Abstract

This study presents a comprehensive comparative analysis of seismic resilience and sustainability between steel and reinforced concrete structures. With growing demand for environmentally responsible and disaster-resilient infrastructure, evaluating the life cycle performance of construction materials has become critical. Three building typologies—10-, 20-, and 30-story residential structures—are analyzed using a life cycle assessment (LCA), life cycle costing (LCC), and incremental dynamic analysis (IDA) to assess environmental, economic, and seismic performance. The results reveal that reinforced concrete structures tend to exert greater environmental impacts, particularly in categories such as carcinogenic emissions, ecotoxicity, and acidification, primarily due to cement production. Steel structures, while associated with higher energy consumption and mineral resource depletion, demonstrated superior seismic performance across all building heights, characterized by a greater level of ductility and collapse capacity. For instance, the 30-story reinforced concrete structure generated approximately 6.93 million kg CO2 eq, compared to 6.79 million kg CO2 eq for its steel counterpart. Steel structures, while associated with higher energy consumption and mineral resource depletion, demonstrated superior seismic performance across all building heights, sustaining up to a 15% greater spectral acceleration before collapse. Additionally, the LCC analysis showed that reinforced concrete is more cost-effective in high-rise construction, especially during the construction stage. These findings offer valuable insights for engineers and decision makers aiming to balance sustainability and structural performance in urban development.

1. Introduction

In the realm of structural engineering, the selection of building materials plays a pivotal role in ensuring the safety, longevity, and sustainability of structures [1,2,3]. As urbanization intensifies and the global population continues to concentrate in seismically active regions, the demand for resilient and sustainable building solutions has become more pressing than ever. Both steel and reinforced concrete (RC) have emerged as primary contenders in this pursuit, each offering distinct advantages and posing unique challenges [4,5,6,7].

The seismic performance of structures is of paramount importance in earthquake-prone regions, where the ability to withstand and dissipate seismic forces is a critical factor in ensuring public safety and minimizing damage [8,9]. Concurrently, considerations of economic viability and environmental sustainability have led to a growing interest in life cycle costing (LCC) and life cycle assessment (LCA) methodologies [10].

LCAs are increasingly being adopted as a decision support tool in the construction industry to evaluate the environmental impacts of building materials and systems throughout their entire life span. They enable designers, engineers, and policymakers to quantify resource use, emissions, and ecological footprints across stages such as material extraction, production, transportation, use, and end of life. International standards such as ISO 14040 and ISO 14044 [11,12] have formalized LCA frameworks, encouraging its integration into green building certification systems and national construction regulations. Similarly, LCC complements LCAs by offering a long-term financial perspective, encompassing not only initial investment but also operational, maintenance, and disposal costs. LCC is particularly valuable in optimizing design choices by accounting for durability, service life, and economic efficiency. The combined application of LCAs and LCC provides a holistic approach to assessing sustainability, allowing stakeholders to balance environmental and economic criteria in selecting construction strategies and materials.

The significance of this research transcends the immediate construction landscape and has broader implications for societal well-being [13,14]. The resilience of structures in the face of seismic events directly influences public safety, economic stability, and the long-term viability of urban infrastructure. Furthermore, as the global community intensifies its focus on sustainable development, the environmental impact of construction materials is under heightened scrutiny. This study not only endeavors to inform the decision-making processes of architects and engineers but also contributes to the overarching goal of creating structures that endure both the forces of nature and the tests of time [8,15,16].

This subject matter has attracted widespread attention from researchers globally, reflecting its critical importance and relevance. Numerous studies have delved into various facets of steel and RC frames, each contributing valuable insights to our collective understanding of these materials. Several studies have investigated the environmental implications and embodied energy associated with different construction frames. Cole and Kernan [17], in their examination of three buildings featuring concrete, steel, and wooden frames, considered factors such as the transportation of workers, materials transfer, heavy equipment usage, and logistical support, aiming for a holistic understanding of energy consumption and greenhouse gas emissions. Guggemos and Horvath [18] explored the environmental impact of office buildings, specifically comparing a concrete construction frame to a steel frame, evaluating greenhouse gas emissions and energy consumption. Peyroteo et al. [19] introduced a novel analytical instrument for conducting LCAs on steel and RC structures. Utilizing a life cycle analysis as its foundation, the assessment focused on five key parameters: energy consumption, water usage, CO2 emissions, SO2 emissions, and NOx emissions. The findings from this analysis revealed that steel structures demonstrated lower sustainability in comparison to RC structures. Robertson et al. [20] conducted an examination of two mid-rise buildings in Canada, comparing RC and laminated timber frames. Basaglia et al. [21] focused on the life cycle phases of multi-story buildings at the University of Sydney, comparing the greenhouse gas emissions of concrete flooring, cross-laminated timber, and timber concrete composites. As the predominant choice for building construction in Iran and other parts of the world revolves around concrete or steel frames, there is a pressing need to scrutinize the environmental effects of these materials. In a comprehensive analysis encompassing three construction frames (concrete, steel, and wood), a study by Lu et al. [22] delved into both the environmental effects and economic considerations of each frame. Balasbaneh et al. [23] utilized LCA and LCC methods to assess the economic and environmental impacts of selected wall and roofing materials from Malaysian residential houses. Balasbaneh and Ramli compared the environmental impacts and costs of steel and concrete prefabricated prefinished volumetric construction structures in Malaysia using LCA and LCC methods [24]. The findings indicate that steel requires more electricity than concrete across all environmental impact categories, whereas concrete is associated with higher overall emissions. Steel demonstrates superior performance compared to concrete by approximately 37% in non-renewable energy consumption, 38% in respiratory inorganic emissions, 43% in land use, and 40% in mineral resource depletion. Conversely, concrete achieves better results—about 54% on average—in terms of greenhouse gas (GHG) emissions. Although steel construction involves higher initial costs, it proves to be more cost-effective in the long term, offering 4% savings compared to concrete systems due to its potential for material recovery, recycling, and reuse.

Several studies have compared the life cycle environmental impacts of steel-frame versus reinforced concrete (RC) buildings. Zhang et al. [25] in China conducted an LCA on two equivalent office buildings (one steel-frame building and one concrete frame building). They found the steel-frame building had much lower embodied energy in its materials production—only ≈25% of the life cycle energy for materials compared to the concrete building. Oladazimi et al. [26] compared two multi-story residential buildings in Tehran—one with a steel frame and one with an RC frame—using a comprehensive cradle-to-grave LCA. Embodied carbon (GWP) was significantly lower for the steel-frame building: the RC building emitted ~9120 tons CO2 over its lifetime and the steel-frame building emitted ~24% less than this. Seyedabadi et al. [27] examined two equivalent mid-rise building designs (steel vs. RC) across different building code regimes (Eurocode, US, Canadian, and Australian standards). The authors found that results vary with structural design requirements: for example, under the European code, the steel-frame building had the highest embodied carbon intensity among the cases, while the concrete frame was about average, resulting in only a minor difference in carbon footprint between the steel and concrete options.

Engineers, in their pursuit of optimal designs, have primarily directed their attention towards specific aspects such as cost, seismic behavior, or their combination. This limited focus has led to a gap in comprehensive analyses that scrutinize the entirety of factors influencing sustainable building designs. Notably, the central concept of sustainability, encapsulating the intricate interplay between environmental, economic, and social dimensions, has been inadequately explored. This research endeavors to address this gap by adopting an inclusive approach that investigates all pertinent factors influencing building sustainability. By eschewing a singular focus and embracing a more comprehensive perspective that encompasses environmental considerations, cost-efficiency, and the seismic resilience of constructed spaces, this research aims to contribute to a more holistic understanding of sustainable building practices.

The structure of this study is organized into four main stages: (1) an environmental performance evaluation through an LCA, (2) economic evaluation using LCC, (3) seismic performance analysis through an IDA, and (4) interpretation and a comparison of the results for three building heights. A key innovation of this study lies in its holistic integration of sustainability and seismic resilience in a unified framework, which is rarely addressed comprehensively in the literature. Unlike previous research that often focuses on either cost, environmental impact, or seismic performance in isolation, this study evaluates all three dimensions simultaneously for both steel and RC structures across varying building heights. Additionally, the use of real far-field earthquake records for a nonlinear IDA, combined with detailed material inventories and cost data, ensures that the comparisons are both technically rigorous and practically applicable to modern urban developments.

2. Methodology

2.1. LCA Analysis

LCA is a comprehensive methodology employed to evaluate the environmental impact of a product, process, or system throughout its entire life cycle [28]. This analytical tool considers various stages, from raw material extraction and production to its use, maintenance, and eventual disposal or recycling [29,30,31,32,33]. The goal is to quantify the environmental burdens associated with each stage, encompassing energy consumption, resource depletion, emissions, and waste generation. By employing LCA, researchers and practitioners gain a holistic understanding of the environmental implications of their choices, enabling informed decision making for sustainable development [34,35,36]. In the context of this study, LCA serves as a vital component in assessing the environmental footprint of construction materials, particularly steel and RC structures, providing valuable insights into their respective contributions to climate change, resource depletion, and other environmental indicators [26,37].

Furthermore, LCA aids in identifying opportunities for improvement and guiding the development of strategies to minimize adverse environmental effects [38,39,40]. It allows for the comparison of different materials or processes, aiding in the selection of options with lower environmental impact. In the realm of construction, in which the choices made have long-lasting implications, LCA is a valuable tool for steering decisions towards materials and practices that align with broader sustainability goals [41,42,43,44]. This study leverages the power of LCA to unravel the environmental complexities associated with steel and RC, shedding light on their life cycle environmental performance and contributing to the overarching objective of fostering sustainable building practices.

2.2. LCC Analysis

LCC is a strategic financial approach that comprehensively evaluates the costs associated with a product, asset, or system over its entire life cycle. Unlike traditional costing methods that primarily consider upfront expenses, LCC takes into account all costs incurred from acquisition to disposal, including operational, maintenance, and end-of-life disposal costs [45,46,47]. This holistic methodology enables a more accurate and informed assessment of the economic viability and sustainability of different options. In the context of this study, LCC serves as a crucial tool in evaluating the economic implications of construction materials [48,49]. By considering costs throughout the life cycle, including maintenance and potential replacement, LCC aids in making decisions that align with long-term economic goals and sustainability objectives [50].

Moreover, LCC facilitates a comparative analysis of different materials or systems, allowing stakeholders to make informed choices based on economic considerations [51]. It provides a robust framework for decision making by highlighting the true costs associated with various options, guiding stakeholders towards choices that optimize both economic and sustainability criteria [46,48,52]. This study leverages LCC as an integral part of its methodology to assess the economic impact of steel and RC, contributing valuable insights to the broader discourse on sustainable construction practices.

2.3. Seismic Analysis

The significance of seismic performance has been tragically underscored by recent events, such as the 2023 Kahramanmaraş earthquakes in Türkiye, which caused catastrophic damage across multiple provinces. Numerous post-earthquake field reports and damage assessments [53,54,55] documented widespread collapse and severe structural failure in reinforced concrete buildings, often due to inadequate detailing, poor material quality, and lack of ductility.

Incremental dynamic analysis (IDA) is a sophisticated structural analysis method employed in earthquake engineering to evaluate the seismic performance of structures [56]. Unlike traditional linear methods [57,58], IDA recognizes the nonlinear behavior of structures under seismic forces, offering a more accurate representation of their response. In the IDA process, a structure is subjected to a series of ground motion records with increasing intensity [59,60,61]. Through a step-by-step approach, the analysis captures the structure’s dynamic response and assesses its performance at various intensity levels. The key advantage of IDA lies in its ability to identify the structure’s performance limits, such as yielding and ultimate states, providing a comprehensive understanding of its seismic resilience. This iterative approach allows engineers to refine their structural designs, ensuring buildings can withstand a range of seismic events. IDA analysis is particularly valuable for structures in seismically active regions, contributing to the advancement of earthquake-resistant engineering practices [62,63].

In this study, twelve far-field ground motion records were utilized for conducting nonlinear IDA, as detailed in Table 1. These motions were selected based on the first component of the recommended set provided by FEMA P695 and sourced from the PEER Strong Motion Database. The chosen records encompass a range of significant earthquake magnitudes, from 6.5 to 7.5, and cover a broad spectrum of epicentral distances between 8.7 and 98.2 km. This selection ensures a representative and diverse set of seismic scenarios for comprehensive structural performance evaluation.

Table 1.

Ground motion properties selected for IDA.

3. Model Description

To assess seismic resilience and sustainability, three three-dimensional buildings, constructed from both steel and RC and varying in height (with 10, 20, and 30 stories), are examined. The 10-, 20-, and 30-story buildings selected in this study represent common high-rise structural typologies in urban development. These building heights were deliberately chosen due to their increasing relevance in densely populated seismic-prone regions, where land use efficiency and vertical expansion are critical.

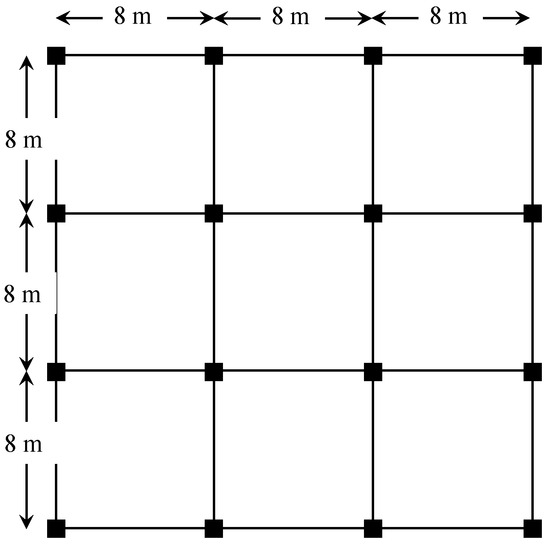

These structures, envisioned in Tehran, comprise three bays in each direction, as shown in Figure 1, and are located in seismic site class II [64]. The seismic response of structures is highly sensitive to local soil conditions, which influence ground motion amplification, frequency content, and duration. In this study, a site class II (medium soil) was used as a reference case, consistent with urban conditions in many seismic-prone regions. However, the literature suggests that reinforced concrete structures, due to their higher initial stiffness, may experience amplified inter-story drifts and shear demands when constructed on soft or liquefiable soils, potentially increasing their vulnerability to brittle failures if not properly detailed. In contrast, steel structures, characterized by greater flexibility and ductility, often perform better under soft soil conditions due to their ability to dissipate energy over prolonged shaking periods and accommodate large deformations. These observations highlight the importance of incorporating site-specific soil profiles into performance-based seismic design and suggest that the relative advantages of steel over concrete may be even more pronounced in softer soil contexts. Future studies should investigate these interactions using site-response analyses and soil-structure interaction (SSI) modeling.

Figure 1.

Floor plan of the RC and steel structures.

The floor height is standardized at 3.5 m, and all buildings are designated for residential use.

For loading considerations, the floor and roof levels bear distributed dead loads of 5.5 and 6.0 kN/m2, respectively, alongside live loads of 2 and 1.5 kN/m2, respectively [65]. A uniform partition load of 1.0 kN/m2 is assumed across all floors, with a distributed load of 6 kN/m for the surrounding walls. These parameters collectively form the basis for evaluating the seismic performance and sustainability of the buildings [66].

For the purpose of calculating the environmental impacts associated with transportation, all construction materials were assumed to be transported by trucks powered by diesel fuel over a uniform transportation distance of 50 km from the production site to the building location.

3.1. Reinforced Concrete (RC) Buildings

The building systems for lateral force resistance are special moment frames. For the design of the RC buildings, a 28-day compressive strength level of 30 MPa for concrete is considered. The longitudinal rebars reinforcing the concrete elements possess a tensile strength of 400 MPa at the yield level, while the yield stress of transverse reinforcements is set at 340 MPa.

Similar to the steel structures, the design of RC buildings is optimized using ETABS V20.2.0 software in compliance with Iranian regulations for RC structures [67]. Detailed quantities of the concrete and rebar required for each structure are meticulously outlined in Table 2.

Table 2.

The life cycle inventory for the RC buildings with different stories.

3.2. Steel Buildings

The lateral load-resisting system used in the buildings is a special moment-resisting frame. The steel frames are constructed using St-37-grade steel, which has a yield strength of 240 MPa and an elastic modulus of 210 GPa. Columns are designed with BOX-shaped cross-sections, while W-shaped sections are adopted for the beams [68]. The flooring system incorporates a composite slab with a thickness of 10 cm, supported by steel IPE220 beams in each span.

The structural models were efficiently designed using ETABS software in accordance with Iranian steel design standards [69]. Based on the optimized designs for buildings with 10, 20, and 30 stories, the required quantities of steel for each case were precisely calculated and are reported in Table 3.

Table 3.

The life cycle inventory for steel buildings with different stories.

4. Results and Discussion

In this section, the results of the LCA, LCC, and seismic response analyses for steel and RC buildings with different heights (10, 20, and 30 stories) are compared with each other.

4.1. LCA Results

A comprehensive LCA was performed to compare the environmental impacts of concrete and steel structural systems in 10-, 20-, and 30-story buildings. The results, summarized in Table 4, reveal distinct differences in the environmental performance of the different structures across multiple impact categories.

Table 4.

Environmental performance of the different structures across multiple impact categories.

Concrete-based structures tend to exhibit higher environmental burdens in categories related to toxicity, air pollution, and ecotoxicity. These outcomes are largely influenced by the nature of cement production, which is a major contributor to emissions of harmful substances during the calcination of limestone and energy-intensive kiln operations.

Firstly, concrete shows significantly higher emissions in both carcinogenic and non-carcinogenic categories. For example, in the 30-story building, the carcinogenic impact of concrete reached over 20,000 kg C2H3Cl eq—more than three times higher than steel. This is primarily due to the production of cement, which releases a wide range of persistent organic pollutants, volatile organic compounds (VOCs), and heavy metals. These substances contribute to long-term toxicity risks for humans and the environment.

In the category of respiratory inorganics, which mainly accounts for fine particulate matter (PM2.5), concrete again shows a dominant impact. This is due to dust emissions from cement handling, aggregate production, and on-site construction processes like mixing and curing. For respiratory organics, the trend continues, driven by emissions of hydrocarbons and aldehydes during material production and transportation. These emissions significantly affect urban air quality and human health, especially in densely populated construction zones.

Concrete buildings also have markedly higher ecotoxicity—both aquatic and terrestrial. The use of admixtures, supplementary cementitious materials (SCMs), and washout water from concrete trucks contributes to leachates that can harm aquatic ecosystems. Furthermore, the extensive mining of raw materials like limestone, sand, and gravel contributes to soil contamination and ecological disturbance, explaining the high terrestrial ecotoxicity values.

In terms of acidification and eutrophication, concrete continues to show higher impacts. These effects stem from the release of sulfur dioxide (SO2), nitrogen oxides (NOx), and phosphate-equivalent compounds throughout its life cycle. Acid rain, smog formation, and water body eutrophication are direct consequences of these emissions. The higher use of diesel-powered machinery and the transport of heavier concrete materials further amplify these emissions.

Even in global warming potential (GWP), concrete slightly surpasses steel, despite steel’s association with energy-intensive processing. This is again attributed to cement’s high CO2 intensity—cement production alone is estimated to account for around 7–8% of global carbon dioxide emissions. In 30-story buildings, concrete produced approximately 6.93 million kg CO2 eq, compared to 6.79 million kg CO2 eq for steel.

Lastly, although the absolute figures are small, concrete also had a higher ozone layer depletion potential, likely due to the use of refrigerants and other chemical agents in machinery and curing additives.

In contrast, steel structures displayed higher environmental impacts in categories related to energy consumption, land use, mineral resource depletion, and ionizing radiation. These outcomes are tied to the complexity of steel production, which involves several energy-intensive stages such as mining, smelting, alloying, and rolling.

One of the most prominent areas in which steel performs worse than concrete is ionizing radiation. The steel buildings, especially the 30-story buildings, showed nearly 45% higher impacts in this category. The source of this impact is primarily the energy mix used during the steel production process. In many regions, electricity generation involves nuclear power and fossil fuels, both of which contribute significantly to ionizing radiation burdens due to uranium fuel cycles and combustion by-products.

Steel structures also showed significantly higher non-renewable primary energy consumption. For instance, in the 30-story design, steel consumed over 74 million MJ of primary energy, about 22% more than concrete. The energy demand in steel production is due to high-temperature furnaces, mechanical shaping, and multiple treatment stages. Even with recycling processes in place, primary steel production remains one of the most energy-intensive industrial activities globally.

Similarly, steel buildings had higher mineral resource depletion, measured in MJ surplus. This indicates the long-term scarcity risk associated with ore extraction. In the 30-story case, steel’s mineral impact exceeded 134,000 MJ, while that of concrete was around 119,700 MJ. The production of structural steel involves the use of high-quality iron ore and various alloying metals, which are limited in supply and require extensive excavation and processing.

The damage category results of concrete and steel structures are presented in Table 5. The four primary damage categories considered are Human Health (DALY), Ecosystem Quality (PDF·m2·yr), Climate Change (kg CO2 eq), and Resource Depletion (MJ of primary energy). These aggregated indicators help understand the broader consequences of material choices on sustainability.

Table 5.

Damage category results of concrete and steel structures.

In the human health category, measured in disability-adjusted life years (DALY), concrete buildings consistently show a higher impact than steel across all building heights. For the 10-story structure, concrete resulted in 0.784 DALY, while steel had a lower impact of 0.615 DALY. This gap widens in taller buildings. For the 30-story building, concrete reached 3.38 DALY, compared to 2.59 DALY for steel. The elevated human health impact from concrete is mainly due to airborne emissions such as particulate matter (PM2.5), nitrogen oxides, and volatile organic compounds released during cement production and on-site construction processes. These pollutants are directly linked to respiratory diseases, cardiovascular problems, and premature mortality, which are captured by the DALY metric.

Concrete also exerts a significantly greater burden on ecosystem quality. This indicator reflects the loss of species diversity over time and area, influenced by toxic emissions, acidification, and eutrophication. For 10-story buildings, concrete results in an ecosystem damage of 154,835 PDF·m2·yr, more than 57% higher than that of steel, which is 98,585 PDF·m2·yr. As the building height increases, this gap becomes more pronounced. For 30-story structures, concrete reaches 719,286 PDF·m2·yr, compared to 385,845 PDF·m2·yr for steel. The reason for this discrepancy lies in the ecotoxicity and acidification potential of concrete production, including emissions from raw material extraction, the use of chemical admixtures, and on-site runoff—all of which negatively affect terrestrial and aquatic ecosystems. Cement production and the use of chemical admixtures in high-volume concrete applications significantly contribute to toxic emissions such as heavy metals and wash water residues, which are weighted heavily in the LCA model under the IMPACT 2002+ methodology.

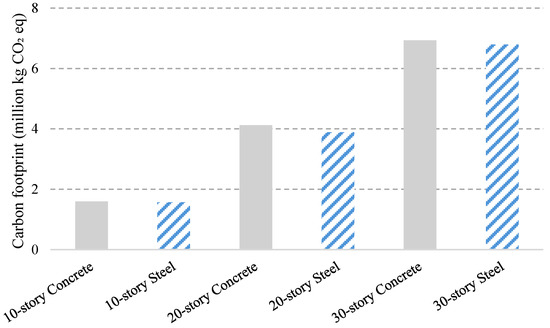

The results for climate change impacts are comparatively close between the two materials, though concrete remains slightly more impactful. In 10-story buildings, concrete generates 1.59 million kg CO2 eq, while steel is responsible for 1.57 million kg CO2 eq. As the number of stories increases, both impacts scale accordingly, with the 30-story concrete structure emitting 6.93 million kg CO2 eq and the steel structure emitting a slightly lower amount of 6.79 million kg CO2 eq. The marginally higher emissions from concrete are mainly due to CO2-intensive cement production, which contributes approximately one ton of CO2 per ton of cement. However, steel production also emits substantial CO2 due to its high energy requirements, particularly in the smelting and rolling stages, leading to similar overall climate change contributions. Figure 2 shows the carbon footprint of concrete and steel structures.

Figure 2.

Construction-stage carbon footprint of concrete and steel structural systems for 10-, 20-, and 30-story structures.

In contrast to the previous categories, steel buildings consistently consume more primary energy resources. For the 10-story design, steel requires 16.67 million MJ compared to 14.79 million MJ for concrete—a difference of about 13%. This gap increases with building height: in the 30-story scenario, steel reaches 74.14 million MJ, while concrete requires 60.94 million MJ. The higher resource depletion in steel buildings is attributed to the intensive energy demands of steel manufacturing, including mining, beneficiation, high-temperature furnaces, and alloying. Despite the recyclability of steel, primary production still dominates the market and contributes heavily to fossil energy consumption.

4.2. LCC Results

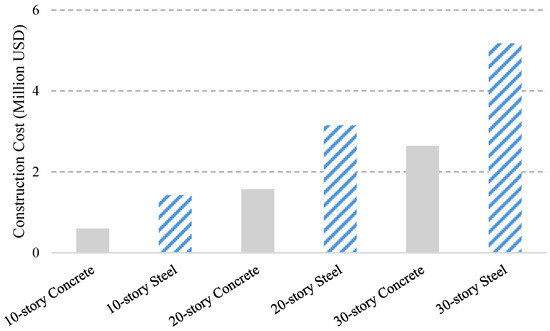

The LCC results of concrete and steel structures over the construction stage are presented in Figure 3. For 10-story buildings, the construction cost of the concrete structure is USD 0.60 million, while the steel structure costs USD 1.43 million. This shows that the steel option is nearly 2.5 times more expensive at this height. The higher cost is primarily driven by the fabrication and processing of steel components. At the 20-story level, the construction cost for the concrete structure increases to USD 1.57 million, whereas that of the steel structure rises sharply to USD 3.15 million. The cost gap becomes even wider, reflecting the greater structural complexity and load demands in taller buildings, which often result in the use of larger or more custom steel sections, increasing both material and labor costs. For 30-story buildings, concrete construction costs reach USD 2.64 million, while steel construction costs peak at USD 5.18 million. Here, again, steel construction is approximately twice as costly as concrete. This significant difference highlights the cost-efficiency of RC in high-rise construction, especially as the building height increases. It should be noted that the LCC analysis in this study considers only the initial construction-stage material costs. Costs related to operations, maintenance, repair, and end-of-life processes were excluded due to the lack of consistent and region-specific data. Future research should incorporate these long-term cost factors to provide a more comprehensive economic assessment.

Figure 3.

Construction-stage costs of concrete and steel structural systems for 10-, 20-, and 30-story structures, expressed in million U.S. dollars.

4.3. IDA Results

In this study, a nonlinear dynamic analysis of the structures was conducted using OpenSees 3.7.1 (Open System for Earthquake Engineering Simulation), an open-source, object-oriented platform specifically developed for the advanced modeling and simulation of structural and geotechnical systems under seismic loading. OpenSees is widely recognized for its robust capabilities in capturing material and geometric nonlinearities, degradation behavior, and collapse mechanisms. To accurately model the nonlinear flexural behavior of both beams and columns, the dispBeamColumn element was used. This displacement-based beam-column element allows for detailed fiber section modeling and is capable of capturing distributed plasticity along the length of the member, which is essential for simulating realistic inelastic behavior under earthquake excitations. In all models, clamped (fixed) boundary conditions were assigned at the base of the structures, and soil–structure interaction (SSI) effects were neglected. While this assumption simplifies the modeling, it is commonly used in comparative studies and provides a consistent basis for evaluating the relative seismic performance of reinforced concrete and steel systems.

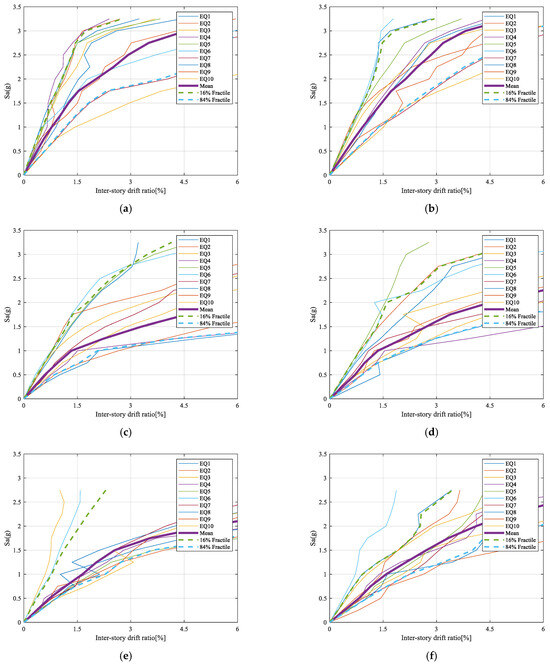

Figure 4 illustrates the IDA curves for steel and RC buildings with three different heights—10, 20, and 30 stories. Each subfigure represents the structural response of a building typology under increasing seismic intensity measures (IMs), such as spectral acceleration, and corresponding engineering demand parameters (EDPs), such as the inter-story drift ratio (IDR). These curves provide insights into the nonlinear dynamic performance of each structural system and highlight the onset of yielding, strength degradation, and ultimate failure levels.

Figure 4.

IDA results for (a) 10-story reinforced concrete structures, (b) 10-story steel structures, (c) 20-story reinforced concrete structures, (d) 20-story steel structures, (e) 30-story reinforced concrete structures, (f) 30-story steel structures.

A clear distinction can be observed in the initial stiffness of the two systems. Reinforced concrete buildings exhibit steeper slopes in the initial portions of their IDA curves, indicating a higher level of stiffness in the elastic range. In contrast, steel buildings demonstrate a more flexible response, as reflected by gentler initial slopes. This flexibility allows the steel structures to undergo larger displacements before yielding, which can be advantageous in dissipating seismic energy and reducing force demands on structural elements.

Another important observation is the difference in ductility and energy dissipation capacity between the two systems. Steel buildings, particularly 20- and 30-story buildings, transition more smoothly into the inelastic range, indicating enhanced ductile behavior and greater resilience under cyclic loading. On the other hand, reinforced concrete buildings show a more abrupt reduction in stiffness after yielding. This behavior suggests a tendency towards more brittle failure mechanisms, which could compromise performance under extreme earthquake scenarios if not properly detailed.

The collapse capacity of steel structures is also notably higher across all building heights. For example, in the 30-story case, steel buildings are able to sustain higher levels of spectral acceleration before reaching instability, while their concrete counterparts exhibit collapse at comparatively lower intensity measures. This indicates that steel structures are more capable of accommodating large nonlinear deformations without catastrophic failure, especially in high-rise applications.

Additionally, the influence of building height on seismic response is significant. As the number of stories increases, both structural systems experience greater displacement demands and a reduction in overall stiffness. However, steel structures appear to manage this transition more effectively. The 30-story steel frame maintains structural stability over a wider range of intensity measures than the corresponding concrete frame, showcasing a better performance in terms of both strength and deformation capacity.

5. Conclusions

This study conducted a holistic evaluation of the seismic resilience and sustainability of reinforced concrete and steel structures across three building heights: 10, 20, and 30 stories. Through a combination of a life cycle assessment (LCA), life cycle costing (LCC), and an incremental dynamic analysis (IDA), the research aimed to provide a robust basis for material selection in structural design from both environmental and performance standpoints.

The following key conclusions can be drawn:

- LCA results:

- Reinforced concrete structures generally exhibited higher environmental impacts in toxicity-related categories (e.g., carcinogens, respiratory organics/inorganics, and ecotoxicity) due to the energy-intensive nature of cement production.

- Steel structures had higher environmental impacts in non-renewable energy use, mineral extraction, and ionizing radiation, primarily driven by energy demands in steel production and resource extraction.

- In terms of global warming potential, both materials produced comparable levels of CO2 emissions, with that of reinforced concrete being slightly higher due to cement’s carbon intensity.

- LCC results:

- Reinforced concrete structures demonstrated better cost-efficiency during the construction stage, particularly for taller buildings, making them a more economical option in terms of the upfront investment.

- Steel structures, while more expensive initially, may offer potential long-term cost benefits through their recyclability and reduced damage during seismic events.

- IDA results:

- Steel buildings exhibited superior ductility, a greater deformation capacity, and higher collapse resistance across all height categories.

- Reinforced concrete structures, though stiffer initially, showed a more brittle response after yielding and reached collapse thresholds at lower seismic intensities.

- The performance gap widened with building height, making steel a more favorable option for high-rise construction in seismic zones.

In conclusion, the selection between steel and reinforced concrete should be guided by project-specific priorities. If cost-efficiency and lower initial environmental impact are primary concerns, reinforced concrete may be preferable. However, for applications requiring enhanced seismic resilience and long-term sustainability, especially for taller structures, steel provides distinct advantages. A balanced, multi-criteria decision-making approach is essential for achieving optimal structural performance and sustainability outcomes in modern construction.

While this study provides a detailed comparison of reinforced concrete and steel structural systems in terms of sustainability and seismic performance, several limitations must be acknowledged. Worker safety, ease of construction, and long-term maintenance were not modeled in the LCA or LCC phases. The operational and functional aspects of buildings, particularly their performance during and after seismic events (e.g., downtime, reparability, and continued usability), are also excluded. Moreover, the IDA analysis does not include soil–structure interaction effects or damage to building contents, which are essential for a comprehensive earthquake resilience evaluation.

While this study focuses on buildings up to 30 stories and new construction scenarios, future research will explore the implications of extending the analysis to taller buildings (e.g., 40+ stories), as well as the application of these methods to retrofitting or adaptive reuse contexts. The integration of high-performance materials such as ultra-high-performance concrete (UHPC) and high-strength steel could significantly influence both buildings’ structural performance and life cycle impacts. These materials will be considered in further investigations to enhance the understanding of trade-offs between seismic resilience and sustainability in more advanced structural systems.

Author Contributions

Conceptualization, H.M.; methodology, H.M.; formal analysis, H.M. and M.A.B.; investigation, H.M. and M.A.B.; resources, H.M. and M.A.B.; data curation, H.M. and M.A.B.; writing—original draft preparation, H.M.; writing—review and editing, H.M. and H.B.; visualization, H.M. and H.B.; supervision, H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to confidentiality issues.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Akadiri, P.O. Understanding barriers affecting the selection of sustainable materials in building projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- Wang, N.; Adeli, H. Sustainable building design. J. Civ. Eng. Manag. 2014, 20, 1–10. [Google Scholar] [CrossRef]

- Eze, E.C.; Ugulu, R.A.; Onyeagam, O.P.; Adegboyega, A.A. Determinants of sustainable building materials (SBM) selection on construction projects. Int. J. Constr. Supply Chain Manag. 2021, 11, 166–194. [Google Scholar] [CrossRef]

- Pessiki, S. Sustainable seismic design. Procedia Eng. 2017, 171, 33–39. [Google Scholar] [CrossRef]

- Gilmore, A.T. Options for sustainable earthquake-resistant design of concrete and steel buildings. Earthq. Struct. 2012, 3, 783–804. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, H. High performance damage-resistant seismic resistant structural systems for sustainable and resilient city: A review. Shock. Vib. 2018, 2018, 1–32. [Google Scholar] [CrossRef]

- Erdogan, E.; Dilaver, Z.; Benzer, N. Sustainable building design in Duzce case with reference to earthquake resistant building design. Afr. J. Agric. Res. 2009, 4, 982–990. [Google Scholar]

- Kc, S.; Gautam, D. Progress in sustainable structural engineering: A review. Innov. Infrastruct. Solut. 2021, 6, 68. [Google Scholar] [CrossRef]

- Ranjbar, N.; Balali, A.; Valipour, A.; Yunusa-Kaltungo, A.; Edwards, R.; Pignatta, G.; Moehler, R.; Shen, W. Investigating the environmental impact of reinforced-concrete and structural-steel frames on sustainability criteria in green buildings. J. Build. Eng. 2021, 43, 103184. [Google Scholar] [CrossRef]

- Kerdlap, P.; Cornago, S. Life cycle costing: Methodology and applications in a circular economy. In An Introduction to Circular Economy; Springer: Berlin/Heidelberg, Germany, 2021; pp. 499–525. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Shabani, K.; Bahmani, M.; Fatehi, H.; Chang, I. Improvement of the geotechnical engineering properties of dune sand using a plant-based biopolymer named serish. Geomech. Eng. 2022, 29, 535–548. [Google Scholar]

- Saffari, R.; Nikooee, E.; Habibagahi, G.; Van Genuchten, M.T. Effects of biological stabilization on the water retention properties of unsaturated soils. J. Geotech. Geoenviron. Eng. 2019, 145, 04019028. [Google Scholar] [CrossRef]

- Hegeir, O.A.; Kvande, T.; Stamatopoulos, H.; Bohne, R.A. Comparative life cycle analysis of timber, steel and reinforced concrete portal frames: A theoretical study on a Norwegian industrial building. Buildings 2022, 12, 573. [Google Scholar] [CrossRef]

- Gupta, A.K.; Shukla, S.K.; Azamathulla, H. Advances in Construction Materials and Sustainable Environment; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Cole, R.J.; Kernan, P.C. Life-cycle energy use in office buildings. Build. Environ. 1996, 31, 307–317. [Google Scholar] [CrossRef]

- Guggemos, A.A.; Horvath, A. Comparison of environmental effects of steel-and concrete-framed buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- Peyroteo, A.; Silva, M.; Jalali, S. Life cycle assessment of steel and reinforced concrete structures: A new analysis tool. Port. SB 2007, 7, 397–402. [Google Scholar]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Basaglia, B.; Lewis, K.; Shrestha, R.; Crews, K. A comparative life cycle assessment approach of two innovative long span timber floors with its reinforced concrete equivalent in an Australian context. In Proceedings of the International Conference on Performance-Based and Life-Cycle Structural Engineering, Brisbane, Australia, 9–11 December 2015. [Google Scholar]

- Lu, H.R.; El Hanandeh, A.; Gilbert, B.P. A comparative life cycle study of alternative materials for Australian multi-storey apartment building frame constructions: Environmental and economic perspective. J. Clean. Prod. 2017, 166, 458–473. [Google Scholar] [CrossRef]

- Tighnavard Balasbaneh, A.; Bin Marsono, A.K.; Kasra Kermanshahi, E. Balancing of life cycle carbon and cost appraisal on alternative wall and roof design verification for residential building. Constr. Innov. 2018, 18, 274–300. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Ramli, M.Z. A comparative life cycle assessment (LCA) of concrete and steel-prefabricated prefinished volumetric construction structures in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 43186–43201. [Google Scholar] [CrossRef]

- Zhang, X.; Su, X.; Huang, Z. Comparison of LCA on Steel-and Concrete-Construction Office Buildings: A Case Study; College of Mechanical Engineering, Tongji University: Shanghai, China, 2007. [Google Scholar]

- Oladazimi, A.; Mansour, S.; Hosseinijou, S.A. Comparative life cycle assessment of steel and concrete construction frames: A case study of two residential buildings in Iran. Buildings 2020, 10, 54. [Google Scholar] [CrossRef]

- Seyedabadi, M.R.; Karrabi, M.; Shariati, M.; Karimi, S.; Maghrebi, M.; Eicker, U. Global building life cycle assessment: Comparative study of steel and concrete frames across European Union, USA, Canada, and Australia building codes. Energy Build. 2024, 304, 113875. [Google Scholar] [CrossRef]

- Mostafaei, H.; Chamasemani, N.F.; Mashayekhi, M.; Hamzehkolaei, N.S.; Santos, P. Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Appl. Sci. 2025, 15, 2479. [Google Scholar] [CrossRef]

- Hollberg, A.; Kiss, B.; Röck, M.; Soust-Verdaguer, B.; Wiberg, A.H.; Lasvaux, S.; Galimshina, A.; Habert, G. Review of visualising LCA results in the design process of buildings. Build. Environ. 2021, 190, 107530. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H. Impact of Fibers on the Mechanical and Environmental Properties of High-Performance Concrete Incorporating Zeolite. J. Com. Sci. 2025, 9, 222. [Google Scholar] [CrossRef]

- van Stijn, A.; Eberhardt, L.C.M.; Jansen, B.W.; Meijer, A. A circular economy life cycle assessment (CE-LCA) model for building components. Resour. Conserv. Recycl. 2021, 174, 105683. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Ghiassi, B.; Mostofinejad, D.; Wu, C. A comparative study of calcium hydroxide, calcium oxide, calcined dolomite, and metasilicate as activators for slag-based HPC. Structures 2023, 58, 105653. [Google Scholar] [CrossRef]

- Dong, Y.; Miraglia, S.; Manzo, S.; Georgiadis, S.; Sørup, H.J.D.; Boriani, E.; Hald, T.; Thöns, S.; Hauschild, M.Z. Environmental sustainable decision making–The need and obstacles for integration of LCA into decision analysis. Environ. Sci. Policy 2018, 87, 33–44. [Google Scholar] [CrossRef]

- Finnegan, S. Life Cycle Assessment (LCA) and Its Role in Improving Decision Making for Sustainable Development; University of Cambridge: Cambridge, UK, 2013. [Google Scholar]

- McManus, M.C.; Taylor, C.M.; Mohr, A.; Whittaker, C.; Scown, C.D.; Borrion, A.L.; Glithero, N.J.; Yin, Y. Challenge clusters facing LCA in environmental decision-making—What we can learn from biofuels. Int. J. Life Cycle Assess. 2015, 20, 1399–1414. [Google Scholar] [CrossRef]

- Mostafaei, H.; Kelishadi, M.; Bahmani, H.; Wu, C.; Ghiassi, B. Development of sustainable HPC using rubber powder and waste wire: Carbon footprint analysis, mechanical and microstructural properties. Eur. J. Environ. Civ. Eng. 2025, 29, 399–420. [Google Scholar] [CrossRef]

- Andrews, E.S. Guidelines for Social Life Cycle Assessment of Products: Social and Socio-Economic LCA Guidelines Complementing Environmental LCA and Life Cycle Costing, Contributing to the Full Assessment of Goods and Services Within the Context of Sustainable Development; UNEP/Earthprint; United Nations Environment Programme: Nairobi, Republic of Kenya, 2009. [Google Scholar]

- Jacquemin, L.; Pontalier, P.-Y.; Sablayrolles, C. Life cycle assessment (LCA) applied to the process industry: A review. Int. J. Life Cycle Assess. 2012, 17, 1028–1041. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Fallah Chamasemani, N. Enhancing the mechanical properties of Ultra-High-Performance Concrete (UHPC) through silica sand replacement with steel slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Husgafvel, R.; Linkosalmi, L.; Sakaguchi, D.; Hughes, M. How to advance sustainable and circular economy-oriented public procurement—A review of the operational environment and a case study from the Kymenlaakso region in Finland. In Circular Economy and Sustainability; Elsevier: Amsterdam, The Netherlands, 2022; pp. 227–277. [Google Scholar]

- Industry, B.T. Sustainable building and construction: Facts and figures. Ind. Environ. 2003, 26, 5–8. [Google Scholar]

- Mostafaei, H.; Bahmani, H. Sustainable High-Performance Concrete Using Zeolite Powder: Mechanical and Carbon Footprint Analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- Mostafaei, H.; Rostampour, M.A.; Chamasemani, N.F.; Wu, C. An In-Depth Exploration of Carbon Footprint Analysis in the Construction Sector with Emphasis on the Dam Industry. In Carbon Footprint Assessments: Case Studies & Best Practices; Springer: Berlin/Heidelberg, Germany, 2024; pp. 45–80. [Google Scholar]

- Weerasinghe, A.S.; Ramachandra, T.; Rotimi, J.O.B. Comparative life-cycle cost (LCC) study of green and traditional industrial buildings in Sri Lanka. Energy Build. 2021, 234, 110732. [Google Scholar] [CrossRef]

- Goulouti, K.; Padey, P.; Galimshina, A.; Habert, G.; Lasvaux, S. Uncertainty of building elements’ service lives in building LCA & LCC: What matters? Build. Environ. 2020, 183, 106904. [Google Scholar]

- Mostafaei, H.; Keshavarz, Z.; Rostampour, M.A.; Mostofinejad, D.; Wu, C. Sustainability Evaluation of a Concrete Gravity Dam: Life Cycle Assessment, Carbon Footprint Analysis, and Life Cycle Costing. Structures 2023, 53, 279–295. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability assessment of circular building alternatives: Consequential LCA and LCC for internal wall assemblies as a case study in a Belgian context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC analysis within a BIM-based environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Salvado, F.; Almeida, N.M.d.; Vale e Azevedo, A. Toward improved LCC-informed decisions in building management. Built Environ. Proj. Asset Manag. 2018, 8, 114–133. [Google Scholar] [CrossRef]

- Oladazimi, A.; Mansour, S.; Hosseinijou, S.A.; Majdfaghihi, M.H. Sustainability identification of steel and concrete construction frames with respect to triple bottom line. Buildings 2021, 11, 565. [Google Scholar] [CrossRef]

- Biolek, V.; Hanák, T. LCC estimation model: A construction material perspective. Buildings 2019, 9, 182. [Google Scholar] [CrossRef]

- Akar, F.; Işık, E.; Avcil, F.; Büyüksaraç, A.; Arkan, E.; İzol, R. Geotechnical and structural damages caused by the 2023 Kahramanmaraş Earthquakes in Gölbaşı (Adıyaman). Appl. Sci. 2024, 14, 2165. [Google Scholar] [CrossRef]

- Demir, A.; Celebi, E.; Ozturk, H.; Ozcan, Z.; Ozocak, A.; Bol, E.; Sert, S.; Sahin, F.Z.; Arslan, E.; Dere Yaman, Z. Destructive impact of successive high magnitude earthquakes occurred in Türkiye’s Kahramanmaraş on February 6, 2023. Bull. Earthq. Eng. 2024, 23, 893–919. [Google Scholar] [CrossRef]

- Yıldız, Ö.; Kına, C. Geotechnical and structural investigations in Malatya province after Kahramanmaraş Earthquake on February 6, 2023. Bitlis Eren Üniversitesi Fen Bilim. Derg. 2023, 12, 686–703. [Google Scholar] [CrossRef]

- Vamvatsikos, D.; Cornell, C.A. Incremental dynamic analysis. Earthq. Eng. Struct. Dyn. 2002, 31, 491–514. [Google Scholar] [CrossRef]

- Mostafaei, H.; Gilani, M.S.; Ghaemian, M. A comparative study between pseudo-static and dynamic analyses on rock wedge stability of an arch dam. Civ. Eng. J. 2018, 4, 179–187. [Google Scholar] [CrossRef]

- Mostafaei, H.; Behnamfar, F.; Alembagheri, M. Nonlinear analysis of stability of rock wedges in the abutments of an arch dam due to seismic loading. Struct. Monit. Maint. 2020, 7, 295–317. [Google Scholar]

- He, X.; Lu, Z. Seismic fragility assessment of a super tall building with hybrid control strategy using IDA method. Soil Dyn. Earthq. Eng. 2019, 123, 278–291. [Google Scholar] [CrossRef]

- Miari, M.; Jankowski, R. Incremental dynamic analysis and fragility assessment of buildings founded on different soil types experiencing structural pounding during earthquakes. Eng. Struct. 2022, 252, 113118. [Google Scholar] [CrossRef]

- Samadi, M.; Jahan, N. Determining the effective level of outrigger in preventing collapse of tall buildings by IDA with an alternative damage measure. Eng. Struct. 2019, 191, 104–116. [Google Scholar] [CrossRef]

- Stanikzai, M.H.; Elias, S.; Rupakhety, R. Seismic response mitigation of base-isolated buildings. Appl. Sci. 2020, 10, 1230. [Google Scholar] [CrossRef]

- Farzampour, A.; Mansouri, I.; Dehghani, H. Incremental dynamic analysis for estimating seismic performance of multi-story buildings with butterfly-shaped structural dampers. Buildings 2019, 9, 78. [Google Scholar] [CrossRef]

- The Iranian Standard No. 2800; Iranian Code of Practice for Seismic Resistance Design of Buildings. Iran National Standards Organization (INSO): Industrial City, Iran, 2015.

- Rostampour, M.A. Calculations of the Building Dead Loads Based on the Various Construction Details; Simaye Danesh Publication: Tehran, Iran, 2023. [Google Scholar]

- Mostafaei, H.; Badarloo, B.; Chamasemani, N.F.; Rostampour, M.A.; Lehner, P. Investigating the Effects of Concrete Mix Design on the Environmental Impacts of Reinforced Concrete Structures. Buildings 2023, 13, 1313. [Google Scholar] [CrossRef]

- Ministry of Roads and Urban Development. Chapter 9: Design of Reinforced Concrete Structures; Ministry of Roads and Urban Development: Tehran, Iran, 2020. [Google Scholar]

- Mostafaei, H.; Mostofinejad, D.; Ghamami, M.; Wu, C. Fully automated operational modal identification of regular and irregular buildings with ensemble learning. Structures 2023, 58, 105439. [Google Scholar] [CrossRef]

- Ministry of Roads and Urban Development. Chapter 10: Design of Steel Structures; Ministry of Roads and Urban Development: Tehran, Iran, 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).