Eco-Efficient Mortars for Sustainable Construction: A Comprehensive Approach

Abstract

1. Introduction

- Producing blends by using a significant amount of FA. Thus, large volumes of the traditional binder were substituted by this industrial by-product, which otherwise would have to be stored in landfills and may also be a source of pollution;

- Concrete compactness and durability are enhanced by these FA contributions, although eventually, the effect will only be felt in the long term due to the slow pozzolanic reaction. The workability of these additions is also enhanced;

- Producing concrete with a very low W/C ratio, with workability controlled by the use of superplasticizers. This can lead to even more compact, stronger, and durable concrete;

- Introducing MTK to ensure the initial strengths necessary to make this concrete competitive in current construction. In addition, using MTK can contribute to an increase in the strength and durability of concrete due to its high reactivity and fineness.

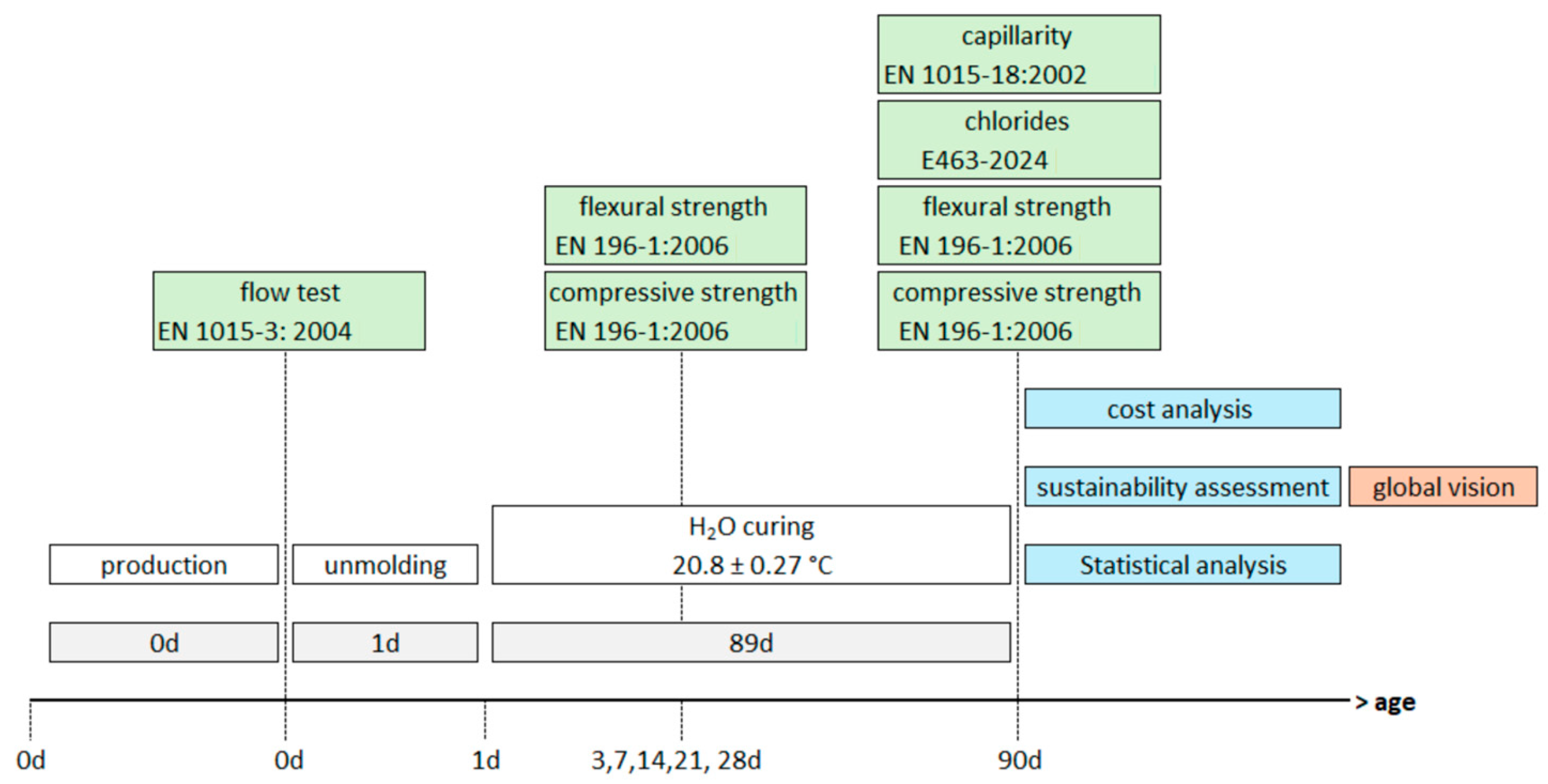

2. Materials and Methods

2.1. Materials

2.1.1. Binders

2.1.2. Aggregates

2.1.3. Superplasticizer

2.2. Methods

3. Results

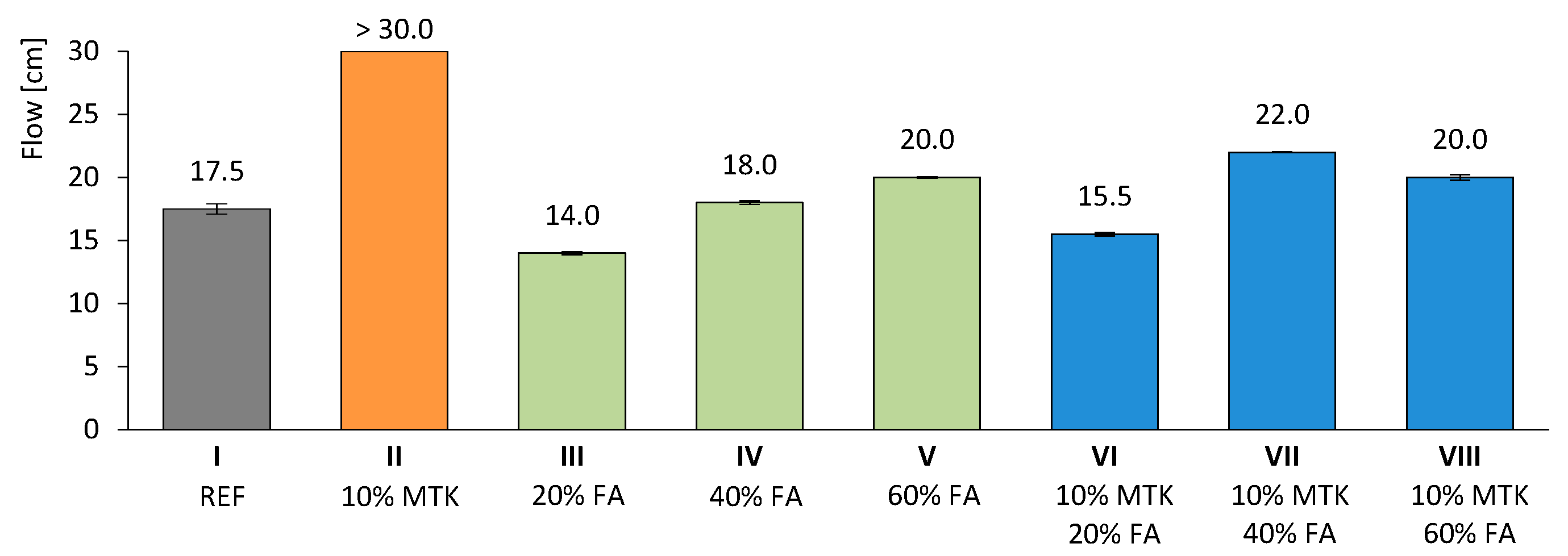

3.1. Workability

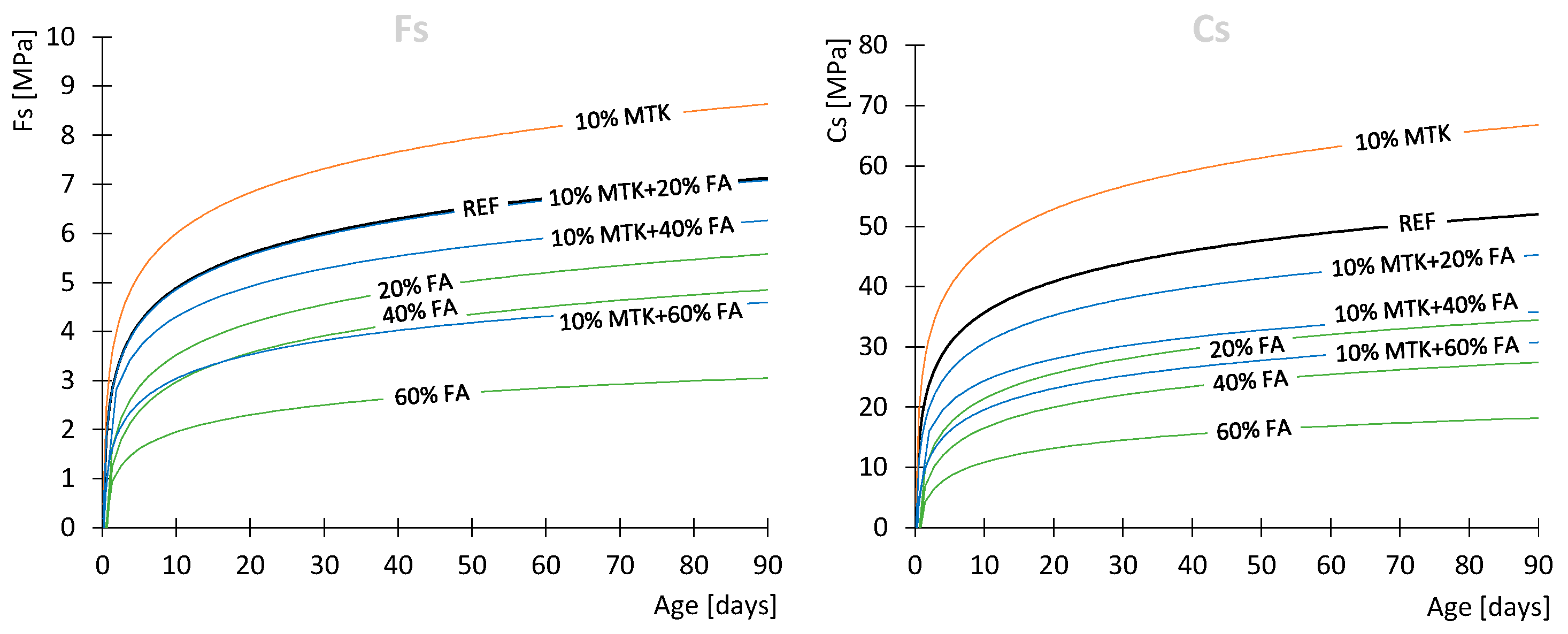

3.2. Mechanical Strength

3.3. Chlorides by Migration

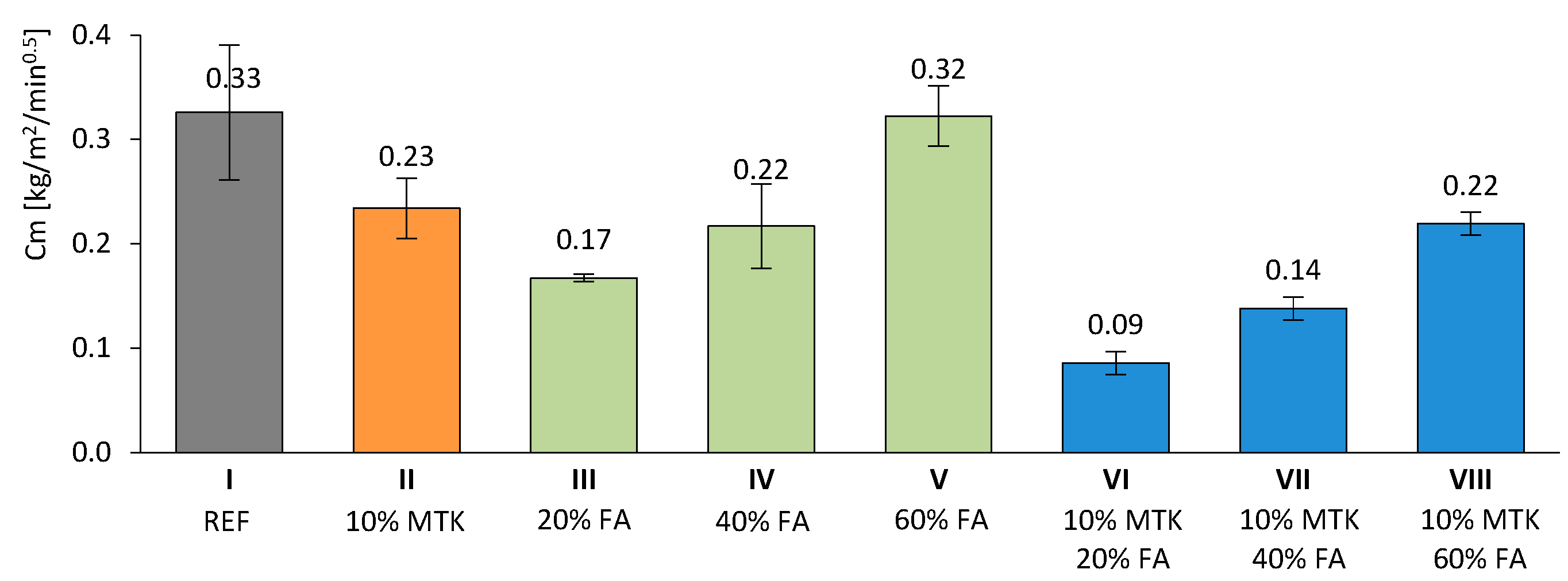

3.4. Water Absorption by Capillarity

3.5. Cost Analysis

3.6. Statistical Analysis

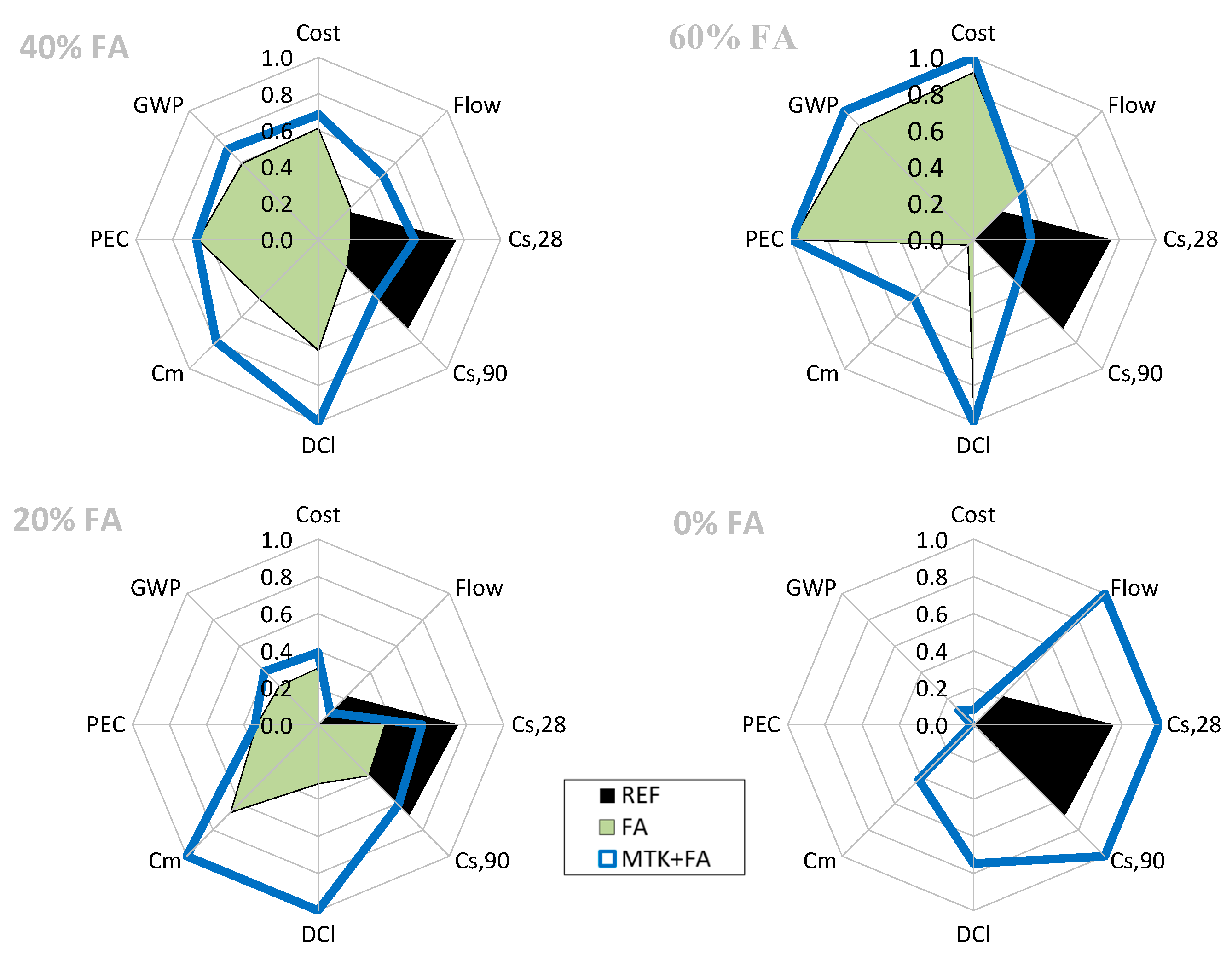

3.7. Sustainability Assessment and Global Vision

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- WMO. WMO Greenhouse Gas Bulletin: The State of Greenhouse Gases in the Atmosphere Based on Global Observations through 2019; WMO: Geneva, Switzerland, 2020. [Google Scholar]

- Al-Ameeri, A.S.; Rafiq, M.I.; Tsioulou, O.; Rybdylova, O. Impact of climate change on the carbonation in concrete due to carbon dioxide ingress: Experimental investigation and modelling. J. Build. Eng. 2021, 44, 102594. [Google Scholar] [CrossRef]

- Barnola, J.M.; Raynaud, D.; Lorius, C.; Barkov, N.I. Historical CO2 record from the Vostok ice core. In Trends: A Compendium of Data on Global Change; Zenodo: Oak Ridge, TN, USA, 2003. [Google Scholar]

- WMO. WMO Greenhouse Gas Bulletin: The State of Greenhouse Gases in the Atmosphere Based on Global Observations through 2015; WMO: Geneva, Switzerland, 2015. [Google Scholar]

- Yan, Y.; Bender, M.L.; Brook, E.J.; Clifford, H.M.; Kemeny, P.C.; Kurbatov, A.V.; Mackay, S.; Mayewski, P.A.; Ng, J.; Severinghaus, J.P.; et al. Two-million-year-old snapshots of atmospheric gases from Antarctic ice. Nature 2019, 574, 663–666. [Google Scholar] [CrossRef] [PubMed]

- Hache, E.; Simoën, M.; Seck, G.S.; Bonnet, C.; Jabberi, A.; Carcanague, S. The impact of future power generation on cement demand: An international and regional assessment based on climate scenarios. Int. Econ. 2020, 163, 114–133. [Google Scholar] [CrossRef]

- Krithika, J.; Ramesh Kumar, G.B. Influence of fly ash on concrete—A systematic review. Mater. Today Proc. 2020, 33, 906–911. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Izumi, Y.; Iizuka, A.; Ho, H.-J. Calculation of greenhouse gas emissions for a carbon recycling system using mineral carbon capture and utilization technology in the cement industry. J. Clean. Prod. 2021, 312, 127618. [Google Scholar] [CrossRef]

- UN. World Population Prospects 2019: Highlights; UN: New York, NY, USA, 2019. [Google Scholar]

- ERMCO. Ready-Mixed Concrete Industry Statistics-Year 2018; ERMCO: Brussels, Belgium, 2018. [Google Scholar]

- ASCE. American Society of Civil Engineering Infrastructure Report Card 2021; ASCE: Reston, VA, USA, 2021. [Google Scholar]

- NOAA. Global Greenhouse Gas Reference Network: Trends in Atmospheric Carbon Dioxide; NOAA: Mauna Loa, HI, USA, 2020. Available online: https://www.esrl.noaa.gov/gmd/ccgg/trends/global.html (accessed on 8 January 2021).

- Isaia, G.C.; Gastaldini, A.L.G. Concrete sustainability with very high amount of fly ash and slag. IBRACON Strutures Mater. J. 2009, 2, 244–253. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G. Environmental and economic perspectives of concrete with high levels of mineral additions: A case study. Ambiente Construído 2008, 4, 19–30. (In Portuguese) [Google Scholar]

- Dal Ri, M. Effects of the Addition of Hydrated Lime in Concrete with High Levels of Mineral Addition on the Penetration of Chlorides and in the Aqueous Solution of the Pores of the Concrete. Ph.D. Thesis, Federal University of Santa Maria, Santa Maria, Brazil, 2002. [Google Scholar]

- Younsi, A.; Turcry, P.; Rozière, E.; Aït-Mokhtar, A.; Loukili, A. Performance-based design and carbonation of concrete with high fly ash content. Cem. Concr. Compos. 2011, 33, 993–1000. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.D.A.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Saillio, M.; Baroghel-Bouny, V.; Pradelle, S.; Bertin, M.; Vincent, J.; d’Espinose de Lacaillerie, J.-B. Effect of supplementary cementitious materials on carbonation of cement pastes. Cem. Concr. Res. 2021, 142, 106358. [Google Scholar] [CrossRef]

- Dindi, A.; Quang, D.V.; Vega, L.F.; Nashef, E.; Abu-Zahra, M.R.M. Applications of fly ash for CO2 capture, utilization, and storage. J. CO2 Util. 2019, 29, 82–102. [Google Scholar] [CrossRef]

- Abdulkareem, M.O.; Abd Majid, M.Z.; Ayeronfe, O. Application of Automobile Used Engine Oils and Silica Fume to Improve Concrete Properties for Eco-Friendly Construction. Environ. Clim. Technol. 2020, 24, 123–142. [Google Scholar] [CrossRef]

- Cardinale, T.; D’Amato, M.; Sulla, R.; Cardinale, N. Mechanical and Physical Characterization of Papercrete as New Eco-Friendly Construction Material. Appl. Sci. 2021, 11, 1011. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Ochsendorf, J.; Norford, L.; Brown, D.; Durschlag, H.; Hsu, S.; Love, A.; Santero, N.; Swei, O.; Webb, A.; Wildnauer, M. Methods, Impacts, and Opportunities in the Concrete Building Life Cycle; Research Report R11-01; MIT (Massachusetts Institute of Technology): Cambridge, MA, USA, 2011. [Google Scholar]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Galina, N.R.; Arce, G.L.A.F.; Ávila, I. Evolution of carbon capture and storage by mineral carbonation: Data analysis and relevance of the theme. Miner. Eng. 2019, 142, 105879. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2021, 48, 741–746. [Google Scholar] [CrossRef]

- Lagerblad, B. Carbon Dioxide Uptake during Concrete Life Cycle—State of the Art; Swedish Cement and Concrete Research Institute: Stockholm, Switzerland, 2005. [Google Scholar]

- Wang, X.-Y. Simulation for optimal mixture design of low-CO2 high-volume fly ash concrete considering climate change and CO2 uptake. Cem. Concr. Compos. 2019, 104, 103408. [Google Scholar] [CrossRef]

- Seraj, S.; Cano, R.; Ferron, R.D.; Juenger, M.C.G. The role of particle size on the performance of pumice as a supplementary cementitious material. Cem. Concr. Compos. 2017, 80, 135–142. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Bumanis, G.; Vitola, L.; Stipniece, L.; Locs, J.; Korjakins, A.; Bajare, D. Evaluation of Industrial by-products as pozzolans: A road map for use in concrete production. Case Stud. Constr. Mater. 2020, 13, e00424. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Qiu, Q. A state-of-the-art review on the carbonation process in cementitious materials: Fundamentals and characterization techniques. Constr. Build. Mater. 2020, 247, 118503. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Volli, V.; Shu, C.-M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef]

- Marieta, C.; Guerrero, A.; Leon, I. Municipal solid waste incineration fly ash to produce eco-friendly binders for sustainable building construction. Waste Manag. 2021, 120, 114–124. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Fontinha, I.; Salta, M. Metallic Components in Construction: Corrosion Behavior and Its Preventio, 3rd ed.; LNEC: Lisbon, Portugal, 2007. [Google Scholar]

- Pillai, R.; Gettu, R.; Santhanam, M. Use of supplementary cementitious materials (SCMs) in reinforced concrete systems—Benefits and limitations. Rev. ALCONPAT 2020, 10, 147–164. [Google Scholar] [CrossRef]

- Kara De Maeijer, P.; Craeye, B.; Snellings, R.; Kazemi-Kamyab, H.; Loots, M.; Janssens, K.; Nuyts, G. Effect of ultra-fine fly ash on concrete performance and durability. Constr. Build. Mater. 2020, 263, 120493. [Google Scholar] [CrossRef]

- Revert, A.B.; Hornbostel, K.; De Weerdt, K.; Geiker, M.R. Macrocell corrosion in carbonated Portland and Portland-fly ash concrete—Contribution and mechanism. Cem. Concr. Res. 2019, 116, 273–283. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Rashid, K.; Zafar, I.; Iqbal Khan, M.; Ababtain, A.A. Production of sustainable green mortar by ultrahigh utilization of fly ash: Technical, economic and environmental assessment. Constr. Build. Mater. 2021, 281, 122617. [Google Scholar] [CrossRef]

- Chancey, R.T. Characterization of Crystalline and Amorphous Phases and Respective Reactivities in a Class F Fly Ash. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, 2008. [Google Scholar]

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties and Materials, 3rd ed.; IBRACON: São Paulo, Brazil, 2008. (In Portuguese) [Google Scholar]

- Moreira, O.; Camões, A.; Malheiro, R.; Jesus, C. High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng 2024, 5, 41–64. [Google Scholar] [CrossRef]

- Mateus, R.; Bragança, L. Construction Technologies for Building Sustainability; Edições Ecopy: Ermesinde, Portugal, 2006. (In Portuguese) [Google Scholar]

- Feizollahbeigi, B.; Mateus, R. An Analysis of the Circularity Indicators at the Building Design Level. In 4th International Conference “Coordinating Engineering for Sustainability and Resilience” & Midterm Conference of CircularB “Implementation of Circular Economy in the Built Environment”; Ungureanu, V., Bragança, L., Baniotopoulos, C., Abdalla, K.M., Eds.; Springer Nature: Cham, Switzerland, 2024. [Google Scholar]

- Camões, A. High Performance Concrete with Incorporation of fly Ash. Ph.D. Thesis, University of Minho, Guimarães, Portugal, 2002. (In Portuguese). [Google Scholar]

- Reis, R. Influence of the Addition of Hydrated Lime on the Carbonation of High Volume Fly Ash Concretes. Ph.D. Thesis, University of Minho, Guimarães, Portugal, 2022. (In Portuguese). [Google Scholar]

- Cai, R.; He, Z.; Tang, S.; Wu, T.; Chen, E. The early hydration of metakaolin blended cements by non-contact impedance measurement. Cem. Concr. Compos. 2018, 92, 70–81. [Google Scholar] [CrossRef]

- Li, W.; Hua, L.; Shi, Y.; Wang, P.; Liu, Z.; Cui, D.; Sun, X. Influence of metakaolin on the hydration and microstructure evolution of cement paste during the early stage. Appl. Clay Sci. 2022, 229, 106674. [Google Scholar] [CrossRef]

- Zunino, F.; Dhandapani, Y.; Jørgen, S.; Joseph, S.; Krishnan, S.; Anuj, P.; Maria, C.; Hanein, T.; Bernal, S.; Skibsted, J.; et al. Hydration and mixture design of calcined clay blended cements: Review by the RILEM TC 282-CCL. Mater. Struct. 2022, 55, 234. [Google Scholar] [CrossRef]

- Hollanders, S.; Adriaens, R.; Skibsted, J.; Cizer, Ö.; Elsen, J. Pozzolanic reactivity of pure calcined clays. Appl. Clay Sci. 2016, 132–133, 552–560. [Google Scholar] [CrossRef]

- Liu, J.-C.; Hossain, M.U.; Xuan, D.; Ali, H.A.; Ng, S.T.; Ye, H. Mechanical and durability performance of sustainable concretes containing conventional and emerging supplementary cementitious materials. Dev. Built Environ. 2023, 15, 100197. [Google Scholar] [CrossRef]

- Weise, K.; Endell, L.M.; Ukrainczyk, N.; Koenders, E. Pozzolanic metakaolin reactivity: Time-dependent influence of calcium hydroxide, alkali hydroxides, and sulfates. Constr. Build. Mater. 2024, 431, 136534. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B.; Jain, A.; Hanifehzadeh, M. Mitigating alkali-silica reaction induced concrete degradation through cement substitution by metakaolin and bentonite. Appl. Clay Sci. 2019, 182, 105257. [Google Scholar] [CrossRef]

- Raheem, A.A.; Abdulwahab, R.; Kareem, M.A. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete—A review. J. Clean. Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Weise, K.; Ukrainczyk, N.; Koenders, E. Pozzolanic Reactions of Metakaolin with Calcium Hydroxide: Review on Hydrate Phase Formations and Effect of Alkali Hydroxides, Carbonates and Sulfates. Mater. Des. 2023, 231, 112062. [Google Scholar] [CrossRef]

- Frías, M.; Cabrera, J. Pore size distribution and degree of hydration of metakaolin–cement pastes. Cem. Concr. Res. 2000, 30, 561–569. [Google Scholar] [CrossRef]

- da Cruz Teixeira, E.; Rossignolo, J.A.; Ferreira, T.I.B.; Medeiros, C.M.; Barbosa, N.P. Study of the transition zone of concretes prepared with metakaolin using sem/eds-associated nanoindentation technique. Constr. Build. Mater. 2024, 412, 134717. [Google Scholar] [CrossRef]

- Fu, X.; Wang, Z.; Tao, W.; Yang, C.; Hou, W.; Dong, Y.; Wu, X. Studies on blended cement with a large amount of fly ash. Cem. Concr. Res. 2002, 32, 1153–1159. [Google Scholar] [CrossRef]

- Filho, J. Systems Portland Cement, Fly Ash and Hydrated Lime: Hydration Mechanism, Microstructure and Carbonation of concrete. Ph.D. Thesis, University of São Paulo, São Paulo, Brazil, 2008. (In Portuguese). [Google Scholar]

- Coutinho, A. Manufacturing and Properties of Concrete—Volume I, 4th ed.; LNEC: Lisbon, Portugal, 2006. (In Portuguese) [Google Scholar]

- CPPE. Fly ash: Cement and concrete applications. Bol. Soc. Port. Química 1995, 56, 13–15. (In Portuguese) [Google Scholar]

- Dinakar, P.; Sahoo, P.K.; Sriram, G. Effect of Metakaolin Content on the Properties of High Strength Concrete. Int. J. Concr. Struct. Mater. 2013, 7, 215–223. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Mermerdaş, K. Improving strength, drying shrinkage, and pore structure of concrete using metakaolin. Mater. Struct. 2008, 41, 937–949. [Google Scholar] [CrossRef]

- Badogiannis, E.; Tsivilis, S. Exploitation of poor Greek kaolins: Durability of metakaolin concrete. Cem. Concr. Compos. 2009, 31, 128–133. [Google Scholar] [CrossRef]

- Sujjavanich, S.; Suwanvitaya, P.; Chaysuwan, D.; Heness, G. Synergistic effect of metakaolin and fly ash on properties of concrete. Constr. Build. Mater. 2017, 155, 830–837. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Hooton, R.D.; Scott, A.; Zibara, H. The effect of supplementary cementitious materials on chloride binding in hardened cement paste. Cem. Concr. Res. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Kocak, Y. Effects of metakaolin on the hydration development of Portland–composite cement. J. Build. Eng. 2020, 31, 101419. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, Y.; Tian, Y.; Wu, P.; Guo, Z.; Qiu, J.; Xing, J.; Xiaowei, G. Modification of high-volume fly ash cement with metakaolin for its utilization in cemented paste backfill: The effects of metakaolin content and particle size. Powder Technol. 2021, 393, 539–549. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y.; Shah, S.P. Effect of nano-metakaolin on establishment of internal structure of fly ash cement paste. J. Build. Eng. 2023, 77, 107484. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y.; Qi, Y.; Zhang, S.; Shah, S.P. Effect of nano-metakaolin on the chloride diffusion resistance of cement mortar with addition of fly ash. J. Build. Eng. 2024, 88, 109171. [Google Scholar] [CrossRef]

- Garg, R.; Garg, R.; Eddy, N.O.; Khan, M.A.; Khan, A.H.; Alomayri, T.; Berwal, P. Mechanical strength and durability analysis of mortars prepared with fly ash and nano-metakaolin. Case Stud. Constr. Mater. 2023, 18, e01796. [Google Scholar] [CrossRef]

- Hasan, Z.A.; Nasr, M.S.; Abed, M.K. Properties of reactive powder concrete containing different combinations of fly ash and metakaolin. Mater. Today Proc. 2021, 42, 2436–2440. [Google Scholar] [CrossRef]

- Abdellatief, M.; Elrahman, M.A.; Elgendy, G.; Bassioni, G.; Tahwia, A.M. Response surface methodology-based modelling and optimization of sustainable UHPC containing ultrafine fly ash and metakaolin. Constr. Build. Mater. 2023, 388, 131696. [Google Scholar] [CrossRef]

- Mo, L.; Lv, L.; Deng, M.; Qian, J. Influence of fly ash and metakaolin on the microstructure and compressive strength of magnesium potassium phosphate cement paste. Cem. Concr. Res. 2018, 111, 116–129. [Google Scholar] [CrossRef]

- Lu, K.; Wang, B.; Han, Z.; Ji, R. Experimental study of magnesium ammonium phosphate cements modified by fly ash and metakaolin. J. Build. Eng. 2022, 51, 104137. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Q.; Zhang, M.; Tang, S.; Pei, Y.; Skoczylas, F.; Feng, S. Effect of fly ash and metakaolin on the mechanical properties and microstructure of magnesium ammonium phosphate cement paste. Constr. Build. Mater. 2024, 424, 135871. [Google Scholar] [CrossRef]

- Sepulcre Aguilar, A.; Pinilla Melo, J.; Hernández Olivares, F. Microstructural analysis of aerated cement pastes with fly ash, Metakaolin and Sepiolite additions. Constr. Build. Mater. 2013, 47, 282–292. [Google Scholar] [CrossRef]

- Lin, R.-S.; Han, Y.; Wang, X.-Y. Experimental study on optimum proportioning of Portland cements, limestone, metakaolin, and fly ash for obtaining quaternary cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00691. [Google Scholar] [CrossRef]

- Alamri, M.; Ali, T.; Ahmed, H.; Qureshi, M.Z.; Elmagarhe, A.; Adil Khan, M.; Ajwad, A.; Sarmad Mahmood, M. Enhancing the engineering characteristics of sustainable recycled aggregate concrete using fly ash, metakaolin and silica fume. Heliyon 2024, 10, e29014. [Google Scholar] [CrossRef] [PubMed]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop—A multi-criteria decision method for concrete optimization. Environ. Impact Assess. Rev. 2019, 74, 73–85. [Google Scholar] [CrossRef]

- Cordoba, G.; Barquero, M.; Bonavetti, V.; Irassar, E.F. Sustainability of concretes with binary and ternary blended cements considering performance parameters. CEMENT 2023, 13, 100077. [Google Scholar] [CrossRef]

- Nie, Y.; Shi, J.; He, Z.; Zhang, B.; Peng, Y.; Lu, J. Evaluation of high-volume fly ash (HVFA) concrete modified by metakaolin: Technical, economic and environmental analysis. Powder Technol. 2022, 397, 117121. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Archer de Carvalho, T.; Gaspar, F.; Marques, A.C.; Mateus, A. Optimization of formulation ratios of geopolymer mortar based on metakaolin and biomass fly ash. Constr. Build. Mater. 2024, 412, 134846. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Tafsirojjaman, T.; Hamah Sor, N.; Sohu, S. Synergic effect of metakaolin and groundnut shell ash on the behavior of fly ash-based self-compacting geopolymer concrete. Constr. Build. Mater. 2021, 311, 125327. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, J.; Kaur, M. Microstructure and strength development of fly ash-based geopolymer mortar: Role of nano-metakaolin. Constr. Build. Mater. 2018, 190, 672–679. [Google Scholar] [CrossRef]

- Li, F.; Yang, Z.; Zhou, S.; Zhang, X.; Liu, D.; Su, Y.; Niu, Q. Fly-ash-based geopolymer modified by metakaolin for greener grouting material. Proc. Inst. Civ. Eng.—Eng. Sustain. 2023, 177, 125–138. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Lai, J.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.-S. Advancing environmental sustainability in construction through innovative low-carbon, high-performance cement-based composites: A review. Mater. Today Sustain. 2024, 26, 100712. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Camões, A.; Aguiar, B.; Jalali, S. Estimating compressive strength of concrete by mortar testing. In Proceedings of the International Conference on Concrete for Structures—INCOS’05, Coimbra, Portugal, 7–8 July 2005; pp. 121–127. [Google Scholar]

- Joseph, J.D. Mortar Testing for Estimating Strength. Concr. Int. 1999, 21, 63–67. [Google Scholar]

- Sabir, B.; Wild, S.; Khatib, J. On the workability and strength development of metakaolin concrete. In Concrete for Environmental Enhancement and Protection; E&FN Spon: London, UK, 1996; pp. 651–656. [Google Scholar]

- Pinto, A.T. Binding Systems Obtained by Metakaolin Alkaline Activation. Master’s Thesis, University of Minho, Guimarães, Portugal, 2004. (In Portuguese). [Google Scholar]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Hafez, H.; Kurda, R.; Al-Ayish, N.; Garcia-Segura, T.; Cheung, W.M.; Nagaratnam, B. A whole life cycle performance-based ECOnomic and ECOlogical assessment framework (ECO2) for concrete sustainability. J. Clean. Prod. 2021, 292, 126060. [Google Scholar] [CrossRef]

- Li, C.; Li, J.; Ren, Q.; Zheng, Q.; Jiang, Z. Durability of concrete coupled with life cycle assessment: Review and perspective. Cem. Concr. Compos. 2023, 139, 105041. [Google Scholar] [CrossRef]

- CIMPOR. Portland-Limestone Cement: CEM II/B-L 325 N; CIMPOR: Lisbon, Portugal, 2022. (In Portuguese) [Google Scholar]

- Pegop. Fly Ash from the Pego Thermoelectric Plant: Self-Control; Pegop: Pego, Portugal, 2013. (In Portuguese) [Google Scholar]

- Ferraz, E.; Gomes, C.S.F.; Wyszomirski, P. Kaolins of North-West Portugal. Mater. Ceram. 2008, 60, 58–63. (In Polish) [Google Scholar]

- Reis, R. Eco-Efficient Concretes Incorporating Fly Ash and Metakaolin. Master’s Thesis, University of Minho, Guimarães, Portugal, 2009. (In Portuguese). [Google Scholar]

- NP EN 933-1:2000; Tests for Geometrical Properties of Aggregates. Part 1: Determination of Particle Size Distribution. Sieving Method. IPQ: Caparica, Portugal, 2000. (In Portuguese)

- Faury, J. Concrete: Influence of Its Inert Components, Rules to Adopt for Its Best Composition, Manufacture and Transport on Construction Sites, 3rd ed.; Dunod: Paris, France, 1958. (In French) [Google Scholar]

- C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2001.

- NP EN 934-2:2003; Admixtures for Concrete, Mortar and Grout. Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling. CEN: Brussels, Belgium, 2003. (In Portuguese)

- EN 1015-3: 2004; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). CEN: Brussels, Belgium, 2004.

- EN 196-1:2006; Cements Test Methods. Part 1: Determination of Strength. IPQ: Caparica, Portugal, 2006. (In Portuguese)

- LNEC. E 463-2024; Determination of the Diffusion Coefficient of Chlorides by a Non-Stationary Migration Test. LNEC: Lisbon, Portugal, 2024. (In Portuguese)

- EN 1015-18:2002; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar (English Version). CEN: Brussels, Belgium, 2002.

- Globalproductprices.com. Cement—Prices by country, around the world. 2023. Available online: https://www.globalproductprices.com/rankings/cement_prices/ (accessed on 12 April 2024).

- Chemanalyst. Metakaolin Price Trend and Forecast. 2023. Available online: https://www.chemanalyst.com/Pricing-data/metakaolin-1121 (accessed on 12 April 2024).

- Chemanalyst. Fly Ash Price Trend and Forecast. 2023. Available online: https://www.chemanalyst.com/Pricing-data/fly-ash-1459 (accessed on 12 April 2024).

- Globalproductprices.com. Sand—Prices by country, around the world. 2023. Available online: https://www.globalproductprices.com/rankings/sand_prices/ (accessed on 12 April 2024).

- Ferreira, J.C.; Patino, C.M. What does p-value really mean? J. Bras. Pneumol. 2015, 41, 1. (In Portuguese) [Google Scholar] [CrossRef] [PubMed]

- Chagas, E. Applied Statistics Course for Beginners; Paulista State University: Marília, Brazil, 2016. (In Portuguese) [Google Scholar] [CrossRef]

- Field, A. Discovering Statistics with SPSS, 2nd ed.; LNEC (Laboratório Nacional de Engenharia Civil): São Paulo, Brazil, 2009. (In Portuguese) [Google Scholar]

- Farias, P. Construção Sustentável: Contributo para o Processo de Construção na Alteração de usos nos Edifícios. Ph.D. Thesis, New University of Lisbon, Lisbon, Portugal, 2010. [Google Scholar]

- Dincer, I. 2.15 Refrigerants☆☆This contribution is a revised and expanded version of a chapter entitled “Refrigerants” published in Refrigeration Systems and Applications (3rd ed., Wiley, 2017) authored by Ibrahim Dincer. In Comprehensive Energy Systems; Dincer, I., Ed.; Elsevier: Oxford, UK, 2018; pp. 435–474. [Google Scholar] [CrossRef]

- Cassagnabère, F.; Escadeillas, G.; Mouret, M.J.C.; Materials, B. Study of the reactivity of cement/metakaolin binders at early age for specific use in steam cured precast concrete. Constr. Build. Mater. 2009, 23, 775–784. [Google Scholar] [CrossRef]

| Constituents [%] | Clinker | 65–79 | Characteristics | Initial set [min] | 75 |

| Limestone | 21–31 | Expandability [mm] | ≤10 | ||

| SO3 | ≤3.5 | ||||

| Cl | ≤0.10 | Comp. str. 7 d [MPa] | 16 | ||

| Other minorities | ≤5 | Comp. str. 28 d [MPa] | 32.5 |

| Chemical composition | Loss on Ignition [%] | 7.30 | Cl− [%] | 0.00 |

| SiO2 [%] | 60.87 | Free CaO [%] | 0.00 | |

| Al2O3 [%] | 20.40 | Na2O [%] | 0.55 | |

| Fe2O3 [%] | 7.82 | K2O [%] | 1.92 | |

| Total CaO [%] | 2.72 | P2O5 [%] | 1,14 | |

| MgO [%] | 1.40 | TiO2 [%] | 1.29 | |

| SO3 [%] | 0.22 | Total SiO2 + Al2O3 + Fe2O3 [%] | 89.09 | |

| Physical properties | Density [kg/m3] | 2360 | Fineness > 45 µm [%] | 27.30 |

| Blaine’s specific surface [m2/kg] | 387.9 | Humidity [%] | 0.16 | |

| Water demand [%] | 0.297 |

| Particule dimension [%] | <30 µm | 99 ± 3 | Unburnt | Loss on Ignition [%] | 12.75 |

| <10 µm | 93 ± 5 | Humidity [%] | Initial | 32 ± 3 | |

| <5 µm | 82 ± 5 | Beads | 18 ± 2 | ||

| <2 µm | 68 ± 6 | After drying | <2 | ||

| Chemical composition [%] | SiO2 | 47.0 | After drying parameters | Burnout | 0.09 |

| Al2O3 | 37.1 | Flexion strength (110 °C) [MPa] | 2.45 ± 0.49 | ||

| Fe2O3 | 1.3 | ||||

| K2O | 2 | After burnout flexion strength [MPa] | 13 ± 3 | ||

| Na2O | 0.2 | ||||

| MgO | 0.15 | Water absorption [%] | 10 ± 2 | ||

| TiO2 | 0.3 | Others | Density [g/cm3] | 2.4–2.7 | |

| CaO | 0.1 | Suspension’s pH | 6–9 |

| B | CEM | MTK | FA | S | W/B | SP | ||

|---|---|---|---|---|---|---|---|---|

| Mixt. | Designation | [kg/m3] | [%] | [%] | [%] | [kg/m3] | [-] | [%L] |

| I | REF | 484 | 100 | 0 | 0 | 1457.9 | 0.55 | 0 |

| II | 10%MTK | 484 | 90 | 10 | 0 | 1449.1 | 0.55 | 1.5 |

| III | 20%FA | 484 | 80 | 0 | 20 | 1422.8 | 0.55 | 0 |

| IV | 40%FA | 484 | 60 | 0 | 40 | 1387.6 | 0.55 | 0 |

| V | 60%FA | 484 | 40 | 0 | 60 | 1352.5 | 0.55 | 0 |

| VI | 10%MTK + 20%FA | 484 | 70 | 10 | 20 | 1414.0 | 0.55 | 0 |

| VII | 10%MTK + 40%FA | 484 | 50 | 10 | 40 | 1378.8 | 0.55 | 0.4 |

| VIII | 10%MTK + 60%FA | 484 | 30 | 10 | 60 | 1343.6 | 0.55 | 1.5 |

| Test | Designation | Post Hoc | Description | Differences |

|---|---|---|---|---|

| Flow | One-Way ANOVA | R-E-G-W | F(3,12) = 12.563; p < 0.001 | MTK ≠ Others |

| Rf | Two-Way ANOVA | R-E-G-W | F(3,114) = 65.955; p < 0.001 | All different |

| Rc | Two-Way ANOVA | R-E-G-W | F(3,255) = 376.619; p < 0.001 | All different |

| Cl | Welch’s One-Way ANOVA | G-H | F(3,19) = 22.0603; p < 0.001 | Ternary ≠ Binary |

| Ternary ≠ MTK | ||||

| Cm | One-Way ANOVA | R-E-G-W | F(3,20) = 6.141; p < 0.004 | Ternary ≠ Binary |

| MTK ≠ Binary | ||||

| MTK ≠ REF | ||||

| F(a,b) = c; p < d | ||||

| R-E-G-W Ryan–Einot–Gabriel–Welsch | a and b = degrees of freedom; c = F-Value | |||

| G-H Games–Howel | d = p-value | |||

| Materials | PEC | GWP | |

|---|---|---|---|

| [kWh/kg] | [g/kg] | ||

| Clinker | [48] | 1.194 | 1000 |

| Lime | [48] | 0.0127 | 32 |

| MTK | [126] | 0.82 | 175 |

| FA | [48] | 0.0093 | 4 |

| S | [16] | 0.025 | 3 |

| W | [16] | 0.31 | 5 |

| Indicator | Parameter | Weights | |

|---|---|---|---|

| Parameter | Indicator | ||

| Environmental | PEC | 0.75 | WG1 = 0.30 |

| GWP | 0.25 | ||

| Functional | Flow | 0.20 | WG2 = 0.50 |

| Cs,28 | 0.25 | ||

| Cs,90 | 0.15 | ||

| D,Cl | 0.20 | ||

| Cm | 0.20 | ||

| Economic | Cost | 1.00 | WG3 = 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, R.; Camões, A.; Ribeiro, M.; Malheiro, R. Eco-Efficient Mortars for Sustainable Construction: A Comprehensive Approach. Buildings 2024, 14, 2812. https://doi.org/10.3390/buildings14092812

Reis R, Camões A, Ribeiro M, Malheiro R. Eco-Efficient Mortars for Sustainable Construction: A Comprehensive Approach. Buildings. 2024; 14(9):2812. https://doi.org/10.3390/buildings14092812

Chicago/Turabian StyleReis, Rui, Aires Camões, Manuel Ribeiro, and Raphaele Malheiro. 2024. "Eco-Efficient Mortars for Sustainable Construction: A Comprehensive Approach" Buildings 14, no. 9: 2812. https://doi.org/10.3390/buildings14092812

APA StyleReis, R., Camões, A., Ribeiro, M., & Malheiro, R. (2024). Eco-Efficient Mortars for Sustainable Construction: A Comprehensive Approach. Buildings, 14(9), 2812. https://doi.org/10.3390/buildings14092812