Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria †

Abstract

1. Introduction

2. The Investigated Route Variants

2.1. General

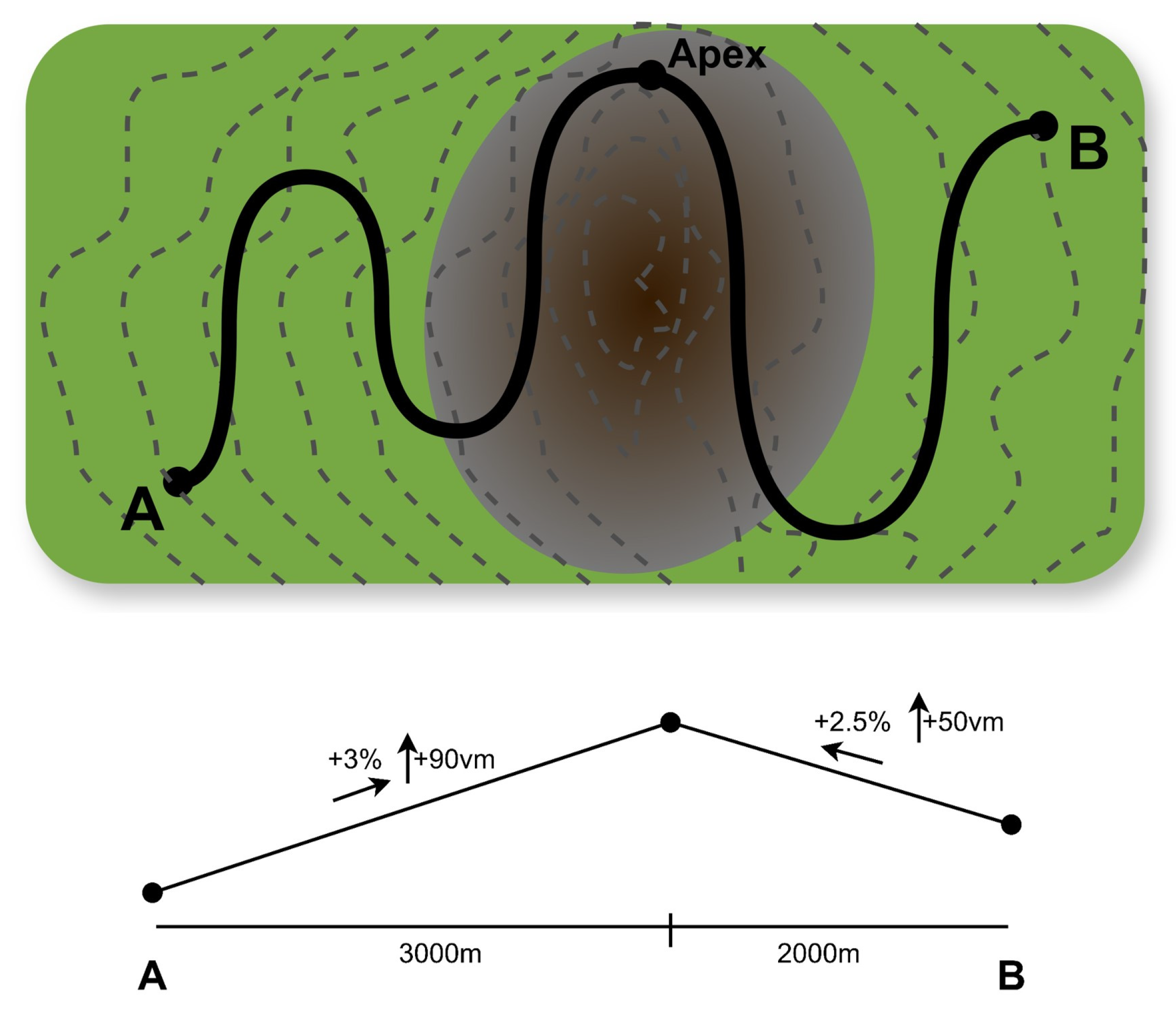

2.2. Route A—Mountain Pass Road

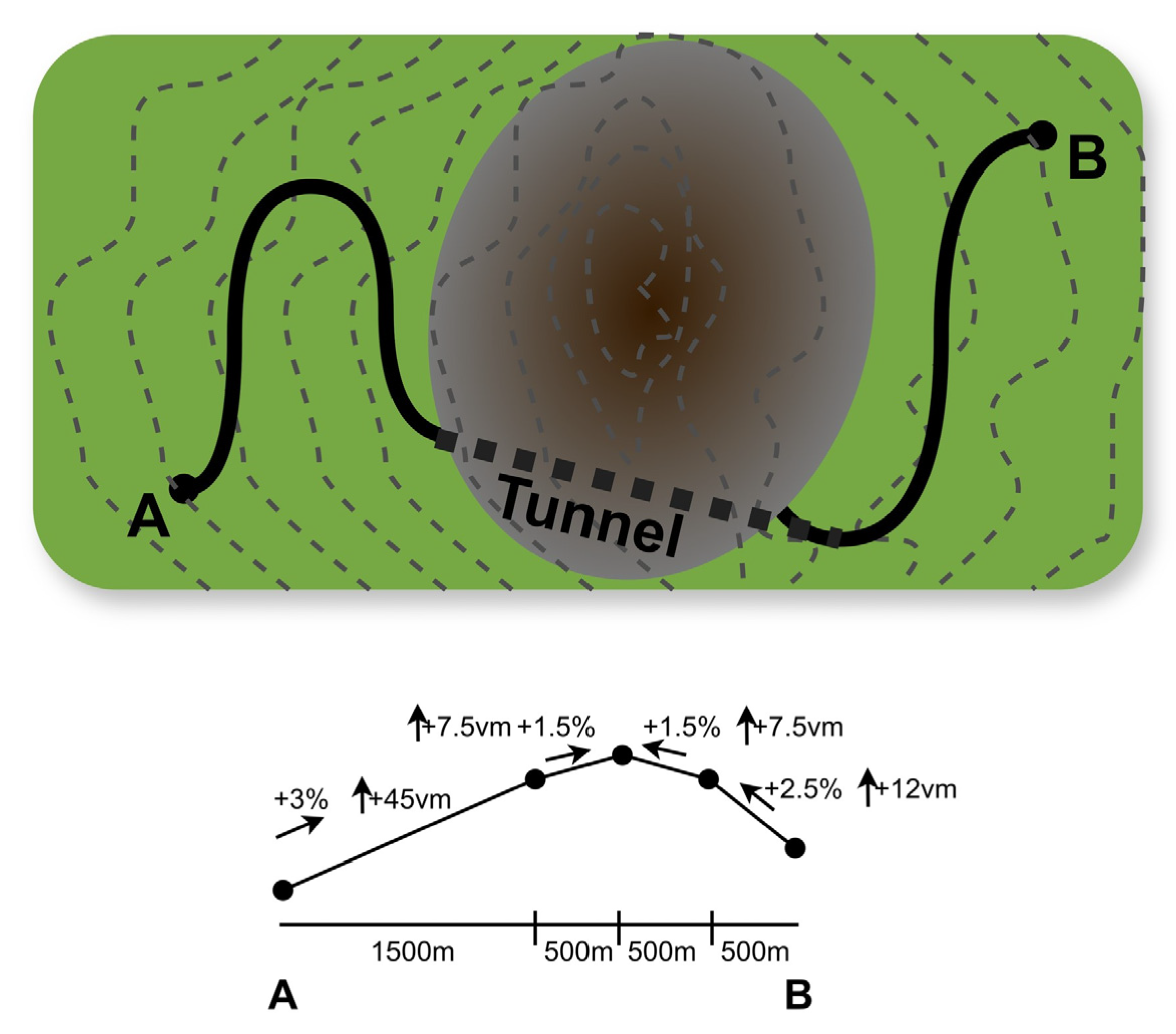

2.3. Route B—Tunnel

3. Materials and Methods

3.1. The Life Cycle Assessments (LCAs)

3.1.1. Functional Unit

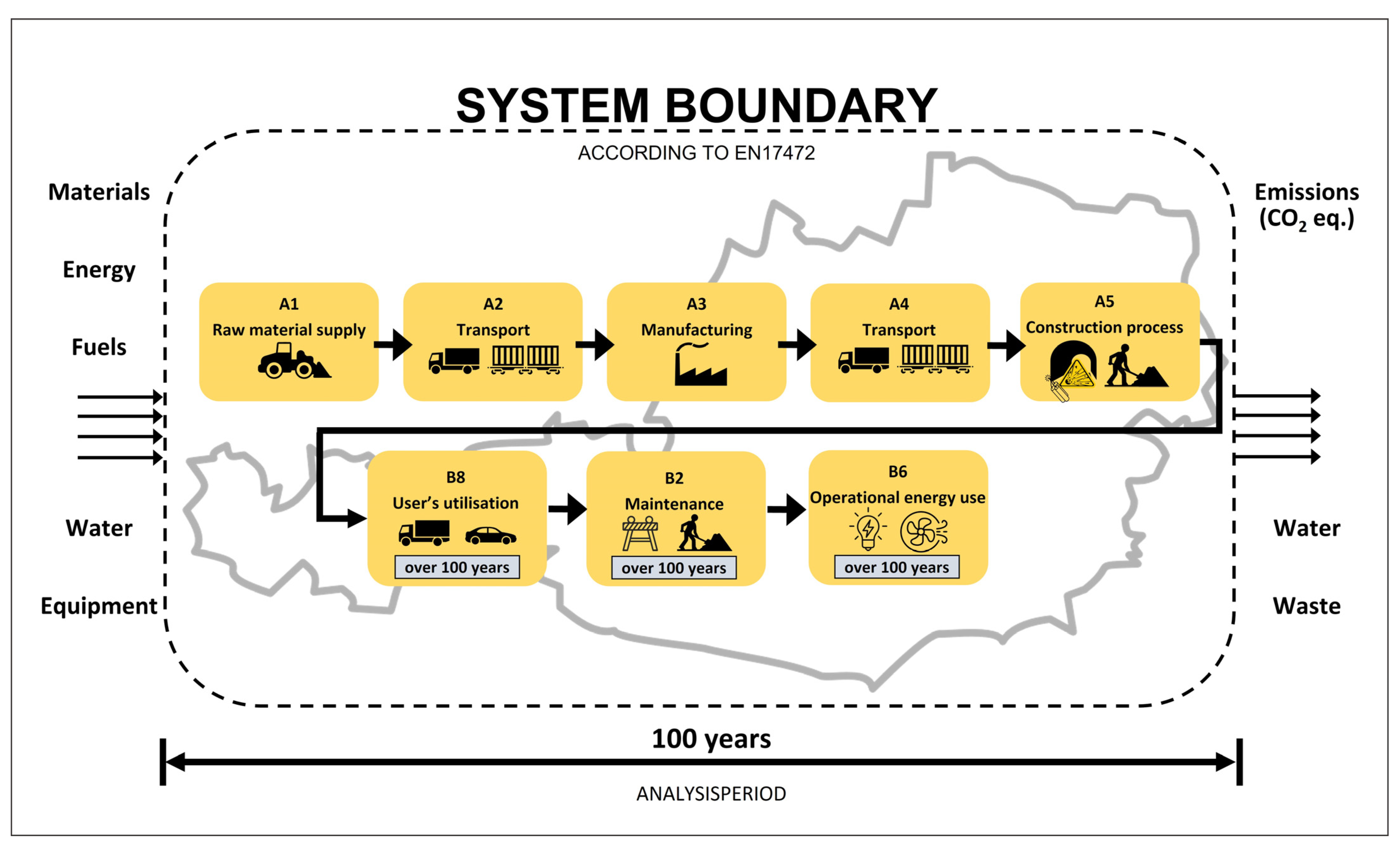

3.1.2. System Boundaries

3.2. The Tunnel LCA

3.2.1. Concrete and Cementitious Products

3.2.2. Steel Products

3.2.3. Bituminous Products

3.2.4. Transport

3.2.5. Construction

3.2.6. Tunnel Operation

3.2.7. Tunnel Maintenance

3.3. The Traffic LCAs

4. Results

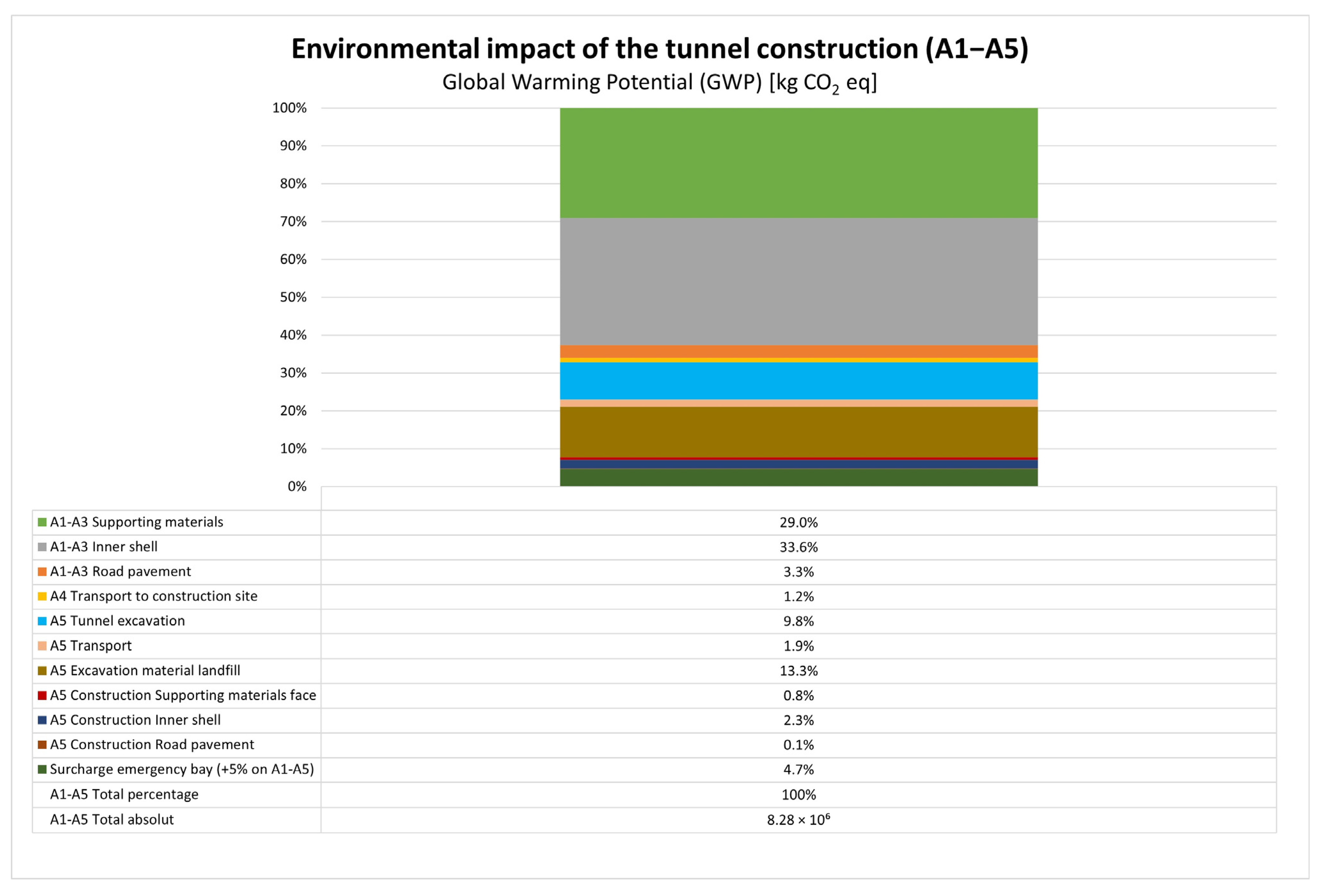

4.1. Tunnel Construction

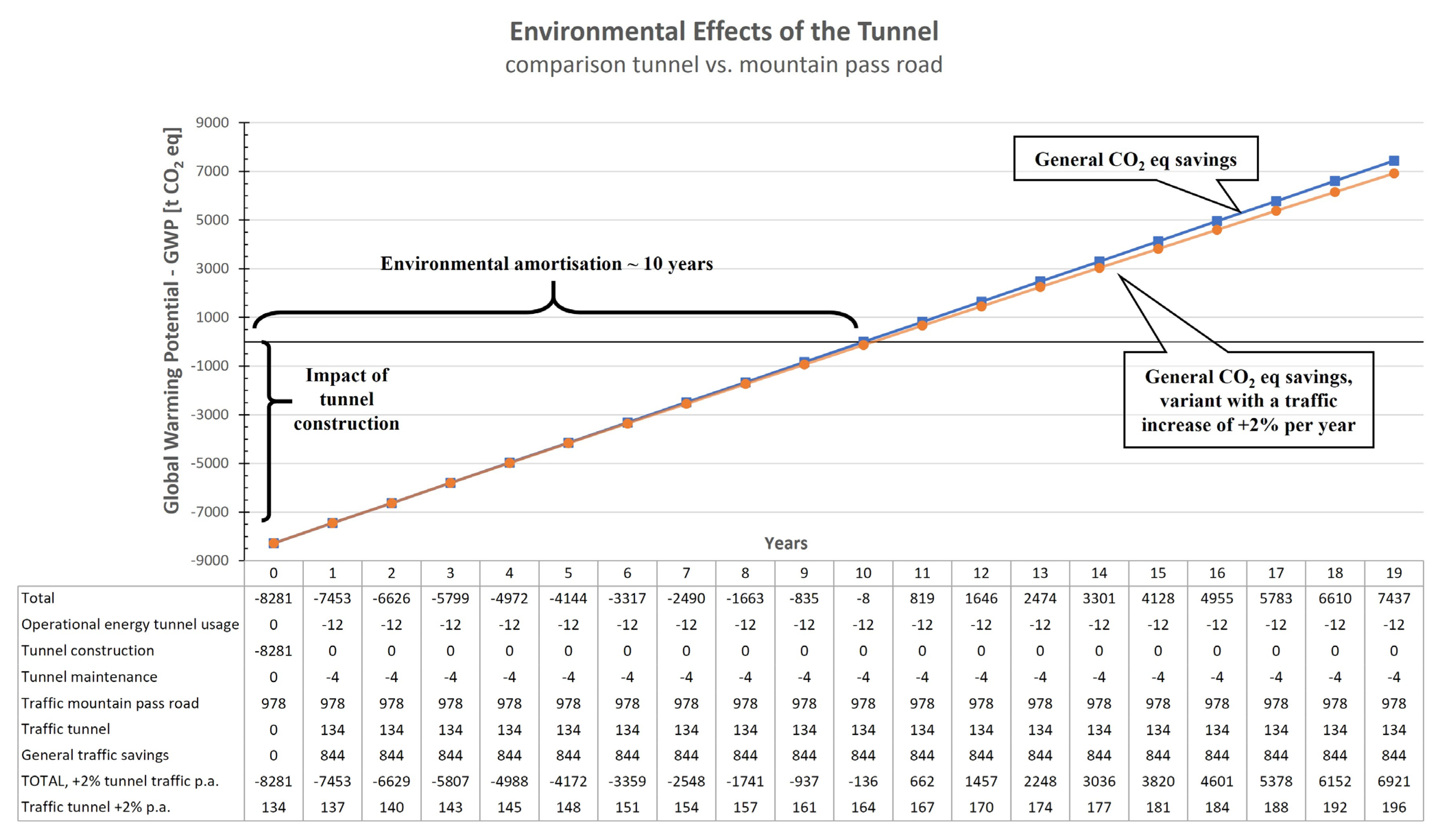

4.2. Tunnel vs. Traffic

5. Discussion and Conclusions

- Life Cycle Assessments (LCAs) are an effective method to support decision-making in transport infrastructure projects, even when applied to simplified or fictitious examples.

- Tunnels can offer significant environmental benefits, particularly by minimizing elevation differences and route lengths, thereby reducing long-term greenhouse gas emissions.

- The results emphasize that topographical optimizations—such as route shortening and reduced gradients—can lead to significant environmental savings throughout the long operational phase.

- The environmental amortization period for tunnel construction is relatively short, even in scenarios with modest reductions in elevation and distance, highlighting the efficiency of such interventions.

- The traffic-specific LCA methodology employed (based on Liebl’s approach) is adequate for assessing elevation-related emissions from uphill and downhill journeys at this level of consideration. However, for even more detailed analyses, more refined models are recommended that include factors such as gear changes and real driving behavior.

- The applied LCA model was developed in accordance with Austrian construction and technology standards, ensuring high regional relevance. Future applications (e.g., for other regions) should always be based on local conditions, including specific materials, construction methods, energy sources, and vehicle fleet composition.

- The early integration of LCA tools into the route selection process is essential to enable data-driven and environmentally responsible infrastructure planning.

- This study concludes that LCAs can play a crucial role in identifying the most sustainable design alternatives and thus support the development of climate-resilient and resource-efficient transport infrastructure.

- The analysis is based on a hypothetical case study and, therefore, only partially reflects the specific geographical, political, or socio-economic conditions that are typical for real infrastructure projects. Effects such as separation mechanisms and spatial crossing of certain areas (e.g., nature conservation areas and protected zones) because of the construction of new transport routes were not taken into account in the course of this study and should be included in further studies. Furthermore, this study is limited to an environmental perspective and does not take economic aspects into account. In order to support decision-making processes holistically, it is essential that costs are examined in the analysis.

- The traffic analysis is based on simplified assumptions about vehicle types and driving behavior. Important factors such as gear changes, acceleration and braking patterns, and driver variability are not taken into account. For example, the traffic analysis was carried out using car equivalents and truck equivalents. Although this approach is not unusual, it could be considered for future detailed studies to include a detailed analysis of different modes of transport, e.g., electric cars, diesel cars, etc. A consideration of real driving cycles would also be conceivable in the future.

- Technological advances that may occur over the 100-year assessment period—such as the increasing spread of electric vehicles or low-emission technologies and materials—are not taken into account by following this study’s objectives. The results are, therefore, based on a linear modeling approach that does not include dynamic interactions. Further studies could investigate these effects in detail.

- To simplify and focus on the presentation of the methodological approach, as described in Section 3.1.2, “System boundaries”, only divergent input and output flows were included in this study. Certain assumptions were made in collaboration with the experts. For example, to simplify matters, it was assumed that the road surface on the pass road and in the tunnel is replaced in the same maintenance cycles. This assumption essentially excludes potential external factors such as natural hazards, climatic changes, traffic accidents, etc. It was also assumed that the two traffic routes would not be dismantled after 100 years. The scope of the LCA is therefore limited to selected phases (A1–A3, A4, A5, B2, B6, and B8), while processes at the end of the life cycle (C1–C4) are explicitly excluded. For the present fictitious example and this study’s objective, this procedure and approach appear to be sufficiently accurate. For further and more detailed analyses, however, it is recommended to map and evaluate all possible life cycle phases and external effects as accurately as possible.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| A1–A3 | raw material supply |

| A1–A5 | construction phase |

| A4 | transport |

| A5 | construction |

| approx. | approximately |

| B2 | maintenance |

| B6 | operational energy use |

| B8 | user’s utilization |

| CO2 | greenhouse gas emission |

| C1–C4 | end-of-life stage |

| e.g., | for example |

| EN | European Standard |

| eq. | equivalent |

| etc. | et cetera |

| GWP | Global Warming Potential |

| ISO | International Organization for Standardization |

| kg | kilogram |

| km | kilometer |

| kWh | Kilowatt hours |

| L | liter |

| LCA | Life Cycle Assessment |

| m | meter |

| m2 | square meter |

| m3 | cubic meter |

| NATM | New Austrian Tunneling Method |

| NOx | nitrogen oxides |

| ÖNORM | Austrian Standard |

| PM | particulate matter |

| RVS | Guidelines and Regulations for Planning, Construction, and Maintenance of Roads |

| s | second |

| SDG | Sustainable Development Goals |

| to | ton |

| UN | United Nations |

| vm | vertical meter |

References

- Gertz, C. Verkehrsplanung, Bau und Betrieb von Verkehrsanlagen; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2021; ISBN 978-3-658-29499-1. [Google Scholar]

- Spang, K. Projektmanagement von Verkehrsinfrastrukturprojekten; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 978-3-662-64130-9. [Google Scholar]

- Maslow, A.H. A theory of human motivation. Psychol. Rev. 1943, 50, 396. [Google Scholar] [CrossRef]

- Österreichische Bautechnik Vereinigung. Ökologisierung & Nachhaltigkeit im Bauwesen—Sachstand; Österreichische Bautechnik Vereinigung: Wien, Austria, 2022; Available online: www.bautechnik.pro (accessed on 12 May 2025).

- Hausberger, L.; Gschösser, F. Nachhaltigkeit von Verkehrsinfrastrukturen: Bewertung auf drei Ebenen. Bau Aktuell 2023, 14, 154. [Google Scholar]

- Heissenberger, R.; Grunicke, U.H.; Raschendorfer, J.; Holzer, C. Sustainable Tunnelling—An infrastructure operator’s, planner’s, contractor’s and scientist’s perspective. Geomech. Tunn. 2022, 15, 811–820. [Google Scholar] [CrossRef]

- Aldrian, W.; Bantle, A.; Juhart, J. CO2 reduction in tunnel construction from a material technology point of view. Geomech. Tunn. 2022, 15, 799–810. [Google Scholar] [CrossRef]

- ÖNORM EN 17472; Nachhaltigkeit von Bauwerken—Bewertung der Nachhaltigkeit von Ingenieurbauwerken—Rechenverfahren. Austrian Standards International (ASI): Wien, Austria, 2022.

- Hausberger, L.; Lutterbach, J.; Gschösser, F. Modeling the Environmental Impact of Passenger Cars Driven on Hilly Roads in Austria: A More Accurate Valuation of Greenhouse Gas Emissions and Further Environmental Indicators for Integral Life Cycle Assessments of Road Infrastructures. Buildings 2024, 14, 263. [Google Scholar] [CrossRef]

- Liebl, J.; Lederer, M.; Rohde-Brandenburger, K.; Biermann, J.-W.; Roth, M.; Schäfer, H. Energiemanagement im Kraftfahrzeug; Springer Fachmedien: Wiesbaden, Germany, 2014; ISBN 978-3-658-04450-3. [Google Scholar]

- Hausberger, L.; Flora, M.; Gschösser, F. Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria. In Proceedings of the 2nd International Conference on Construction Engineering and Management (iCCPMCE-2024), Sydney, Australia, 20–22 November 2024. [Google Scholar]

- ÖNORM EN ISO 14040; Umweltmanagement—Ökobilanz—Grundsätze und Rahmenbedingungen. Austrian Standards International (ASI): Wien, Austria, 2021.

- ÖNORM EN 15804; Nachhaltigkeit von Bauwerken—Umweltproduktdeklarationen—Grundregeln für die Produktkategorie Bauprodukte. Austrian Standards International (ASI): Wien, Austria, 2022.

- Klöpffer, W.; Grahl, B. Ökobilanz (LCA): Ein Leitfaden für Ausbildung und Beruf; WILEY-VCH: Weinheim, Germany, 2007; ISBN 978-3-527-32043-1. [Google Scholar]

- Stefan, C.; Grunicke, U.; Prändl-Zika, V.; Weninger-Vycudil, A.; Hula, A.; Van Linn, A.; Brozek, B.; Prammer, D.; Mellert, L.D. Optimierte Instandsetzungsplanung der Tunnelspezifischen Baulichen und Elektromaschinellen Ausrüstung Mittels LCA: OptimAL; 2020. Available online: https://projekte.ffg.at/anhang/603383f3e02af_OPtimAL_Ergebnisbericht.pdf (accessed on 19 March 2025).

- Deutscher Ausschuss für unterirdisches Bauen e. V.—German Tunneling Committee. Empfehlungen für die Ermittlung von Lebenszykluskosten für Tunnel. 2023. Available online: https://www.daub-ita.de/fileadmin/documents/daub/gtcrec4/2023-03-24_DAUB_LZK_Empfehlung_mit_%C3%96PNV_und_DB.pdf?utm_source=chatgpt.com (accessed on 19 March 2025).

- Hoffeller, M. Bestimmung der Investitionskosten von Verkehrswegen, Brücken und Tunneln zum Zeitpunkt der Realisierungsentscheidung über die Gesamtnutzungsdauer unter besonderer Berücksichtigung der Objektkonzeption. Ph.D. Thesis, TUM School of Engineering and Design, Munich, Germany, 2023. [Google Scholar]

- Frischknecht, R. Lehrbuch der Ökobilanzierung; Springer Spektrum: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-662-54762-5. [Google Scholar]

- Ecoinvent. ecoinvent v3.10 Database. Available online: https://ecoinvent.org/the-ecoinvent-database/ (accessed on 22 May 2024).

- Ökobaudat. Ökobaudat—Sustainable Construction Information Portal. Available online: https://www.oekobaudat.de/ (accessed on 22 May 2024).

- Flora, M.; Purrer, W.; Bergmeister, K. Characteristics and potential of the NATM, ADECO-RS and mechanised methods of tunnelling / Charakteristika und Potenziale der Tunnelbaumethoden NÖT, ADECO-RS und TVM. Geomech. Tunn. 2011, 4, 489–498. [Google Scholar] [CrossRef]

- Austrian Research Association for Roads, Railways and Transport. RVS 09.01.22 Tunnelquerschnitte; Austrian Research Association for Roads, Railways and Transport (FSV): Wien, Austria, 2010. [Google Scholar]

- ÖNORM B 2203-1: 2023 03 01; Untertagebauarbeiten, Teil 1: Zyklischer Vortrieb. Austrian Standards International: Wien, Austria, 2023.

- Hausberger, L.; Ressler, C.; Cordes, T.; Gschösser, F. Detaillierte Ökobilanzdaten für spezifische Betonsorten hergestellt in Österreich. Beton Stahlbetonbau 2024, 120, 263–270. [Google Scholar] [CrossRef]

- TPH Bausysteme GmbH. Datenblatt F8000; TPH Bausysteme GmbH: Norderstedt, Germany, 2023. [Google Scholar]

- Institut Bauen und Umwelt e.V. Baustähle: Offene Walzprofile und Grobbleche. Available online: https://ibu-epd.com/veroeffentlichte-epds/ (accessed on 29 August 2023).

- Bau EPD GmbH. EPD Betonstahl Marienhütte 2020. Available online: https://www.bau-epd.at/fileadmin/user_upload/epds_Deutsch/BAU-EPD-MARIENHUETTE-2020-1-Ecoinvent-Baustahl_20200326.pdf (accessed on 26 September 2024).

- Pretec Norge AS. EPD-Self-Drilling-Anchor. Available online: https://epd-global.com/getfile.php/13205229-1741716592/EPDer/Byggevarer/St%C3%A5lkonstruksjoner/NEPD-8850-8511_Self-Drilling-Anchor--Pc-Coat-.pdf (accessed on 19 March 2025).

- European Union. Eurostat—Lorries and Road Tractors by Age and Type of Vehicle. 2023. Available online: https://ec.europa.eu/eurostat/databrowser/view/road_eqs_lorroa/default/table?lang=en&category=road.road_eqs (accessed on 19 March 2025).

- IG-L—Abgasklassen-Kennzeichnungsverordnung—AbgKlassV: BGBl. II Nr. 120/2012 II. Available online: https://www.ris.bka.gv.at/GeltendeFassung.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20007781 (accessed on 12 May 2025).

- Wirtschaftskammer Österreich. Feststellung der richtigen Euro-Abgasklasse. Available online: https://www.wko.at/transport/abgasklassenzuordnung (accessed on 19 March 2025).

- Europäische Kommission. Europäische Abfallartenkatalog (EAK), 2021. Available online: https://www.statistik.bayern.de/mam/statistik/bauen_wohnen/abfall/europabfallkatalog.pdf (accessed on 12 May 2025).

- Sprenger, J. Treibhausgas-Bilanz von Tunnelinnenschalen. Master’s Thesis, University of Innsbruck, Innsbruck, Austria, 2023. [Google Scholar]

- Gschösser, F. Fernpasstunnel—Ökobilanzstudie 2023, 2023. Available online: https://www.tirol.gv.at/fileadmin/buergerservice/Beauftragte_Gutachten_Studien_Umfragen/20230620_Fernpasstunnel_OEkobilanz_2023.pdf (accessed on 12 May 2025).

- Lischka, G. Weiterentwicklung der Lebenszyklusemissionsprognose für Fahrzeugflotten um Motorräder im Inlandsverkehr sowie LKW unter Berücksichtigung des Inlands- und Transitverkehrs. Master’s Thesis, Technische Universität Wien, Wien, Austria, 2022. [Google Scholar]

- Gschösser, F.; Purrer, W.; Sander, P. Expanding Boundaries—Environmental Effects of an Alpine Summit Tunnel 2016; vdf Hochschulverlag AG an der ETH Zürich: Zurich, Switzerland, 2016. [Google Scholar] [CrossRef]

| Direction of Travel | Car Eq. | Truck Eq. | Total Vehicles |

|---|---|---|---|

| Location A to B | 1250 | 45 | 1295 |

| Location B to A | 1000 | 20 | 1020 |

| Direction of Travel | Car Eq. | Truck Eq. | Total Vehicles |

|---|---|---|---|

| Location A to B | 1500 | 54 | 1554 |

| Location B to A | 1200 | 24 | 1224 |

| Description | Amount | Unit | Related to Life Cycle Phase |

|---|---|---|---|

| Shotcrete | 7705 | m3 | A1–A3 |

| Reinforcing steel | 136 | to | A1–A3 |

| Anchors | 349 | to | A1–A3 |

| Arches | 40 | to | A1–A3 |

| Grouting (Mortar and Injections) | 109 | to | A1–A3 |

| Concrete inner lining | 13100 | m3 | A1–A3 |

| Asphalt pavement | 1350 | m3 | A1–A3 |

| Diesel | 144034 | L | A5 |

| Electricity | 956559 | kWh | A5 |

| Water | 682 | m3 | A5 |

| Explosives | 169 | to | A5 |

| Description | Distance | Unit | Related to Life Cycle Phase |

|---|---|---|---|

| Excavated rock material | 5 | km | A5 |

| Shotcrete | 15 | km | A4 |

| Concrete inner lining | 15 | km | A4 |

| Reinforcing steel | 200 | km | A4 |

| Anchors and Arches | 200 | km | A4 |

| Grouting (Mortar and Injections) | 15 | km | A4 |

| Asphalt pavement | 20 | km | A4 |

| Unbound base course | 10 | km | A4 |

| Machinery and equipment | 20 | km | A5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hausberger, L.; Flora, M.; Gschösser, F. Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria. Buildings 2025, 15, 1669. https://doi.org/10.3390/buildings15101669

Hausberger L, Flora M, Gschösser F. Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria. Buildings. 2025; 15(10):1669. https://doi.org/10.3390/buildings15101669

Chicago/Turabian StyleHausberger, Lukas, Matthias Flora, and Florian Gschösser. 2025. "Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria" Buildings 15, no. 10: 1669. https://doi.org/10.3390/buildings15101669

APA StyleHausberger, L., Flora, M., & Gschösser, F. (2025). Environmental Impacts of Road Traffic and Route Variants: An Accurate Way to Support Decision-Making Processes of Mountain Roads and Tunnels in Austria. Buildings, 15(10), 1669. https://doi.org/10.3390/buildings15101669