Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements

Abstract

1. Introduction

2. Experimental Tests

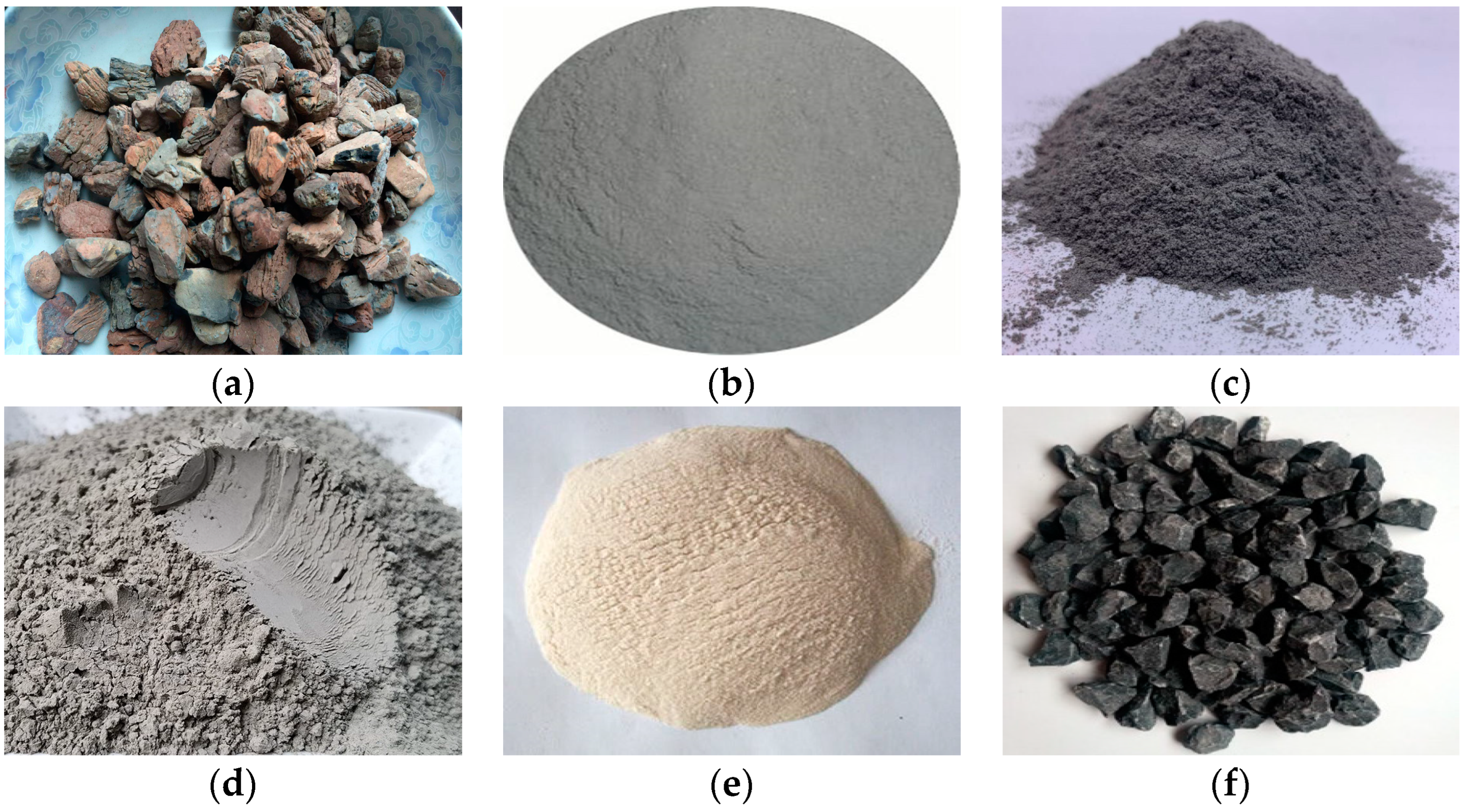

2.1. Materials

2.2. Mix Proportions and Strength Calculation

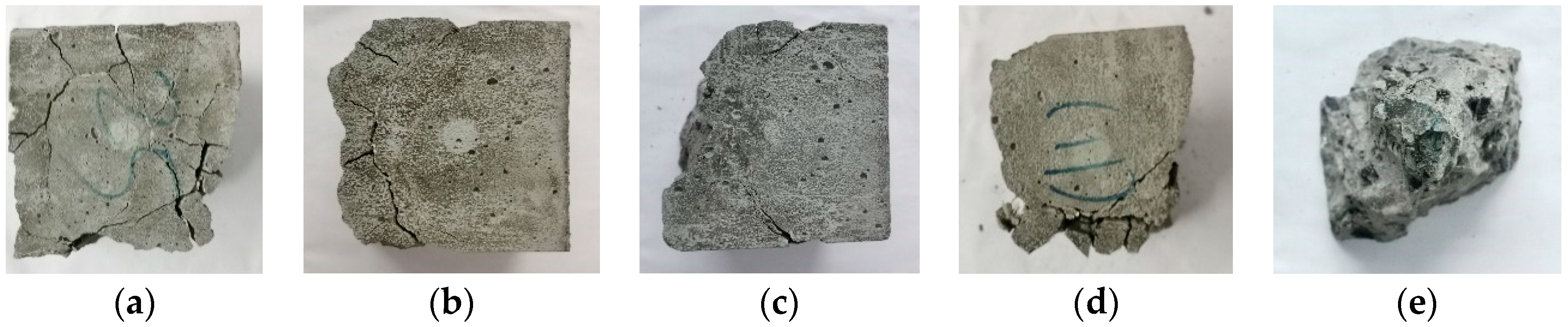

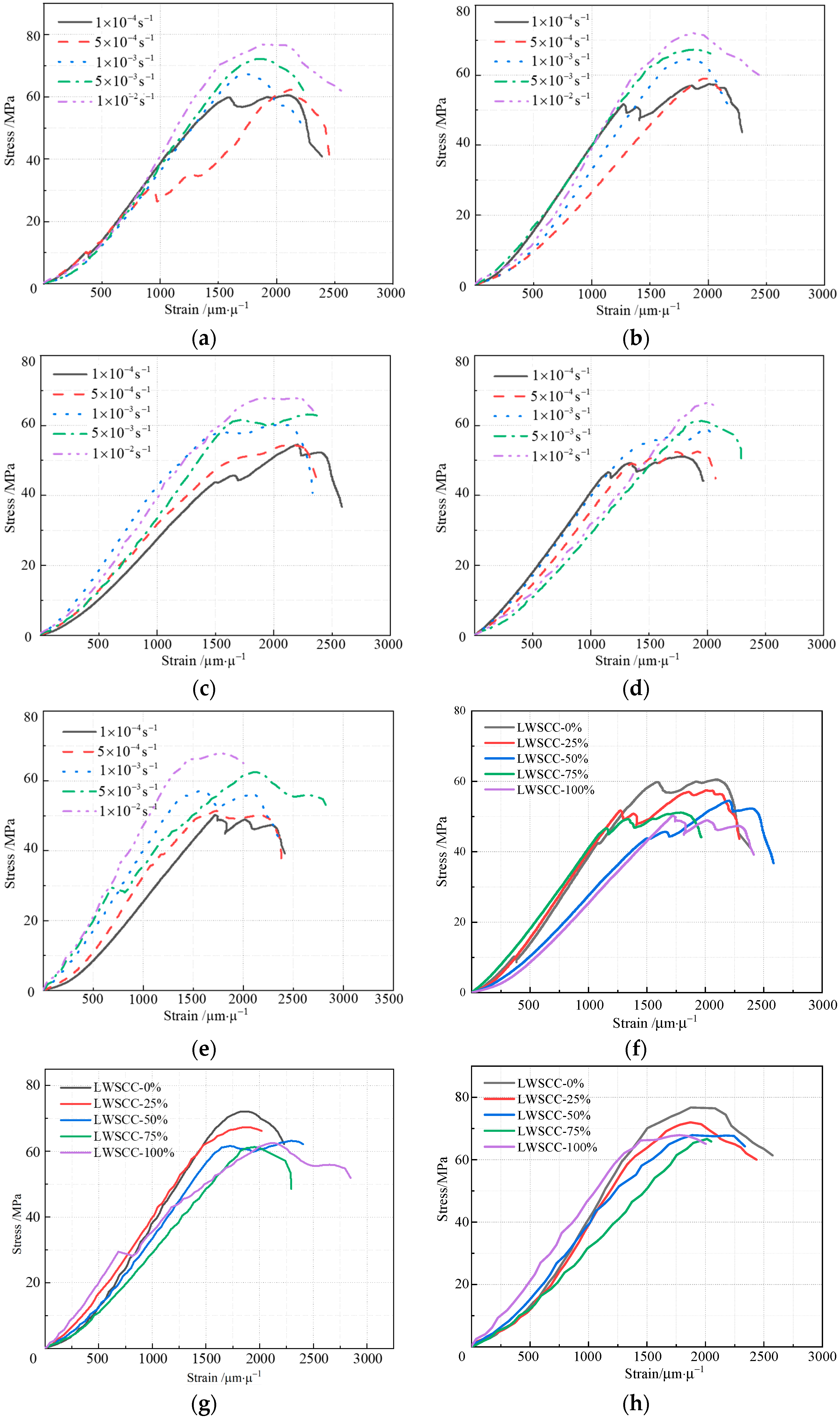

2.3. Uniaxial Compression Test Results of Shale Ceramsite Concrete

3. Mechanical Behavior of the HSLC Slab

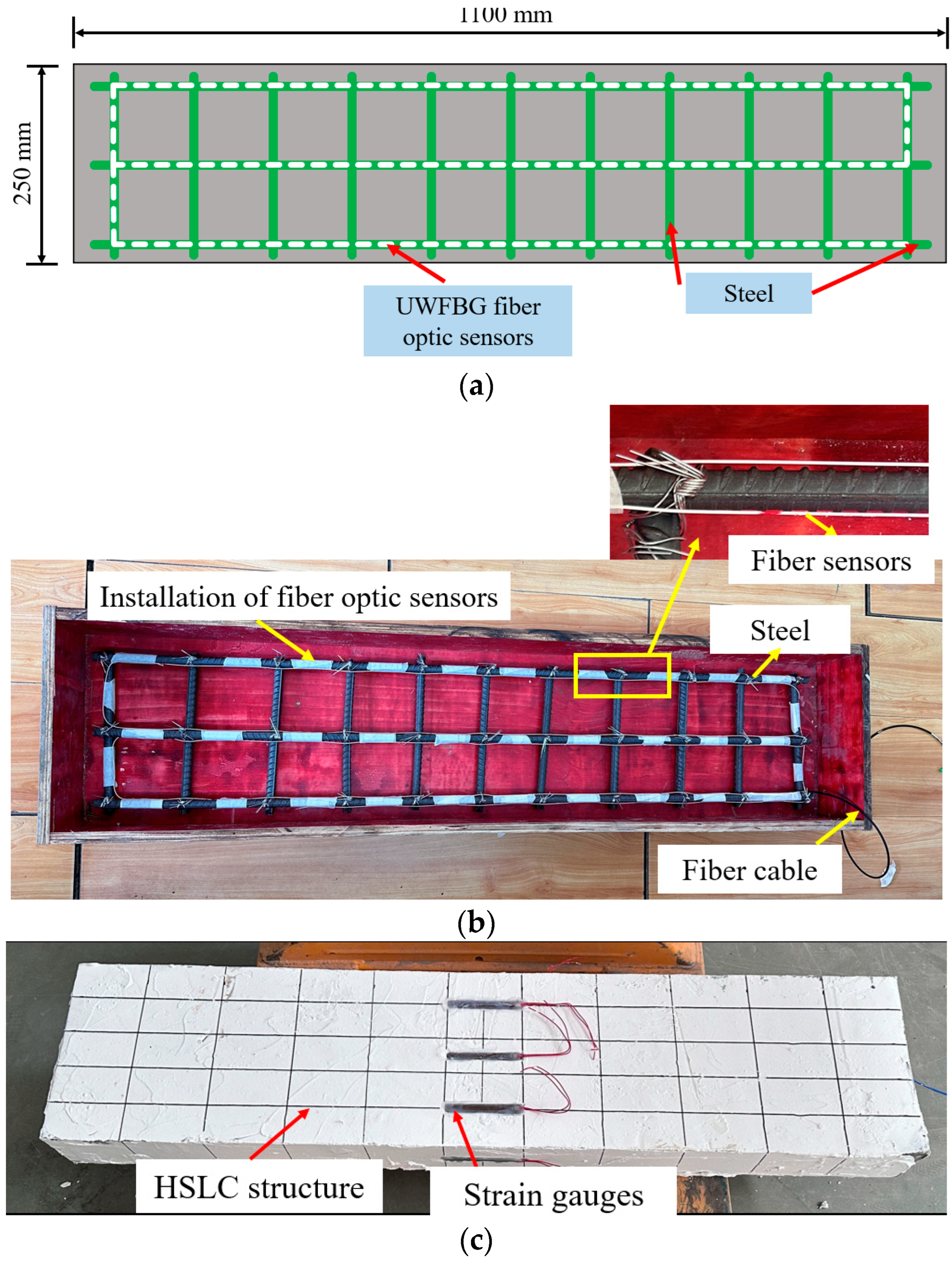

3.1. Model Preparation

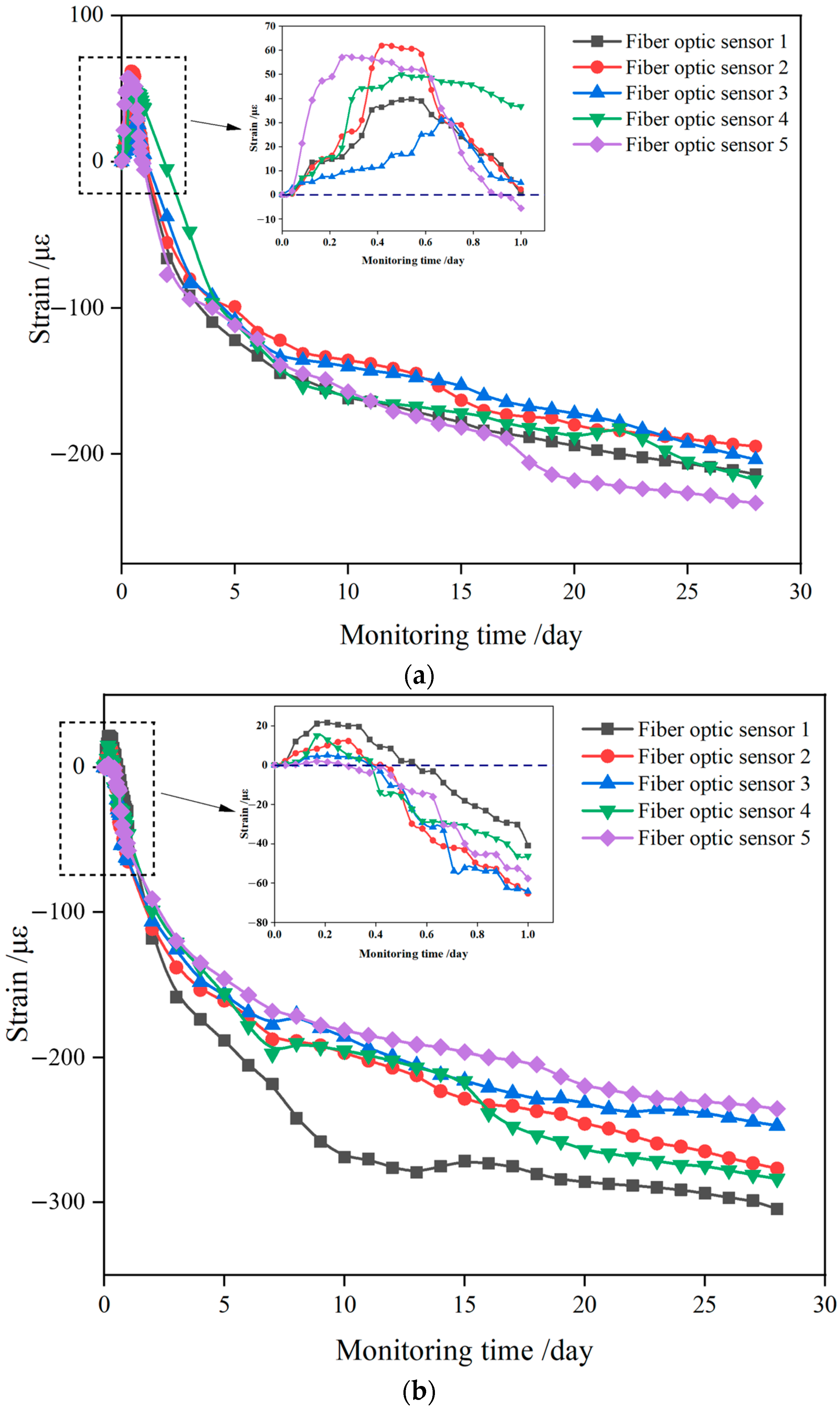

3.2. Analysis of Early Deformation Characteristics

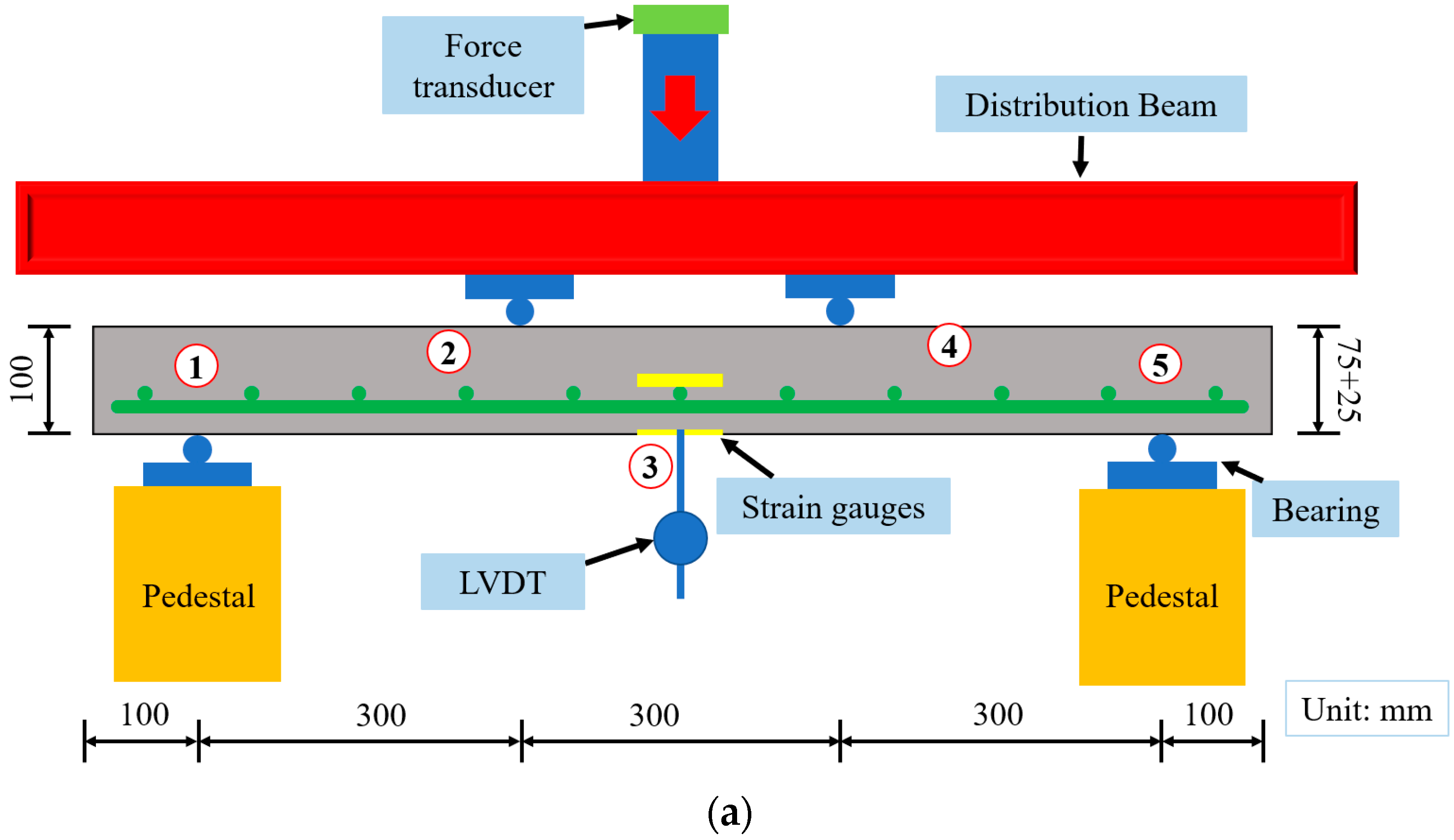

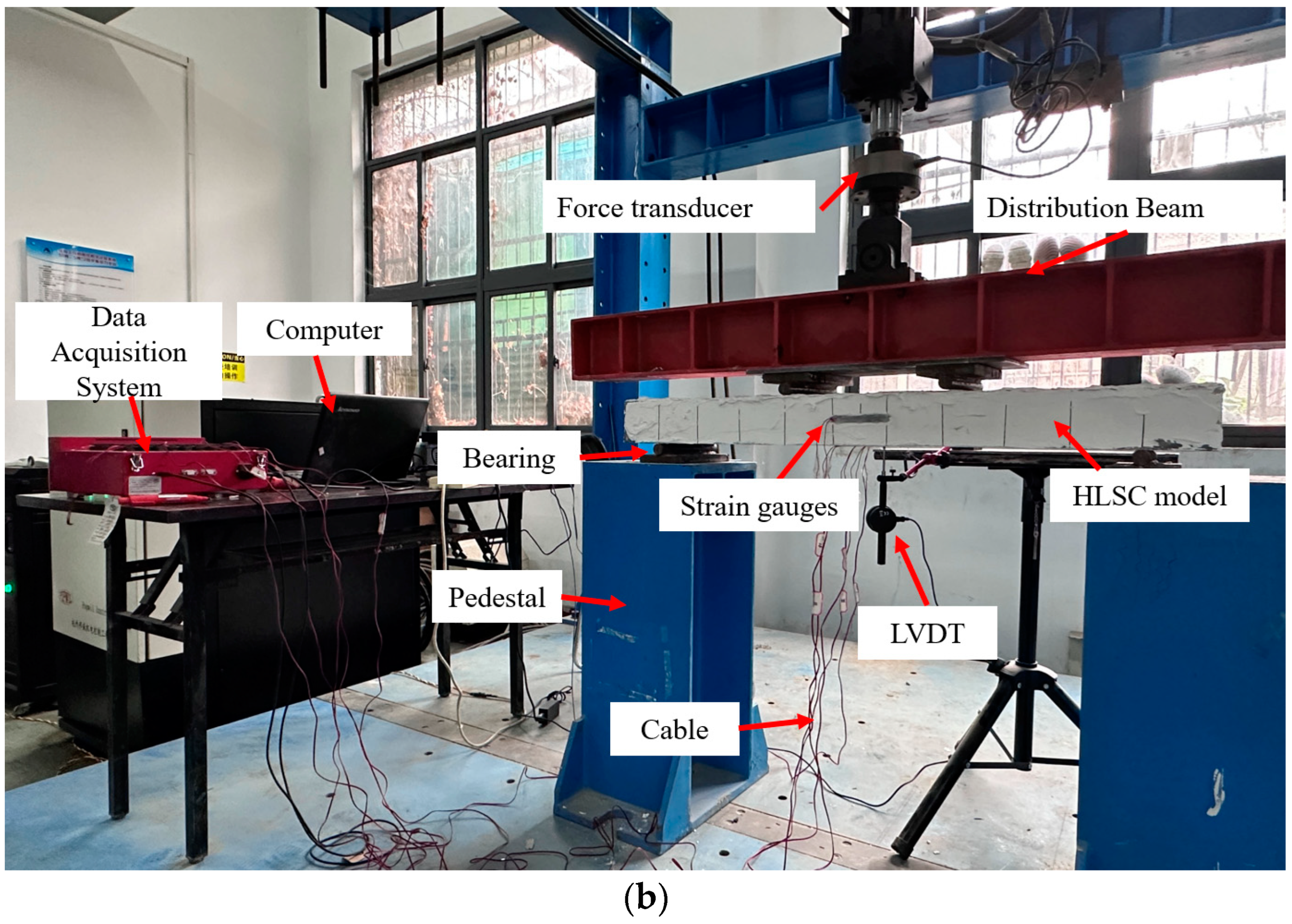

3.3. Flexural Performance Test of Bridge Deck Pavement Slabs

- (1)

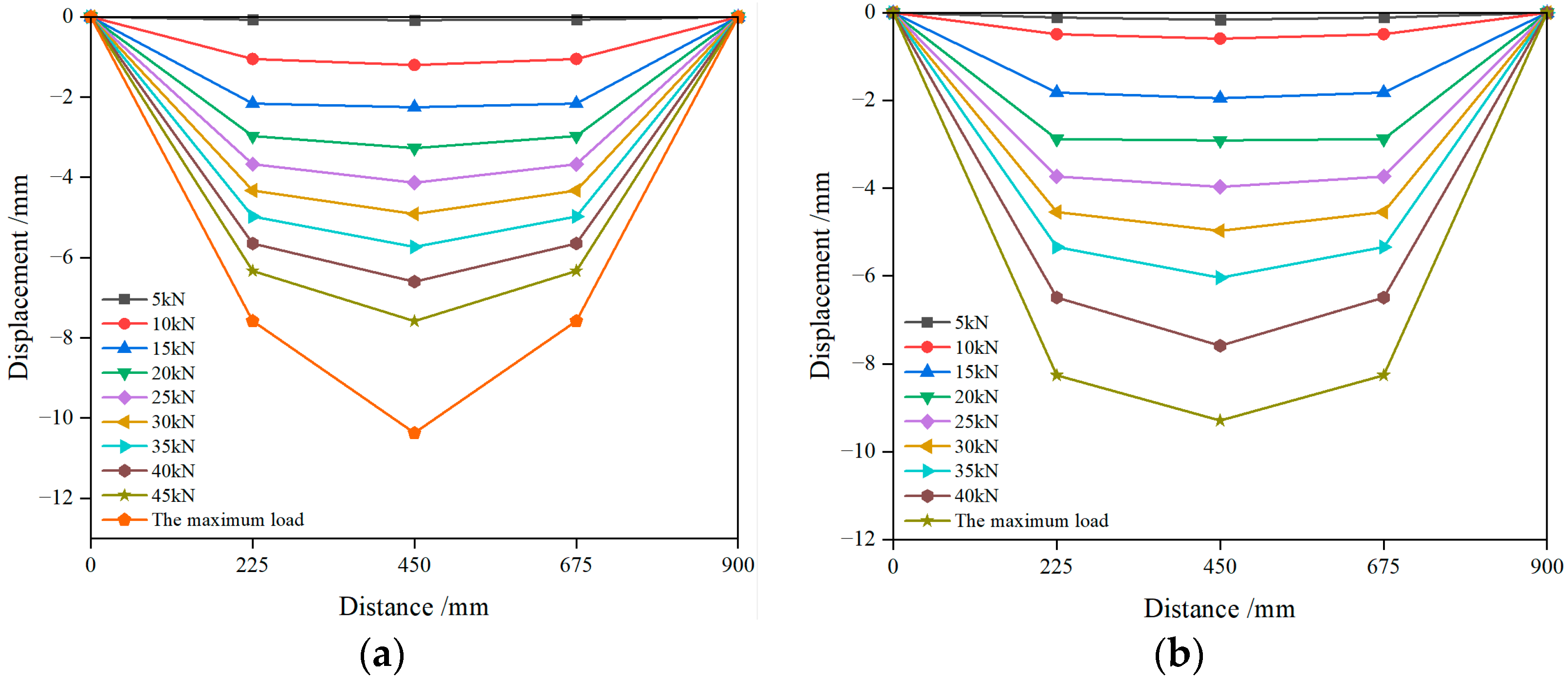

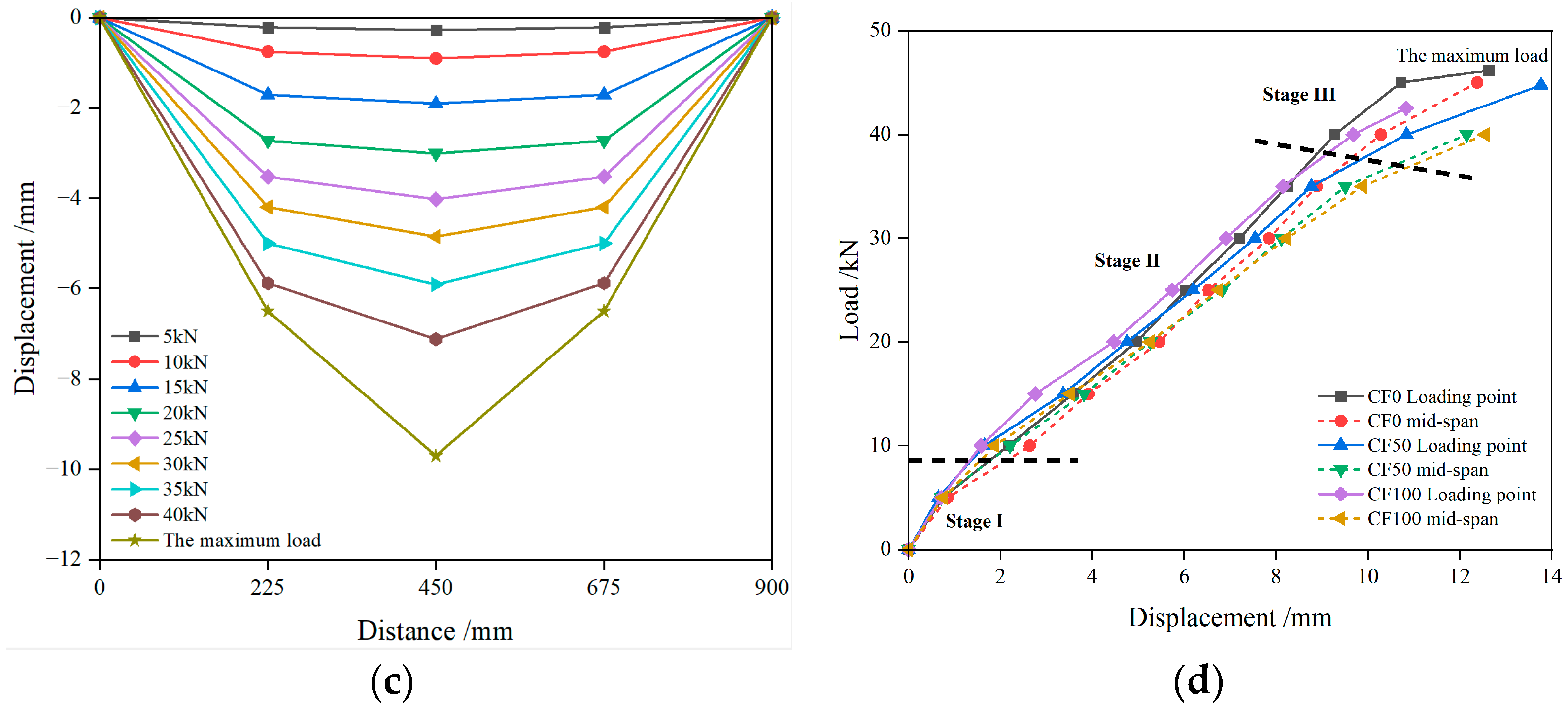

- Load-Deflection Behavior

- (2)

- Load–Strain Behavior

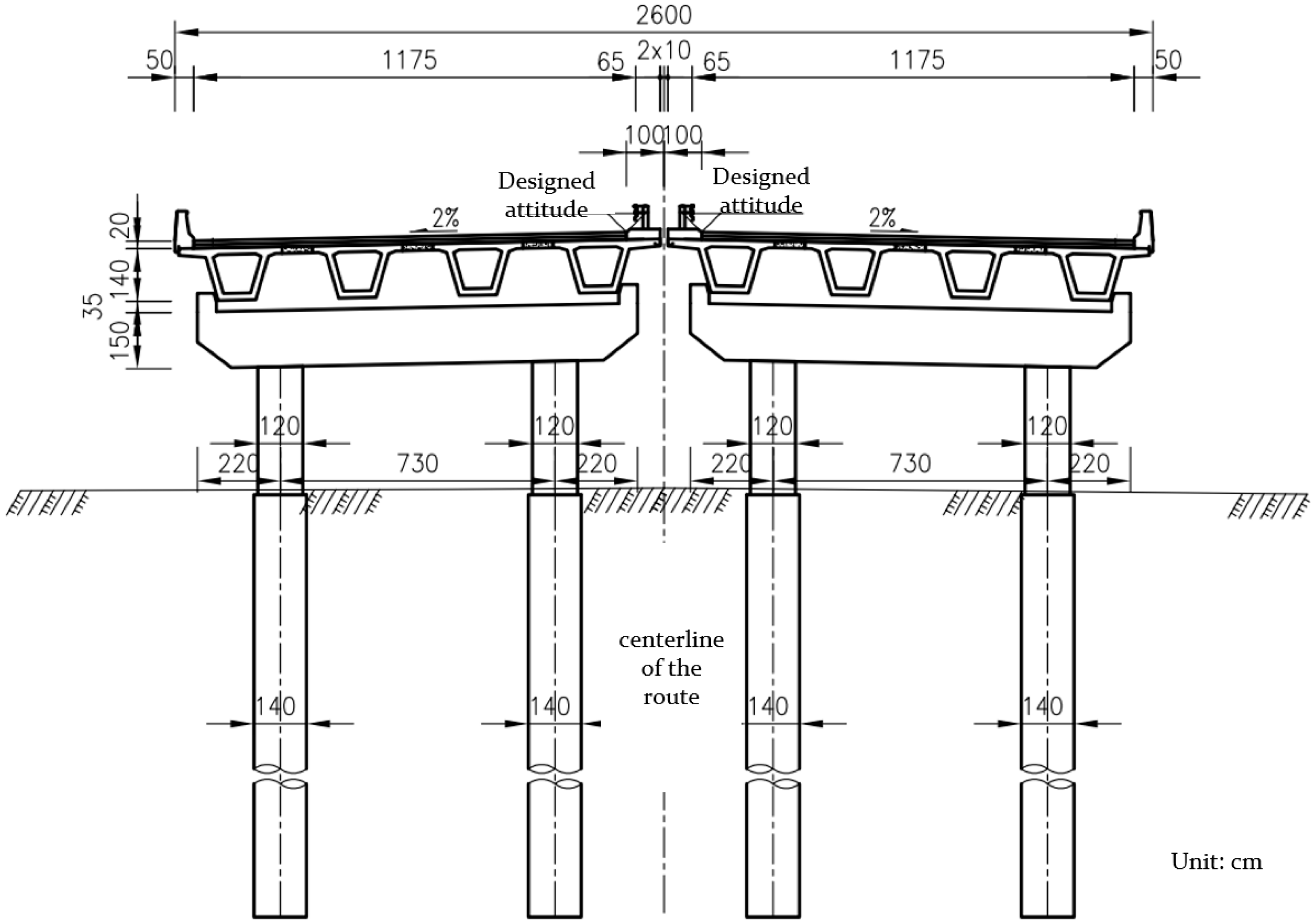

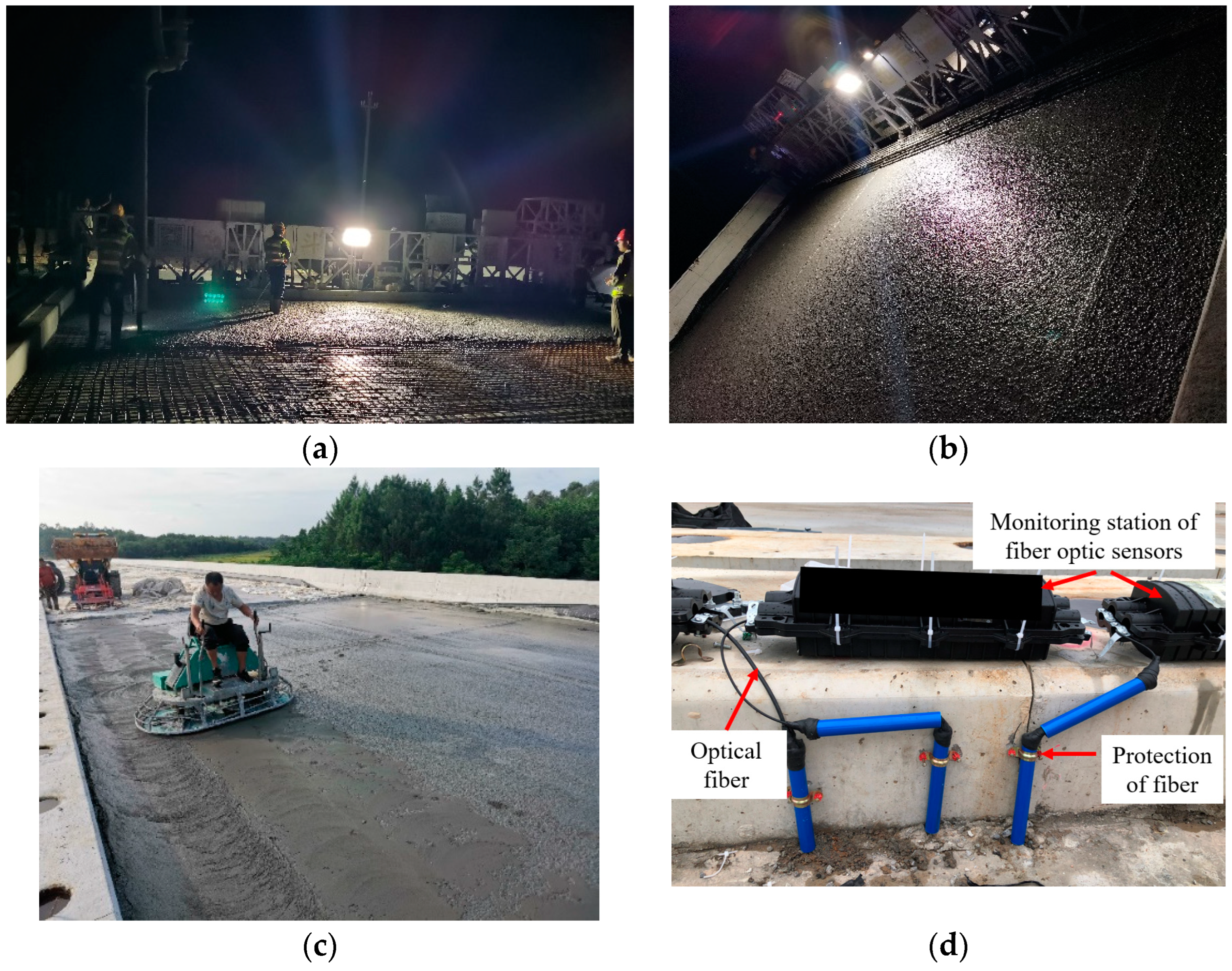

4. Field Applications

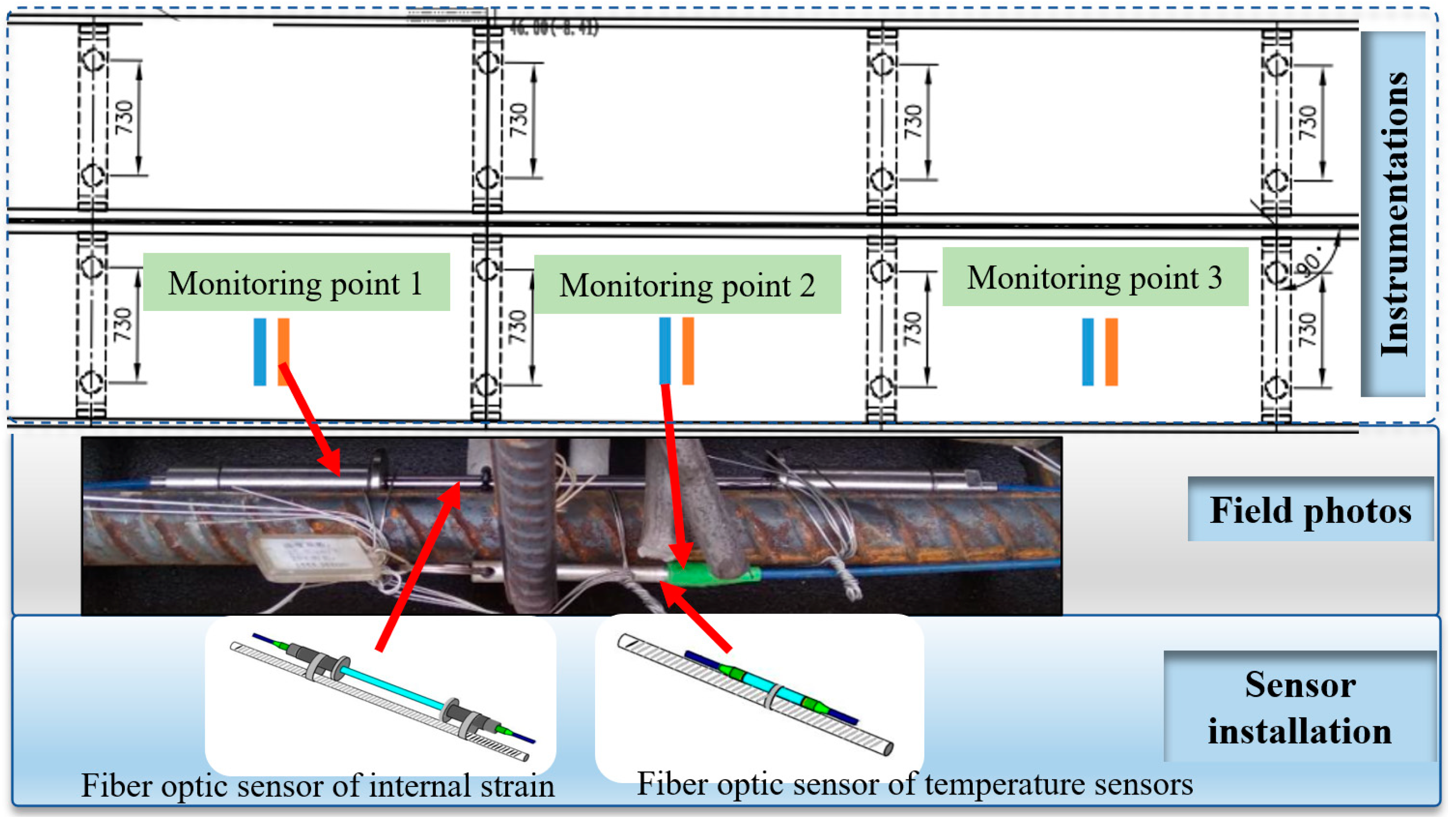

4.1. Field Instrumentations

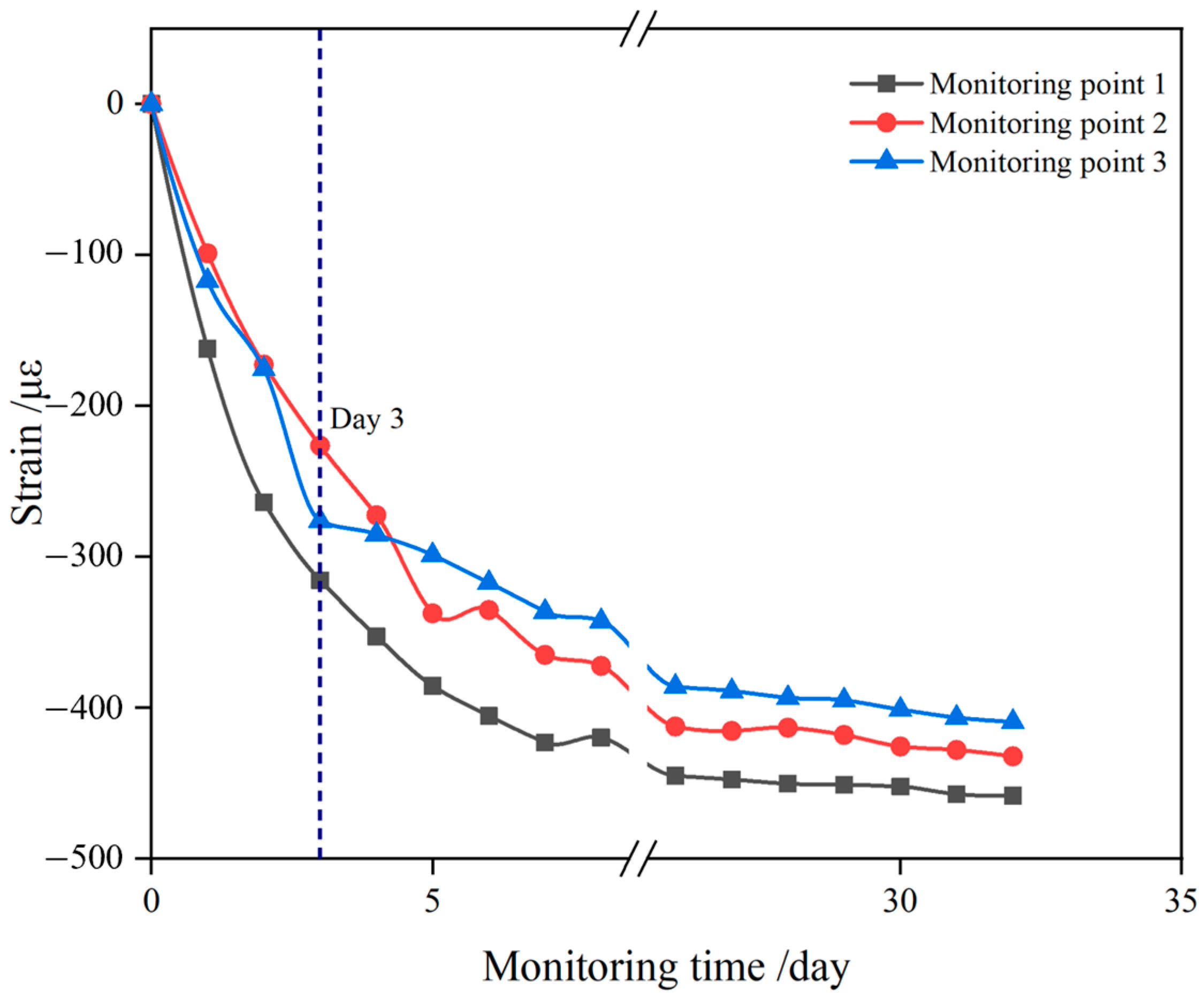

4.2. Results Analysis

5. Conclusions

- 1.

- Physical uniaxial compression tests revealed that the compressive strength of HSLC decreases as the shale ceramsite content increases;

- 2.

- By appropriately installing and deploying FBG sensors, the deformation performance of concrete in actual engineering projects was monitored. The results indicated that the trend of shrinkage deformation of the on-site concrete was largely consistent with that observed indoors. As the concrete strength increased, its shrinkage deformation tended to stabilize. This indirectly demonstrates that the on-site concrete has good deformation stability and mechanical properties, making it suitable for normal use in field conditions;

- 3.

- According to on-site monitoring results, the shrinkage strain of the concrete was more pronounced than indoors, particularly noticeable during the first three days. Therefore, it is necessary to enhance early-stage curing of the concrete to reduce drying shrinkage deformation. Given the impact of external environmental factors and construction practices, it is reasonable to observe some differences in shrinkage deformation between indoor and outdoor lightweight aggregate concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, D.S.; Zhang, Z.J.; Qin, Y.; Liu, T.; Cheng, Z. Effect of particle size distribution on dynamic properties of cemented coral sand under SHPB impact loading. Soil Dyn. Earthq. Eng. 2022, 162, 107438. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Q.K.; Xu, D.S.; Fan, X.C. Study of the effects of fine coral powder and salinity on the mechanical behaviour of coral sand-seawater cement mortar. Constr. Build. Mater. 2021, 313, 125476. [Google Scholar] [CrossRef]

- Raithby, K.; Lydon, F. Lightweight concrete in highway bridges. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 133–146. [Google Scholar] [CrossRef]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Mohamed, S.; Brabha, N.; Julian, T.; Keerthan, P.; Marco, C. Development and prospectives of lightweight high strength concrete using lightweight aggregates. Constr. Build. Mater. 2023, 362, 129628. [Google Scholar]

- Blanco, F.; García, P.; Mateos, P.; Ayala, J. Characteristics and properties of lightweight concrete manufactured with cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, D.S.; Zhang, S.S.; Fan, X.C. Dynamic behavior of carbon nanotubes and basalt fiber reinforced coral sand cement mortar at high strain rates. Constr. Build. Mater. 2022, 340, 127396. [Google Scholar] [CrossRef]

- Kahn, L.F. Lightweight Concrete for High Strength/High Performance Precast Prestressed; Georgia Institute of Technology: Atlanta, GA, USA, 2004. [Google Scholar]

- Harmon, K.S. Engineering Properties of Structural Lightweight Concrete; Carolina Stalite Company: Salisbury, NC, USA, 2007. [Google Scholar]

- He, Y.; Zhang, X.; Zhang, Y.; Zhou, Y. Effects of particle characteristics of lightweight aggregate on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 2014, 72, 270–282. [Google Scholar] [CrossRef]

- Cui, H.; Lo, T.Y.; Memon, S.A.; Xu, W. Effect of lightweight aggregates on the mechanical properties and brittleness of lightweight aggregate concrete. Constr. Build. Mater. 2012, 35, 149–158. [Google Scholar] [CrossRef]

- Yang, J.H.; Xu, L.; Fan, X.; Yu, J.Y. Strength tests of shale ceramsite concrete with part gravel coarse aggregates. Mater. Adminicle 2015, 82–86. [Google Scholar]

- Ding, Q.; Xiang, W.; Zhang, G.; Hu, C. Effect of pre-wetting lightweight aggregates on the mechanical performances and microstructure of cement pastes. J. Wuhan Univ. Technol.-Mater Sci. Ed. 2020, 35, 140–146. [Google Scholar] [CrossRef]

- Nguyen, L.; Beaucour, A.-L.; Ortola, S.; Noumowé, A. Influence of the volume fraction and the nature of fine lightweight aggregates on the thermal and mechanical properties of structural concrete. Constr. Build. Mater. 2014, 51, 121–132. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Sikora, P.; Kim, D.J.; El Madawy, M.E.; Elrahman, M.A. Effect of different expanded aggregates on durability-related characteristics of lightweight aggregate concrete. Mater. Charact. 2021, 173, 110907. [Google Scholar] [CrossRef]

- Lepage, S.; Baalbaki, M.; Dallaire, E.; Aïtcin, P. Early shrinkage development in a high performance concrete. Cem. Concr. Aggreg. 1999, 21, 31–35. [Google Scholar] [CrossRef]

- Xu, D.S.; Dong, L.J.; Lalit, B.; Liu, H.B. Early-warning system with quasi-distributed fiber optic sensor networks and cloud computing for soil slopes. IEEE Access 2017, 5, 25437–25444. [Google Scholar] [CrossRef]

- Xu, D.S.; Zhao, Y.M.; Liu, H.B.; Zhu, H.H. Deformation monitoring of metro tunnel with a new ultrasonic-based system. Sensors 2017, 17, 1758. [Google Scholar] [CrossRef] [PubMed]

- Yun, Y.-W.; Jang, I.-Y. Research on early age deformation of high performance concrete by fiber bragg grating sensor. KSCE J. Civ. Eng. 2008, 12, 323–328. [Google Scholar] [CrossRef]

- Silva KK, S.; Silva, F.N.; Mahfoud, T.; Khelidj, A.; Brientin, A.; Azevedo, A.C.; Delgado, J.M.; de Lima, A.B. On the use of embedded fiber optic sensors for measuring early-age strains in concrete. Sensors 2021, 21, 4171. [Google Scholar] [CrossRef]

- Yun, Y.W.; Jang, I.Y.; Kim, S.K.; Park, S.M. Early-age autogenous shrinkage of high-performance concrete columns by embedded fiber bragg-grating sensor. Trans Tech Publ. 2009, 419–420, 1–4. [Google Scholar] [CrossRef]

- Yazdizadeh, Z.; Marzouk, H.; Hadianfard, M.A. Monitoring of concrete shrinkage and creep using Fiber Bragg Grating sensors. Constr. Build. Mater. 2017, 137, 505–512. [Google Scholar] [CrossRef]

- Jia, W.Y. Continual Rigid Frame Bridge SpanDown-Warping Prevention and Control; Changan University: Xi’an, China, 2011. [Google Scholar]

- Qin, Y.; Wang, Q.K.; Xu, D.S.; Yan, J.M.; Zhang, S.S. A fiber Bragg grating based earth and water pressures transducer with three-dimensional fused deposition modeling for soil mass. J. Rock Mech. Geotech. Eng. 2022, 14, 663–669. [Google Scholar] [CrossRef]

- Xu, D.S.; Su, Z.Q.; Qin, Y.; Lalit, B. A hybrid FBG-based pressure and vibration transducer with a 3D fused deposition modelling approach. Meas. Sci. Technol. 2022, 33, 065106. [Google Scholar] [CrossRef]

- Feng, W.Q.; Zhang, T.Y.; Li, Y.X.; Xu, D.S. Experimental Study of Interface Performance between Calcareous Sand and Steel Pile with Different Surface Roughness and Temperatures. Ocean Eng. 2024, 292, 116469. [Google Scholar] [CrossRef]

- Xu, D.S.; Jiang, L.; Qin, Y.; Shen, H.; Ji, B.F. High-precision FBG-based sensor for soil settlement monitoring: A comparative study with magnetic settlement gauges and PIV technique. Sens. Actuators A Phys. 2024, 366, 114935. [Google Scholar] [CrossRef]

- Singh, M.J.; Choudhary, S.; Chen, W.B.; Wu, P.C.; Goyal, M.K.; Rajput, A.; Borana, L. Applications of fibre Bragg grating sensors for monitoring geotechnical structures: A comprehensive review. Measurement 2023, 218, 113171. [Google Scholar] [CrossRef]

- Shen, J.H.; Hu, M.J.; Wang, X.; Zhang, C.Y.; Xu, D.S. SWCC of Calcareous Silty Sand Under Different Fines Contents and dry Densities. Front. Environ. Sci. 2021, 9, 682907. [Google Scholar] [CrossRef]

- Xu, D.S.; Yan, J.M.; Liu, Q.C. Behavior of discrete fiber-reinforced sandy soil in large-scale simple shear tests. Geosynth. Int. 2021, 28, 598–608. [Google Scholar] [CrossRef]

- Zhang, X.L.; Peng, X.B.; Li, X.J.; Zhou, Z.; Xu, C.; Dou, Z.; Liu, B. Three-Dimensional Seismic Response in Complex Site Conditions: A New Approach Based on an Auxiliary-Model Method. J. Earth Sci. 2021, 32, 1152–1165. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Zhang, C.C.; Shi, B.; Chen, Z.Y.; Zhao, X.Y.; Wang, Z. Artificial intelligence-based distributed acoustic sensing enables automated identification of wire breaks in prestressed concrete cylinder pipe. J. Appl. Geophys. 2024, 224, 105378. [Google Scholar] [CrossRef]

- Ma, P.H.; Peng, J.B.; Zhuang, J.Q.; Zhu, X.; Liu, C.; Cheng, Y.; Zhang, Z. Initiation Mechanism of Loess Mudflows by Flume Experiments. J. Earth Sci. 2022, 33, 1166–1178. [Google Scholar] [CrossRef]

- Tian, X.X. The Producing and Properties Studying of Lightweight and High Strength Concrete Applied in Bridge Pavement; South China University of Technology: Guangzhou, China, 2015. [Google Scholar]

- Cheng, L. Design of Mixture Proportions and Study on Performance of LC50 Lightweight Aggregate Concretes; Changsha University of Science & Technology: Changsha, China, 2013. [Google Scholar]

- Yang, Y.T. Research on strength performance of haycite for light aggregate concrete of bridge deck pavement. N. Commun. 2018, 85–88. [Google Scholar]

- Wang, S.; Zhao, J.; Wu, X.; Yang, J.; Wang, Q. Elastic properties and damage evolution analysis for lightweight shale ceramsite concrete. Int. J. Appl. Mech. 2023, 15, 2350040. [Google Scholar] [CrossRef]

| Aggregate | Mud Content(%) | Cylinder Compressive Strength (MPa) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Water Absorption (%) | Bulk Void Ratio (%) | Maximum Particle Size (mm) |

|---|---|---|---|---|---|---|---|

| 60 min | |||||||

| Shale ceramsite | 0.8 | 6.8 | 1350 | 780 | 3 | 35 | 5~20 |

| No. | Gel Materials (kg) | Cement (kg) | Water–Cement Ratio | Sand Ratio | Fly Ash (kg) | Silica Fume (kg) | Water Reducer (kg) | Ceramsite Ratio | Slump (mm) | 28-Day Strength (Mean) (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| ① | 510 | 408 | 0.28 | 43% | 76.5 | 25.5 | 7.65 | 100% | 108 | 56.3 |

| ② | 510 | 408 | 0.3 | 43% | 76.5 | 25.5 | 7.65 | 100% | 164 | 55.4 |

| ③ | 510 | 408 | 0.32 | 43% | 76.5 | 25.5 | 7.65 | 100% | 224 | 52.5 |

| ④ | 510 | 408 | 0.34 | 43% | 76.5 | 25.5 | 7.65 | 100% | 245 | 41.24 |

| Cement (kg/m3) | Silica Fume (kg/m3) | Fly Ash (kg/m3) | Shale Ceramsite (kg/m3) | Medium Sand (kg/m3) | Net Water Amount (kg/m3) | Water Reducer (kg/m3) | Slump (mm) |

|---|---|---|---|---|---|---|---|

| 408 | 25.5 | 76.5 | 517.2 | 745.8 | 163.2 | 7.65 | 224 |

| Specimen | Aggregate kg/m3 | Gel material kg/m3 | Additive kg/m3 | Water kg/m3 | ||||

|---|---|---|---|---|---|---|---|---|

| Ceramsite | Basalt | Sand | Cement | Silica Fume | Flyash | Water Reducer | ||

| LWSCC-0% | / | 1015.4 | 745.8 | 408 | 25.5 | 76.5 | 7.65 | 163.2 |

| LWSCC-25% | 129.3 | 761.55 | 745.8 | 408 | 25.5 | 76.5 | 7.65 | 163.2 |

| LWSCC-50% | 258.6 | 507.7 | 745.8 | 408 | 25.5 | 76.5 | 7.65 | 163.2 |

| LWSCC-75% | 387.9 | 253.85 | 745.8 | 408 | 25.5 | 76.5 | 7.65 | 163.2 |

| LWSCC-100% | 517.2 | / | 745.8 | 408 | 25.5 | 76.5 | 7.65 | 163.2 |

| No. | Initial Wavelength (nm) | kε | kT (nm/°C) |

|---|---|---|---|

| Strain sensor 1 | 1538.386 | 0.00712 | 0.0168 |

| Strain sensor 2 | 1548.087 | 0.00712 | 0.0163 |

| Strain sensor 3 | 1559.650 | 0.00712 | 0.0162 |

| Temperature 1 | 1535.969 | - | 0.0097 |

| Temperature 2 | 1553.737 | - | 0.0096 |

| Temperature 3 | 1541.932 | - | 0.0098 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Q.; Qin, Y.; Hou, C.; Gao, H.; Li, M. Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements. Buildings 2024, 14, 2783. https://doi.org/10.3390/buildings14092783

Song Q, Qin Y, Hou C, Gao H, Li M. Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements. Buildings. 2024; 14(9):2783. https://doi.org/10.3390/buildings14092783

Chicago/Turabian StyleSong, Qi, Yue Qin, Chuantan Hou, Hongwu Gao, and Mengzhao Li. 2024. "Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements" Buildings 14, no. 9: 2783. https://doi.org/10.3390/buildings14092783

APA StyleSong, Q., Qin, Y., Hou, C., Gao, H., & Li, M. (2024). Study of the Mechanical Behavior of High-Strength Lightweight Concrete and Its Application to Bridge Pavements. Buildings, 14(9), 2783. https://doi.org/10.3390/buildings14092783