Lojze Dolinar [62], which stands in front of the town hall in Ljubljana (Slovenia), and a horse’s head on the door handles of the National University Library in Ljubljana (Slovenia) (reference for the horse’s head, Figure 6). From these references, it was deduced that Plečnik’s horse should stand straight and upright, which makes it very solid. Its head is slightly turned towards the body but not tilted. This gives the impression that the rider seems to have pulled the reins towards it. The horse is heavy and has very pronounced muscles, which gives it an angry expression. It has a short mane, which is aligned at the front at the ear line and continues over the head along the neck to the withers. The ears are pointed forwards, towards the rider’s gaze. The tail is long, reaching the hooves, and wavy [62]. In the 3D modelling of the horse, some interpretations were made according to the horse’s silhouette as seen in the photograph of a scale wooden model: a different position of the head and ears, a longer and falling mane and a more accentuated chest.

Figure 6.

Horse’s head, designed by Plečnik, on the entrance door handle to the National and University Library in Ljubljana (Photo: Anja Škerjanc).

The reference for the horse’s head style was taken from the door handle of the entrance to the National and University Library (Figure 6), which has a very similar head and neck shape to King Peter’s horse [62], and also has its head turned towards itself. Figure 6 shows that the horse does not have such emphasised musculature, although it has some facial features (e.g., the cheekbones) that are very strongly emphasised. Its mane is shorter and starts somewhere in the same place as that of King Peter’s horse and ends at the end of the neck with a flowing transition. The ears are laid back and the mouth is slightly open.

2.1.4. Hussite Soldiers

The collected references [50,55,56,57,58,63] of Hussite soldiers include illustrations and various other depictions. They served us primarily to determine what kind of clothing and equipment the Hussite soldiers wore. The sources show that the soldiers were dressed quite simply. They wore trousers and a longer top that could reach above or below the knees. They wore belts to which they could attach their weapons. Some were protected by metal shields and metal suits. Almost all wore a kind of undercap or bonnet that covered the shoulders and reached down to the chest in a semi-circular shape. They are usually depicted wearing leather boots or ankle boots. They carry various helmets, swords and shields. The features noted in the references were then compared with these elements on a photograph of a wooden model.

According to the wooden scale model (Figure 3 right), a guard is standing at the top of the stairs on the left and a monk on the right. The guard is holding a sword in his hands, which reaches down to the ground, and the monk is holding a chalice at chest height. The photo of the wooden model shows that the monk is wearing a long robe with a bonnet that falls freely over the monk’s upper back. The robe has long sleeves and reaches down to the ground. The monk has a long beard and short hair. The guard wears a helmet and a kind of undercap that ends in a semicircle on the chest, and we assume that this also applies to the upper back.

A Hussite soldier stands at the top of each pillar supporting half of the dome. As can be seen in the photo of the wooden model, they are all in a fixed position. The soldiers on the sides of the dome have a shield on the outside, which they hold with one hand and the other on their bodies. The soldier in the centre has a shield in front of him, which he holds with both hands somewhere on his waist. All three shields reach from the ground to just above the waist. The other two soldiers are holding swords in their hands. The swords reach up to their waists. The soldiers are dressed in simple, long, free-falling clothing. They are wearing half-caps and helmets.

It was observed that the soldiers above and the guard below are dressed similarly, i.e., simply and without details, so we modelled them after the references of the army commander Žižek [50,51,52,59,60,61]. The soldiers and the guard are dressed in long skirts that reach down to their ankles. Over this, they each wear a long shirt separated from the skirt by a belt. They wear leather boots. They wear a kind of undercap or a special cloak that covers the shoulders, extends in a semicircle to the chest and upper back and has a high collar that merges into a bonnet or undercap [52,64,65,66].

2.1.5. Props

The Hussite soldiers are depicted in the references with very different helmets. The photograph of the wooden scale model shows them wearing a narrow helmet that tightly encircles the head and widens in the lower part, or a helmet that reaches over the eyes and has eyeholes [52,66,67].

After careful examination of the photograph of the wooden model and consultation with the art historian at the Plečnik House, it was decided to design a helmet for the soldiers that would fit the head perfectly. This helmet is slightly wider at the bottom and reaches over the ears. It has a cut-out face [52,66,67,68]. The swords and shields are not clearly recognisable on the photo of the wooden model, especially the swords that were consequently 3D reconstructed as a simple object with a detail at the top of the hilt [52,66,67,68].

The Hussite soldiers used various shields, but the most common were those with a convex central surface. This can also be seen in the photo of the wooden scale model. The shields can have a square or pentagonal shape with rounded edges. The lower edge is flat and narrower, while the upper part of the shield is wider and can be flat or triangular. Some have an additional convex detail on the top of the convex part. After reviewing and comparing references, a pentagonal shield was designed with a convex centre part and very little convex detail [52,64,65,66,68].

Plečnik was also very famous for designing chalices [69]. In the photo of the wooden model, the chalice is very large, robust and undefined. We conclude that this is due to the material of the model (i.e., wood) and that it was difficult to produce a smaller chalice with details carved in wood.

The main reference for the chalice was the St Andrew’s chalice from 1913 [69,70]. In the 3D interpretation of the chalice, the curved rim of the cup was omitted, but the rim was executed in a spherical shape. As the monk is holding the chalice in his hands according to the plans of the monument, thus covering the relief ornaments, the details of the chalice were not reconstructed.

2.2. 3D Modelling and 3D Interpretation

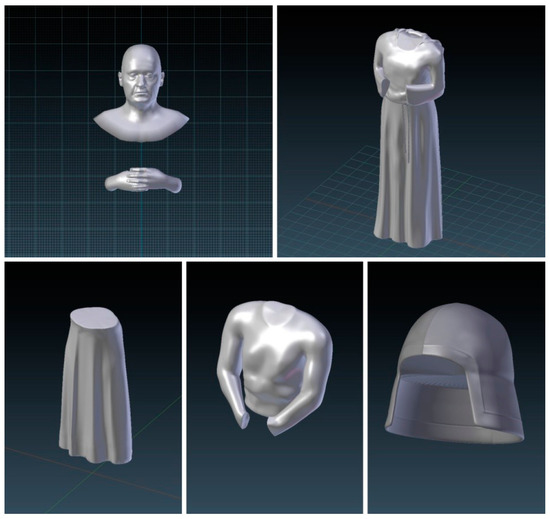

The monument was modelled manually using references that we considered suitable. The architectural part was modelled entirely in Blender 2.8 (Blender Foundation, Amsterdam, The Netherlands), while we used other approaches for the sculptural part. The bodies of the figures were created with the MakeHuman 1.1.1 (MakeHuman Team, Italy) and exported to Blender, where we further edited and finished them, giving them clothes with a textile simulation and adding modelled props. When modelling the sculptures of the military leader, soldiers, monks, props, textiles and animal, we used digital sculpting, which is also available in Blender, in addition to polygonal modelling from primitives and with transformations to obtain organic and detailed models. When modelling, we used the photo of the wooden model as a basis (Figure 3 right). Besides, we also examined other references and derived possible interpretations for the design of the elements of the sculptures and their details as well as the architectural part. Figure 7 shows the models of military leader and monk.

Figure 7.

Final model of Jan Žižka on horseback (upper left and right), final model of the hood (lower left) and the entire monk from the front (lower right).

Figure 8.

Final model of the guard below and the helmet.

Figure 9.

3D model of sword, chalice and shield.

2.3. 3D Printing

In this study, FDM (Fused Deposition Modelling) technology was used to print the architectural parts of the monument, while SLA (Stereolithography) technology was chosen for the detailed human figures. FDM technology was deemed more suitable for the architectural elements as it allows for a larger print volume and produces durable, stable parts at a relatively low cost. Its ability to process simple geometric shapes with sufficient strength made it ideal for structural components such as columns, steps and the base of the monument. Although FDM does not offer the finest surface detail and usually leaves visible layer lines, these were less critical with the clean, linear shapes of the architectural design.

In contrast, SLA technology was used for the smaller figures as it can produce high-resolution, highly detailed prints with smooth surfaces. The fine textures of the clothing, facial features and body proportions required a level of precision that could not be achieved with FDM. SLA’s resin-based printing offers exceptional visual quality, which was critical to faithfully reproducing the character and expression of the figures. However, the SLA process has a smaller build volume, is more expensive and the resulting prints are more brittle, making it less suitable for the larger structural parts of the monument. By combining both techniques, the project achieved a balance between scale, strength and detail so that the final model is both visually and functionally flawless.

2.3.1. Determination of the Dimensions

Before printing, we first had to determine the exact dimensions and proportions using the references available to us. The most important references for determining the proportions were the architectural plan and the photo of the wooden model. We found that the ratio between the column and the figure on the column is one to five. This means that each column is about five times as high as the figure (Figure 10 left). This is true for both references (the architectural plan and the photo of the wooden model), although the figures appear lower on the architectural plan and slimmer and taller on the photo.

Figure 10.

Determination of the proportions between the soldiers at the top and the column (left), and determination of the proportions of the steps (right).

An important relationship with the references that we took into account when modelling the architectural work is the size of the staircase (width) and the distance of the lower part of the monument from the staircase to the first columns. We have found that this distance and the width of the stairs are approximately the same (Figure 10 right).

Once we had determined the ratio of figure to column, we were able to determine the size of our figures.

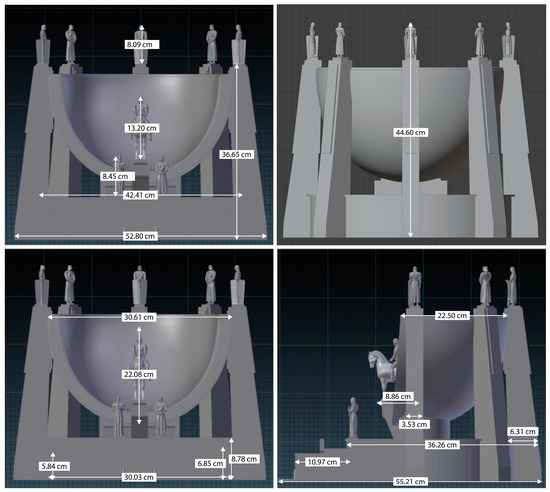

The final dimensions were determined based on the size of the figures so that they are not too small, as they are an important part of the monument. The total width of the monument (including the columns) was 52.80 cm and the depth was 55.21 cm. The size of the columns was 36.60 cm. The figures at the top were 8.00 cm tall, the figures at the bottom were 8.30 cm and the figure of Žižka on horseback was 13.2 cm. The remaining dimensions can be seen in the pictures. We decided to print the figures of the soldiers, the guard and the monk at a size of 8.30 cm and the figure of Žižka on horseback at a size of 13.20 cm (Figure 11).

Figure 11.

Preparing a model for printing with dimensions.

2.3.2. Cutting and Preparation of the Architectural Part

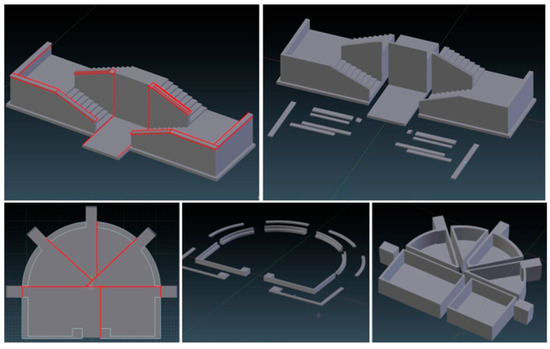

The size of the monument exceeded the working volume of the 3D printer (250 mm × 235 mm × 165 mm), so we cut the architectural part into smaller pieces after determining the size of the monument. We made sure to cut the models in the places where they are least visible (Figure 12).

Figure 12.

Section of the architectural part of the monument.

The preparation also included importing STL files into the Voxelizer (Zmorph, Wrocław, Poland) program to prepare 3D print models. We adjusted the size, the rotation around all three axes and the position in the direction of the Z-axis and aligned the imported model. We set the layer thickness to 0.2 mm, the infill density to 40%, the rhombic infill pattern, the base of the first layer and the fan settings for PLA. We added support material to the model in certain places. The model with all settings was then converted to G-code and exported for 3D printing.

2.3.3. Figure Preparation

We adjusted the size of the figures to the dimensions we had determined. Then we deleted the excess body parts that were covered by the clothes and the upper parts of the shoes that protruded under the skirt, and closed all the open parts of the body, clothes and props (Figure 13).

Figure 13.

Erasing excess body parts (left) and closing models (right); closed surfaces on skirt (left), shirt (middle) and helmet (right).

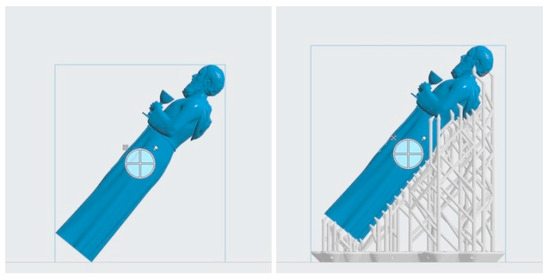

We imported the STL files into the PreForm (Formlabs, Somerville, MA, USA) program, which is used to prepare models for 3D printing with the Form2 printer, which works on the principle of stereolithography. When starting the program, we selected the 3D printer type (Form2), white material and a layer thickness of 0.1 mm. We then added a support to the imported model. We rotated the model by about 45° so that it lay partially (diagonally) on its back. We then added support material (Figure 14) to the model on the Supports tab using the Generate Selected function. There we set the support density to 1.00 and the contact point size to 0.5.

Figure 14.

Adding supports in PreForm.

2.3.4. 3D Print of the Architectural Part

To print the architectural part of the monument, we used a technology based on the extrusion of thermoplastics. We printed with a ZMorph VX 3D printer from Zmorph (Zmorph S.A., Wrocław, Poland). The printer has a working volume of 250 × 235 × 165 mm. For printing, we used white polylactic acid (PLA) with a diameter of 1.75 mm. We printed in an open system; all other printing parameters are listed in Table 1.

Table 1.

Printing parameters with thermoplastic extrusion technology.

The architectural part was printed in 52 parts, for which we used about 5.2 kg of material. The total printing time was about 501 h, assuming a printing speed of 100%.

2.3.5. 3D Printing of Figures

The figures were printed using stereolithography technology, which is based on the photopolymerisation process in a bath. We used a Form2 printer from Formlabs for printing. The printer has a working volume of 145 mm × 145 mm × 175 mm and a Viola laser with a wavelength of 405 nm. Since it is a printer with reverse stereolithography technology, the objects are printed from the work surface downwards. We used a white, opaque, liquid photopolymer with a matte finish produced by Formlabs.

We printed 14 objects (8 figures and 6 columns) using SLA technology, for which we used about 344 mL of liquid photopolymer. The total printing time was about 28 h and 15 min.

2.3.6. Finishing and Processing After 3D Printing

First, we removed the supports from the printed objects of the architectural part of the monument with support material using an olive wood knife. We sanded all parts with P600 sandpaper for wet sanding to smooth the texture of the layers of the printed objects.

We then dried the parts, made sure there were no contaminants on the surfaces and glued them using Neostik EP-102 Epoxy Extra two-component adhesive. The glued parts were then filled at the joints with the white two-component polyester putty S.M.A.R.T. Fine Putty. Once the putty had dried, the joints were sanded to create a smooth surface.

The individual parts were then painted. For the paint, we used white, matt acrylic multipurpose spray paint from the Satacolor brand.

Once the painted pieces were dry, we assembled the entire architectural piece and glued the pieces together with super glue. Even at this stage, we still had to fill some of the joints between the parts as holes had appeared. After filling, we sanded these parts and painted them again.

The printed figures and columns were carefully removed from the working plate, and the photopolymer residues were removed in two solvent baths (90% IPA). The figures were left in the baths for 6 min each and stirred and turned several times during this time to dissolve the uncured photopolymer on all parts. The objects were then removed from the bath and air dried to evaporate the alcohol.

After printing, the object must also be irradiated with a UV light source until it is fully cured. The objects were irradiated with UV light from all sides for around 3 min.

As soon as the figures were cured, the supports were removed. To do this, each support was clamped directly next to the figure using pliers. After removing the supports, the objects were sanded to remove all the remains of the supports. We sanded with P600 and P1000 sandpaper, which is intended for wet sanding.

The figures were then thoroughly washed, dried and painted with Satacolor acrylic multipurpose spray paint in matt white.

2.4. Evaluation and Analysis of User-Experience

We tested the usability using the semantic differential method. The test was carried out in two parts. In the first part, we used a questionnaire to determine adjective pairs, according to which the visitors rated the user experience of the reproduction in the gallery in the second part.

2.4.1. First Part—Determination of Adjective Pairs

The first part of the study took place in Plečnik’s house with 32 participants with entry level knowledge of graphic arts. The participants took part in the tests voluntarily (22% male, 78% female, 44% do not visit museums, 53% visit museums 1–5 a year and 3% 6–10 a year). The first part of the usability analysis took place in Plečnik’s house, where the students looked at the 3D-printed reconstruction and references.

The participants used several adjectives to describe and evaluate the 3D-printed reconstruction and compare it with the respective reference (sketch, construction plan and photo of a wooden model). They had to focus on the architectural part, the figures, the clothes and accessories as well as the props. The comparison was carried out with regard to the following points:

- Correspondence of the 3D-printed model with Plečnik’s style shown in the references;

- Representation of reliefs and details in relation to the references;

- Spatial representation in relation to the references;

- Quality and clarity of presentation in relation to the references.

Finally, they had to evaluate the correspondence of each part of the monument in the 3D printed model with the same part in each reference (sketch, architectural plan and photo of a wooden model). They rated using a five-point Likert scale, where 1—does not match at all and 5—matches perfectly.

2.4.2. Pivot Test

Based on the results of the first part, we have prepared a pivot test. The adjectives we obtained in the first part of the test for each part of the monument (architectural part, figures, clothing and clothing accessories, and props) were combined them into adjective pairs by assigning an antonym to each adjective. The questionnaire was divided into three parts, namely the comparison of the 3D-printed model with an individual reference (sketch, blueprint and photo of a wooden model). Each participant selected five adjective pairs for each part of the monument that best described the comparison with a particular reference. The selected adjective pairs were then ranked from one to five, with first place being the pair that best described the comparison and fifth being the pair that described it the least.

Nine participants with entry level knowledge of textile and fashion design participated in the pivot test (11% male, 89% female, 11% do not visit museums, 67% do visit museums 1–5 a year and 11% 6–10 a year). The tests took place on a voluntary basis on the premises of the Plečnik House and thus in a gallery environment. The respondents were presented with the aim of the study and then had time to complete a test questionnaire with adjective pairs of the semantic differential. Semantic differential adjective pairs are presented in Table 2.

Table 2.

Semantic differential adjective pairs.

2.4.3. Part Two—Semantic Differential

From the adjective pairs for each part of the monument, we selected five that were chosen most frequently and placed in the highest positions. From the adjective pairs, we formed a semantic differential using a five-point numerical Likert scale (from one to five). We placed adjectives with a negative or negating meaning on the left-hand side and those with a positive meaning on the right-hand side. The selected adjectives and the semantic differential questionnaire are shown in Table 3. In the second part, the participants observed the 3D-printed reconstruction of the monument and the references.

Table 3.

A part of the questionnaire for analysing adjective pairs using the semantic differential method.

Forty-three participants with entry level knowledge of graphic arts participated in the second part of the study (23% male, 77% female, 21% do not visit museums 65% do visit museums 1–5, 9% 6–10 a year. Also, in this part of the study, respondents answered voluntarily, and were informed about the purpose of the study and then gave their opinion on adjective pairs on the correspondence of parts of the 3D reconstruction with the references (correspondence of style and execution of the 3D print).

3. Results and Discussion

3.1. 3D Printed Reproduction

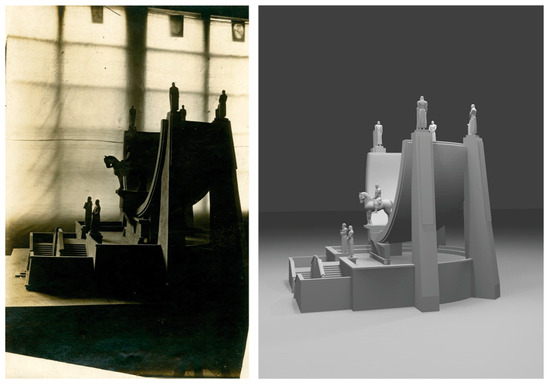

The result of the work is a 3D printed reproduction of the model measuring 52.80 cm in width, 55.21 cm in depth and 44.60 cm in height (Figure 15). The work was awarded the honorary Valvasor Award in 2018, the most prestigious award for museum activities in Slovenia.

Figure 15.

3D printed reconstruction of the model.

After detailed examination and comparison of the 3D-printed reconstruction with the photo of the wooden model, we can see (Figure 16) that there are differences in the access to the staircase below. In Plečnik’s model, the staircase can be reached via two small steps, while in our model, it can be reached via one long step. The Žižek platform appears to be slightly inclined towards the inside of the dome in Plečnik’s model, while it is horizontal in the reconstruction. We can also see that the protruding details on the outside of the columns are slightly longer in our reproduction. Due to the lighting of the photo of Plečnik’s wooden model and the materials used, it appears heavier and more massive than the 3D-printed reproduction.

Figure 16.

Comparison of the wooden model (left) (source: Plečnik House) with the visualisation of the 3D reconstructed monument (right).

After a detailed examination and comparison of the sculptural part of the 3D-printed reproduction with the sculptural part of the photograph, we can see that the horse on Plečnik’s model is more robust, with sharper features and a more pronounced shoulder area. The horse on the 3D-printed reproduction has softer and smoother lines, the reins are thinner, and the mane does not stand out as much. 3D printing with stereolithography technology allows us to achieve high precision so that all details (mane strands, eyes, nose, bridle) are clearly visible on the horse in the 3D-printed reproduction (Figure 17). The military leader’s clothing is also reproduced in greater detail. Figure 17, Figure 18 and Figure 19 shows comparison of the photo reference and 3D printed Jan Žižka and a horse, the monk and soldiers.

Figure 17.

Comparison of Jan Žižka and a horse.

Figure 18.

Comparison of a monk and a guard.

Figure 19.

Comparison of soldiers.

We estimate that we have come closer to the appearance of the Hussite soldiers and Jan Žižka with the figures. We tried to adopt Plečnik’s style as much as possible, but this was a great challenge, both because of the distinctiveness of the model and because of the different technologies and materials used to make the models.

3.2. Results of User Experience Analysis

3.2.1. First Part of the Test—Obtaining Adjective Pairs and Evaluating the Match

We reviewed the results of the description of the comparison of individual parts of the 3D-printed model of the monument, eliminated repetitive adjectives and combined adjectives with exactly the same meaning. Since we did not want to manipulate the adjectives and consequently interfere with the testing process, we used all the adjectives that the test participants gave us.

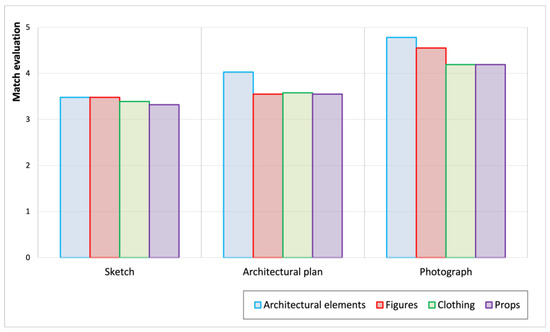

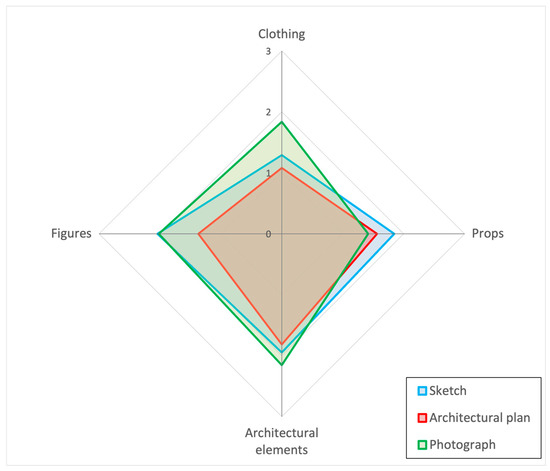

In addition to the description of the comparison between the 3D-printed reconstruction and the individual reference, the participants evaluated the comparison between the 3D-printed reconstruction and the individual reference (Figure 3: References of the Plečnik monument (sketch—left; architectural plan—central; and photograph of the wooden model—right). From the results obtained, we calculated the average ratings. Figure 20 shows that the participants in the study found the 3D-printed reproduction most similar to the wooden model in the photo and least similar to the sketch, which is to be expected since we mostly used the photo of the wooden model as a template for the reproduction.

Figure 20.

Evaluation of the comparison of the 3D printed model with references on sketches, architectural plans and photographs (n = 9).

If we focus on each reference individually, we can see that the similarity scores for the sketch are very close for each part. The sketches are most similar to the architectural part of the reconstruction and the figures, which received a value of 3.48. This is followed by the clothing with a score of 3.39 and the props with a score of 3.32. The low scores are due to differences in layout, unclear shapes and a low level of detail in the sketches. Due to the fuzziness of the figures, the scores are very close to each other. The test participants most likely did not differentiate between the figure and the clothing.

When evaluating the comparison with the architectural plan, it is noticeable that the architectural part performs very well with a score of 4.03. The other parts of the monument that follow it show only very slight differences in their evaluation. The participants rated the figures and props at 3.55 and the costumes at 3.58. The similarity between the architectural part of the reconstruction and the architectural part of the plan is logical on the one hand, as we started from the architectural plan when modelling. The figures are still somewhat unclear in the architectural plan, but the costumes are better defined than in the picture. The placement of the two lower figures is different from the final version, and Žižka is on a horse in motion and jumping from a stack of chalices. It is interesting that the participants rated the comparison of the props with such a high score, even though there are no props on the architectural plan.

The participants rated the architectural part of the 3D reconstruction as most similar to the architectural part in the photo of the wooden model. Although we had initially modelled the architectural part according to the blueprint, we subsequently adapted it to the appearance in the photo. The architectural part received a score of 4.78 in this comparison, followed by the figures with a score of 4.55, which are defined as in the 3D printed model and appear calm. The costumes and props received a score of 4.19. We conclude that the score would have been higher if the photo had been taken under better conditions and more details had been visible.

3.2.2. First Part of the Test—Pivot Test

In the pivot test, participants chose from five pairs of adjectives, which they ranked from one to five, with first place describing the comparison the best and fifth place the least. Users chose the adjectives for comparison with each reference separately and for each part of the monument separately.

In order to select five pairs, we first calculated the ratio between the average score and the number of selections (how many times a particular pair was selected in the top five) of a particular pair for each part of the monument when comparing the 3D printed model to a single reference. Since we initially compared with three references and the final test involved only one comparison, we finally calculated the average value of the ratio. In the second part of the test, we selected five pairs of adjectives for each part of the monument that had the lowest ratio between the average score and the number of selections.

The adjective pair not-detailed–detailed was chosen for all parts of the monument, the pair unfinished–finished for the architectural plan and clothing, and the pair unclear–clear was chosen for clothing and props, while the other pairs were different. From this, we can conclude that the participants paid close attention to details.

3.2.3. Second Part of Testing—Semantic Differential

In the second part of the testing, the participants evaluated the comparison of individual parts of the reconstruction with all the references together (e.g., the level of detail of the architectural part of the reconstruction compared to the references). They rated the comparison on a five-point scale. If the rating of the comparison is higher than the centre of the scale (i.e., three), it means that they perceive the comparison with the adjective on the right side (which is positive in our case); if the rating is lower than three, they perceive it with the adjective on the left side (which is negative or negated in our case).

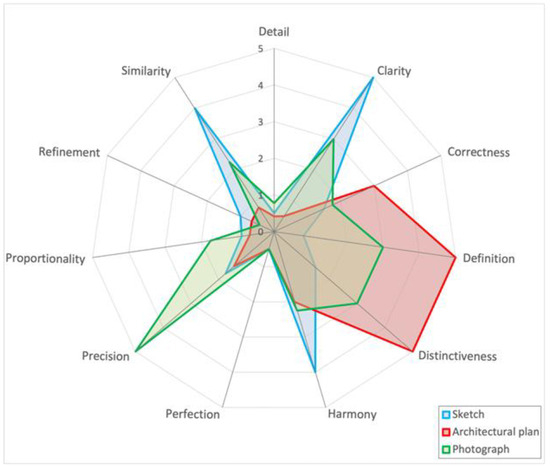

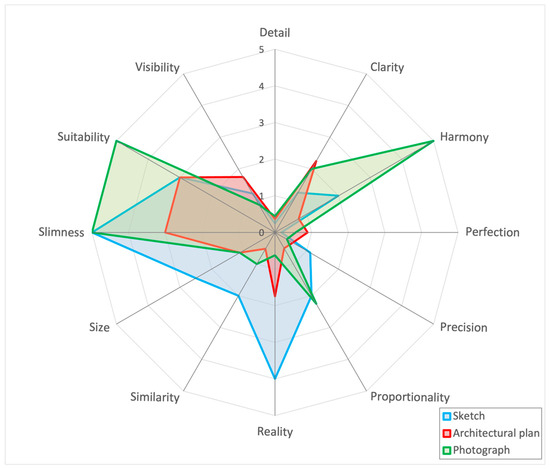

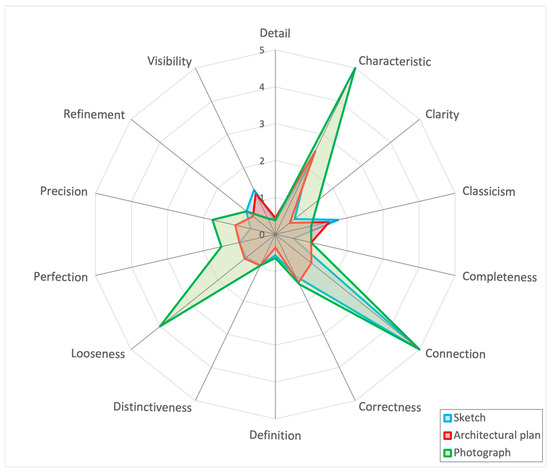

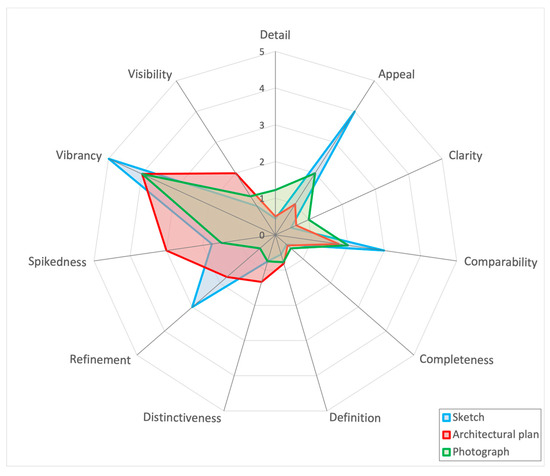

In Figure 21, Figure 22, Figure 23, Figure 24 and Figure 25, we compare those adjective pairs that were evaluated across all forms of references. Each pair is summarised with a one-word description of the attribute we inquired about in the adjective pair. We were particularly interested in which reference (sketch, architectural plan or photograph) more accurately described the individual content segments we focused on when creating the model, namely, the architectural elements, figures, clothing and props.

Figure 21.

Comparison of the architectural elements of a 3D printed model with references (n = 43).

Figure 22.

Comparison of the figures on a 3D printed model with references (n = 43).

Figure 23.

Comparison of the clothing elements on a 3D printed model with references (n = 43).

Figure 24.

Comparison of the props on a 3D printed model with references (n = 43).

Figure 25.

Average rating of the effectiveness of visualisations for individual parts of the monument.

In Figure 21, we see a rating of the architectural elements of a 3D-printed model according to each reference. The sketch receives the highest score for clarity and similarity, indicating that sketches are often clear and easy to compare with other representations. The architectural plan excels in definition and distinctiveness, which emphasises its structured and clearly defined nature. The photograph, on the other hand, has the highest value in precision and proportionality, which emphasises its ability to accurately capture details from the real world. While sketches and photographs have some overlap, sketches focus more on conceptual representation, while photographs emphasise accuracy and refinement. The architectural plan is characterised by its strong definition and correctness, making it more technical and structured.

In Figure 22, we see an evaluation of the figures on a 3D-printed model according to each reference. The sketch performs best in terms of reality and similarity, indicating that while sketches can resemble conceptual references, they may lack precision. The architectural plan scores highest for detail and clarity, emphasising its structured and technical nature. The photograph stands out in harmony, slimness, suitability, and visibility, showing that photographs better reflect the proportions and aesthetics of the real world. While the sketch and architectural plan share some similarities in structure, the strength of the photograph lies in its realism and suitability for representation. The architectural plan offers a balance between precision and clarity, making it a technical guide, while the sketch is more focused on conceptualisation and visualisation. Photography, with its emphasis on real proportions and harmony, offers the most accurate representation of physical form.

In Figure 23 we see an evaluation of the clothing elements on a 3D-printed model according to each reference. The sketch performs relatively well in terms of detail and clarity, suggesting that sketches provide a clear yet interpretable representation. The architectural plan scores best in terms of correctness and definition, emphasising its structured and technical precision. The photograph stands out significantly in characteristic, connection and perfection, highlighting its ability to capture the real world in its accuracy, depth and form. While sketches and architectural plans share some similarities in terms of definition and structure, photographs excel in refinement and distinctiveness, providing a more holistic and visually complete representation. The architectural plan maintains a balance between completeness and correctness, making it an important technical guide. The sketch, on the other hand, leans toward conceptualisation and visualisation, focusing more on interpretative representation rather than exact precision. The photograph, with its emphasis on realism and distinctiveness, provides the most accurate and comprehensive representation of form and structure.

In Figure 24, we see an evaluation of the props on a 3D-printed model according to each reference. The sketch scores highest in appeal, clarity and vibrancy, suggesting that sketches are visually engaging and conceptually expressive. The architectural plan performs well in spikedness and distinctiveness, indicating that it offers structured yet recognisable design elements. The photograph excels in definition and completeness, highlighting its ability to capture realistic and well-defined details. While sketches emphasise artistic representation and visual clarity, architectural plans focus on structural accuracy and distinctive elements. The photograph, with its strong completeness and definition, provides the most precise and tangible representation. The differences between these three types of representation reflect their unique purposes: sketches are more interpretative, architectural plans are more technical and photographs offer the most accurate representation of the real world.

By comparing adjective pairs used across all visualisation methods of the monument’s elements, we can determine how a particular visualisation influenced the perception of the monument. However, we note that no definitive statement can be made as to whether one visualisation method has a more positive effect on the success of the representation. For clothing, photography proves to be the most effective, while for props, both sketches and architectural plans perform best. In the case of architectural elements and figures, no single visualisation method can be described as superior. The reasons for this lie in the different adjective pairs that were used for the evaluation.

If the results of all adjective pairs are averaged and only the difference in the effectiveness of the visualisation of certain parts of the monument is considered, it can be concluded that photograph is the most successful for clothing, figures and architectural elements. However, it is least effective for props, with sketches proving to be the best visualisation method in this category (Figure 25).

Although the test participants considered the photograph to be the most relevant, the creators rated the architectural plan as the most relevant. This illustrates the influence of purpose or motivation, which play a decisive role for the user. For the creators, accuracy and precision of the reference were the most important factors, while the test participants focused on the overall impression and the similarity between the reference and the final model.

When focusing solely on the perceived success of the reproductions—regardless of the original references—the results showed that architectural elements were rated as the most successful, with an average score of 1.97 out of 5. Statues followed with 1.81, while props, despite their level of detail, were slightly less convincing, scoring 1.61. Clothing received the lowest rating, with an average score of just 1.40.

4. Conclusions

The presented research shows an example of a study of gallery experience with a semantic differential using the example of a 3D reconstruction of an unrealised architectural sacral monument by the famous Slovenian architect Plečnik and thus, the use of qualitative metric methods to assess the correspondence of the style of the 3D reconstruction with the architectural style expressed by the author through existing references and plans for the monument. The documentation provided to us when we started creating the 3D-printed reconstruction of the model was not sufficient, so we looked for references to the Hussite soldiers and their leader Jan Žižka in other sources. A thorough and analytical approach, taking into account all existing reference types, provided us with enough data about the monument and enabled the process of 3D modelling.

Since the photo of the wooden model does not show any details, we used other works by Plečnik and sculptures created in collaboration with him to interpret the level of detail.

According to the result of semantic differential, the 3D-printed reconstruction of Jan Žižka’s monument is assessed as a good approximation of Plečnik’s style. The reconstruction of the architectural part of the monument, which was initially modelled after Plečnik’s blueprint and completed based on a photograph of a wooden model, was evaluated as very successful. The sculptural part presented us with a greater challenge. Plečnik worked with various sculptors who planned and produced a stylistically appropriate sculptural part of his architecture. When compared with the main visual reference, the photo of a wooden model, we conclude that the reconstruction of the sculptural part was very close to Plečnik’s style. The respondents of the differential semantic study believed that the architectural part of the 3D-printed model fits Plečnik’s references best, followed by the figures with clothes and props. In their opinion, the reconstruction comes closest to the wooden model in the photo.

The majority of participants rated the model as better compared to the references. Only the resemblance of the figures was rated worse or negatively, as the participants thought that the figures differed from the references. The results of the study, therefore, show that the 3D-printed reconstruction improves the user experience. The model showed the participants certain information that they could not see in the references and that was lost with the loss of the wooden model. This allowed them to better visualise certain parts of the model that are less visible and perhaps somewhat unclear on the references.

We can confirm the hypothesis that a thorough analytical approach to consider all existing types of references will provide us with sufficient data about the monument and enable the 3D modelling process. The second working hypothesis, in which we assumed that we would approach Plečnik’s style with a 3D printed model, is also confirmed. The 3D printed reproduction improved the experience of the exhibition visitors and their perception of both the architectural and sculptural elements of the monument to the military leader Jan Žižka, so we can also confirm the third hypothesis.

The results of the 3D-printed reconstruction were successfully nominated for the Valvazor Prize, which contributed to the national expansion of the use of 3D technologies for museum purposes and the digital and physical 3D replication of Plečnik’s architectural heritage. The 3D-printed reconstruction of the monument represents an important research contribution to the use of 3D technologies and in particular 3D printing in unrealised architectural heritage. By analysing the user experience through a qualitative method, we were also able to successfully assess the quality of the work and the experience of the gallery visitors for whom the reconstruction is intended. The research was a pioneer at the national level in the introduction of the semantic differential method for analysing the museum experience, which provides guidelines for the design of visitor-oriented 3D reconstructed architectural heritage objects. Nevertheless, the research framework is also used as a case study in the education of students on the application of 3D technologies in the interpretation and presentation of cultural and architectural heritage [71].

The research certainly has some limitations. In the initial phase of the reconstruction, AI tools were included to reconstruct a 3D model from a photograph. It turned out that the photo was of too low quality (in addition, we only had one photograph) to be suitable for AI recognition of 3D form and details, so we abandoned AI-assisted approaches and proceeded with observational methods of reference with interpretive recreation of the style in the 3D reconstruction. Another limitation of the study is the number of respondents, which was small in our first part of the study. A higher number of participants in the initial stage of the research could have resulted in a different set of adjectives, on the basis of which we composed the questionnaires for the second stage of the research. Furthermore, expanding the profile of respondents could lead to defining other adjective pairs that were used in the second phase of the research, and thus, in analysing the correspondence of style and implementation of the 3D-printed reconstruction compared to the references. After the exhibition and research were completed, the 3D printing was not refined and improved according to visitors’ opinions, which we certainly see as an opportunity for further research into figures, design details of personal features and clothing.

Author Contributions

Conceptualisation, H.G.T., T.N.K. and A.Š.; methodology, H.G.T. and T.N.K.; validation, H.G.T. and T.N.K.; formal analysis, A.Š. and J.A.; investigation, H.G.T. and T.N.K.; resources, A.Š.; data curation, A.Š. and H.G.T.; writing—original draft preparation, H.G.T.; writing—review and editing, H.G.T., T.N.K. and J.A.; visualisation, A.Š. and J.A.; supervision, H.G.T. and T.N.K.; project administration, H.G.T.; funding acquisition, H.G.T. and J.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was founded by the Slovenian Research Agency (No. P2-0450).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors of the study would like to thank the Plečnik House in Ljubljana, which made the study possible, and Ana Porok in particular. The authors would also like to thank Matej Pivar for his cooperation in the technical implementation of 3D printing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Münster Sander, A.; Fabrizio, I.; Bluemel, I.; Fallavollita, F.; Foschi, R.; Grellert, M.; Ioannides, M.; Jahn, P.H.; Kurdiovsky, R.; Kuroczyński, P.; et al. Handbook of Digital 3D Reconstruction of Historical Architecture; Springer: London, UK, 2024. [Google Scholar] [CrossRef]

- Münster, S.; Apollonio, F.I.; Bluemel, I.; Fallavollita, F.; Foschi, R.; Grellert, M.; Ioannides, M.; Jahn, P.H.; Kurdiovsky, R.; Kuroczyński, P.; et al. Basics and Definitions. In Handbook of Digital 3D Reconstruction of Historical Architecture; Springer Nature: Cham, Switzerland, 2024; Volume 28, pp. 13–39. [Google Scholar] [CrossRef]

- Neumüller, M.; Reichinger, A.; Rist, F.; Kern, C. 3D Printing for Cultural Heritage: Preservation, Accessibility, Research and Education. In 3D Research Challenges in Cultural Heritage; Ioannides, M., Quak, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 8355, pp. 119–134. [Google Scholar] [CrossRef]

- Bülow, W.; O’Nils, J.; Lewis, T. On the Ethics of Reconstructing Destroyed Cultural Heritage Monuments. J. Am. Philos. Assoc. 2020, 6, 483–501. [Google Scholar] [CrossRef]

- Hrausky, A. Simboli v Plečnikovi Arhitekturi: Ljubljana 1921–1957; Lili in Roza, D.O.O: Ljubljana, Slovenia, 2016. [Google Scholar]

- Hrausky, A.; Koželj, J.; Prelovšek, D. Jože Plečnik: Dunaj, Praga, Ljubljana, 1st ed.; Cankarjeva Založba: Ljubljana, Slovenia, 2017. [Google Scholar]

- Prelovšek, D.; Rakovec, A.; Lazarini, F.; Whyte, I.B.; Valena, T. Jože Plečnik: Arhitektura Večnosti: Teme, Metamorfoze, Ideje, 1st ed.; Vaupotič, N., Translator; Založba ZRC: Ljubljana, Slovenia, 2017. [Google Scholar]

- Plečnik in Sveto. Available online: https://mgml.si/sl/plecnikova-hisa/razstave/269/plecnik-in-sveto/ (accessed on 1 June 2025).

- Jurca, T. Plečnik in Sveto. Muzej in Galerije Mesta Ljubljane, 2019. Plečnikova Hiša. Available online: https://mgml.si/sl/plecnikova-hisa/publikacije/81/tomaz-jurca-plecnik-in-sveto-razprodano/ (accessed on 17 July 2025).

- Gomes, L.; Bellon, O.R.P.; Silva, L. 3D reconstruction methods for digital preservation of cultural heritage: A survey. Pattern Recognit. Lett. 2014, 50, 3–14. [Google Scholar] [CrossRef]

- Çubuk, G. 3D printing for the reinterpretation of architectural heritage: Proposal of a model. Cult. Herit. Sci. 2024, 5, 24–37. [Google Scholar] [CrossRef]

- Bent, G.R.; Pfaff, D.; Brooks, M.; Radpour, R.; Delaney, J. A practical workflow for the 3D reconstruction of complex historic sites and their decorative interiors: Florence as It Was and the church of Orsanmichele. Herit. Sci. 2022, 10, 118. [Google Scholar] [CrossRef]

- Rodriguez-Garcia, B.; Guillen-Sanz, H.; Checa, D.; Bustillo, A. A systematic review of virtual 3D reconstructions of Cultural Heritage in immersive Virtual Reality. Multimed. Tools Appl. 2024, 83, 89743–89793. [Google Scholar] [CrossRef]

- Jaramillo, P.; Sipiran, I. Cultural Heritage 3d Reconstruction with Diffusion Networks. In European Conference on Computer Vision; Springer Nature: Cham, Switzerland, 2024; pp. 104–117. [Google Scholar] [CrossRef]

- Diz-Mellado, E.; Perez-Fenoy, J.; Mudarra-Mata, M.; Rivera-Gómez, C.; Galan-Marin, C. Enhancing 3D-printed clay models for heritage restoration through 3D scanning. Appl. Sci. 2024, 14, 10898. [Google Scholar] [CrossRef]

- Llull, C.; Baloian, N.; Bustos, B.; Kupczik, K.; Sipiran, I.; Baloian, A. Evaluation of 3d Reconstruction for Cultural Heritage Applications. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Paris, France, 1–6 October 2023; pp. 1642–1651. [Google Scholar] [CrossRef]

- Zachos, A.; Anagnostopoulos, C.N. Using terrestrial laser scanning, unmanned aerial vehicles and mixed reality methodologies for digital survey, 3D modelling and historical recreation of religious heritage monuments. arXiv 2023. [Google Scholar] [CrossRef]

- Apollonio, F.I.; Fallavollita, F.; Giovannini, E.C.; Foschi, R.; Corso, S. The Reconstruction of Drawn Architecture. Stud. Digit. Herit. 2017, 1, 380–395. [Google Scholar] [CrossRef]

- Condorelli, F.; Rinaudo, F. Cultural heritage reconstruction from historical photographs and videos. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, 42, 259–265. [Google Scholar] [CrossRef]

- Santagati, C.; Inzerillo, L.; Di Paola, F. Image-based modeling techniques for architectural heritage 3D digitalization: Limits and potentialities. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, 40, 555–560. [Google Scholar] [CrossRef]

- Münster, S.; Apollonio, F.I.; Bluemel, I.; Fallavollita, F.; Foschi, R.; Grellert, M.; Ioannides, M.; Jahn, P.H.; Kurdiovsky, R.; Kuroczyński, P.; et al. Workflows. In Handbook of Digital 3D Reconstruction of Historical Architecture; Springer Nature: Cham, Switzerland, 2024; Volume 28, pp. 81–105. ISBN 9783031433627. [Google Scholar]

- Alshawabkeh, Y.; Baik, A.; Miky, Y. Integration of laser scanner and photogrammetry for heritage BIM enhancement. ISPRS Int. J. Geo-Inf. 2021, 10, 316. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, X.; Luo, L.; Wan, H.; Ren, H. An Overview of GIS-RS Applications for Archaeological and Cultural Heritage under the DBAR-Heritage Mission. Remote Sens. 2023, 15, 5766. [Google Scholar] [CrossRef]

- Gîrbacia, F. An Analysis of Research Trends for Using Artificial Intelligence in Cultural Heritage. Electronics 2024, 13, 3738. [Google Scholar] [CrossRef]

- Aniwaa. 3D Printing and 3D Scanning for Archeology and Museums. Available online: https://www.aniwaa.com/guide/3d-printers/3d-printing-for-archeology-and-museology/ (accessed on 18 February 2025).

- Ioannides, M.; Ioannidis, C.; Enkleistriotis, A.N.; Castrillo, D.; Chatzigrigoriou, P.; Papageorgiou, E.; Leventis, G.; Nikolakopoulou, V.; Athanasiou, V.; Bourexis, F.; et al. Towards Monuments’ Holistic Digital Documentation: The Saint Neophytos Enkleistriotis Case Study. In Digital Heritage. Progress in Cultural Heritage: Documentation, Preservation, and Protection; Ioannides, M., Fink, E., Moropoulou, A., Hagedorn-Saupe, M., Fresa, A., Liestøl, G., Rajcic, V., Grussenmeyer, P., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 10058, pp. 442–473. [Google Scholar] [CrossRef]

- Dzwierzynska, J.; Prokop, A. Reconstruction of Historic Monuments—A Dual Approach. Sustainability 2022, 14, 14651. [Google Scholar] [CrossRef]

- Pieraccini, M.; Guidi, G.; Atzeni, C. 3D Digitizing of Cultural Heritage. J. Cult. Herit. 2001, 2, 63–70. [Google Scholar] [CrossRef]

- Milosz, M.; Kęsik, J. Special Issue on 3D Information Technologies in Cultural Heritage Preservation and Popularization—Motivations, Works Overview, and the Future. Appl. Sci. 2023, 13, 204. [Google Scholar] [CrossRef]

- Parfenov, V.; Igoshin, S.; Masaylo, D.; Orlov, A.; Kuliashou, D. Use of 3D Laser Scanning and Additive Technologies for Reconstruction of Damaged and Destroyed Cultural Heritage Objects. QuBS 2022, 6, 11. [Google Scholar] [CrossRef]