Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning

Abstract

1. Introduction

2. Background

2.1. Thermal Comfort Models

2.2. Machine Learning Algorithms in Predicting Thermal Comfort

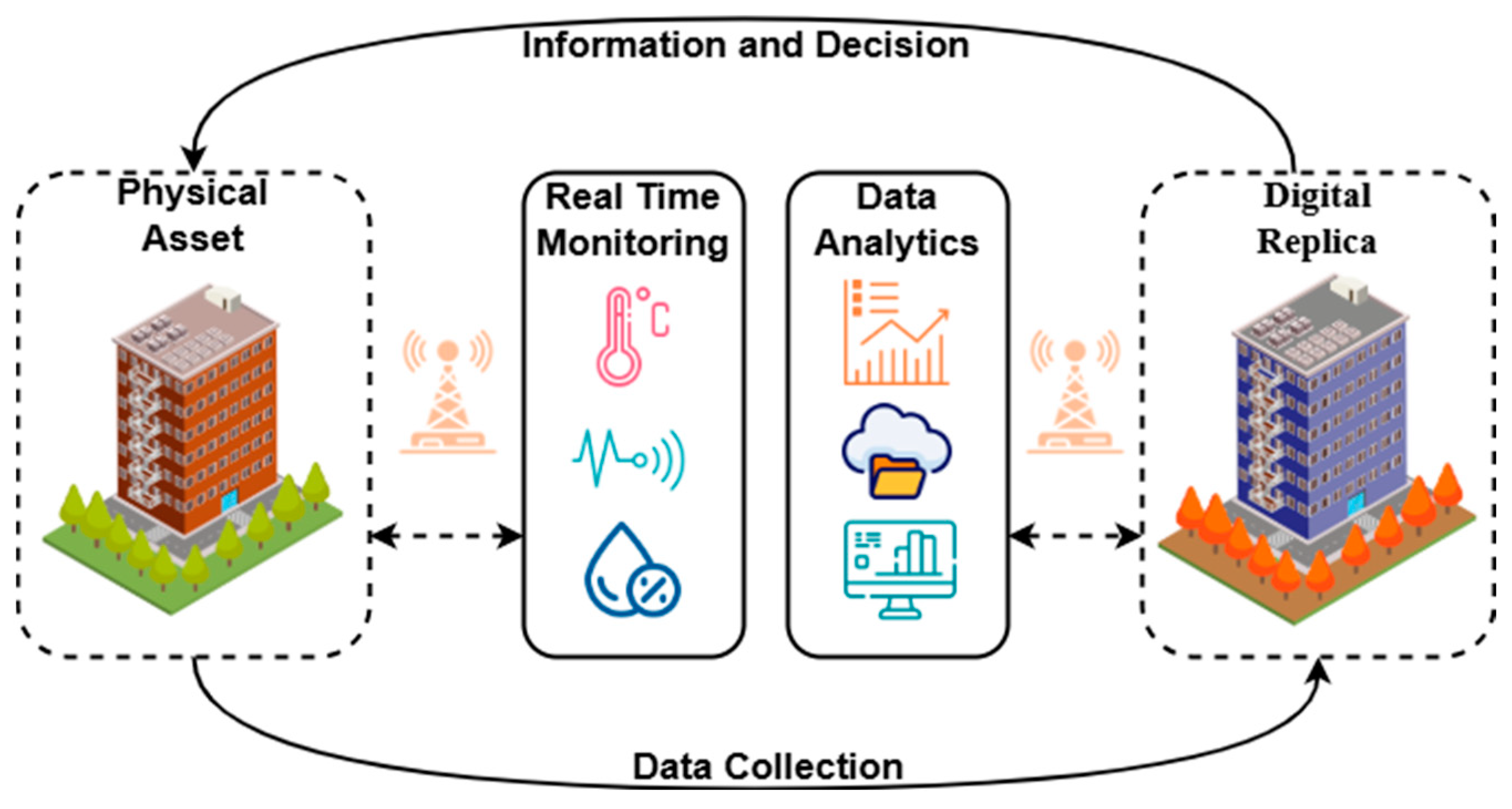

2.3. Digital Twin

3. Research Aim

- To create a web-based, open-source, user-friendly platform integrated with IoT sensors for the real-time monitoring and visualization of thermal comfort indices in a BIM environment.

- To improve thermal comfort assessments by employing ML algorithms such as LSTM networks and FB Prophet, enabling the prediction and maintenance of optimal indoor conditions tailored according to the user’s custom preferences.

- To establish a DT framework that facilitates automated dynamic control and optimization of HVAC preventing it from becoming over-controlled, as excessive temperature adjustments and compressor cycling can lead to high power consumption without achieving optimal thermal comfort.

4. Materials and Methods

4.1. System Architecture and Components

4.1.1. IoT Module Hardware Configuration

4.1.2. IoT Architecture

- Sensor Layer

- 2.

- Communication Layer

- 3.

- Support Layer

- 4.

- Application Layer

- 5.

- Security Layer

4.1.3. Digital Twin Elements

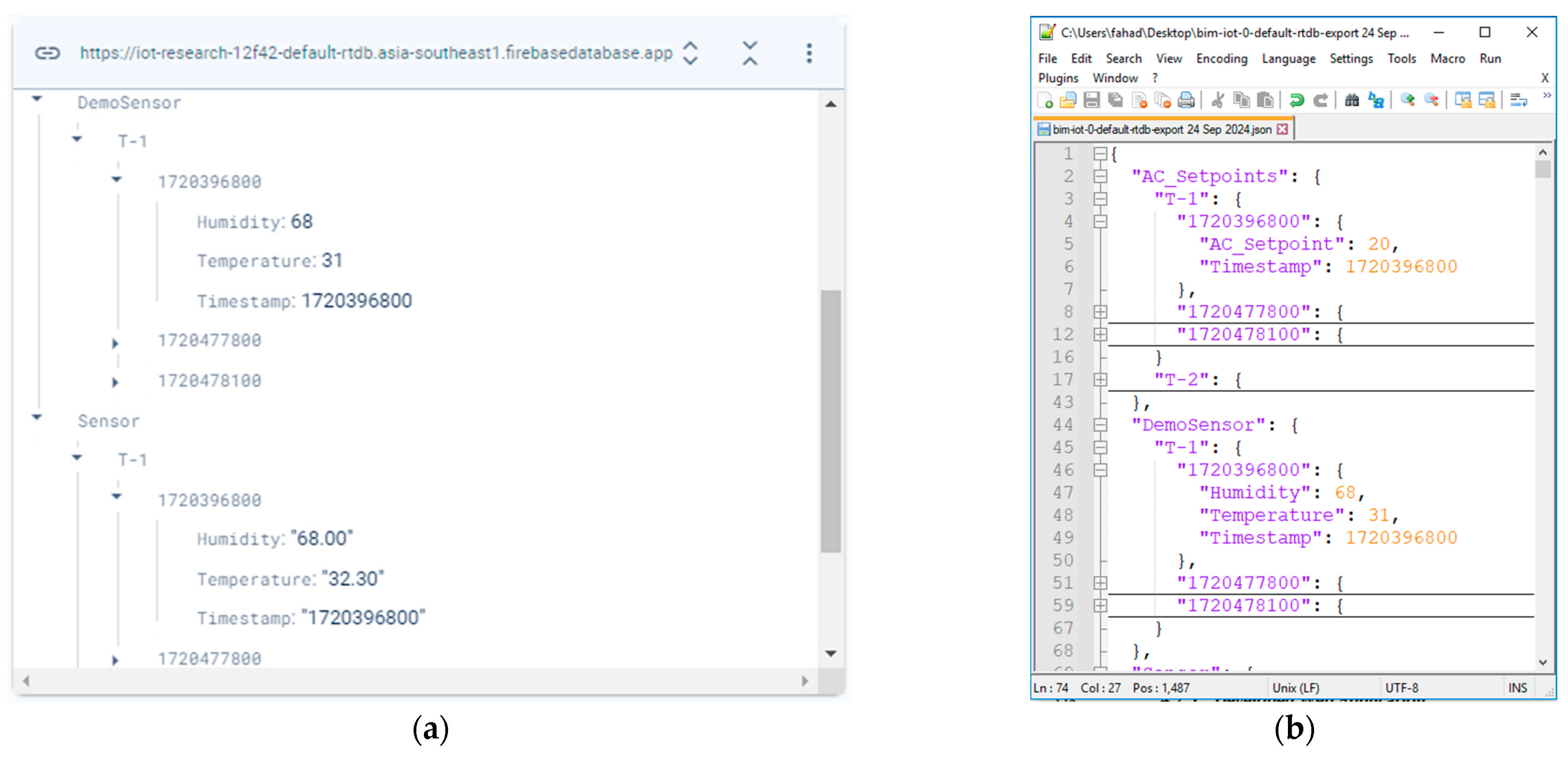

4.1.4. Real-Time Database

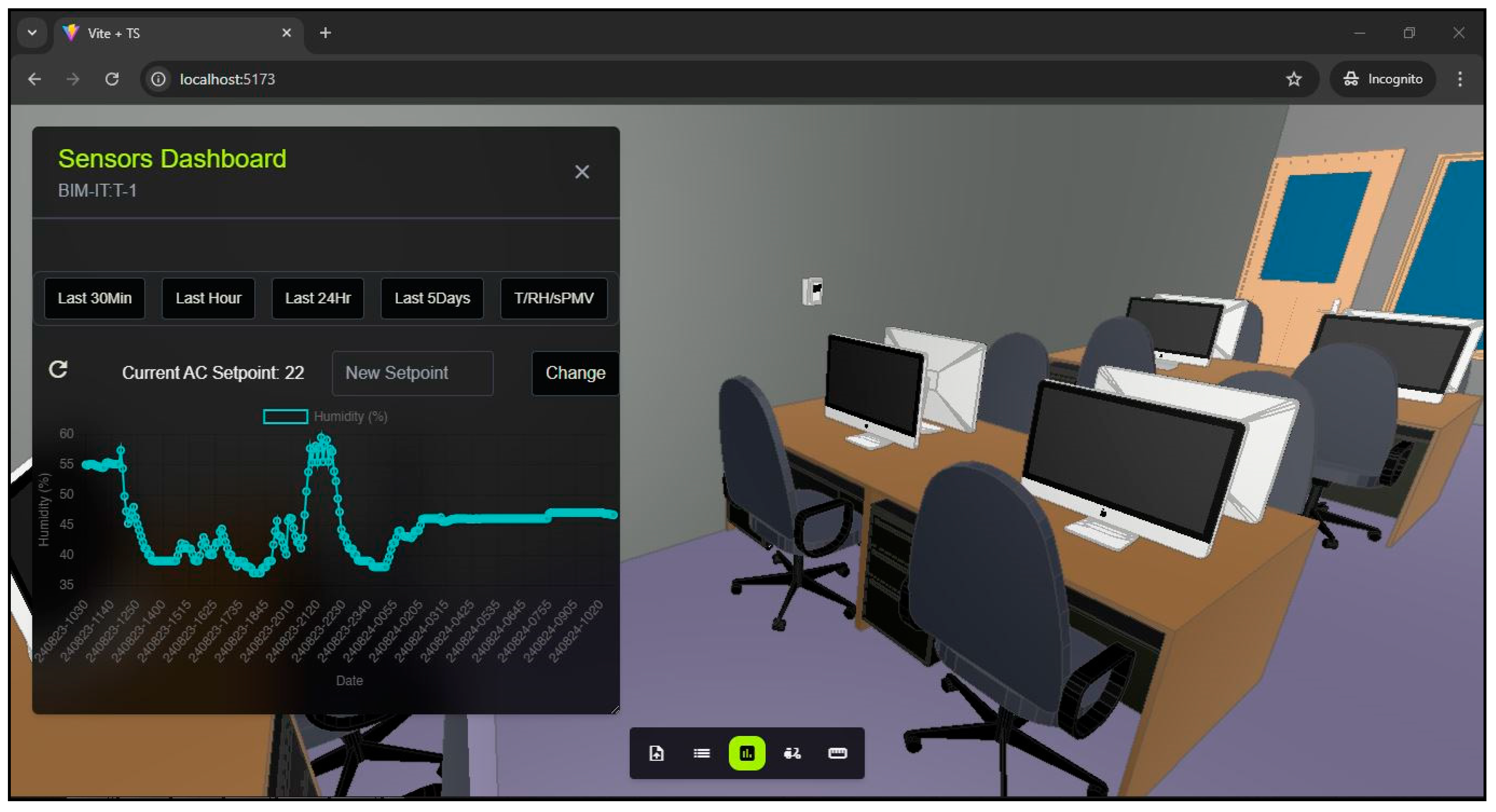

4.1.5. Developed Web Application

4.2. Data Processing

4.2.1. Thermal Comfort Model

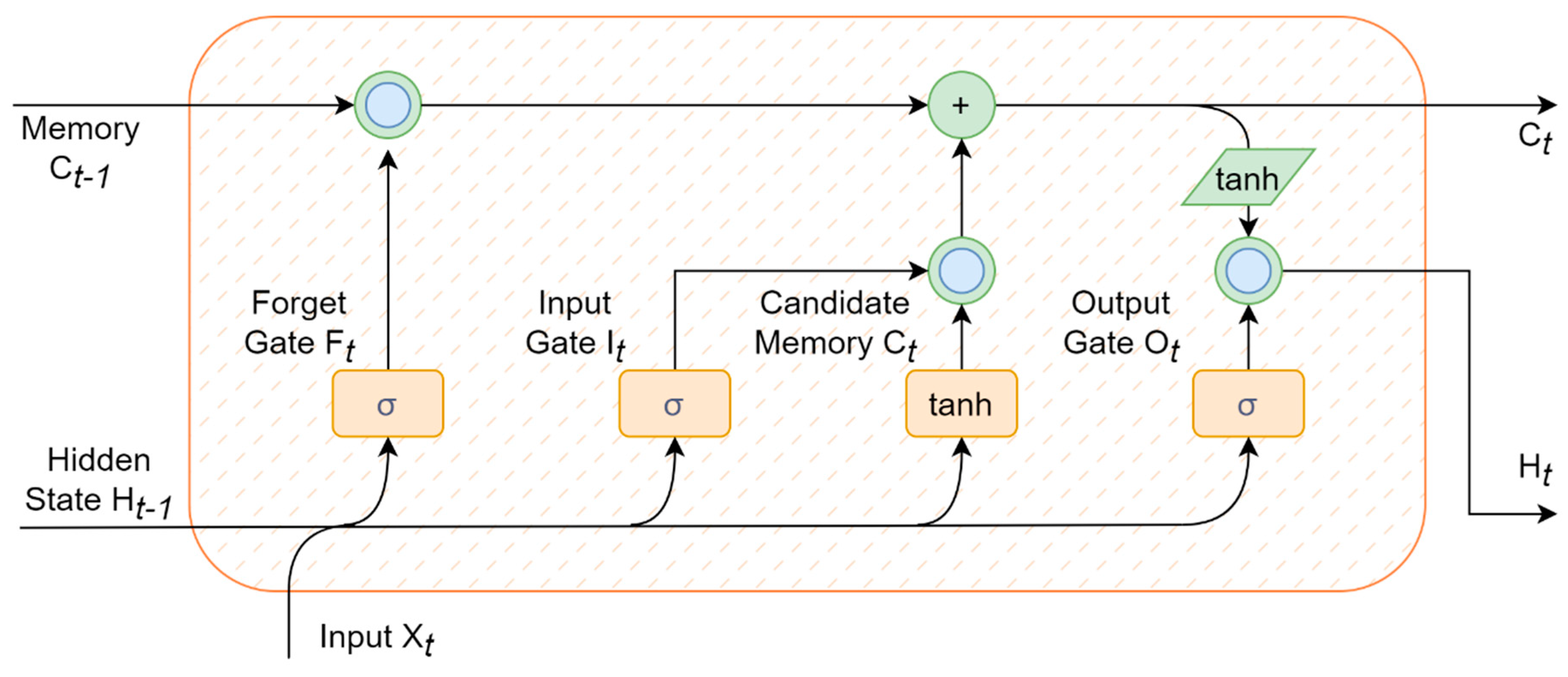

4.2.2. Machine Learning Tools

5. Experimental Design

6. Results

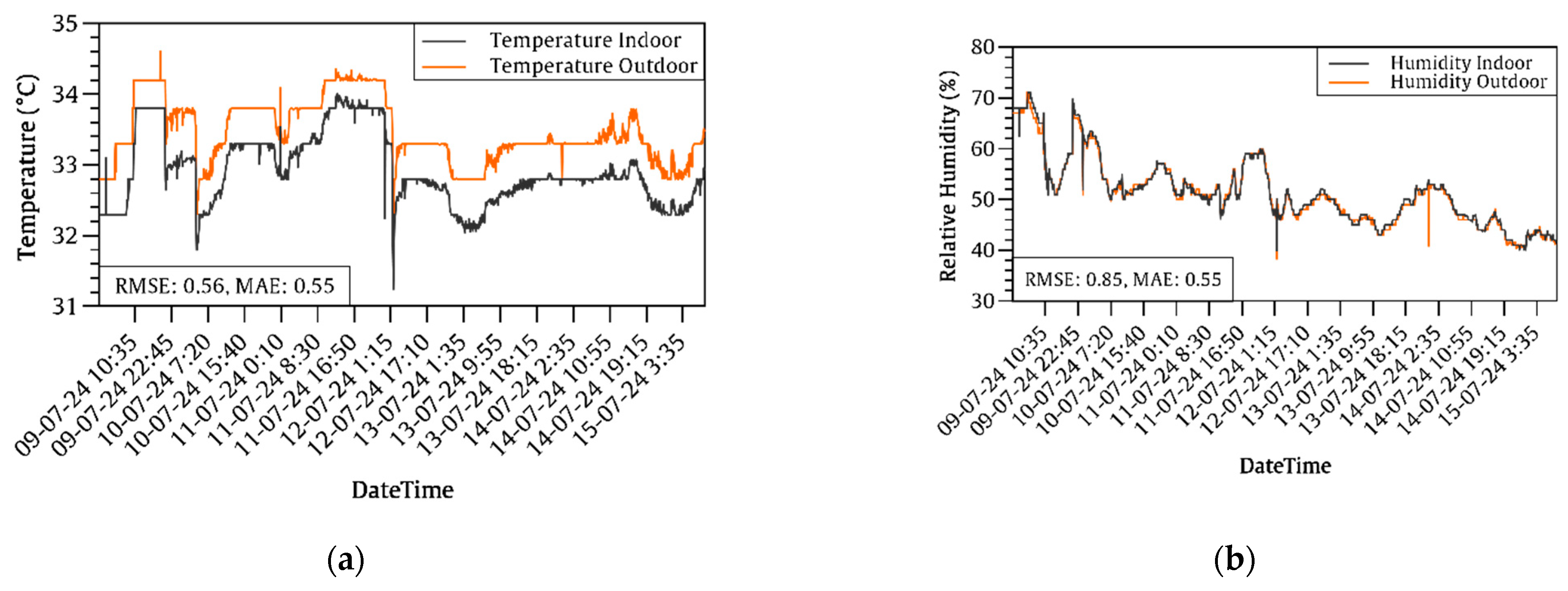

6.1. Pre-Calibration

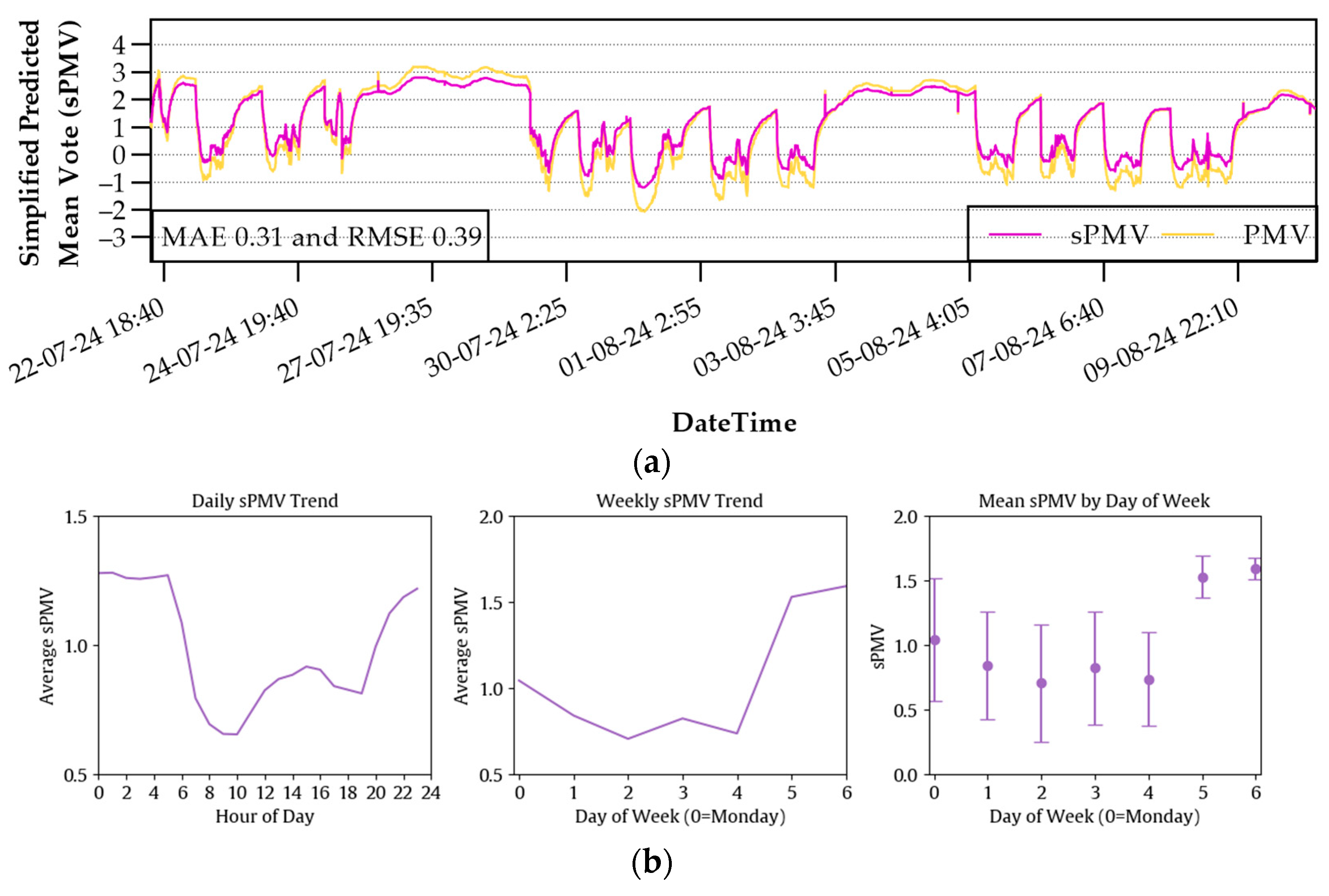

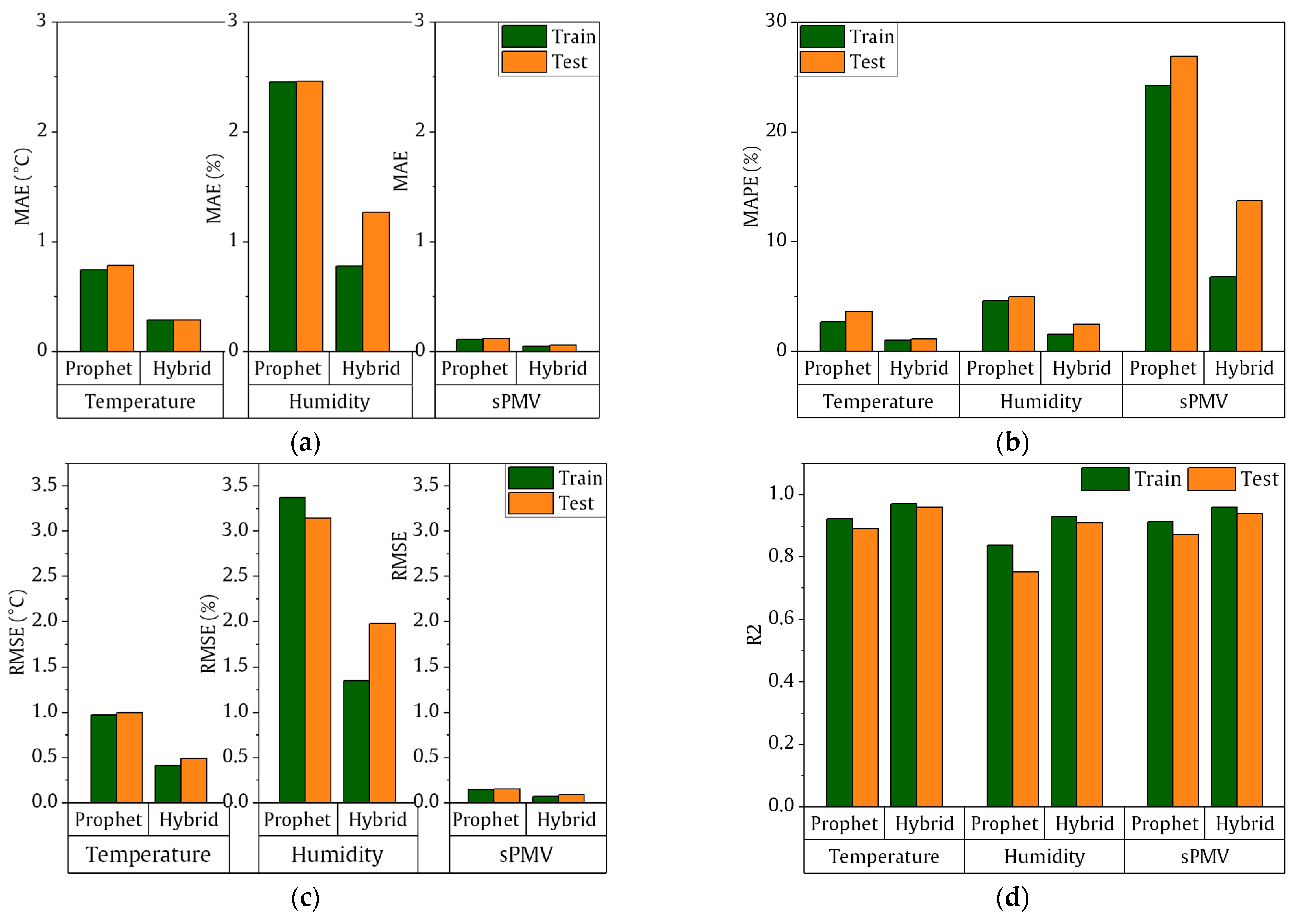

6.2. Results of Field Data

7. Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zahid, H.; Elmansoury, O.; Yaagoubi, R. Dynamic Predicted Mean Vote: An IoT-BIM Integrated Approach for Indoor Thermal Comfort Optimization. Autom. Constr. 2021, 129, 103805. [Google Scholar] [CrossRef]

- Ma, N.; Aviv, D.; Guo, H.; Braham, W.W. Measuring the Right Factors: A Review of Variables and Models for Thermal Comfort and Indoor Air Quality. Renew. Sustain. Energy Rev. 2021, 135, 110436. [Google Scholar] [CrossRef]

- Singh, D.; Akram, S.V.; Singh, R.; Gehlot, A.; Buddhi, D.; Priyadarshi, N.; Sharma, G.; Bokoro, P.N. Building Integrated Photovoltaics 4.0: Digitization of the Photovoltaic Integration in Buildings for a Resilient Infra at Large Scale. Electronics 2022, 11, 2700. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward Smart-Building Digital Twins: BIM and IoT Data Integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Liu, Z.; Cui, J.; Osmani, M.; Demian, P. Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building. Buildings 2023, 13, 288. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 55-2013; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2013.

- Mannan, M.; Al-Ghamdi, S.G. Indoor Air Quality in Buildings: A Comprehensive Review on the Factors Influencing Air Pollution in Residential and Commercial Structure. Int. J. Environ. Res. Public Health 2021, 18, 3276. [Google Scholar] [CrossRef]

- Saadatifar, S.; Sawyer, A.O.; Byrne, D.J.; Zhang, Y. Balancing Thermal Comfort with Energy Consumption in Buildings Using Digital Twins, IoT Sensors, and Real-Time Dashboards to Inform Occupant Decision Making. ASHRAE Trans. 2023, 129, 720. [Google Scholar]

- Sharma, V.; Mistry, V. Human-Centric HVAC Control: Balancing Comfort and Energy Efficiency. Eur. J. Adv. Eng. Technol. 2024, 10, 42–48. [Google Scholar]

- Buratti, C.; Ricciardi, P.; Vergoni, M. HVAC Systems Testing and Check: A Simplified Model to Predict Thermal Comfort Conditions in Moderate Environments. Appl. Energy 2013, 104, 117–127. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, K.; Wang, Y. Comparative Analysis of Thermal Preference Prediction Performance in Different Conditions Using Ensemble Learning Models Based on ASHRAE Comfort Database II. Build. Environ. 2022, 223, 109462. [Google Scholar] [CrossRef]

- Villa, V.; Naticchia, B.; Bruno, G.; Aliev, K.; Piantanida, P.; Antonelli, D. Iot Open-Source Architecture for the Maintenance of Building Facilities. Appl. Sci. 2021, 11, 5374. [Google Scholar] [CrossRef]

- Desogus, G.; Frau, C.; Quaquero, E.; Rubiu, G. From Building Information Model to Digital Twin: A Framework for Building Thermal Comfort Monitoring, Visualizing, and Assessment. Buildings 2023, 13, 1971. [Google Scholar] [CrossRef]

- Gil, S.; Mikkelsen, P.H.; Gomes, C.; Larsen, P.G. Survey on Open-Source Digital Twin Frameworks–A Case Study Approach. Softw. Pract. Exp. 2024, 54, 929–960. [Google Scholar] [CrossRef]

- Silva, D.G.; Coutinho, C.; Costa, C.J. Factors Influencing Free and Open-Source Software Adoption in Developing Countries—An Empirical Study. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100002. [Google Scholar] [CrossRef]

- Mansi, S.A.; Barone, G.; Forzano, C.; Pigliautile, I.; Ferrara, M.; Pisello, A.L.; Arnesano, M. Measuring Human Physiological Indices for Thermal Comfort Assessment through Wearable Devices: A Review. Measurement 2021, 183, 109872. [Google Scholar] [CrossRef]

- Ole Fanger, P. Thermal Comfort. Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970; 244p. [Google Scholar]

- Orosa, J.A. Research on General Thermal Comfort Models. Eur. J. Sci. Res. 2009, 27, 217–227. [Google Scholar]

- Cheung, T.; Schiavon, S.; Parkinson, T.; Li, P.; Brager, G. Analysis of the Accuracy on PMV—PPD Model Using the ASHRAE Global Thermal Comfort Database II. Build. Environ. 2019, 153, 205–217. [Google Scholar] [CrossRef]

- Mirzabeigi, S.; Khalili Nasr, B.; Mainini, A.G.; Blanco Cadena, J.D.; Lobaccaro, G. Tailored WBGT as a Heat Stress Index to Assess the Direct Solar Radiation Effect on Indoor Thermal Comfort. Energy Build. 2021, 242, 110974. [Google Scholar] [CrossRef]

- Kim, J.; Schiavon, S.; Brager, G. Personal Comfort Models—A New Paradigm in Thermal Comfort for Occupant-Centric Environmental Control. Build. Environ. 2018, 132, 114–124. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, R.; Toftum, J.; Essah, E.; Li, B. Machine Learning-Based Approach to Predict Thermal Comfort in Mixed-Mode Buildings: Incorporating Adaptive Behaviors. J. Build. Eng. 2024, 87, 108877. [Google Scholar] [CrossRef]

- Kocaman, E.; Kuru Erdem, M.; Calis, G. Machine Learning Thermal Comfort Prediction Models Based on Occupant Demographic Characteristics. J. Therm. Biol. 2024, 123, 103884. [Google Scholar] [CrossRef] [PubMed]

- Morresi, N.; Casaccia, S.; Sorcinelli, M.; Arnesano, M.; Uriarte, A.; Torrens-Galdiz, J.I.; Revel, G.M. Sensing Physiological and Environmental Quantities to Measure Human Thermal Comfort through Machine Learning Techniques. IEEE Sens. J. 2021, 21, 12322–12337. [Google Scholar] [CrossRef]

- Cipollone, V.; Morresi, N.; Casaccia, S.; Revel, G.M. Robot-Based Measurement of Comfort through Thermal Infrared Imaging and Wearable Sensors. In Proceedings of the 2023 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Kuala Lumpur, Malaysia, 22–25 May 2023. [Google Scholar]

- Zhang, H.; Lee, S.; Tzempelikos, A. Bayesian Meta-Learning for Personalized Thermal Comfort Modeling. Build. Environ. 2024, 249, 111129. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, X.; Tu, R.; Huang, J.; Li, Y. Thermal Comfort Modeling of Office Buildings Based on Improved Random Forest Algorithm. In Proceedings of the 2022 IEEE 11th Data Driven Control and Learning Systems Conference (DDCLS), Chengdu, China, 3–5 August 2022. [Google Scholar]

- Chai, Q.; Wang, H.; Zhai, Y.; Yang, L. Using Machine Learning Algorithms to Predict Occupants’ Thermal Comfort in Naturally Ventilated Residential Buildings. Energy Build. 2020, 217, 109937. [Google Scholar] [CrossRef]

- Qavidel Fard, Z.; Zomorodian, Z.S.; Korsavi, S.S. Application of Machine Learning in Thermal Comfort Studies: A Review of Methods, Performance and Challenges. Energy Build. 2022, 256, 111771. [Google Scholar] [CrossRef]

- Fathi, S.; Srinivasan, R.; Fenner, A.; Fathi, S. Machine Learning Applications in Urban Building Energy Performance Forecasting: A Systematic Review. Renew. Sustain. Energy Rev. 2020, 133, 110287. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Rajasekar, E.; Natarajan, S.; McCullen, N. A Comparative Assessment of SARIMA, LSTM RNN and Fb Prophet Models to Forecast Total and Peak Monthly Energy Demand for India. Energy Policy 2022, 168, 113097. [Google Scholar] [CrossRef]

- Shohan, M.J.A.; Faruque, M.O.; Foo, S.Y. Forecasting of Electric Load Using a Hybrid LSTM-Neural Prophet Model. Energies 2022, 15, 2158. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital Twin Application in the Construction Industry: A Literature Review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Zhan, H.; Hwang, B.G.; Zhu, H.; Ang, S.H.P. Towards a Sustainable Built Environment Industry in Singapore: Drivers, Barriers, and Strategies in the Adoption of Smart Facilities Management. J. Clean. Prod. 2023, 425, 138726. [Google Scholar] [CrossRef]

- Hosamo, H.; Hosamo, M.H.; Nielsen, H.K.; Svennevig, P.R.; Svidt, K. Digital Twin of HVAC System (HVACDT) for Multiobjective Optimization of Energy Consumption and Thermal Comfort Based on BIM Framework with ANN-MOGA. Adv. Build. Energy Res. 2023, 17, 125–171. [Google Scholar] [CrossRef]

- Lydon, G.P.; Caranovic, S.; Hischier, I.; Schlueter, A. Coupled Simulation of Thermally Active Building Systems to Support a Digital Twin. Energy Build. 2019, 202, 109298. [Google Scholar] [CrossRef]

- ElArwady, Z.; Kandil, A.; Afiffy, M.; Marzouk, M. Modeling Indoor Thermal Comfort in Buildings Using Digital Twin and Machine Learning. Dev. Built Environ. 2024, 19, 100480. [Google Scholar] [CrossRef]

- Shahinmoghadam, M.; Natephra, W.; Motamedi, A. BIM- and IoT-Based Virtual Reality Tool for Real-Time Thermal Comfort Assessment in Building Enclosures. Build. Environ. 2021, 199, 107905. [Google Scholar] [CrossRef]

- Sonta, A.; Dougherty, T.R.; Jain, R.K. Data-Driven Optimization of Building Layouts for Energy Efficiency. Energy Build. 2021, 238, 110815. [Google Scholar] [CrossRef]

- Shah, K.; Prabhakar, T.V.; Sarweshkumar, C.R.; Abhishek, S.V.; Vasanth Kumar, T. Construction of a Digital Twin Framework Using Free and Open-Source Software Programs. IEEE Internet Comput. 2022, 26, 50–59. [Google Scholar] [CrossRef]

- Parracho, D.F.R.; Poças Martins, J.; Barreira, E. A Workflow for Photogrammetric and Thermographic Surveys of Buildings with Drones. In New Advances in Building Information Modeling and Engineering Management; Digital Innovations in Architecture, Engineering and Construction; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Arowoiya, V.A.; Moehler, R.C.; Fang, Y. Digital Twin Technology for Thermal Comfort and Energy Efficiency in Buildings: A State-of-the-Art and Future Directions. Energy Built Environ. 2024, 5, 641–656. [Google Scholar] [CrossRef]

- Maxwell, E. Open Standards, Open Source, and Open Innovation: Harnessing the Benefits of Openness. Innov. Technol. Gov. Glob. 2006, 1, 119–176. [Google Scholar] [CrossRef]

- AlBalkhy, W.; Karmaoui, D.; Ducoulombier, L.; Lafhaj, Z.; Linner, T. Digital Twins in the Built Environment: Definition, Applications, and Challenges. Autom Constr 2024, 162, 105368. [Google Scholar] [CrossRef]

- Maier, A.; Sharp, A.; Vagapov, Y. Comparative Analysis and Practical Implementation of the ESP32 Microcontroller Module for the Internet of Things. In Proceedings of the 2017 Internet Technologies and Applications (ITA), Wrexham, UK, 12–15 September 2017. [Google Scholar]

- Zhong, C.L.; Zhu, Z.; Huang, R.G. Study on the IOT Architecture and Gateway Technology. In Proceedings of the 2015 14th International Symposium on Distributed Computing and Applications for Business Engineering and Science (DCABES), Guiyang, China, 18–24 August 2015. [Google Scholar]

- Bello, O.; Zeadally, S. Toward Efficient Smartification of the Internet of Things (IoT) Services. Future Gener. Comput. Syst. 2019, 92, 663–673. [Google Scholar] [CrossRef]

- Wang, T.; Gan, V.J.L.; Hu, D.; Liu, H. Digital Twin-Enabled Built Environment Sensing and Monitoring through Semantic Enrichment of BIM with SensorML. Autom. Constr. 2022, 144, 104625. [Google Scholar] [CrossRef]

- Ohyver, M.; Moniaga, J.V.; Sungkawa, I.; Subagyo, B.E.; Chandra, I.A. The Comparison Firebase Realtime Database and MySQL Database Performance Using Wilcoxon Signed-Rank Test. Procedia Comput. Sci. 2019, 157, 396–405. [Google Scholar] [CrossRef]

- Deng, H.; Liu, Y.; Liu, Y.; Xu, L.; Wang, C. Web-Based Approach for Systematic Analysis and Interactive Visualization of the Industry Foundation Classes Data: A Case Study in Duct Design. J. Asian Archit. Build. Eng. 2023, 22, 1361–1372. [Google Scholar] [CrossRef]

- Cipollone, V.; Morresi, N.; Serroni, S.; Casaccia, S.; Giovanardi, M.; Pracucci, A.; Arnone, D.; Revel, G.M. AI-Based Methodology for Thermal Comfort Measurement: Application of a Simplified Comfort Model on a Real-Life Case Study. In Proceedings of the 2024 IEEE International Workshop on Metrology for Living Environment (MetroLivEnv), Chania, Greece, 12–14 June 2024; pp. 286–291. [Google Scholar]

- Rohles, F.H. Thermal Sensations of Sedentary Man in Moderate Temperatures. Hum. Factors J. Hum. Factors Ergon. Soc. 1971, 13, 553–560. [Google Scholar] [CrossRef]

- Taylor, S.J.; Letham, B. Forecasting at Scale. Am. Stat. 2018, 72, 37–45. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Williams, R.; Kilaru, V.J.; Snyder, E.G.; Kaufman, A.; Dye, T.; Rutter, A.; Russell, A.; Hafner, H. Air Sensor Guidebook; US Environmental Protection Agency: Washington, DC, USA, 2014.

- ANSI ANSI A117.1-2017; Accessible and Usable Buildings. American National Standards Institute: Washington, DC, USA, 2017.

- Andivi Mounting Guidelines for Sensors & General Sensor Installation Recommendations. Available online: https://www.andivi.com/mounting-guidelines-for-sensors-recommendations-sensor-installation (accessed on 19 February 2025).

- Khan, A.N.; Rizwan, A.; Ahmad, R.; Kim, D.H. An OCF-IoTivity Enabled Smart-Home Optimal Indoor Environment Control System for Energy and Comfort Optimization. Internet Things 2023, 22, 100712. [Google Scholar] [CrossRef]

- Rahmani Asl, M.; Zarrinmehr, S.; Bergin, M.; Yan, W. BPOpt: A Framework for BIM-Based Performance Optimization. Energy Build. 2015, 108, 401–412. [Google Scholar] [CrossRef]

- Natephra, W.; Motamedi, A. BIM-Based Live Sensor Data Visualization Using Virtual Reality for Monitoring Indoor Conditions. In Proceedings of the 24th International Conference on Computer-Aided Architectural Design Research in Asia (CAADRIA), Wellington, New Zealand, 15–18 April 2019; Volume 2. [Google Scholar]

- Yeom, S.; Kim, J.; Kang, H.; Jung, S.; Hong, T. Digital Twin (DT) and Extended Reality (XR) for Building Energy Management. Energy Build. 2024, 323, 114746. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Främling, K. A Framework for Integrating BIM and IoT through Open Standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

| Component | Supply Voltage | Current | Memory/Measuring Range |

|---|---|---|---|

| ESP32 Wroom | 2.2 V~3.6 V | 80 mA | Flash Memory: 4 MB |

| KY005 | 5 V | 30~60 mA | - |

| DHT22 | 3.5 V~5.5 V | 0.3 mA | Humidity: 0~100 ± 1%; temperature: −40~80 °C ± 0.5 |

| Statistic | Indoor Humidity % | Indoor Temperature °C | Outdoor Humidity % | Outdoor Temperature °C |

|---|---|---|---|---|

| Count | 1645 | 1645 | 1645 | 1645 |

| Mean | 51.37 | 32.91 | 50.36 | 33.76 |

| Std | 6.69 | 0.50 | 7.80 | 1.64 |

| Min | 32.10 | 31.06 | 23.10 | 31.8 |

| 25% | 46.98 | 32.56 | 46.00 | 33.27 |

| 50% | 51.00 | 32.80 | 50.50 | 33.3 |

| 75% | 54.00 | 33.29 | 53.80 | 33.8 |

| Max | 71.00 | 34.69 | 71.00 | 45.25 |

| Statistic | Indoor Humidity % | Indoor Temperature °C | Outdoor Humidity % | Outdoor Temperature °C |

|---|---|---|---|---|

| Count | 8440 | 8440 | 8440 | 8440 |

| Mean | 52.14 | 29.06 | 57.11 | 34.35 |

| Std | 8.62 | 3.65 | 10.66 | 3.34 |

| Min | 33.90 | 20.65 | 15 | 26.81 |

| 25% | 45.10 | 25.80 | 50.8 | 32.21 |

| 50% | 50.90 | 29.61 | 59.1 | 33.8 |

| 75% | 59.10 | 32.07 | 65.9 | 35.6 |

| Max | 76.90 | 36.91 | 75 | 51.3 |

| Model | Parameter | Current Value |

|---|---|---|

| FB Prophet | Seasonality (weekly) | Period = 7; Fourier Order = 14 |

| Regressors | Outdoor Temperature and Humidity | |

| Prediction Frequency | 1D | |

| LSTM | Look-back Window | 48 h (24 steps at 5 min intervals) |

| LSTM Layers and Neurons | 3 layers, 64 neurons each | |

| Batch Size | 16 | |

| Epochs | 50 | |

| Optimizer | Adam | |

| Loss Function | MSE |

| MAE | RMSE | MAPE | R2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Train | Test | Train | Test | Train | Test | Train | Test | ||

| Temperature | Prophet | 0.7429 °C | 0.788 °C | 0.97 °C | 0.9986 °C | 2.68 | 3.65 | 0.9225 | 0.891 |

| Hybrid | 0.29 °C | 0.29 °C | 0.41 °C | 0.49 °C | 1.03 | 1.12 | 0.97 | 0.96 | |

| Humidity | Prophet | 2.4557% | 2.4593 | 3.3718% | 3.1411% | 4.66 | 4.99 | 0.8382 | 0.7518 |

| Hybrid | 0.78% | 1.27% | 1.35% | 1.98% | 1.58 | 2.49 | 0.93 | 0.91 | |

| sPMV | Prophet | 0.1107 | 0.1215 | 0.1466 | 0.1542 | 24.27 | 26.87 | 0.914 | 0.8732 |

| Hybrid | 0.05 | 0.06 | 0.07 | 0.09 | 6.83 | 13.73 | 0.96 | 0.94 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, F.; Mirzabeigi, S. Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning. Buildings 2025, 15, 1584. https://doi.org/10.3390/buildings15101584

Iqbal F, Mirzabeigi S. Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning. Buildings. 2025; 15(10):1584. https://doi.org/10.3390/buildings15101584

Chicago/Turabian StyleIqbal, Fahad, and Shayan Mirzabeigi. 2025. "Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning" Buildings 15, no. 10: 1584. https://doi.org/10.3390/buildings15101584

APA StyleIqbal, F., & Mirzabeigi, S. (2025). Digital Twin-Enabled Building Information Modeling–Internet of Things (BIM-IoT) Framework for Optimizing Indoor Thermal Comfort Using Machine Learning. Buildings, 15(10), 1584. https://doi.org/10.3390/buildings15101584