Abstract

With the advancement of urbanization, recycled aggregate concrete derived from construction waste has received increasing research attention. This study primarily focuses on a novel method to enhance the mechanical properties of recycled aggregate concrete derived from brick–concrete waste by mixing short-cut BFRP fibers. A series of experimental tests, including an axial compression test, a splitting tensile test, and a bending test, were conducted on specimens of RBCAC (recycled brick–concrete aggregate concrete) with different brick–concrete ratios and BFRP fiber contents. The effects of the brick–concrete ratio and BFRP content on various mechanical properties were systematically investigated. The results indicate that the brick–concrete ratio significantly affects the mechanical properties of RBCAC. The compressive strength decreased by approximately 2.0–4.7% as the brick-to-aggregate ratio increased from 0.25 to 4, with the peak strength (34.3 MPa) occurring at a ratio of 0.67. In addition, a strong linear relationship was observed between the compressive strength and other mechanical properties of BFRP-RBCAC. Based on the experimental data, the existing constitutive model for recycled concrete was modified by introducing a brick–concrete ratio correction factor and a fiber reinforcement factor. The proposed compression constitutive model is suitable for recycled brick–concrete aggregate concrete incorporating hybrid BFRP fibers.

1. Introduction

In the past three decades, with the rapid urbanization in China, tens of thousands of aged buildings have been demolished and renovated, generating substantial amounts of solid waste. The disposal of these construction wastes in landfills leads to severe contamination of soil and a reduction in water quality. Moreover, stockpiling above ground occupies space and compromises urban aesthetics. The environmental concerns arising from urban demolition waste are becoming increasingly severe. Thus, the effective management and utilization of construction waste should receive attention. Simultaneously, with societal progress and economic development, there has been a dramatic increase in demand for buildings, accompanied by significantly higher requirements for their functional performance. However, building renovations and urban renewal processes consume vast amounts of natural resources, posing considerable threats to the ecological environment. Considering both aspects, the conversion of construction waste into recycled aggregates to produce recycled aggregate concrete (RAC) presents a viable solution. This approach not only effectively addresses the pollution problems caused by the accumulation of urban construction waste but also facilitates the recycling and reuse of resources.

Over the past two decades, research on recycled concrete has become a focal point in the international civil engineering community. Numerous researchers have consistently observed that recycled concrete exhibits lower compressive strength and splitting tensile strength compared to conventional concrete, with the strength decreasing as the proportion of recycled aggregates increases [1,2,3,4,5]. Valeria et al. reported that replacing 30% of natural aggregates with recycled aggregates decreased the splitting tensile strength of concrete by 7.44 to 20% compared to conventional concrete [6]. In contrast, Tabsh, S.W. found that mixtures prepared with high-strength recycled concrete coarse aggregates exhibited compressive strength that was nearly equivalent to that of natural coarse aggregate concrete. However, when recycled aggregates derived from low-strength or unknown-strength concrete were used, the concrete strength significantly decreased, with reductions ranging from 8 to 24% for the same mix proportions [7]. Through a mechanistic analysis of recycled concrete, Zhang [8] determined that the inferior mechanical properties of recycled concrete stem from recycled aggregates’ inherent characteristics, including high water absorption, elevated moisture content, and poor interfacial bonding strength.

Traditional research on recycled concrete has primarily focused on construction waste derived from the demolition of reinforced concrete frame structures. However, in China’s urbanization process, a significant portion of construction waste originates from rural or urban brick-masonry structures, which contain clay bricks, mixed mortar, and concrete blocks, with clay bricks constituting a substantial proportion. This phenomenon has garnered increasing attention from scholars in recent years, as the resource utilization of brick–concrete construction waste holds significant practical implications. Liu et al. [9] demonstrated that 30% is the optimal replacement rate when using both recycled brick coarse aggregates and recycled concrete coarse aggregates. Compared to conventional recycled concrete, the performance of brick–concrete recycled concrete is significantly influenced by the brick–concrete ratio. While a higher brick content can reduce production costs to some extent, it may also lead to decreased concrete strength and increased water absorption. Zhang J et al. [10] observed that as the replacement rate of recycled brick aggregates increases, both the compressive strength and splitting tensile strength of RBCAC decrease, and the elastic modulus is lower than that of conventional concrete. Additionally, RBCA concrete exhibits higher porosity and a more loosely structured interfacial transition zone compared to ordinary concrete. Jisheng Q et al. [11] found that when the brick–concrete ratio is 5:5, the mechanical properties of RBCAC are optimal, with compressive strength, flexural strength, and splitting tensile strength increasing by 10.84%, 11.61%, and 15.08%, respectively. Zeliang Y et al. [12] reported that as the brick content increases, the peak stress and elastic modulus of recycled concrete decrease, while the peak strain increases. This effect is most pronounced when the brick content reaches 30%. Ahmad I S et al. [13] discovered that concrete made from both virgin and recycled brick–concrete exhibits compressive strength below the design strength at 28 days. Kumar N et al. [14] observed that as the brick aggregate replacement ratio increased from 10% to 20%, the compressive strength improved, but when the replacement ratio reached 30%, the compressive strength declined. Cavalline T L et al. [15] investigated the use of crushed recycled brick masonry from on-site demolition as a replacement for traditional coarse aggregates and found that the strength of recycled concrete decreases to varying degrees as the brick aggregate content increases.

Due to the inherent drawbacks of using brick–concrete recycled aggregates, numerous scholars have attempted to address the mechanical deficiencies of recycled concrete by incorporating fibers. Extensive research has demonstrated that the addition of fibers is an effective approach. Nazarimofrad et al. [16] found that the use of silica fume and steel fibers significantly enhances the splitting tensile strength of recycled aggregate concrete. DAS et al. [17] showed that basalt fiber-reinforced polymer (BFRP) provides more pronounced improvements in the mechanical properties of recycled concrete, but there is an optimal range for fiber content. Excessive fiber content can also weaken the mechanical performance of recycled concrete, with 0.5% BFRP content identified as the optimal dosage. However, Dong Teng [18] demonstrated that 0.3% is the optimal content for compressive strength, while 0.6% is the best dosage for the flexural strength of recycled concrete. Numerous studies have confirmed that the incorporation of FRP fibers can indeed enhance the interfacial bonding forces in recycled concrete, improving the connections between recycled aggregates as well as between mortar and aggregates, thereby enhancing the mechanical properties of recycled concrete, particularly the splitting tensile and flexural strengths [19,20].

As previously mentioned, numerous scholars have investigated the mechanical properties of recycled aggregate concrete derived from brick–concrete construction waste. However, many of the aforementioned studies focused on clay brick waste from rural buildings, while the role of mixed mortar has often been overlooked. In contrast, the demolition targets in traditional industrial cities are typically masonry structures that were built between the 1960s and 1980s and are characterized by distinct Eastern European and Soviet architectural styles. These structures contain a higher proportion of mixed mortar or concrete recycled aggregates, with a lower brick–concrete ratio (B/C) and more diverse brick–concrete proportions, making them unique. In such studies, the brick–concrete ratio (B/C) is an essential parameter that cannot be ignored. Although research on this parameter remains limited, prior studies have demonstrated that the ratio of recycled brick to recycled concrete in recycled construction aggregates is one of the key factors influencing the mechanical properties of brick–concrete recycled concrete [21,22].

This study investigates the influence of the brick–concrete ratio and BFRP content on the mechanical properties of brick–concrete recycled concrete, examining the strength degradation patterns and failure mode transition mechanisms under multi-parameter coupling effects. A synergistic interaction equation for the relationship between the brick–concrete ratio and fiber content is proposed to quantify the degree to which BFRP fibers increase toughness under varying brick–concrete ratios. By introducing a brick–concrete ratio correction factor and a fiber reinforcement factor, a new constitutive model for brick–concrete recycled concrete incorporating hybrid BFRP fibers is established.

2. Experimental Methods

2.1. Materials

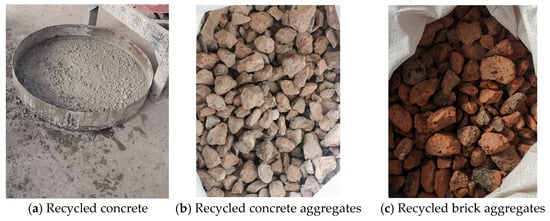

The brick–concrete recycled aggregate concrete used in this study was provided by an ecological technology company in Shenyang. Both the recycled concrete coarse aggregates and recycled brick aggregates were sourced from aged masonry-structure buildings constructed in the 1970s–1980s. The compressive strength of the waste concrete ranged from 20 to 40 MPa, while the compressive strength of the fired waste bricks ranged from 7.5 to 10 MPa. The cement used was P·O 42.5 ordinary Portland cement with machine-made sand with a fineness modulus of 3.2, continuously graded crushed stone with a particle size of 5 to 25 mm, and a high-performance polycarboxylate-based water reducer with a water reduction rate of 27%. The mixing water was laboratory tap water. The construction waste underwent screening and recycling, followed by crushing and washing on a mechanical production line to obtain uniform brick–concrete recycled aggregates with a particle size of 15 mm (Figure 1). The natural aggregates, recycled concrete aggregates, and recycled brick aggregates used to make test specimens conformed to the continuous particle size grading requirements for coarse aggregates (5 to 31.5 mm) specified in the Chinese code “Specification for mix proportion design of ordinary concrete” [23] for concrete preparation.

Figure 1.

Recycled brick–concrete aggregates with uniform particle size.

Natural aggregates and brick–concrete recycled aggregates were obtained through a series of processing steps, including screening, washing, drying, and compaction. Multiple samples were taken and weighed, and the results indicated that the crushed brick aggregates accounted for approximately 20% of the waste brick–concrete aggregates. The surface of brick–concrete aggregates exhibited more pores compared to natural aggregates and was covered with a relatively thin layer of gray powder. In contrast, recycled concrete aggregates consisted of mortar fragments and crushed stone covered with mortar, and their surfaces displayed even more pronounced porosity. Due to the use of sieving for separation, the machine-made aggregates had a more uniform gradation. Table 1 presents the basic characteristics of the aggregates required for producing recycled concrete. Fundamental performance tests of the aggregates revealed that, compared to natural crushed stone aggregates, waste brick recycled aggregates exhibited a higher crushing index and water absorption. However, the mixed recycled aggregates showed a significant improvement in the crushing index and a noticeable enhancement in water absorption properties.

Table 1.

Performance indices of concrete aggregates.

Short-cut basalt fiber-reinforced polymer (BFRP) fibers with lengths ranging from 8 to 12 mm were incorporated. The fibers are bonded and reinforced through a resin matrix, resulting in a texture with a fibrous appearance combined with resin characteristics. The color of the BFRP fabric may vary depending on the resin matrix used, but it typically appears dark gray, as shown in Figure 2. The physical properties of BFRP are presented in Table 2.

Figure 2.

Materials used in the test.

Table 2.

Fiber performance indices.

2.2. Specimen Design

This study aimed to investigate the effects of the brick–concrete ratio (mass ratio of brick aggregates to concrete aggregates) and BFRP fiber content on the mechanical properties of brick–concrete recycled aggregate concrete. A total of 12 groups, comprising 48 specimens, were designed. Among them, Group E served as the control group without recycled aggregates or BFRP fibers, while Group E1 included 0.2% BFRP fibers based on the control mix to isolate the effect of fibers only. Groups G, H, and M correspond to brick–concrete ratios of 0.25, 0.67, and 4, with recycled brick aggregate contents of 5%, 10%, and 20%, respectively, and recycled concrete aggregate contents adjusted to 20, 15, and 10%, forming recycled concrete with different proportions of the aggregates. Groups G1, G2, and G3 incorporated 0.1%, 0.2%, and 0.3% BFRP fibers, respectively, with a baseline brick–concrete ratio of 0.25 (5% recycled brick, 20% recycled concrete) to analyze the influence of the fiber content. The fiber content has been the focus of most related studies [24]. It is widely recognized that excessive fiber content has a significant negative impact on the performance of concrete due to workability loss or fiber balling. However, in this study, we mainly focus on the positive function of BFRP. Therefore, the BFRP content was maintained at low levels of 0.1–0.3%.

The total volume of recycled aggregates was strictly controlled, while cement, sand, and other components remained consistent (details in Table 3). Specimens were prepared in accordance with the Chinese code “Standard for Test Methods of Concrete physical and mechanical properties” [25]: 24 cubic specimens (150 × 150 × 150 mm) were prepared for compressive strength tests, 7 cubic specimens of the same size for splitting tensile strength tests, 7 prismatic specimens (100 × 100 × 400 mm) for flexural strength tests, and 10 prismatic specimens (150 × 150 × 300 mm) for uniaxial compressive stress–strain curve tests. According to the code mentioned above, the test blocks were left in an environment with a temperature of 20 ± 5 °C for at least 24 h, after which they were demolded, numbered, and removed from the molds.

Table 3.

Mix ratio design of recycled brick–concrete aggregate.

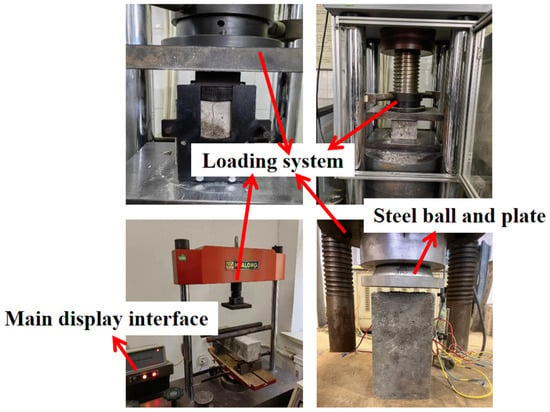

2.3. Specimen Setup and Procedure

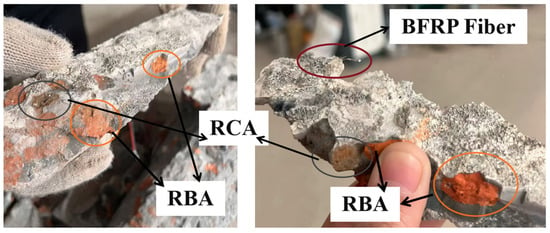

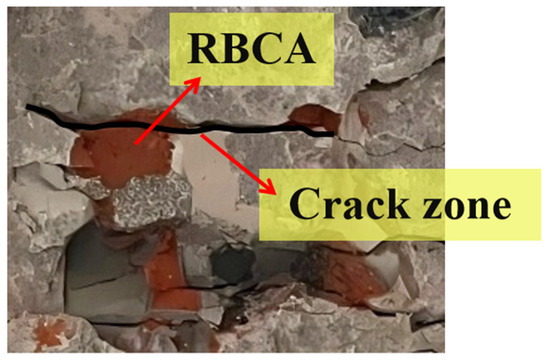

The test methods were conducted in accordance with reference [23]. Compressive strength tests were performed using a 300 ton compression testing machine, as shown in Figure 3. The specimens were placed between loading plates connected by spherical hinges at both ends. A splitting tensile test was performed to evaluate the tensile properties of the concrete. Based on the experimental design, some specimens incorporated basalt fibers to study the tensile performance of brick–concrete recycled aggregate concrete. In the splitting tensile test, the specimen was aligned along its centerline, with semi-circular loading blocks placed at the midpoint of the top and bottom surfaces. The test was completed by applying a load to the upper and lower curved loading plates, as illustrated in Figure 3. In the flexural strength test, standard specimens of 100 × 100 × 400 mm were placed on two rollers of the loading platform. A vertical load was applied to the top, similar to a three-point bending beam loading method, to determine the ultimate flexural strength, as depicted in Figure 3. The complete stress–strain curve under uniaxial compression was obtained using a 2000 kN servo-controlled testing machine (Jiangsu Donghua Testing Technology Co., Ltd., Taizhou, China) with a displacement control rate of 0.5 mm/min, and data were collected using a DH3825 data acquisition system(Jiangsu Donghua Testing Technology Co., Ltd., Taizhou, China). As shown in Figure 4, the examination of the fracture surfaces revealed that nearly all brick aggregates exhibited a fractured morphology, while the cement paste interface bonding the brick aggregates remained intact. In the case of recycled brick–concrete aggregates, the cement paste interfaces bonding the recycled concrete aggregates and the brick aggregates cracked simultaneously; however, the majority of the recycled concrete aggregates did not fracture.

Figure 3.

Experimental setup.

Figure 4.

Internal failure of test block. RBA—recycled brick aggregate; RCA—recycled concrete aggregate.

2.4. Specimen Failure Modes

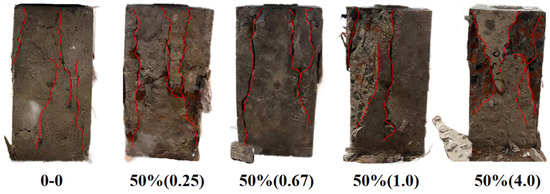

After conducting axial compression tests on 12 groups, comprising 48 specimens in total, as shown in Figure 5, distinct failure patterns were observed during the compressive strength tests. The specimens exhibited noticeable bulging at both ends and spalling in the middle section. This spalling phenomenon was particularly pronounced in specimens with higher recycled aggregate content.

Figure 5.

Compressive test block.

Figure 6 illustrates the failure cross-sections of brick–concrete recycled aggregate concrete specimens incorporating BFRP fibers during splitting tensile tests. The characteristics of the split failure are distinct, manifesting as a crack along the centerline, which is wider at the top and narrower at the bottom. Additionally, the split surfaces of the specimens exhibit a relatively symmetrical morphology. The moment of crack initiation directly reflects the tensile strength of the recycled aggregate concrete.

Figure 6.

Splitting test block.

In the flexural strength tests, the fracture surfaces of recycled brick–concrete aggregate specimens were located between the two concentrated load lines, and sudden fracture occurred as the load increased. As the content of crushed bricks increased, the cross-section tended to become more uniform, with splitting observed in the crushed bricks. Fractures in the concrete specimens occurred not only within the crushed bricks but also at the bonding interfaces between them. For brick–concrete recycled aggregate concrete incorporating BFRP, as shown in Figure 7, the failure during flexural tests was typically located at the mid-span of the specimens. The fracture initiated from cracks at the mid-span and gradually propagated towards both sides. When the specimens reached their ultimate load-bearing capacity, a sudden fracture occurred. The fracture surface formed along the crack path was very neat, and the overall fracture morphology exhibited symmetrical characteristics.

Figure 7.

Flexural test block.

The typical failure patterns of the specimens are illustrated in Figure 8 and Figure 9. All specimens exhibited brittle failure, with macroscopic primary cracks penetrating the entire specimen and numerous vertical cracks distributed across the surface. These macroscopic cracks determined the ultimate failure of the specimens. However, the failure morphology varied depending on the brick–concrete ratio of the recycled aggregates. It was observed that as the replacement rate of recycled aggregates increased, the number of surface cracks initially decreased and then increased. The most severe damage occurred at a brick–concrete ratio of 4, primarily due to the close relationship between the brittle characteristics of concrete specimens and their compressive strength. At brick–concrete ratios of 1.5 and 1, the extent of damage was relatively minor.

Figure 8.

Failure mode of recycled brick–concrete under axial compression.

Figure 9.

Damage status of RBA.

3. Analysis of Experimental Results

The experimental results for eight different scenarios, comprising a total of 38 specimens, are detailed in Table 4. The average strength and standard deviations are shown in Table 4.

Table 4.

Ultimate compressive, flexural, and splitting strengths of specimens at each mix ratio.

In the experiments, four groups of specimens (G, G1, G2, G3) were compared to investigate the influence of different basalt fiber contents on the mechanical properties of brick–concrete recycled aggregate concrete containing the same brick–concrete ratio. In addition, four groups of specimens (G2, H2, I2, J2) were compared to examine the variation trends in the mechanical properties of brick–concrete recycled aggregate concrete incorporating BFRP; these specimens had the same basalt fiber content but varying brick–concrete ratios.

3.1. The Influence of Recycled Aggregate Content on the Mechanical Properties of Recycled Concrete

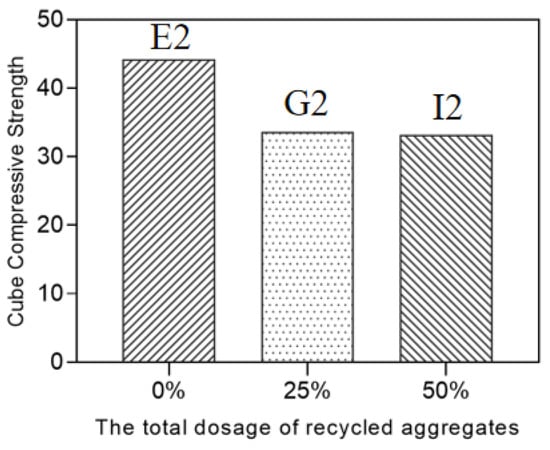

3.1.1. Cube Compressive Strength

Based on the experimental results, the ultimate strength was analyzed. Figure 10 compares the compressive strength of specimens with total recycled aggregate contents of 0, 25, and 50%. As shown in the figure, when the recycled aggregate content increased from 0% to 25%, the cube compressive strength decreased from 44.2 to 33.2 MPa. When the recycled aggregate content increased from 25 to 50%, the compressive strength decreased from 33.6 to 33.2 MPa. These results indicate that as the content of brick–concrete recycled aggregates increases, the compressive strength of recycled concrete decreases, demonstrating that the incorporation of brick–concrete recycled aggregates has a negative impact on the compressive strength of recycled concrete.

Figure 10.

The influence of the blending ratio of recycled aggregates on the compressive strength of cubes.

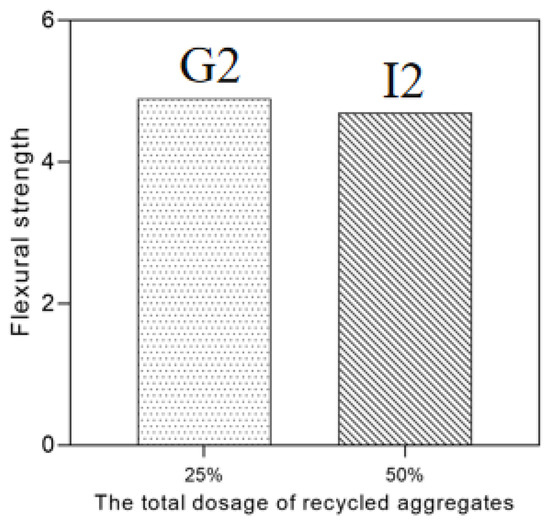

3.1.2. Flexural Strength

Figure 11 compares the flexural strength of specimens with the same brick–concrete ratio and BFRP fiber content but different total recycled aggregate contents. As shown in the figure, the flexural strength of specimens with 25% recycled aggregate content is 4.9 MPa, while it decreases to 4.7 MPa when the recycled aggregate content increases to 50%. This indicates that, under these experimental conditions, the flexural strength decreases by 0.2 MPa as the recycled aggregate content increases from 25 to 50%.

Figure 11.

The influence of the blending ratio of recycled aggregates on flexural strength.

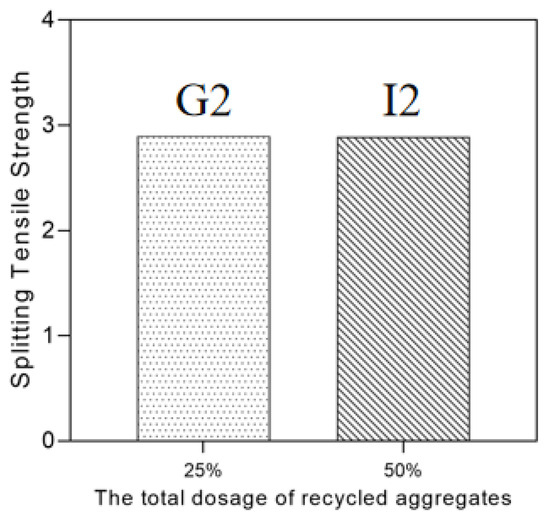

3.1.3. Splitting Tensile Strength

Figure 12 compares the splitting tensile strength of specimens with the same brick–concrete ratio and BFRP fiber content but different total recycled aggregate contents. The splitting tensile strength at 50% recycled aggregate content (2.89 MPa) is slightly higher than that at 25% recycled aggregate content (2.9 MPa). Numerically, the increase in recycled aggregate content from 25 to 50% has a minimal impact on splitting tensile strength.

Figure 12.

The influence of the blending ratio of recycled aggregates on the splitting strength.

3.1.4. Tensile-to-Compressive Strength Ratio

The tensile-to-compressive ratio, defined as the ratio of the splitting tensile strength to the cube compressive strength, is commonly used to evaluate the toughness of concrete [24]. A lower tensile-to-compressive ratio indicates greater brittleness and poorer toughness of the concrete [25]. In this study, the mechanical properties of BFRP-reinforced brick–concrete recycled concrete were analyzed, revealing a strong linear relationship with a high degree of correlation between compressive strength and other mechanical properties. The fitted regression equations further confirm this relationship. Specifically, flexural strength and splitting tensile strength both exhibit a linear dependence on compressive strength, increasing proportionally as compressive strength increases. Experimental data for different recycled aggregate contents (25 and 50%) support these observations, demonstrating consistent trends in the mechanical behavior of brick–concrete recycled aggregate concrete under axial compression.

3.2. The Influence of Brick–Concrete Ratio on the Mechanical Properties of Recycled Concrete

3.2.1. Cube Compressive Strength

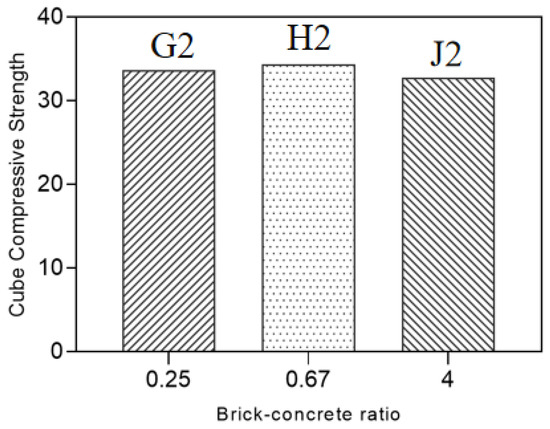

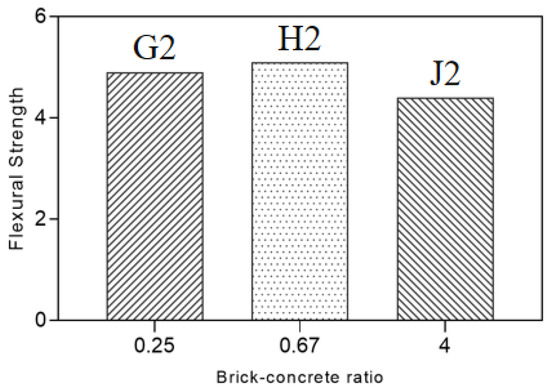

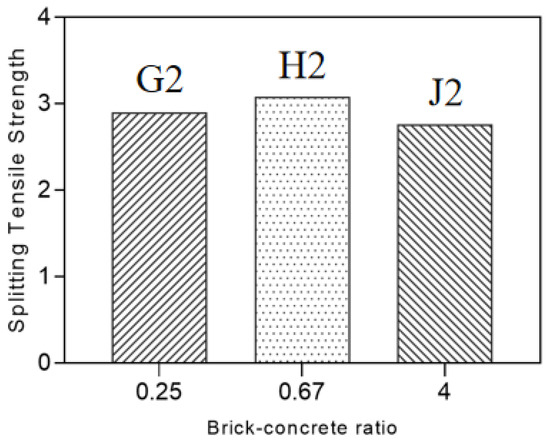

Figure 13 compares the compressive strength of specimens with different brick–concrete ratios and the same total recycled aggregate content. When the brick–concrete ratio is 0.67, the cube compressive strength reaches its maximum value of 34.3 MPa. At a brick–concrete ratio of 0.25, the compressive strength is 33.6 MPa, while at a brick–concrete ratio of 4, the compressive strength is the lowest at 32.7 MPa. These results indicate that, under the same conditions, the ultimate strength of specimens with brick–concrete ratios of 0.25 and 4 is lower than that of specimens with a brick–concrete ratio of 0.67. However, relatively speaking, the compressive strength of specimens with a brick–concrete ratio of 0.25 is lower than that of specimens with a brick–concrete ratio of 4.

Figure 13.

The influence of brick–concrete ratio on the compressive strength of cubes.

3.2.2. Flexural Strength

Figure 14 compares the flexural strength of specimens with different brick–concrete ratios and the same total recycled aggregate content. As shown in the figure, the flexural strength reaches its maximum value of 5.1 MPa when the brick–concrete ratio is 0.67. At a brick–concrete ratio of 0.25, the flexural strength is 4.9 MPa, while at a brick–concrete ratio of 4, the flexural strength is the lowest at 4.4 MPa. These results demonstrate that the flexural strength of brick–concrete recycled aggregate concrete varies with different brick–concrete ratios and does not change monotonically with the brick–concrete ratio.

Figure 14.

The influence of the brick–concrete ratio on flexural strength.

3.2.3. Splitting Tensile Strength

Figure 15 compares the splitting tensile strength of specimens with different brick–concrete ratios and the same total recycled aggregate content. Among the three brick–concrete ratios, the splitting tensile strength of brick–concrete recycled concrete is the highest at 3.08 MPa when the brick–concrete ratio is 0.67. At a brick–concrete ratio of 0.25, the splitting tensile strength is 2.90 MPa, while at a brick–concrete ratio of 4, the splitting tensile strength is the lowest at 2.76 MPa. This indicates that the ultimate strength of specimens with brick–concrete ratios of 0.25 and 4 is lower than that of specimens with a brick–concrete ratio of 0.67. This trend is consistent with the patterns for splitting tensile strength and flexural strength in Figure 14 and Figure 15. These results demonstrate that when the proportion of recycled brick aggregates is high, the compressive, splitting tensile, and flexural strengths are all affected. However, when the proportions of brick aggregates and mixed mortar aggregates are similar, the relative strength loss is minimized.

Figure 15.

The influence of the brick–concrete ratio on splitting strength.

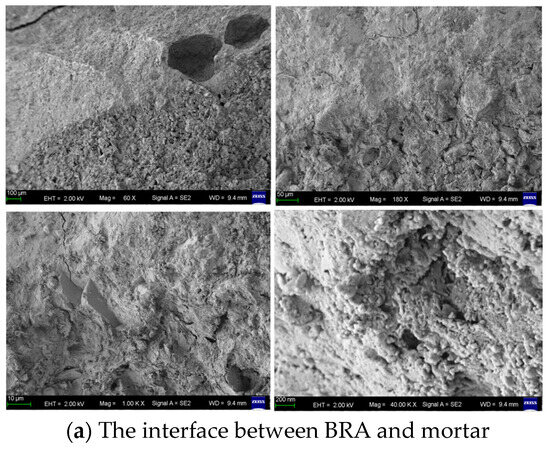

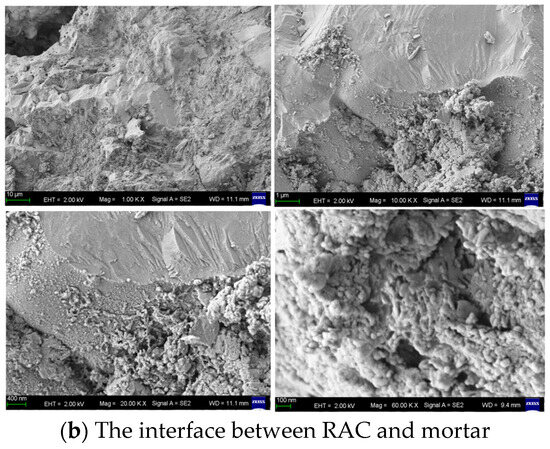

All the strength parameters of recycled brick–concrete aggregate concrete, including compressive strength, flexural strength, and splitting strength, exhibit consistent patterns. Specimens with a brick–concrete ratio of approximately 0.67 have the greatest strength. There are three possible explanations for this observation. The first one is the complementarity of particle gradation. Recycled brick aggregates have a relatively irregular shape and a rough surface, while particles of mixed mortar recycled aggregates are relatively round. The two have certain complementarity in particle morphology and gradation. Figure 16a,b show that the interfaces between BAC and mortar and between RAC and mortar combine perfectly. Secondly, the inclusion of brick aggregates in a proportion comparable to concrete aggregates is conducive to improving the structure of the interface transition zone between cement mortar and recycled aggregates. Additionally, cementitious materials, such as cement, remaining in the recycled aggregates of mixed mortar have some activity and can continue to participate in the hydration reaction in fresh concrete. Although recycled brick aggregates have relatively low activity, they can be used as inert aggregates to provide support. When the dosages of the two are similar, their effects complement each other, which is conducive to improving the strength of concrete.

Figure 16.

SEM images.

The above comparisons of the mechanical properties of BFRP-RBCAC reveal similar patterns for common recycled aggregate concrete. The mechanical properties deteriorated with the content of recycled aggregate, as concluded in the existing literature [1,3,6]. However, few studies have focused on the influence of the content ratio of brick and concrete aggregates.

3.2.4. Tensile-to-Compressive Strength Ratio

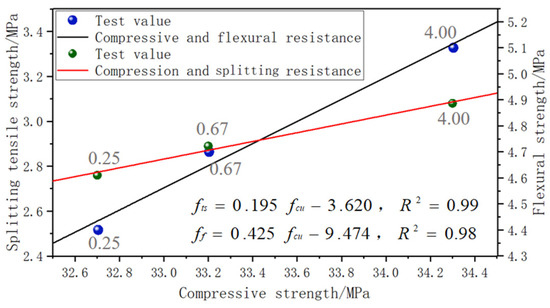

Figure 17 illustrates the relationship between the compressive strength, flexural strength, and splitting tensile strength of specimens with different brick–concrete ratios and the same total recycled aggregate content. In the figure, blue points represent the flexural strength versus compressive strength, while green points represent the splitting tensile strength versus compressive strength. As shown in the figure, both flexural strength and splitting tensile strength exhibit a linear positive correlation with compressive strength.

Figure 17.

The relationships between various mechanical properties.

3.3. The Influence of BFRP Fiber Content on the Mechanical Properties of Recycled Concrete

3.3.1. Cube Compressive Strength

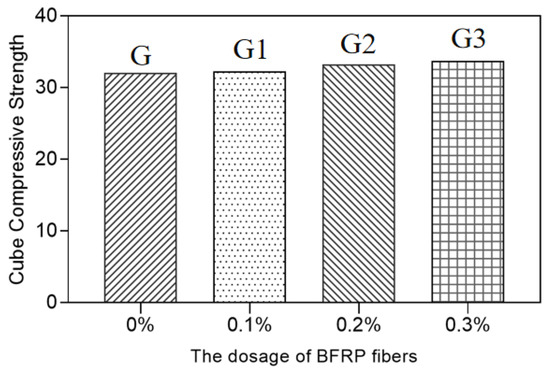

According to the results shown in Figure 18 regarding the influence of different BFRP contents on the cube compressive strength of concrete, the effect of BFRP fibers on compressive strength is limited. Under the condition of a consistent brick–concrete ratio, as the BFRP fiber content increased from 0 to 0.1, 0.2, and 0.3%, the compressive strength of concrete did not exhibit a significant increasing trend. Specifically, when the BFRP fiber content was 0.1%, the variation in compressive strength was minimal. Although there was a degree of strength improvement when the fiber content increased to 0.2 and 0.3%, the extent of the enhancement did not achieve the expected significant strengthening effect. These findings indicate that for brick–concrete recycled concrete with a total recycled aggregate content of 25%, the incorporation of BFRP fibers is not an effective means to enhance its compressive bearing capacity. Subsequent research may consider exploring other more efficient strengthening measures.

Figure 18.

The influence of BFRP fiber content on the compressive strength of cubes.

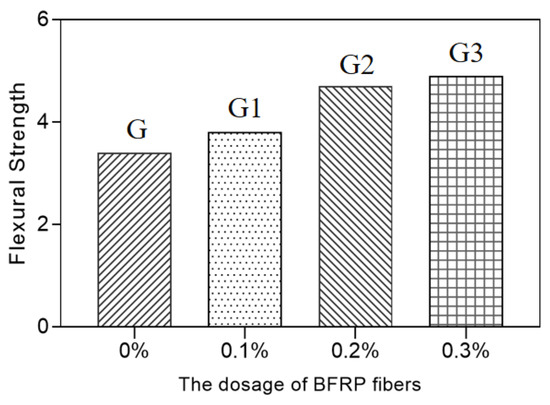

3.3.2. Flexural Strength

Figure 19 compares the flexural strength of specimens with the same brick–concrete recycled aggregate mix proportion and different BFRP contents. As shown in the figure, the flexural strength of concrete gradually increases with higher BFRP fiber content. Compared to the cube compressive strength and splitting tensile strength, the effect of BFRP fibers on flexural strength is more pronounced. When the fiber content is 0.1%, the flexural strength increases by 13.3%. With a fiber content of 0.2%, the flexural strength increases by 38.2%, and with a fiber content of 0.3%, the flexural strength increases by 50%. Therefore, the incorporation of BFRP fibers in brick–concrete recycled aggregate concrete results in the most significant improvement in the flexural performance of recycled concrete.

Figure 19.

The influence of BFRP fiber dosage on flexural strength.

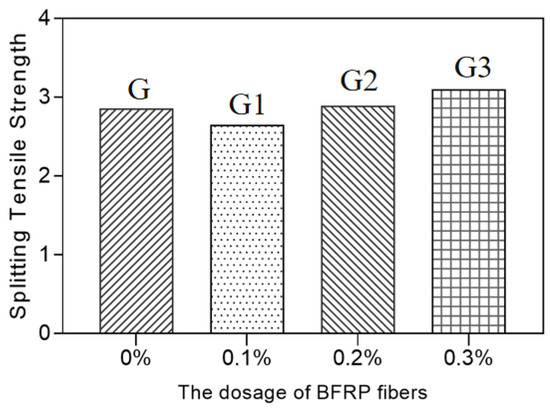

3.3.3. Splitting Tensile Strength

Figure 20 illustrates the influence of different BFRP contents on the splitting tensile strength of concrete cubes. As shown in the figure, BFRP fibers have a more significant effect on the splitting tensile strength of concrete cubes compared to their compressive strength. In this experiment, the splitting tensile strength of cubes with 0.1% BFRP fiber content was slightly lower than that of specimens without BFRP fibers. However, the splitting tensile strength of specimens with 0.2% BFRP fiber content showed a noticeable improvement compared to those without fibers, and this improvement became even more pronounced when the fiber content increased to 0.3%. These results indicate that BFRP fibers with contents below 0.2% have a limited effect on the splitting tensile strength of recycled concrete. It can therefore be concluded that the incorporation of BFRP fibers does influence the splitting tensile performance of concrete.

Figure 20.

The influence of the BFRP fiber dosage on splitting strength.

As mentioned above, the strength of recycled concrete is closely related to the dosage of BFRP fibers. BFRP is able to improve the bearing capacity of specimens bearing flexure and splitting tensile forces to a greater extent than those bearing a compressive force. This finding can be explained by fracture mechanics theories. When recycled concrete is under compression, internal microcracks mainly tend to close due to the action of compressive stress. Although BFRP has a restrictive effect, the stress state inside the concrete limits the space for BFRP to exert its function. Because the driving force for crack propagation is relatively small, it is difficult for BFRP to completely prevent crack propagation, so its ability to improve the compressive strength of concrete is limited. However, when recycled concrete is under a flexural or tensile force, tensile cracks perpendicular to the direction of the tensile force or bending moment will occur internally. These cracks are prone to expand under tensile stress, but BFRP can play a bridging role in the crack propagation process and restrict the further development of the cracks. BFRP has high toughness and strength. When concrete is subjected to tension or bending, it can absorb and dissipate a large amount of energy. When cracks appear in the concrete, BFRP can withstand part of the tensile force through its own tensile deformation, delay the propagation of cracks, and thereby enhance the flexural and tensile strengths of the concrete.

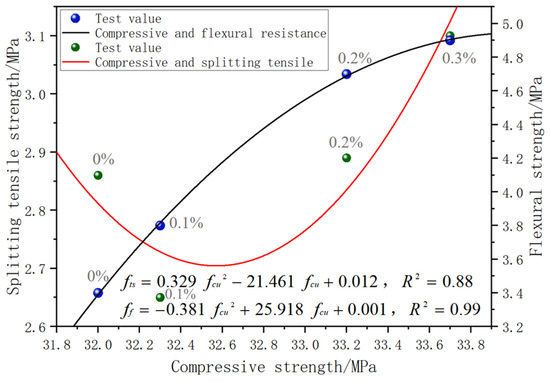

3.3.4. Tensile-to-Compressive Strength Ratio

Studies have shown that concrete typically exhibits a low tensile-to-compressive ratio, and the addition of a certain proportion of fibers can enhance this ratio and improve toughness [26]. Figure 21 illustrates the relationship between the compressive strength, flexural strength, and splitting tensile strength of brick–concrete recycled aggregate concrete with different BFRP contents under axial compression. As shown in the figure, the flexural strength demonstrates a well-fitted quadratic curve relationship with compressive strength, indicating that, within the scope of this experiment, this quadratic curve effectively describes their correlation. Although the splitting tensile strength also exhibits a quadratic curve relationship with compressive strength, the goodness of fit is slightly lower compared to that with flexural strength.

Figure 21.

The relationships between various mechanical properties.

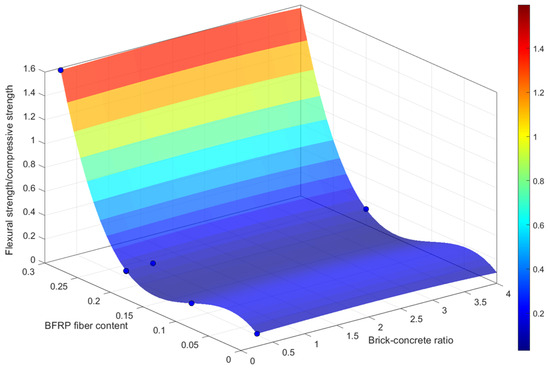

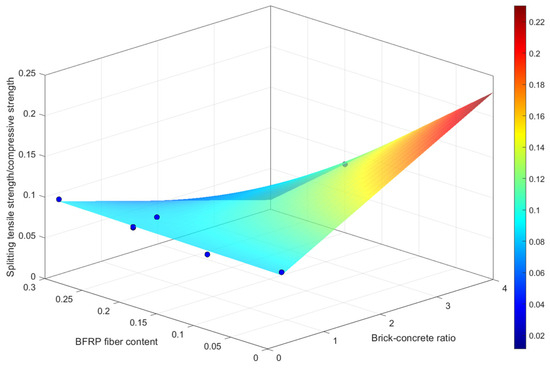

4. Theoretical Analysis

4.1. Splitting and Flexural Strength Prediction Models

In this study of brick–concrete recycled aggregate concrete, a theoretical model formula for the ratio of splitting tensile strength to compressive strength was derived by fitting the experimental data. The experimental investigation of the mechanical properties of brick–concrete recycled aggregate concrete revealed that all mechanical performance indicators differ from those of the control group. Consequently, the conversion formulas for the strength indices of brick–concrete recycled aggregate concrete differ from those of ordinary concrete. Analysis of the mechanical performance data from various test groups indicates significant linear increasing or decreasing trends in the mechanical properties across all groups. As shown in Figure 22 and Figure 23, the ratios of mechanical properties to compressive strength for BFRP-reinforced brick–concrete recycled concrete exhibit a strong nonlinear relationship with both the brick–concrete ratio (B/C) and fiber content (BFRP), with a high degree of correlation. The fitted regression equation is as follows:

Figure 22.

Splitting strength prediction model.

Figure 23.

Flexural strength prediction model.

In the equation, fcu represents the compressive strength (MPa); fts denotes the splitting tensile strength (MPa); indicates the flexural strength (MPa); and is the fiber volume fraction. All other mechanical properties vary with changes in compressive strength. The ranges of splitting tensile strength and flexural strength can be reasonably estimated based on the known compressive strength by using the mechanical conversion model for brick–concrete recycled aggregate concrete. However, this model has certain limitations. It was derived from specific experimental conditions and data ranges, and its accuracy may be affected when applied to brick–concrete ratios and fiber contents outside the tested ranges. Subsequent research could expand the experimental scope to include more types of recycled aggregates, more fiber varieties, and wider ranges of variables, thereby enhancing the model’s universality. The formulas for predicting the splitting tensile strength and flexural strength have some practical value, as they can be used for rough estimation on-site where splitting tensile and flexural strength tests cannot be carried out.

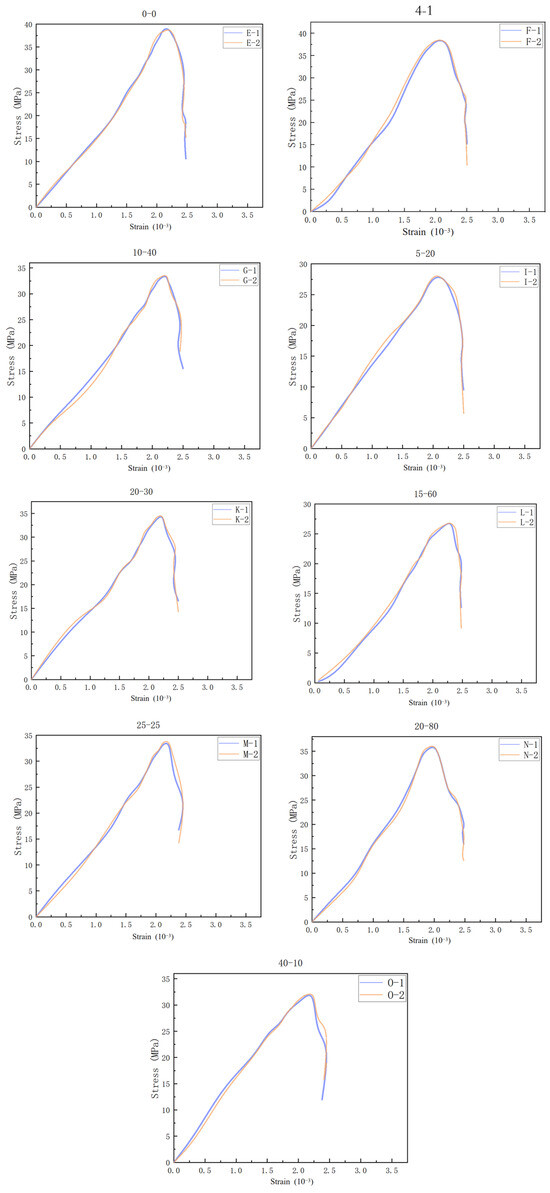

4.2. Elastic Modulus Calculation Formula

Figure 24 presents the measured compressive stress–strain relationship curves for different recycled aggregate replacement rates, with each curve representing the average of two specimen surfaces. The key mechanical characteristics of the curves, including peak stress, peak strain, and elastic modulus, are calculated and presented in Table 5. Here, peak stress refers to the uniaxial compressive strength, which is the axial stress at peak strain. Based on the complete uniaxial compressive stress–strain curve tests of RBCAC specimens, it can be concluded that the failure mode of RBCAC is similar to that of ordinary concrete, primarily characterized by shear failure. The typical stress–strain curves and failure modes were obtained from relevant references in the existing literature [27].

Figure 24.

The measured compressive stress–strain relationship curve.

Table 5.

Main test results of axial compression test of recycled brick–concrete aggregate.

Based on the characteristics of the uniaxial compressive classic stress–strain curve reported in the existing literature [28], the failure process of RBCAC can be divided into four typical stages: (1) the linear elastic stage (before 0.4 ultimate strength); (2) the micro-crack development stage; (3) the peak softening stage, with the material entering the plastic flow stage when the stress reaches 0.9fc; and (4) the failure stage. This failure mode reveals the dynamic evolution process of the material from microscopic damage accumulation to macroscopic structural instability.

After the specimens undergo the aforementioned failure stages, the strain continues to increase. In the ascending segment of the uniaxial compressive stress–strain curve of RBCAC, the initial elastic modulus E0 of each group decreases nonlinearly with increasing brick–concrete ratios. For example, in the reference group, E0 = 25.89 GPa; when the brick–concrete ratio increases to 0.25 (25% RBCAC 0.25 group), E0 decreases to 17.00 GPa, a reduction of approximately 34.3%. Table 5 lists the characteristic indicators of the stress–strain curves for each group based on the experimental results, including peak stress, peak strain, and ultimate strain.

As shown in Figure 24, the brick–concrete ratio (B/C) significantly influences the peak stress and strain of recycled concrete. The peak stress of the reference group (E) is 39.03 MPa, while for specimens incorporating recycled brick aggregates, the peak stress of the low-brick–concrete-ratio group (F) is 38.63 MPa (a decrease of 1.0% compared to the reference group). The peak stress further decreases to 36.50 MPa for brick–concrete-ratio group G and drops to 28.19 MPa for brick–concrete-ratio group O, representing a total reduction of 27.8%. These results indicate that the peak stress exhibits a nonlinear attenuation trend with increasing brick–concrete ratios. The peak strain of the reference group is 1.52 × 10−3, which increases to 1.65 × 10−3 for the low-brick–concrete-ratio group F. For brick–concrete-ratio groups G and O, the peak strain reaches 2.16 × 10−3 and 2.96 × 10−3, respectively.

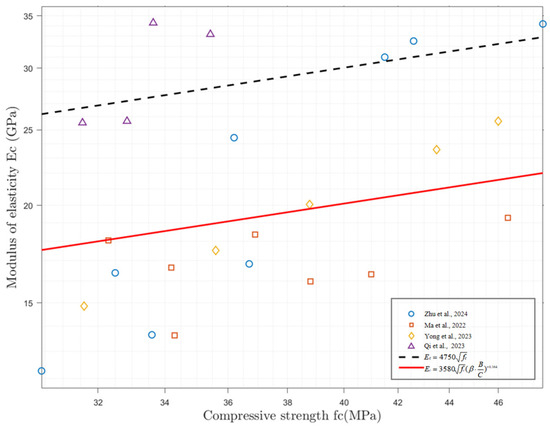

The elastic modulus is a key indicator of the deformation behavior of concrete materials. In this study, based on the empirical formula for the elastic modulus in the European standard EN 1992-1-1 (Eurocode 2: Design of Concrete Structures) and 30 sets of experimental data on the compressive strength and elastic modulus of brick–concrete recycled aggregate concrete from references [28,29,30], a modified elastic modulus model suitable for brick–concrete recycled aggregate concrete is proposed (Table 6). The fitting results are shown in Figure 25. The regression formula (in power function form) is given by Equation (4), where the coefficient 4630 is 2.5% lower than the 4750 specified in the European standard. The reason for this difference can be attributed to the interfacial defects and increased porosity of recycled aggregates. As shown in Table 7, the differences between the experimental and calculated data increase with increasing brick–concrete ratios. Figure 25 and Table 7 reflect the weakening effect of the porosity of recycled brick aggregates on stiffness. This model is applicable to brick–concrete recycled concrete.

Table 6.

Calculation models of compressive strength and elastic modulus.

Figure 25.

Modified elastic modulus model Data sourced from [28,30,31,32].

Table 7.

Calculated and tested values of elastic modulus of recycled brick–concrete aggregate.

Based on the experimental data from this study (brick–concrete ratios B/C = 0.25, 0.67, 4.0), when the brick–concrete ratio is 0.25, the correction factor is 1 − 0.021 × 0.25 = 0.995, and the predicted value is Ec = 14.4 GPa, with an error of only 1.4% compared to the experimental value of 14.6 GPa. When the brick–concrete ratio is 4.0, the correction factor is 0.916, and the predicted value is Ec = 12.3 GPa, with an error of only 1.6% compared to the experimental value of 12.5 GPa.

The modified method in Equation (4) has practical value in that the elastic modulus of recycled concrete with different brick–concrete ratios can be predicted more accurately.

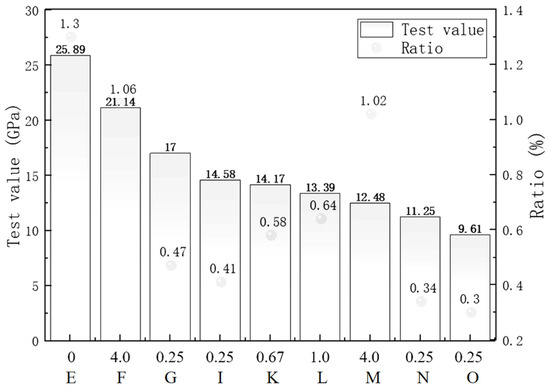

Table 7 presents the experimental and calculated values of the elastic modulus. Based on the uniaxial compression test data of prismatic specimens (150 × 150 × 300 mm), the ratio of the experimental elastic modulus (Etest) of RBCAC to the value calculated from the modified formula exhibits a significant pattern (Table 7). Using Equation (4), the ratio of the experimental value (25.89 GPa) for the reference group (E) to the calculated value (19.91 GPa) reaches 1.30. The brick–concrete ratio significantly influences the elastic modulus, with the calculated value from the modified formula gradually decreasing as the brick–concrete ratio increases. For example, when the brick–concrete ratio is 4.0, the calculated value from the modified formula is 20.24 GPa, while the experimental value is 12.48 GPa, resulting in a ratio of 0.617. This reflects the stiffness degradation caused by interfacial defects at high brick–concrete ratios. The accuracy of the modified model is superior to that of a formula accounting for only the compressive strength correlation, as the introduction of the brick–concrete ratio parameter more precisely captures the variation in the elastic modulus.

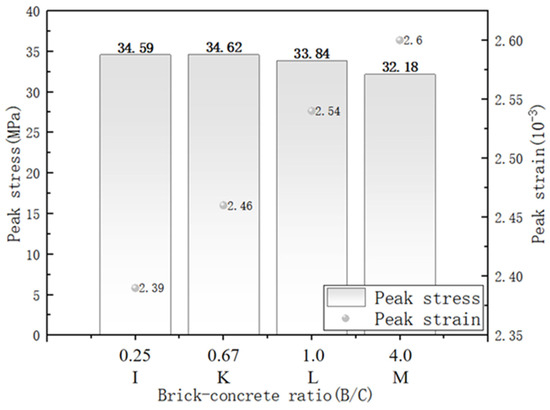

Figure 26 compares the peak stress and peak strain of recycled brick-concrete composites under varying brick-to-concrete ratios (1:4, 2:3, 1:1, 4:1). The peak stress ranges from 32.18 to 34.62 MPa, while the strain increases from 2.39 to 2.60 with higher brick content. Figure 27 presents the peak stresses and normalized ratios across different mix groups, showing a decreasing trend in stress (9.61–25.89 GPa) and fluctuating normalized ratios.

Figure 26.

Comparison of peak stress and strain under different brick–concrete ratios.

Figure 27.

Peak stress and peak strain of brick–concrete recycled concrete.

4.3. Axial Compression Constitutive Model

The constitutive relationship is the mathematical relationship between stress, strain, and deformation that describes the mechanical behavior of materials. To accurately characterize the mechanical behavior of concrete under external loads, numerous scholars have proposed a wide range of empirical models for ordinary concrete, recycled concrete, high-strength concrete, and other materials. These models primarily take the form of polynomials, exponential functions, trigonometric functions, rational fractions, and so on. Based on the uniaxial compression test results for prismatic specimens (150 × 150 × 300 mm), the ascending and descending segments of the stress–strain curve for RBCAC conform to the basic form proposed in the literature [33], with the dimensionless equation as follows:

In the equation, y = σ/fc, x = ε/εc, a = E0/Ec, and Ec = fc/εc represent the stress, strain, peak stress, and peak strain, respectively; a is the shape parameter for the ascending segment, b is the brittleness parameter for the descending segment, fc and εc denote the peak stress and peak strain, respectively, and E0 and Ec represent the initial elastic modulus and peak secant modulus, respectively.

The stiffness factor for the ascending segment a and the brittleness factor for the descending segment b are parameters determined by fitting the experimental data. For the reference group (E), a = 2.10 and b = 0.80, consistent with the model for ordinary concrete. However, for the brick–concrete-ratio group O, due to the degradation of the interfacial transition zone in recycled brick aggregates, a decreases to 1.25 and b increases to 1.12, indicating the reduced initial stiffness and enhanced brittleness of the material. The quantitative relationship between parameter a and the brick–concrete ratio is given by a = 2.10[1 − 0.018(B/C)] (R2 = 0.905), while b follows b = 0.80 + 0.0025(B/C)1.3 (R2 = 0.882). For every 10% increase in the brick–concrete ratio, a decreases by 0.378. For example, when the brick–concrete ratio is 0.25, a = 1.58, indicating that recycled brick aggregates reduce the initial stiffness of the material. For every 10% increase in the brick–concrete ratio, b increases by 0.055. When the brick–concrete ratio is 0.25, b = 0.95, with an error of only 2.2% compared to the experimental value of 0.93, validating the rationality of the formula. Therefore, the modified model based on the existing model from the literature can accurately characterize the nonlinear mechanical behavior of RBCAC, with parameters a and b showing significant correlations with the brick–concrete ratio (R2 > 0.87). This model provides a theoretical basis for the structural analysis of brick–concrete recycled aggregate concrete.

Based on the uniaxial compression test data, a modified model (Equation (7)) is proposed, incorporating two parameters: the brick–concrete ratio (B/C) and the fiber content (Vf). β denotes the total content of recycled aggregates, B/C is the ratio of recycled brick aggregates to recycled concrete aggregates, and Vf denotes the fiber volume fraction. In Equation (6), fc represents the peak stress (MPa) and εc denotes the peak strain; both parameters are obtained directly from the experimental data.

The new constitutive model of recycled concrete considering different brick–concrete ratios can be used in further finite element analyses or mechanical derivation in future studies.

4.4. Finite Element Model and Validation

4.4.1. ABAQUS Model Setup and Parameter Configuration

ABAQUS 2020 (Dassault Systèmes, France) was employed to establish a finite element model of a brick–concrete recycled concrete prism (150 × 150 × 300 mm) to simulate the uniaxial compression test. The material constitutive model selected was the modified model (Equation (7)) with the following parameter settings.

The elastic modulus was calculated using Equation (4), where fc represents the cube compressive strength, and B/C denotes the brick–concrete ratio. The Poisson’s ratio of the concrete was set to 2. Based on the fitting of experimental data, the ascending segment parameter a = 2.10[1 − 0.018(B/C)], and the descending segment parameter b = 0.80 + 0.0025(B/C)1.3.

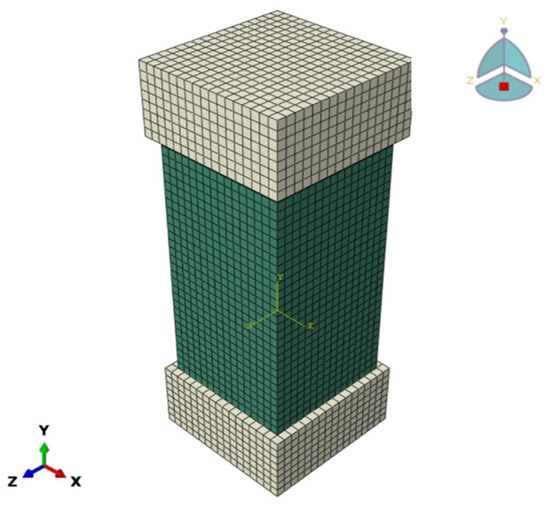

The model employed C3D8R eight-node linear reduced-integration solid elements with a mesh size of 10 mm (Figure 28). Through mesh convergence analysis, it was determined that when the element size is less than 15 mm, the error in peak stress is less than 2%. The boundary conditions were defined as fully fixed at the bottom, with a displacement load applied at the top.

Figure 28.

Grid division diagram and load application diagram.

4.4.2. Model Validation

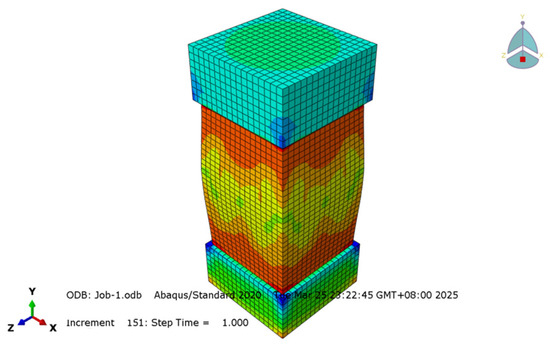

A typical case (B/C = 0.25) was selected for simulation, and the stress–strain curve was compared with the experimental results, as shown in Figure 29. The simulated peak stress was 36.2 MPa, compared to the experimental value of 36.5 MPa; the simulated peak strain was 2.18 × 10−3, compared to the experimental value of 2.16 × 10−3.

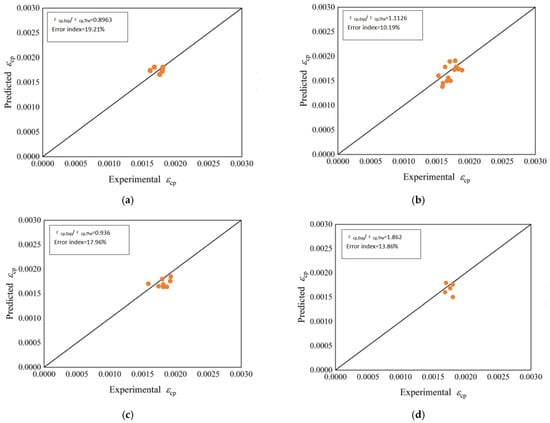

Figure 29.

ECP damage cloud map.

This study evaluated existing models by comparing the experimentally measured average axial stress–strain with the model predictions, as shown in Figure 30a–d. From Figure 30, it can be observed that the model can accurately predict the ultimate axial strain of confined concrete in brick–concrete recycled concrete components reported by Yongcheng Ji [30], Ma Kunlin [31], Zhu Chao [28], and Qi Lin [32]. The prediction is most accurate for Qi Lin’s [32] data, with a slight overestimation of the ultimate axial strain for Ma Kunlin’s data [31] and a slight underestimation for Zhu Chao’s data [28]. However, the overall predictions are accurate. These results demonstrate that the finite element calculations are in good agreement with the experimental results, further validating the correctness of the uniaxial compression constitutive model established in this study for brick–concrete recycled concrete incorporating BFRP.

Figure 30.

Ultimate axial stress and ultimate axial strain: experimental results versus predictions: (a) Yongcheng Ji et al. [30]; (b) Ma et al. [31]; (c) Zhu et al. [28]; (d) Qi et al. [32].

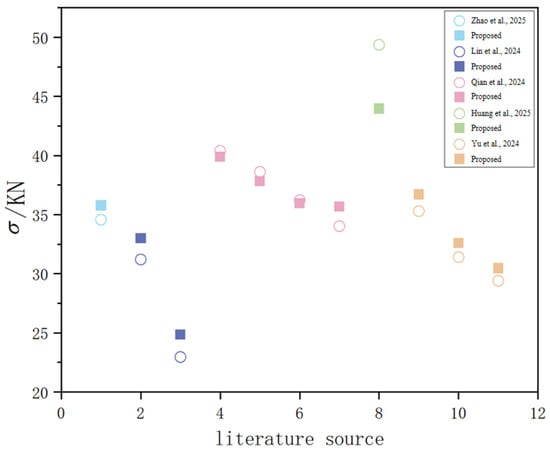

In order to verify the reliability of the constitutive relationship, more experimental data were obtained from additional studies, and a comparative analysis was conducted. As shown in Figure 31, the peak stress values of 11 specimens from five previous studies were compared [34,35,36,37,38]. These specimens are particularly suitable for the conditions of the proposed constitutive model. The results show that most of the calculated values agree well with the test data.

Figure 31.

Comparison of calculated peak stress and test data for specimens in existing literature [34,35,36,37,38].

Table 8 summarizes the peak stress data of recycled concrete specimens reported in previous studies [34,35,36,37,38]. By comparing the experimental peak stresses from these references with the model-predicted values, the error distributions between them are systematically presented. This multi-dataset validation demonstrates the applicability and reliability of the proposed model in predicting peak stress, providing critical references for both mechanical performance studies and model applications of recycled aggregate concrete.

Table 8.

Comparison of experimental and predicted values of peak stress.

4.4.3. Parameter Analysis

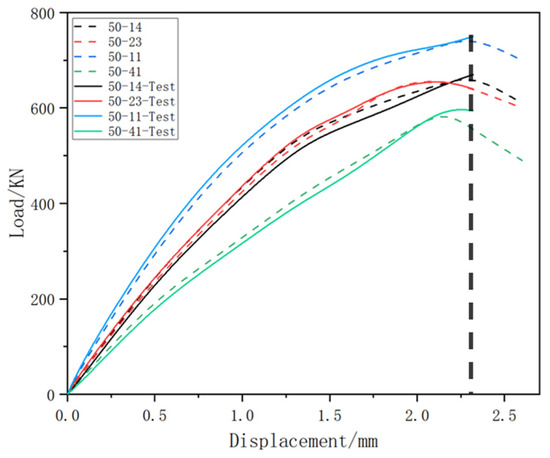

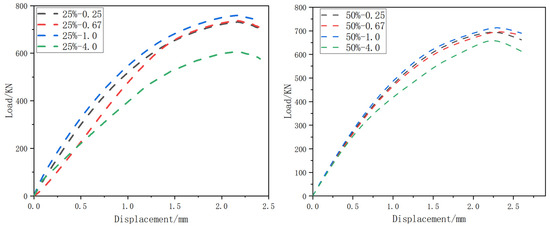

In Figure 32 and Figure 33, the left graph presents the load–displacement simulation curves for different brick–concrete ratios at a total recycled aggregate content of 25%, while the right graph shows the corresponding curves at a total recycled aggregate content of 50%. Comparative analysis of the two graphs reveals that as the recycled aggregate content increases from 25 to 50%, the strength curve exhibits a declining trend. This clearly indicates that higher recycled aggregate content leads to lower strength. Under the same total recycled aggregate content conditions (25 and 50%), the peak load corresponding to the curves increases as the brick–concrete ratio approaches 1. These simulation results align with the experimental findings, demonstrating the significant influence of recycled aggregate content and the brick–concrete ratio on strength. This provides critical theoretical reference and data support for subsequent engineering practices and in-depth research.

Figure 32.

Comparison of load–displacement test simulation curves.

Figure 33.

Comparison of load–displacement simulation curves.

In this research, a new constitutive model of BFRP-RBCAC was developed based on experiments and the existing theoretical model. However, this model’s application is limited to the ranges and materials used in this study: (1) the content of BFRP fibers in BFRP-RBCAC ranged from 0.1 to 0.3%; (2) the brick–concrete ratio ranged from 0.25 to 4.0; (3) the properties of fibers and bending materials fulfill the basic conditions mentioned herein. These limitations will be overcome in our further research, where we will consider more parameters and factors.

5. Conclusions

This study focused on the effects of different brick–concrete ratios on the mechanical properties of brick–concrete recycled aggregate concrete incorporating BFRP. The following conclusions were drawn:

- With an increase in the replacement rate of recycled brick aggregates, the strength indices of concrete exhibit varying degrees of reduction. However, when the proportions of brick aggregates and mixed mortar aggregates are comparable, the relative strength loss is minimized. While different BFRP contents have a limited effect on cube compressive strength, they significantly improve the splitting tensile strength and flexural performance of recycled concrete.

- Strong correlations were observed between the splitting tensile strength, flexural strength, and compressive strength of brick–concrete recycled aggregate concrete. Based on these relationships, conversion formulas for the mechanical properties of brick–concrete recycled aggregate concrete were established.

- A modified formula for the elastic modulus of brick–concrete recycled concrete was proposed, which includes the brick–concrete ratio and fiber content as variables. The accuracy of this formula was validated. Additionally, the strong correlations between splitting tensile strength, flexural strength, and compressive strength were further utilized to develop conversion formulas for mechanical properties.

- The uniaxial compressive stress–strain curve of RBCAC was obtained, and the variation patterns and mechanisms of parameters such as the elastic modulus, peak stress, and peak strain were analyzed. A uniaxial compression constitutive model for RBCAC was established by modifying the existing model from the literature, specifically by incorporating parameters such as the brick–concrete ratio and fiber content, to characterize the nonlinear mechanical behavior of recycled brick–concrete aggregate concrete. Furthermore, the experimental results were validated using finite element software, and ABAQUS (2020) was employed to predict the load–displacement curves of brick–concrete recycled aggregate concrete. It was found that strength increases with the brick–concrete ratio up to a certain threshold; however, when the ratio exceeds 1, strength begins to decline.

Author Contributions

Software, C.X.; Formal analysis, Y.S. (Yamei Sun); Investigation, Y.S. (Yanbiao Shi); Resources, Y.W.; Writing—original draft, Y.S. (Yuanyuan Sun); Writing—review & editing, D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the Natural Science Foundation of Liaoning Province of China [Grant No. 2024-MS-209].

Data Availability Statement

The data are available on request from the corresponding author due to privacy restrictions.

Conflicts of Interest

Author Chi Xv was employed by the company Liaoning Hui Zhicheng Testing Technology Co., Ltd. Author Yunlin Wang was employed by the company Shenyang Construction Engineering Quality Testing Center Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Tian, Y.; Wang, L.; Kong, D.; Zhou, T.; Ren, C.; Yang, R.; Yuan, Q. Effect evaluation and mechanism analysis of steel slag fine aggregate on the strengths of recycled aggregate concretes. Eur. J. Environ. Civ. Eng. 2025, 29, 1178–1195. [Google Scholar] [CrossRef]

- Junior, J.K.Q.; Kankam, C.K. The Strength Characteristics of Concrete Blended with Recycled Concrete, Quarry Dust and Broken Glass. J. Eng. Res. Rep. 2022, 23, 10–21. [Google Scholar] [CrossRef]

- Yi-Cun, C.; Yu-Yin, W.; Huan, Z.; Chen, J.; Geng, Y. Different influence of replacement ratio of recycled aggregate on uniaxial stress-strain relationship for recycled concrete with different concrete strengths. Structures 2022, 42, 284–308. [Google Scholar]

- Ayub, T.; Khan, A.U.R.; Mahmood, W. Effect of Recycled Concrete Aggregates on Compressive Strength and Water Permeability of Concrete. Int. J. Energy Environ. 2021, 14, 25–32. [Google Scholar] [CrossRef]

- Yang, S. Effect of Different Types of Recycled Concrete Aggregates on Equivalent Concrete Strength and Drying Shrinkage Properties. Appl. Sci. 2018, 8, 2190. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behavior of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Zhang, H.R. Mechanism of Performance Deterioration and Engineering Application of Recycled Aggregate Concrete Based on Interfacial Parameters. Ph.D. Dissertation, Zhejiang University, Hangzhou, China, 2024. [Google Scholar]

- Liu, X.; Wu, J.; Zhao, X.; Yan, P.; Ji, W. Effect of brick waste content on mechanical properties of mixed recycled concrete. Constr. Build. Mater. 2021, 292, 123320. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, D.; Dong, H.; Sun, Y. Analytical and experimental investigation of bond behavior of confined recycled brick-concrete aggregate concrete. J. Build. Eng. 2025, 100, 111452. [Google Scholar] [CrossRef]

- Qiu, J.; Wang, J.; Feng, Z.; Xiao, Z.; Li, L. Study on the modification mechanism of recycled brick-concrete aggregate concrete based on water glass solution immersion method. J. Build. Eng. 2024, 82, 108303. [Google Scholar] [CrossRef]

- Yao, Z.; Lang, M.; Qi, Y.; Zhang, Y.; LingHu, T.; Dang, F. Research of Meso-mechanical Performances of Recycled Brick Concrete. J. Phys. Conf. Ser. 2023, 2607, 012007. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Rahman, S.; Alam, S. Water Permeability Properties of Concrete made from Recycled Brick Concrete as Coarse Aggregate. IOP Conf. Ser. Mater. Sci. Eng. 2020, 809, 012015. [Google Scholar] [CrossRef]

- Kumar, N.; Saxena, A.K.; Soni, G.; Qureshi, F. Analysis of Concrete Made from Recycled Bricks. Int. J. Eng. Tech. Res. 2017, 6, 220–223. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Weggel, D.C. Recycled brick masonry aggregate concrete: Use of brick masonry from construction and demolition waste as recycled aggregate in concrete. Struct. Surv. 2013, 31, 160–180. [Google Scholar] [CrossRef]

- Nazarimofrad, E.; Shaikh, F.U.A.; Nili, M. Effects of steel fibre and silica fume on impact behaviour of recycled aggregate concrete. J. Sustain. Cem.-Based Mater. 2017, 6, 54–68. [Google Scholar] [CrossRef]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fiber reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Dong, T.; Liao, W.J.; Liu, J.J. Influence of basalt fiber on mechanical properties of recycled aggregate concrete and numerical simulation study. Concrete 2022, 1, 92–96. [Google Scholar]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, C.; Liang, X.; Chen, S.; Li, M.; Huang, W.; Huang, R. Study on Mechanical Properties of Steel Fiber Rubber Recycled Brick Concrete. E3S Web Conf. 2021, 233, 03011. [Google Scholar] [CrossRef]

- Gong, S.; Bai, L.; Tan, Z.; Xu, L.; Bai, X.; Huang, Z. Mechanical Properties of Polypropylene Fiber Recycled Brick Aggregate Concrete and Its Influencing Factors by Gray Correlation Analysis. Sustainability 2023, 15, 11135. [Google Scholar] [CrossRef]

- Peng, M.; Huang, H.X.; Liao, Q.H. Experimental study on the basic mechanical properties of basalt fiber reinforced concrete. Concrete 2012, 1, 74–75. [Google Scholar]

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- Kheyroddin, A.; Ahmadi, M.; Kioumarsi, M. Using intelligent system approach for shear strength forecasting of steel fiber-reinforced concrete beams. In Proceedings of the SynerCrete’18: Interdisciplinary Approaches for Cement-based Materials and Structural Concrete, Funchal, Portugal, 24–26 October 2018. [Google Scholar]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Standardization Administration of China: Beijing, China, 2019.

- Wang, H.Z. Research progress on mechanical and durability properties of basalt fiber reinforced recycled concrete. Synth. Fibers 2023, 52, 75–78. [Google Scholar]

- Zhang, W.J.; Bao, C.C.; Kong, X.Q. Study on the influence of hybrid fiber content on the mechanical properties of recycled concrete. Sci. Technol. Eng. 2016, 16, 106–112+123. [Google Scholar]

- Zhu, C.; Zhao, W.T.; Yu, W.H. Basic mechanical properties and constitutive model of recycled brick-concrete aggregate concrete. Acta Mater. Compos. Sin. 2024, 41, 898–910. [Google Scholar]

- Yuan, C.F.; Li, S.; Zeng, L. Study on mechanical properties of recycled concrete with mixed brick-concrete coarse aggregate. Bull. Chin. Ceram. Soc. 2018, 37, 398–402. [Google Scholar]

- Ji, Y.; Wang, D. Constitutive model of waste brick concrete based on Weibull strength theory. Case Stud. Constr. Mater. 2023, 18, e01738. [Google Scholar] [CrossRef]

- Ma, K.L.; Huang, X.Y.; Hu, M.W. Damage constitutive relationship of recycled brick-concrete coarse aggregate concrete. J. Build. Mater. 2022, 25, 131–141. [Google Scholar]

- Qi, L.; Zhang, Z.; Yu, B.Y. Study on freeze-thaw constitutive model of recycled brick-concrete aggregate concrete. Concrete 2023, 6, 56–60. [Google Scholar]

- Guo, Z.H.; Shi, X.D. Principles and Analysis of Reinforced Concrete; Tsinghua University Press: Beijing, China, 2023; p. 19. [Google Scholar]

- Zhao, D.; Zhang, J.; Liang, H.; Sun, Y. Mechanical properties and constitutive models of rectilinear stirrup confined recycled brick-concrete aggregate concrete. Constr. Build. Mater. 2025, 470, 140532. [Google Scholar] [CrossRef]

- Lin, W.; Hu, R.; Zhou, Y.; Xu, W.; Zhuang, J. Effect of carbonation on the cyclic behavior of recycled aggregate concrete: Test, simulation and constitutive model. Constr. Build. Mater. 2024, 452, 138718. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, J.; Zhang, R.; Lu, X. Research into the internal flaw evolution mechanism and the constitutive model of recycled aggregate concrete under monotonic and cyclic loading. Constr. Build. Mater. 2024, 421, 135667. [Google Scholar] [CrossRef]

- Huang, D.; Chen, X.; Liu, Z.; Lu, Y.; Li, S. Microwire steel fiber-reinforced geopolymer recycled aggregate concrete under uniaxial compression and tension: Mechanical properties and constitutive models. Constr. Build. Mater. 2025, 459, 139772. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, X.; Tang, Y. Damage constitutive model of polypropylene-fibre-reinforced recycled aggregate concrete. Mag. Concr. Res. 2024, 76, 535–547. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).