Research on Mechanical Properties of Cement Emulsified Asphalt Mortar Under the Influence of Water-to-Cement Ratios and Water-Reducing Agent

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Raw Materials

2.2. Experimental Methods

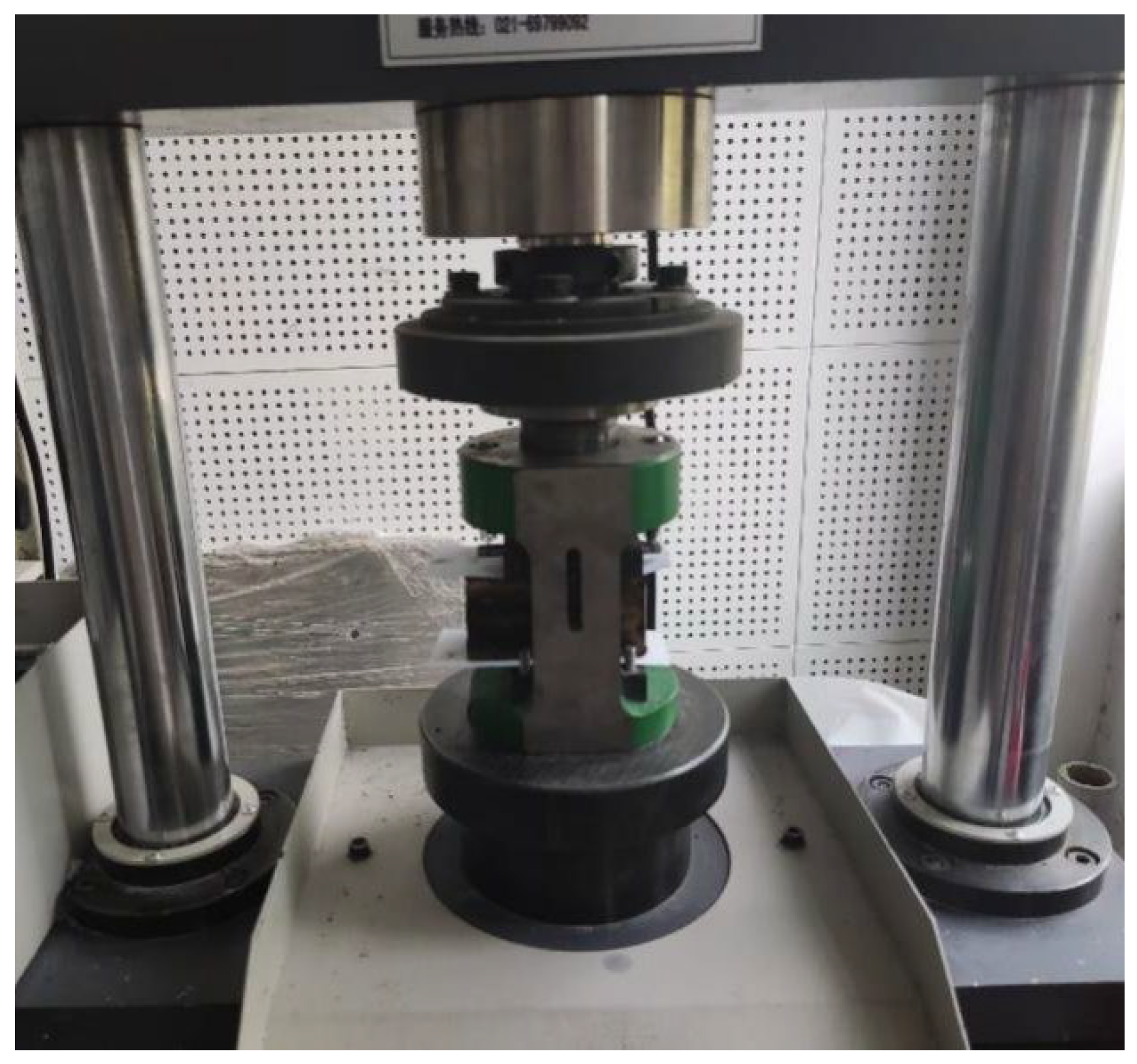

2.2.1. Compressive Strength Test Method

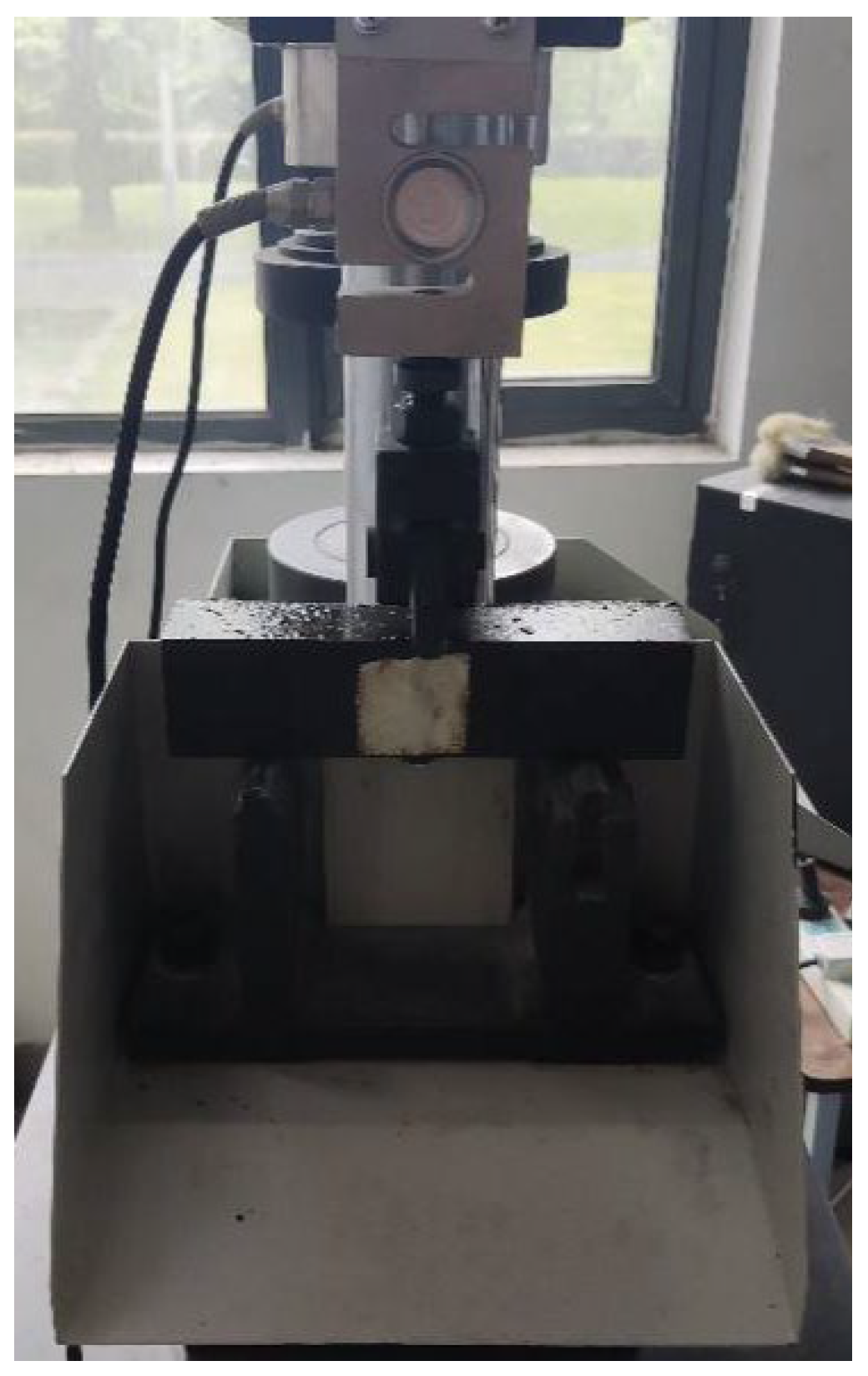

2.2.2. Flexural Strength Test Method

2.2.3. Microscopic Test

3. Experimental Results and Analysis

3.1. Strength Trends of CA Mortar

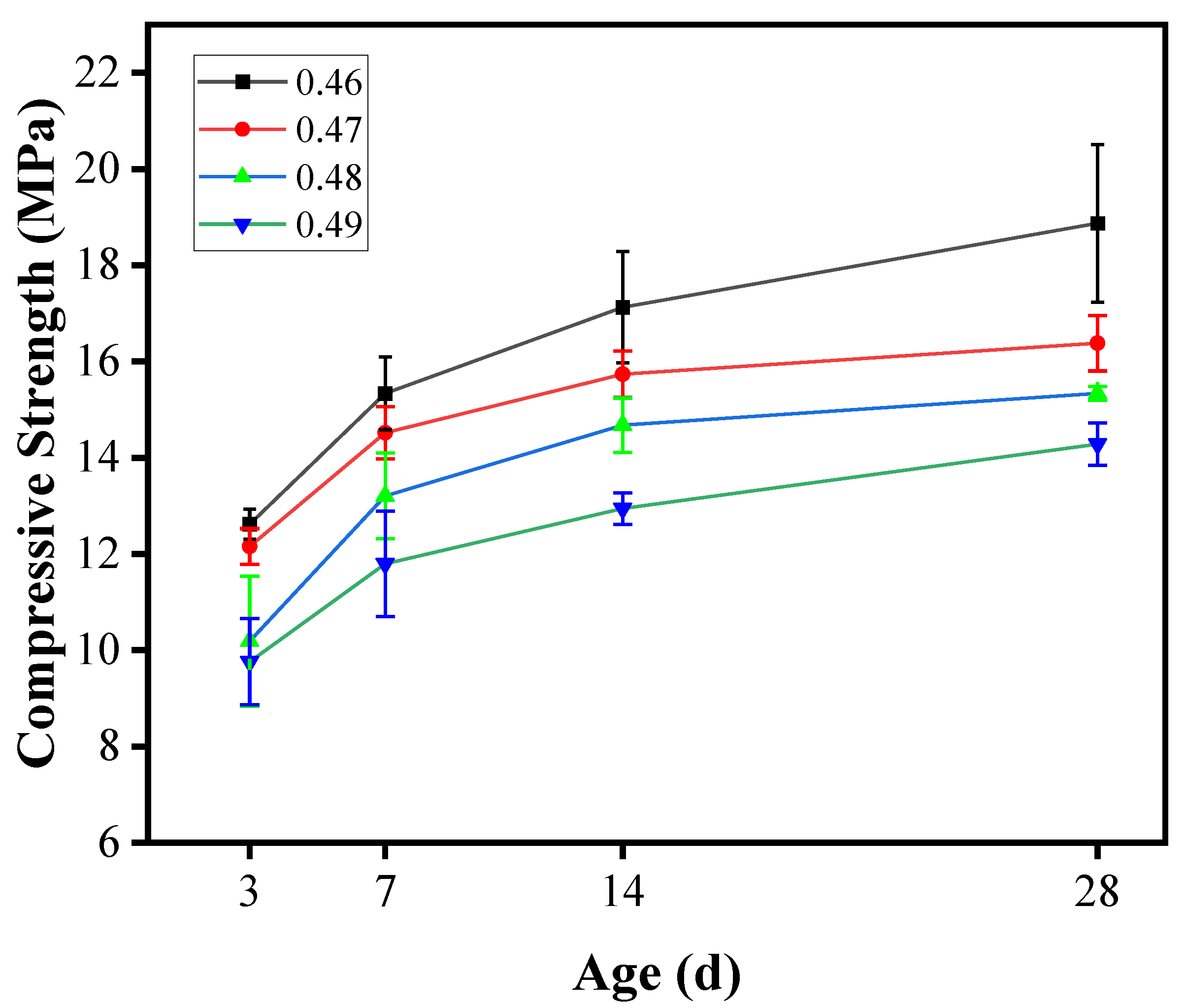

3.1.1. Effect of Water-to-Cement Ratio on the Compressive Strength of CA Mortar

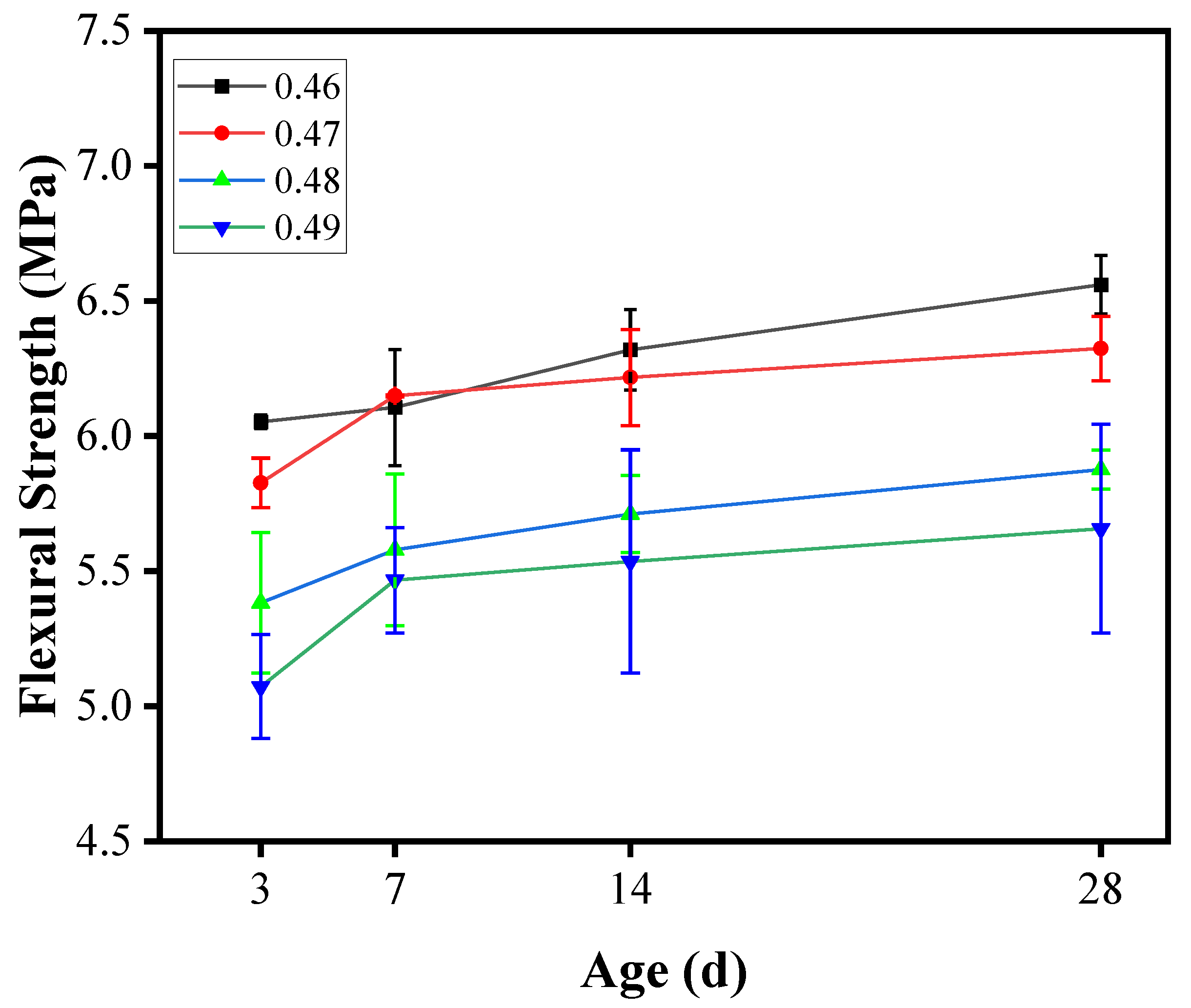

3.1.2. Effect of Water-to-Cement Ratio on the Flexural Strength of CA Mortar

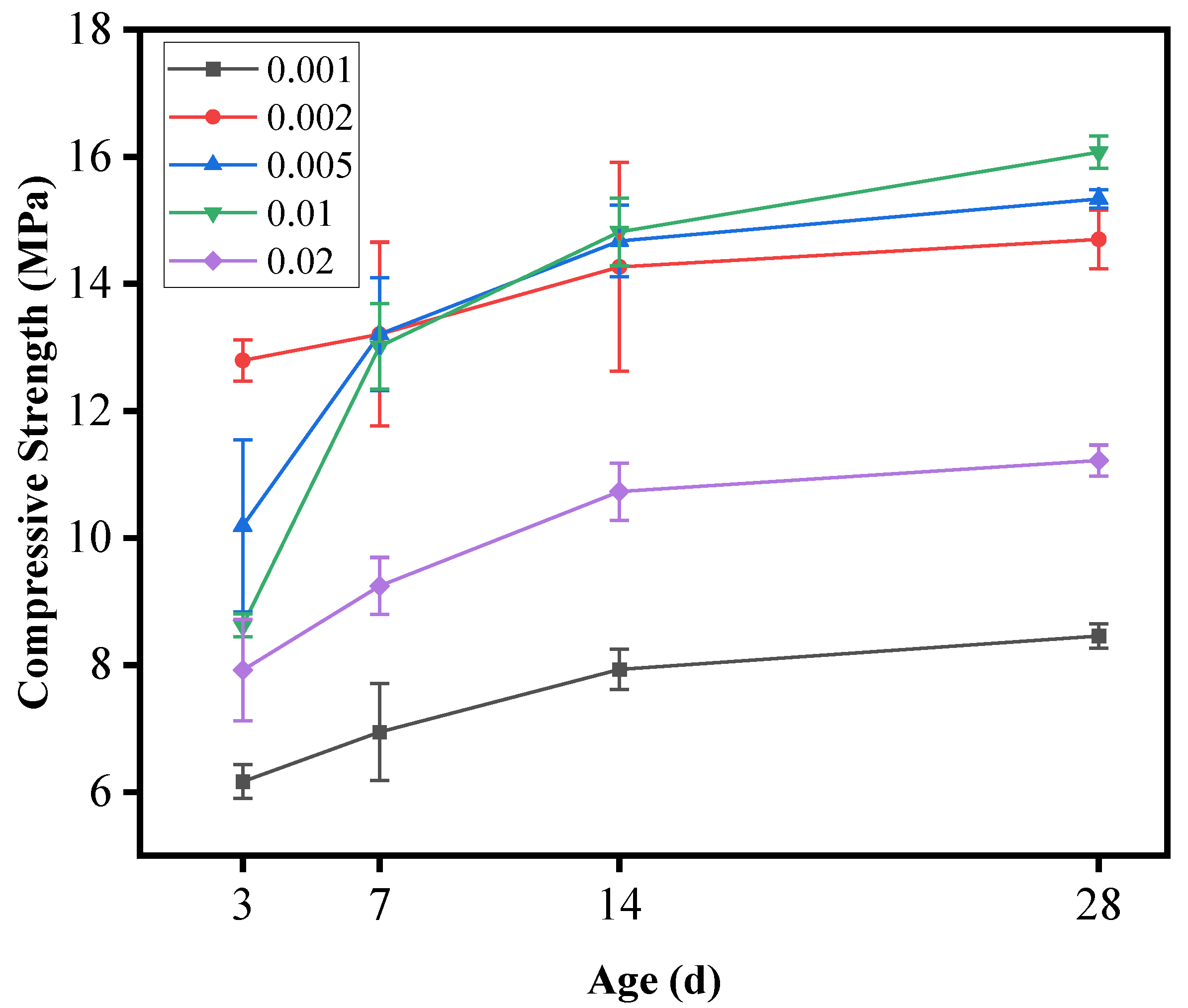

3.1.3. Effect of Water-Reducing Agent on the Compressive Strength of CA Mortar

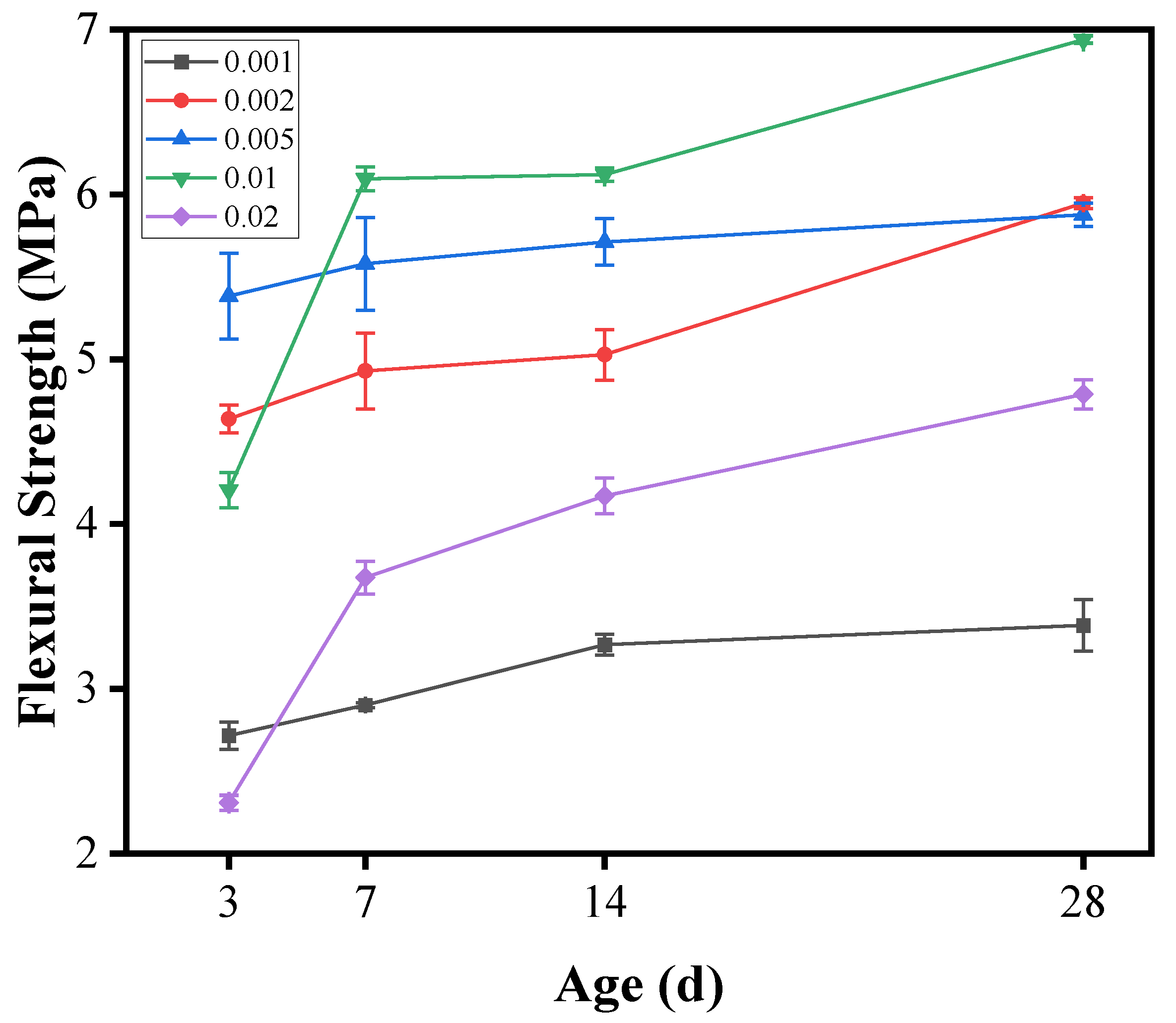

3.1.4. Effect of Water-Reducing Agent on the Flexural Strength of CA Mortar

3.2. Strength Mechanism of CA Mortar

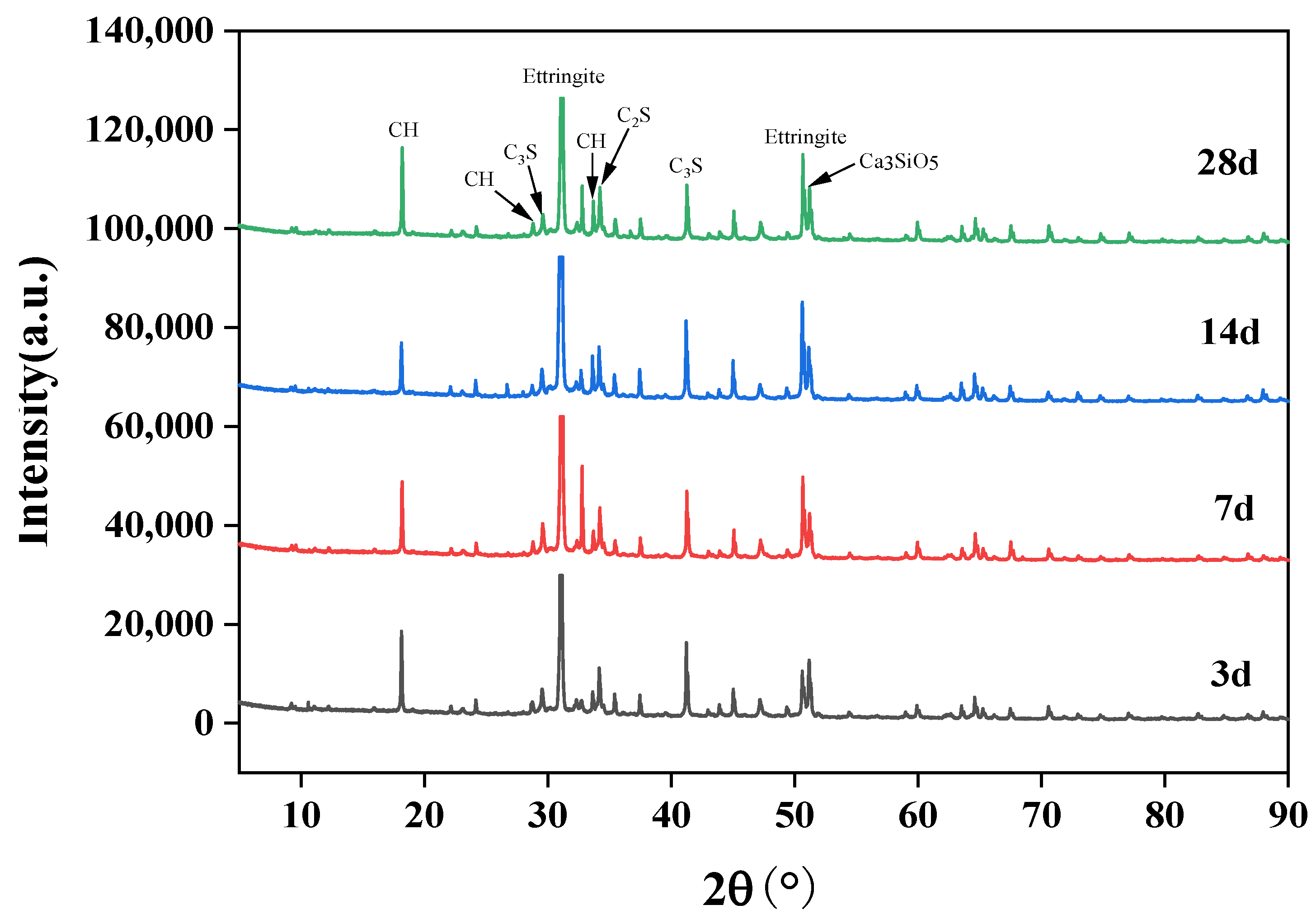

3.2.1. Hydration Products Analysis

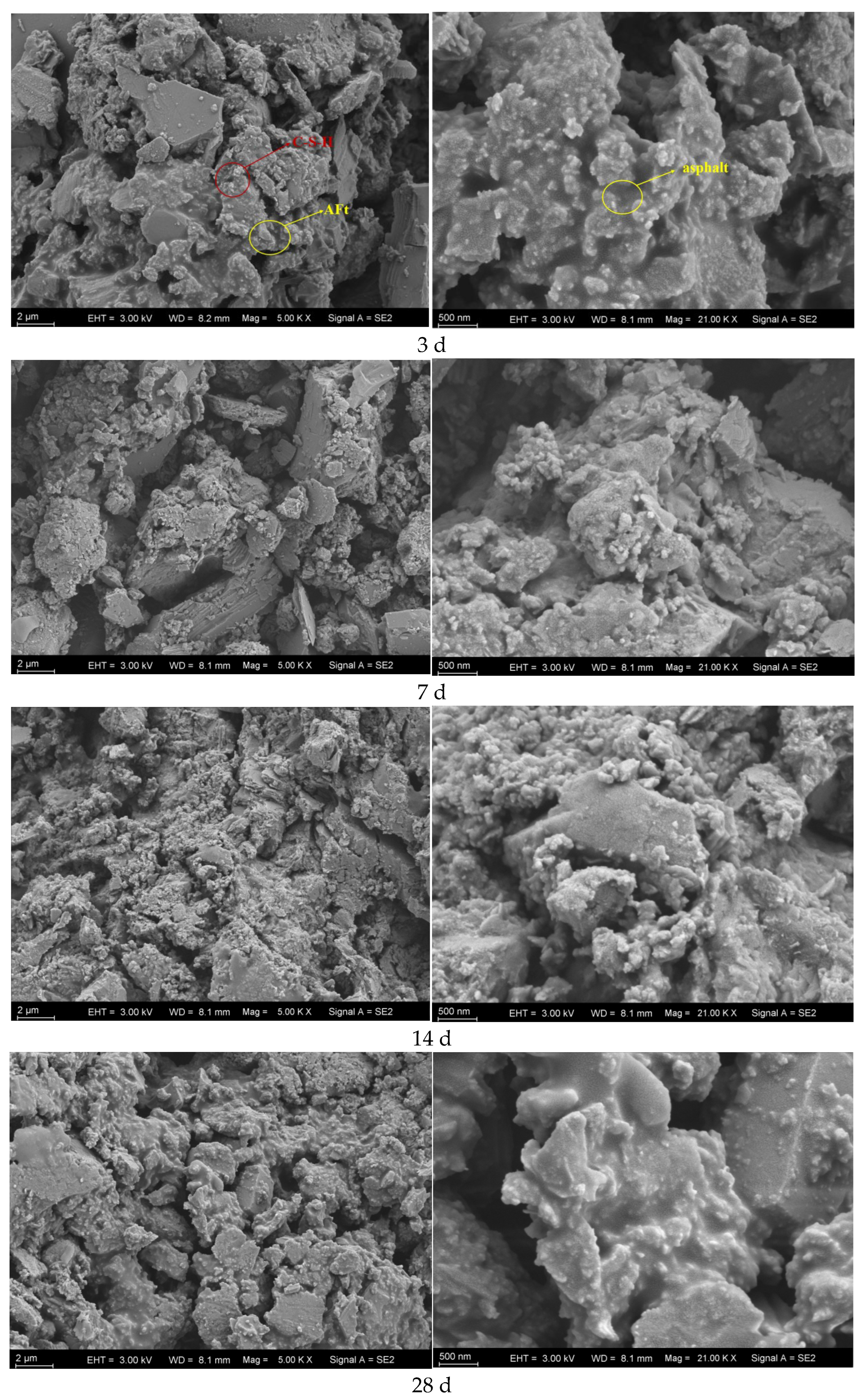

3.2.2. Temporal Variation in Microstructure in CA Mortar

4. Conclusions

- (1)

- Compressive strength and flexural strength of CA mortar shows a decreasing trend as water-to-cement ratio increases. The compressive strength and flexural strength of CA mortar increases rapidly in the early stage, with the 3-day compressive strength reaching more than 65% of the 28-day compressive strength, and the 7-day compressive strength reaching more than 80% of the 28-day compressive strength, with the 3-day flexural strength reaching about 90% of the 28-day flexural strength, and the 7-day flexural strength reaching more than 93% of the 28-day flexural strength. The formation of flexural strength is basically completed within the first 7 days.

- (2)

- Both the compressive strength and flexural strength of CA mortar show a pattern of first increasing and then decreasing as the water-reducing agent dosage increases. The water-reducing agent dosage range of 0.2% to 1.0% is a more reasonable range.

- (3)

- The hydration reaction of CA mortar is nearly completed at 3 days. As the age increases, the encapsulating effect of asphalt slows down the cement hydration, resulting in a lower rate of hydration product formation and limited strength improvement. The main hydration product is Ettringite, which is the primary source of strength in CA mortar. In addition, at 28 days, there are still significant amounts of unhydrated C3S and C2S inside the material, indicating that the presence of asphalt has a certain inhibitory effect on the hydration reaction of cement, and the material still has potential for further hydration.

5. Future Work

- (1)

- The influence of other factors on the mechanical properties of CA mortar requires further study.

- (2)

- The coupled effect of cement hydration and the demulsification of emulsified asphalt on the mechanical properties of CA mortar should be further refined.

- (3)

- The influence of different curing conditions on the mechanical properties of cement emulsified asphalt mortar.

- (4)

- Establishment and optimization of stress–strain constitutive model of cement emulsified asphalt mortar.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, S.; Li, J.; Zhang, Z.; Wu, H.; Liu, G. Factors influencing the performance of cement emulsified asphalt mortar–A review. Constr. Build. Mater. 2021, 279, 122479. [Google Scholar] [CrossRef]

- Wang, Z.; Shu, X.; Rutherford, T.; Huang, B.; Clarke, D. Effects of asphalt emulsion on properties of fresh cement emulsified asphalt mortar. Constr. Build. Mater. 2015, 75, 25–30. [Google Scholar] [CrossRef]

- Al-Raqeb, H.; Ghaffar, S.H.; Al-Kheetan, M.J.; Chougan, M. Understanding the challenges of construction demolition waste management towards circular construction: Kuwait Stakeholder’s perspective. Clean. Waste Syst. 2023, 4, 100075. [Google Scholar] [CrossRef]

- Jin, S.; Zhao, Y.; Zhang, Y.; Xu, Z. Effects of curing conditions on the microstructure and strength of CA mortar. Concrete 2024, 9, 157–162. [Google Scholar]

- Zhao, L.; He, H.; Hu, A. Study on the temperature characteristics of CRTS I-type slab ballastless track on bridges. Railw. Stand. Des. 2024, 1–9. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, S.; Zhang, H.; Zeng, X.H. Research progress on the viscoelastic properties of cement emulsified asphalt mortar for high-speed railway slab ballastless track. Mater. Rev. 2024, 38, 23060058-10. Available online: http://kns.cnki.net/kcms/detail/50.1078.TB.20231110.0936.002.html (accessed on 1 December 2024).

- Yuan, Q.; Xiang, G.; Zheng, X.; Zhang, X.; Wang, Y. Analysis of the service status of CRTS II type slab track mortar filling layer. J. Railw. Sci. Eng. 2024, 1–9. Available online: http://kns.cnki.net/kcms/detail/11.2104.U.20230829.1536.002.html (accessed on 1 December 2024).

- Yang, R.; Wang, J.; Jiang, H.; Chen, S.; Du, J. Effects of post-pouring belt void of base slab on track structure and train operation of CRTSII slab track. J. Transp. Eng. 2019, 19, 71–78. [Google Scholar]

- Duan, F.; Wang, T. Study on the effect of mixing process on the performance of CRTSII-type slab cement emulsified asphalt mortar. Railw. Constr. 2013, 7, 103–105. [Google Scholar]

- Xiong, W. Mechanism and Control Technology of Bubble Generation in the Pouring Process of CRTS-II-Type Cement Emulsified Asphalt Mortar. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2012. [Google Scholar]

- Wang, Q.; Yan, P.; A Ru, H. Analysis of factors affecting the compressive strength of high-strength cement asphalt mortar. J. Build. Mater. 2009, 12, 519–522+527. [Google Scholar]

- Tian, Q.; Zhang, M.; Cai, J.; Yuan, Y.; Deng, D. Calculation formula for compressive strength of high-strength cement emulsified asphalt mortar. Bull. Chin. Ceram. Soc. 2020, 39, 1722–1727. [Google Scholar] [CrossRef]

- Tan, Y.; Ouyang, J.; Wang, J.; Lim, Y.; Chen, Y. Study on the strength influencing factors and strength mechanism of CA mortar. J. Harbin Inst. Technol. 2011, 43, 80–83. [Google Scholar]

- Hu, S.; Li, Y.; Xie, B.; Wang, F. Study on the effect of water-reducing agent on the strength of CRTSII-type CA mortar. J. Beijing Univ. Technol. 2010, 36, 1482–1487. [Google Scholar]

- Fu, Q.; Xie, Y.; Zheng, K.; Cai, F.; Zhou, X. Ageing effects on the mechanical properties of cement-emulsified asphalt mortar. J. Beijing Univ. Technol. 2013, 39, 1607–1612. [Google Scholar]

- Wang, Q.; Yan, P.; A Ru, H.; Yang, J.; Kong, X. Strength mechanism of cement-asphalt mortar. J. Mater. Civ. Eng. 2011, 23, 1353–1359. [Google Scholar]

- JTG E30-2005; Technical Regulations for Cement and Cement Concrete Testing in Highway Engineering. Ministry of Communications: Delhi, India, 2005.

- Shi, J.; Liu, B.; Tan, J.; Dai, J.; Chen, J.; Ji, R. Experimental studies and microstructure analysis for rapid-hardening cement emulsified asphalt mortar. J. Constr. Eng. Manag. 2020, 146, 04020130. [Google Scholar] [CrossRef]

- Umar, H.A.; Zeng, X.; Lan, X.; Zhu, H.; Li, Y.; Zhao, H.; Liu, H. A review on cement asphalt emulsion mortar composites, structural development, and performance. Materials 2021, 14, 3422. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Ouyang, J.; Lv, J.; Li, Y. Effect of emulsifier on cement hydration in cement asphalt mortar. Constr. Build. Mater. 2013, 47, 159–164. [Google Scholar] [CrossRef]

- Liu, B.; Liang, D. Effect of mass ratio of asphalt to cement on the properties of cement modified asphalt emulsion mortar. Constr. Build. Mater. 2017, 134, 39–43. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, H.; Li, G.; Ma, Y.; Li, Q. Effects of styrene-butadiene rubber on viscosity and mechanical properties of cement emulsified asphalt paste. J. Highw. Transp. Technol. 2023, 40, 29–36. [Google Scholar]

- Zhu, X.; Hong, J.; Li, W. Competitive adsorption behavior of water-reducing agent and emulsified asphalt in cement asphalt paste. J. Harbin Inst. Technol. 2018, 50, 55–60. [Google Scholar]

- Hao, X. Optimization Design and Performance Study of High Early-Strength Cement-Emulsified Asphalt Grouting Materials. Master’s Thesis, Chang’an University, Xi’an, China, 2023. [Google Scholar]

| Material Type | Cement | Emulsified Asphalt | Manufactured Sand | Water | Water-Reducing Agent |

|---|---|---|---|---|---|

| Parameters | P.I 42.5 | Cationic 60% solid content | 40–80 mesh | potable water meeting testing standards | Polycarboxylate superplasticizer |

| Material | Cement | Emulsified Asphalt | Manufactured Sand | Water (Total) | Water-Reducing Agent |

|---|---|---|---|---|---|

| Mass Ratio | 1 | 0.5 | 1.2 | 0.46~0.49 | 0.0001~0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Jiao, H.; Zhou, B.; Liu, F.; Zhang, F.; Luo, Y.; Yuan, J. Research on Mechanical Properties of Cement Emulsified Asphalt Mortar Under the Influence of Water-to-Cement Ratios and Water-Reducing Agent. Buildings 2025, 15, 22. https://doi.org/10.3390/buildings15010022

Zhao C, Jiao H, Zhou B, Liu F, Zhang F, Luo Y, Yuan J. Research on Mechanical Properties of Cement Emulsified Asphalt Mortar Under the Influence of Water-to-Cement Ratios and Water-Reducing Agent. Buildings. 2025; 15(1):22. https://doi.org/10.3390/buildings15010022

Chicago/Turabian StyleZhao, Ce, Huacheng Jiao, Bing Zhou, Fei Liu, Feilin Zhang, Yong Luo, and Jie Yuan. 2025. "Research on Mechanical Properties of Cement Emulsified Asphalt Mortar Under the Influence of Water-to-Cement Ratios and Water-Reducing Agent" Buildings 15, no. 1: 22. https://doi.org/10.3390/buildings15010022

APA StyleZhao, C., Jiao, H., Zhou, B., Liu, F., Zhang, F., Luo, Y., & Yuan, J. (2025). Research on Mechanical Properties of Cement Emulsified Asphalt Mortar Under the Influence of Water-to-Cement Ratios and Water-Reducing Agent. Buildings, 15(1), 22. https://doi.org/10.3390/buildings15010022