Experimental Study on the Mechanical Properties of Steel Fiber Ferronickel Slag Powder Concrete

Abstract

1. Introduction

2. Materials and Methods

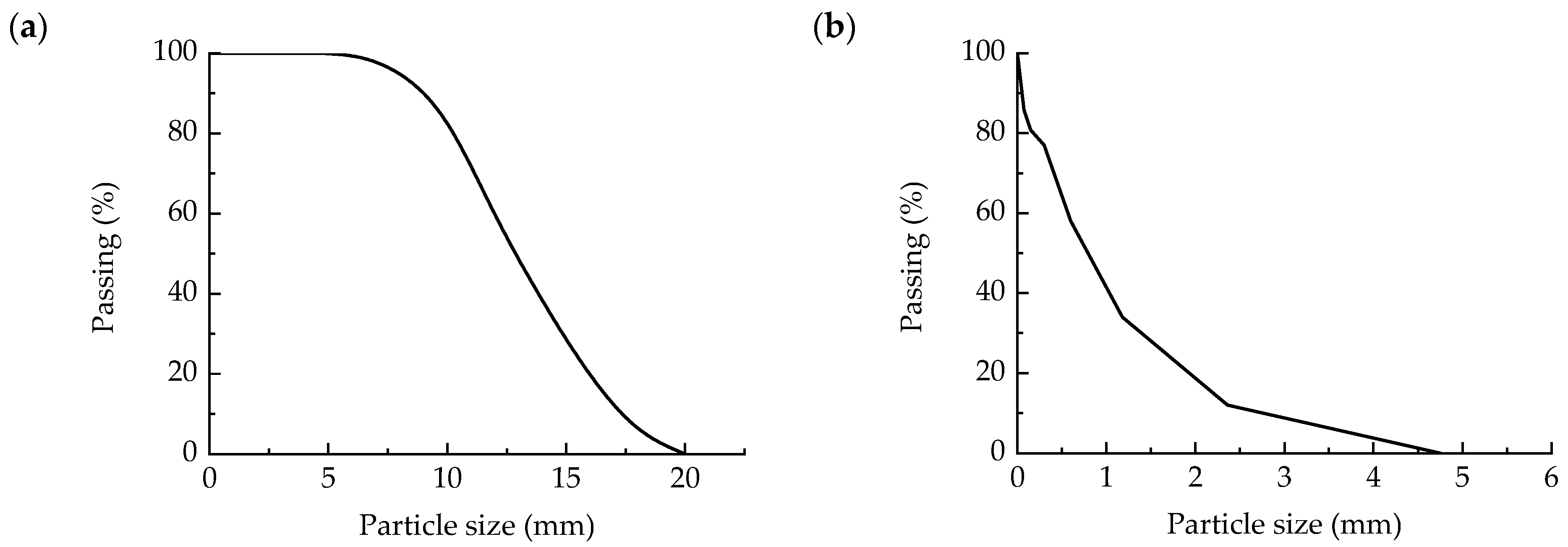

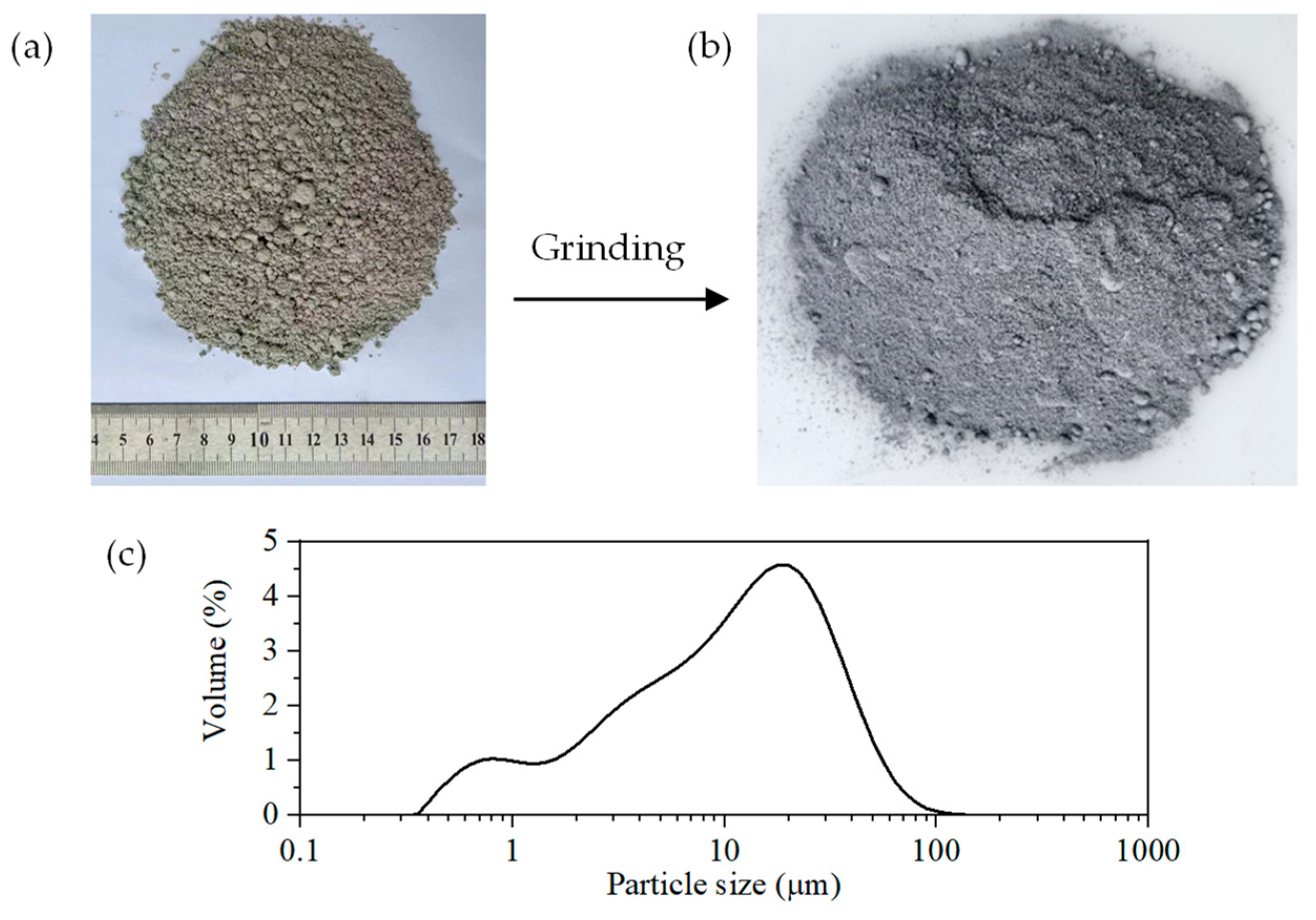

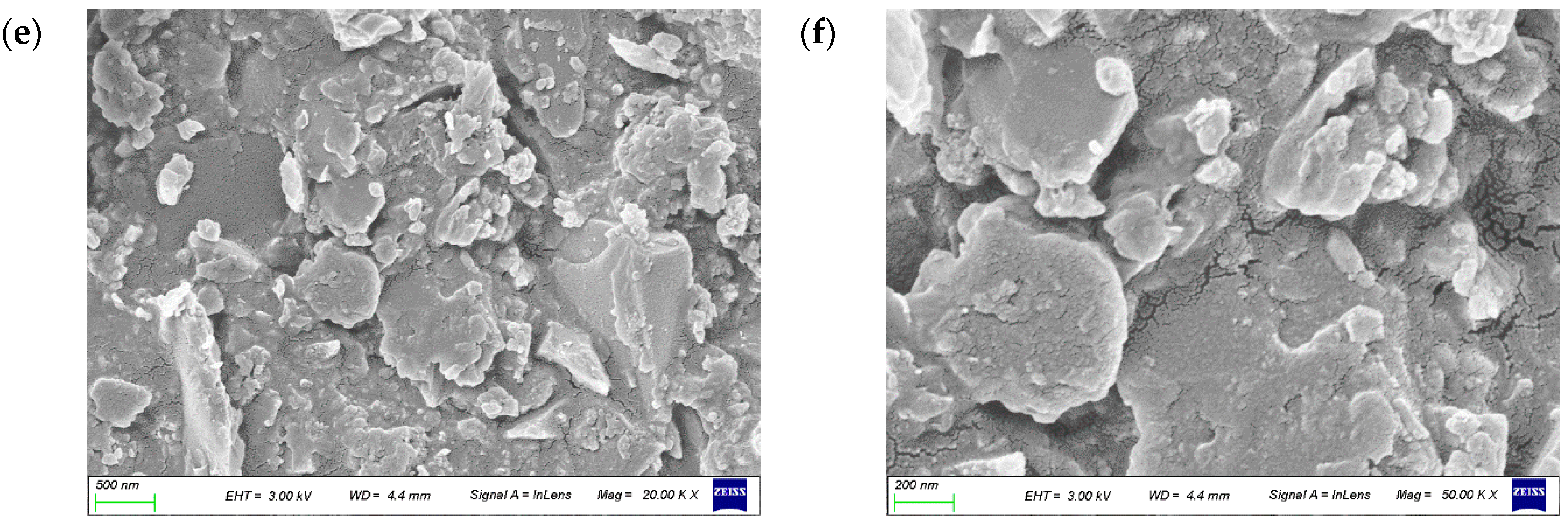

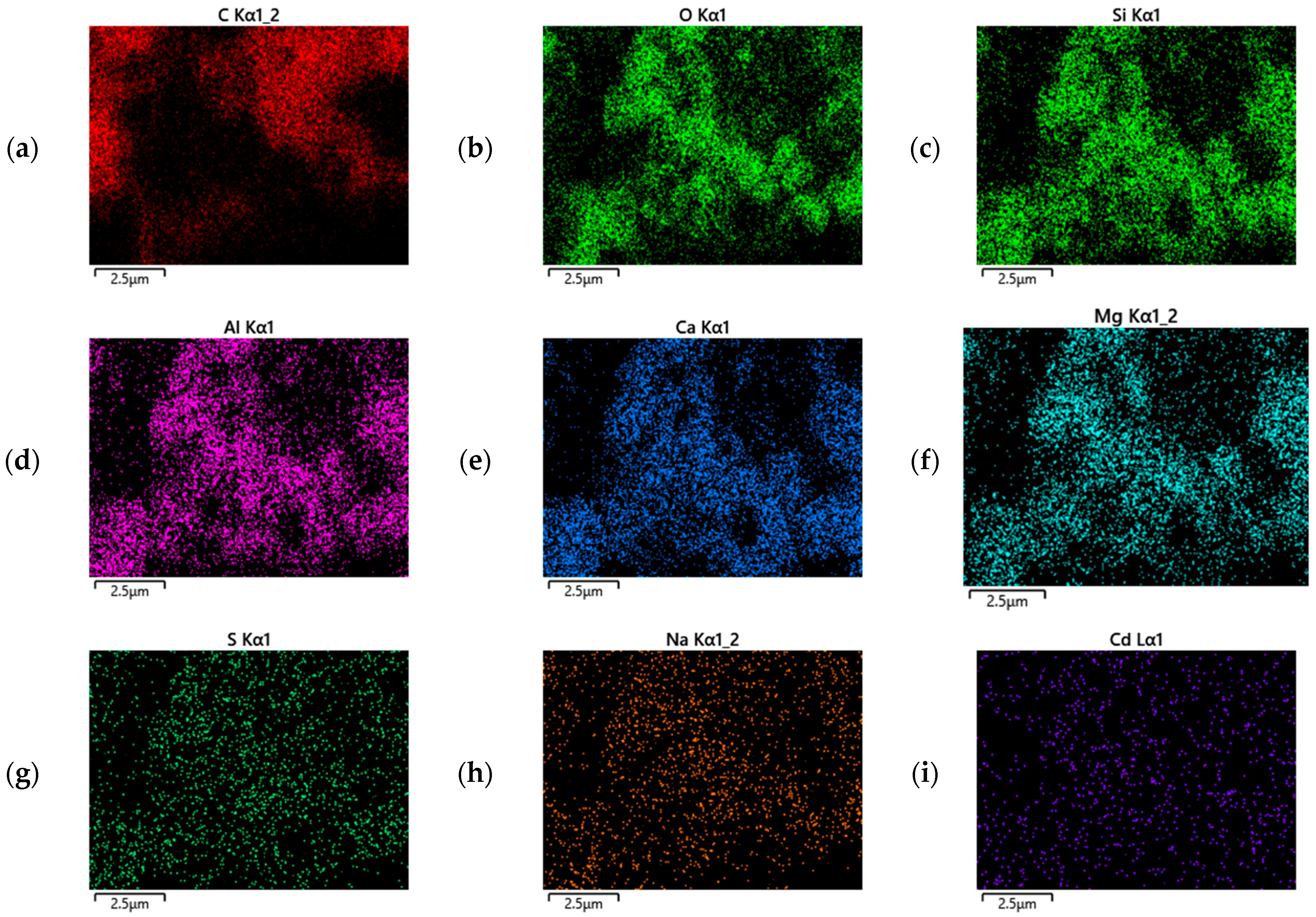

2.1. Raw Materials

2.2. Mix Proportion

2.3. Strength Test

2.4. Stress–Strain Testing

3. Results and Discussion

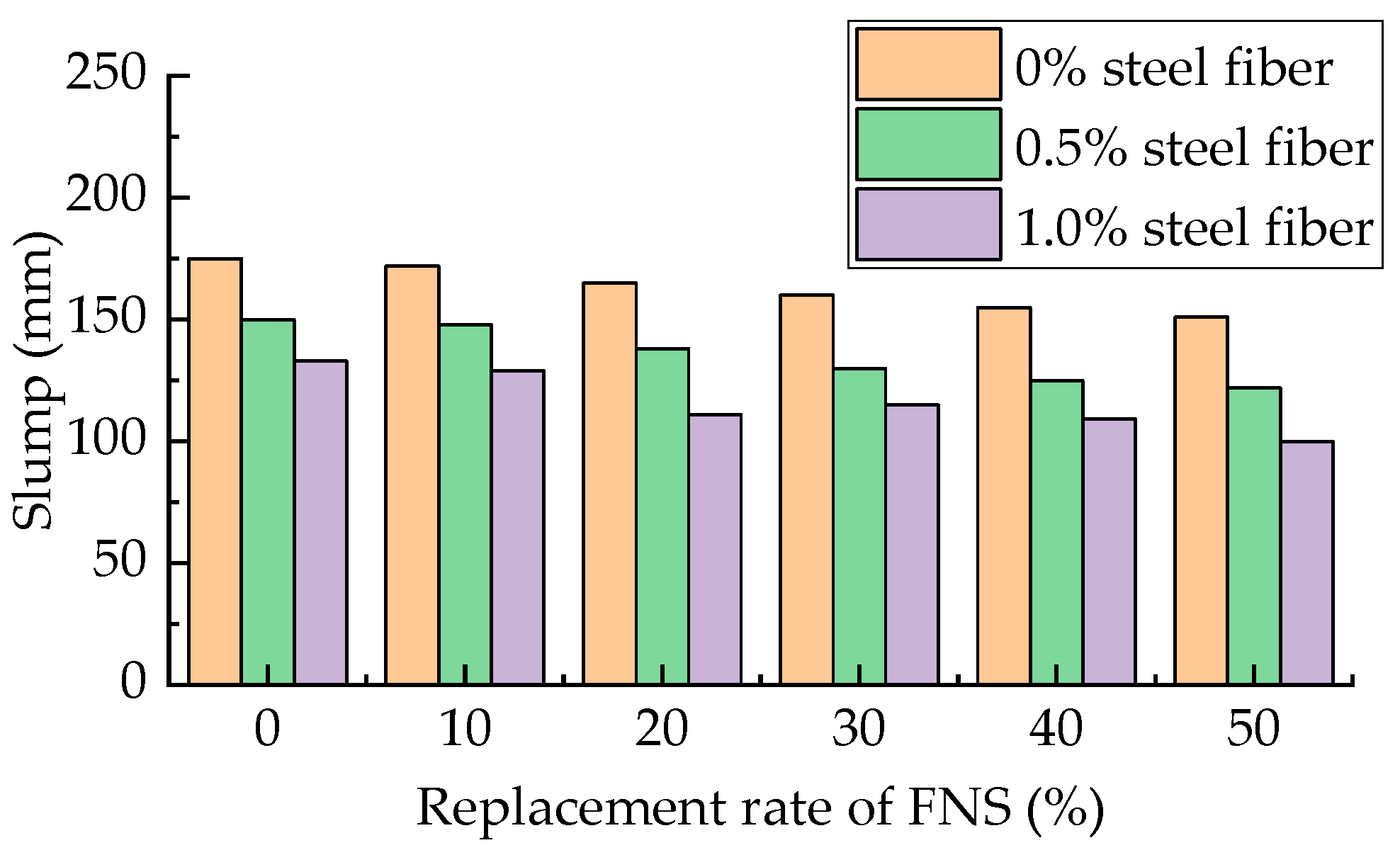

3.1. Slump

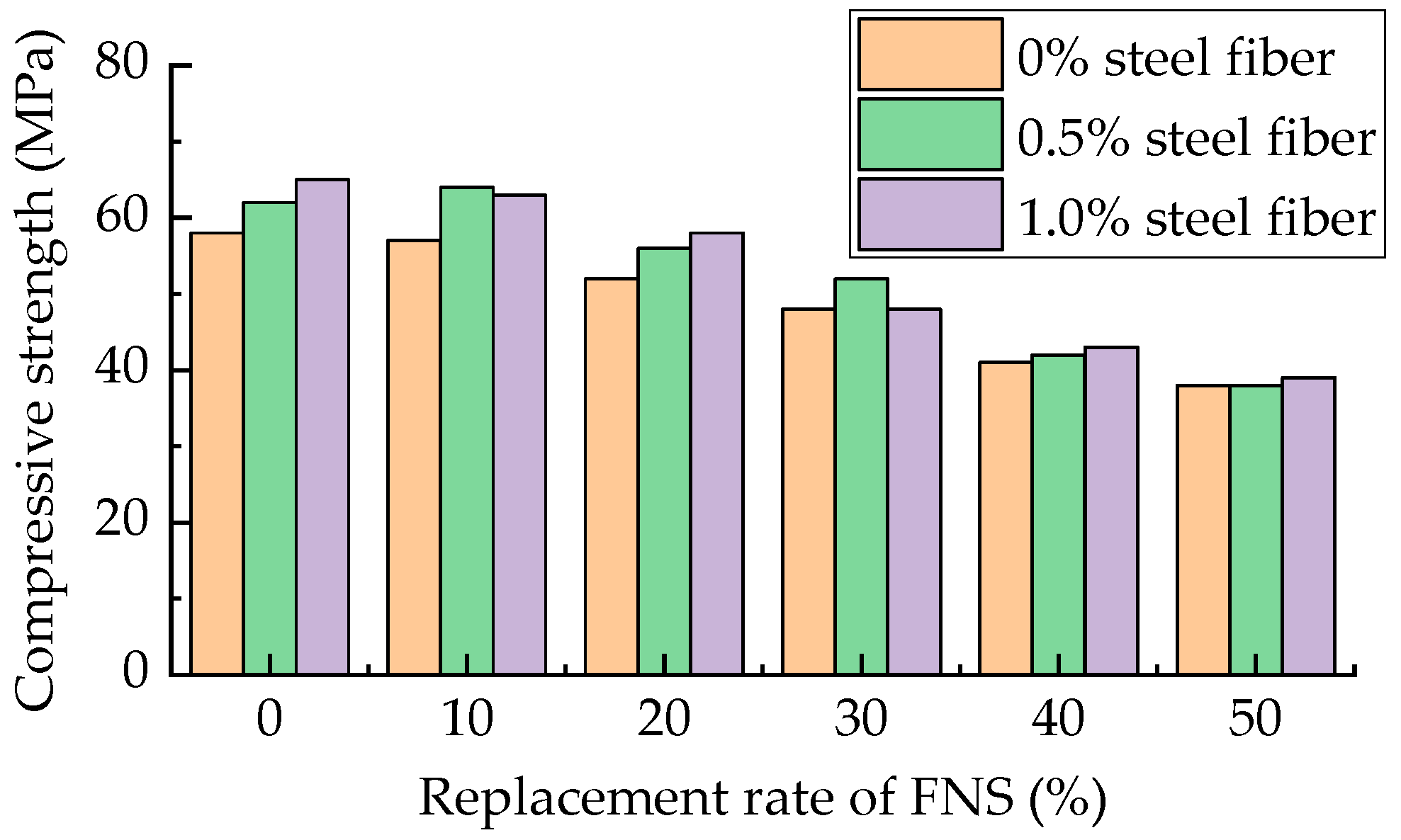

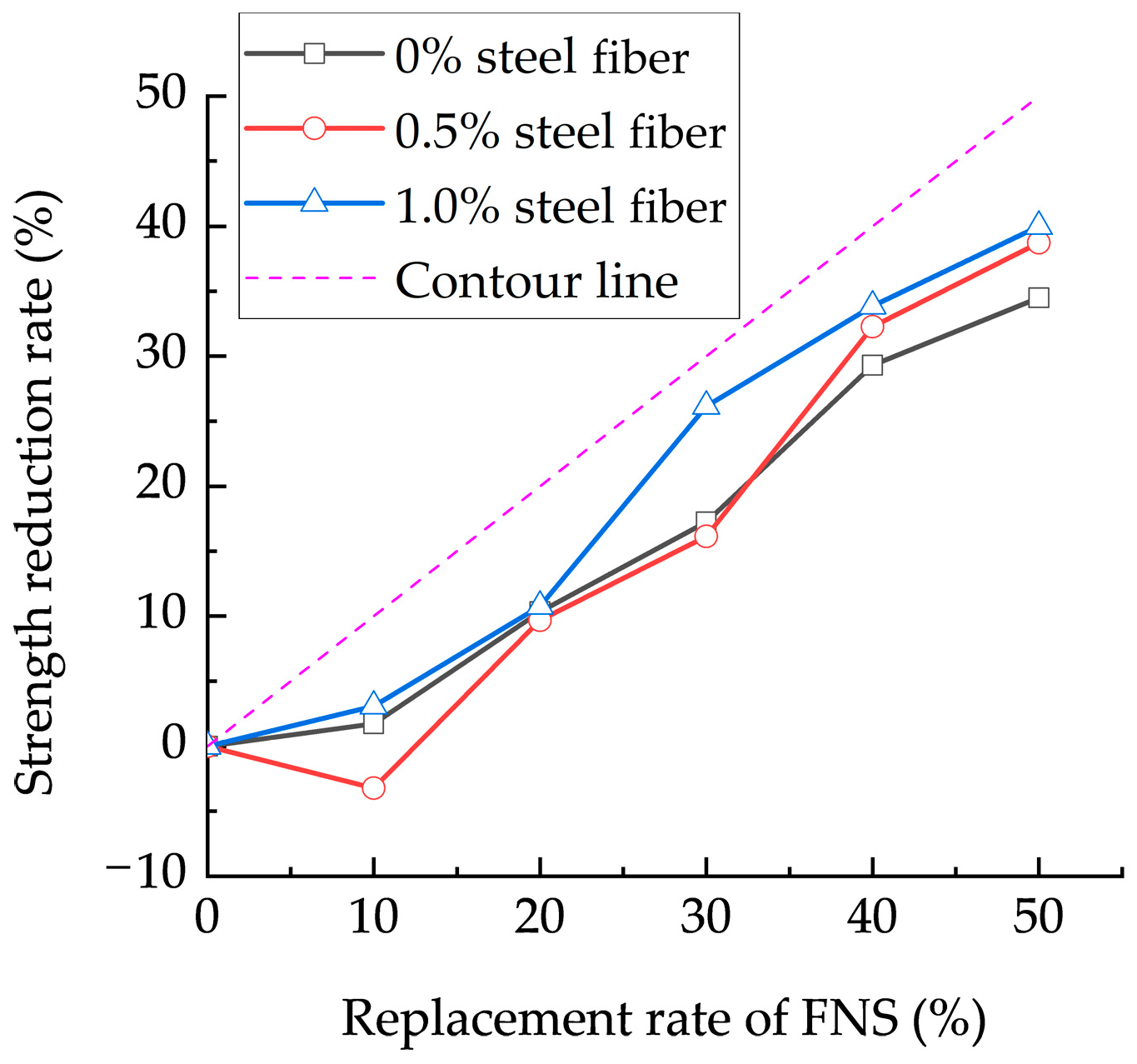

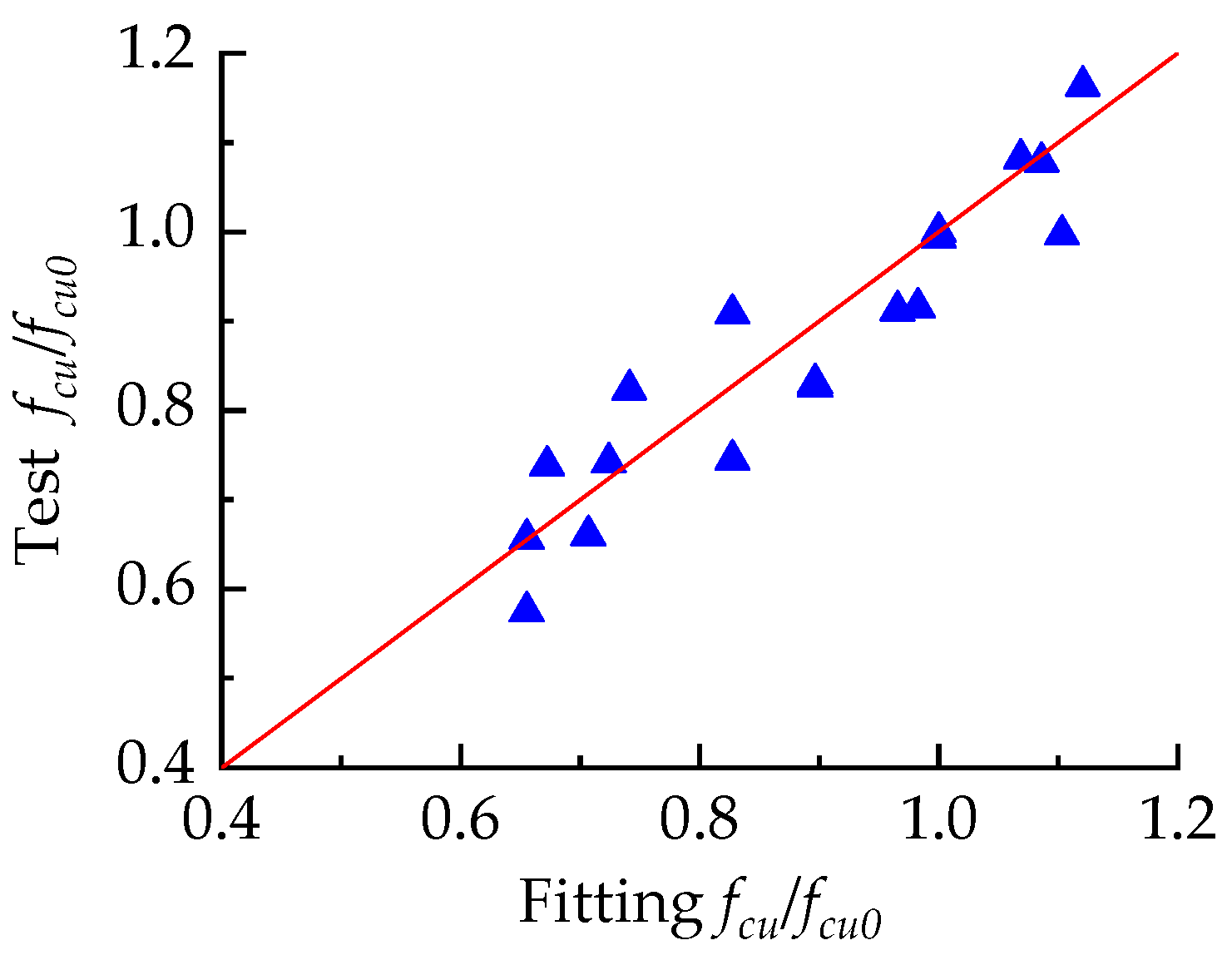

3.2. Compressive Strength

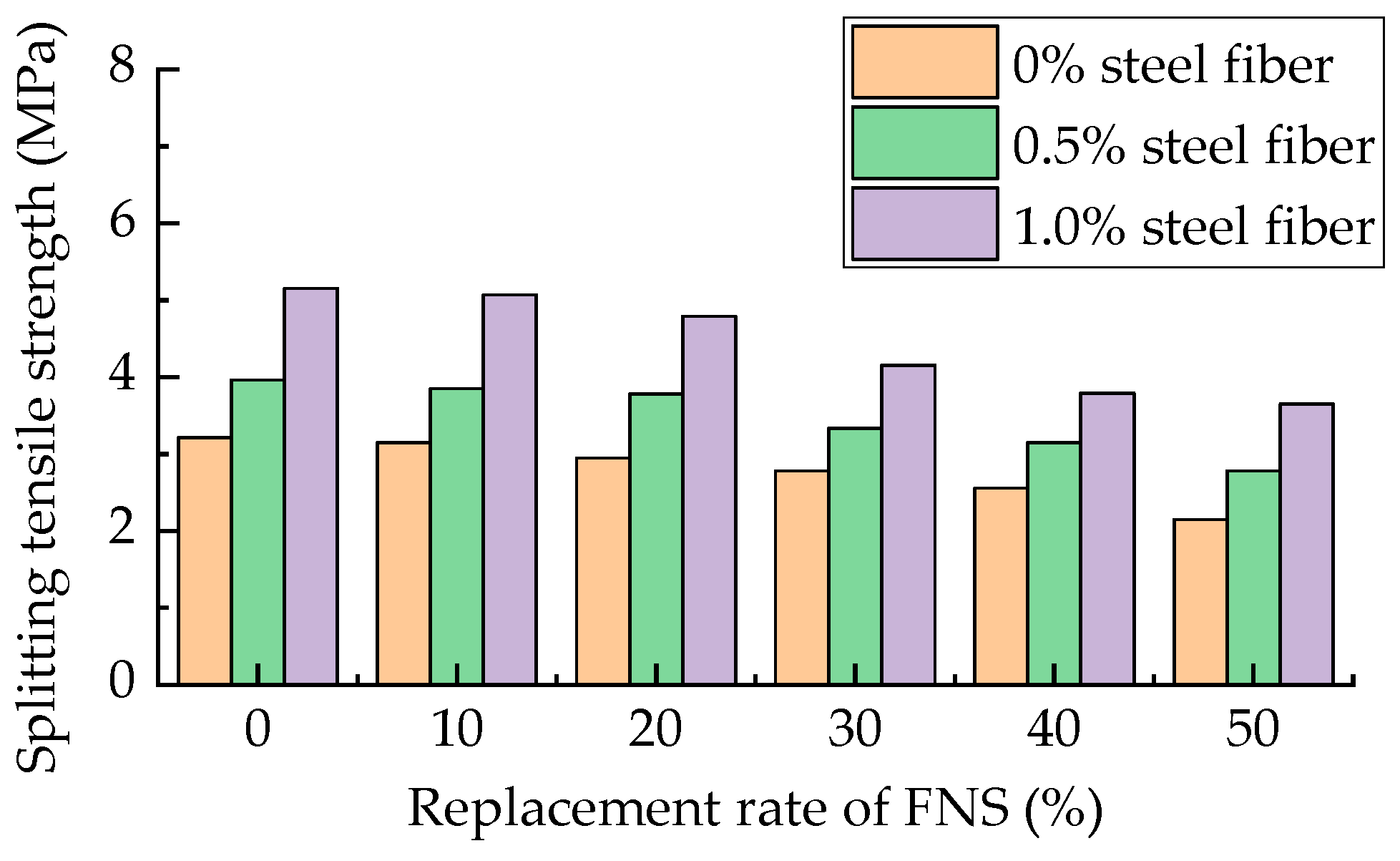

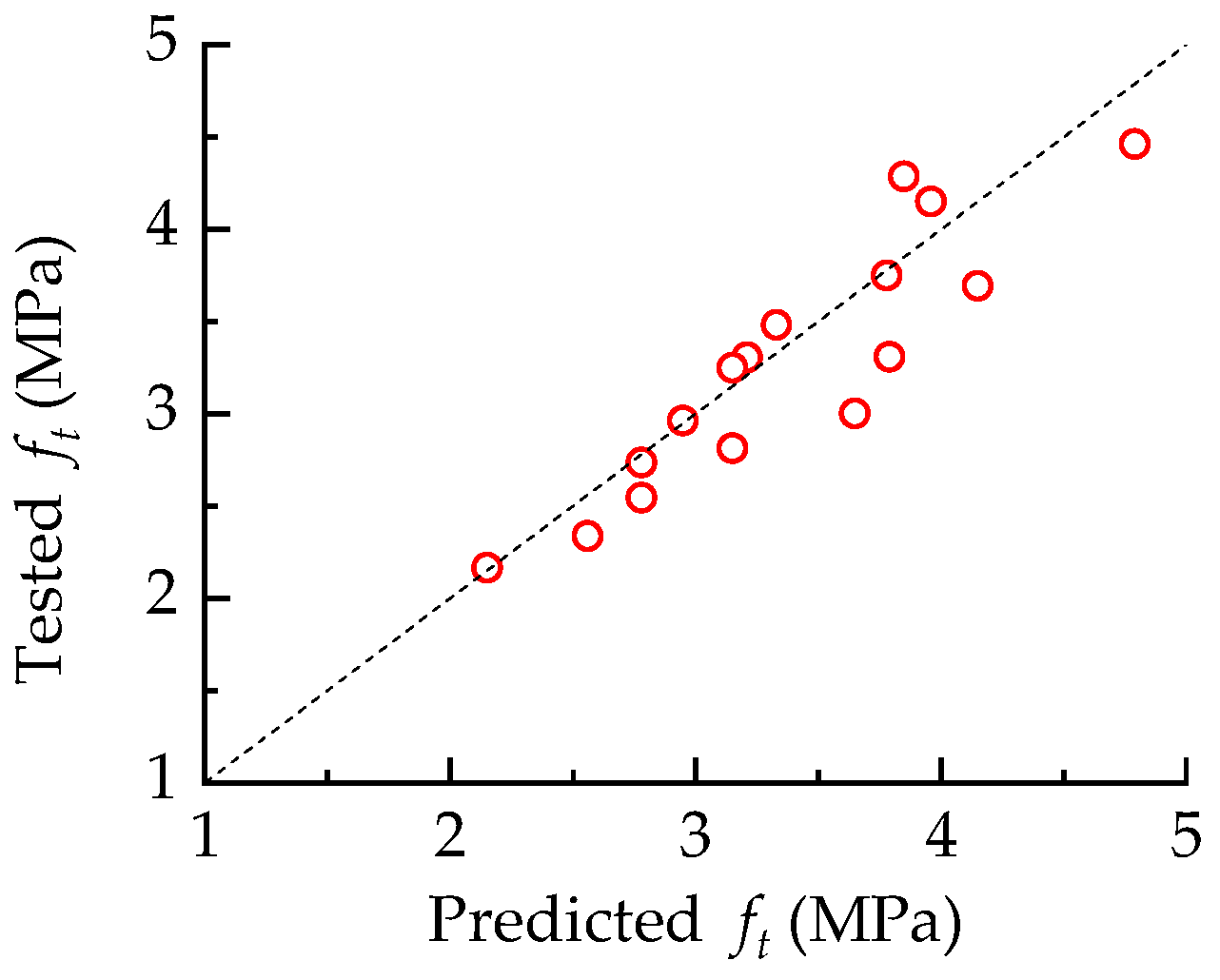

3.3. Splitting Tensile Strength

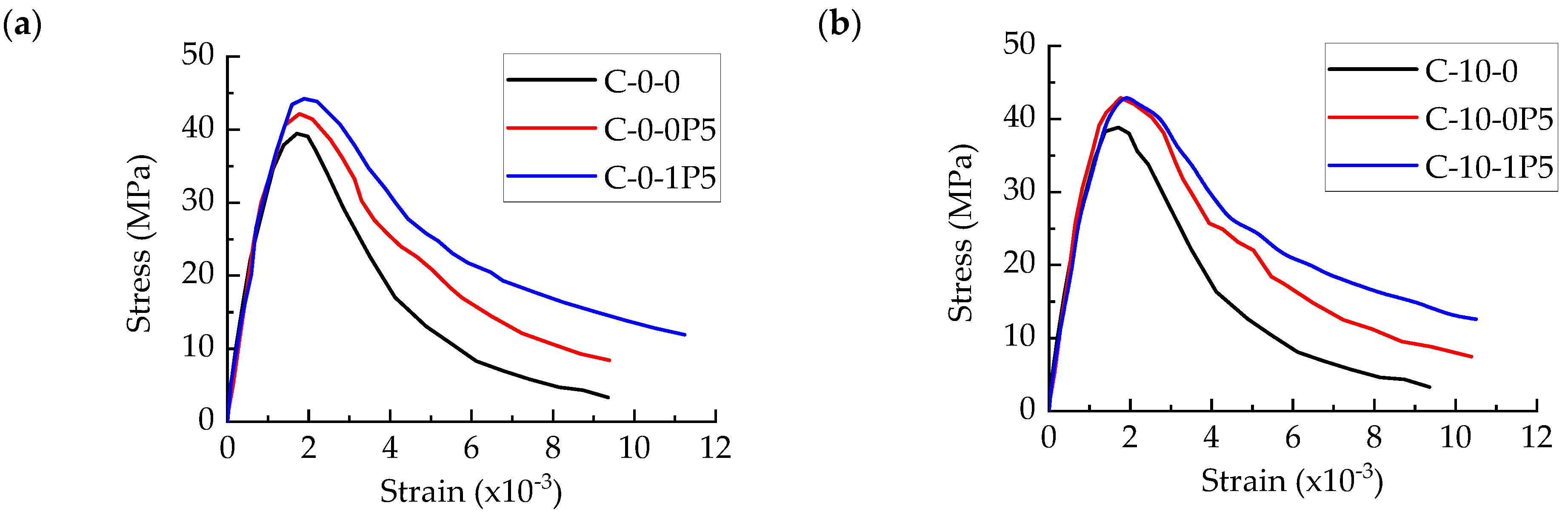

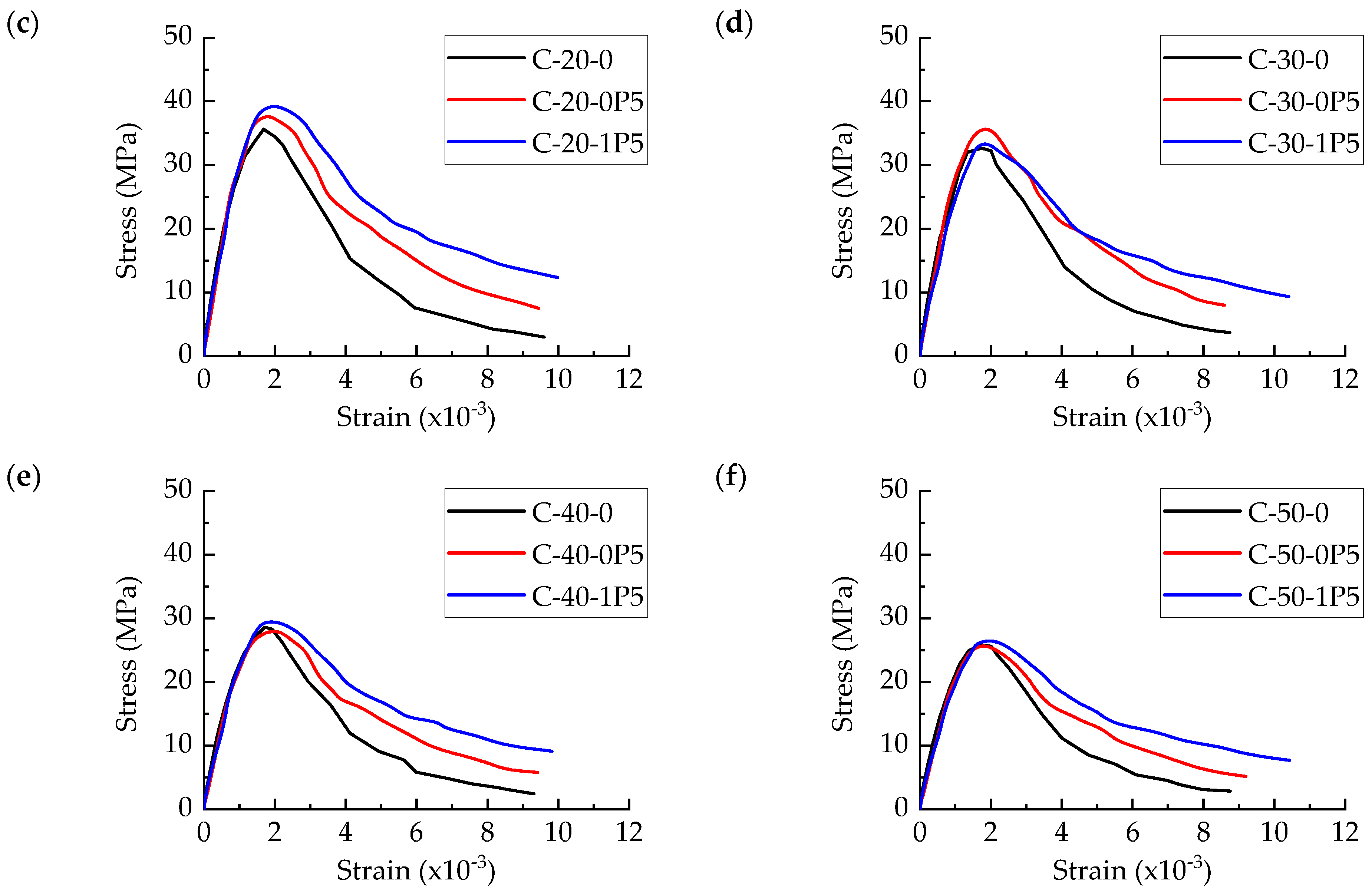

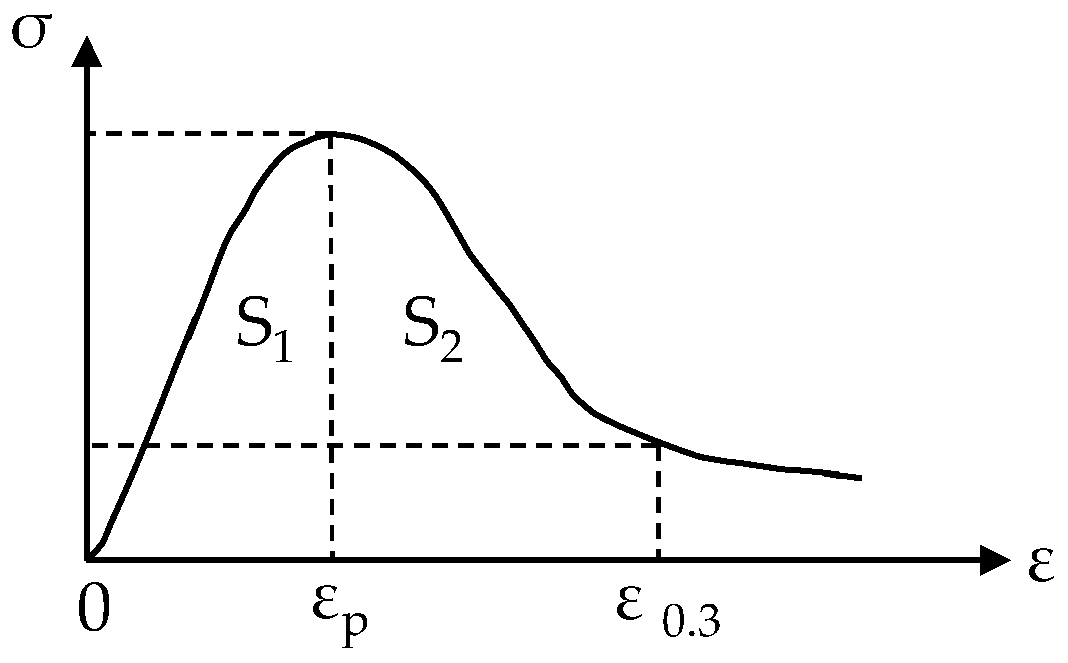

3.4. Compression Stress–Strain Curve

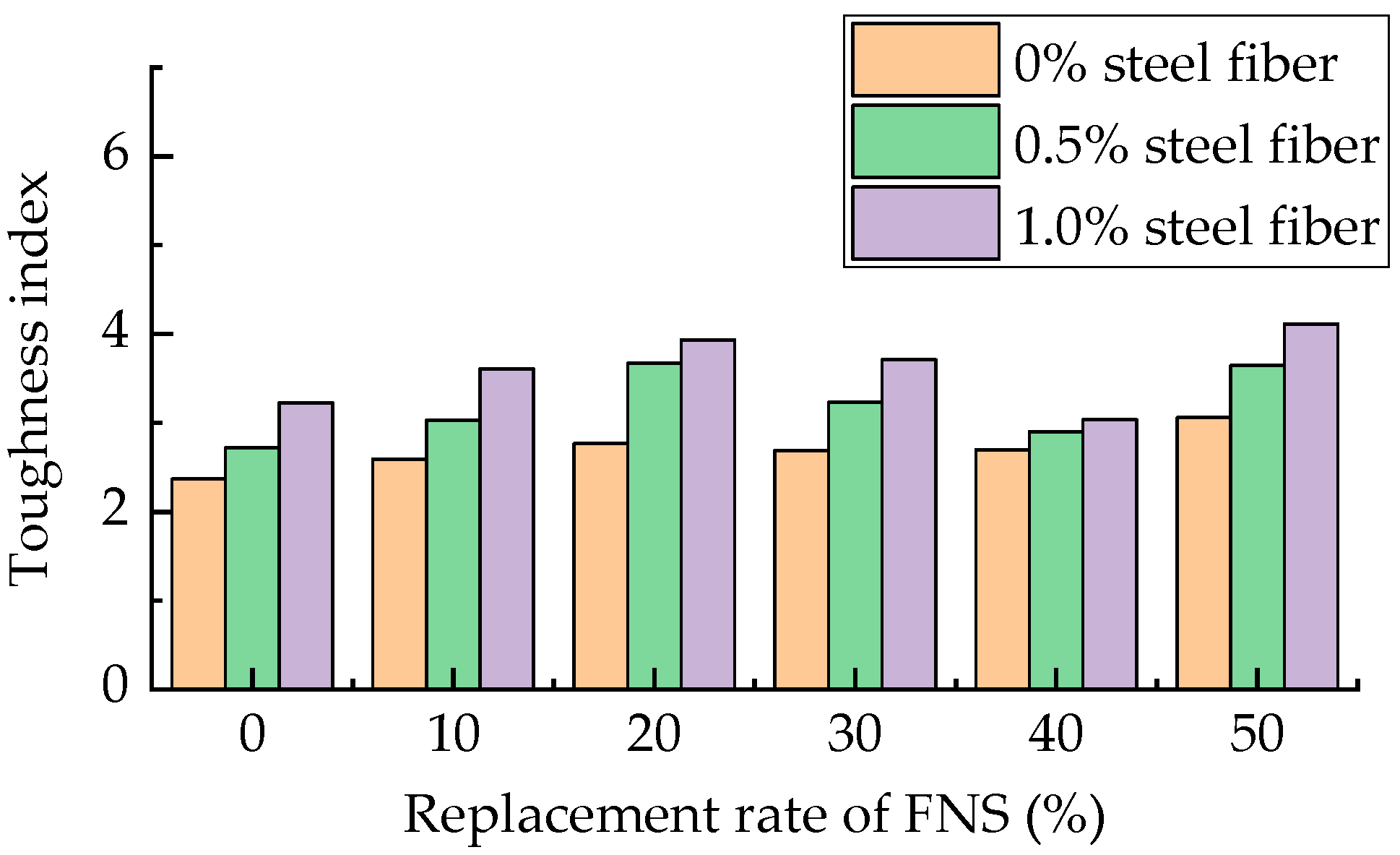

3.5. Toughness Index

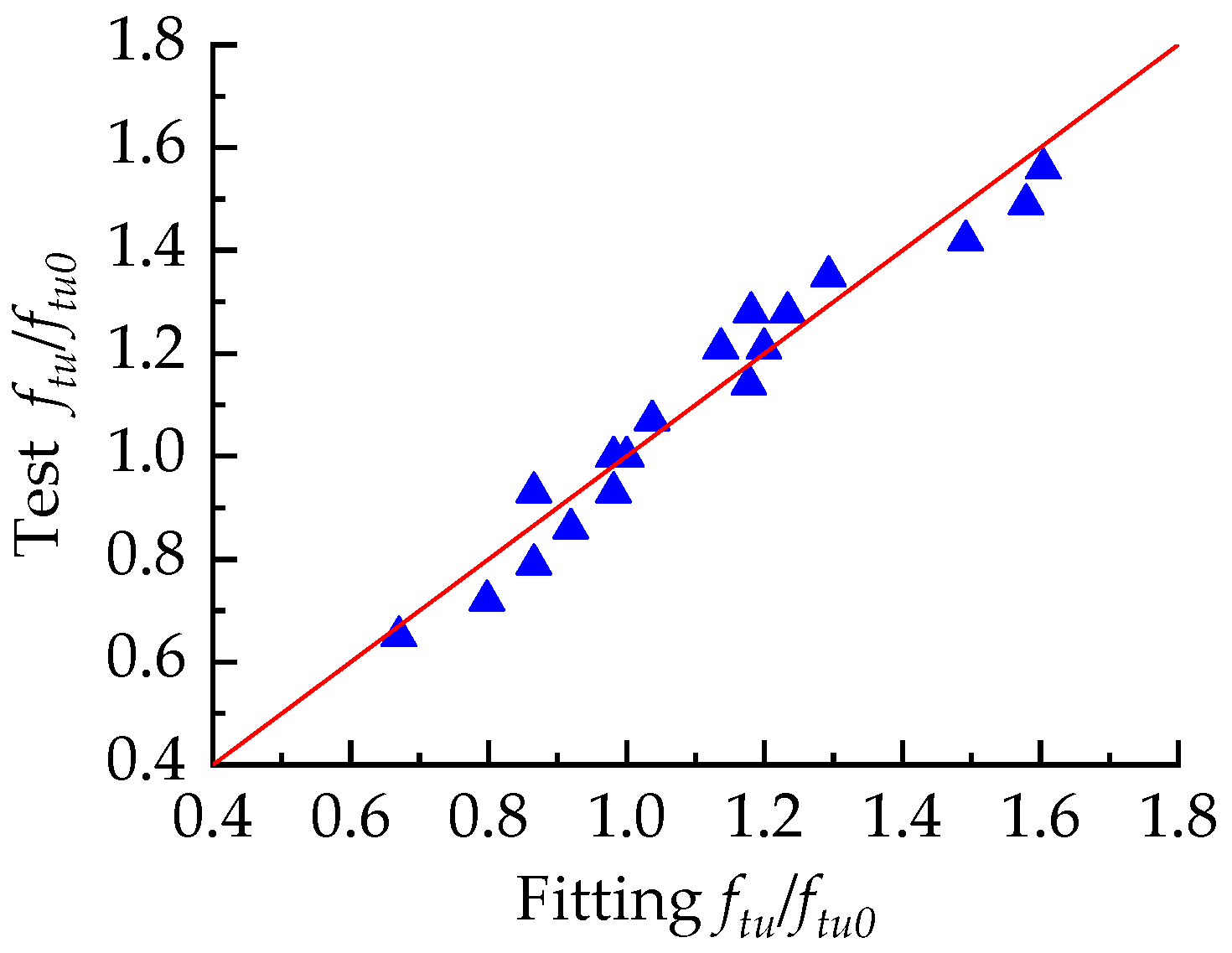

3.6. Relationship between Splitting Tensile Strength and Compressive Strength

4. Conclusions

- (1)

- With an increase in steel fiber content, the slump of SFNSPC under various FNSP replacement rates diminishes and essentially exhibits a linear declining pattern. The decline in SFNSPC is not statistically significant, but it does occur when the replacement rate of FNSP rises. The suggested ratio of SFNSPC slump to regular concrete yields good fitting results.

- (2)

- The compressive strength of SFNSPC is positively impacted by steel fibers, though not significantly. The compressive strength of SFNSPC reduces with a rise in the FNSP replacement rate under the same steel fiber content; however, this strength decrease is not statistically significant for small FNSP replacement rates. The viability of FNSP as an auxiliary cementitious material in terms of concrete strength is demonstrated by the fact that its replacement rate is consistently lower than the strength reduction rate. The suggested ratio of SFNSPC’s compressive strength to that of regular concrete fits the data quite well.

- (3)

- The splitting tensile strength of SFNSPC is significantly influenced by steel fibers, and it rises as the amount of steel fiber in SFNSPC increases. As the rate at which FNSP is replaced rises, so does the rate at which SFNSPC’s strength is reduced. The rate at which splitting tensile strength decreases is not as great as that of compressive strength, and the rate at which FNSP is replaced is consistently less than that of strength reduction. The suggested ratio of the splitting tensile strength of SFNSPC to that of regular concrete fits the data quite well.

- (4)

- By varying mix proportions, the stress–strain curve trend of SFNSPC is essentially consistent and mostly separates into the following sections: a rising part and a descending part. The descending portion of the curve is significantly influenced by the steel fiber composition. The descending section curve becomes smoother as the quantity of steel fibers increases. The SFNSPC specimens’ compressive toughness is positively impacted by steel fibers.

- (5)

- The toughness index is significantly impacted by steel fiber content; however it is not significantly affected by the replacement rate of FNSP at different levels of steel fiber content. The toughness index increases with the amount of steel fiber supplied. When 0.5% and 1.0% steel fiber is added to concrete with varying FNSP replacement rates, the toughness index rises by 8–30% and 12–43%, respectively, in comparison with SFNSPC without the addition of steel fibers.

- (6)

- In the design of SFNSPC, the replacement rate of FNSP and the content of steel fiber can be first established to determine the performance requirements. Then, the performance requirements of ordinary concrete can be established according to the relationship between the performance of SFNSPC and ordinary concrete. Finally, the mix ratio of ordinary concrete can be designed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-Driven Based Estimation of Waste-Derived Ceramic Concrete from Experimental Results with Its Environmental Assessment. J. Mater. Res. Technol. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Zeybek, Ö.; Bahrami, A.; Çelik, A.İ.; Othuman Mydin, M.A.; Karalar, M.; Hakeem, I.Y.; Roy, K.; Jagadesh, P. Optimum Usage of Waste Marble Powder to Reduce Use of Cement toward Eco-Friendly Concrete. J. Mater. Res. Technol. 2023, 25, 4799–4819. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.N.N.; Sarker, P.K. Value Added Utilization of By-Product Electric Furnace Ferronickel Slag as Construction Materials: A Review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef]

- Kim, H.; Lee, C.H.; Ann, K.Y. Feasibility of Ferronickel Slag Powder for Cementitious Binder in Concrete Mix. Constr. Build. Mater. 2019, 207, 693–705. [Google Scholar] [CrossRef]

- Sun, J.; Feng, J.; Chen, Z. Effect of Ferronickel Slag as Fine Aggregate on Properties of Concrete. Constr. Build. Mater. 2019, 206, 201–209. [Google Scholar] [CrossRef]

- Bao, J.; Yu, Z.; Wang, L.; Zhang, P.; Wan, X.; Gao, S.; Zhao, T. Application of Ferronickel Slag as Fine Aggregate in Recycled Aggregate Concrete and the Effects on Transport Properties. J. Clean. Prod. 2021, 304, 127149. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A.; Kim, T.; Khan, M.S.H. Performance of Fly Ash Concrete with Ferronickel Slag Fine Aggregate against Alkali-Silica Reaction and Chloride Diffusion. Cem. Concr. Res. 2021, 139, 106265. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K. Durability Characteristics of Concrete Using Ferronickel Slag Fine Aggregate and Fly Ash. Mag. Concr. Res. 2018, 70, 865–874. [Google Scholar] [CrossRef]

- Nuruzzaman, M.; Camargo Casimiro, J.O.; Sarker, P.K. Fresh and Hardened Properties of High Strength Self-Compacting Concrete Using by-Product Ferronickel Slag Fine Aggregate. J. Build. Eng. 2020, 32, 101686. [Google Scholar] [CrossRef]

- Qi, A.; Liu, X.; Wang, Z.; Chen, Z. Mechanical Properties of the Concrete Containing Ferronickel Slag and Blast Furnace Slag Powder. Constr. Build. Mater. 2020, 231, 117120. [Google Scholar] [CrossRef]

- Han, F.; Zhang, H.; Li, Y.; Zhang, Z. Recycling and Comprehensive Utilization of Ferronickel Slag in Concrete. J. Clean. Prod. 2023, 414, 137633. [Google Scholar] [CrossRef]

- Tang, Z.; Peng, H.; Mei, P.; Huang, F.; Yi, S.; Feng, F. Performance Analysis of Ferronickel Slag-Ordinary Portland Cement Pervious Concrete. Materials 2024, 17, 1628. [Google Scholar] [CrossRef]

- Qi, A.; Liu, X.; Xu, R.; Huang, Y. Bond Behavior of Steel Reinforcement in Concrete Containing Ferronickel Slag and Blast Furnace Slag Powder. Constr. Build. Mater. 2020, 262, 120884. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, S.; Lin, W.; Qi, A.; Chen, Z. Experimental Behaviors of Prefabricated Members Made of Ferronickel Slag Concrete. Constr. Build. Mater. 2020, 261, 120519. [Google Scholar] [CrossRef]

- Liu, X.; Chen, S.; Qi, A.; Lin, W.; Wu, H. Flexural Performance of Reinforced Beams Made with Composite Ferronickel Slag Concrete. Constr. Build. Mater. 2021, 310, 125251. [Google Scholar] [CrossRef]

- Muthukumarana, T.V.; Arachchi, M.A.V.H.M.; Somarathna, H.M.C.C.; Raman, S.N. A Review on the Variation of Mechanical Properties of Carbon Fibre-Reinforced Concrete. Constr. Build. Mater. 2023, 366, 130173. [Google Scholar] [CrossRef]

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical Properties of Macro Polypropylene Fibre-Reinforced Concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical Properties of Fibre Reinforced Concrete with Recycled Fibres. Constr. Build. Mater. 2019, 198, 323–331. [Google Scholar] [CrossRef]

- Noor Abbas, A.-G.; Nora Aznieta Abdul Aziz, F.; Abdan, K.; Azline Mohd Nasir, N.; Fahim Huseien, G. Experimental Study on Durability Properties of Kenaf Fibre-Reinforced Geopolymer Concrete. Constr. Build. Mater. 2023, 396, 132160. [Google Scholar] [CrossRef]

- Li, W.; Shumuye, E.D.; Shiying, T.; Wang, Z.; Zerfu, K. Eco-Friendly Fibre Reinforced Geopolymer Concrete: A Critical Review on the Microstructure and Long-Term Durability Properties. Case Stud. Constr. Mater. 2022, 16, e00894. [Google Scholar] [CrossRef]

- Yıldızel, S.A.; Özkılıç, Y.O.; Bahrami, A.; Aksoylu, C.; Başaran, B.; Hakamy, A.; Arslan, M.H. Experimental Investigation and Analytical Prediction of Flexural Behaviour of Reinforced Concrete Beams with Steel Fibres Extracted from Waste Tyres. Case Stud. Constr. Mater. 2023, 19, e02227. [Google Scholar] [CrossRef]

- Yan, P.; Chen, B.; Afgan, S.; Aminul Haque, M.; Wu, M.; Han, J. Experimental Research on Ductility Enhancement of Ultra-High Performance Concrete Incorporation with Basalt Fibre, Polypropylene Fibre and Glass Fibre. Constr. Build. Mater. 2021, 279, 122489. [Google Scholar] [CrossRef]

- GB/T 14684-2011; Specification of Sand for Building, General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- Wang, D.; Wang, Q.; Zhuang, S.; Yang, J. Evaluation of Alkali-Activated Blast Furnace Ferronickel Slag as a Cementitious Material: Reaction Mechanism, Engineering Properties and Leaching Behaviors. Constr. Build. Mater. 2018, 188, 860–873. [Google Scholar] [CrossRef]

- Chi, L.; Lu, S.; Li, Z.; Huang, C.; Jiang, H.; Peng, B. Recycling of Ferronickel Slag Tailing in Cementitious Materials: Activation and Performance. Sci. Total Environ. 2023, 861, 160706. [Google Scholar] [CrossRef]

- Zhou, Y.; Shi, C. Experimental Study of Electric Furnace Ferronickel Slag as a Supplementary Cementitious Material in Massive High-Strength Concrete. J. Therm. Anal. Calorim. 2022, 147, 4983–4993. [Google Scholar] [CrossRef]

- Zhai, M.; Zhu, H.; Liang, G.; Wu, Q.; Zhang, C.; Hua, S.; Zhang, Z. Enhancing the Recyclability of Air-Cooled High-Magnesium Ferronickel Slag in Cement-Based Materials: A Study of Assessing Soundness through Modifying Method. Constr. Build. Mater. 2020, 261, 120523. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, T.; Yang, Z.; Zhan, W.; Zhang, Y. Sustainable Use of Ferronickel Slag in Cementitious Composites and the Effect on Chloride Penetration Resistance. Constr. Build. Mater. 2020, 240, 117969. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Construction Industry Press: Beijing, China, 2019.

- Zheng, J.; Qi, L.; Zheng, Y.; Zheng, L. Mechanical Properties and Compressive Constitutive Model of Steel Fiber-Reinforced Geopolymer Concrete. J. Build. Eng. 2023, 80, 108161. [Google Scholar] [CrossRef]

| Apparent Density kg/m3 | Natural Packing Density kg/m3 | Water Absorption Rate % | Crushing Index % | Clay Lump % | Void Rate % | |

|---|---|---|---|---|---|---|

| Indicator requirements | ≥2500 | ≥1350 | <2.0 | <20 | <0.5 | <47 |

| Tested result | 2750 | 1570 | 0.40 | 13.50 | 0.10 | 35.6 |

| Apparent Density kg/m3 | Fineness Modulus | Bulk Density kg/m3 | Crushing Index % | Clay Lump % | Stone Powder Content % | |

|---|---|---|---|---|---|---|

| Indicator requirements | ≥2500 | 2.3–3.0 | ≥1350 | <25 | <1.0 | <7 |

| Tested result | 2750 | 2.7 | 1621 | 13 | 0.3 | 5.9 |

| Component | CaO | SiO2 | Al2O3 | MgO | SO3 | MnO | Others |

|---|---|---|---|---|---|---|---|

| % | 35.58 | 30.91 | 16.71 | 10.27 | 2.25 | 1.12 | 3.16 |

| No. | Water /kg | Cement /kg | FNS /kg | Sand /kg | Coarse Aggregate /kg | Fly Ash/ kg | Superplasticizer/% | Steel Fiber/ % |

|---|---|---|---|---|---|---|---|---|

| C-0-0 | 162 | 383 | 0 | 617 | 1147 | 59 | 0.9 | 0 |

| C-10-0 | 162 | 345 | 38 | 617 | 1147 | 59 | 0.9 | 0 |

| C-20-0 | 162 | 306 | 77 | 617 | 1147 | 59 | 0.9 | 0 |

| C-30-0 | 162 | 268 | 115 | 617 | 1147 | 59 | 0.9 | 0 |

| C-40-0 | 162 | 230 | 153 | 617 | 1147 | 59 | 0.9 | 0 |

| C-50-0 | 162 | 192 | 192 | 617 | 1147 | 59 | 0.9 | 0 |

| C-0-0P5 | 162 | 383 | 0 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-10-0P5 | 162 | 345 | 38 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-20-0P5 | 162 | 306 | 77 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-30-0P5 | 162 | 268 | 115 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-40-0P5 | 162 | 230 | 153 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-50-0P5 | 162 | 192 | 192 | 617 | 1147 | 59 | 0.9 | 0.5 |

| C-0-1P0 | 162 | 383 | 0 | 617 | 1147 | 59 | 0.9 | 1.0 |

| C-10-1P0 | 162 | 345 | 38 | 617 | 1147 | 59 | 0.9 | 1.0 |

| C-20-1P0 | 162 | 306 | 77 | 617 | 1147 | 59 | 0.9 | 1.0 |

| C-30-1P0 | 162 | 268 | 115 | 617 | 1147 | 59 | 0.9 | 1.0 |

| C-40-1P0 | 162 | 230 | 153 | 617 | 1147 | 59 | 0.9 | 1.0 |

| C-50-1P0 | 162 | 192 | 192 | 617 | 1147 | 59 | 0.9 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, P.; Li, X.; Zhang, Q.; Feng, F. Experimental Study on the Mechanical Properties of Steel Fiber Ferronickel Slag Powder Concrete. Buildings 2024, 14, 2471. https://doi.org/10.3390/buildings14082471

Hu P, Li X, Zhang Q, Feng F. Experimental Study on the Mechanical Properties of Steel Fiber Ferronickel Slag Powder Concrete. Buildings. 2024; 14(8):2471. https://doi.org/10.3390/buildings14082471

Chicago/Turabian StyleHu, Pengcheng, Xiaodong Li, Qingyan Zhang, and Fan Feng. 2024. "Experimental Study on the Mechanical Properties of Steel Fiber Ferronickel Slag Powder Concrete" Buildings 14, no. 8: 2471. https://doi.org/10.3390/buildings14082471

APA StyleHu, P., Li, X., Zhang, Q., & Feng, F. (2024). Experimental Study on the Mechanical Properties of Steel Fiber Ferronickel Slag Powder Concrete. Buildings, 14(8), 2471. https://doi.org/10.3390/buildings14082471