1. Introduction

Concrete material is frequently used in the construction industry for the following reasons: it is easy to access the raw materials required to produce concrete, concrete is cost-effective, and it can be used in simple construction processes [

1]. It is formed by using cementitious materials, aggregates, and water, as well as, when necessary, the addition of admixtures, additives, and other materials in accordance with certain design ratios, after uniform mixing and blending, maintenance, and molding of the composite material in line with specific requirements. Because of its high compressive strength, durability, and wide range of advantages, it is widely used in military construction, commercial buildings, roads and bridges, water conservancy projects, and other fields [

2]. However, with the continuous development of concrete materials and the vigorous promotion of urbanization, the production of metallurgical slag, construction waste, and other by-products is also climbing [

3,

4]. Most of the treatment of these solid wastes currently takes place in piles and landfills, with a secondary utilization rate of resources of only about 10%. This not only causes land resource tension but also aggravates environmental pollution [

5,

6,

7]. Solid wastes still face the serious challenge of underutilization, and how to improve the utilization of these solid wastes is the focus of the current research.

At present, there are two main ways to prepare manganese metal in the industry: one is to prepare manganese metal via the electrolysis of manganese sulphate solution, and the other is to prepare manganese metal via high-temperature smelting of manganese–iron alloys. Both preparation methods produce waste slag in the preparation process, especially through the high-temperature smelting of ferromanganese alloys, where the high-temperature slag discharged is rapidly cooled by water to form a type of blast furnace slag with potential water hardness and volcanic ash, named silica–manganese slag [

8,

9,

10]. The production of silica–manganese alloys discharges a large amount of silica–manganese slag waste, and currently, silica–manganese slag treatment is primarily carried out by piling up the waste and transporting it to a landfill or reselling it at a low price. Not only does this increase the cost for enterprises, but it also creates harmful elements that penetrate into soil and pollute groundwater [

11,

12]. Silica–manganese slag contains highly vitreous SiO

2 and Al

2O

3, and its composition is similar to that of cement; thus, it is considered as a raw material in the preparation of concrete, turning waste into treasure [

13,

14]. Through experimental studies, Allahverdi et al. [

15] found that when 35% of cement was replaced with water-quenched manganese slag, the 28 d strength of the concrete was still higher than 35 MPa, and the bulk stability was satisfactory. Kumar et al. [

16] ball-milled silica–manganese slag to improve its activity and ground it finely into a cementitious material with physical properties similar to those of cement. They found that its hydration products were hydrated calcium silicate (C-S-H gel) and tobermorite. Frias et al. [

17] studied the effect of silica–manganese slag on the erosion resistance of concrete by incorporating 15% silica–manganese slag into cement and curing it under different solutions for 45 d. They concluded that silica–manganese slag improves the resistance of concrete to seawater erosion. Patil et al. [

18] performed an experimental study on the use of silica–manganese slag as a non-conventional or human-made aggregate material for road and railroad construction and concluded that when used for rigid pavements, the compressive strength, split tensile strength, and flexural strength (modulus of rupture) of the concrete fabricated from silica–manganese slag aggregates met the design requirements.

In the northwest of China, most concrete buildings are in saline and alkaline environments. The main erosion ions in the soil are SO

42−, Cl

−, K

+, and Mg

2+, and the service life of buildings is greatly reduced when buildings are in this environment for a long time. Whereas freeze–thaw cycles are prevalent in cold regions, the double damage of salt freezing puts the safety of concrete buildings to a serious test [

19,

20]. Salt freezing damage involves freezing and thawing damage and salt erosion, which interact with each other to influence [

21] the concrete matrix structure. The concrete matrix structure belongs in a saturated water state. When the environment repeatedly alternates between high- and low-temperature states, concrete freezing and thawing damage is likely to occur [

22,

23]. When concrete is in extremely cold saline areas, due to the alternating positive and negative temperature changes, the concrete will continue to freeze and thaw in cycles. When this process is accompanied by salt ion erosion, in the long run, it will result in the external surface mortar falling off and the concrete cracking. This results in the early decommissioning of the concrete structure or the service life of the project being far less than its engineered design life. Engineering disaster cases, which have happened from time to time, have resulted in huge economic and resource losses and even, tragically, human casualties [

23,

24].

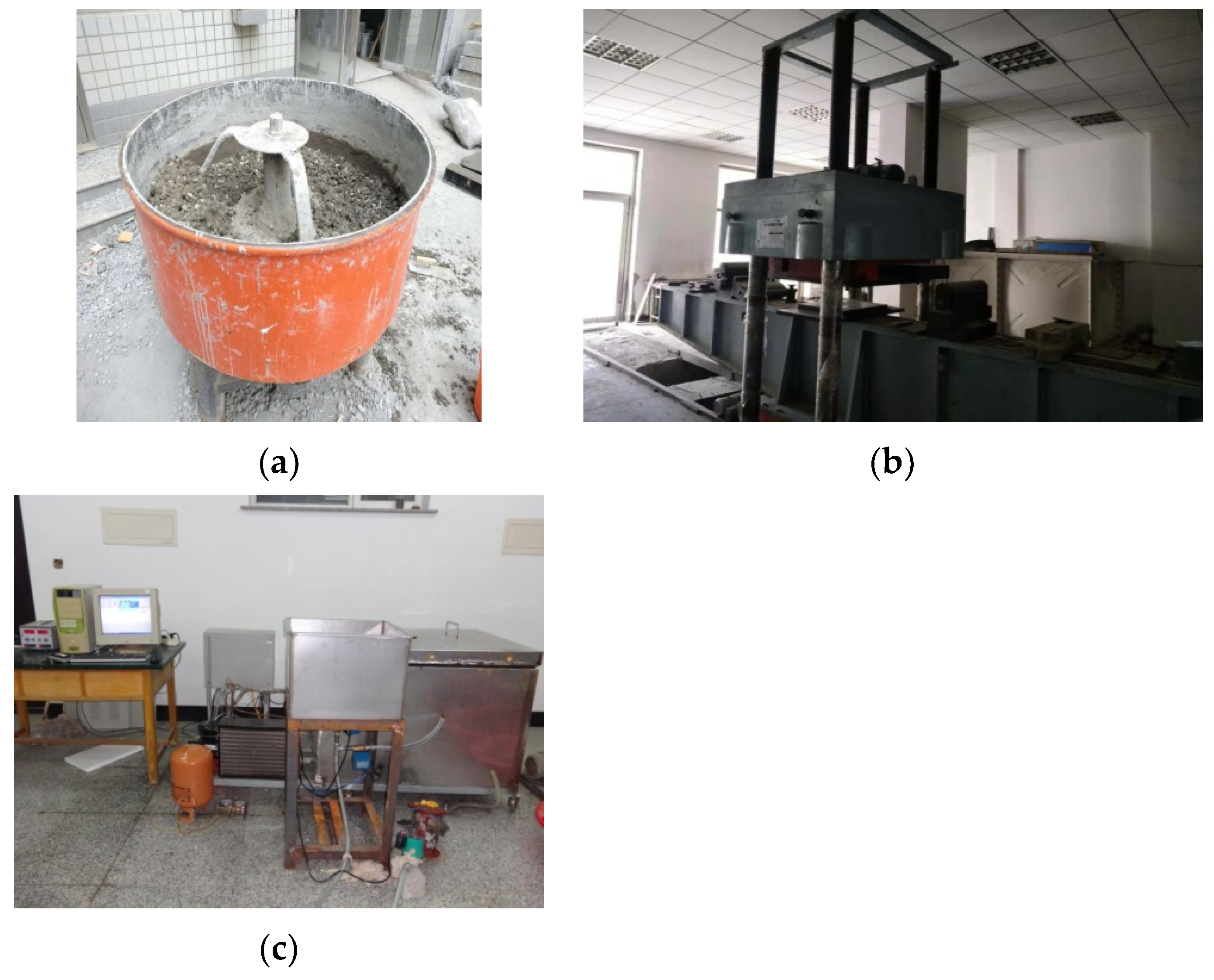

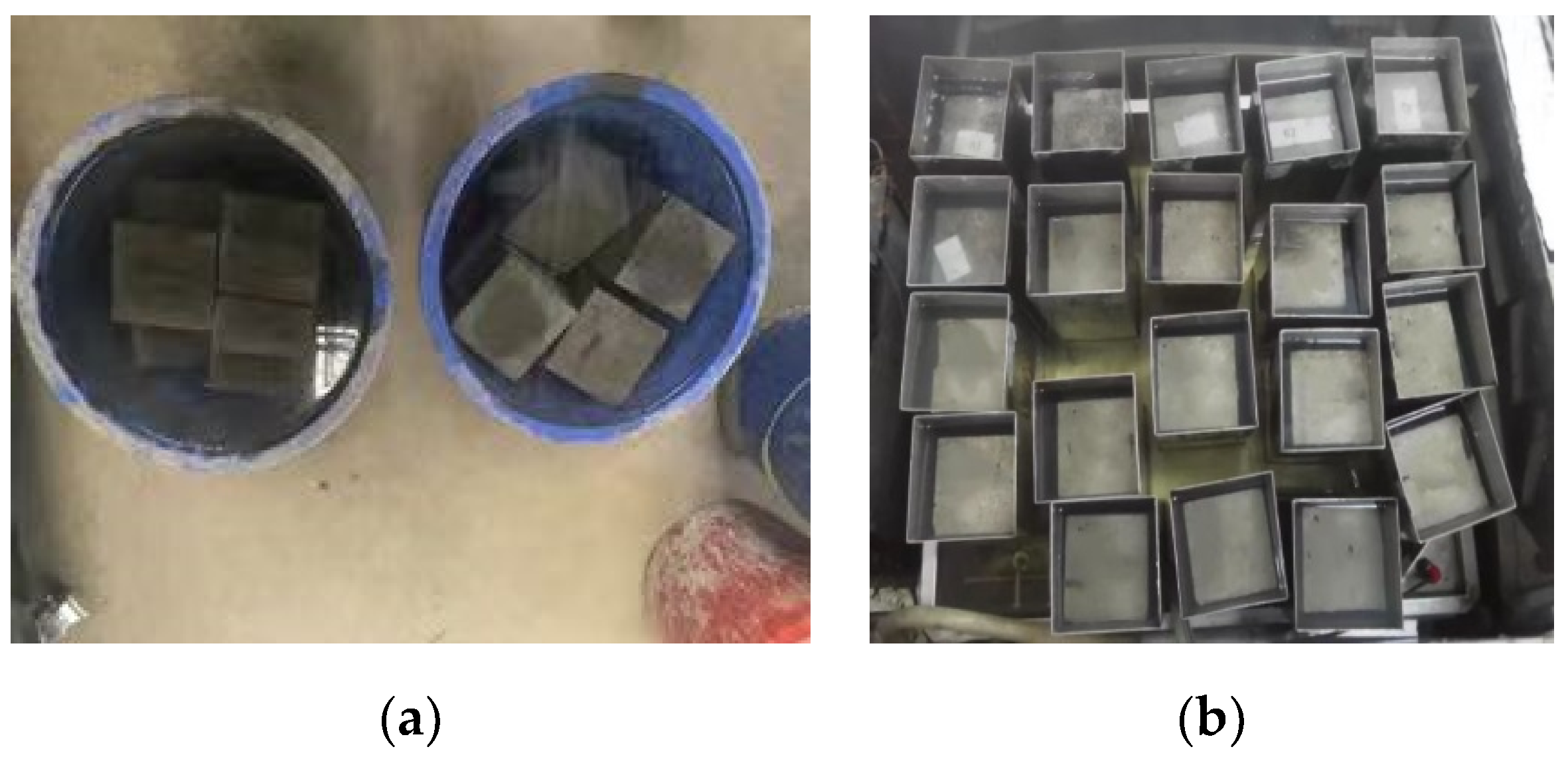

Concrete structure durability damage is the result of multiple factors, and there is little research on the concrete damage law and its modeling under the combined effect of salt erosion and freeze–thaw cycles. Therefore, in this study, we carry out tests related to the analytical investigation of silica–manganese slag concrete under the action of mixed salt–freeze–thaw cycles. The mechanical properties (slump and cubic compressive strength) and salt freeze resistance of silica–manganese slag concrete are investigated using silica–manganese slag instead of cement as the main variable. Finally, a probability distribution is introduced into the study of salt freezing damage in silica–manganese slag concrete, and a damage model for silica–manganese slag concrete under the salt freezing cycle is deduced through the relationship between the damage variables and the relative strength. Our aim is to improve the durability of silica–manganese slag concrete under the salt freezing cycle and to provide a theoretical basis for real-world engineering that can prevent and mitigate disasters in saline areas.

5. Scanning Electron Microscopy Analysis

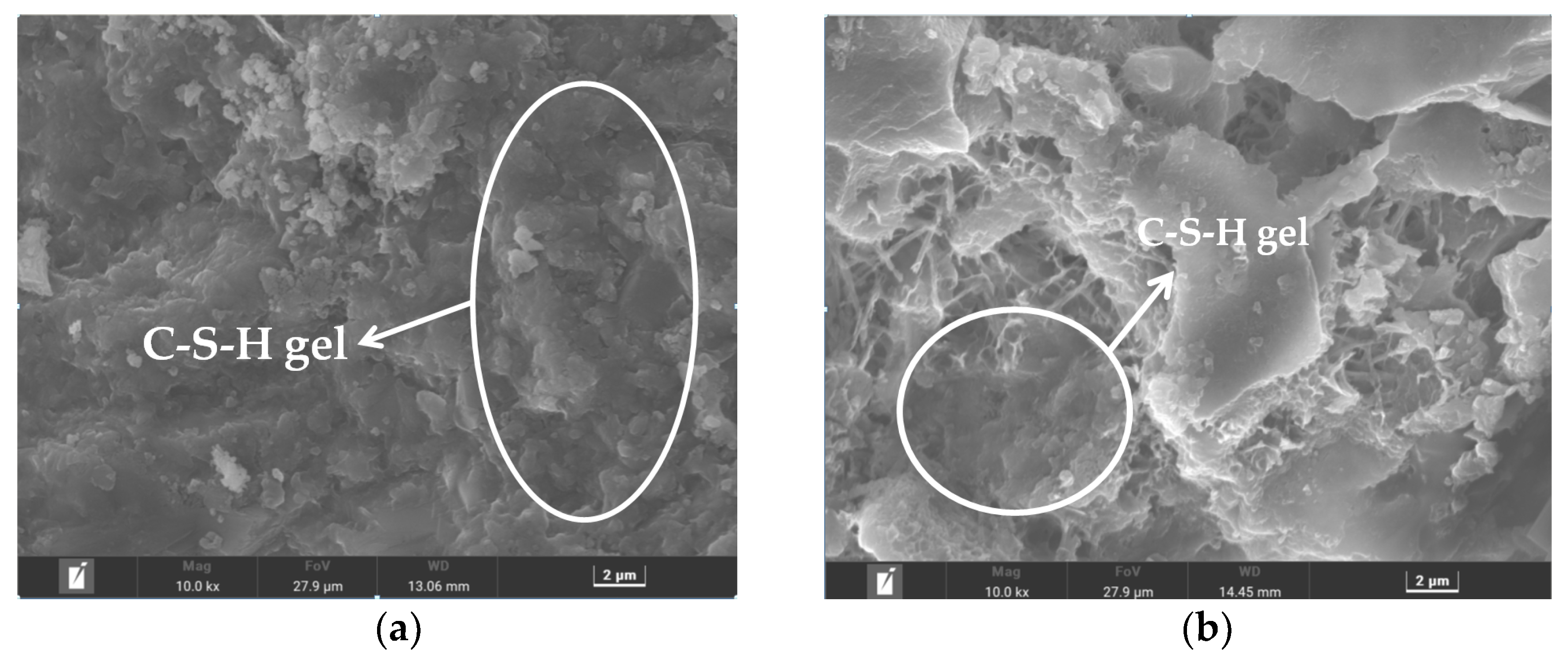

In

Figure 9, it is observed that the hydrates are in bulk and continuous form and are interglued with the hydrated calcium silicate with a reticulated structure (C-S-H gel) and with the calcium hydroxide with a lamellar structure. The hydrated calcium silicate possesses cement-like properties, and its uneroded areas are structurally intact, with no cracks and greater densification, which improves the internal structure of the concrete and increases its strength [

36].

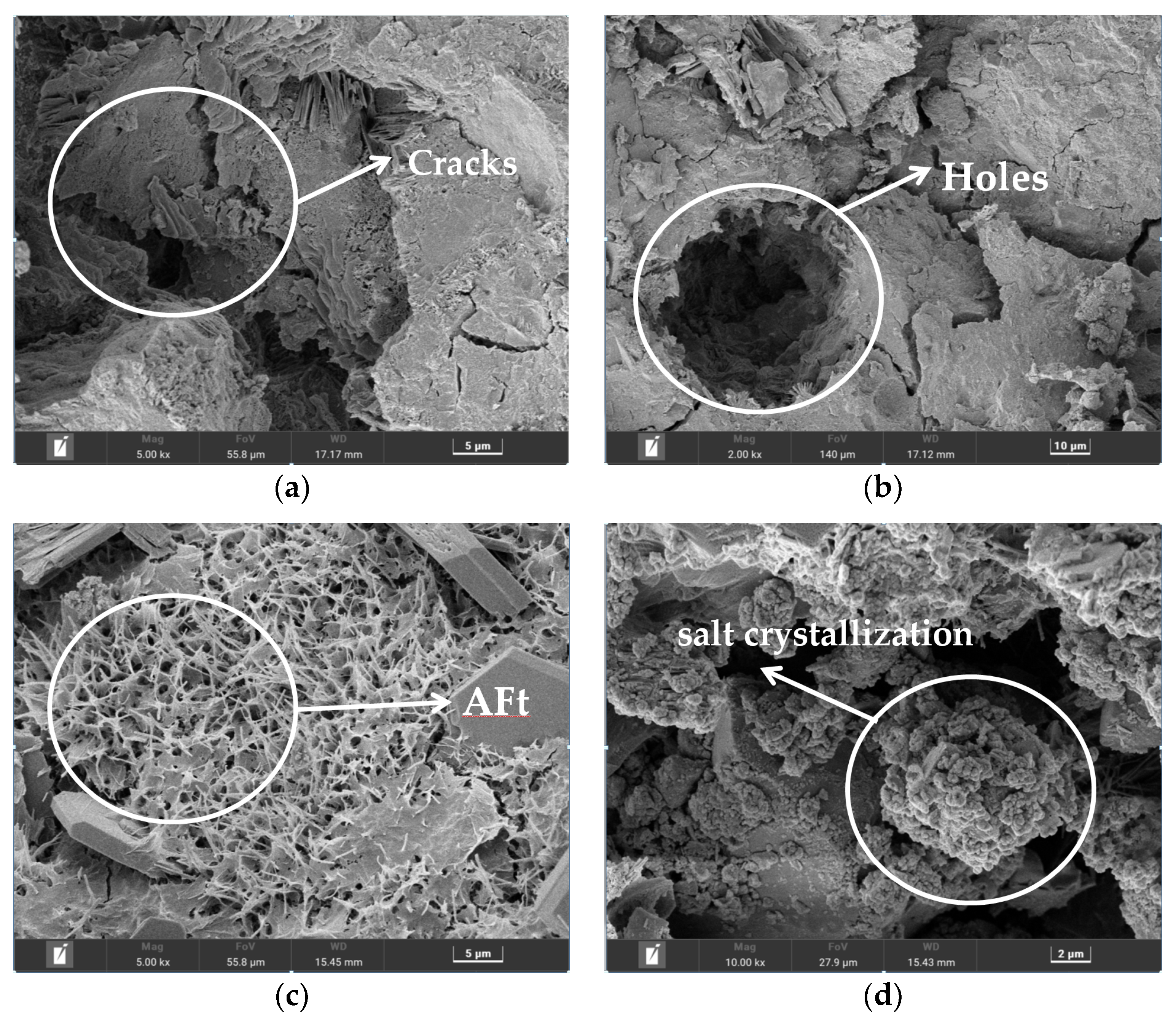

As can be seen from

Figure 10a,b, after the specimen is subjected to salt freezing cycles, the connection between the aggregate and the cement paste is gradually weakened, the transition zone of the cement–aggregate interface becomes loose and porous, and the aggregate and cement paste in the transition zone of the interface may even be directly separated. In addition, the pore size is gradually increased. This is because salt freezing damage to concrete can be viewed as a special form of freeze–thaw damage to concrete, which is far more severe than the damage produced by water freezing. (1) The water retention and hygroscopicity of salt increases the initial water saturation of concrete to some extent. When the initial water saturation is greater than the critical water saturation, tensile stresses are generated in the concrete; with an increase in the number of salt freezes, the damage to the concrete becomes increasingly severe [

37]. (2) When the temperature drops below 0 °C, part of the water inside the concrete freezes, and at the same time, the concentration of the salt solution inside the pores increases and produces a concentration difference, which causes the salt concentration balance inside the concrete to be broken. The free water in the other pores that is not frozen will flow to this place in order to reduce the concentration and establish a new equilibrium. The transfer of pore solution from one capillary pore to another generates osmotic pressure. When the osmotic pressure reaches or exceeds a critical value, it will crack the cement paste. (3) Supercooled water, due to the action of salt, is a type of water that remains liquid and unstable below 0 °C. It is not stable. It will cause icing in the concrete capillaries to accelerate and generate greater internal stresses which, in turn, will cause greater damage to the concrete interior. (4) When the salt solution melts, it needs to absorb heat from the concrete, making the temperature of the concrete in the frozen state drop, causing the formation of a temperature gradient in its interior, generating temperature stresses, and accelerating the rate of salt freezing damage to the concrete [

38].

In

Figure 10c, it can be seen that the formation of interlocking needle and granular corrosion products in the hydration products weakens the interconnection between the hydration products. As a result, the hydration forms a honeycomb shape, resulting in increased pore size and interconnection and reducing the densification of the hardened cementitious material and the formation of erosion channels. The formation of corrosion products requires the consumption of calcium hydroxide and calcium aluminate hydrate, which ultimately produces very low solubility and swollen, water-absorbing and needle-like crystals of calcium thioaluminate hydrate (AFt). As the number of salt freezing cycles increases, increasing amounts of calcium hydroxide and hydrated calcium aluminate in the hydration products are consumed, generating large amounts of agglomerated AFt. Where corrosion products gather, weak zones are easily formed, leading to the formation of microcracks in the concrete under the action of freezing pressure, crystallization pressure, and osmotic pressure, allowing a large number of corrosion ions to enter the interior of the concrete and the corrosion products to grow further. The interior of the paste becomes loose, more holes are formed, and the connection between the internal pores and crack is further strengthened.

Increasing granular salt crystal accumulation can be seen in

Figure 10d. The chloride salt solution reacts with Ca(OH)

2 within the concrete to form CaCl

2⋅Ca(OH)

2⋅nH

2O complex salt. The compound salt is an expansive substance that is mainly concentrated in the surface layer of the concrete. When concrete is subjected to salt freezing, the freezable water inside it freezes and produces a volume expansion of about 9%, which can easily cause spalling of the concrete surface. In addition, because the generation of complex salt consumes a large amount of Ca(OH)

2 in the concrete, preferential access to the specimen inside the chlorine salt involved in the reaction of C

3A and other minerals is generated by the brittle “Friedel” salt, with the brittleness hindering the continuation of hydration and disrupting the equilibrium between C-S-H and Ca(OH)

2. This leads to the decomposition of C-S-H gel, accelerating the collapse of the concrete surface and damaging the structure of the concrete. This produces decomposition of the C-S-H gel, accelerating the collapse of the concrete surface and destroying the concrete structure.

In a single environment, both chloride and sulfate can react with monosulfide-type hydrated calcium thioaluminate (AFm), with the chloride erosion product being “Friedel” salt and the sulfate erosion product being calcovanadate (AFt). However, the erosion products in the composite solution of the two salts has an impact on the factors affecting its erosion in a number of ways, including reactant concentration, erosion time, erosion mode, and the nature of the two ions in the erosion process performance. Cl

− diffuses much faster than SO

42−, and because both can react with the hydration products of cement, the erosion products are related to the relative concentrations of SO

42− and Cl

− [

39]. At higher concentrations of chloride salts, the “Friedel” salts are produced in large quantities, which improve the internal pore structure of the concrete and slow down the erosion of sulfates. On the contrary, if the concentration of sulfate is high, sulfate reacts with the hydration product AFm to form a large amount of AFt which, in turn, reduces the chemical binding of chloride ions. When the difference between the concentrations of sulfate and chloride salts in solution is small, the reaction pattern can be divided into the following steps [

40]. (1) The fast-diffusing chloride ions first react with the hydration products of the cement to form “Friedel” salts. (2) Sulfate ions react with CH to form gypsum, which reduces the pH of the solution. (3) The “Friedel” salts decompose under low-pH conditions. (4) Sulfate ions continue to enter the cementitious matrix to form AFt. Balonisd et al. [

41] investigated the relationship between the transformations of Cl-AFm, SO-AFm, and CO

3-AFm by synthesizing “Friedel” salt, as shown in

Figure 11. It can be found that the three salts can be converted into each other, and the main controlling factors are the concentrations of Cl

− and SO

42−.

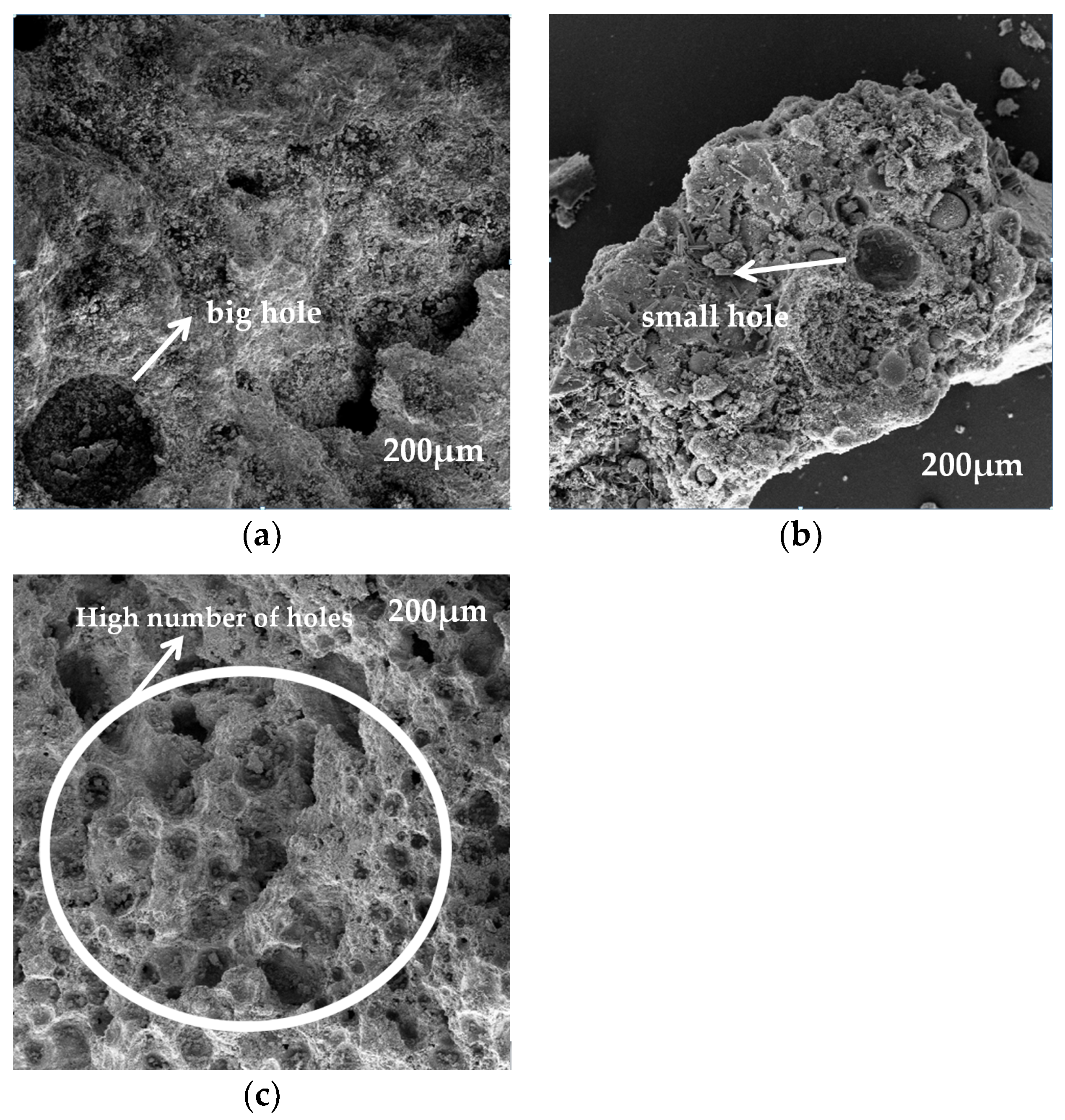

As can be seen from

Figure 11, there are also differences in the pore structure of aerated concrete prepared with different substitution rates of silica–manganese slag. As can be seen in

Figure 12a, the pore wall thickness of the pores is high, and the pore samples are mostly circular, when the silica–manganese slag substitution rate is 0%. It can be seen in

Figure 12b that when the substitution rate of silica–manganese slag is 10%, the hydration products that play the role of skeleton support increase, the pore wall is thick, the porosity is low, and most of them are closed pores.

Figure 12c shows that the pore size distribution is not uniform during the continuous increase in the silica–manganese slag substitution rate to 20%, and there is an overlapping of pores. Most of these are connected pores. It can be seen that when the replacement rate of silica–manganese slag is too high, the main reason for the decrease in performance is the thinning of the pore wall. After the thickness of the pore wall is reduced, the support force of the specimen becomes weak, and it is easy to form connected pores, thus reducing the mechanical properties of the material.

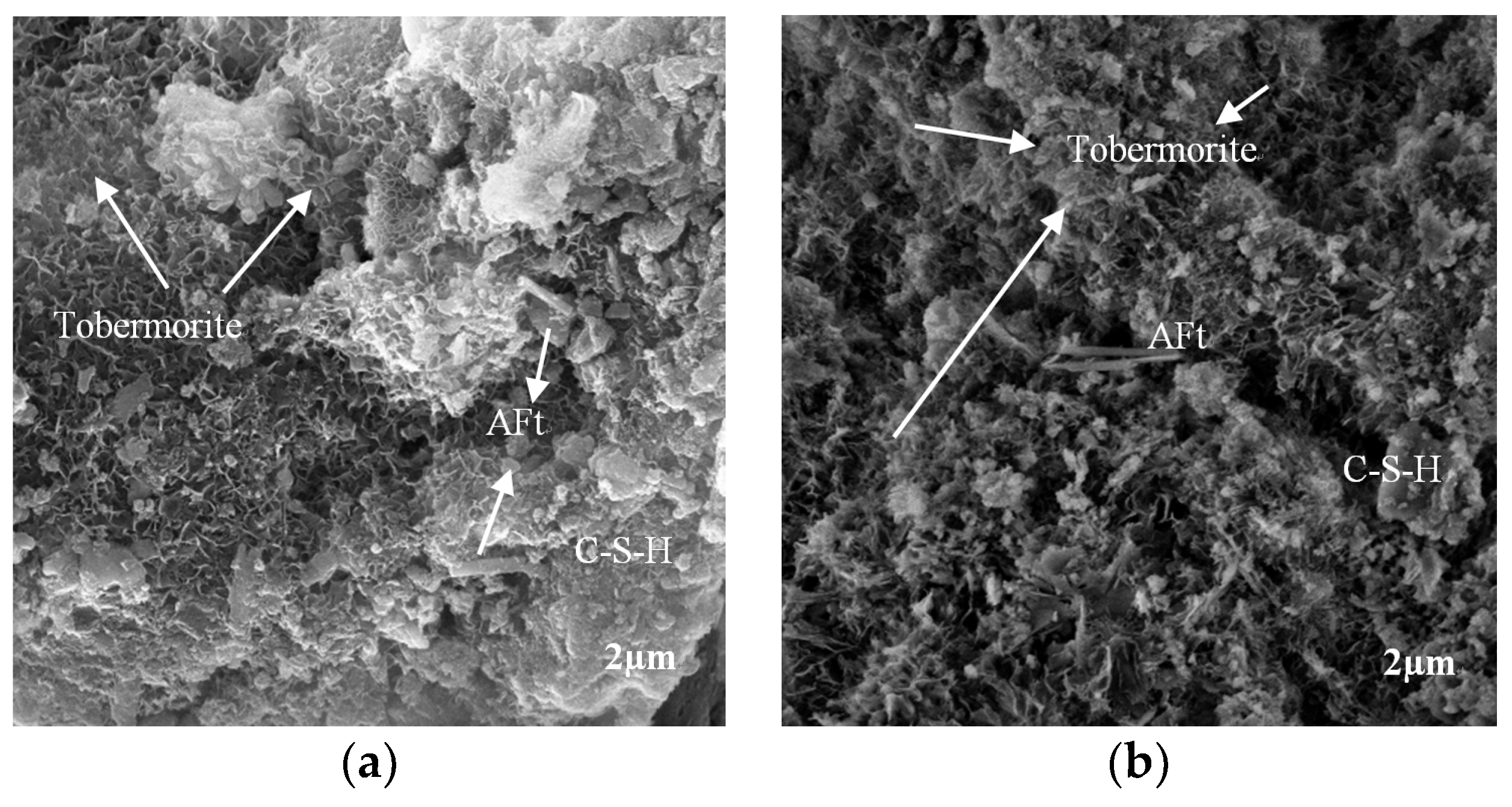

Figure 13 shows that when the replacement rate of silica–manganese slag is 10%, the hydration products of aerated concrete are dense and there is a large amount of well-crystallized flocculated C-S-H gel. This gel is tightly intertwined with 1~4 µm long rod-shaped calcium alumina and part of the blade-shaped tobermorite. A small amount of the raw materials not involved in the reaction are covered by the hydration products, and the hydration reaction is more complete, forming a denser mesh structure. The concrete specimens, with leaf-shaped and needle-shaped tobermorite crystals and C-S-H gel, are interlaced longitudinally and transversely to form a three-dimensional mesh structure. In the concrete specimens, the leaf-like and needle-like tobermorite crystals and C-S-H gel were interlaced to form a three-dimensional mesh skeleton structure which was connected with the C-S-H gel, playing a more effective role in providing strength and support [

42,

43]. During the hydration process, SiO

2 in the silica–manganese slag is activated, and the degree of crystallization of the hydrated calcium silicate is increased, producing tobermorite crystals. In addition, it is mainly because silica–manganese slag replaces cement that the content of tricalcium aluminate (C

3A) in cement is reduced. C

3A is the main reactant for the generation of hydrated calcium silicate, and the most important factor is that sodium sulphate can react with hydrated calcium silicate to produce calcium vanadate. Therefore, silica–manganese slag is added to lower the amount of calcium vanadate produced, thereby improving the specimen’s resistance to salt freezing.

6. Damage Modeling of Silica–Manganese Slag Concrete under Salt Freezing Cycle

In predicting the service life of concrete structures, the duration predicted using deterministic models is somewhat ambiguous; thus, it is necessary to accurately predict the service life of concrete by using the probabilistic method. The Weibull model is frequently used to reflect the probability distribution of material failure, and its service life prediction function is widely used in various fields [

44].

The cubic compressive strength (

S) was chosen to be explored as the value of the damage variable (

D). The evolution formula is shown in Equation (4), and the calculated values are shown in

Table 5.

Here,

S0 represents the compressive strength at the initial time, and

Sn is the compressive strength after

n salt freezing cycles.

The probability density function of the two-parameter Weibull model for different numbers of salt freezing cycles is provided in Equation (5):

Integrating with respect to the density allows one to obtain the distribution function of the two-parameter Weibull model, as shown in Equation (6), for different numbers of salt freezing cycles:

The corresponding reliability function for the two-parameter Weibull is Equation (7):

The failure rate function for the two-parameter Weibull is Equation (8):

Equation (9) calculates the damage degree value and the distribution function:

Constant deformation and simultaneous logarithms on both sides of Equation (9) produce the following equation, Equation (10):

If we let

,

,

, and

, the equation for the line is obtained via equivalent substitution, as shown in Equation (11):

In each equation, η is the value of the degree of material damage, β is the Weibull shape parameter, and N is the number of salt freezing cycles.

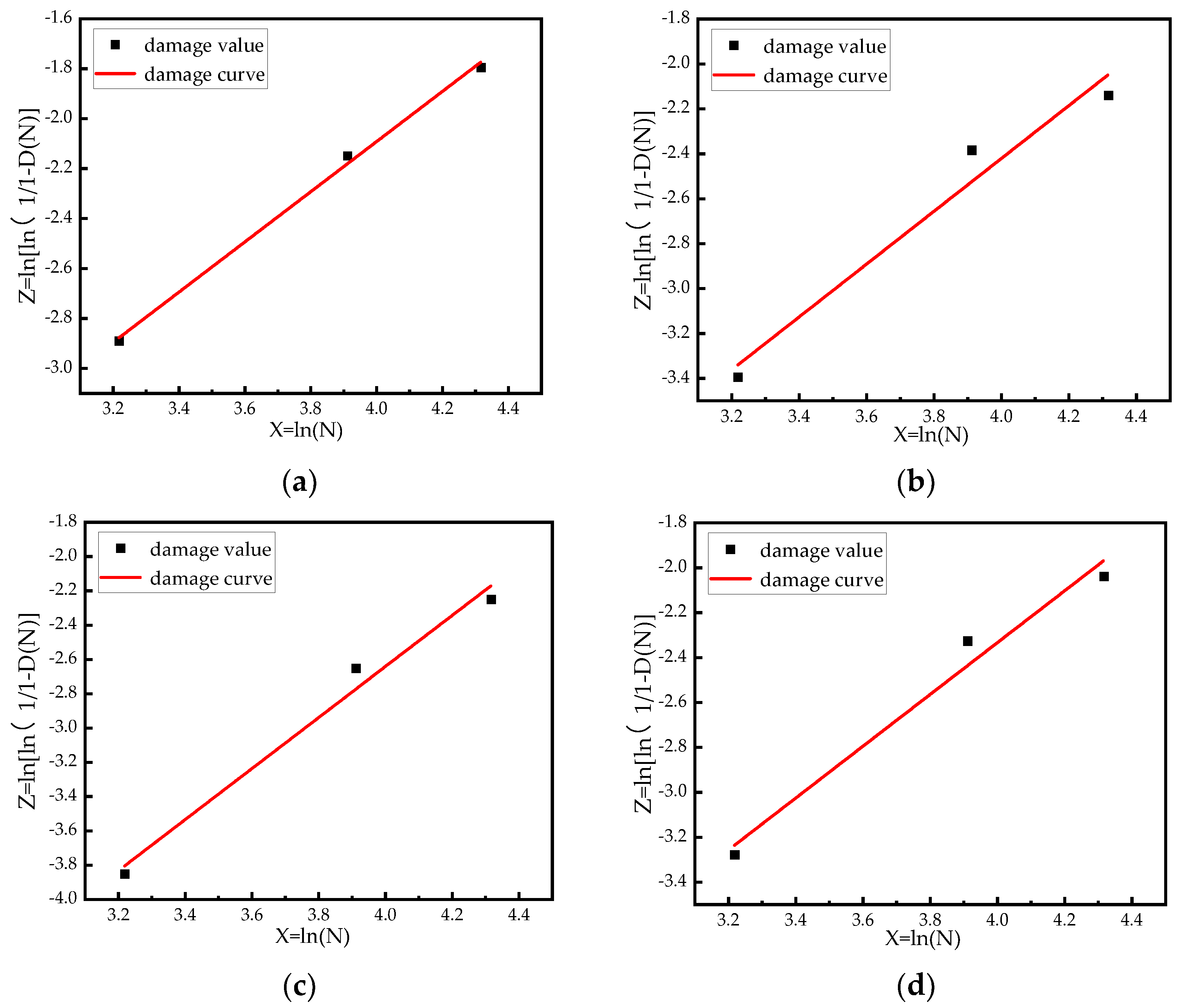

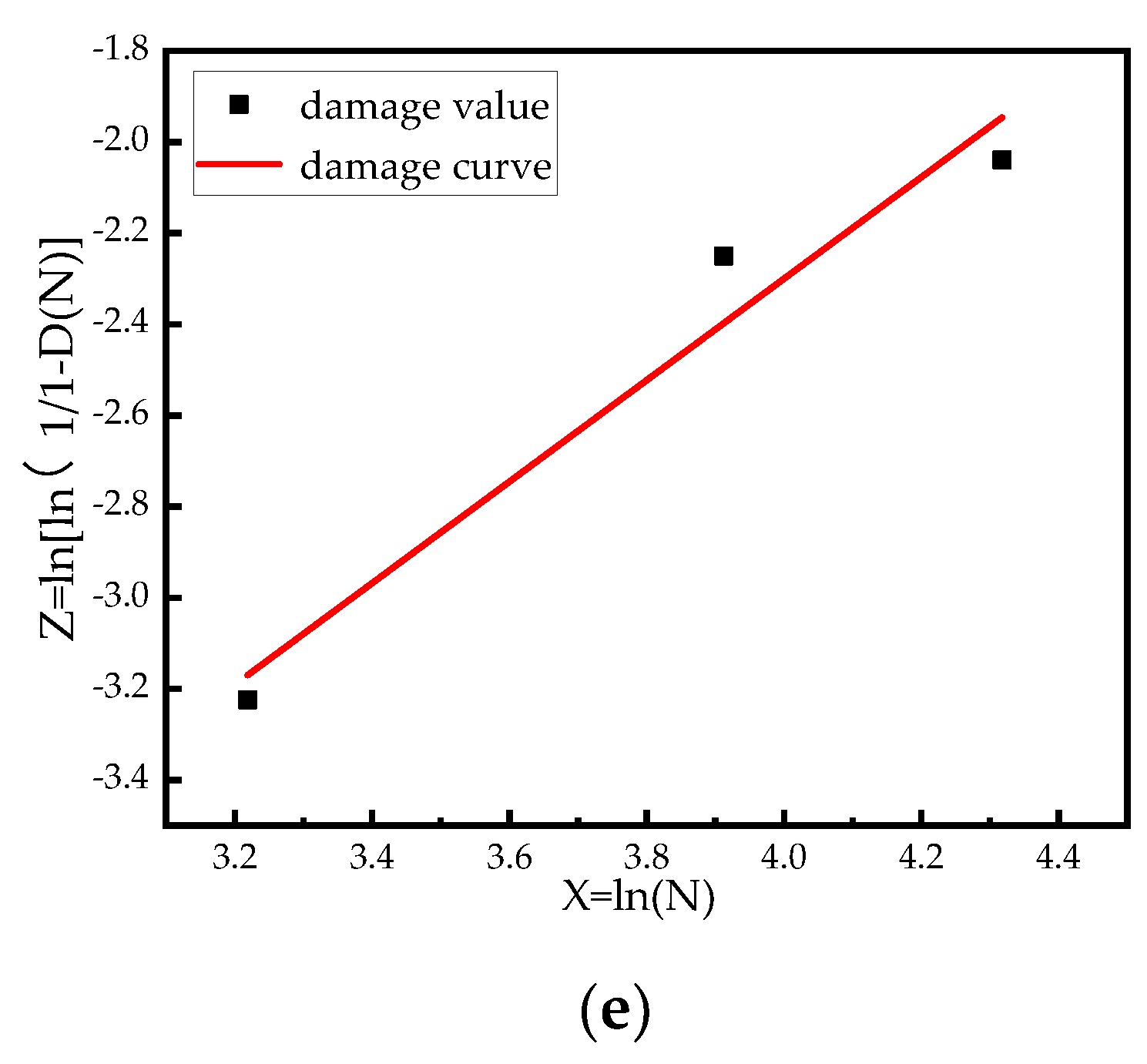

The fitting of the damage degree value data with the Weibull distribution yielded a fitting plot, as shown in

Figure 14. The relevant parameters are shown in

Table 6.

The values of each parameter in the table were brought into Equation (5) to obtain specific expressions for the values of the damage variables and the number of cycles for each mix ratio, as shown in

Table 7.

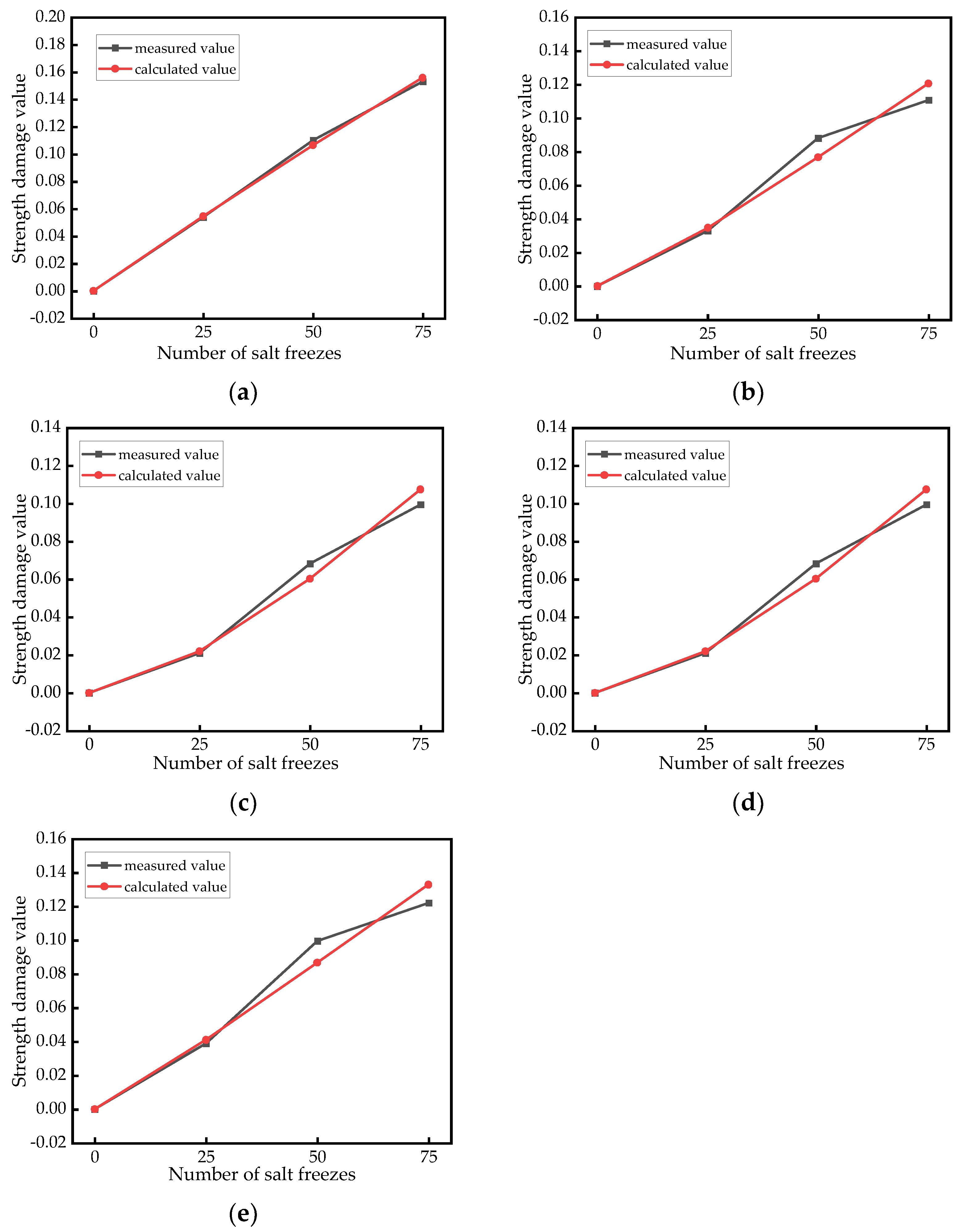

Figure 15 shows the results of assigning a value to the number of salt freezing cycles

N in

Table 7 and comparing it with the measured value.

From

Figure 14, it can be seen that the values of the degree of damage of each group of specimens are uniformly distributed on both sides of the fitted curve of the Weibull distribution function, and the distribution characteristics of each group are roughly the same. These values are approximately the same as those of the linear distribution, allowing us to conclude that the model’s fitting correlation is high. As can be seen from

Table 6, the fitting parameters of each group are above 0.916, which permits us to conclude that the Weibull model has a good fitting effect. From

Figure 15, it can be seen that the error between the measured value and the calculated value is small, indicating that the damage pattern of the specimen corresponding to the test under the action of salt freezing can be better analyzed and predicted with the Weibull distribution function. After the specimens were subjected to the same number of salt freezes, the damage value was smallest when the replacement rate of silica–manganese slag was 10%, which was in line with the tests carried out in the previous section. The damage values of the remaining groups of silica–manganese slag concrete were smaller than those of the basic group C-1. This confirms that silica–manganese slag can improve the resistance of specimens to salt freezing.

7. Conclusions

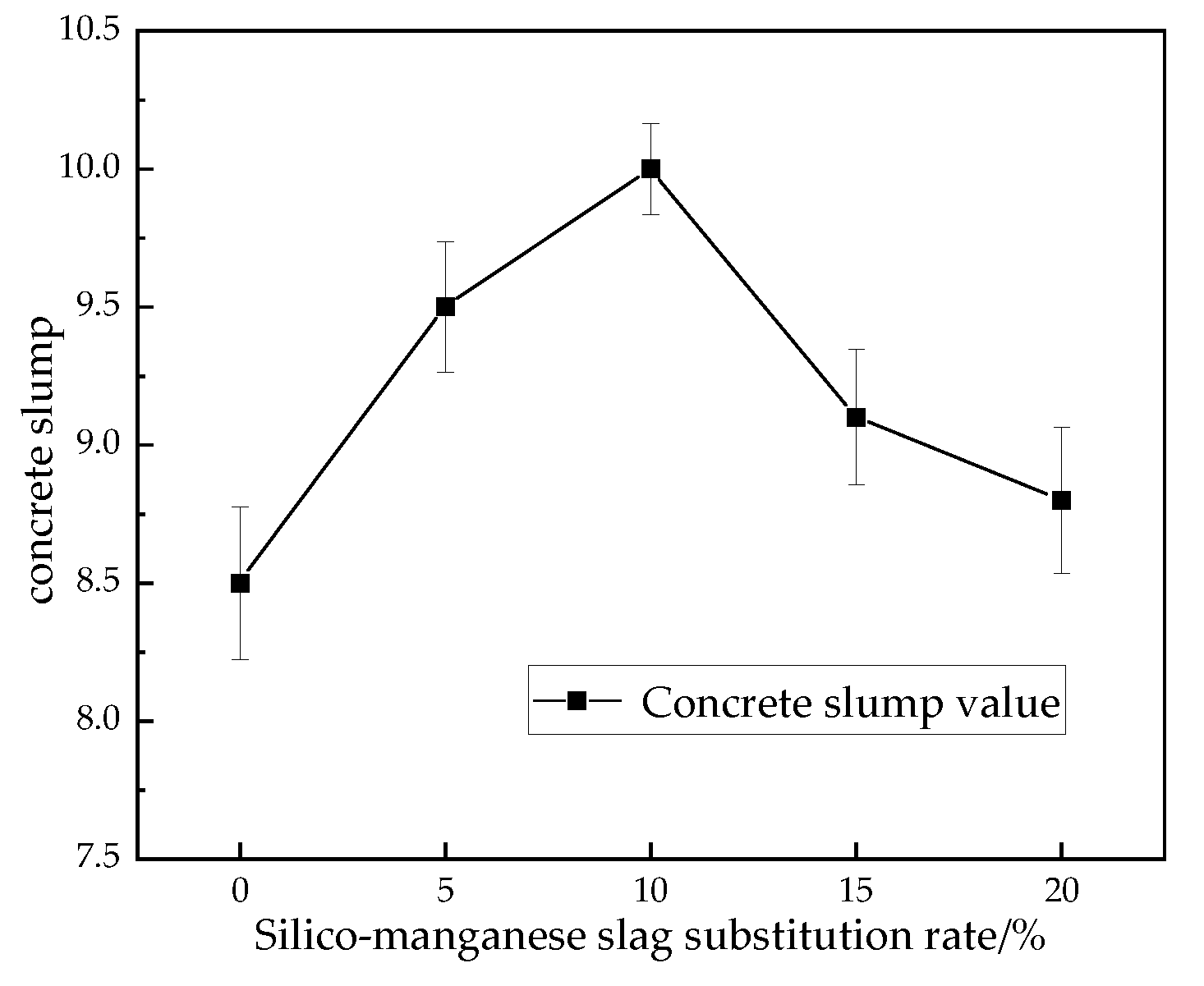

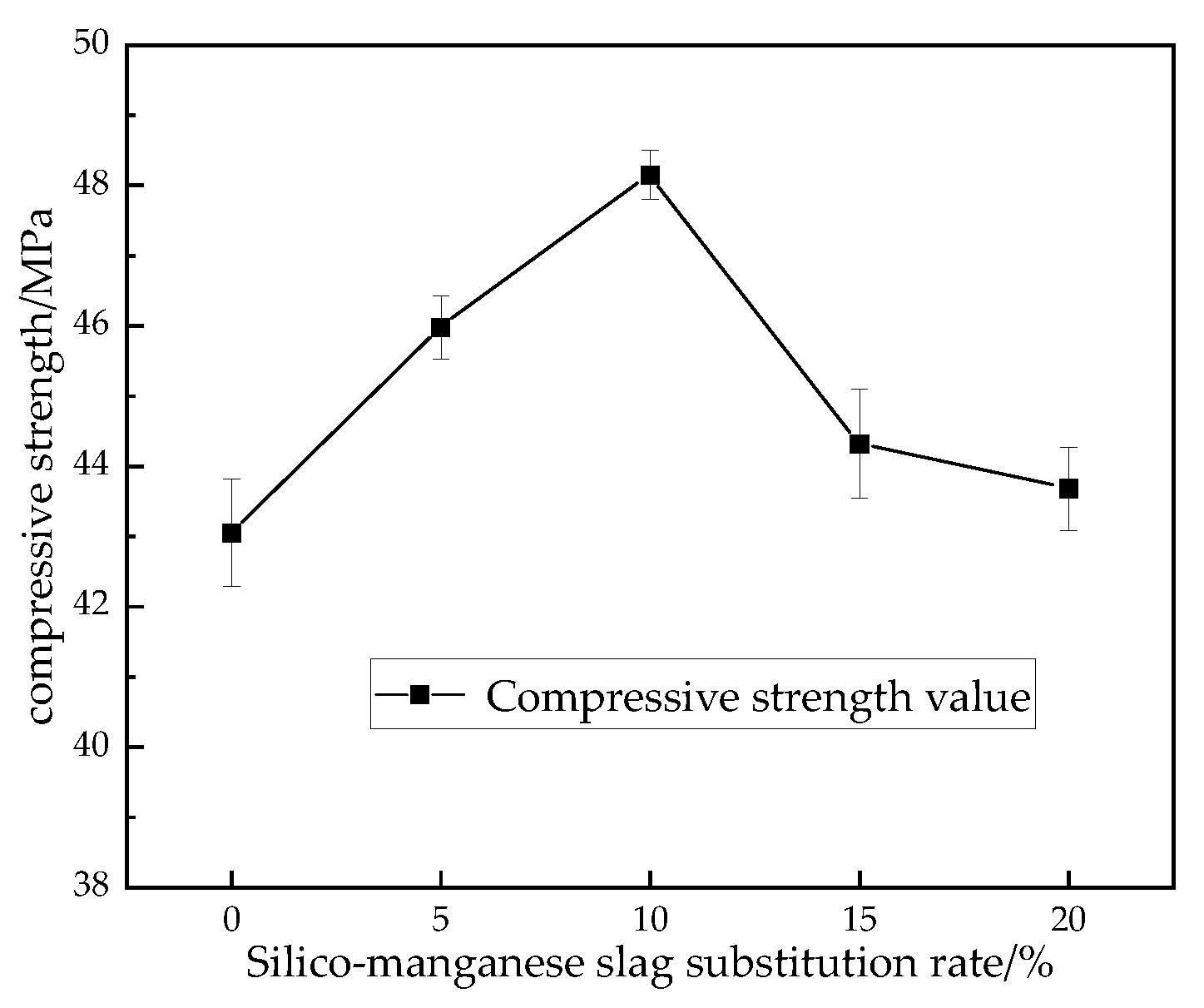

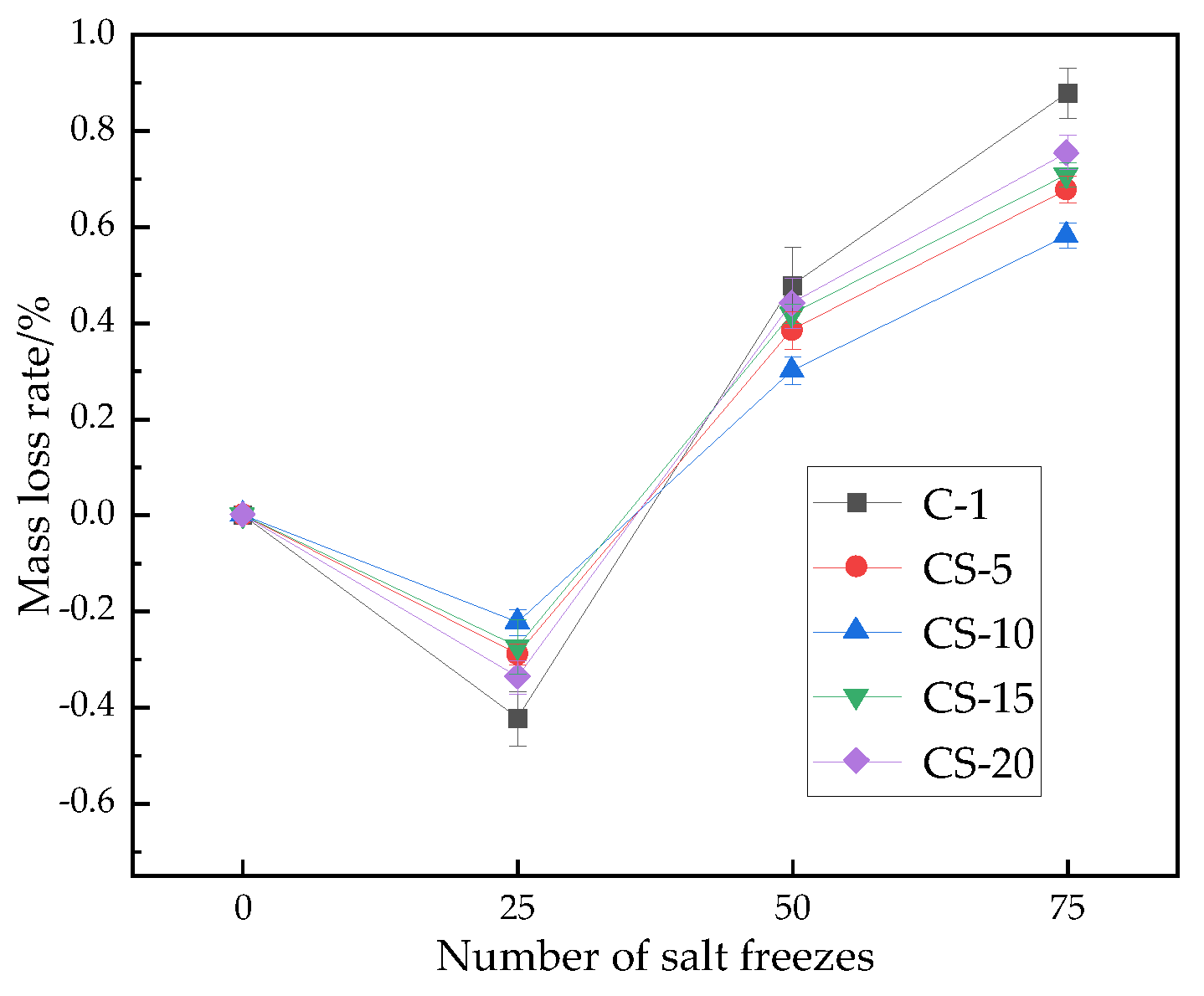

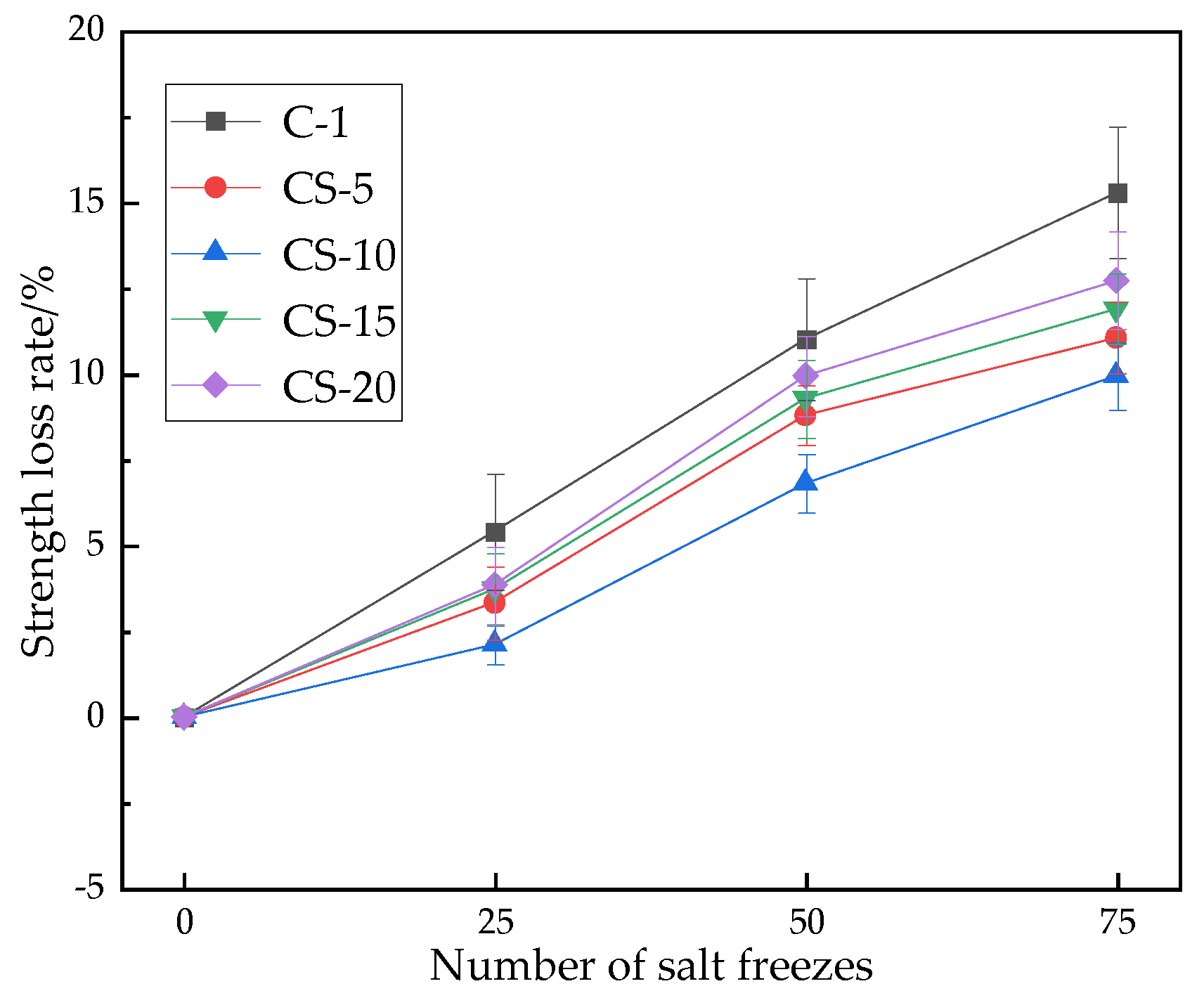

(1) Silica–manganese slag had an enhancing effect on the slump, compressive strength, and salt freezing resistance of concrete. When the substitution rate was 10%, the slump and compressive strength reached 10.0 cm and 48.15 MPa, respectively; these rates were enhanced by 17.64% and 11.85% compared with the basic group. After the salt freezing cycles reached 75, the mass loss rate and strength loss rate were lower than those in the rest of the groups, reaching 0.582% and 9.954%, respectively; these rates were 33.71% and 34.96% lower than those in the basic group.

(2) With the freezing and thawing cycle playing a supporting role in the main aggregate and because of the continuous dry and wet freezing and the expansion and salt erosion, the structure began to appear separated and broken, leading directly to a loss of strength. However, silica–manganese slag contains Al2O3, SiO2, and other chemical elements, and, like fly ash, it has a volcanic ash effect and an activity effect. Silica–manganese dregs can help reduce the generation of AFt in cement hydration products. Silica–manganese dregs and hydration of cement hydrates can form a supportive skeleton structure, filling the pores and cracks in the internal structure and making the concrete structure more dense. However, silica–manganese slag is not suitable for particularly large replacement rates.

(3) Electron microscope scanning showed that when the substitution rate of silica–manganese slag was 10%, the hydration products of the specimen were mostly tobermorite crystals and C-S-H gels with high support strength, and the pore walls of the air holes were thicker, with fewer connecting pores. The hydration reaction was the most thorough at this rate, and various hydrides were interspersed longitudinally and formed a three-dimensional reticulated skeleton structure. Analyzing the macroscopic data and microscopic images led us to conclude that the recommended replacement rate of silica–manganese slag is 10%.

(4) The fitting coefficients for the two-parameter Weibull model were above 0.916, and the experimental and predicted values had high correlation and agreement, indicating that the model had a good fitting effect. This shows that the established damage model can predict the performance of silica–manganese slag concrete and provide a theoretical basis for subsequent investigations.

(5) Although the mechanical properties and salt freezing resistance of silica–manganese slag concrete were investigated in the tests, in order to study the properties of silica–manganese slag concrete more comprehensively, studies should be carried out on the penetration rate of corrosive ions, the performance of silica–manganese slag concrete under dry and wet cycling, and the performance of silica–manganese slag concrete under high-temperature environments.