Abstract

Biomass residues from the agricultural industry, logging and wood processing activities have become a valuable fuel source. If processed under pyrolysis combustion, several products are generated. Bio-oil and gases are essential alternatives to fossil coal-based fuels for energy and electricity production, whose need is constantly growing. Biochar, the porous carbon-based lightweight product, often ends up as a soil fertilizer. However, it can be applied in other industrial sectors, e.g., in plastics production or in modifying cementitious materials intended for construction needs. This work dealt with the application of small amounts of softwood-based biochar up to 2.0 wt.% on hydration kinetics and a wide range of physical and mechanical properties, such as water transport characteristics and flexural and compressive strengths of modified cement pastes. In the comparison with reference specimens, the biochar incorporation into cement pastes brought benefits like the reduction of open porosity, improvement of strength properties, and decreased capillary water absorption of 7-day and 28-day-cured cement pastes. Moreover, biochar-dosed cement pastes showed an increase in heat evolution during the hydration process, accompanied by higher consumption of clinker minerals. Considering all examined characteristics, the optimal dosage of softwood-derived biochar of 1.0 wt.% of Portland cement can be recommended.

1. Introduction

Worldwide, there is an increasing demand for the utilization of different liquid and gas fuels for energy purposes, particularly electricity production. The development of industries, the rising standard of living of the population, the development of electromobility, etc., have induced increased electricity consumption. Except for wind and solar, these needs are still met by fossil fuels, particularly non-renewable coal, whose combustion has environmental and human health-related impacts [1]. In a responsible approach, there is a need to shift to more environmentally friendly alternative fuels, such as biomass-derived residues and wastes with carbon-neutral behavior [2]. Biomass has been represented by underutilized crops produced in large quantities, such as corn straw, rape, wheat straw, and rice straw [3]. Another group includes wood-based residues originating from wood processing during the production of lumber and furniture. Biomass burning under specific conditions (low-oxygen or oxygen-free atmosphere) at several hundred degrees Celsius generates several products. Bio-oil and gas-like products are essential because of their high energy concentration and calorific value. The last product, biochar, is specific for its micro-porous structure, high carbon content, high pH, and capability to immobilize heavy metals [4,5]. Therefore, biochar is applied in many different areas, such as controlling water pollution, remediating soils, filling materials for plastics, and construction industry applications [6].

The construction industry is one of the key sectors affecting the world economy. It is estimated that to ensure housing capacity for the growing world population, it will be necessary to construct 230 billion m2 of new buildings by 2060 [7]. The production of concrete and steel contributes considerably to the global warming effect. Even if the construction industry belongs to the hard-to-decarbonize sectors [8], it is necessary to adopt strategies for mitigating embodied emissions related to material production [9,10]. A promising approach is to use carbon-storing materials, which are applied in large quantities and with a long-term service life. With annual consumption expected to be more than 25 billion tons, concrete is a suitable candidate for carbon sequestration [11,12,13]. Coal combustion-derived fly ash is a favorite carbon-based mineral admixture modifying concrete mixes in concrete production. It is known for its positive effect on the workability of fresh cement-based composites and its contribution to long-term strength improvement [14,15]. Nonetheless, coal combustion for energetic purposes has been limited throughout the EU, and thus, the stocks of fly ash are running low. As a possible substituent, bio-based materials with high carbon storage capacity have been identified [16,17]. Some estimates suggest that the intensive adoption of bio-based materials in primary building structures will increase carbon-storing capacity from 7 Gt in 2020 to 60 Gt CO2 in 2050 [7].

Biochar may provide an alternative to traditionally used materials to improve some properties of cement-based composites. As reported by Gupta and Kua [18] and Asadi et al. [19], biochar, due to its low density, can, in higher amounts, lighten the structure of typically dense materials on cement bases. Accordingly, in work conducted by Praneeth, a biochar addition of 10% decreased thermal transport by up to 26% [20]. On the other hand, works by Sirico et al. [21], Wang. et al. [22] and Asadi Zeidabadi et al. [23] showed that biochar added in amounts up to 15 wt.% reduced the strength characteristics of cement-based materials. Moreover, higher biochar dosages into cement-based composites, typically about 5.0 wt.% and more, may result in workability worsening or workability loss caused by its high specific surface area and consequent high water absorption [24,25]. The strength properties of biochar-added cementitious materials may vary depending not only on biochar content but also on the feedstock used for pyrolysis, the pyrolysis temperature, and residence time [26]. In this context, authors such as Akhtar and Sarman [14] and Cuthbertson et al. [27] pointed out the uneven behavior of biochar on the strength properties of concrete, whereas 7-day specimens showed lower strength than those measured for reference concrete. However, after 28 days of curing, significant strength improvements were observed compared with the reference material. Furthermore, Gupta et al. indicated that biochar dosage at low addition levels, up to 2.0% by weight, should improve strength properties [28]. In the study conducted by Sikora et al., higher dosages of biochar up to 20 wt.% for cementitious composite modification were applied. The authors found that lower biochar additions up to 5 wt.% did not influence the performance of the produced composites. On the other hand, higher biochar dosages up to 20 wt.% influenced hydration kinetics, whereas the decrease in cumulative heat was observed. Furthermore, flexural and compressive strengths by 49% and 29% were reduced, respectively, and a water absorption coefficient increase of 60% was recorded [29].

As is evident from the mentioned findings, research works focused on some properties of biochar-based materials, e.g., particular strength characteristics, are broadly available. There is a lack of work aiming to transport properties, solve hydration kinetics, provide porosity-related data, and provide a comprehensive insight into the issue of biochar acting when added into cement-based materials. Moreover, in most cases, data after the 28-day curing period of biochar-dosed composites are reported only, and early hydration period results are rarely presented. In this context, this paper aims to examine the influence of experimentally produced soft-wood biochar on the hydration kinetics of cement pastes and the relationship between physical–mechanical properties and water-induced transport properties. Experimental analyses revealed a positive effect of biochar on the formation of denser structures of cement pastes, promoting increased mechanical resistance and, importantly, reduced water transport.

2. Materials and Methods

2.1. Raw Materials

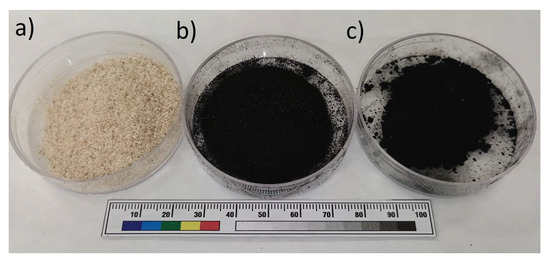

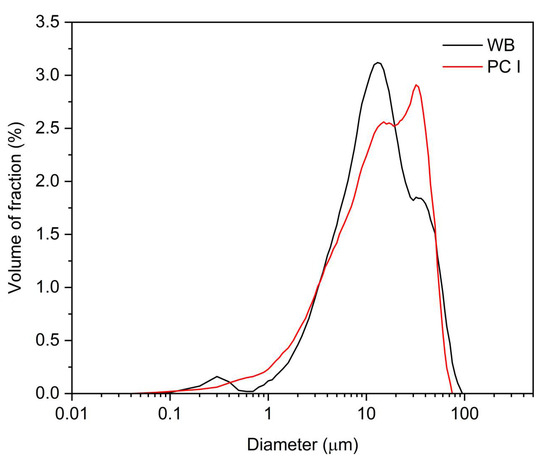

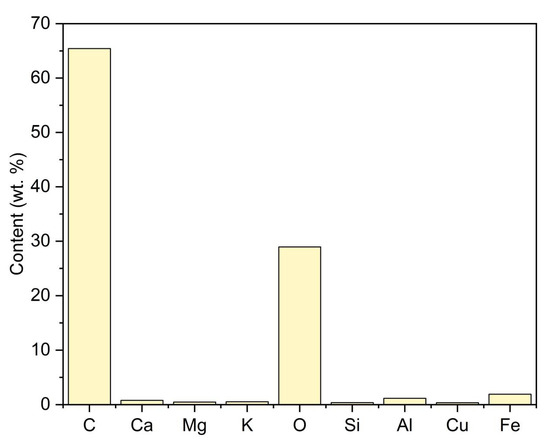

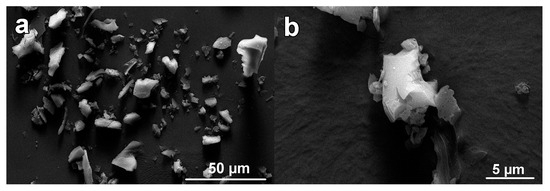

The experimental investigation was performed on cement pastes with different softwood-based biochar content. In this context, Portland cement of grade 42.5 with an initial rapid strength gain (PC I) produced by Heidelberg Materials CZ, Corp., Prague, Czech Republic, was used. The available oxide and mineralogical composition of PC I is listed in Table 1. PC I was replaced by experimentally produced biochar (WB) in small portions. The primary raw material, wood sawdust with particles up to 1 mm, was obtained from a spruce wood processing plant (Wotan Forest, Corp., České Budějovice, Czech Republic). Soft-wood residues were dried at 80 ± 3 °C for 24 h to remove excessive moisture and subsequently subjected to a pyrolysis process. The pyrolysis burning with a low-oxygen atmosphere started at 20 ± 1 °C and continued with a ramp-like increase in temperature of 5 °C·min−1 up to the maximum temperature point of 350 °C. To ensure optimal burnout, the residential time was set to 60 min. In the last step, the obtained burned biochar was ground for 30 s using Retsch MM 400 mill (Retsch GmbH, Haan, Germany). The woody feedstock burned biochar and fine-ground biochar are depicted in Figure 1. Due to the grounding process, the obtained biochar has an optimal particle size comparable to that of PC I, as shown in Figure 2. The basic material characteristics of both PC I and biochar are listed in Table 2. Biochar introduces a very light carbon-rich material (see in Figure 3) due to its origin and thus possesses very low powder density, more than three times lower compared with PC I. Very fragmented-like particle shapes, as is visible in Figure 4, are responsible for considerable specific surface area reaching up to 900 m2·kg−1 (EN 196-6 [30]).

Table 1.

Chemical and mineralogical composition of PC I.

Figure 1.

Wood-based biochar image of (a) softwood residues, (b) burned biochar, (c) ground biochar (WB).

Figure 2.

Particle size distribution of PC I and prepared biochar.

Table 2.

Material characteristics of raw powders.

Figure 3.

Elemental composition of produced biochar; standard deviation was less than 1%.

Figure 4.

SEM images of softwood-based biochar particles at lower magnification (a) and details of one particle at higher magnification (b).

2.2. Mixing and Sampling

The exact composition of the produced cement pastes is summarized in Table 3. Reference paste (P-R) consists of Portland cement and water, whereas the water-to-cement ratio (w/c) was 0.3. It is important to note that the w/c ratio was kept constant for all prepared pastes, and the influence of WB addition on the consistency of fresh mixes was evaluated via changes in flow values. Other mixes were added with WB in the amount of 0.5 up to 2.0% of cement weight. From the presented flow values, it is visible that increasing WB addition decreases the workability of fresh pastes. In this context, the flow value at 2.0 wt.% of WB addition was reduced by about 17%, compared with P-R.

Table 3.

Formulations of prepared pastes.

Fresh paste mixes were made using a laboratory mixer according to EN 196-3 [31]. The mixing technology is described in detail in [32]. Standardized prismatic specimens with the size (40 × 40 × 160) mm3 were cast in two steps, whereas each layer was compacted with the Matest C278-1 apparatus (Matest, S.p.A., Treviolo, Italy) for 30 s. After 1 day of curing, filled molds in a laboratory environment (20 ± 1 °C, 45 ± 5% room humidity), specimens were stored in water (20 ± 1 °C) up to testing at the age of 7 or 28 days.

2.3. Measuring Procedures

According to EN 1097-3 [24], the powder density was measured. The expanded combined uncertainty for the applied method was 1.5%. For specific gravity determination, the device AccuPyc II 1340 (MicroMetrics Co., Ltd., Norcross, GA, USA) was used. The expanded combined uncertainty of specific gravity measurements was below 1%. The particle size distribution of both fine-powdered materials, PC I and WB, was performed with the laser analyzer Cilas LD 1090 (Cilasariane Group, Orléans, France). The standard EN 196-6 [33] for the specific surface area determination methodology was adopted with the combined expanded uncertainty of about 9%. The elemental composition of the biochar specimen was determined using an energy-dispersive fluorescence spectrometer Axios WD-XRF (PANanalytical, Almemo, The Netherlands), equipped with the SuperQ software for data analysis. The scanning electron microscope (SEM) Quanta 450 FEG (FEI, Brno, Czech Republic) was adopted to observe the structural details of the studied biochar using 10 nm-thick gold coating samples and using 20 kV-accelerated voltage and a secondary electron detector.

The flow values were obtained and evaluated via EN 1015-3 [34]. Bulk densities of hardened specimens were measured according to EN 1015-10 [35]. The expanded combined uncertainty was 2.0% for the applied method. Open porosity was determined according to the principle described in EN 1936 [36]. A detailed description of the procedure is provided in [37]. The expanded combined uncertainty of open porosity measurements does not exceed 3.5%. Strength properties of flexural and compressive strengths were determined using EN 196-1 [33]. The uncertainty of both strength parameters was up to 5.7%. More details can be found in [30]. The capillary water absorption was measured and evaluated according to EN 1015-18 [38]. Absorption coefficient values were calculated on the weight differences of specimens obtained between 10 and 90 min. The isothermal conduction calorimetry (ICC) method with the 8-channel device TAM-Air (TA Instruments, Germany) was used to monitor the hydration process, as reported in detail elsewhere [39]. The prepared slurry was measured for 3 days at 25 °C, and two replicates were performed

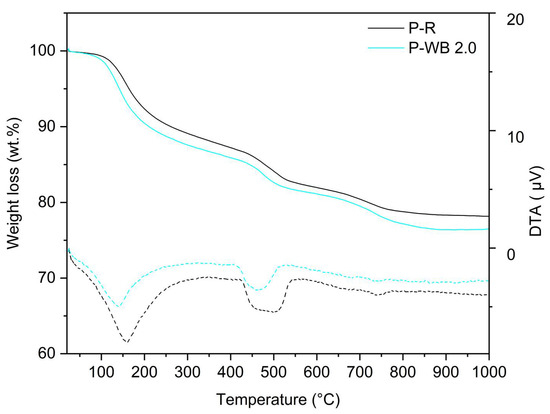

A combination of differential thermal analysis (DTA)–thermogravimetric analysis (TGA) was performed with an STA 504 thermal analyzer device (TA Instruments, Eschborn, Germany) on 28-day cement pastes, concretely for P-R and P-WB 2.0. Measurements were performed under a simultaneous nitrogen flow in a constant volume of 5 L·min−1 at a heating rate of 20 °C·min−1 in the temperature range of 30–1000 °C. The weight of the specimen was approximately 10 mg.

The mineralogical composition of hardened cement pastes was quantified using Rietveld refinement (software Topas 4.2) from measured X-ray powder diffraction (XRPD) patterns detected with the D8 Advance instrument (Bruker, Bremen, Germany).

3. Results and Discussion

3.1. Bulk Density and Open Porosity Results

Results of bulk density and open porosity obtained for the reference paste (P-R) and pastes added with ground biochar for 7- and 28-day-aged specimens are summarized in Table 4. At 7 days, the bulk density of P-R reached the average value of 1736.1 kg·m−3. The WB incorporation in the whole range of substitutions had a minimum influence on bulk density changes in the early hydration period. Only minor changes were detected in open porosity values where all P-WB specimens showed lower values in comparison with the reference, and values were identified as being lower for 0.8, 0.7, 0.4 and 0.4% for specimens P-WB 0.5, P-WB 1.0, P-WB 1.5, and P-WB 2.0, respectively. After 28 days of specimen hydration in water, the bulk density of all specimens increased, and, a more noticeable decrease in open porosity values for specimens with WB content was detected. Again, the lowest values were detected for WB specimens, and the maximum decrease of 1.8% was found for P-WB 1.0 in comparison with P-R. The discussed data pointed out the obvious porosity reduction related to softwood biochar incorporation, which may be positively reflected in the improvement of the mechanical properties of WB specimens. The decrease in open porosity leading to more compact cement paste microstructures may be explained by the role of fine biochar particles with a high specific surface area in supporting the cement hydration process by offering additional nucleation sites [40].

Table 4.

Bulk density and open porosity values of 7- and 28-day-aged specimens.

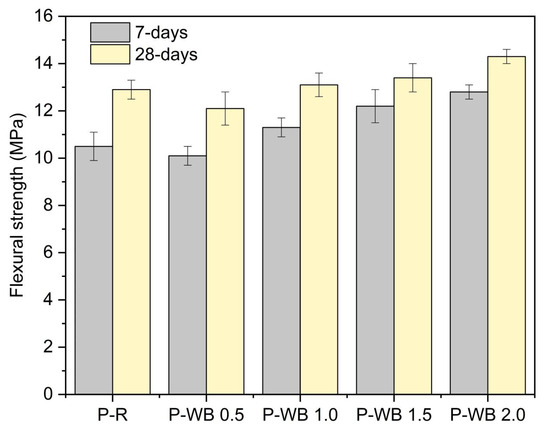

3.2. Mechanical Properties

The development of flexural strengths obtained for 7- and 28-day specimens with softwood-based biochar content and reference material is outlined in Figure 5. Moreover, flexural strength data are summarized in Table 5, considering their statistical significance at a 95% confidence interval, with a p-value < 0.05. Considering early flexural strengths, except for the lowest WB content of 0.5 wt.%, all-dosed specimens reached higher strengths than P-R. The most noticeable strength improvements of 16.2% and 21.9% were recorded for 7-day hardened pastes P-WB 1.5 and P-WB 2.0, respectively. In contrast, P-WB 0.5 showed a flexural strength loss of almost 4.0%. Flexural strength measurements recorded for 28-day specimens indicate only slightly increased values for all specimens as a consequence of increased hydration. Again, the lowest amount of added biochar in cement paste (P-WB 0.5) caused a decrease in flexural strength exceeding 6.0% compared to the reference specimen. Specimens with WB content above 0.5 wt.% showed comparable or higher strength if compared with P-R; strength improvements of 1.6%, 3.9%, and 10.9% were observed in P-WB 1.0, P-WB 1.0 and P-WB 2.0, respectively. These findings correspond to the results published by Suarez-Riera et al. [41], in which powdered biochar was added into cement pastes up to 5.0 wt.%. Nevertheless, the authors pointed out that the most effective flexural strength improvement was reached at 2.0 wt.% of biochar content.

Figure 5.

Flexural strengths of P-R and WB-dosed pastes aged for 7 and 28 days.

Table 5.

Flexural strengths after 7 days and 28 days. Data were verified for statistical significance via t-test at a 95% confidence interval according to presented p-values.

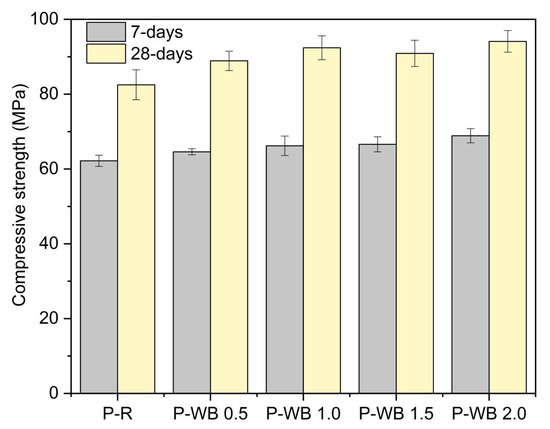

Experimental results of 7- and 28-day compressive strength measurement of produced pastes are summarized in Figure 6. Moreover, compressive strength data are summarized in Table 6, considering their statistical significance at a 95% confidence interval, with a p-value < 0.05. In both testing periods, data exhibited increased compressive strengths for biochar-enriched hardened materials. After 7 days, strength gains reached 3.9% (P-WB 0.5), 6.4% (P-WB 1.0), 7.1% (P-WB 1.5) and 10.8% (P-WB 2.0) in comparison with the reference average value of 62.2 MPa. A 28-day curing of specimens led to a more significant increase in compressive strength compared with the 7-day values. In this context, more than a 10% increase in compressive strength for specimens with biochar addition from 1.0 to 2.0 wt.% was observed. The highest contribution, 14.1%, reached P-WB 2.0 specimens. From an overall point of view, the presented and discussed strength-related data are significant (pcritical < 0.05); thus, they provide a verified data set revealing the positive effect of soft-wood-based biochar on the improvement of the cement-based matrix. Zhao et al. modified cement pastes with biochar that were added up to 2.5 wt.%; additionally, an increase in compressive strength by 7% at 7 and 28 days were reported [42]. The improvement of the mechanical properties of biochar cement-based composites may have several explanations [43,44,45]. Fine biochar with particle sizes comparable to cement grains can support nucleation sites and promote cement hydration, resulting in better mechanical properties [43]. This behavior can also be combined with the filling effect of finer biochar [44] that helps to densify the cement-based matrix and leads to a decrease in porosity values, as seen in Table 3. Another explanation may be the effect of biochar particles on the propagation of crack paths within cement-based matrices. In cases where biochar particles exhibit brittleness, this phenomenon is known to cause torsion in the crack path, thereby increasing the flexural strength enhancement [45].

Figure 6.

Compressive strengths of P-R and WB-dosed pastes aged for 7 and 28 days.

Table 6.

Compressive strengths after 7 days and 28 days. Data were verified for statistical significance via t-test at a 95% confidence interval according to presented p-values.

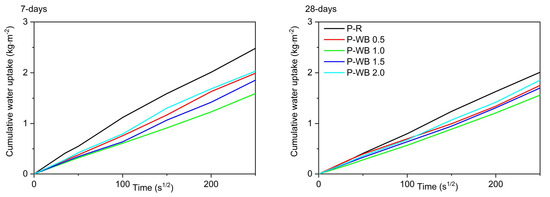

3.3. Water Transport Characteristics—Capillary Water Absorption

The results of capillary water absorption produced specimens aged for 7 days and 28 days are shown in Figure 7 (on the left) as curves, depending on the square root of the time. Plotted curves show the capillary-induced water suction ability of test specimens, and only the initial part of the performed experiments is presented. One can see decreased water suction for 28-day-aged specimens, versus 7-day-aged specimens, due to the continuing cement hydration process leading to the densification of the cement-based matrix. Absorption coefficient values were calculated on the weight differences of specimens obtained between 10 and 90 min and are summarized for both 7-day and 28-day specimens in Table 7. The highest ability for water suction was detected for reference paste (P-R) with a water absorption coefficient of 0.0121 kg·m−2·s−1/2. With softwood-based biochar incorporations up to 2.0 wt.%, decreased water suction was recorded in all specimens. The lowest absorption coefficient was measured for P-WB 1.0, in which a decrease of 27.3% was measured in comparison with the reference. This behavior is supported by the dense inner structure of paste specimens with 1.0 wt.% biochar content and is in correlation with previously reported and discussed results of open porosity (see Table 3) and mechanical properties (Figure 5 and Figure 6). Results of liquid water transport measured for 28-day specimens are summarized in Figure 7 (on the right). The ongoing hydration process, accompanied by the reduced porosity of pastes (Table 3), resulted in a decreased ability of water suction compared with the cement-based composite aged for 7 days. Nonetheless, similar trends were preserved. Again, the highest tendency of water suction was recorded for P-R and the highest decrease in the water absorption coefficient, 38.9% with respect to the P-R, was detected for specimen P-WB 1.0. Also, the order of specimens with the gradually increasing water absorption coefficients was kept the same: P-R, P-WB 2.0, P-WB 0.5, P-WB 1.5, and P-WB 1.0. However, a significant decrease in absorption coefficients for at least 19.5% was recorded for all biochar-containing specimens. In general, the water transport properties of produced specimens are closely related to the microstructural properties of cement matrices, especially the pore network and its connectivity. Biochar particles contain micro-scale pores capable of retaining water. Then, the gradual release of the retained water contributes to better hydration of the cement particles [41]. As the most effective for water uptake and subsequent retention, pores of sizes below 30 µm were determined [46]. If the biochar particles are dosed in higher amounts above 10 wt.%, the increased tendency for water uptake was reported as a consequence of the combined effects of light and porous biochar particles on the increase in the composite’s porosity and high water-retention capacity [26,47].

Figure 7.

Liquid water uptake of P-R and WB dosed pastes aged for 7 and 28 days. The decreased water suction ability of biochar dosed cement pastes was observed.

Table 7.

Absorption coefficients obtained for 7- and 28-day-aged specimens.

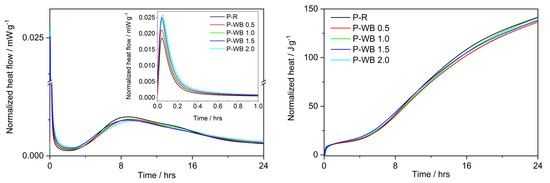

3.4. Hydration Process Cement Pastes with Biochar

The results obtained from the ICC measurements of produced specimens are graphically represented in Figure 8 and summarized in Table 8. As shown in the graphs depicted in Figure 8, the addition of softwood-based biochar to Portland cement was found to have a positive influence on hydration kinetics. The observed trend is correlated with the extant literature on the subject [48]. The lowest cumulative hydration heat evolution after one day was observed in P-R. However, an increase in heat evolution was recorded in biochar-dosed specimens. The highest heat evolution value was detected for P-WB 2.0. No major differences were found in the time needed to reach the maximum of hydration peaks. In general, biochar dosages caused a slight acceleration of times to reach these peaks, which is in line with previous findings [49]. In view of the early hydration–induction period at 1 h, a partial improvement of heat evolution of biochar-enriched specimens was recorded. In addition, higher cumulative hydration heat was recorded for specimens with dosed wood-based biochar, and the content of added biochar was identified as playing a significant role. Such findings are important, since cumulative heat is directly proportional to the degree of cement hydration [50].

Figure 8.

Records from ICC measurement of P-R and WB-dosed pastes.

Table 8.

Heat evolution data of P-R and WB-dosed pastes.

3.5. Thermogravimetric Analysis of 28-Day Cement Paste Specimens

To provide further support for the analyses already presented, DTA-TGA was performed on the specimens with the highest biochar content (P-WB 2.0) for illustrative purposes, and P-R was used for comparison. The data obtained from the thermogravimetric analysis of specimens aged for 28 days are summarized in Figure 9 and in Table 9. The analysis revealed three major temperature regions of thermal decomposition for both examined specimens. Temperatures of up to approximately 250 °C have been shown to correspond to the release of physically bound water from pores. In addition to the dehydration reactions that result from the loss of water from calcium silicate hydrates (C-S-H gel), the decomposition of ettringite and monocarboaluminate has also been observed [51]; portlandite decomposition was detected at 420–550 °C [52,53]; and at temperatures around 550 °C, calcium carbonate compounds start to decompose [53].

Figure 9.

DTA-TGA curves for P-R and WB dosed pastes aged for 28 days; DTA curves are represented graphically by dashed lines, while TGA curves are represented by solid lines.

Table 9.

Overview of quantified weight loss data for P-R and P-WB 2.0 pastes aged for 28 days.

The highest weight change connected with the decomposition at temperatures up to 550 °C was determined for P-WB 2.0. This is related to the higher content of C-S-H gels. Concurrently, TG analysis demonstrated that biochar-incorporated hardened specimens exhibited higher weight loss at temperatures ranging from 550 to 800 °C during decomposition compared to P-R. As indicated by the available literature, a higher level of biochar incorporation in the P-WB 2.0 specimen is consistent with a corresponding higher level of weight loss. This phenomenon can be attributed, at least in part, to the final high-temperature decomposition of the hydrated gel-like phases [20]. Temperatures in excess of 550 °C have also been observed to induce further decomposition of biochar composed of cellulose-like materials, a process that results in the release of carbon dioxide (CO2) [2,3,51].

3.6. Mineraloxical Composition of 28-Day Cement Paste Specimens

Data on mineralogical phases obtained from the analysis of detected XPRD patterns for both the reference paste and cement paste with 2.0 wt.% WB are summarized in Table 10. At first glance, it is possible to observe an increased consumption of clinker minerals, such as alite, belite and brownmillerite, on behalf of P-WB 2.0 and in comparison with P-R. Accordingly, the increased portlandite formation, one of the cement-hydration products for paste with biochar addition, was detected. The aforementioned aspects highlight the higher complexity of Portland cement hydration, which promotes the mechanical resistance of biochar-dosed cement paste [22,40]. Furthermore, the higher formation of carbonate compounds (vaterite, aragonite, calcite) may be related to the chemical transformation of portlandite [49,50] due to the environmental aspects and/or presence of additives favoring their formation as reported in, e.g., works and references therein [54,55,56]. The obtained results showed only a negligible difference in total amorphous phase content between P-R and P-WB 2.0. In the previous works, an increased presence of calcium-silicate-hydrate gels for biochar-enriched specimens is suggested [57,58].

Table 10.

XPRD data measured on 28-day cement pastes.

4. Conclusions

In this study, softwood-based biochar, derived from the pyrolysis process, was utilized as a partial substitute for Portland cement, with substitution levels ranging from 0.5 to 2.0 wt.%. Produced cement pastes with a constant water-to-binder ratio were examined in view of blended cement physical–mechanical properties, water uptake ability of 7- and 28-day water-cured specimens and hydration kinetics. The experimental measurements and the subsequent data analysis led to the following findings:

- The produced biochar with a similar particle size distribution to that obtained for PC I represented material with almost a 2.5 times higher specific surface area in comparison with PC I. This aspect resulted in the gradual decrease in workability of cement paste with increased biochar dosages.

- Softwood-based biochar additions help partially reduce the open porosity of produced specimens concerning the reference. At the curing period of 7 days, the most noticeable porosity decrease was detected for P-WB 0.5 and P-WB 1.0. With a continuing hydration process of up to 28 days, the lowest open porosity was detected for the specimen with 1.0 wt.% of admixture.

- From the point of view of mechanical resistivity, biochar additions of 1.0–2.0 wt.% seem to be a practical choice in the formation of a cement-based matrix with higher strength performance. The highest flexural strength increases by more than 21% (at 7 days) and 16% (at 28 days) were recorded for P-WB 2.0, with respect to P-R. In the same specimen, the highest compressive strengths were also detected.

- The water suction was significantly lower for specimens containing softwood-based biochar additives than for P-R. The lowest ability for water uptake was reported for specimens with 1.0 wt.% biochar content when the absorption coefficient was found to decrease by 27.3% and 38.9% after 7- and 28-day-cured periods, respectively.

- A partial increase in heat evolution after 3 days was observed during the hydration process specimens containing biochar.

- Obtained mineralogical composition of and biochar-dosed pastes revealed higher consumption of clinker minerals and increased formation of portlandite.

Considering the summarized findings, it is recommended that an optimal amount of Portland cement substitution with softwood-based biochar originating from the pyrolysis process is 1.0 wt.%. Even if used in such amounts, the application of biochar in cement binders may help to reduce the environmental impact and contribute to the long-term sustainability of the construction industry.

Author Contributions

Conceptualization, J.P.; methodology, R.Š.; software, L.Z. and J.Š.; validation, R.Š.; formal analysis, L.Z. and J.Š.; investigation, L.Z.; resources, L.P.; data curation, L.Z.; writing—original draft preparation, J.P.; writing—review and editing, J.P. and R.Š.; visualization, L.Z.; supervision, J.P.; project administration, L.P.; funding acquisition, R.Š. and J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Institute of Technology and Business, under project No. 03SVV2325, and by the Czech Science Foundation GA ČR (Grant Number 24-10430S), the Czech Academy of Sciences, Institute of Theoretical and Applied Mechanics-RVO 68378297.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bukhtiyarova, M.; Lunkenbein, T.; Kähler, K.; Schlögl, R. Methanol Synthesis from Industrial CO2 Sources: A Contribution to Chemical Energy Conversion. Catal. Lett. 2017, 147, 416–427. [Google Scholar] [CrossRef]

- Altıkat, A.; Alma, M.H.; Altıkat, A.; Bilgili, M.E.; Altıkat, S. A Comprehensive Study of Biochar Yield and Quality Concerning Pyrolysis Conditions: A Multifaceted Approach. Sustainability 2024, 16, 937. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, P.; Yuan, X.; Li, Y.; Han, L. Effect of Pyrolysis Temperature and Correlation Analysis on the Yield and Physicochemical Properties of Crop Residue Biochar. Bioresour. Technol. 2020, 296, 122318. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Han, G. Production of Solid Fuel Biochar from Waste Biomass by Low Temperature Pyrolysis. Fuel 2015, 158, 159–165. [Google Scholar] [CrossRef]

- Zhang, J.; Su, Y.; Zhang, C.; Li, M.; Zhu, X.; Zhang, Y.; Tsang, D.C.W. Alterations in Rheo-Viscoelastic Properties of Cement Composites with Biochar Incorporation as Bio-Based Admixture. Constr. Build. Mater. 2024, 439, 137358. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Hedenqvist, M.S.; Lin, R.J.T.; Sarmah, A.K.; Bhattacharyya, D. An Attempt to Find a Suitable Biomass for Biochar-Based Polypropylene Biocomposites. Environ. Manag. 2018, 62, 403–413. [Google Scholar] [CrossRef]

- Pomponi, F.; Hart, J.; Arehart, J.H.; D’Amico, B. Buildings as a Global Carbon Sink? A Reality Check on Feasibility Limits. One Earth 2020, 3, 157–161. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.; Graedel, T.; Schellnhuber, H. Buildings as a Global Carbon Sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Mekky, K.M.; Ibrahim, M.G.; Sharobim, K.; Fujii, M.; Nasr, M. Evaluating Environmental and Economic Benefits of Using Biochar in Concrete: A Life Cycle Assessment and Multi-Criteria Decision-Making Framework. Case Stud. Constr. Mater. 2024, 21, e03712. [Google Scholar] [CrossRef]

- Pokorný, J.; Ševčík, R.; Šál, J. The Design and Material Characterization of Reclaimed Asphalt Pavement Enriched Concrete for Construction Purposes. Materials 2020, 13, 4986. [Google Scholar] [CrossRef] [PubMed]

- Roychand, R.; Li, J.; Kilmartin-Lynch, S.; Saberian, M.; Zhu, J.; Youssf, O.; Ngo, T. Carbon Sequestration from Waste and Carbon Dioxide Mineralisation in Concrete—A Stronger, Sustainable and Eco-Friendly Solution to Support Circular Economy. Constr. Build. Mater. 2023, 379, 131221. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Carbon Sequestration and Storage in Concrete: A State-of-the-Art Review of Compositions, Methods, and Developments. J. CO2 Util. 2023, 70, 102443. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel Biochar-Concrete Composites: Manufacturing, Characterization and Evaluation of the Mechanical Properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef] [PubMed]

- Oner, A.; Akyuz, S.; Yildiz, R. An Experimental Study on Strength Development of Concrete Containing Fly Ash and Optimum Usage of Fly Ash in Concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Adesina, A. Recent Advancements in the Use of Biochar for Cementitious Applications: A Review. J. Build. Eng. 2020, 32, 101705. [Google Scholar] [CrossRef]

- Kampragkou, P.; Stefanidou, M. The Role of Different Bio-Additives in the Properties of Cement Mortars. Circ. Econ. Sust. 2025. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H. Factors Determining the Potential of Biochar As a Carbon Capturing and Sequestering Construction Material: Critical Review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal Conductivity of Concrete—A Review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar Admixtured Lightweight, Porous and Tougher Cement Mortars: Mechanical, Durability and Micro Computed Tomography Analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A.; Dalcanale, E.; Domenichelli, I.; Fornoni, P.; Moretti, E. Mechanical Characterization of Cement-Based Materials Containing Biochar from Gasification. Constr. Build. Mater. 2020, 246, 118490. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as Green Additives in Cement-Based Composites with Carbon Dioxide Curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Asadi Zeidabadi, Z.; Bakhtiari, S.; Abbaslou, H.; Ghanizadeh, A.R. Synthesis, Characterization and Evaluation of Biochar from Agricultural Waste Biomass for Use in Building Materials. Constr. Build. Mater. 2018, 181, 301–308. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of Biochar Addition on Long-Term Behavior of Concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Falliano, D.; Carvajal, J.F.; Celi, A.C.B.; Ferro, G.A.; Tulliani, J.M.; Lavagna, L.; Restuccia, L. The Effect of Different Biochar on the Mechanical Properties of Cement-Pastes and Mortars. Buildings 2023, 13, 2900. [Google Scholar] [CrossRef]

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, N.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A Review on Mechanical, Thermal, and Environmental Properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from Residual Biomass as a Concrete Filler for Improved Thermal and Acoustic Properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Biochar-Mortar Composite: Manufacturing, Evaluation of Physical Properties and Economic Viability. Constr. Build. Mater. 2018, 167, 874–889. [Google Scholar] [CrossRef]

- Sikora, P.; Woliński, P.; Chougan, M.; Madraszewski, S.; Węgrzyński, W.; Papis, B.K.; Federowicz, K.; Ghaffar, S.H.; Stephan, D. A Systematic Experimental Study on Biochar-Cementitious Composites: Towards Carbon Sequestration. Ind. Crops Prod. 2022, 184, 115103. [Google Scholar] [CrossRef]

- EN 196-6; Methods of Testing Cement—Part 6: Determination of Fineness. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- EN 196-3; Methods of Testing Cement—Part 3: Determination of Setting Times and Soudness. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- Pokorný, J.; Ševčík, R.; Zárybnická, L.; Podolka, L. The Role of High Carbon Additives on Physical–Mechanical Characteristics and Microstructure of Cement-Based Composites. Buildings 2023, 13, 1585. [Google Scholar] [CrossRef]

- EN 196-1; Method of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2000.

- EN 1015-10; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and Total Open Porosity. European Committee for Standardization (CEN): Brussels, Belgium, 2007.

- Pokorný, J.; Ševčík, R.; Šál, J.; Fiala, L.; Zárybnická, L.; Podolka, L. Bio-Based Aggregate in the Production of Advanced Thermal-Insulating Concrete with Improved Acoustic Performance. Constr. Build. Mater. 2022, 358, 129436. [Google Scholar] [CrossRef]

- EN 1015-18; Methods of Test for Mortar for Masonry. Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Zárybnická, L.; Pokorný, J.; Machotová, J.; Ševčík, R.; Šál, J.; Viani, A. Study of Keto-Hydrazide Crosslinking Effect in Acrylic Latex Applied to Portland Cements with Respect to Physical Properties. Constr. Build. Mater. 2023, 375, 130897. [Google Scholar] [CrossRef]

- Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials 2023, 16, 2809. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Lavagna, L.; Carvajal, J.F.; Tulliani, J.-M.; Falliano, D.; Restuccia, L. Enhancing Cement Paste Properties with Biochar: Mechanical and Rheological Insights. Appl. Sci. 2024, 14, 2616. [Google Scholar] [CrossRef]

- Zhao, Z.; El-Naggar, A.; Kau, J.; Olson, C.; Tomlinson, D.; Chang, S.X. Biochar Affects Compressive Strength of Portland Cement Composites: A Meta-Analysis. Biochar 2024, 6, 21. [Google Scholar] [CrossRef]

- Senadheera, S.S.; Gupta, S.; Kua, H.W.; Hou, D.; Kim, S.; Tsang, D.C.W.; Ok, Y.S. Application of Biochar in Concrete—A Review. Cem. Concr. Compos. 2023, 143, 105204. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, Y.U.; Jeon, J.; Yun, B.Y.; Kang, Y.; Kim, S. Analysis of Biochar-Mortar Composite as a Humidity Control Material to Improve the Building Energy and Hygrothermal Performance. Sci. Total Environ. 2021, 775, 145552. [Google Scholar] [CrossRef]

- Ahmad, S.; Tulliani, J.-M.; Ferro, G.; Khushnood, R.; Restuccia, L.; Jagdale, P. Crack Path and Fracture Surface Modifications in Cement Composites. Frat. Ed Integrita Strutturale 2015, 9, 524–533. [Google Scholar] [CrossRef]

- Shafie, T.S.; Salleh, A.; Lau, L.H.; Rahman, M.; Ghani, W. Effect of Pyrolysis Temperature on the Biochar Nutrient and Water Retention Capacity. J. Purity Util. React. Environ. 2012, 1, 293–307. [Google Scholar]

- Gupta, S.; Kua, H.W. Effect of Water Entrainment by Pre-Soaked Biochar Particles on Strength and Permeability of Cement Mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Berti, D.; Biscontin, G.; Lau, J. Effect of Biochar Filler on the Hydration Products and Microstructure in Portland Cement–Stabilized Peat. J. Mater. Civ. Eng. 2021, 33, 04021263. [Google Scholar] [CrossRef]

- Gupta, S.; Muthukrishnan, S.; Kua, H.W. Comparing Influence of Inert Biochar and Silica Rich Biochar on Cement Mortar—Hydration Kinetics and Durability under Chloride and Sulfate Environment. Constr. Build. Mater. 2021, 268, 121142. [Google Scholar] [CrossRef]

- Patel, R.; Babaei-Ghazvini, A.; Dunlop, M.J.; Acharya, B. Biomaterials-Based Concrete Composites: A Review on Biochar, Cellulose and Lignin. Carbon Capture Sci. Technol. 2024, 12, 100232. [Google Scholar] [CrossRef]

- Yang, X.; Lin, R.-S.; Han, Y.; Wang, X.-Y. Behavior of Biochar-Modified Cementitious Composites Exposed to High Temperatures. Materials 2021, 14, 5414. [Google Scholar] [CrossRef]

- Castellote, M.; Alonso, C.; Andrade, C.; Turrillas, X.; Campo, J. Composition and Microstructural Changes of Cement Pastes Upon Heating, as Studied by Neutron Diffraction. Cem. Concr. Res. 2004, 34, 1633–1644. [Google Scholar] [CrossRef]

- Song, H.; Jeong, Y.; Jun, Y.; Yoon, S.; Oh, J.E. A Study of Thermal Decomposition of Phases in Cementitious Systems Using HT-XRD and TG. Constr. Build. Mater. 2018, 169, 648–661. [Google Scholar] [CrossRef]

- Ševčík, R.; Pérez-Estébanez, M.; Viani, A.; Šašek, P.; Mácová, P. Characterization of Vaterite Synthesized at Various Temperatures and Stirring Velocities without Use of Additives. Powder Technol. 2015, 284, 265–271. [Google Scholar] [CrossRef]

- Ševčík, R.; Mácová, P.; Estébanez, M.P.; Viani, A. Influence of Additions of Synthetic Anhydrous Calcium Carbonate Polymorphs on Nanolime Carbonation. Constr. Build. Mater. 2019, 228, 116802. [Google Scholar] [CrossRef]

- Zhang, D.; Ghouleh, Z.; Shao, Y. Review on Carbonation Curing of Cement-Based Materials. J. CO2 Util. 2017, 21, 119–131. [Google Scholar] [CrossRef]

- Cuesta, A.; Morales-Cantero, A.; De la Torre, A.G.; Aranda, M.A.G. Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances. Materials 2023, 16, 1462. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation Seeding with Calcium Silicate Hydrate—A Review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).