Integration of Lean Construction and BIM in Sustainable Built Environment: A Review and Future Research Directions

Abstract

1. Introduction

- RQ1: What are the research trends of the integration of LC and BIM?

- RQ2: What are the benefits of integration of LC and BIM in the context of sustainable built environments?

- RQ3: What are the current barriers impeding the integration of LC and BIM in the context of sustainable built environments?

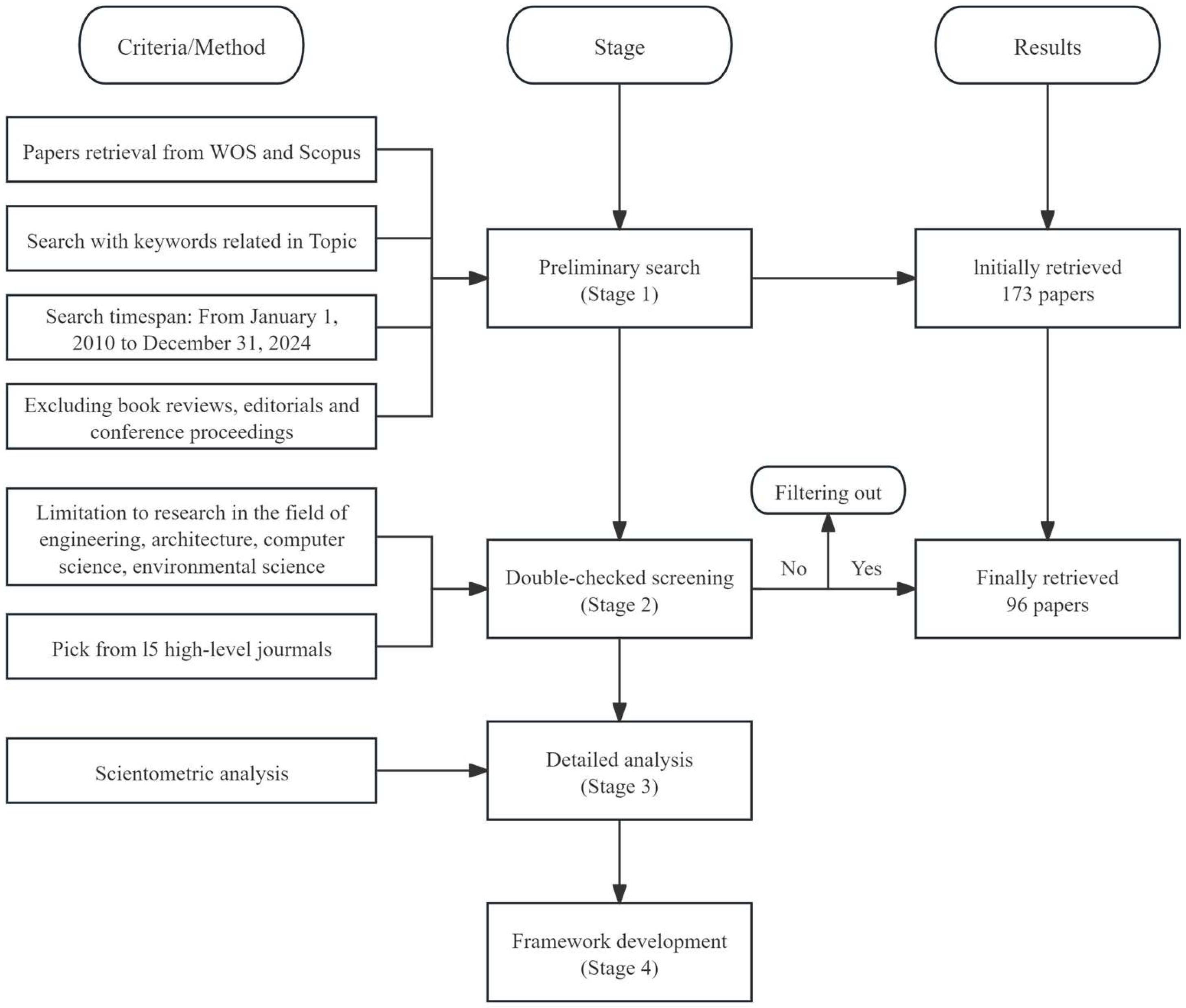

2. Methodology

2.1. Paper Retrieval

2.2. Review Steps

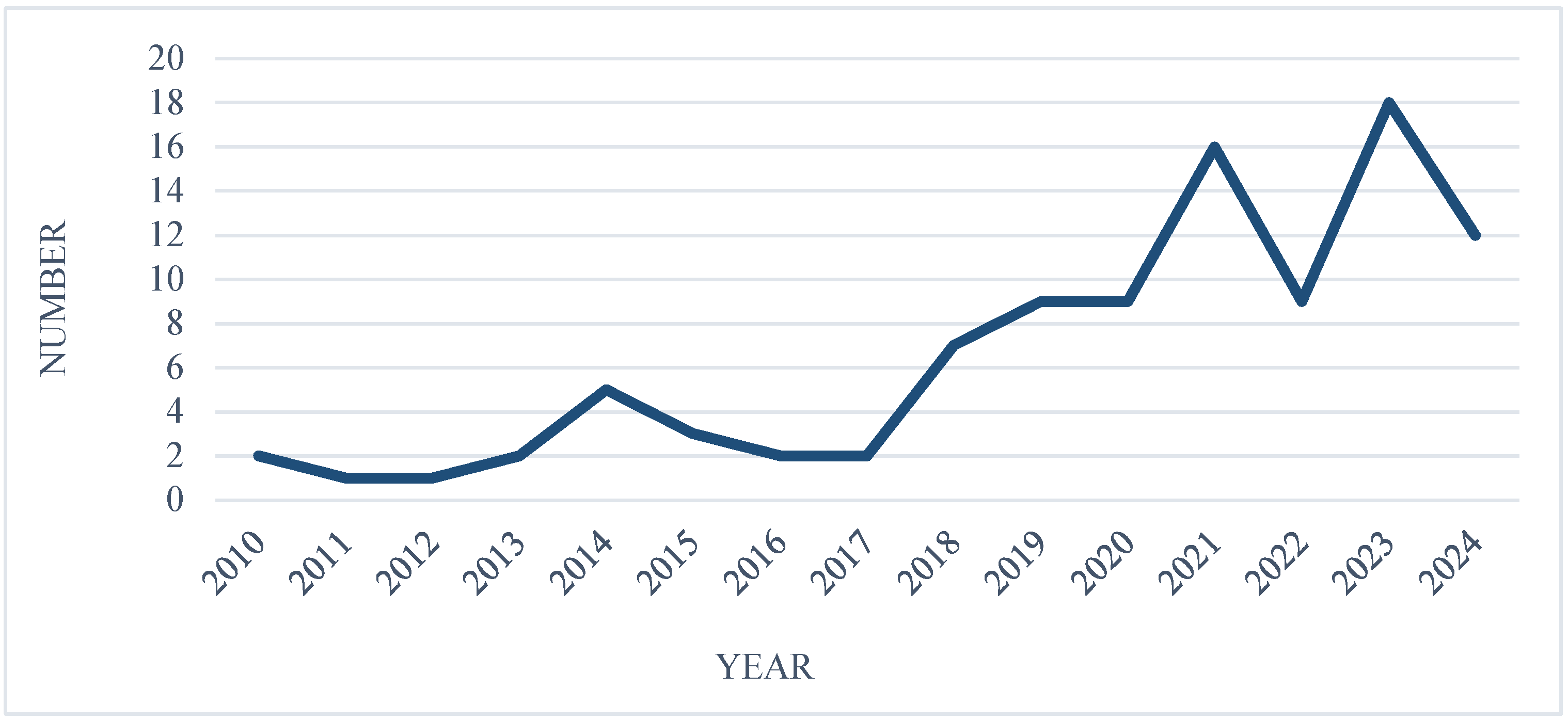

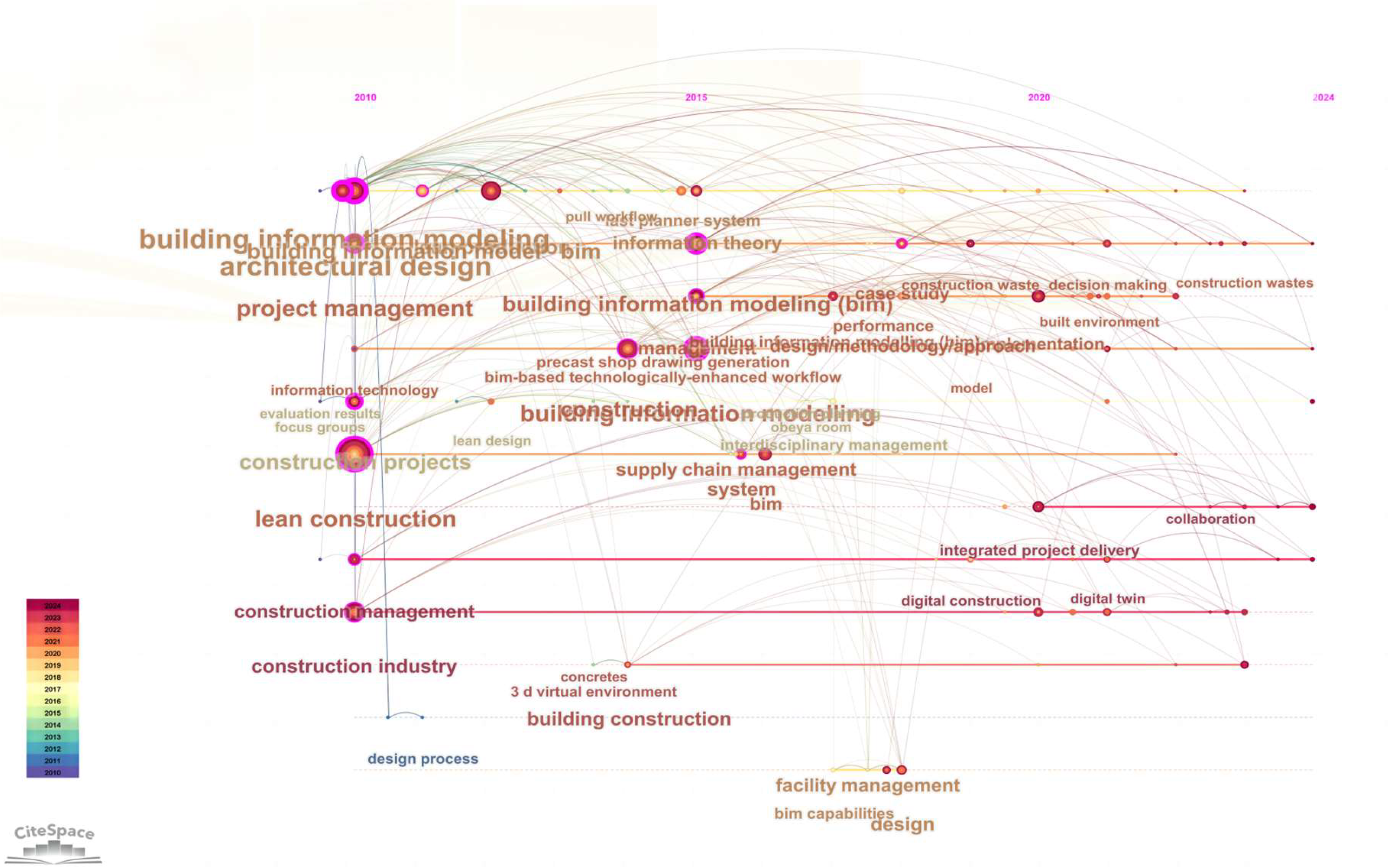

3. Bibliometric Analysis

3.1. Time Series Analysis

3.2. The Keyword Co-Occurrence Network

4. The Evolution of LC Research

4.1. The Evolutionary Stages of LC Research

4.2. The Key Dimensions of LC Research

4.3. The Four Applications of LC Tools

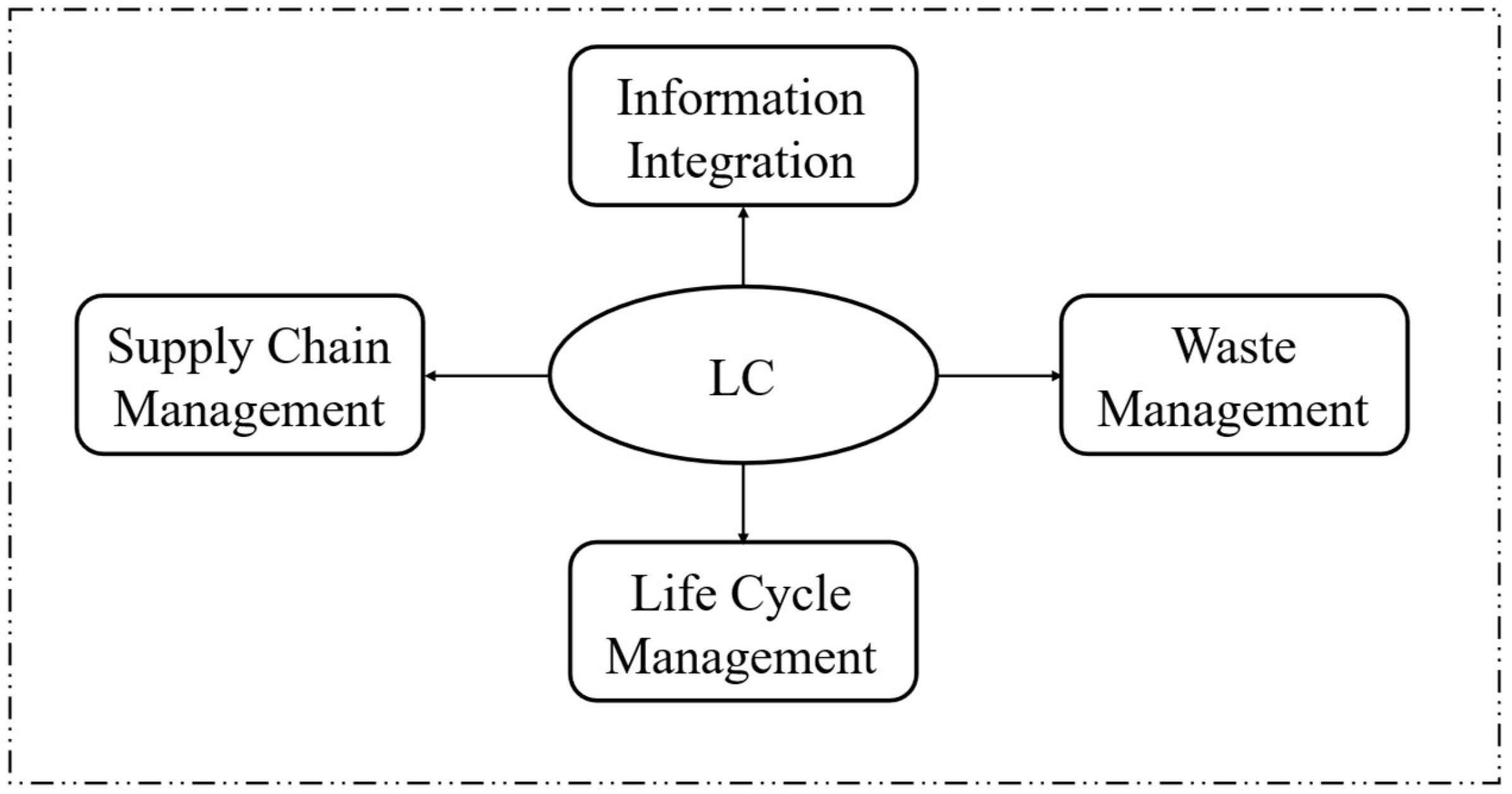

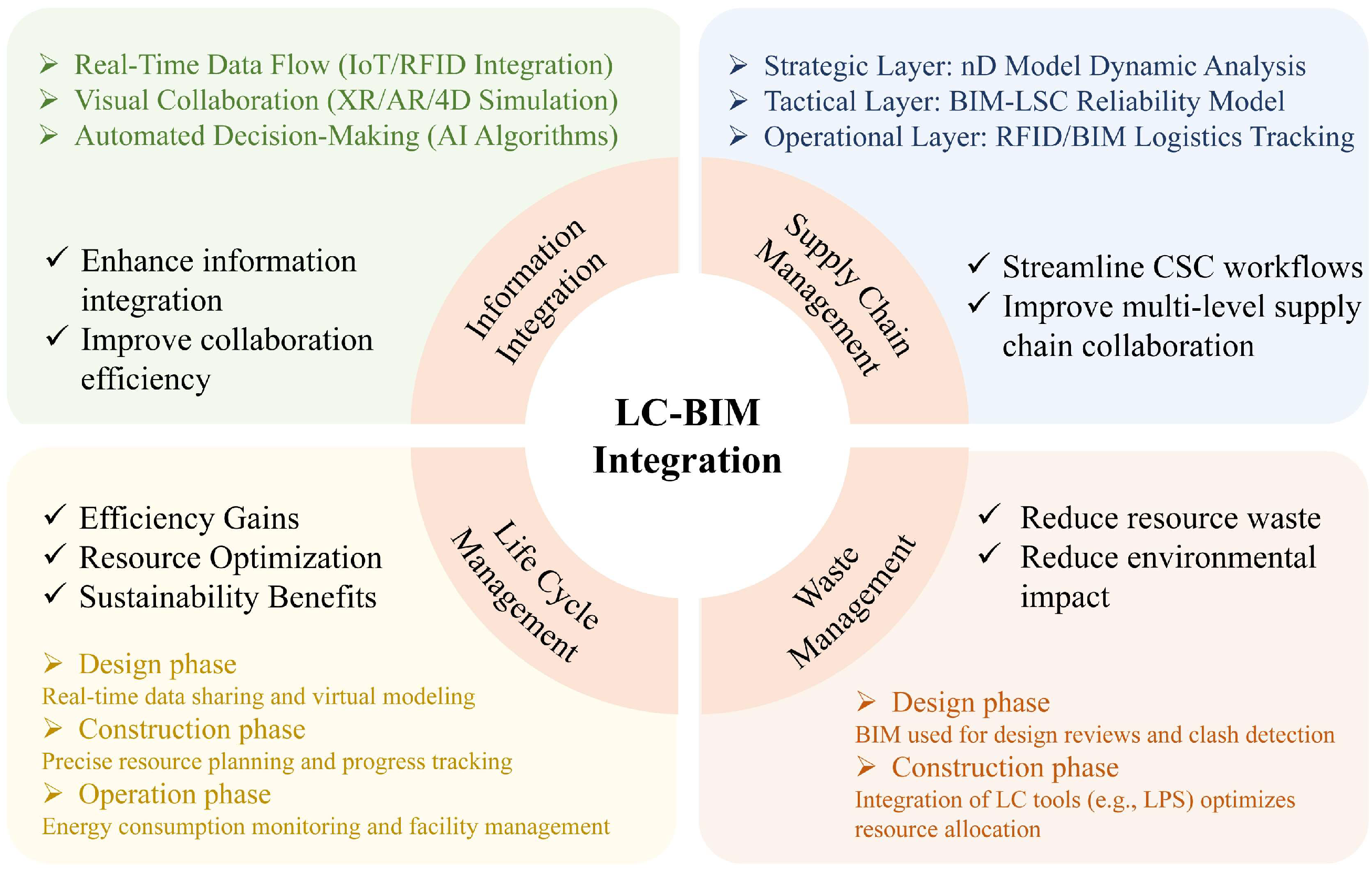

5. A Framework of the Integrated BIM-LC

5.1. Information Integration

5.2. Supply Chain Management

5.3. Waste Management

5.4. Life Cycle Management

6. Discussion

6.1. Technical Challenges in BIM-LC Integration

6.1.1. Limited System Interoperability

6.1.2. Data Inconsistency and Semantic Gaps

6.1.3. Data Privacy and Security

6.2. Application Challenges in BIM-LC Integration

6.2.1. Stakeholder Resistance

6.2.2. Lifecycle Management

6.2.3. Supply Chain Management (SCM)

6.2.4. Waste Management

6.3. Measurable Performance Indicator

7. Conclusions

- Enhanced Interoperability: develop LC-specific ontologies using semantic web technologies (e.g., RDF) to align with BIM standards like IFC.

- Integration with Emerging Technologies: leverage DT for real-time process simulation and AI for predictive analytics in SCM.

- Lifecycle-Oriented Frameworks: expand BIM-LC integration to encompass demolition and circular economy practices.

- Standardized Sustainability Metrics: establish quantifiable indicators (e.g., waste-to-value ratios) to better align BIM-LC workflows with global sustainability goals.

- Policy and Collaboration: advocate for government mandates on BIM-LC interoperability standards and incentivize IPD models to foster stakeholder collaboration.

Author Contributions

Funding

Conflicts of Interest

References

- Solaimani, S.; Sedighi, M. Toward a holistic view on lean sustainable construction: A literature review. J. Clean. Prod. 2019, 248, 119213. [Google Scholar] [CrossRef]

- Pradhan, N.L.; Chaltsev, D.; Monizza, G.P.; Matt, D.T.; Schimanski, C.P. Integrating bim with lean construction approach: Functional requirements and production management software. Autom. Constr. 2021, 132, 103969. [Google Scholar]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, V.; Rotimi, J.O.B.; Vilasini, N. Lean and BIM Implementation Barriers in New Zealand Construction Practice. Buildings 2022, 12, 1645. [Google Scholar] [CrossRef]

- El Mounla, K.; Beladjine, D.; Beddiar, K.; Mazari, B. Lean-BIM Approach for Improving the Performance of a Construction Project in the Design Phase. Buildings 2023, 13, 654. [Google Scholar] [CrossRef]

- Aziz, N.M.; Zainon, N. Driving factors for lean-BIM implementation in Malaysia’s construction industry: Qualitative interview-based study. Smart Sustain. Built Environ. 2023, 12, 872–891. [Google Scholar] [CrossRef]

- Mayouf, M.; Jones, J.; Elghaish, F.; Emam, H.; Ekanayake, E.; Ashayeri, I. Revolutionising the 4D BIM Process to Support Scheduling Requirements in Modular Construction. Sustainability 2024, 16, 476. [Google Scholar] [CrossRef]

- Fang, Y.Q.; Gao, S.; Jiang, Y.W.; Li, S.Q. BIM and lean construction in prefabricated housing construction in China. Int. J. Lean Six Sigma 2023, 14, 1329–1353. [Google Scholar] [CrossRef]

- Evans, M.; Farrell, P.; Elbeltagi, E.; Dion, H. Barriers to integrating lean construction and integrated project delivery (IPD) on construction megaprojects towards the global integrated delivery (GID) in multinational organisations: Lean IPD&GID transformative initiatives. J. Eng. Des. Technol. 2023, 21, 778–818. [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B. An overview of challenges of BIM and lean construction implementation in the New Zealand construction industry. In Proceedings of the AUBEA: Australasian Universities Building Education Association Conference 2019, Noosa, Australia, 6–8 November 2019; Volume 714. [Google Scholar]

- Hei, S.G.; Zhang, H.; Luo, S.; Zhang, R.Z.; Zhou, C.; Cong, M.; Ye, H.Y. Implementing BIM and Lean Construction Methods for the Improved Performance of a Construction Project at the Disassembly and Reuse Stage: A Case Study in Dezhou, China. Sustainability 2024, 16, 656. [Google Scholar] [CrossRef]

- Mellado, F.; Lou, E.C.W. Building information modelling, lean and sustainability: An integration framework to promote performance improvements in the construction industry. Sust. Cities Soc. 2020, 61, 13. [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, P.; Rotimi, J.O.B. Lean and BIM integration benefits construction management practices in New Zealand. Constr. Innov. 2023, 24, 106–133. [Google Scholar] [CrossRef]

- Karatas, I.; Budak, A. Influence on construction waste of the lean-building information modelling interaction. Proc. Inst. Civ. Eng.-Eng. Sustain. 2023, 177, 242–255. [Google Scholar] [CrossRef]

- Eldeep, A.M.; Farag, M.A.; Abd El-hafez, L. Using BIM as a lean management tool in construction processes—A case study. Ain Shams Eng. J. 2022, 13, 101556. [Google Scholar] [CrossRef]

- Pérez, C.T.; Costa, D.B. Increasing production efficiency through the reduction of transportation activities and time using 4D BIM simulations. Eng. Constr. Archit. Manag. 2021, 28, 2222–2247. [Google Scholar] [CrossRef]

- Ibarra, J.F.V.; Isatto, E.L.; Formoso, C.T.; Viana, D.D. BIM+Lean for integrating production and quality control at the construction site. Ambiente Construído 2022, 22, 7–25. [Google Scholar] [CrossRef]

- Moradi, S.; Sormunen, P. Integrating lean construction with BIM and sustainability: A comparative study of challenges, enablers, techniques, and benefits. Constr. Innov.-Engl. 2023, 24, 188–203. [Google Scholar] [CrossRef]

- Yan, P.; Zhang, F.M.; Zhang, F.; Geng, L.N. A Systematic Review and Conceptual Framework of Urban Infrastructure Cascading Disasters Using Scientometric Methods. Buildings 2025, 15, 1011. [Google Scholar] [CrossRef]

- Yang, Y.N.; Wei, Z.Y.; Zhang, Z.C. Stakeholder Relationship in Construction Projects: A Mixed Methods Review. Buildings 2023, 13, 3122. [Google Scholar] [CrossRef]

- Yin, J.; Aidi, H.A.; Nuzul, A.H.; Nabilah, A.B. A Bibliometrics-Based Systematic Review of Safety Risk Assessment for IBS Hoisting Construction. Buildings 2023, 13, 1853. [Google Scholar] [CrossRef]

- Mok, K.Y.; Shen, G.Q.; Yang, J. Stakeholder management studies in mega construction projects: A review and future directions. Int. J. Proj. Manag. 2015, 33, 446–457. [Google Scholar] [CrossRef]

- Oppong, G.D.; Chan, A.P.C.; Dansoh, A. A review of stakeholder management performance attributes in construction projects. Int. J. Proj. Manag. 2017, 35, 1037–1051. [Google Scholar] [CrossRef]

- Jin, R.; Zou, X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A science mapping approach based review of construction safety research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Iyiola, C.O.; Shakantu, W.; Daniel, E.I. Digital Technologies for Promoting Construction and Demolition Waste Management: A Systematic Review. Buildings 2024, 14, 3234. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, X. Research on the literature of green building based on the Web of Science: A scientometric analysis in CiteSpace (2002–2018). Sustainability 2019, 11, 3716. [Google Scholar] [CrossRef]

- Jayanetti, J.; Perera, B.; Waidyasekara, K.; Siriwardena, M. Critical Analysis of Lean Construction Maturity Models: A Systematic Literature Review. Buildings 2023, 13, 1508. [Google Scholar] [CrossRef]

- Adhi, A.B.; Muslim, F. Development of Stakeholder Engagement Strategies to Improve Sustainable Construction Implementation Based on Lean Construction Principles in Indonesia. Sustainability 2023, 15, 6053. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G. Implementing lean construction: Stabilizing work flow. Lean Constr. 1994, 2, 105–114. [Google Scholar]

- da Silva, E.N.; Mello, L.; Pinto, G.O. Challenges for lean construction adoption in the Brazilian industry: A study in construction companies, universities and class organizations. Constr. Innov. 2023, 23, 1130–1150. [Google Scholar] [CrossRef]

- Garcés, G.; Peña, C. A Review on Lean Construction for Construction Project Management. Rev. Ing. Constr. 2023, 38. [Google Scholar] [CrossRef]

- Gonzalez, V.; Alarcon, L.F.; Mundaca, F. Investigating the relationship between planning reliability and project performance. Prod. Plan. Control. 2008, 19, 461–474. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of Lean and Building Information Modeling in Construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Pérez, Y.; Avila, J.; Sánchez, O. Influence of BIM and Lean on mitigating delay factors in building projects. Results Eng. 2024, 22, 18. [Google Scholar] [CrossRef]

- Salama, T.; Salah, A.; Moselhi, O. Integrating critical chain project management with last planner system for linear scheduling of modular construction. Constr. Innov. 2021, 21, 525–554. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.Y.; Castro-Lacouture, D.; Hu, Y.Q. Lean manufacturing applications in prefabricated construction projects. Autom. Constr. 2023, 150, 16. [Google Scholar] [CrossRef]

- Piras, G.; Muzi, F.; Tiburcio, V.A. Digital Management Methodology for Building Production Optimization through Digital Twin and Artificial Intelligence Integration. Buildings 2024, 14, 2110. [Google Scholar] [CrossRef]

- Ullah, K.; Lill, I.; Witt, E. An overview of BIM adoption in the construction industry: Benefits and barriers. In Proceedings of the 10th Nordic Conference on Construction Economics and Organization, Tallinn, Estonia, 7–8 May 2019; 2019; pp. 297–303. [Google Scholar]

- Ahmad, Z.; Thaheem, M.J.; Maqsoom, A. Building information modeling as a risk transformer: An evolutionary insight into the project uncertainty. Autom. Constr. 2018, 92, 103–119. [Google Scholar] [CrossRef]

- Van Tam, N.; Quoc Toan, N.; Phong, V.V.; Durdyev, S. Impact of BIM-related factors affecting construction project performance. Int. J. Build. Pathol. Adapt. 2023, 41, 454–475. [Google Scholar] [CrossRef]

- Heigermoser, D.; de Soto, B.G.; Abbott, E.L.S.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Edwards, D.J.; Li, H.; Papadonikolaki, E.; Cao, D. Collaboration barriers in BIM-based construction networks: A conceptual model. Int. J. Proj. Manag. 2019, 37, 839–854. [Google Scholar] [CrossRef]

- Teizer, J.; Golovina, O.; Embers, S.; Wolf, M. A serious gaming approach to integrate BIM, IoT, and Lean construction in construction education. In Proceedings of the Construction Research Congress 2020: Project Management and Controls, Materials, and Contracts, Tempe, AZ, USA, 8–10 March 2020; pp. 21–30. [Google Scholar]

- Chen, Q.; Adey, B.T.; Haas, C.; Hall, D.M. Using look-ahead plans to improve material flow processes on construction projects when using BIM and RFID technologies. Constr. Innov. 2020, 20, 471–508. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A. Synergies of Lean, BIM, and Extended Reality (LBX) for Project Delivery Management. Sustainability 2023, 15, 4969. [Google Scholar] [CrossRef]

- Ratajczak, J.; Riedl, M.; Matt, D.T. BIM-based and AR application combined with location-based management system for the improvement of the construction performance. Buildings 2019, 9, 118. [Google Scholar] [CrossRef]

- Sbiti, M.; Beddiar, K.; Beladjine, D.; Perrault, R.; Mazari, B. Toward BIM and LPS Data Integration for Lean Site Project Management: A State-of-the-Art Review and Recommendations. Buildings 2021, 11, 196. [Google Scholar] [CrossRef]

- Koseoglu, O.; Sakin, M.; Arayici, Y. Exploring the BIM and lean synergies in the Istanbul Grand Airport construction project. Eng. Constr. Archit. Manag. 2018, 25, 1339–1354. [Google Scholar] [CrossRef]

- Michaud, M.; Forgues, E.-C.; Carignan, V.; Forgues, D.; Ouellet-Plamondon, C. A lean approach to optimize BIM information flow using value stream mapping. J. Inf. Technol. Constr. (ITcon) 2019, 24, 472–488. [Google Scholar] [CrossRef]

- Barkokebas, B.; Khalife, S.; Al-Hussein, M.; Hamzeh, F. A BIM-lean framework for digitalisation of premanufacturing phases in offsite construction. Eng. Constr. Archit. Manag. 2021, 28, 2155–2175. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.B.; de Soto, B.G. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 16. [Google Scholar] [CrossRef]

- Koskela, L.; Vrijhoef, R.; Dana Broft, R. Construction supply chain management through a lean lens. Success. Constr. Supply Chain. Manag. Concepts Case Stud. 2020, 38, 109–125. [Google Scholar]

- Pryke, S. Construction Supply Chain Management: Concepts and Case Studies; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 3. [Google Scholar]

- Meng, X. Lean management in the context of construction supply chains. Int. J. Prod. Res. 2019, 57, 3784–3798. [Google Scholar] [CrossRef]

- Le, P.L.; Nguyen, N.T.D. Prospect of lean practices towards construction supply chain management trends. Int. J. Lean Six Sigma 2022, 13, 557–593. [Google Scholar] [CrossRef]

- Wen, S.P.; Tang, H.D.; Ying, F.; Wu, G.D. Exploring the Global Research Trends of Supply Chain Management of Construction Projects Based on a Bibliometric Analysis: Current Status and Future Prospects. Buildings 2023, 13, 373. [Google Scholar] [CrossRef]

- Zhang, J.X.; Li, H.; Golizadeh, H.; Zhao, C.D.; Lyu, S.; Jin, R.Y. Reliability evaluation index for the integrated supply chain utilising BIM and lean approaches. Eng. Constr. Archit. Manag. 2020, 27, 997–1038. [Google Scholar] [CrossRef]

- Le, P.L.; Jarroudi, I.; Dao, T.-M.; Chaabane, A. Integrated construction supply chain: An optimal decision-making model with third-party logistics partnership. Constr. Manag. Econ. 2021, 39, 133–155. [Google Scholar] [CrossRef]

- Papadonikolaki, E.; Wamelink, H. Inter-and intra-organizational conditions for supply chain integration with BIM. Build. Res. Inf. 2017, 45, 649–664. [Google Scholar] [CrossRef]

- Nikakhtar, A.; Hosseini, A.A.; Wong, K.Y.; Zavichi, A. Application of lean construction principles to reduce construction process waste using computer simulation: A case study. Int. J. Serv. Oper. Manag. 2015, 20, 461–480. [Google Scholar] [CrossRef]

- Grilo, A.; Jardim-Goncalves, R. Value proposition on interoperability of BIM and collaborative working environments. Autom. Constr. 2010, 19, 522–530. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply chain management for prefabricated building projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Ding, L.; Zhou, Y.; Akinci, B. Building Information Modeling (BIM) application framework: The process of expanding from 3D to computable nD. Autom. Constr. 2014, 46, 82–93. [Google Scholar] [CrossRef]

- Le, P.L.; Elmughrabi, W.; Dao, T.-M.; Chaabane, A. Present focuses and future directions of decision-making in construction supply chain management: A systematic review. Int. J. Constr. Manag. 2020, 20, 490–509. [Google Scholar] [CrossRef]

- Deng, Y.; Gan, V.J.; Das, M.; Cheng, J.C.; Anumba, C. Integrating 4D BIM and GIS for construction supply chain management. J. Constr. Eng. Manag. 2019, 145, 04019016. [Google Scholar] [CrossRef]

- Li, X.; Shen, G.Q.; Wu, P.; Fan, H.; Wu, H.; Teng, Y. RBL-PHP: Simulation of lean construction and information technologies for prefabrication housing production. J. Manag. Eng. 2018, 34, 04017053. [Google Scholar] [CrossRef]

- Babalola, O.; Ibem, E.O.; Ezema, I.C.; Olanipekun, A. Assessment of the role of lean construction practices in environmental sustainability. In Proceedings of the 3rd International Conference on Science and Sustainable Development (ICSSD 2019) “Science, Technology and Research: Keys to Sustainable Development”, Ota, Nigeria, 6–8 May 2019; p. 012002. [Google Scholar]

- Terreno, S.; Asadi, S.; Anumba, C. An exploration of synergies between lean concepts and BIM in FM: A review and directions for future research. Buildings 2019, 9, 147. [Google Scholar] [CrossRef]

- Moghadam, M. Lean-Mod: An Approach to Modular Construction Manufacturing Production Efficiency Improvement. Ph.D. Thesis, Faculty of Graduate Studies and Research, Edmonton, AL, Canada, 2014. [Google Scholar]

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. Analyzing the association between lean design management practices and BIM uses in the design of construction projects. J. Constr. Eng. Manag. 2021, 147, 04021010. [Google Scholar] [CrossRef]

- Wong, J.H.; Rashidi, A.; Arashpour, M. Evaluating the Impact of Building Information Modeling on the Labor Productivity of Construction Projects in Malaysia. Buildings 2020, 10, 66. [Google Scholar] [CrossRef]

- Moballeghi, E.; Pourrostam, T.; Abbasianjahromi, H.; Makvandi, P. Assessing the Effect of Building Information Modeling System (BIM) Capabilities on Lean Construction Performance in Construction Projects Using Hybrid Fuzzy Multi-criteria Decision-Making Methods. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 47, 1871–1891. [Google Scholar] [CrossRef]

- Gbadamosi, A.-Q.; Mahamadu, A.-M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-Based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Mandujano R, M.G.; Alarcon, L.; Kunz, J.; Mourgues, C. Identifying waste in virtual design and construction practice from a Lean Thinking perspective: A meta-analysis of the literature. Rev. Construcción 2016, 15, 107–118. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Mathur, A. Synergising lean objectives through BIM to enhance productivity and performance. Int. J. Product. Perform. Manag. 2022, 72, 2135–2154. [Google Scholar] [CrossRef]

- Li, S.; Fang, Y.; Wu, X. A systematic review of lean construction in Mainland China. J. Clean. Prod. 2020, 257, 120581. [Google Scholar] [CrossRef]

- Aquere, A.L.; Dinis-Carvalho, J.; Lima, R.M. Project Cell: Cellular organization of the building design process. J. Constr. Eng. Manag. 2013, 139, 538–546. [Google Scholar] [CrossRef]

- Moradi, S.; Sormunen, P. Lean and Sustainable Project Delivery in Building Construction: Development of a Conceptual Framework. Buildings 2022, 12, 1757. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.M.; Aye, L. Lean Practices Using Building Information Modeling (BIM) and Digital Twinning for Sustainable Construction. Sustainability 2021, 13, 161. [Google Scholar] [CrossRef]

- Albalkhy, W.; Sweis, R.; Jai, H.; Lafhaj, Z. The integration between Lean Construction and the Internet of Things (IoT): A systematic literature review. Smart Sustain. Built Environ. 2024, 31. [Google Scholar] [CrossRef]

- Likita, A.J.; Jelodar, M.B.; Vishnupriya, V.; Rotimi, J.O.B. A guideline for BIM and lean integrated construction practice. Smart Sustain. Built Environ. 2025, 28. [Google Scholar] [CrossRef]

- Aburumman, M.O.; Sweis, R.; Sweis, G.J. Investigating building information modelling (BIM) and lean construction: The potential BIM-lean interactions synergy and integration in the Jordanian construction industry. Int. J. Lean Six Sigma 2024, 15, 400–438. [Google Scholar] [CrossRef]

- Falcao, T.F.; Carvalho, M.T.M.; Brandstetter, M. Proposal of an Artefact in the Design of BIM Systematizing Lean Concepts and Tools through Neural Networks. Buildings 2023, 13, 1020. [Google Scholar] [CrossRef]

- Akter, J.; Datta, S.D.; Islam, M.; Tayeh, B.A.; Sraboni, S.A.; Das, N. Assessment and analysis of the effects of implementing building information modelling as a lean management tool in construction management. Int. J. Build. Pathol. Adapt. 2024, 18. [Google Scholar] [CrossRef]

- Andújar-Montoya, M.D.; Galiano-Garrigós, A.; Echarri-Iribarren, V.; Rizo-Maestre, C. BIM-LEAN as a Methodology to Save Execution Costs in Building Construction-An Experience under the Spanish Framework. Appl. Sci. 2020, 10, 1913. [Google Scholar] [CrossRef]

- Nie, P.; Dahanayake, K.C.; Sumanarathna, N. Exploring UAE’s transition towards circular economy through construction and demolition waste management in the pre-construction stage-A case study approach. Smart Sustain. Built Environ. 2024, 13, 246–266. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Faria, P.S.; Sotelino, E.D.; do Carmo, C.S.T.; Nascimento, D.L.M. Evaluating Construction Projects’ Alternatives Using Lean Construction and Sustainability Principles in an Information Model Framework. Sustainability 2023, 15, 6517. [Google Scholar] [CrossRef]

- Chen, J.J.; Lu, W.S.; Lou, J.F. Automatic concrete defect detection and reconstruction by aligning aerial images onto semantic-rich building information model. Comput.-Aided Civil Infrastruct. Eng. 2023, 38, 1079–1098. [Google Scholar] [CrossRef]

- Arayici, Y.; Tokdemir, O.B.; Kassem, M. A quantitative, evidence-based analysis of correlations between lean construction and building information modelling. Smart Sustain. Built Environ. 2023, 12, 975–1001. [Google Scholar] [CrossRef]

- Baiburin, A.K. Civil Engineering Quality Assessment in Terms of Construction Safety Index. In Proceedings of the International Conference on Industrial Engineering (ICIE), Saint Petersburg, Russia, 16–19 May 2017; pp. 800–806. [Google Scholar]

- Villaschi, F.S.; Carvalho, J.P.; Bragança, L. BIM-Based Method for the Verification of Building Code Compliance. Appl. Syst. Innov. 2022, 5, 64. [Google Scholar] [CrossRef]

- Valinejadshoubi, M.; Moselhi, O.; Iordanova, I.; Valdivieso, F.; Shakibabarough, A.; Bagchi, A. The Development of an Automated System for a Quality Evaluation of Engineering BIM Models: A Case Study. Appl. Sci. 2024, 14, 3244. [Google Scholar] [CrossRef]

- Maraqa, M.J.; Sacks, R.; Spatari, S. Quantitative assessment of the impacts of BIM and lean on process and operations flow in construction projects. Eng. Constr. Archit. Manag. 2021, 28, 2176–2198. [Google Scholar] [CrossRef]

- Kifokeris, D.; Tezel, A. Blockchain and lean construction: An exploration of bidirectional synergies and interactions. Archit. Eng. Des. Manag. 2025, 21, 171–189. [Google Scholar] [CrossRef]

| Journal Title | Number of Selected Papers |

|---|---|

| Buildings | 17 |

| Automation in Construction | 16 |

| Engineering, Construction and Architectural Management | 15 |

| Sustainability | 13 |

| Journal of Construction Engineering and Management | 9 |

| Construction Innovation-England | 7 |

| International Journal of Lean Six Sigma | 4 |

| Canadian Journal of Civil Engineering | 3 |

| Journal of Cleaner Production | 3 |

| Journal of Civil Engineering and Management | 2 |

| Journal of Building Engineering | 2 |

| Journal of Management in Engineering | 1 |

| Ain Shams Engineering Journal | 1 |

| Developments in the Built Environment | 1 |

| Computer-Aided Civil and Infrastructure Engineering | 1 |

| Tools | Information Integration | Supply Chain Management | Waste Management | Life Cycle Management |

|---|---|---|---|---|

| 5s onsite management | √ | √ | √ | |

| Justin-time (JIT) | √ | √ | √ | √ |

| Value based management (VBM)or value stream mapping (VSM) | √ | √ | ||

| Concurrent engineering (CE) | √ | √ | ||

| Lean Six Sigma | √ | |||

| Prefabrication | √ | √ | ||

| Virtual design construction (VDC) | √ | √ | √ | |

| Integrated project delivery | √ | √ | ||

| Target value design (TVD) | √ | |||

| Last planner system (LPS) | √ | |||

| Benchmarking | √ | |||

| Pull scheduling/planning | √ | √ | √ | |

| Kanban system | √ | √ | ||

| Total quality management (TQM) | √ | √ | ||

| Continuous flow (CF) | √ | √ |

| Dimension | Performance Indicators | Measurement Focus |

|---|---|---|

| Economic | Cost Saving Indicator Budget Deviation Index | Measures avoided costs [83] and budget accuracy [84] |

| Environmental Sustainability | CDW Generation Rate/Quantity CDW Recycling Rate Total Carbon Emissions Carbon Emission Intensity (CEI) | Tracks waste reduction [85], recycling efficiency [85,86], and carbon footprint per unit area [10,87] |

| Quality | Defect Rate (DR) Zero Defect Rate Compliance Metrics BIM Model Average Quality Score (AQS) | Quantifies defects [88,89,90], regulatory adherence [91], and BIM model accuracy/consistency for decision-making [92] |

| Schedule | Percent Plan Complete (PPC) CFI Index Time Savings Delays Avoided | Evaluates on-time task completion [34,65,93], process efficiency [93], reduced cycle time, and avoided rework delays [84] |

| Technology Innovation | Data Interoperability Technology Integration Index | Assesses data-sharing efficiency and integration depth with emerging tech (e.g., DT [78], blockchain [94], and AR/XR [44]) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Chen, C.; Liu, X.; Zhang, Z. Integration of Lean Construction and BIM in Sustainable Built Environment: A Review and Future Research Directions. Buildings 2025, 15, 2411. https://doi.org/10.3390/buildings15142411

Yang Y, Chen C, Liu X, Zhang Z. Integration of Lean Construction and BIM in Sustainable Built Environment: A Review and Future Research Directions. Buildings. 2025; 15(14):2411. https://doi.org/10.3390/buildings15142411

Chicago/Turabian StyleYang, Yingnan, Chunxiao Chen, Xin Liu, and Zhicheng Zhang. 2025. "Integration of Lean Construction and BIM in Sustainable Built Environment: A Review and Future Research Directions" Buildings 15, no. 14: 2411. https://doi.org/10.3390/buildings15142411

APA StyleYang, Y., Chen, C., Liu, X., & Zhang, Z. (2025). Integration of Lean Construction and BIM in Sustainable Built Environment: A Review and Future Research Directions. Buildings, 15(14), 2411. https://doi.org/10.3390/buildings15142411