A New Approach to Expanding Interior Green Areas in Urban Buildings

Abstract

1. Introduction

1.1. The Benefits of Indoor Greening

1.2. The Challenges of Indoor Greening

1.3. The Issues of Ceiling Planting

1.4. The Objectives for Developing a New Indoor Planting System

- A planter designed for inverted planting of various species with a watertight cultivating unit.

- An artificial light source will be integrated beneath the planter to ensure adequate and consistent illumination for both plant growth and daily activities.

- The system will not incur extra costs on daily electricity consumption under the proposed conditions.

- The planter will be an enclosed environment, allowing air exchange while preventing insect breeding and indoor humidity.

- To avoid overwatering, the system should enable plants to directly regulate their nutrient solution intake, rather than relying on artificial capillary action or other physical methods.

- Frequent replenishment of water or nutrient solutions will not be necessary, thereby reducing the maintenance workload.

2. Materials and Methods

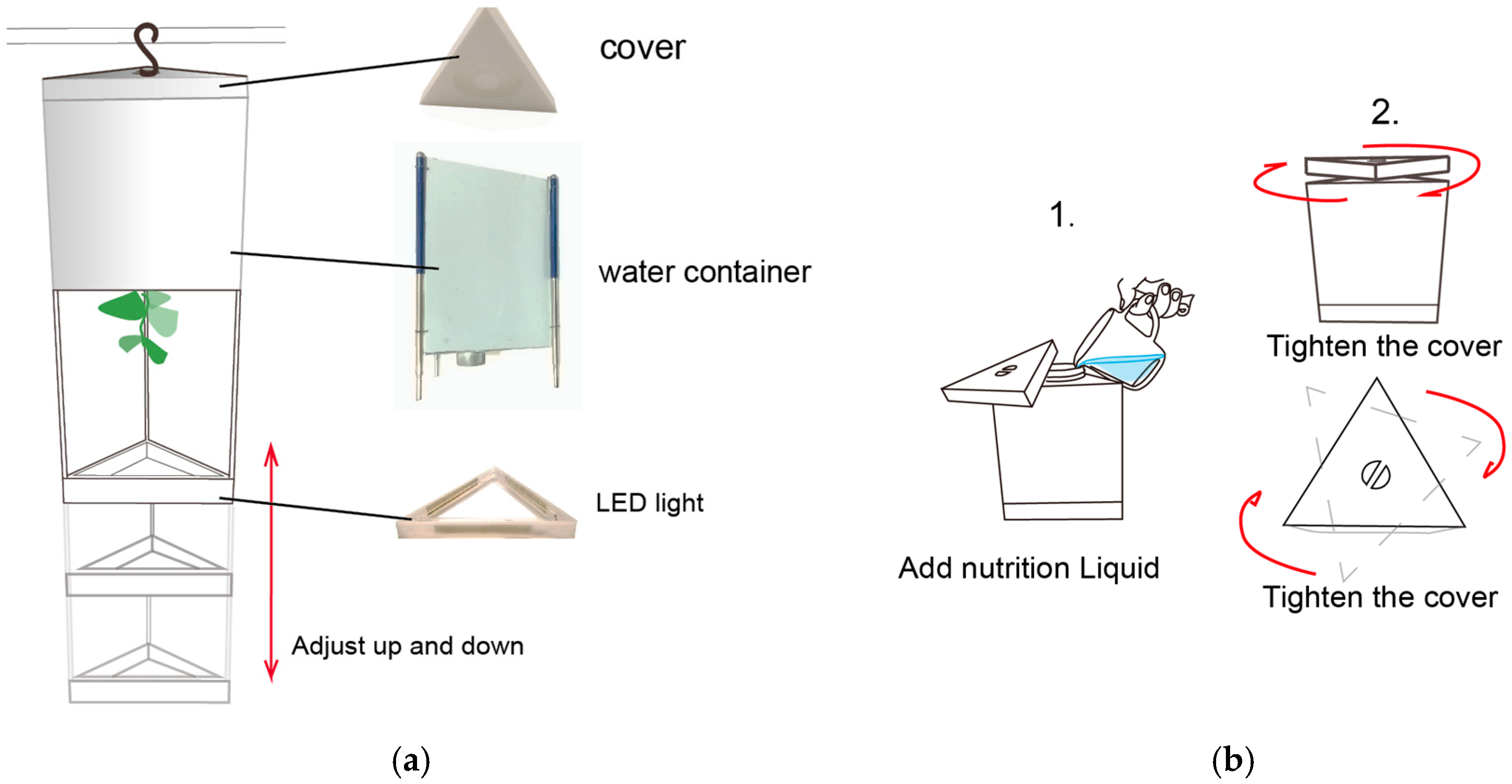

2.1. System Structure

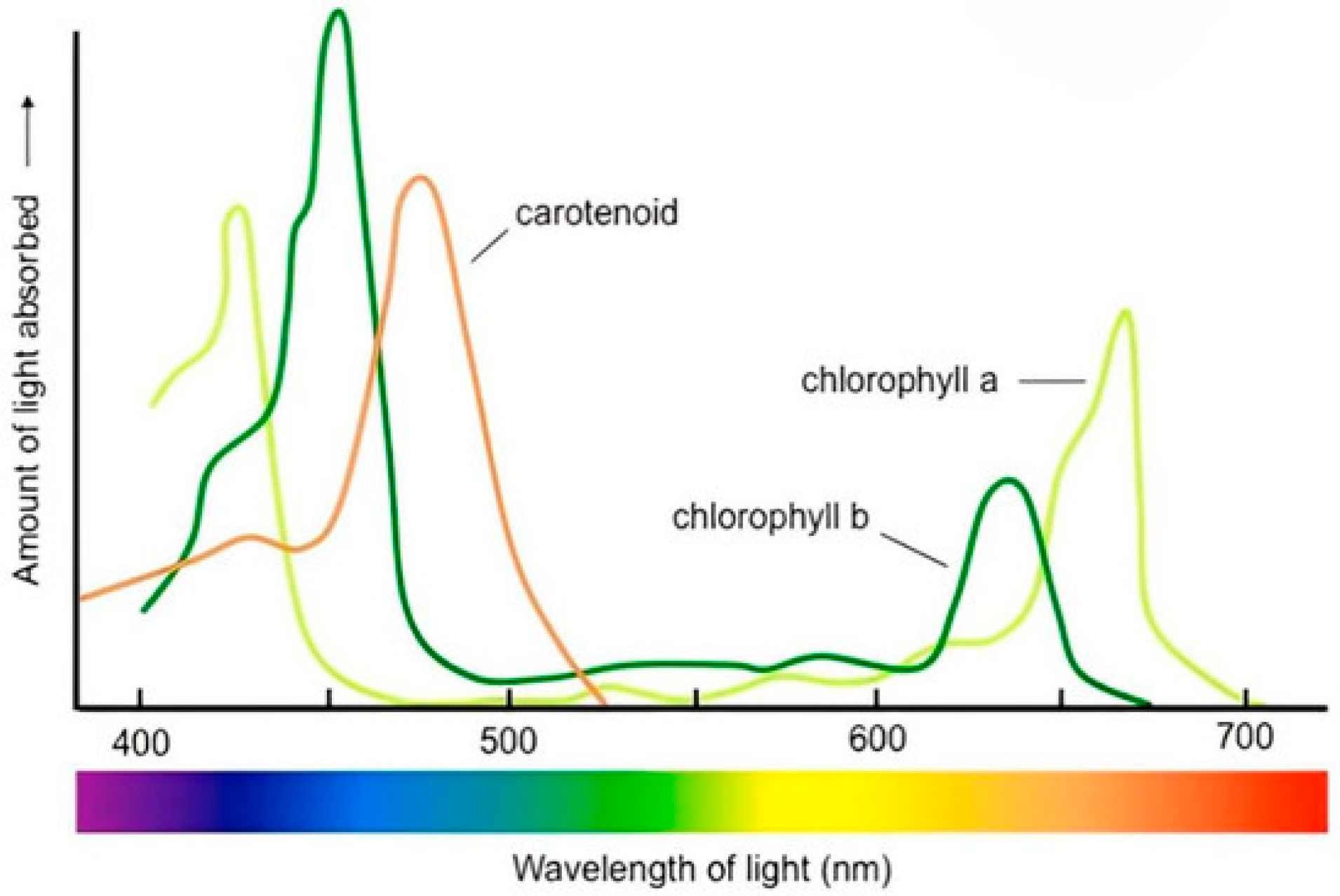

2.2. Lighting Source

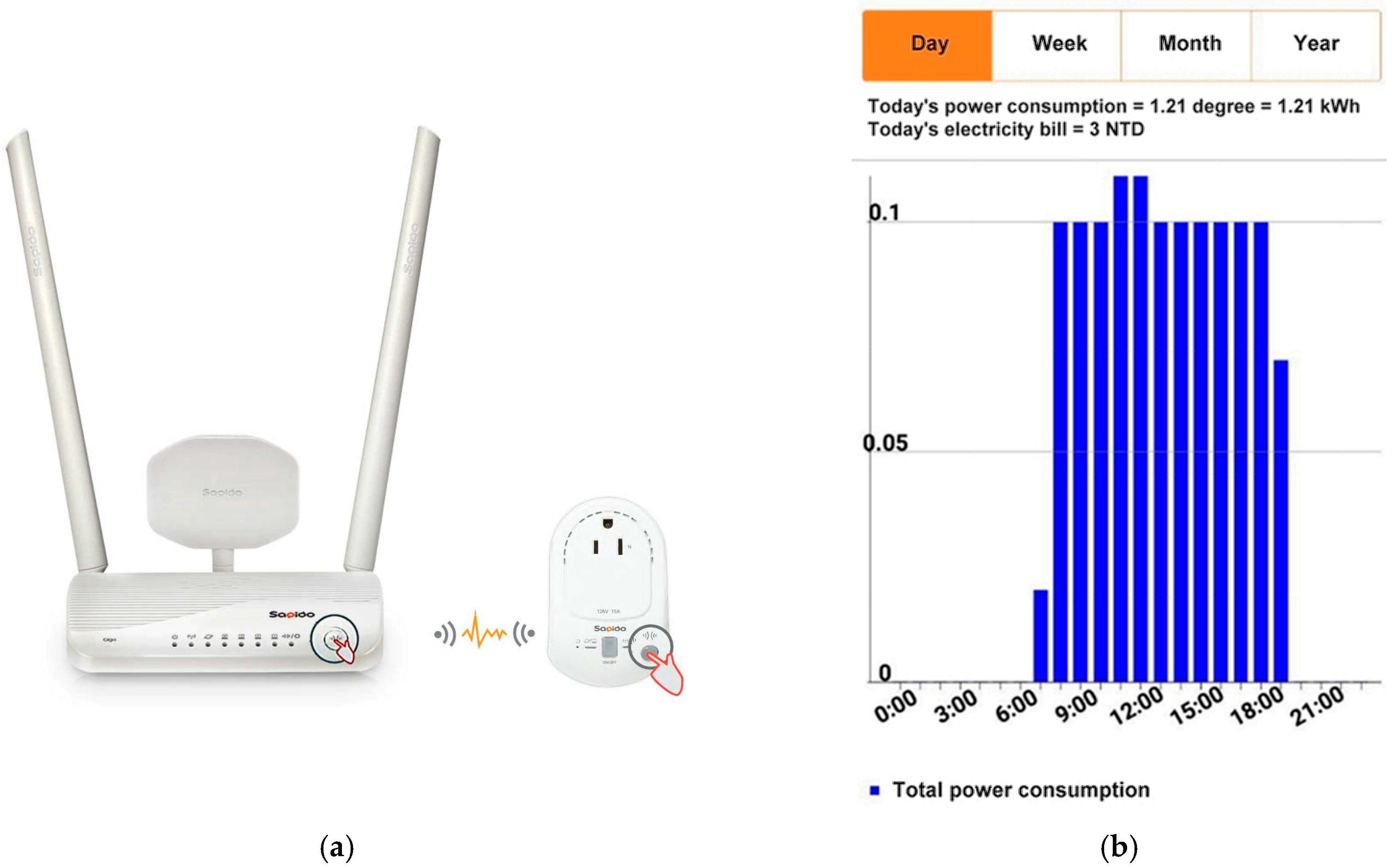

2.3. Power Consumption

2.4. Nutrient Solution

3. Results and Discussion

3.1. Plant Cultivation and Transplanting

3.2. Pest Control

3.3. Temperature Control

4. Applications and Further Improvement

- Minimum GnPR requirement: 4.0.

- Landscape Replacement Areas (LRA) requirement:100%.

- Site Area: 10,000 m2.

- Building coverage ratio: 50%.

- Floor area of a single floor: 5000 m2.

- Total number of floors in the building: 10.

- Ceiling cultivation plant: Brassica rapa subsp. chinensis (Bok Choy); Leaf Area Index (LAI): 2.

- Total number of ceiling planting floors: 8 floors.

- Greenery ratio of the ceiling on each floor: 25%.

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- United Nations. World Urbanization Prospects: The 2014 Revision–Highlights; Statistical Papers–United Nations (Ser. A), Population and Vital Statistics Report; United Nations: New York, NY, USA, 2014; ISBN 978-92-1-056809-8. Available online: https://www.un-ilibrary.org/content/books/9789210568098 (accessed on 24 April 2025).

- United Nations Department of Economic and Social Affairs. World Urbanization Prospects: The 2018 Revision; United Nations: New York, NY, USA, 2019; ISBN 978-92-1-004314-4. Available online: https://www.un-ilibrary.org/content/books/9789210043144 (accessed on 24 April 2025).

- Food and Agriculture Organization. FAO Framework for the Urban Food Agenda; FAO: Rome, Italy, 2019; ISBN 978-92-5-131274-2. Available online: http://www.fao.org/documents/card/en/c/ca3151en (accessed on 24 April 2025).

- Montgomery, M.R. The Urban Transformation of the Developing World. Science 2008, 319, 761–764. Available online: https://www.science.org/doi/10.1126/science.1153012 (accessed on 24 April 2025). [CrossRef] [PubMed]

- Daneshyar, E. Residential Rooftop Urban Agriculture: Architectural Design Recommendations. Sustainability 2024, 16, 1881. [Google Scholar] [CrossRef]

- Taipei City Government. Taipei City New Building Greening Implementation Rules. 2016. Volume Taipei City 13-11-4009. Available online: https://www.laws.taipei.gov.tw/Law/LawSearch/LawFileList/FL080927 (accessed on 23 May 2025).

- Singapore Urban Redevelopment Authority. LUSH Checklist of LRA Requirements for Public Sector Developments. 2022. Available online: https://www.ura.gov.sg/-/media/Corporate/Guidelines/Development-control/Documents/LUSH-Checklist-For-Public-Sector-Developments.pdf (accessed on 23 May 2025).

- Singapore Urban Redevelopment Authority. Landscaping for Urban Spaces and High-Rises (LUSH). 2022. Available online: https://www.ura.gov.sg/Corporate/Guidelines/Development-Control/Non-Residential/Commercial/Greenery (accessed on 23 May 2025).

- Singapore National Parks Board Flora & Fauna Web. 2025. Available online: https://www.nparks.gov.sg/florafaunaweb (accessed on 23 May 2025).

- Zhang, X.-D.; Meng, Y.; Li, X. The Tree Roots Penetrated the Roof to Form a Spectacular “Root Waterfall.” The Scene in Front of Them Shocked Everyone! Mammoth News. 2020. Available online: https://www.sohu.com/a/400180457_100070278 (accessed on 24 April 2025).

- Klepeis, N.E.; Nelson, W.C.; Ott, W.R.; Robinson, J.P.; Tsang, A.M.; Switzer, P.; Behar, J.V.; Hern, S.C.; Engelmann, W.H. The National Human Activity Pattern Survey (NHAPS): A Resource for Assessing Exposure to Environmental Pollutants. J. Expo. Sci. Environ. Epidemiol. 2001, 11, 231–252. [Google Scholar] [CrossRef] [PubMed]

- Apte, M.G.; Fisk, W.J.; Daisey, J.M. Associations Between Indoor CO2 Concentrations and Sick Building Syndrome Symptoms in U.S. Office Buildings: An Analysis of the 1994–1996 BASE Study Data: Associations Between Indoor CO2 Concentrations and SBS Symptoms in U.S. Office Buildings. Indoor Air 2000, 10, 246–257. [Google Scholar] [CrossRef] [PubMed]

- Wood, R.A.; Burchett, M.D.; Alquezar, R.; Orwell, R.L.; Tarran, J.; Torpy, F. The Potted-Plant Microcosm Substantially Reduces Indoor Air VOC Pollution: I. Office Field-Study. Water Air Soil Pollut. 2006, 175, 163–180. Available online: http://link.springer.com/10.1007/s11270-006-9124-z (accessed on 23 May 2025). [CrossRef]

- Orwell, R.L.; Wood, R.L.; Tarran, J.; Torpy, F.; Burchett, M.D. Removal of Benzene by the Indoor Plant/Substrate Microcosm and Implications for Air Quality. Water Air Soil Pollut. 2004, 157, 193–207. [Google Scholar] [CrossRef]

- Ye, D.-M. Handbook on Application and Management of Plants for Purifying Indoor Air: Home Living Edition; Ministry of Environment: Taipei City, Taiwan, 2010; ISBN 978-986-02-3024-6. Available online: https://w3.ncet.com.tw/a2/Ty-airarea/upload/file/d9sOJhxTjnuOR4DwxIBiBXD787OfOzxzflvcEPJv.pdf (accessed on 23 May 2025).

- Kutschera, U. 150 Years of an Integrative Plant Physiology. Nat. Plants 2015, 1, 15131. [Google Scholar] [CrossRef] [PubMed]

- Dauchot, G.; Aubry, C.; Crème, A.; Dorr, E.; Gabrielle, B. Energy Consumption as the Main Challenge Faced by Indoor Farming to Shorten Supply Chains. Clean. Circ. Bioecon. 2024, 9, 100127. [Google Scholar] [CrossRef]

- Song, S.; Hou, Y.; Lim, R.B.H.; Gaw, L.Y.F.; Richards, D.R.; Tan, H.T.W. Comparison of Vegetable Production, Resource-Use Efficiency and Environmental Performance of High-Technology and Conventional Farming Systems for Urban Agriculture in the Tropical City of Singapore. Sci. Total Environ. 2022, 807, 150621. [Google Scholar] [CrossRef] [PubMed]

- Ricardo, D. On the Principles of Political Economy and Taxation; John Murray: London, UK, 1817; Available online: https://books.google.com/books/about/On_the_Principles_of_Political_Economy_a.html?hl=zh-TW&id=cUBKAAAAYAAJ (accessed on 23 May 2025).

- Marilynn How to Add a “Green Ceiling” to Your Home–The New Way L.A. Restaurants Are Bringing the Outdoors In. Cupcakes Cashmere. 2018. Available online: https://cupcakesandcashmere.com/decor/how-to-add-a-green-ceiling-to-your-home-bavel-restaurant-interior-design (accessed on 30 May 2025).

- SED-IA Architects Passion Fruit Ceiling. Facebook. Available online: https://www.facebook.com/photo/?fbid=2227456157274701&set=ecnf.100042567837253 (accessed on 23 May 2025).

- Bier, L.M.; White, C.L. Cultural Diplomacy as Corporate Strategy: An Analysis of Pasona Group’s “New Tohoku” Program in Japan. Place Brand. Public Dipl. 2021, 17, 180–192. [Google Scholar] [CrossRef]

- Kinsman Company Down Under Pots. Kinsm. Co. 2025. Available online: https://www.kinsmangarden.com/category/Down-Under-Pots (accessed on 24 April 2025).

- BOSKKE Sky Planter Recycled Medium White by BOSKKE. Amazone. 2025. Available online: https://pse.is/7ddeth (accessed on 24 April 2025).

- Jung, C.; Arar, M. Natural vs. Artificial Light: A Study on the Influence of Light Source on Chlorophyll Content and Photosynthetic Rates on Indoor Plants. Buildings 2023, 13, 1482. [Google Scholar] [CrossRef]

- Viršilė, A.; Olle, M.; Duchovskis, P. LED Lighting in Horticulture. In Light Emitting Diodes for Agriculture; Dutta Gupta, S., Ed.; Springer: Singapore, 2017; pp. 113–147. ISBN 978-981-10-5806-6. [Google Scholar] [CrossRef]

- Zhang, T.; Shi, Y.; Piao, F.; Sun, Z. Effects of Different LED Sources on the Growth and Nitrogen Metabolism of Lettuce. Plant Cell Tissue Organ Cult. PCTOC 2018, 134, 231–240. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Zhou, X.; Liu, Y.; Lei, B. A Dual-Emitting Core–Shell Carbon Dot–Silica–Phosphor Composite for LED Plant Grow Light. RSC Adv. 2017, 7, 16662–16667. [Google Scholar] [CrossRef]

- Dai, M.; Tan, X.; Ye, Z.; Chen, X.; Zhang, Y.; Ruan, Y.; Ma, B.; Kong, D. Analysis of Lettuce Transcriptome Reveals the Mechanism of Different Light/Dark Cycle in Promoting the Growth and Quality. Front. Plant Sci. 2024, 15, 1394434. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Jeong, S.-Y.; Chun, K. Effect on Lettuce Growth Depending on LED Light Distance. ARPN J. Eng. Appl. Sci. 2018, 13, 518–522. Available online: https://www.researchgate.net/publication/323837029_Effect_on_lettuce_growth_depending_on_LED_light_distance (accessed on 24 April 2025).

- Nordin, M.K.B.; Saaid, M.F.B.; Fisol, M.S.B.M.; Ahmad, A.B.; Ali, M.S.A.B.M. Automated LED Grow Light Distance Control for Indoor Hydroponics. In Proceedings of the 2023 IEEE International Conference on Agrosystem Engineering, Technology & Applications (AGRETA), Shah Alam, Malaysia, 9 September 2023; IEEE: Piscataway, NJ, USA, 2023. [Google Scholar] [CrossRef]

- Dai, M.; Tan, X.; Ye, Z.; Ren, J.; Chen, X.; Kong, D. Optimal Light Intensity for Lettuce Growth, Quality, and Photosynthesis in Plant Factories. Plants 2024, 13, 2616. [Google Scholar] [CrossRef] [PubMed]

- Penuela, J.; Ben, C.; Boldyrev, S.; Gentzbittel, L.; Ouerdane, H. The Indoor Agriculture Industry: A Promising Player in Demand Response Services. Appl. Energy 2024, 372, 123756. [Google Scholar] [CrossRef]

- Sapido Company WSG70n Smart Control Insight Switch. Sapido. 2025. Available online: https://drive.google.com/file/d/10cop4CWt-YYI0xQWNKwl82ISITx9awES/view?usp=sharing (accessed on 24 April 2025).

- Singapore National Parks Board Brassica rapa Pak Choi Group. Flora Fauna Web. 2025. Available online: https://www.nparks.gov.sg/florafaunaweb/flora/6/5/6525 (accessed on 23 May 2025).

- Siraj, M.A.; Medha, M.M.; Nahar, A.U.; Islam, M.A.; Seidel, V. Mangrove Endophytes and Their Natural Metabolites: Role in Promoting Plant Health. In Microbial Endophytes and Plant Growth; Elsevier: Amsterdam, The Netherlands, 2023; pp. 99–116. ISBN 978-0-323-90620-3. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9780323906203000155 (accessed on 23 May 2025).

- U.S. Department of Energy LED Lighting. Energy Saver. 2025. Available online: https://www.energy.gov/energysaver/led-lighting (accessed on 24 April 2025).

- Huang, Y. How to Help Foliage Plants Survive The Hot Summer? Wind × Evapotranspiration × Humidity Is The Key! Gorgeous Space. 2022. Available online: https://today.line.me/tw/v2/article/GgYx3V6 (accessed on 24 April 2025).

- Huang, Y. Plant More Plants; Suncolor: Taipei City, Taiwan, 2022; ISBN 978-957-658-822-8. [Google Scholar]

| Name of Plant | Feature and Application |

|---|---|

| Mentha canadensis | For tea, aromatherapy, mosquito repellent, cooking spice |

| Stevia rebaudiana | For tea, aromatherapy, mosquito repellent, cooking spice |

| Lavandula | For tea, aromatherapy, mosquito repellent, cooking spice |

| Salvia rosmarinus | For tea, aromatherapy, mosquito repellent, cooking spice |

| Euphorbia pulcherrima | Ornamental; high efficiency in absorbing CO2; average ability in absorbing formaldehyde |

| Nephrolepis exaltata | Highly efficient in absorbing CO2 and VOCs (formaldehyde, trichloroethylene, xylene, benzene) |

| Chamaedorea elegans | Highly efficient in absorbing CO2 and VOCs (formaldehyde, ammonia, trichloroethylene, xylene, toluene) |

| Chlorophytum comosum | Highly efficient in absorbing CO2 and VOCs (formaldehyde, trichloroethylene, xylene) |

| Case | Introduction | Advantage | Disadvantage |

|---|---|---|---|

| The restaurants in Los Angeles [20] | Restaurants in Los Angeles, like Bavel, Coffee for Sasquatch, and Rosaliné, use wooden trusses for long planting troughs with hidden irrigation and drainage systems for ferns and ivy. | Ivy drapes down to the dining area, creating a green roof that gives customers the feel of dining under a rainforest canopy instead of in a busy city center. | The planting systems rely on sunlight that enters through the skylight. However, seasonal changes and climate fluctuations can result in unstable sunlight, which may hinder the healthy growth of plants. As a result, restaurants must incur substantial maintenance costs to ensure the greening. |

| SED-IA Architects [21] | This international architects’ office in Taipei features a composite ceiling with planting troughs. Passiflora edulis is planted under fluorescent lights, growing horizontally across the ceiling grid. | The office’s indoor temperature of 25 degrees Celsius is ideal for growing passion fruit. Gardening can also help employees relax during busy periods. | The embedded fluorescent lights above the plants may cast shadows from the leaves and troughs to the workspace below. Additionally, the planting device for upward-growing plants is primarily suited for climbing plants growing horizontally, limiting its use for ornamental, vegetable, and functional plants on ceilings. |

| Pasona Tokyo headquarters [22] | The company grows edible crops, vegetables, and ornamental plants using indoor office ceilings, floors, and walls, employing both soil and hydroponic methods. | The headquarters building showcases a green corporate image and is a model for urban greening demonstration and education. | The spray irrigation soil-based farming system increases humidity, attracting pests and mildew that can harm office environments. Additionally, it raises electricity consumption and carbon footprint, making it impractical for most offices and homes. |

| Device | Introduction | Advantage | Disadvantage |

|---|---|---|---|

| Down Under Pot [23] | The pot has two openings. The large opening makes it easy to place a mature plant facing upwards in the container, and then cover it with soil and compact it. After waiting about a week, allow the plant roots to grasp the soil in the pot, then hang the pot upside down. |

|

|

| New Improved Hanging Tomato Planter [22] | This soil-based planter comprises a frame and nonwoven fabric, with a bottom hole for downward plant growth. A container positioned above this planter can store 1 gallon of water. This container utilizes capillary matting, enabling water to gradually infiltrate the soil beneath through capillary action. |

|

|

| Sky Planter [24] |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-G.; Chiu, C.-W.; Chung, P.-S. A New Approach to Expanding Interior Green Areas in Urban Buildings. Buildings 2025, 15, 1965. https://doi.org/10.3390/buildings15121965

Kuo C-G, Chiu C-W, Chung P-S. A New Approach to Expanding Interior Green Areas in Urban Buildings. Buildings. 2025; 15(12):1965. https://doi.org/10.3390/buildings15121965

Chicago/Turabian StyleKuo, Chyi-Gang, Chien-Wei Chiu, and Pei-Shan Chung. 2025. "A New Approach to Expanding Interior Green Areas in Urban Buildings" Buildings 15, no. 12: 1965. https://doi.org/10.3390/buildings15121965

APA StyleKuo, C.-G., Chiu, C.-W., & Chung, P.-S. (2025). A New Approach to Expanding Interior Green Areas in Urban Buildings. Buildings, 15(12), 1965. https://doi.org/10.3390/buildings15121965