Mechanical Properties of Recycled Concrete Containing Brick–Concrete Waste Aggregates with Basalt Fiber-Reinforced Polymer (BFRP) Fibers

Abstract

1. Introduction

2. Experimental Methods

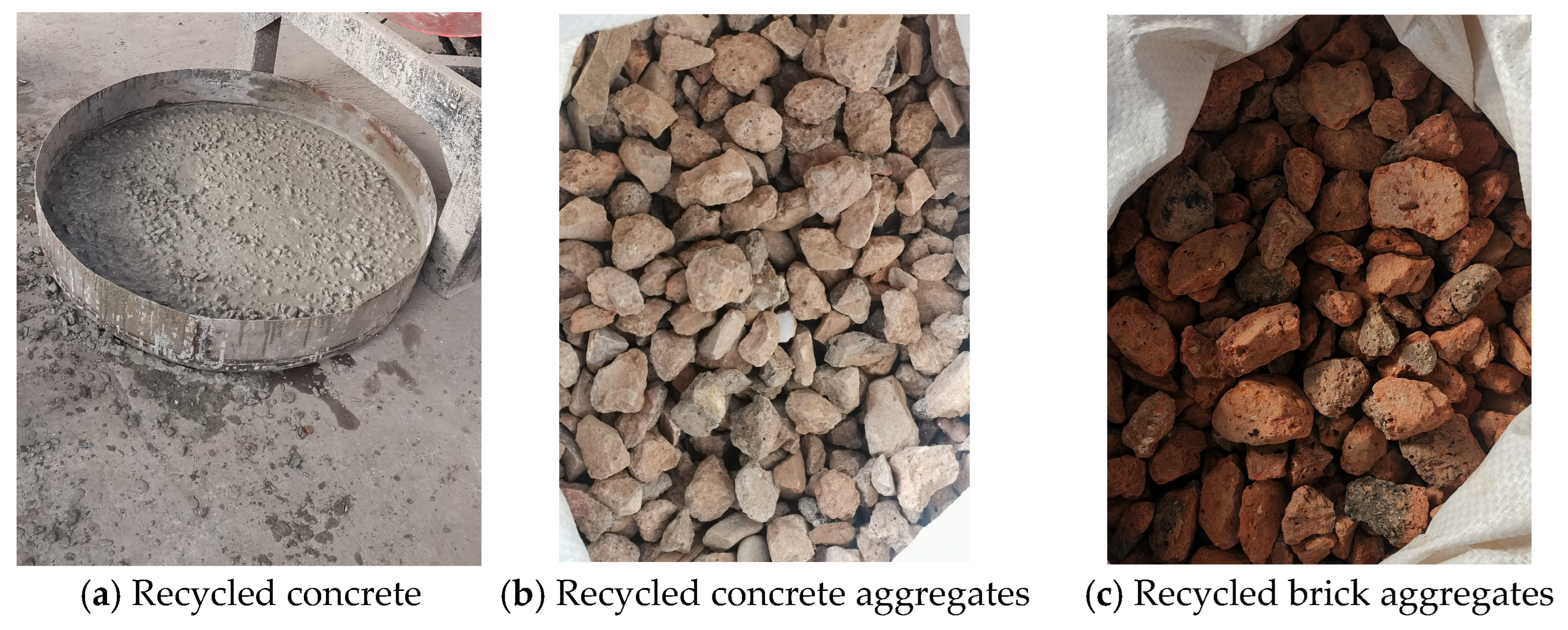

2.1. Materials

2.2. Specimen Design

2.3. Specimen Setup and Procedure

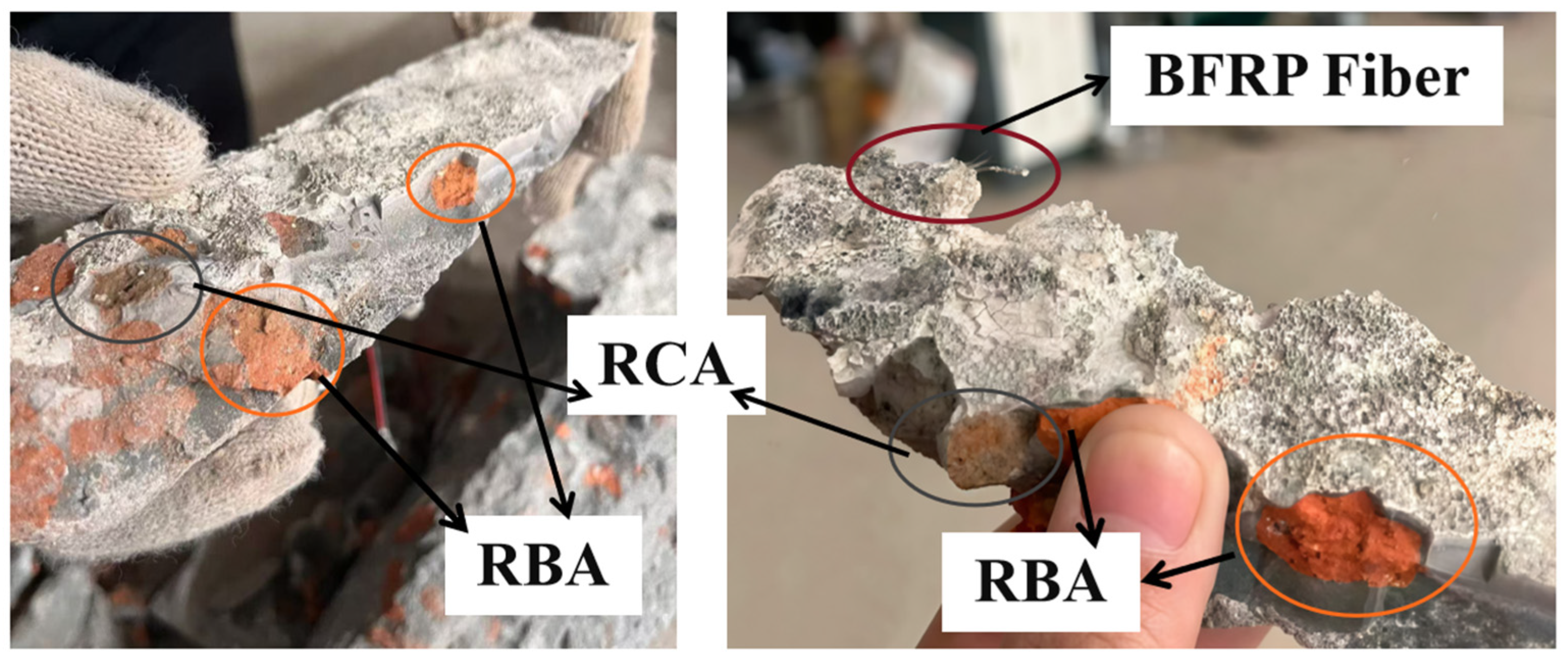

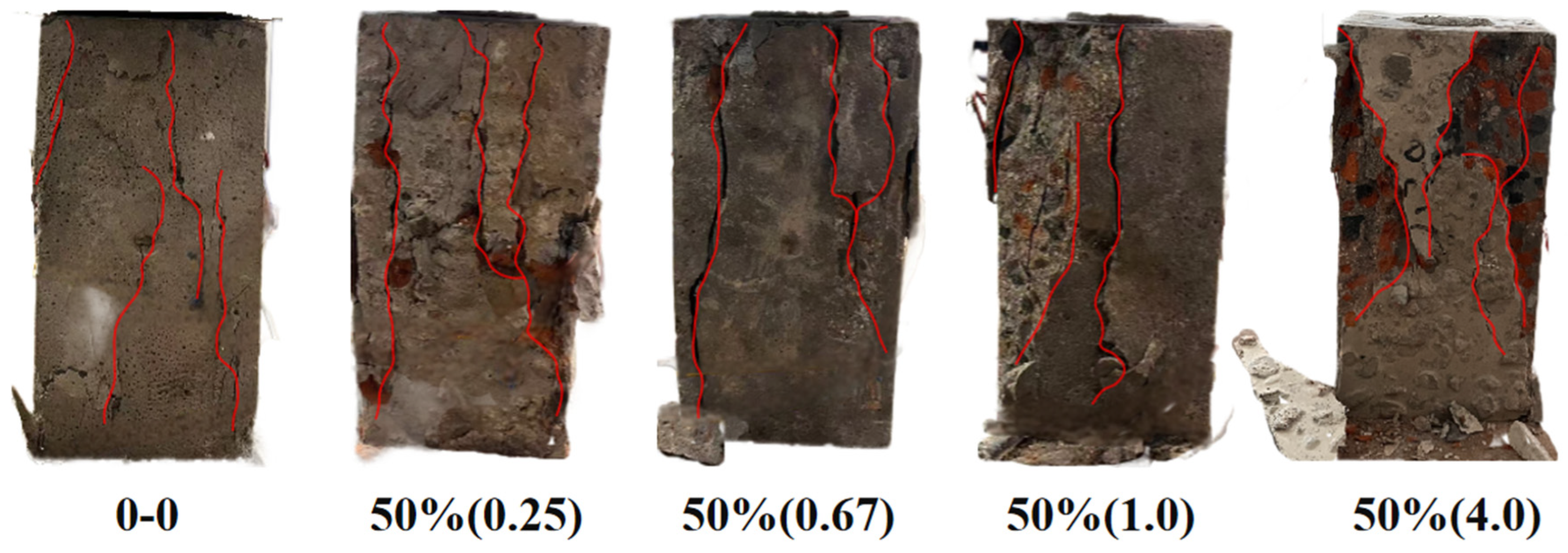

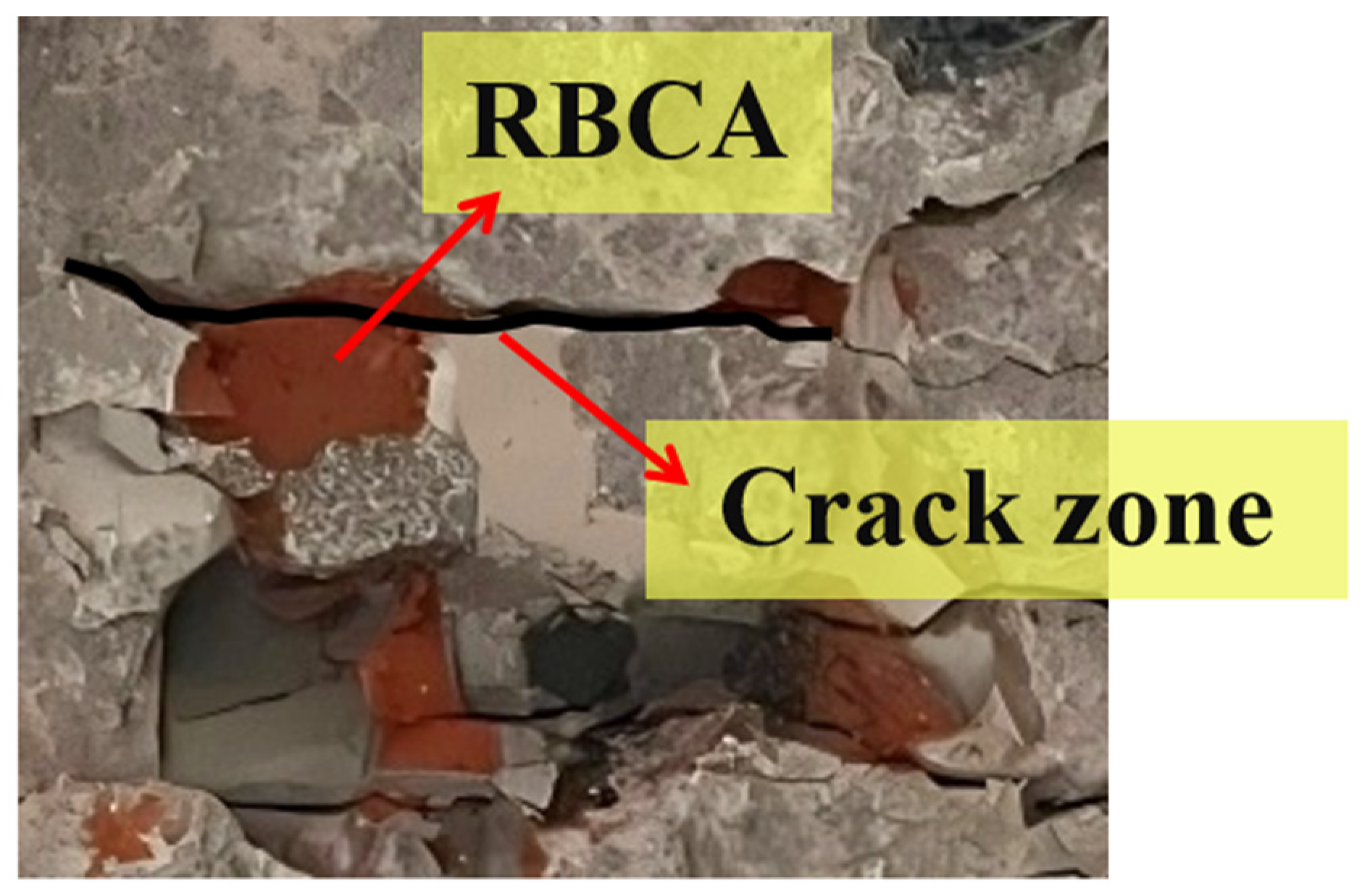

2.4. Specimen Failure Modes

3. Analysis of Experimental Results

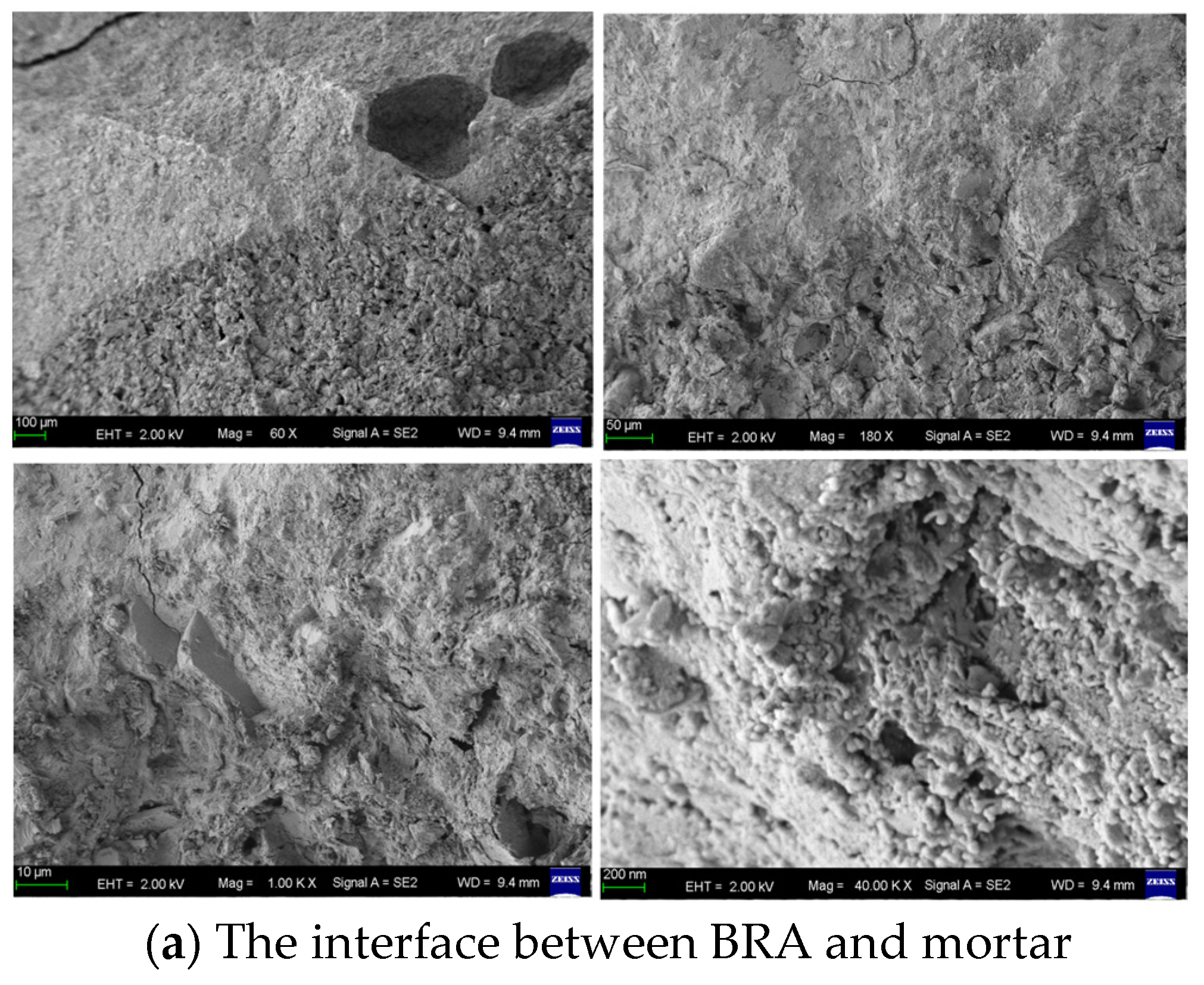

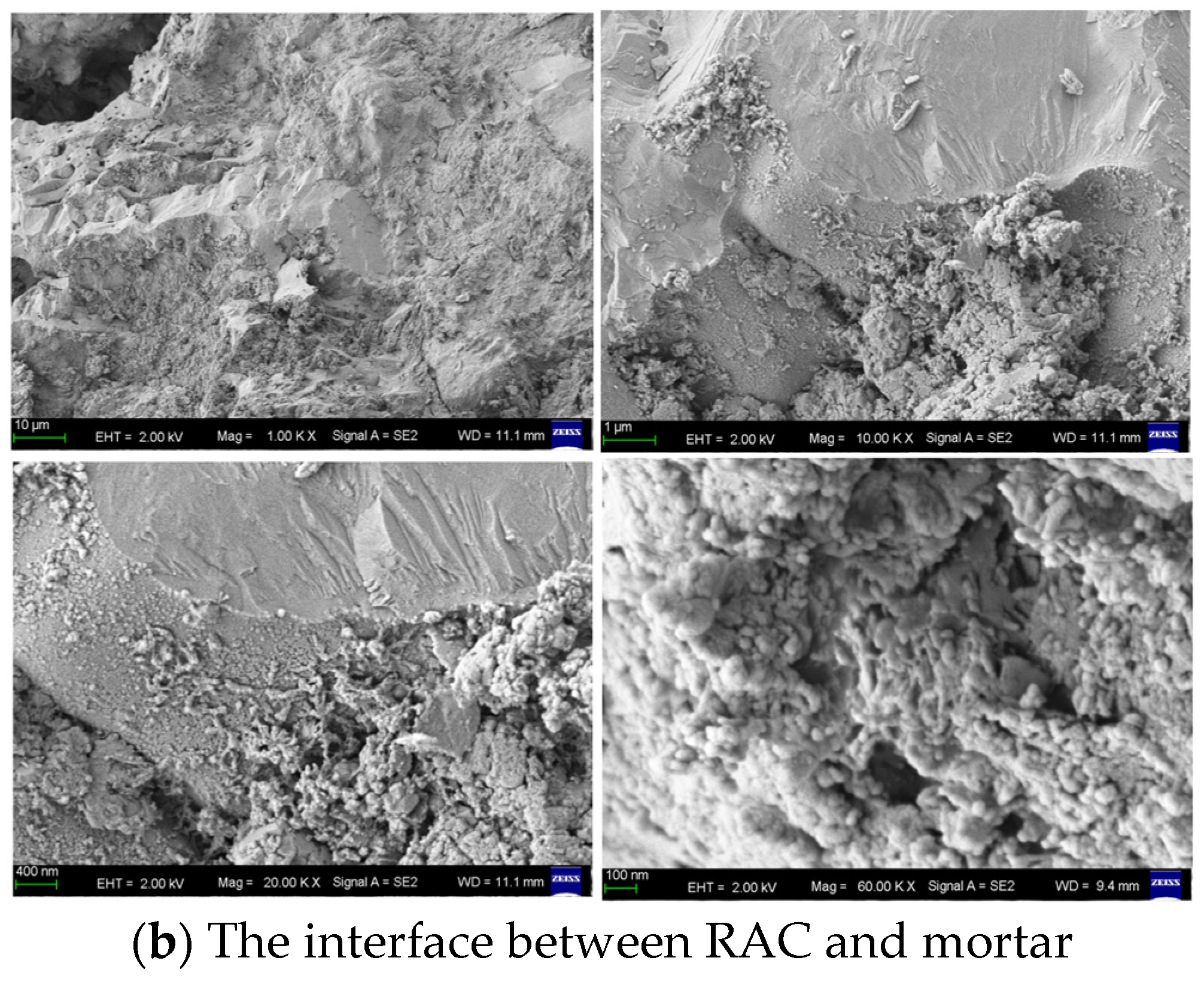

3.1. The Influence of Recycled Aggregate Content on the Mechanical Properties of Recycled Concrete

3.1.1. Cube Compressive Strength

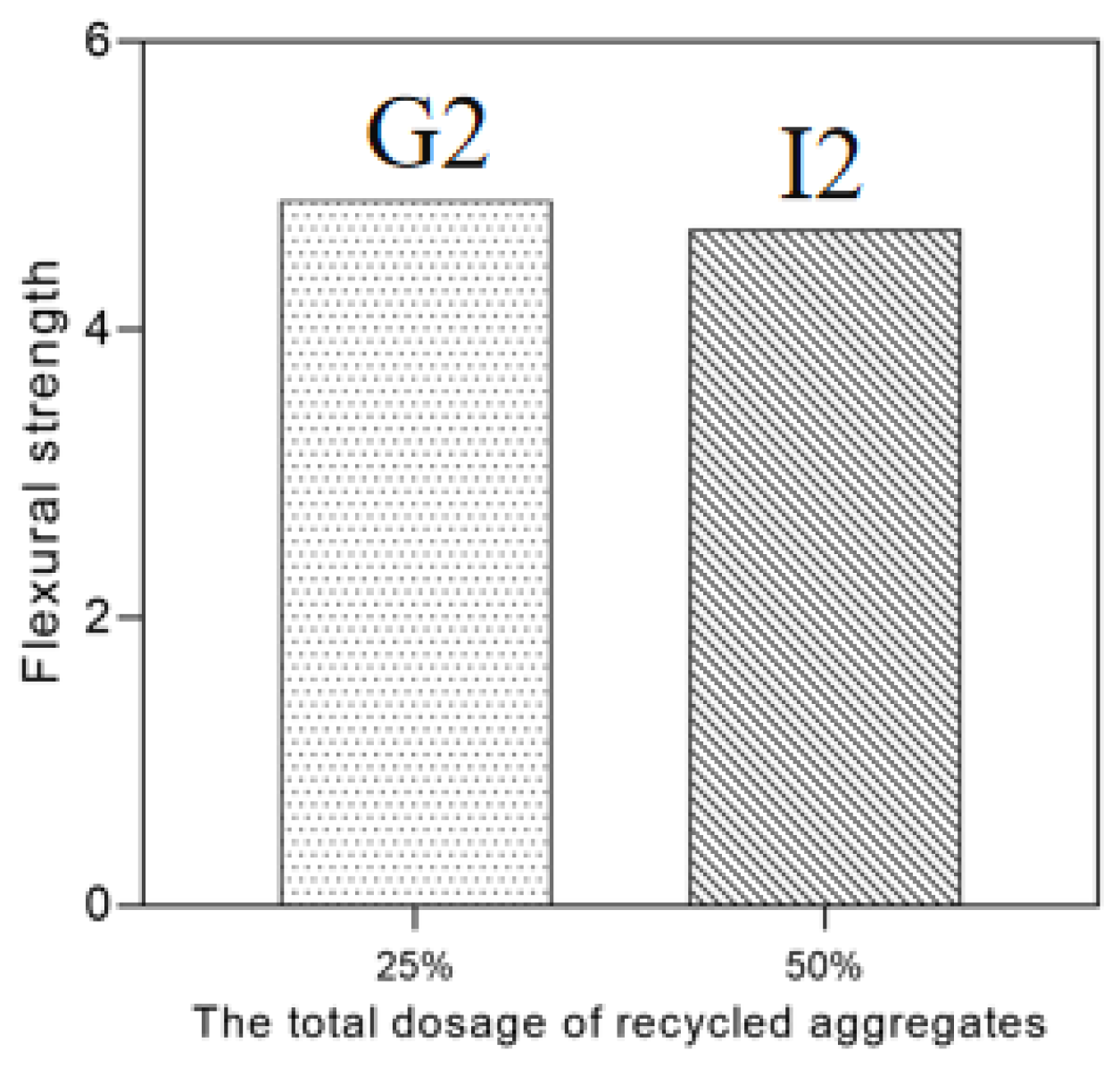

3.1.2. Flexural Strength

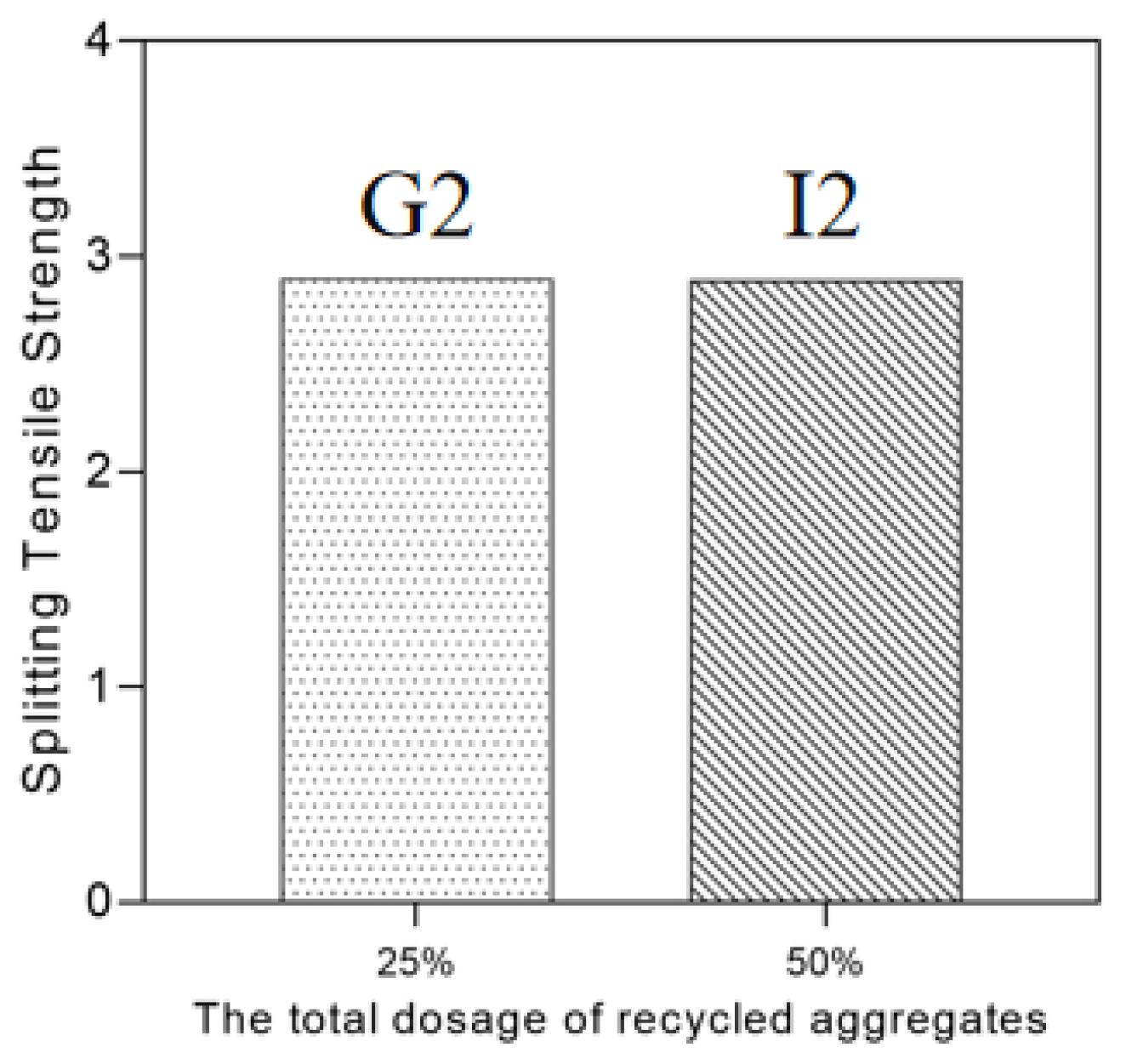

3.1.3. Splitting Tensile Strength

3.1.4. Tensile-to-Compressive Strength Ratio

3.2. The Influence of Brick–Concrete Ratio on the Mechanical Properties of Recycled Concrete

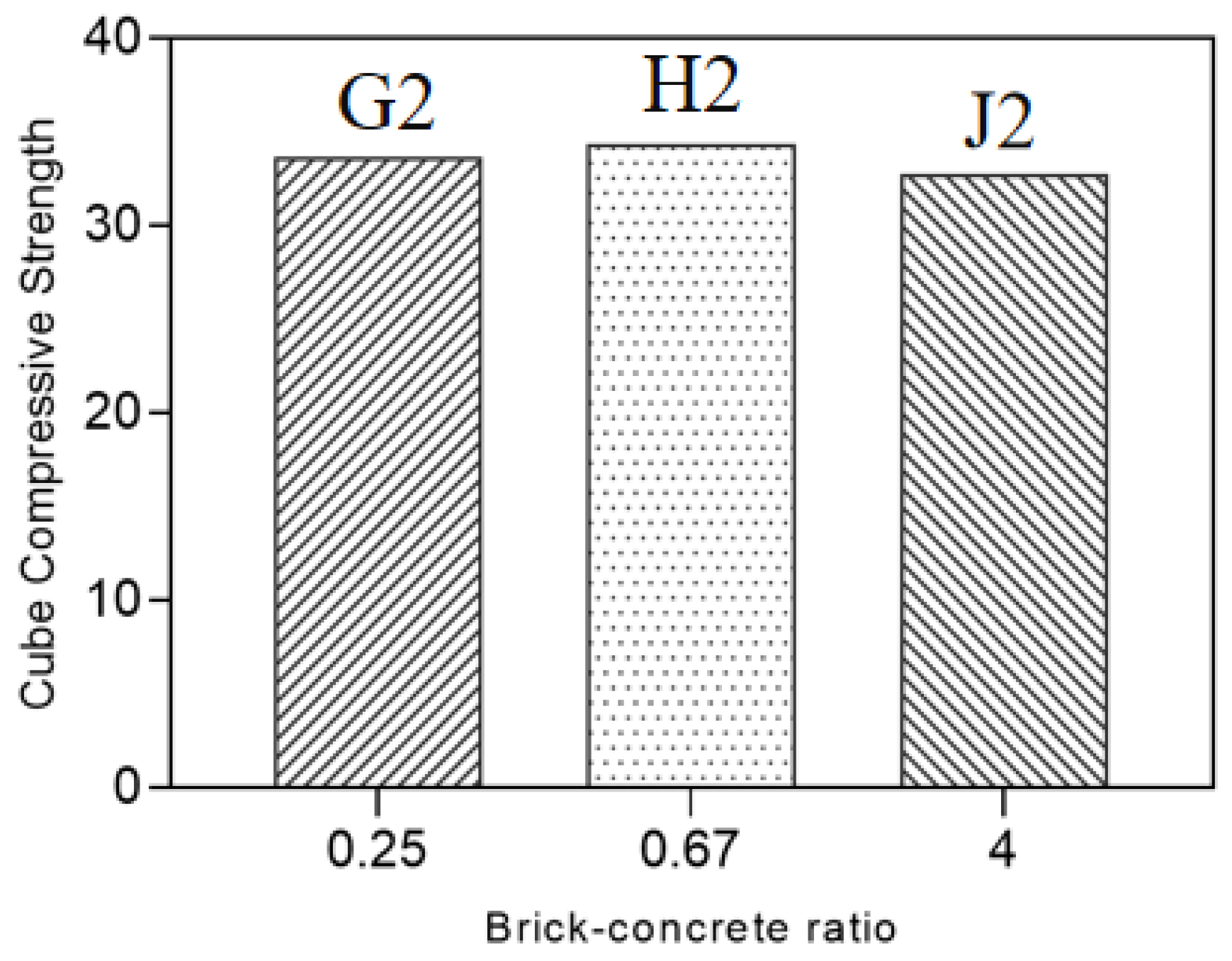

3.2.1. Cube Compressive Strength

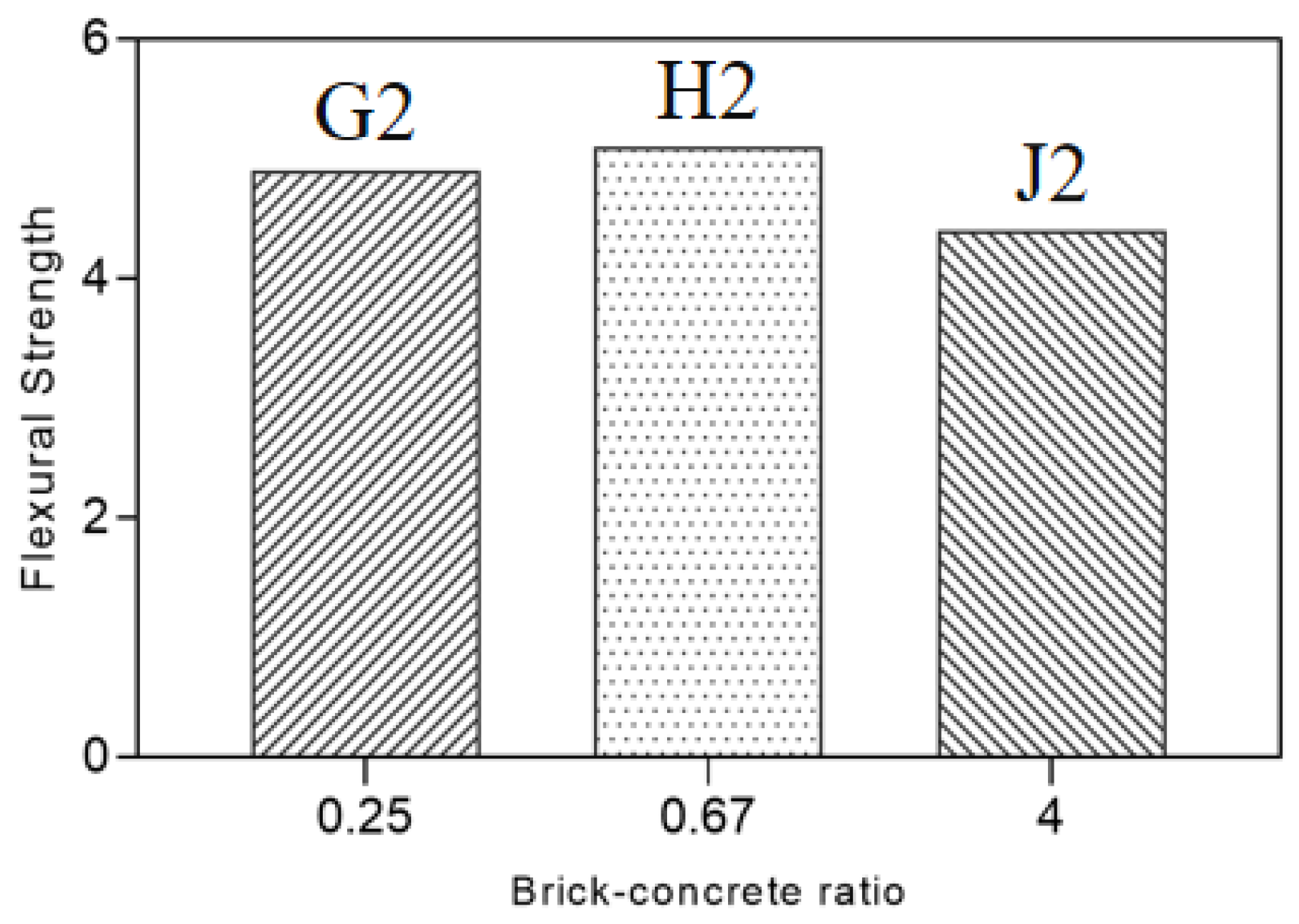

3.2.2. Flexural Strength

3.2.3. Splitting Tensile Strength

3.2.4. Tensile-to-Compressive Strength Ratio

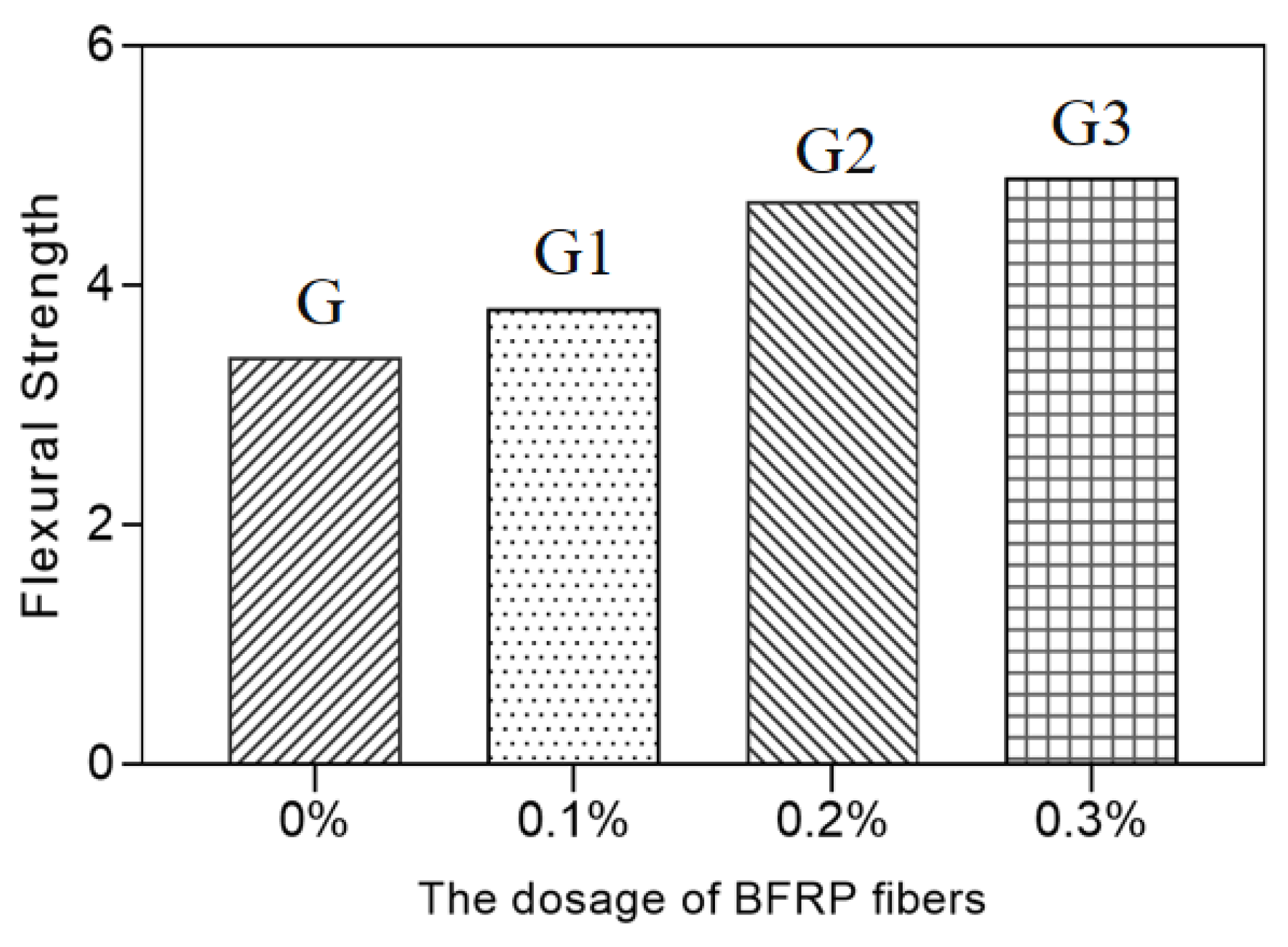

3.3. The Influence of BFRP Fiber Content on the Mechanical Properties of Recycled Concrete

3.3.1. Cube Compressive Strength

3.3.2. Flexural Strength

3.3.3. Splitting Tensile Strength

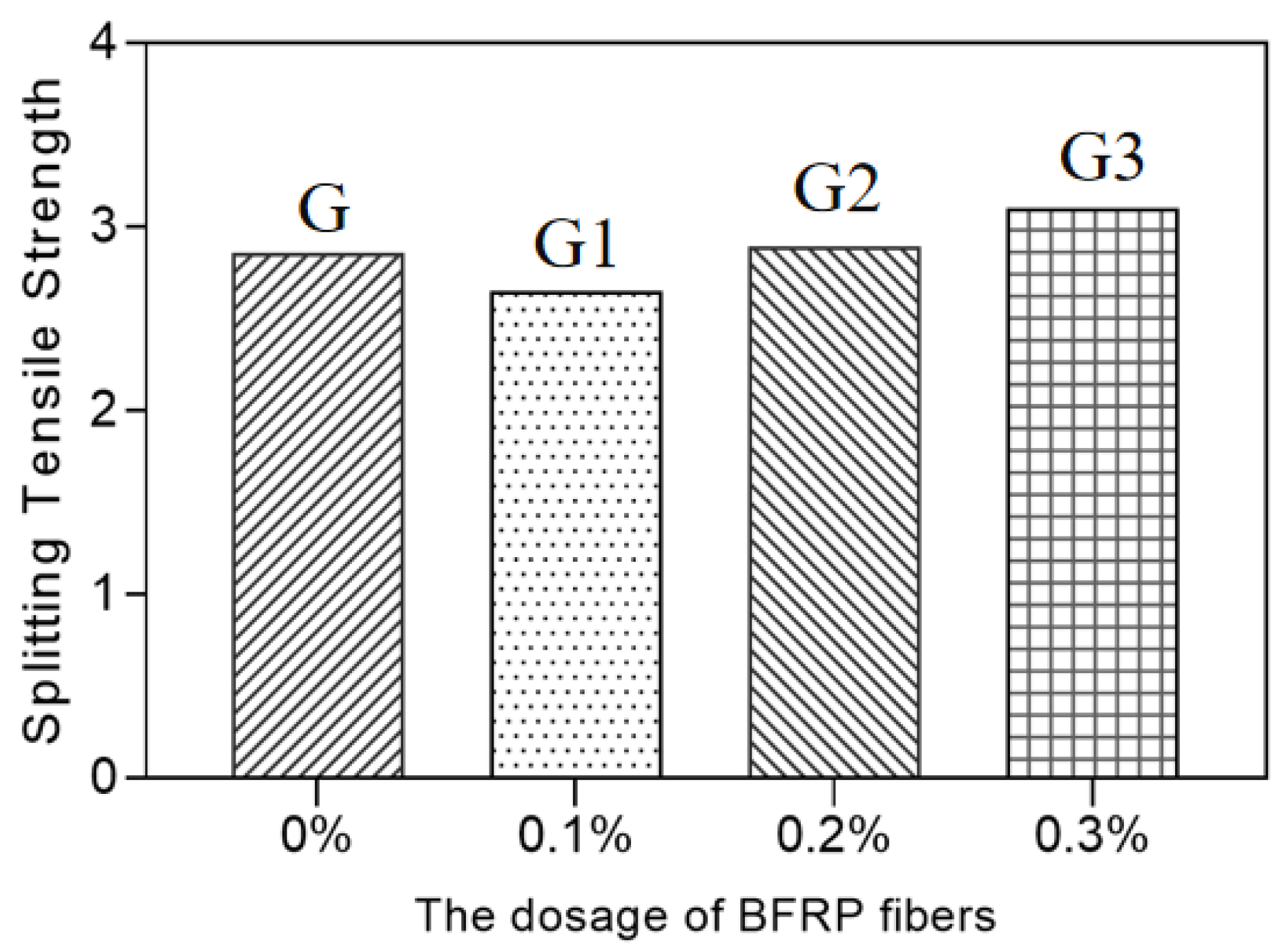

3.3.4. Tensile-to-Compressive Strength Ratio

4. Theoretical Analysis

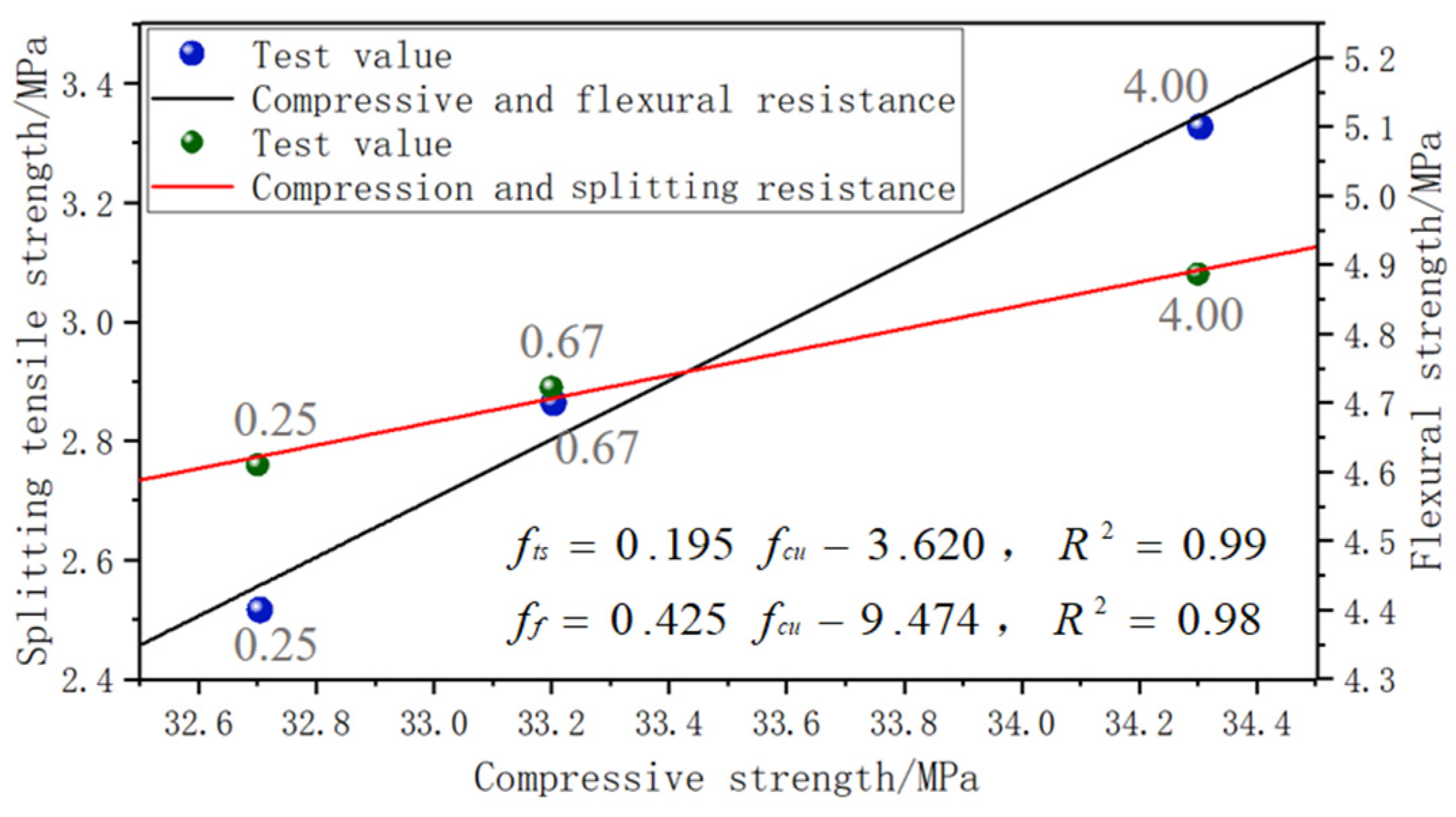

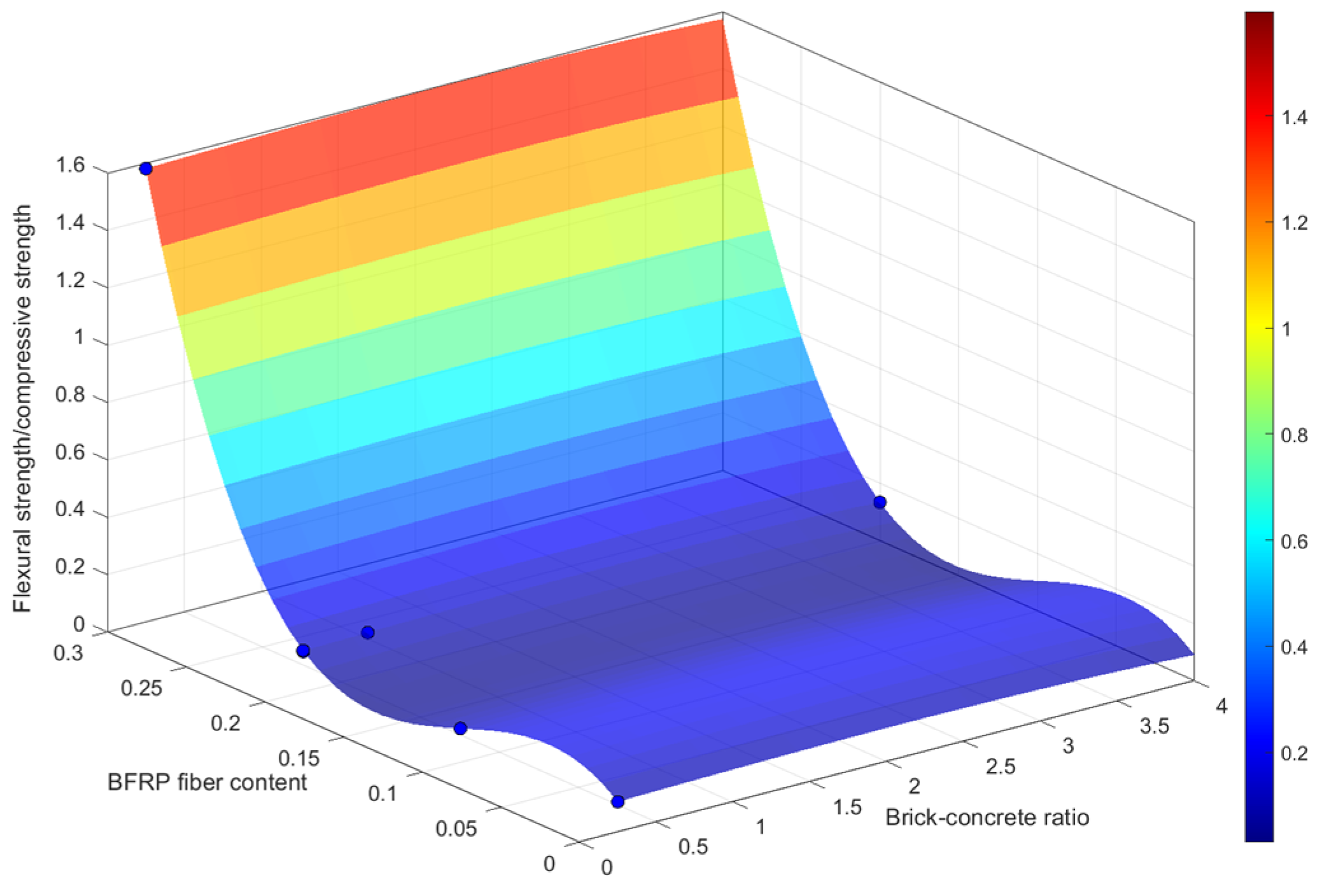

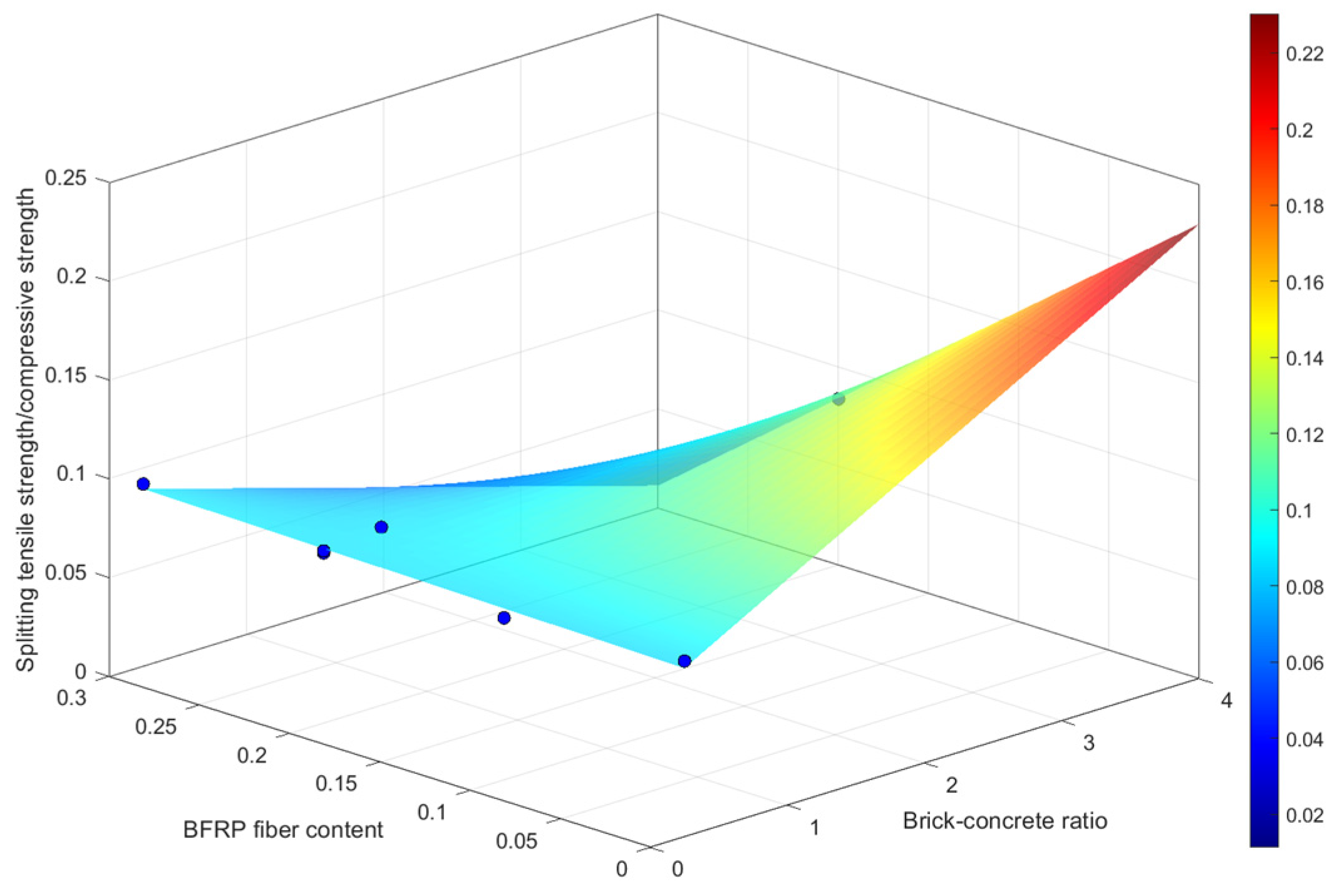

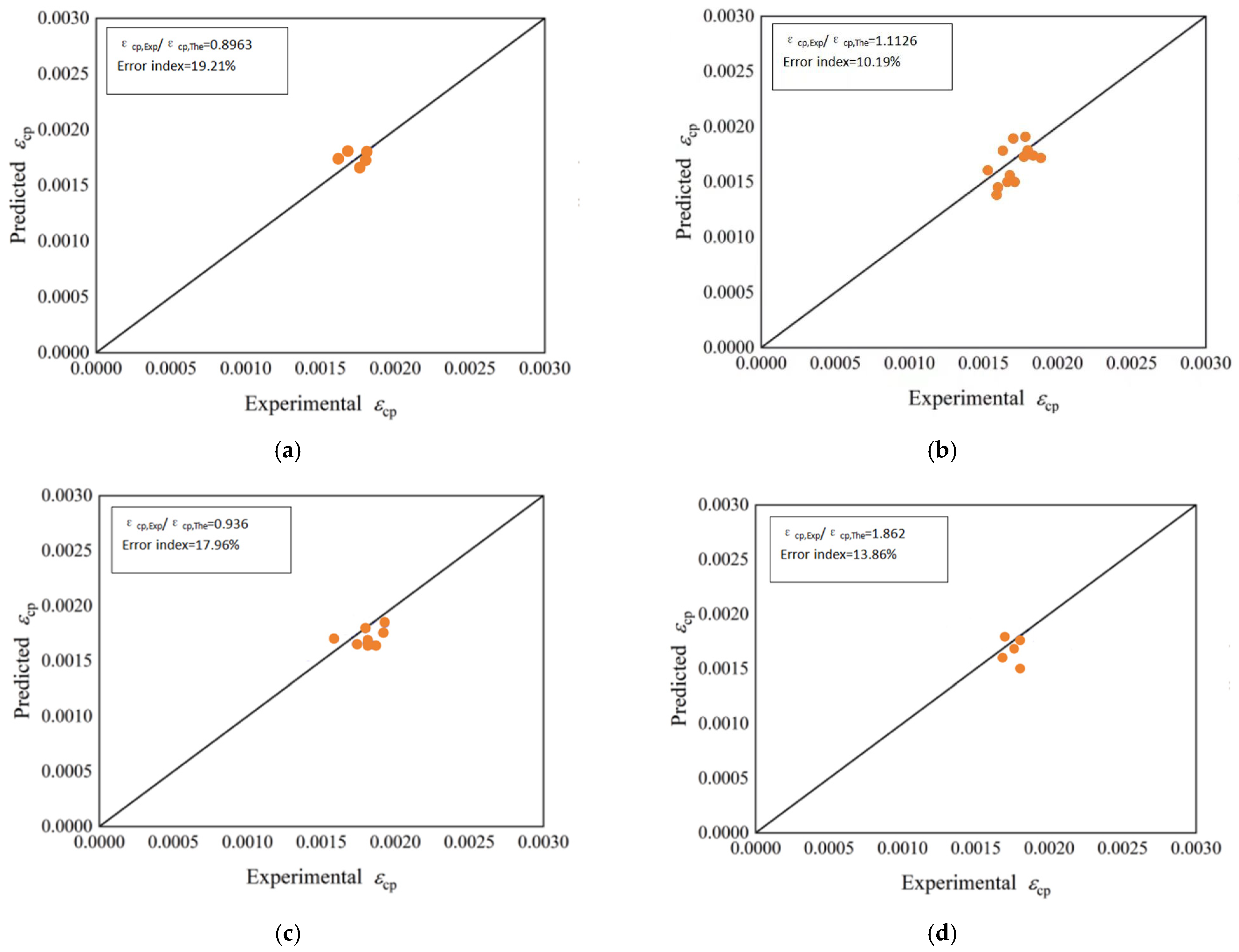

4.1. Splitting and Flexural Strength Prediction Models

4.2. Elastic Modulus Calculation Formula

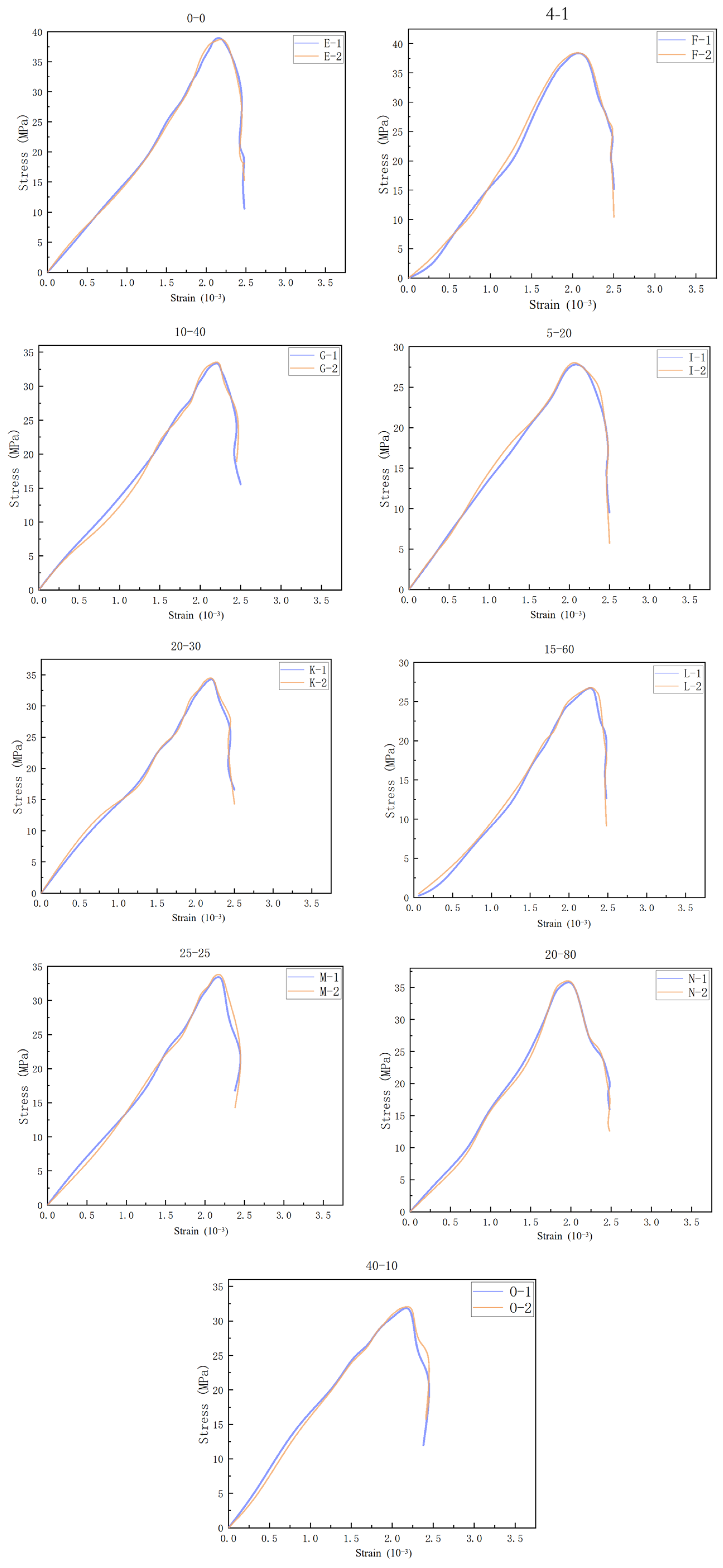

4.3. Axial Compression Constitutive Model

4.4. Finite Element Model and Validation

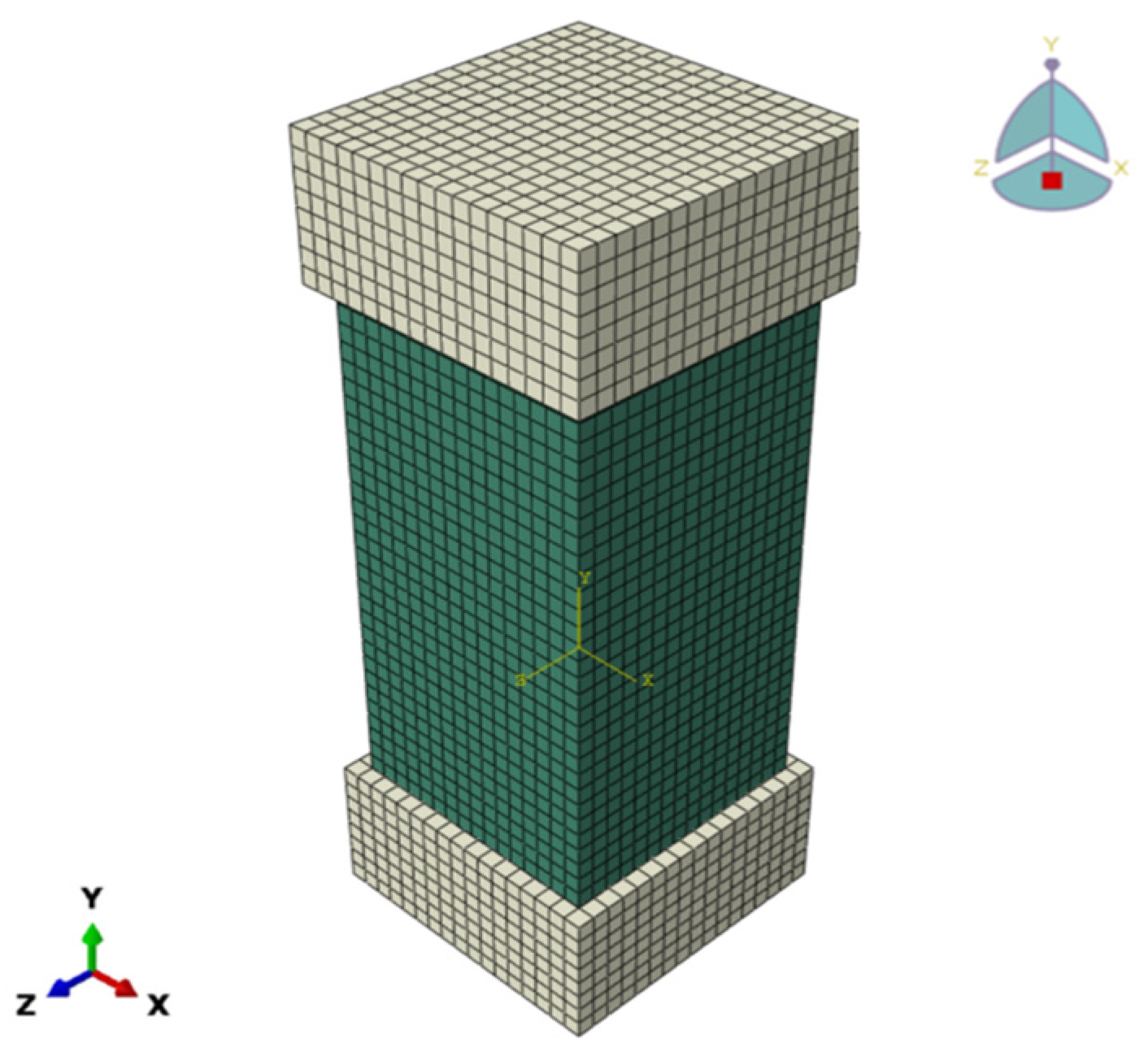

4.4.1. ABAQUS Model Setup and Parameter Configuration

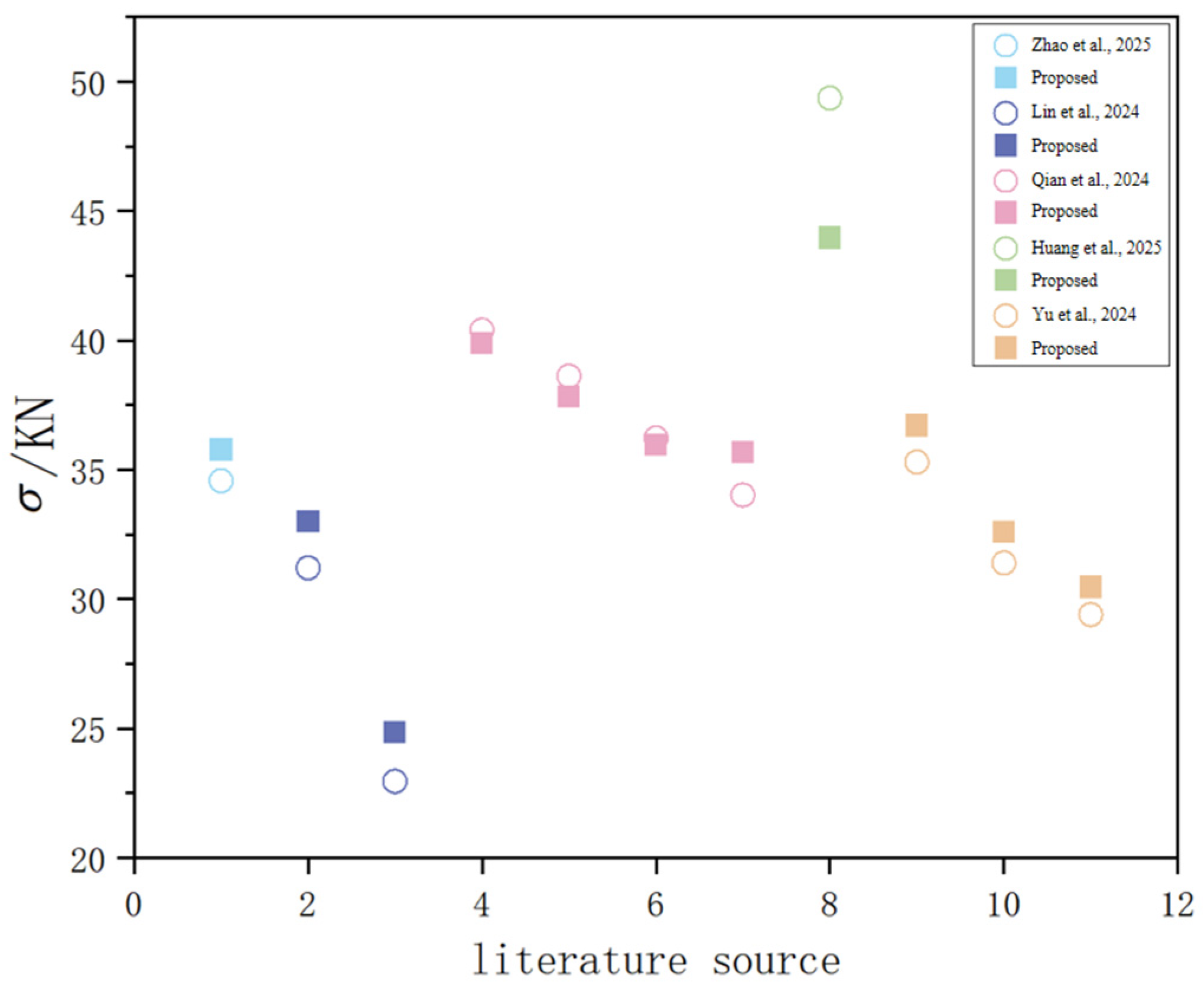

4.4.2. Model Validation

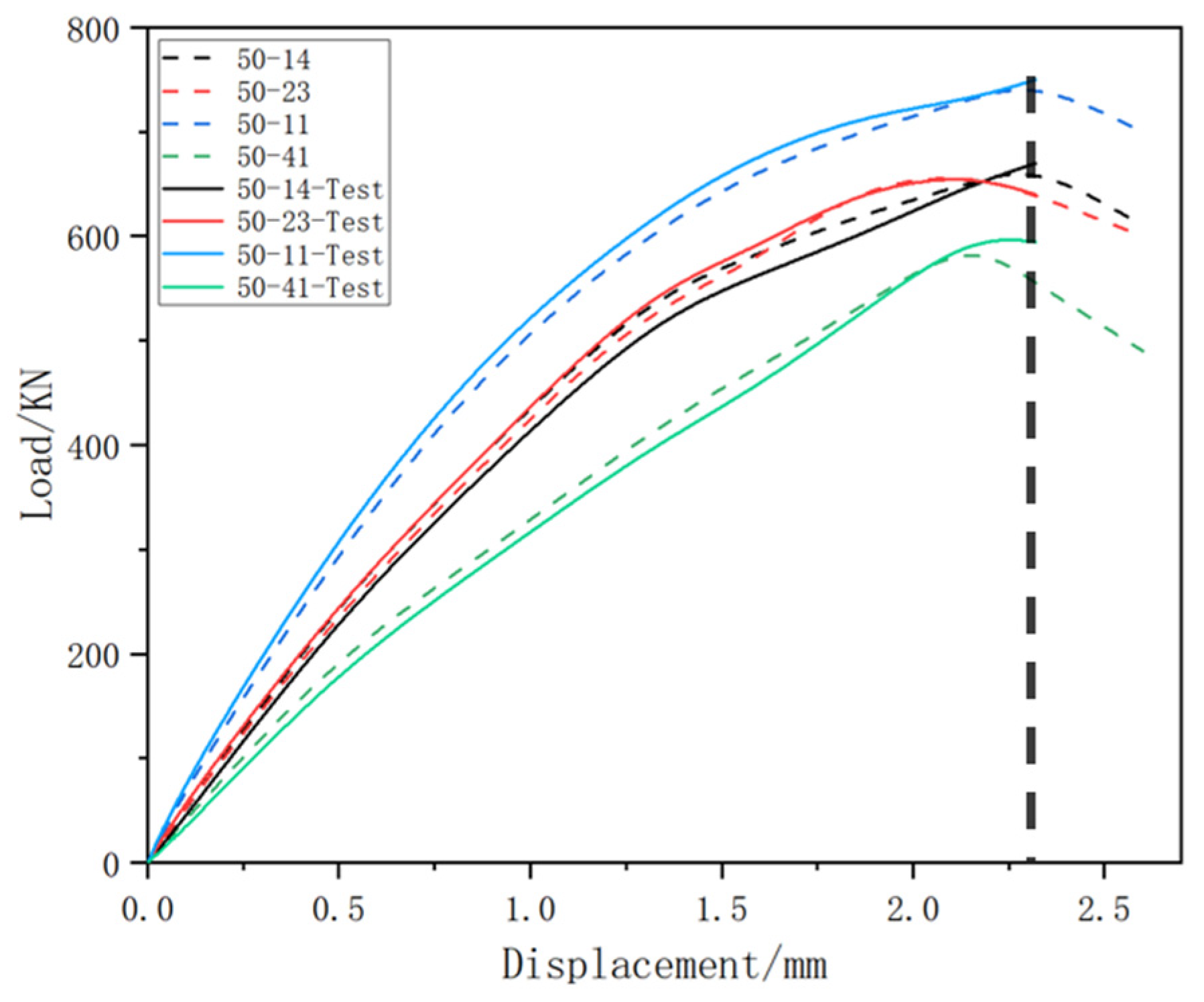

4.4.3. Parameter Analysis

5. Conclusions

- With an increase in the replacement rate of recycled brick aggregates, the strength indices of concrete exhibit varying degrees of reduction. However, when the proportions of brick aggregates and mixed mortar aggregates are comparable, the relative strength loss is minimized. While different BFRP contents have a limited effect on cube compressive strength, they significantly improve the splitting tensile strength and flexural performance of recycled concrete.

- Strong correlations were observed between the splitting tensile strength, flexural strength, and compressive strength of brick–concrete recycled aggregate concrete. Based on these relationships, conversion formulas for the mechanical properties of brick–concrete recycled aggregate concrete were established.

- A modified formula for the elastic modulus of brick–concrete recycled concrete was proposed, which includes the brick–concrete ratio and fiber content as variables. The accuracy of this formula was validated. Additionally, the strong correlations between splitting tensile strength, flexural strength, and compressive strength were further utilized to develop conversion formulas for mechanical properties.

- The uniaxial compressive stress–strain curve of RBCAC was obtained, and the variation patterns and mechanisms of parameters such as the elastic modulus, peak stress, and peak strain were analyzed. A uniaxial compression constitutive model for RBCAC was established by modifying the existing model from the literature, specifically by incorporating parameters such as the brick–concrete ratio and fiber content, to characterize the nonlinear mechanical behavior of recycled brick–concrete aggregate concrete. Furthermore, the experimental results were validated using finite element software, and ABAQUS (2020) was employed to predict the load–displacement curves of brick–concrete recycled aggregate concrete. It was found that strength increases with the brick–concrete ratio up to a certain threshold; however, when the ratio exceeds 1, strength begins to decline.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, Y.; Wang, L.; Kong, D.; Zhou, T.; Ren, C.; Yang, R.; Yuan, Q. Effect evaluation and mechanism analysis of steel slag fine aggregate on the strengths of recycled aggregate concretes. Eur. J. Environ. Civ. Eng. 2025, 29, 1178–1195. [Google Scholar] [CrossRef]

- Junior, J.K.Q.; Kankam, C.K. The Strength Characteristics of Concrete Blended with Recycled Concrete, Quarry Dust and Broken Glass. J. Eng. Res. Rep. 2022, 23, 10–21. [Google Scholar] [CrossRef]

- Yi-Cun, C.; Yu-Yin, W.; Huan, Z.; Chen, J.; Geng, Y. Different influence of replacement ratio of recycled aggregate on uniaxial stress-strain relationship for recycled concrete with different concrete strengths. Structures 2022, 42, 284–308. [Google Scholar]

- Ayub, T.; Khan, A.U.R.; Mahmood, W. Effect of Recycled Concrete Aggregates on Compressive Strength and Water Permeability of Concrete. Int. J. Energy Environ. 2021, 14, 25–32. [Google Scholar] [CrossRef]

- Yang, S. Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties. Appl. Sci. 2018, 8, 2190. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behavior of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Zhang, H.R. Mechanism of Performance Deterioration and Engineering Application of Recycled Aggregate Concrete Based on Interfacial Parameters. Ph.D. Dissertation, Zhejiang University, Hangzhou, China, 2024. [Google Scholar]

- Liu, X.; Wu, J.; Zhao, X.; Yan, P.; Ji, W. Effect of brick waste content on mechanical properties of mixed recycled concrete. Constr. Build. Mater. 2021, 292, 123320. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, D.; Dong, H.; Sun, Y. Analytical and experimental investigation of bond behavior of confined recycled brick-concrete aggregate concrete. J. Build. Eng. 2025, 100, 111452. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, J.; Feng, Z.; Xiao, Z.; Li, L. Study on the modification mechanism of recycled brick-concrete aggregate concrete based on water glass solution immersion method. J. Build. Eng. 2024, 82, 108303. [Google Scholar] [CrossRef]

- Yao, Z.; Lang, M.; Qi, Y.; Zhang, Y.; LingHu, T.; Dang, F. Research of Meso-mechanical Performances of Recycled Brick Concrete. J. Phys. Conf. Ser. 2023, 2607, 012007. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Rahman, S.; Alam, S. Water Permeability Properties of Concrete made from Recycled Brick Concrete as Coarse Aggregate. IOP Conf. Ser. Mater. Sci. Eng. 2020, 809, 012015. [Google Scholar] [CrossRef]

- Kumar, N.; Saxena, A.K.; Soni, G.; Qureshi, F. Analysis of Concrete Made from Recycled Bricks. Int. J. Eng. Tech. Res. 2017, 6, 220–223. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Weggel, D.C. Recycled brick masonry aggregate concrete: Use of brick masonry from construction and demolition waste as recycled aggregate in concrete. Struct. Surv. 2013, 31, 160–180. [Google Scholar] [CrossRef]

- Nazarimofrad, E.; Shaikh, F.U.A.; Nili, M. Effects of steel fibre and silica fume on impact behaviour of recycled aggregate concrete. J. Sustain. Cem.-Based Mater. 2017, 6, 54–68. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Dong, T.; Liao, W.J.; Liu, J.J. Influence of basalt fiber on mechanical properties of recycled aggregate concrete and numerical simulation study. Concrete 2022, 1, 92–96. [Google Scholar]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, C.; Liang, X.; Chen, S.; Li, M.; Huang, W.; Huang, R. Study on Mechanical Properties of Steel Fiber Rubber Recycled Brick Concrete. E3S Web Conf. 2021, 233, 03011. [Google Scholar] [CrossRef]

- Gong, S.; Bai, L.; Tan, Z.; Xu, L.; Bai, X.; Huang, Z. Mechanical Properties of Polypropylene Fiber Recycled Brick Aggregate Concrete and Its Influencing Factors by Gray Correlation Analysis. Sustainability 2023, 15, 11135. [Google Scholar] [CrossRef]

- Peng, M.; Huang, H.X.; Liao, Q.H. Experimental study on the basic mechanical properties of basalt fiber reinforced concrete. Concrete 2012, 1, 74–75. [Google Scholar]

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- Kheyroddin, A.; Ahmadi, M.; Kioumarsi, M. Using intelligent system approach for shear strength forecasting of steel fiber-reinforced concrete beams. In Proceedings of the SynerCrete’18: Interdisciplinary Approaches for Cement-based Materials and Structural Concrete, Funchal, Portugal, 24–26 October 2018. [Google Scholar]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standardization Administration of China: Beijing, China, 2019.

- Wang, H.Z. Research progress on mechanical and durability properties of basalt fiber reinforced recycled concrete. Synth. Fibers 2023, 52, 75–78. [Google Scholar]

- Zhang, W.J.; Bao, C.C.; Kong, X.Q. Study on the influence of hybrid fiber content on the mechanical properties of recycled concrete. Sci. Technol. Eng. 2016, 16, 106–112+123. [Google Scholar]

- Zhu, C.; Zhao, W.T.; Yu, W.H. Basic mechanical properties and constitutive model of recycled brick-concrete aggregate concrete. Acta Mater. Compos. Sin. 2024, 41, 898–910. [Google Scholar]

- Yuan, C.F.; Li, S.; Zeng, L. Study on mechanical properties of recycled concrete with mixed brick-concrete coarse aggregate. Bull. Chin. Ceram. Soc. 2018, 37, 398–402. [Google Scholar]

- Ji, Y.; Wang, D. Constitutive model of waste brick concrete based on Weibull strength theory. Case Stud. Constr. Mater. 2023, 18, e01738. [Google Scholar] [CrossRef]

- Ma, K.L.; Huang, X.Y.; Hu, M.W. Damage constitutive relationship of recycled brick-concrete coarse aggregate concrete. J. Build. Mater. 2022, 25, 131–141. [Google Scholar]

- Qi, L.; Zhang, Z.; Yu, B.Y. Study on freeze-thaw constitutive model of recycled brick-concrete aggregate concrete. Concrete 2023, 6, 56–60. [Google Scholar]

- Guo, Z.H.; Shi, X.D. Principles and Analysis of Reinforced Concrete; Tsinghua University Press: Beijing, China, 2023; p. 19. [Google Scholar]

- Zhao, D.; Zhang, J.; Liang, H.; Sun, Y. Mechanical properties and constitutive models of rectilinear stirrup confined recycled brick-concrete aggregate concrete. Constr. Build. Mater. 2025, 470, 140532. [Google Scholar] [CrossRef]

- Lin, W.; Hu, R.; Zhou, Y.; Xu, W.; Zhuang, J. Effect of carbonation on the cyclic behavior of recycled aggregate concrete: Test, simulation and constitutive model. Constr. Build. Mater. 2024, 452, 138718. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, J.; Zhang, R.; Lu, X. Research into the internal flaw evolution mechanism and the constitutive model of recycled aggregate concrete under monotonic and cyclic loading. Constr. Build. Mater. 2024, 421, 135667. [Google Scholar] [CrossRef]

- Huang, D.; Chen, X.; Liu, Z.; Lu, Y.; Li, S. Microwire steel fiber-reinforced geopolymer recycled aggregate concrete under uniaxial compression and tension: Mechanical properties and constitutive models. Constr. Build. Mater. 2025, 459, 139772. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, X.; Tang, Y. Damage constitutive model of polypropylene-fibre-reinforced recycled aggregate concrete. Mag. Concr. Res. 2024, 76, 535–547. [Google Scholar] [CrossRef]

| Aggregate Types | Apparent Density /kg/m3 | Moisture Content/% | Crushing Index/% | Water Absorption/% |

|---|---|---|---|---|

| Natural Aggregates | 2720 | 0.2% | 8.6% | 1.2% |

| Recycled Brick Aggregates | 2340 | 0.55% | 33.2% | 15.2% |

| Recycled Brick–Concrete Aggregates | 2540 | 0.48% | 17.3% | 4.87% |

| Fiber Types | Length/mm | Diameter/μm | Tensile Strength/MPa | Elastic Modulus/GPa |

|---|---|---|---|---|

| Basalt Fiber | 8 | 17 | 3000 | 110 |

| Serial Number | Brick–Concrete Ratio/% | Cement/kg/m3 | Water /kg/m3 | Natural Aggregates /kg/m3 | Admixtures /kg/m3 | Sand /kg/m3 | Recycled Brick Aggregate Content /kg/m3 | Proportion of Recycled Brick Aggregates/% | Recycled Concrete Aggregate Content /kg/m3 | Proportion of Recycled Concrete Aggregates/% | Fiber Content/% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E | - | 540 | 165.0 | 790.0 | 16 | 900 | 0 | 0 | 0.00 | 0 | 0 |

| E2 | - | 540 | 165.0 | 790.0 | 16 | 900 | 0 | 0 | 0.00 | 0 | 0.2 |

| F | 4 | 540 | 175.0 | 750.5 | 16 | 900 | 29.63 | 4 | 19.75 | 1 | 0 |

| G | 0.25 | 540 | 203.7 | 592.5 | 16 | 900 | 39.50 | 5 | 158.00 | 20 | 0 |

| G1 | 0.25 | 540 | 203.7 | 592.5 | 16 | 900 | 39.50 | 5 | 158.00 | 20 | 0.1 |

| G2 | 0.25 | 540 | 203.7 | 592.5 | 16 | 900 | 39.50 | 5 | 158.00 | 20 | 0.2 |

| G3 | 0.25 | 540 | 203.7 | 592.5 | 16 | 900 | 39.50 | 5 | 158.00 | 20 | 0.3 |

| H | 0.67 | 540 | 204.7 | 592.5 | 16 | 900 | 19.75 | 10 | 29.63 | 15 | 0 |

| H2 | 0.67 | 540 | 204.7 | 592.5 | 16 | 900 | 19.75 | 10 | 29.63 | 15 | 0.2 |

| I | 0.25 | 540 | 204.2 | 395.0 | 16 | 900 | 79.00 | 10 | 316.00 | 40 | 0 |

| I2 | 0.25 | 540 | 204.2 | 395.0 | 16 | 900 | 79.00 | 10 | 316.00 | 40 | 0.2 |

| J | 4 | 540 | 205.2 | 592.5 | 16 | 900 | 29.63 | 20 | 19.75 | 5 | 0 |

| J2 | 4 | 540 | 205.2 | 592.5 | 16 | 900 | 29.63 | 20 | 19.75 | 5 | 0.2 |

| K | 0.67 | 540 | 204.7 | 395.0 | 16 | 900 | 158.00 | 20 | 237.00 | 30 | 0 |

| L | 1 | 540 | 195.0 | 395.0 | 16 | 900 | 197.50 | 25 | 179.50 | 25 | 0 |

| M | 4 | 540 | 200.0 | 395.0 | 16 | 900 | 316.00 | 40 | 49.00 | 10 | 0 |

| N | 0.25 | 540 | 208.0 | 197.5 | 16 | 900 | 118.50 | 15 | 474.00 | 60 | 0 |

| O | 0.25 | 540 | 215.0 | 0 | 16 | 900 | 158.00 | 20 | 632.00 | 80 | 0 |

| Specimen Numbering and Grouping | 1 | 2 | 3 | Average Strength /MPa | Standard Deviation | Splitting Tensile Strength/MPa | Flexural Strength/MPa |

|---|---|---|---|---|---|---|---|

| E2 | 45.2 | 44.2 | 43.3 | 44.2 | 0.95 | - | - |

| G | 30.5 | 31.8 | 33.7 | 32.0 | 1.61 | 2.86 | 3.4 |

| G1 | 30.1 | 33.0 | 33.8 | 32.3 | 1.95 | 2.65 | 3.8 |

| G2 | 33.0 | 33.8 | 34.0 | 33.6 | 0.53 | 2.90 | 4.9 |

| G3 | 33.0 | 34.1 | 34.0 | 33.7 | 0.61 | 3.10 | 4.9 |

| H2 | 33.8 | 35.0 | 34.1 | 34.3 | 0.62 | 3.08 | 5.1 |

| I2 | 32.2 | 33.9 | 33.5 | 33.2 | 0.89 | 2.89 | 4.7 |

| J2 | 31.7 | 32.9 | 33.5 | 32.7 | 0.92 | 2.76 | 4.4 |

| Serial Number | Type | Peak Stress fc /MPa | Peak Strain/με | Ascending Portion 0.4 fc /MPa | Strain of 0.4 fc /με | Elastic Modulus /GPa | Descending Portion 0.85 fc /MPa | Peak Strain of 0.85 fc /με |

|---|---|---|---|---|---|---|---|---|

| E | 0%PBC | 39.03 | 1.52 | 15.61 | 0.60 | 25.89 | 33.18 | 1.73 |

| F | 5%RBCAC(4.00) | 38.63 | 1.65 | 15.45 | 0.73 | 21.14 | 32.84 | 1.89 |

| G | 25%RBCAC(0.25) | 36.50 | 2.16 | 14.60 | 0.86 | 17.00 | 31.03 | 2.23 |

| G1 | 25%RBCAC–0.1%B | 36.50 | 2.16 | 14.60 | 0.86 | 17.00 | 31.03 | 2.23 |

| I | 50%RBCAC(0.25) | 34.59 | 2.39 | 13.84 | 0.95 | 14.58 | 29.40 | 2.47 |

| K | 50%RBCAX(0.67) | 34.62 | 2.46 | 13.85 | 0.98 | 14.17 | 29.43 | 2.58 |

| L | 50%RBCAX(1.00) | 33.84 | 2.54 | 13.54 | 1.01 | 13.39 | 28.76 | 2.69 |

| M | 50%RBCAC(4.00) | 32.18 | 2.60 | 12.87 | 1.03 | 12.48 | 27.35 | 2.81 |

| N | 75%RBCAC(0.25) | 30.19 | 2.71 | 12.08 | 1.07 | 11.25 | 25.66 | 2.97 |

| O | 100%RBCAC(0.25) | 28.19 | 2.96 | 11.28 | 1.17 | 9.61 | 23.96 | 3.09 |

| Source of References | Number of Data Sets | fc Range/MPa | Ec Range/GPa |

|---|---|---|---|

| Yongcheng Ji [30] | 5 | 31.6–46 | 11.8–22.65 |

| Ma Kunlin [31] | 13 | 19.6–46.4 | 10.63–16.28 |

| Zhu Chao [28] | 8 | 30.4–47.9 | 9.27–31.18 |

| Qi Lin [32] | 4 | 31.55–35.43 | 22.53–31.15 |

| Serial Number | Type | Test Value/GPa | fcu/MPa | Calculated Value/GPa | Ratio |

|---|---|---|---|---|---|

| E | 0%PBC | 25.89 | 39.03 | 19.91 | 1.30 |

| F | 5%RBCAC(4.00) | 21.14 | 38.63 | 19.80 | 1.06 |

| G | 25%RBCAC(0.25) | 17.00 | 36.50 | 36.73 | 0.47 |

| I | 50%RBCAC(0.25) | 14.58 | 34.59 | 35.85 | 0.41 |

| K | 50%RBCAC(0.67) | 14.17 | 34.62 | 24.61 | 0.58 |

| L | 50%RBCAC(1.00) | 13.39 | 33.84 | 20.82 | 0.64 |

| M | 50%RBCAC(4.00) | 12.48 | 32.18 | 11.96 | 1.02 |

| N | 75%RBCAC(0.25) | 11.25 | 30.19 | 33.41 | 0.34 |

| O | 100%RBCAC(0.25) | 9.61 | 28.19 | 32.31 | 0.30 |

| Literature | Specimen | Peak Stress/MPa | Predicted Value | Error |

|---|---|---|---|---|

| Zhao et al. [34] | RAC 30-0 | 35.77 | 34.57 | 3.47% |

| Lin et al. [35] | N100 | 32.98 | 31.20 | 5.70% |

| R100 | 24.85 | 22.95 | 8.28% | |

| Li et al. [36] | NAC | 39.28 | 40.39 | 2.74% |

| RAC-25 | 35.82 | 38.62 | 7.25% | |

| RAC-50 | 32.96 | 36.23 | 9.02% | |

| RAC-100 | 35.96 | 34.02 | 5.70% | |

| Huang et al. [37] | R0-S0 | 43.96 | 49.36 | 10.94% |

| Yu et al. [38] | R-0-0 | 36.69 | 35.3 | 3.94% |

| R-25-0 | 32.59 | 31.4 | 3.78% | |

| R-50-0 | 30.45 | 29.4 | 3.57% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Hou, D.; Shi, Y.; Sun, Y.; Xv, C.; Wang, Y. Mechanical Properties of Recycled Concrete Containing Brick–Concrete Waste Aggregates with Basalt Fiber-Reinforced Polymer (BFRP) Fibers. Buildings 2025, 15, 2047. https://doi.org/10.3390/buildings15122047

Sun Y, Hou D, Shi Y, Sun Y, Xv C, Wang Y. Mechanical Properties of Recycled Concrete Containing Brick–Concrete Waste Aggregates with Basalt Fiber-Reinforced Polymer (BFRP) Fibers. Buildings. 2025; 15(12):2047. https://doi.org/10.3390/buildings15122047

Chicago/Turabian StyleSun, Yuanyuan, Dongxu Hou, Yanbiao Shi, Yamei Sun, Chi Xv, and Yunlin Wang. 2025. "Mechanical Properties of Recycled Concrete Containing Brick–Concrete Waste Aggregates with Basalt Fiber-Reinforced Polymer (BFRP) Fibers" Buildings 15, no. 12: 2047. https://doi.org/10.3390/buildings15122047

APA StyleSun, Y., Hou, D., Shi, Y., Sun, Y., Xv, C., & Wang, Y. (2025). Mechanical Properties of Recycled Concrete Containing Brick–Concrete Waste Aggregates with Basalt Fiber-Reinforced Polymer (BFRP) Fibers. Buildings, 15(12), 2047. https://doi.org/10.3390/buildings15122047