Systematic Methodology for Estimating the Social Dimension of Construction Projects—Assessing Health and Safety Risks Based on Project Budget Analysis

Abstract

1. Introduction

1.1. Risk Identification Tools

1.2. Prevention Through Design

2. Materials and Methods

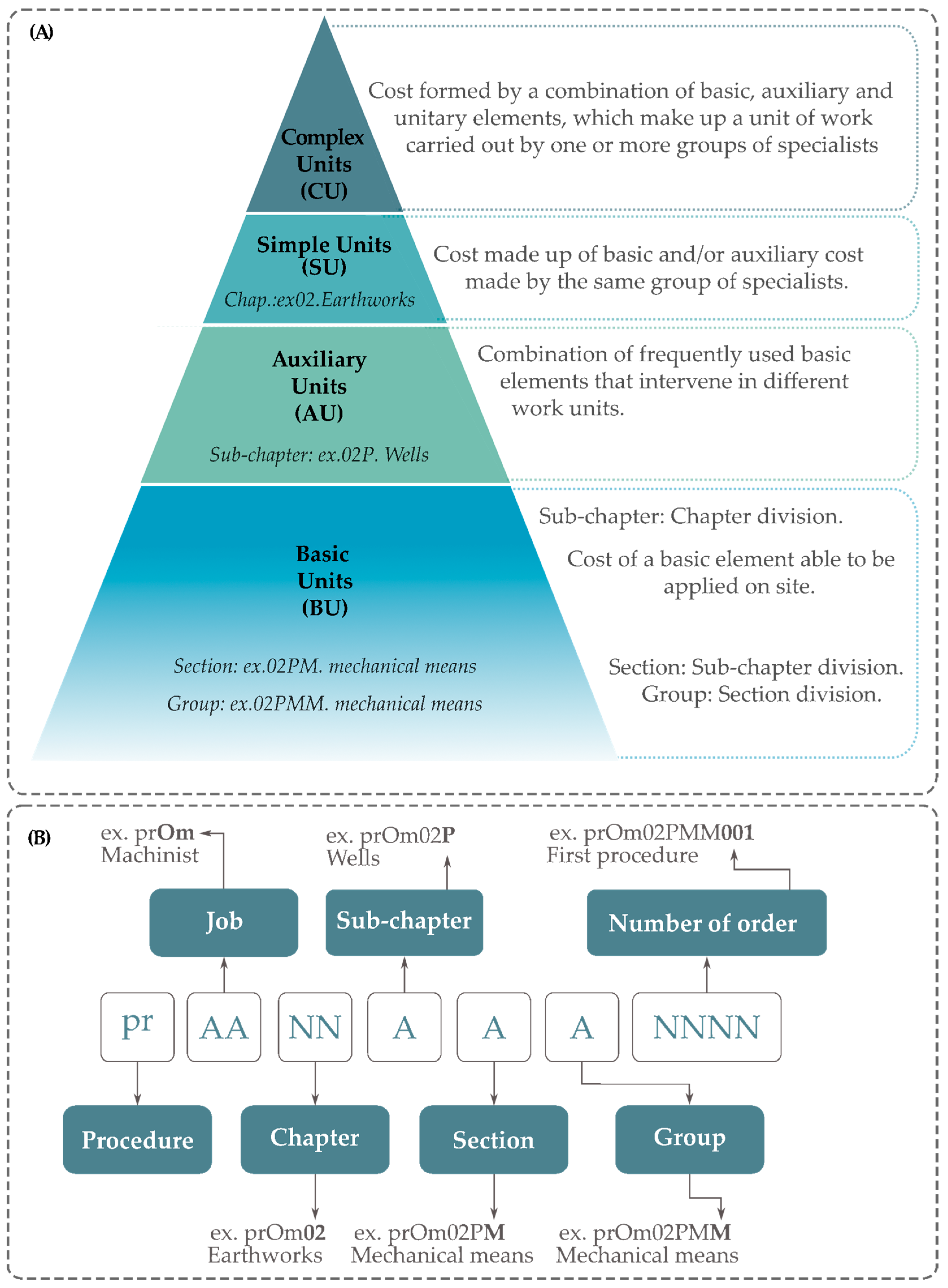

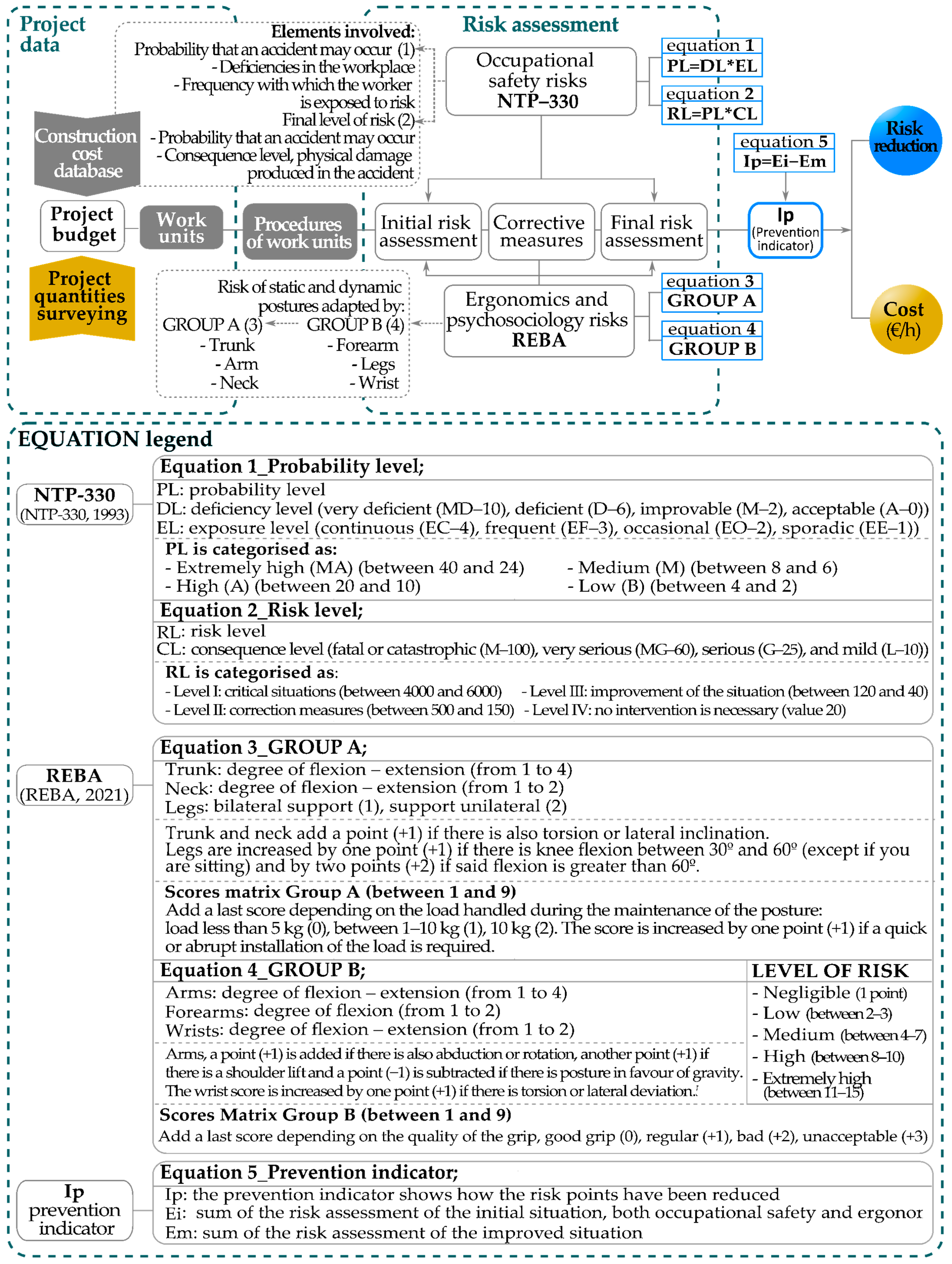

- Project data: Analysis and identification of the different work units contained in the project budget. These work units provide information on worker hours and the type of work they perform (Figure 1).

- Procedures of work units: The definition of the work procedures associated with the work units contained in the budget.

- Risk assessment: For the assessment of accident risks, the holistic model proposed by Marrero et al. (2024) [29] is employed. This assessment provides the initial risk level of the work procedures, before incorporating corrective measures. Once the corrective measures are applied, the risk assessment is conducted again. (Figure 1).

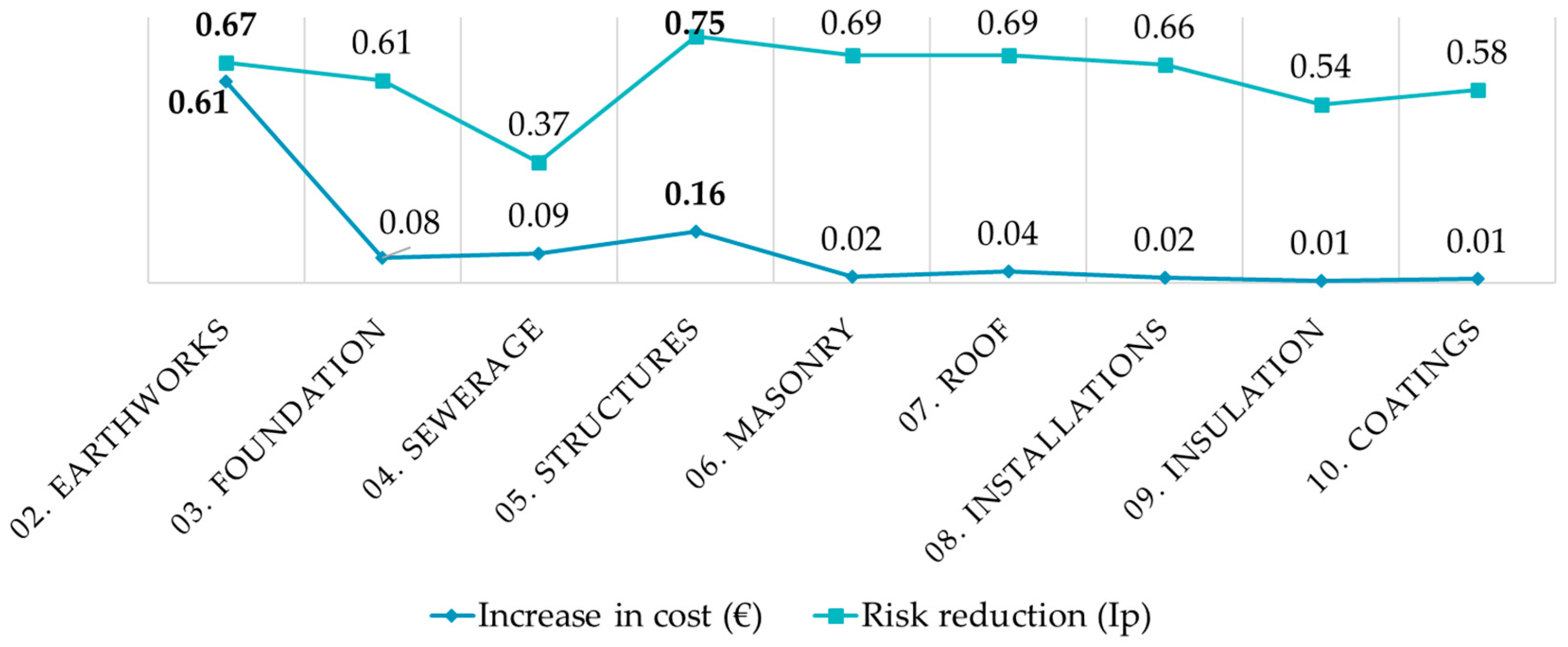

- Prevention Indicator (IP): The qualitative and quantitative evaluation conducted on the risks identified in their initial state and in their final state, after the application of the corrective measures, allows the development of the prevention indicator, which provides two results in parallel (Figure 1):

- Risk reduction: This indicates the reduction in the level of risk that has been achieved with the incorporation of the corrective measures applied.

- Cost (EUR): The determination of the economic cost of the corrective measures applied to achieve the reduction in the level of risk.

2.1. Classification of Construction Work

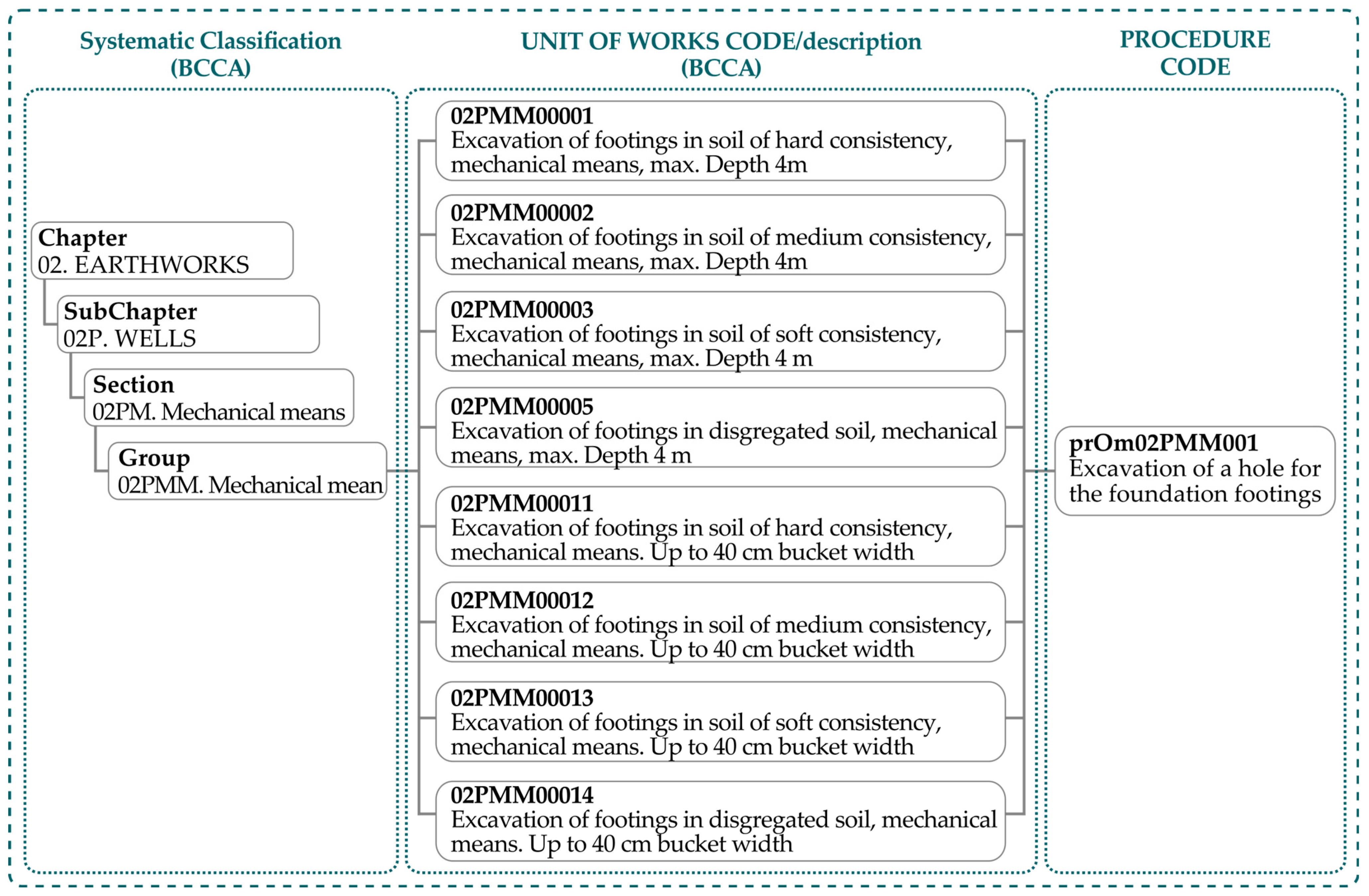

2.2. Standardisation and Classification of Working Procedures

2.3. Project Data

2.4. Procedures of Work Units

2.5. Risk Assessment

2.6. Prevention Indicator (Ip)

3. Case Study

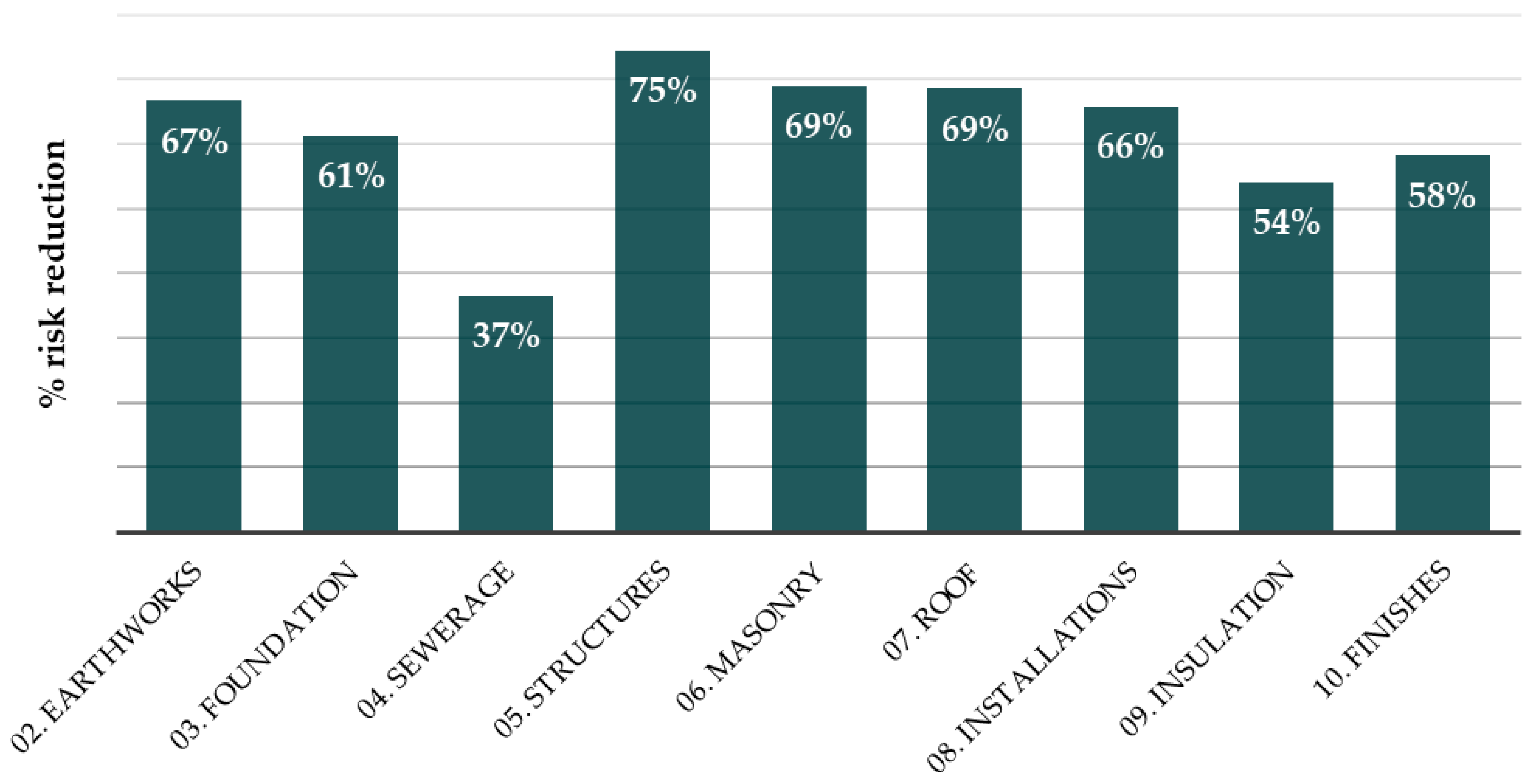

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1

| Prevention Measures per Chapter | Prevention Measures per Type | |

|---|---|---|

| 02. Earthworks | 06. Masonry | Collective protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| |

| ||

| ||

| ||

| 03. Foundation | 07. Roofs | Individual Protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| |

|

| |

|

| |

| 04. Sewerage system | 08. Installations |

|

|

|

|

|

|

|

|

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| 05. Structures | 09. Insulation | Signalling and delimitation of spaces |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| |

| 10. Coatings | |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| ||

| Work Units | Budget | |||

|---|---|---|---|---|

| Procedure | Quantity (Unit) | Unit Cost (EUR/Unit) | Cost (EUR) | |

| Chapter 02, Earthworks | ||||

| Excavation, in shafts, with mechanical means up to 4 m and loading by truck | ||||

| 02PMM00012 | Digging in wells and loading by truck | |||

| PrOm02PMM001 | Backhoe excavation | |||

| Situation corrected | ||||

| Technical factor | ||||

| Machines | Backhoe loader | 0.00 | ||

| Auxiliary means | ||||

| Installations | ||||

| Collective protections | ||||

| Personal protections | Safety helmet | 1.00 | 1.69 | 1.69 |

| Reflective vest | 1.00 | 2.77 | 2.77 | |

| Non-slip safety boots | 1.00 | 27.79 | 27.79 | |

| Signage and delimitation of spaces | Perimeter shoulder | 50.00 | 1.75 | 87.50 |

| Delimit passage areas | 20.00 | 1.75 | 35.00 | |

| Organizational factor | Cleaning of the pits | 0.00 | ||

| 5 min breaks every 30 min | 0.00 | |||

| Environmental factor | ||||

| prAl02PMM001 | Profiling of bottoms and sides | |||

| Situation corrected | ||||

| Technical factor | ||||

| Machines | ||||

| Auxiliary means | Ladder | 0.00 | ||

| Installations | ||||

| Collective protections | ||||

| Personal protections | Safety helmet | 1.00 | 1.69 | 1.69 |

| Reflective vest | 1.00 | 2.77 | 2.77 | |

| Non-slip and safety boots | 1.00 | 27.79 | 27.79 | |

| Safety gloves | 1.00 | 4.15 | 4.15 | |

| Lumbar girdle | 1.00 | 11.99 | 11.99 | |

| Signage and delimitation of spaces | Delimit passage areas | 0.00 | ||

| Perimeter shoulder | 0.00 | |||

| Organizational factor | Cleaning of the pits | 0.00 | ||

| 5 min breaks every 30 min | 0.00 | |||

| Environmental factor | ||||

| Total cost of earthmoving prevention measures | Total cost corrected situation | 203.14 | ||

| CHAPTER | ACCD Unit Code | Code of Procedures | Ip | % Risk Reduction | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | Initial Risk | Final Risk | By Procedures | By Work Unit | By Chapter | Total | ||||

| 02 Earthworks | ||||||||||

| Digging foundation pads | 02PMM00012 | prOm02PMM001 | 4 | 15 | 1 | 5 | 75% | 67% | 67% | 65% |

| prAl02PMM001 | 11 | 4 | 64% | |||||||

| 03 Foundation | ||||||||||

| Concrete slab | 03ACC00010 | prFe03ACC001 | 23 | 9 | 61% | 61% | 61% | |||

| 03HAZ00002 | prHo03HAZ001 | 17 | 6 | 65% | 65% | |||||

| Contour beams | 05HAC00010 | prFe05HAC002 | 26 | 10 | 62% | 62% | ||||

| 03ERM00001 | prEn03ERM001 | 14 | 7 | 50% | 50% | |||||

| 05HHJ00003 | prHo05HHJ002 | 17 | 8 | 53% | 53% | |||||

| 04 Sewer system | ||||||||||

| Buried sewer system | 04EAS00002 | prAl04EAS001 | 11 | 41 | 8 | 26 | 27% | 37% | 37% | |

| prAl04EAS002 | 19 | 10 | 47% | |||||||

| prAl04EAS003 | 11 | 8 | 27% | |||||||

| 04EAP90002 | prAl04EAP001 | 13 | 40 | 8 | 23 | 38% | 43% | |||

| prAl04EAP002 | 17 | 7 | 59% | |||||||

| prAl04EAP003 | 10 | 8 | 20% | |||||||

| 04ECP90007 | prAl04ECP001 | 14 | 46 | 5 | 17 | 64% | 63% | |||

| prAl04ECP002 | 18 | 7 | 61% | |||||||

| prAl04ECP003 | 14 | 5 | 64% | |||||||

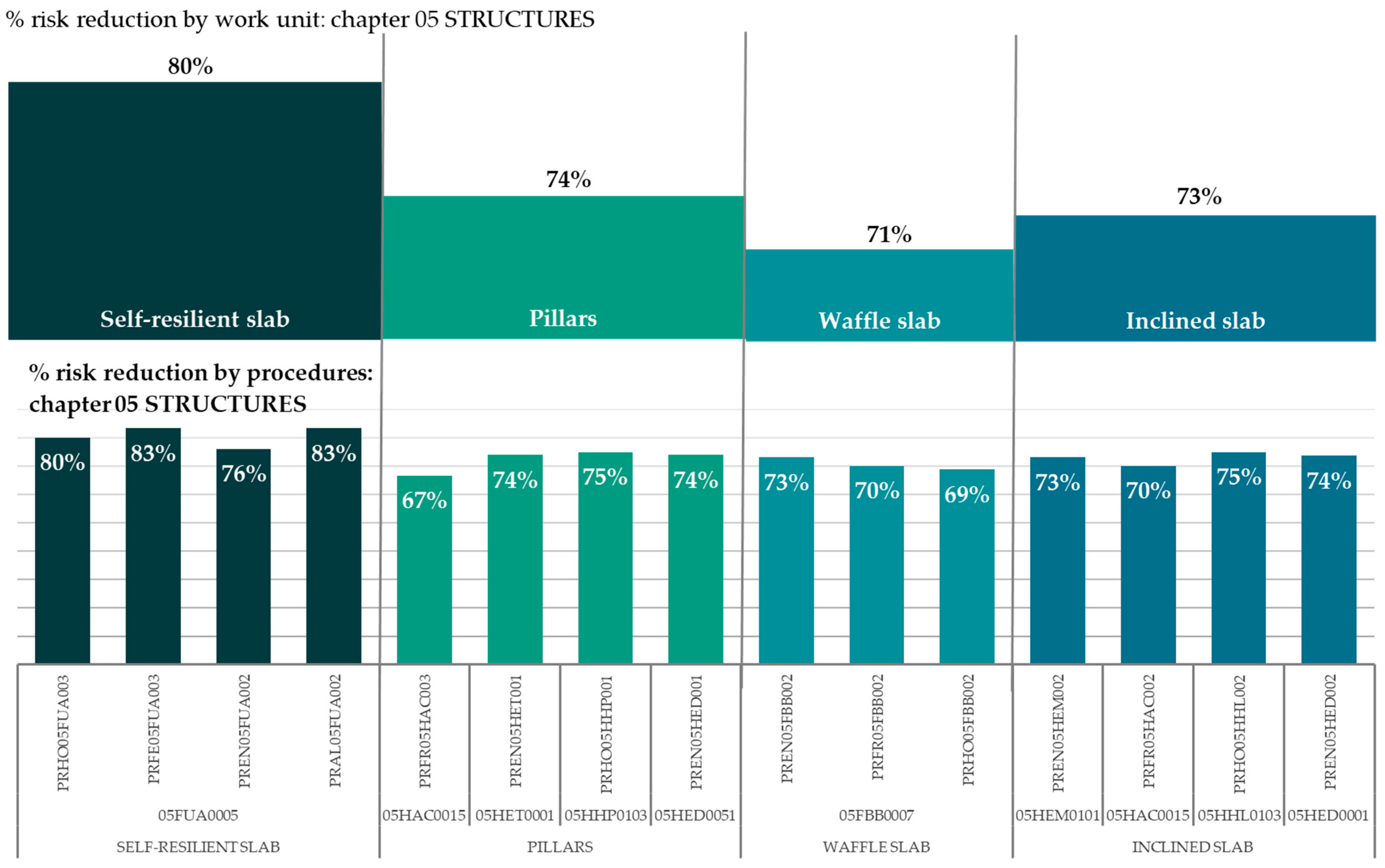

| 05 Structure | ||||||||||

| Self-resilient slab | 05FUA00005 | prAl05FUA002 | 18 | 87 | 3 | 17 | 83% | 80% | 75% | |

| prEn05FUA002 | 25 | 6 | 76% | |||||||

| prFe05FUA003 | 24 | 4 | 83% | |||||||

| prHo05FUA003 | 20 | 4 | 80% | |||||||

| Pillars | 05HAC00015 | prFe05HAC003 | 18 | 6 | 67% | 67% | ||||

| 05HET00001 | prEn05HET001 | 23 | 6 | 74% | 74% | |||||

| 05HHP00103 | prHo05HHP001 | 16 | 4 | 75% | 75% | |||||

| 05HED00051 | prEn05HED001 | 23 | 6 | 74% | 74% | |||||

| Waffle slab | 05FBB00007 | prEn05FBB002 | 26 | 62 | 7 | 18 | 73% | 71% | ||

| prFe05FBB002 | 20 | 6 | 70% | |||||||

| prHo05FBB002 | 16 | 5 | 69% | |||||||

| Inclined slab | 05HEM00101 | prEn05HEM002 | 26 | 7 | 73% | 73% | ||||

| 05HAC00015 | prFe05HAC002 | 20 | 6 | 70% | 70% | |||||

| 05HHL00103 | prHo05HHL002 | 16 | 4 | 75% | 75% | |||||

| 05HED00001 | prEn05HED002 | 19 | 5 | 74% | 74% | |||||

| 06 Masonry work | ||||||||||

| Enclosure | 06LPM00001 | prAl06LPM001 | 15 | 5 | 67% | 67% | 69% | |||

| 06LPM00004 | prAl06LPM002 | 13 | 5 | 62% | 62% | |||||

| Partitions | 06DSS00001 | prAl06DSS001 | 17 | 4 | 76% | 76% | ||||

| 07 Roof | ||||||||||

| Flat roof | 06LPM00001 | prAl06LPM001 | 17 | 6 | 65% | 65% | 69% | |||

| 07HNF00021 | prAl07HNF001 | 10 | 65 | 4 | 11 | 60% | 68% | |||

| prIm07HNF002 | 17 | 4 | 76% | |||||||

| prAl07HNF003 | 10 | 3 | 70% | |||||||

| prAl07HNF004 | 10 | 0 | 70% | |||||||

| prAl07HNF005 | 10 | 0 | 70% | |||||||

| prAl07HNF006 | 8 | 0 | 50% | |||||||

| 10CEE00001 | prAl10CEE001 | 11 | 6 | 45% | 45% | |||||

| 07HNE00001 | prAl07HNE001 | 18 | 44 | 3 | 10 | 83% | 77% | |||

| prIm07HNE002 | 16 | 4 | 75% | |||||||

| prAl07HNE003 | 10 | 3 | 70% | |||||||

| 08 Installations | ||||||||||

| Electricity Installation | 08ECC00001 | prAl08ECC001 | 16 | 27 | 8 | 14 | 79% | 48% | 66% | |

| prEl08ECC001 | 11 | 6 | 45% | |||||||

| 08EDD00004 | prAl08EDD001 | 17 | 28 | 8 | 14 | 79% | 50% | |||

| prEl08EDD001 | 11 | 6 | 45% | |||||||

| 08ELL00001 | prAl08ELL001 | 15 | 25 | 7 | 12 | 79% | 52% | |||

| prEl08ELL001 | 10 | 5 | 50% | |||||||

| 08ETT00003 | prAl08ETT001 | 15 | 25 | 0 | 0 | 79% | 52% | |||

| prEl08ETT001 | 10 | 0 | 50% | |||||||

| 8EWW00040 | prAl08EWW001 | 12 | 18 | 5 | 7 | 79% | 61% | |||

| prEl08EWW001 | 6 | 2 | 67% | |||||||

| 08EID00007 | prEl08EID001 | 5 | 2 | 60% | 60% | |||||

| 08EIM00102 | prEl08EIM001 | 5 | 2 | 60% | 60% | |||||

| Water Installation | 08FAC00204 | prFo08FAC001 | 11 | 3 | 73% | 73% | ||||

| 08FAC00410 | prFo08FAC002 | 11 | 30 | 3 | 9 | 73% | 70% | |||

| prAl08FAC001 | 19 | 6 | 68% | |||||||

| 08FDP00022 | prFo08FDP001 | 12 | 31 | 3 | 8 | 75% | 74% | |||

| prAl08FDP001 | 19 | 5 | 74% | |||||||

| 08FDP00050 | prFo08FDP002 | 12 | 31 | 3 | 8 | 75% | 74% | |||

| prAl08FDP002 | 19 | 5 | 74% | |||||||

| 08FDP00091 | prFo08FDP003 | 12 | 31 | 3 | 8 | 75% | 74% | |||

| prAl08FDP003 | 19 | 5 | 74% | |||||||

| 08FFP90300 | prFo08FFP001 | 13 | 33 | 5 | 11 | 62% | 67% | |||

| prAl08FFP001 | 20 | 6 | 70% | |||||||

| 08FFP90320 | prFo08FFP002 | 13 | 33 | 5 | 11 | 62% | 67% | |||

| prAl08FFP002 | 20 | 6 | 70% | |||||||

| 08FFP90830 | prFo08FFP003 | 15 | 35 | 5 | 11 | 67% | 69% | |||

| prAl08FFP003 | 20 | 6 | 70% | |||||||

| 08FGN00103 | prFo08FGN001 | 12 | 3 | 75% | 75% | |||||

| 08FSW00101 | prFo08FSW001 | 11 | 27 | 3 | 6 | 73% | 78% | |||

| prAl08FSW001 | 16 | 3 | 81% | |||||||

| 08FTC00651 | prFo08FTC001 | 13 | 32 | 5 | 11 | 62% | 66% | |||

| prAl08FTC001 | 19 | 6 | 68% | |||||||

| 08FVL00003 | prFo08FVL001 | 12 | 3 | 75% | 75% | |||||

| 08FVW00002 | prFo08FVW001 | 12 | 3 | 75% | 75% | |||||

| 09 Insulation | ||||||||||

| Insulation | 09TPP90220 | prAl09TPP001 | 32 | 50 | 14 | 23 | 56% | 54% | 54% | |

| prAm09TPP002 | 18 | 9 | 50% | |||||||

| Finishes | ||||||||||

| Trimming and plastering walls | 10CGG00006 | prYe10CGG002 | 15 | 9 | 40% | 40% | 58% | |||

| Tiling | 10AAE00023 | prAt10AAE002 | 29 | 14 | 52% | 52% | ||||

| Ceramic flooring | 10SCS00003 | prSo10SCS001 | 19 | 7 | 63% | 63% | ||||

| Terrazzo flooring | 10STS00001 | prSo10STS001 | 19 | 7 | 63% | 63% | ||||

| Plaster ceiling | 10TET00005 | prEs10TET001 | 18 | 8 | 56% | 56% | ||||

| Trimming and plastering walls | 10CGG00005 | prYe10CGG001 | 15 | 9 | 40% | 40% | ||||

| Tiles of staircase | 10PNP00001 | prSo10PNP001 | 16 | 5 | 69% | 69% | ||||

| 10PNZ00001 | prSo10PNZ001 | 16 | 5 | 69% | 69% | |||||

| Monolayer | 10CWW00006 | prAl10CWW001 | 15 | 5 | 67% | 67% | ||||

| 10CWW00012 | prAl10CWW002 | 15 | 5 | 67% | 67% | |||||

| 10CWW00021 | prAl10CWW003 | 15 | 5 | 67% | 67% | |||||

References

- Hollnagel, E. Risk + Barriers = Safety? Saf. Sci. 2008, 46, 221–229. [Google Scholar] [CrossRef]

- Winge, S.; Albrechtsen, E.; Arnesen, J. A Comparative Analysis of Safety Management and Safety Performance in Twelve Construction Projects. J. Saf. Res. 2019, 71, 139–152. [Google Scholar] [CrossRef] [PubMed]

- Ahn, H.; Son, S.; Park, K.; Kim, S. Cost Assessment Model for Sustainable Health and Safety Management of High-Rise Residential Buildings in Korea. J. Asian Archit. Build. Eng. 2021, 21, 689–700. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Behm, M.; Rajendran, S. Design’s Role in Construction Accident Causality and Prevention: Perspectives from an Expert Panel. Saf. Sci. 2008, 46, 675–691. [Google Scholar] [CrossRef]

- Gambatese, J.; Gibb, A.; Bust, P.; Behm, M. Expanding prevention through design (PTD) in practice: Innovation, change, and a path forward. J. Constr. Proj. Manag. Innov. 2017, 7, 1995–2006. Available online: https://hdl.handle.net/10520/EJC-c23fb9e63 (accessed on 22 February 2025).

- Jin, Z.; Gambatese, J.; Karakhan, A.; Nnaji, C. Analysis of Prevention through Design Studies in Construction: A Subject Review. J. Saf. Res. 2023, 84, 138–154. [Google Scholar] [CrossRef]

- BOE.Es-BOE-A-1997-22614; RD_1627/97 Real Decreto 1627/1997, de 24 de Octubre, Por El Que Se Establecen Disposiciones Mínimas de Seguridad y de Salud En Las Obras de Construcción. Ministerio de la Presidencia: Madrid, Spain, 1997.

- Ruiz-Pérez, M.R.; Alba-Rodríguez, M.D.; Marrero, M. Evaluation of Water Footprint of Urban Renewal Projects. Case Study in Seville, Andalusia. Water Res. 2022, 221, 118715. [Google Scholar] [CrossRef]

- Freire-Guerrero, A.; Alba-Rodríguez, M.D.; Marrero, M. A Budget for the Ecological Footprint of Buildings Is Possible: A Case Study Using the Dwelling Construction Cost Database of Andalusia. Sustain. Cities Soc. 2019, 51, 101737. [Google Scholar] [CrossRef]

- Swuste, P.; Frijters, A.; Guldenmund, F. Is It Possible to Influence Safety in the Building Sector?: A Literature Review Extending from 1980 until the Present. Saf. Sci. 2012, 50, 1333–1343. [Google Scholar] [CrossRef]

- Zalk, D.M.; Spee, T.; Gillen, M.; Lentz, T.J.; Garrod, A.; Evans, P.; Swuste, P. Review of Qualitative Approaches for the Construction Industry: Designing a Risk Management Toolbox. Saf. Health Work 2011, 2, 105–121. [Google Scholar] [CrossRef]

- Forteza, F.J.; Sesé, A.; Carretero-Gómez, J.M. CONSRAT. Construction Sites Risk Assessment Tool. Saf. Sci. 2016, 89, 338–354. [Google Scholar] [CrossRef]

- Karakhan, A.A.; Gambatese, J.A. Identification, Quantification, and Classification of Potential Safety Risk for Sustainable Construction in the United States. J. Constr. Eng. Manag. 2017, 143, 04017018. [Google Scholar] [CrossRef]

- Dewlaney, K.S.; Hallowell, M.R.; Fortunato, B.R. Safety Risk Quantification for High Performance Sustainable Building Construction. J. Constr. Eng. Manag. 2012, 138, 964–971. [Google Scholar] [CrossRef]

- Fortunato, B.R., III; Hallowell, M.; Behm, M.; Hallowell, M.R.; Dewlaney, K. Identification of Safety Risks for High-Performance Sustainable Construction Projects. J. Constr. Eng. Manag. 2012, 138, 499–508. [Google Scholar] [CrossRef]

- Bong, S.; Rameezdeen, R.; Zuo, J.; Li, R.Y.M.; Ye, G. The Designer’s Role in Workplace Health and Safety in the Construction Industry: Post-Harmonized Regulations in South Australia. Int. J. Constr. Manag. 2015, 15, 276–287. [Google Scholar] [CrossRef]

- Dharmapalan, V.; Gambatese, J.A.; Fradella, J.; Moghaddam Vahed, A. Quantification and Assessment of Safety Risk in the Design of Multistory Buildings. J. Constr. Eng. Manag. 2015, 141, 04014090. [Google Scholar] [CrossRef]

- Osburn, L.; Lee, H.W.; Gambatese, J.A. Formal Prevention through Design Process and Implementation for Mechanical, Electrical, and Plumbing Worker Safety. J. Manag. Eng. 2022, 38, 05022011. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Roca, X.; Fuertes, A. Mitigating Construction Safety Risks Using Prevention through Design. J. Saf. Res. 2010, 41, 107–122. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Building Information Modelling (BIM) to Enhance Occupational Safety in Construction Activities: Research Trends Emerging from One Decade of Studies. Buildings 2020, 10, 98. [Google Scholar] [CrossRef]

- Melzner, J.; Zhang, S.; Teizer, J.; Bargstädt, H.-J.; Ju¨, J.; Melzner, J.; Bargsta¨dt, H.-J.; Bargsta¨dt, B. A Case Study on Automated Safety Compliance Checking to Assist Fall Protection Design and Planning in Building Information Models. Taylor Fr. 2013, 31, 661–674. [Google Scholar] [CrossRef]

- Qi, J.; Issa, R.R.A.; Olbina, S.; Hinze, J. Use of Building Information Modeling in Design to Prevent Construction Worker Falls. J. Comput. Civ. Eng. 2014, 28, A4014008. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Lee, J.K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Yuan, J.; Li, X.; Xiahou, X.; Tymvios, N.; Zhou, Z.; Li, Q. Accident Prevention through Design (PtD): Integration of Building Information Modeling and PtD Knowledge Base. Autom. Constr. 2019, 102, 86–104. [Google Scholar] [CrossRef]

- Nnaji, C.; Gambatese, J.; Karakhan, A.; Osei-Kyei, R. Development and Application of Safety Technology Adoption Decision-Making Tool. J. Constr. Eng. Manag. 2020, 146, 04020028. [Google Scholar] [CrossRef]

- Cortés-Pérez, J.P.; Cortés-Pérez, A.; Prieto-Muriel, P. BIM-Integrated Management of Occupational Hazards in Building Construction and Maintenance. Autom. Constr. 2020, 113, 103115. [Google Scholar] [CrossRef]

- Collinge, W.H.; Farghaly, K.; Mosleh, M.H.; Manu, P.; Cheung, C.M.; Osorio-Sandoval, C.A. BIM-Based Construction Safety Risk Library. Autom. Constr. 2022, 141, 104391. [Google Scholar] [CrossRef]

- Zou, Y. BIM and Knowledge Based Risk Management System; University of Liverpool: Liverpool, UK, 2017. [Google Scholar]

- Marrero, M.; Rivero-Camacho, C.; Martínez-Rocamora, A.; Alba-Rodríguez, D.; Lucas-Ruiz, V. Holistic Assessment of the Economic, Environmental, and Social Impact of Building Construction. Application to Housing Construction in Andalusia. J. Clean. Prod. 2024, 434, 140170. [Google Scholar] [CrossRef]

- UNE-EN ISO 16739-1:2020; Intercambio de Datos En La Industria de Construcción y En La Gestión de Inmuebles Mediante IFC (Industry Foundation Classes). Parte 1: Esquema de Datos (ISO 16739-1:2018) (Ratificada Por La Asociación Española de Normalización En Abril de 2020). Asociación Española de Normalización: Madrid, Spain. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0063503 (accessed on 2 February 2025).

- RD_2015/97 Royal Decree 1215/1997, of July 18, Which Establishes the Minimum Health and Safety Provisions for the Use of Work Equipment by Workers. Available online: https://www.boe.es/buscar/act.php?id=BOE-A-1997-17824 (accessed on 12 March 2023).

- BEDEC Construction Cost Bases; Institute of Construction Technology of Catalonia ITeC: Barcelona, Spain. Available online: https://itec.es/servicios/bedec/ (accessed on 4 March 2019).

- Rivero-Camacho, C.; Marrero, M. Water Footprint of the Life Cycle of Buildings: Case Study in Andalusia, Spain. In Advances of Footprint Family for Sustainable Energy and Industrial Systems; Green Energy and Technology; Springer: Cham, Switzerland, 2022; pp. 135–165. [Google Scholar] [CrossRef]

- CYPE. CYPE Arquitectura, Ingeniería y Construcción. Available online: https://www.cype.es/ (accessed on 12 March 2023).

- BPCM Base de Precios de La Construcción, Madrid. Available online: https://www.comunidad.madrid/servicios/vivienda/base-datos-construccion (accessed on 20 November 2023).

- PRECIOCENTRO Generador de Precios Descompuestos. Available online: https://preciocentro.com/ (accessed on 12 March 2023).

- ACCD Ministry of Development and Housing/Housing and Rehabilitation/Andalusian Construction Cost Database. Available online: https://www.juntadeandalucia.es/organismos/fomentoarticulaciondelterritorioyvivienda/areas/vivienda-rehabilitacion/planes-instrumentos/paginas/vivienda-bcca.html (accessed on 30 April 2025).

- FIEBDC Formato de Intercambio Estándar de Bases de Datos de Construcción. Available online: https://www.fiebdc.es/ (accessed on 12 March 2023).

- NTP-330 NTP 330; Simplified Accident Risk Assessment System. National Institute of Safety and Hygiene at Work: Madrid, Spain. Available online: https://www.sesst.org/wp-content/uploads/2020/11/ntp_330.pdf (accessed on 30 April 2025).

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Waters, T.R.; Putz-Anderson, V.; Garg, A.; Fine, L.J. Revised NIOSH Equation for the Design and Evaluation of Manual Lifting Tasks. Ergonomics 1993, 36, 749–776. [Google Scholar] [CrossRef]

- Borg, G.; Ljunggren, G.; Ceci, R. The Increase of Perceived Exertion, Aches and Pain in the Legs, Heart Rate and Blood Lactate during Exercise on a Bicycle Ergometer. Eur. J. Appl. Physiol. Occup. Physiol. 1985, 54, 343–349. [Google Scholar] [CrossRef]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting Working Postures in Industry: A Practical Method for Analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- Corlett, E.N.; Bishop, R.P. A Technique for Assessing Postural Discomfort. Ergonomics 1976, 19, 175–182. [Google Scholar] [CrossRef] [PubMed]

- McAtamney, L.; Nigel Corlett, E. RULA: A Survey Method for the Investigation of Work-Related Upper Limb Disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef] [PubMed]

- REBA NTP 601; Método REBA (Rapid Entire Body Assessment). National Institute of Safety and Hygiene at Work: Madrid, Spain. Available online: https://www.insst.es/documentacion/colecciones-tecnicas/ntp-notas-tecnicas-de-prevencion/17-serie-ntp-numeros-576-a-610-ano-2003/ntp-601-evaluacion-de-las-condiciones-de-trabajo-carga-postural.-metodo-reba-rapid-entire-body-assessment-. (accessed on 30 April 2025).

- Sangsawang, T.; Yang, L. Predicting Student Achievement Using Socioeconomic and School-Level Factors. Artif. Intell. Learn. 2025, 1, 20–34. [Google Scholar] [CrossRef]

- Ghaffar, S.A.; Setiawan, W.C.; Ghaffar, S.A.; Setiawan, W.C. Metaverse Dynamics: Predictive Modeling of Roblox Stock Prices Using Time Series Analysis and Machine Learning. Int. J. Res. Metaverse 2024, 1, 77–93. [Google Scholar] [CrossRef]

- ISO_45001:2018 ISO 45001:2018(En); Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland. Available online: https://www.iso.org/obp/ui/#iso:std:iso:45001:ed-1:v1:en (accessed on 12 June 2025).

- González-Vallejo, P.; Solís-Guzmán, J.; Llácer, R.; Marrero, M. La Construcción de Edificios Residenciales En España En El Período 2007-2010 y Su Impacto Según El Indicador Huella Ecológica. Inf. Constr. 2015, 67, e111. [Google Scholar] [CrossRef]

- Hamid, A.; Singh, B. Cost of Compliance with Health and Safety Management System among Contractor in Construction Industry. In Proceedings of the National Seminar on Civil Engineering Research, Johor Bahru, Malaysia, 14–15 April 2014; Universiti Teknologi Malaysia, Ed.; Universiti Teknologi Malaysia: Johor Bahru, Malaysia, 2014; pp. 14–15. [Google Scholar]

- Feng, Y. Effects of Safety Investments on Safety Performance of Building Projects. Saf. Sci. 2013, 59, 28–45. [Google Scholar] [CrossRef]

- Gurcanli, G.E.; Bilir, S.; Sevim, M. Activity Based Risk Assessment and Safety Cost Estimation for Residential Building Construction Projects. Saf. Sci. 2015, 80, 1–12. [Google Scholar] [CrossRef]

- Ibarrondo-Dávila, M.P.; López-Alonso, M.; Rubio-Gámez, M.C. Managerial Accounting for Safety Management. The Case of a Spanish Construction Company. Saf. Sci. 2015, 79, 116–125. [Google Scholar] [CrossRef]

- Camino López, M.A.; Ritzel, D.O.; Fontaneda, I.; González Alcantara, O.J. Construction Industry Accidents in Spain. J. Saf. Res. 2008, 39, 497–507. [Google Scholar] [CrossRef]

- Ketabi, A.B.; Heravi, G. Developing a Framework for Evaluating Construction Project Safety Levels and Optimal Cost Allocation to Safety Influential Factors. Eng. Constr. Archit. Manag. 2022, 29, 643–668. [Google Scholar] [CrossRef]

- Khosravi, Y.; Asilian-Mahabadi, H.; Hajizadeh, E.; Hassanzadeh-Rangi, N.; Bastani, H.; Behzadan, A.H. Factors Influencing Unsafe Behaviors and Accidents on Construction Sites: A Review. Taylor Fr. 2014, 20, 111–125. [Google Scholar] [CrossRef] [PubMed]

- Haslam, R.; Hide, S.; Atkinson, S.; Pavitt, T.; Gibb, A. Causal Factors in Construction Accidents; Health and Safety Executive: London, UK, 2003. [Google Scholar]

- Talarico, L.; Reniers, G. Risk-Informed Decision Making of Safety Investments by Using the Disproportion Factor. Process Saf. Environ. Prot. 2016, 100, 117–130. [Google Scholar] [CrossRef]

- Ma, Y.; Zhao, Q.; Xi, M. Decision-Makings in Safety Investment: An Opportunity Cost Perspective. Saf. Sci. 2016, 83, 31–39. [Google Scholar] [CrossRef]

- Hayadi, B.H.; El Emary, I.M.M. Predicting Campaign ROI Using Decision Trees and Random Forests in Digital Marketing. J. Digit. Mark. Digit. Curr. 2024, 1, 1–20. [Google Scholar] [CrossRef]

- Hery; Widjaja, A.E. Predictive Modeling of Blockchain Stability Using Machine Learning to Enhance Network Resilience. J. Curr. Res. Blockchain 2024, 1, 124–138. [Google Scholar] [CrossRef]

- Buchdadi, A.D.; Al, A.S.M.; Dharmawan Buchdadi, A.; Salamh, A.; Al-Rawahna, M. Temporal Crime Pattern Analysis Using Seasonal Decomposition and K-Means Clustering. J. Cyber Law 2025, 1, 65–87. [Google Scholar] [CrossRef]

- Dewi, D.A.; Kurniawan, T.B. Exploring Financial Trends through Topic Modeling and Time-Series Analysis: A Clustering Approach Using Latent Dirichlet Allocation (LDA) on Twitter Data. J. Digit. Soc. 2025, 1, 91–108. [Google Scholar] [CrossRef]

| Project Data. Definition of Unit Cost | |||||

|---|---|---|---|---|---|

| 02PMM00002 | m3 | ||||

| Excavation of holes in earth of medium consistency conducted with mechanical means up to a maximum depth of 4 m, including extraction at the edges and profiling of bottom and sides. | |||||

| Measured volume in natural profile. | |||||

| Code | Concept | Quantity | Cost | Cost | |

| TP00100 | h SPECIAL LABOURER | 0.120 | 18.90 | 2.27 | |

| ME00400 | h BACKHOE | 0.130 | 34.98 | 4.55 | |

| Direct costs | 6.82 | ||||

| 10.62% Indirect costs | 0.72 | ||||

| Procedures of work units | |||||

| Code | Procedure | ||||

| prAl02PMM001 | Profiling of bottom and sides | ||||

| prOm02PMM001 | Hole digging with backhoe | ||||

| Division of the procedure into tasks/subtasks | |||||

| prAl02PMM001 | Profiling of bottom and sides | ||||

| Starting situation | |||||

| |||||

| Description of Level 1. Tasks and subtasks | |||||

| 1. Checking the depth in the hole. 1.1. By means of a tape measure and as a reference set a pike that delimits the foundation concrete pad: it must be verified that the measurement is correct. 2. Hand profiling of the hole. 2.1. The slopes of the hole must be outlined by hand with a shovel to avoid any debris that could damage it. The earth at the edge of the excavation is shovelled. | |||||

| Final situation | |||||

| |||||

| Identification of procedure risks (example of a procedure) | |||||

| prAl02PMM001 | Profiling of bottom and sides | ||||

| Occupational safety risk | |||||

Risk identification:

| |||||

| Ergonomics risk | |||||

Risk identification:

| |||||

| 02PMM00002 | m3 | |||||||||

| Code | Procedure | |||||||||

| prAl02PMM001 | Profiling of bottom and sides | |||||||||

| Safety at work | Risk number | Probability (P) | Consequence (C) | PXC | Initial assessment | Ergonomics | Risk number | Initial assessment | ||

| 1 | 24 | 100 | 2400 | I | 4 | 3 | A-3 | 3 | ||

| 2 | 24 | 100 | 2400 | I | 4 | |||||

| Σ safety hazards at work | 8 | Σ ergonomic risks | 3 | |||||||

| Final summary | 11 | |||||||||

| 02PMM00002 | m3 | |

| Code | Procedure | |

| prAl02PMM001 | Profiling of bottom and sides | |

| Corrected situation | ||

| Technical factor | Auxiliary means |

|

| Personal protection |

| |

| Collective protection | --- | |

| Signalling and delimitation of spaces |

| |

| Organisational factor |

| |

| Environmental factor |

| |

| 02PMM00002 | m3 | |||||||

| Code | Procedure | |||||||

| prAl02PMM001 | Profiling of bottom and sides | |||||||

| Improved situation | ||||||||

| Safety at work | Risk | Corrected assessment | Ergonomics | Risk | Corrected assessment | |||

| 1 | IV | 1 | 3 | M-2 | 2 | |||

| 2 | IV | 1 | ||||||

| Σ safety hazards at work | 2 | Σ ergonomic risks | 2 | |||||

| Final summary | 4 | |||||||

| Cost (EUR/m2) | Risk Indicator (Ip/m2) | Cost per Risk (EUR/Ip) (EUR/Reduction) | |||

|---|---|---|---|---|---|

| Chapters | Initial | Corrected | Initial | Corrected | |

| 02. Earthworks | 0.53 | 0.86 | 0.024 | 0.008 | 0.03 |

| 03. Foundation | 11.57 | 12.48 | 0.078 | 0.03 | 0.03 |

| 04. Sewer system | 7.89 | 8.6 | 0.066 | 0.042 | 0.05 |

| 05. Structures | 83.02 | 96.06 | 0.496 | 0.126 | 0.06 |

| 06. Masonry | 71.43 | 72.88 | 0.072 | 0.022 | 0.05 |

| 07. Roof | 20.59 | 21.34 | 0.219 | 0.069 | 0.01 |

| 08. Installations | 59.46 | 60.55 | 0.741 | 0.253 | 0 |

| 09. Insulation | 27.78 | 28.01 | 0.08 | 0.037 | 0.01 |

| 10. Finishes | 105.86 | 107.25 | 0.379 | 0.158 | 0.01 |

| Total | 388.14 | 408.02 | 2.155 | 0.746 | 0.24 |

| Increased cost/decreased risk in the project per m2 | |||||

| Total | (EUR/m2) | % | Total | (Ip/m2) | % |

| Cost increase | 19.89 | 5.12 | Ip reduction | 1.41 | 65.4 |

| Code | Unit | Concept | Q | Cost (EUR) | H&S Risks |

|---|---|---|---|---|---|

| 05FBB00037 | m2 | Reticular slabs with recoverable coffers | 594.28 | 26,534.60 | 66 |

| 05FUA00005 | m2 | Concrete slab with self-resistant beams | 594.28 | 32,822.08 | 62 |

| % improvement impact | −19% | +6% | |||

| 10CWW00006 + 06LPM00001 | m2 | Single layer coating with aggregates on brick + wall of small drills bricks | 656.235 | 23,197.91 | 90 |

| 621.4 | 22,208.84 | 15 | |||

| 06LPM00002 | m2 | Wall of small drills bricks with exposed face | 656.235 | 31,715.80 | 15 |

| % improvement impact | −30% | −86% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alba-Rodríguez, M.D.; Lucas-Ruiz, V.; Marrero, M. Systematic Methodology for Estimating the Social Dimension of Construction Projects—Assessing Health and Safety Risks Based on Project Budget Analysis. Buildings 2025, 15, 2313. https://doi.org/10.3390/buildings15132313

Alba-Rodríguez MD, Lucas-Ruiz V, Marrero M. Systematic Methodology for Estimating the Social Dimension of Construction Projects—Assessing Health and Safety Risks Based on Project Budget Analysis. Buildings. 2025; 15(13):2313. https://doi.org/10.3390/buildings15132313

Chicago/Turabian StyleAlba-Rodríguez, María D., Valeriano Lucas-Ruiz, and Madelyn Marrero. 2025. "Systematic Methodology for Estimating the Social Dimension of Construction Projects—Assessing Health and Safety Risks Based on Project Budget Analysis" Buildings 15, no. 13: 2313. https://doi.org/10.3390/buildings15132313

APA StyleAlba-Rodríguez, M. D., Lucas-Ruiz, V., & Marrero, M. (2025). Systematic Methodology for Estimating the Social Dimension of Construction Projects—Assessing Health and Safety Risks Based on Project Budget Analysis. Buildings, 15(13), 2313. https://doi.org/10.3390/buildings15132313