Abstract

Modern bridge construction towards a higher degree of low carbonization and assembly has been the general trend, while developing and broadening the low-carbon and assembled-oriented Accelerated Bridge Construction (ABC) technology can better realize the trade-offs between construction quality, efficiency, cost and sustainability. In the current mainstream ABC technologies such as precast-assembled concrete bridge and assembled steel bridge schemes, it is difficult to achieve an excellent balance between the above multicriterion trade-offs. To this end, this paper proposes a novel low-carbon and assembled composite bridge scheme as an innovative case of ABC technology based on a 26.7 km-length urban viaduct project in China with urgent environmental protection and assembly demands. Construction sustainability, the comprehensive economy and low-carbon performance are well balanced by the collaborative application of new steel–concrete composite structures, the rapid assembly interface design and low-carbon material technologies. The proposed scheme has been applied to a completed real-scale bridge, and the whole construction process only experienced 105 days of effective time, accompanied with slight environmental interference and construction noise and a small amount of labor and equipment input. In addition, the safety of the bridge, the rationality of the design concept and the calculation method have been verified by the static and dynamic loading tests of the real-scale bridge.

1. Introduction

In recent years, under the background of the increasing traffic demand in China, a new expressway for urban traffic and reconstruction and extension projects for existing highways have gradually spread [1,2]. Urban standard-span bridges (20–40 m spans) are numerous and commonly found in densely populated, traffic-concentrated, and environmentally sensitive areas. The onsite bridge construction activities can have significant impacts on the environment, mobility and safety [3,4]. Noise, dust, lane closures and other adverse effects caused by the traditional bridge construction process will most likely determine the feasibility of the bridge scheme [5]. With the continuous implementation of the carbon peaking and carbon neutrality goals in China, the environmental protection requirements of urban bridge schemes have been referred to an unprecedented decision-making priority. Minimizing the impact of bridge construction activities on the existing traffic, environment and surrounding residents has become a new requirement for bridge engineering in the development of a harmonious society [6].

In order to solve the above environmental protection needs, accelerated bridge construction (ABC) [7,8,9] has rapidly developed and become the mainstream technology of urban bridge construction. The basic connotation of ABC is to adopt highly prefabricated and rapid assembly methods to minimize the adverse impact of bridge construction on the existing environment and traffic, as well as speeding up construction and reducing engineering risks and investment [10]. At present, ABC gradually develops in the direction of low carbonization and assembly. The industrialization-oriented ABC characterized by standardized design, industrial prefabrication and assembly construction is ushering in unprecedented development opportunities [11,12] and it is the general trend for modern bridge construction to move towards a higher level of assembly. The large-scale application of low-carbon and assembled (LA) bridge technology [13,14] with multiple performance attributes, such as an excellent structural quality, weak environmental impact, less traffic interference, low construction cost and rapid on-site assembly, can open up a new situation for the integration and development of digital technology, intelligent manufacturing, rapid assembly and intelligent equipment industry and promote the development of the industrial chain of the process, equipment, management and maintenance [15,16,17,18,19,20].

To realize the LA goal, assembled bridge schemes such as the precast-assembled concrete bridge (P-ACB) and assembled steel bridge (ASB) have been developed and widely used. The P-ACB was originally proposed to solve a series of problems of on-site-cast concrete bridges such as high carbon emissions, a high input of labor and equipment, a long construction period and a strong environmental impact [21,22]. At present, the research frontier of P-ACB focuses on the prefabrication and installation of substructures such as capping beams and piers. The components are prefabricated in the factory with an overall or segmented prefabrication scheme, and transported to the site through large-scale transport equipment for modular assembly. The pre-embedded holes, steel bars or specific connecting materials are designed at the assembly interfaces between capping beams and piers to realize the connection. The structural form and performance improvement of the connection are the key factors affecting the reliability of P-ACB. Zhen et al. [23] proposed a novel connection adopting lap-spliced large-diameter bars and ultra-high-performance concrete grout to accelerate the assemble progress of precast bridge piers. Shafieifar et al. [24] envisioned a new connection detail, where the capping beam and the pier are spliced in the pier and joined with a closure joint of ultra-high-performance concrete. Li et al. [25] proposed precast segmental ultra-high-performance concrete piers with post-tensioned tendons to realize the LA goal. Some scholars [26,27,28] also proposed to adopt a high-performance grouted sleeve to realize the connection of segmented columns or capping beams.

The P-ACB technology can greatly accelerate the construction, especially for urban bridges in scenarios of environmental protection requirements, small traffic impact requirements, limited on-site areas, difficult construction organization and complex construction conditions. However, for the overall prefabrication scheme, the large size of the prefabricated components will bring strict requirements on the trafficability of large-scale transport lines and the capacity of hoisting equipment. For the segmented prefabrication scheme, the large number of assembly interfaces will bring the problems of the high demand of assembly accuracy, complex connection details and the low reliability of the connection quality. Therefore, the application of the P-ACB is limited to developed coastal cities. For instance, the maximum mass and height of the prefabricated concrete piers of Hangzhou Bay Bridge [29] in the Zhejiang province, China, are 458 t and 17.38 m, respectively, while the prefabricated piers of the Hong Kong–Zhuhai–Macao Bridge [30], China, need to be transported and installed by large floating cranes at sea.

The ASB is a typical type of LA bridge, since almost no concrete material is used, accompanied with fewer carbon emissions from the cement production and lightweight steel components which facilitate on-site assembly [31,32]. Thus, the ASB embodies a considerably higher degree of LA performance than P-ACB. The main structural forms of ASB are a steel box, steel plate and steel truss girder, where a large number of stiffeners are arranged to maintain stability, which leads to high steel consumption and large welding work. To this end, many scholars performed a structural optimization design with the goal of reducing steel consumption, carbon emissions and cost. D. Martínez-Muñoz et al. [33] carried out an optimization of a box-girder steel bridge, with cost and emissions as objective functions, through applying the unsupervised learning technique of the k-means and the continuous swarm intelligence metaheuristics. Fé van Lookeren Campagne [34] generated a steel truss bridge using only reclaimed steel, by optimizing the material usage in relation to the function and avoiding cut-off waste, which achieves a 63% reduction in carbon emission compared to a traditionally designed new steel truss bridges. Zekeriya Aydın et al. [35] performed a size, layout and tendon profile optimization of a prestressed steel-trusses bridge using the Jaya algorithm to minimize carbon emissions and cost under the constraint conditions of ensuring the stability of the steel structure. Nevertheless, to realize the large-scale popularization and application of the ASB, some key technical problems must be overcome, such as the high investment consumption of construction and life-cycle maintenance, redundant multi-links of processing, manufacturing, coating and transportation, high industrialization requirements of assembly, welding and bolting and difficult quality control [36].

To this end, a composite bridge combines the double advantages of steel and concrete materials, and eliminates the problems of the high cost and poor stability performance of ASB and the problems of the heavy self-weight and high material consumption of P-ACB [37,38,39]. Therefore, based on the sustainable needs of a specified engineering project, this paper proposes a novel LA composite bridge scheme with less material consumption, lower carbon emissions, lighter components, reliable structural safety and an acceptable engineering cost. The advanced design concept, new structure and material application of the LA composite bridge structural system are elaborated in detail, and the comprehensive sustainable effects on economic and social indicators are provided through an engineering application.

2. Engineering Project Overview

2.1. Project Information

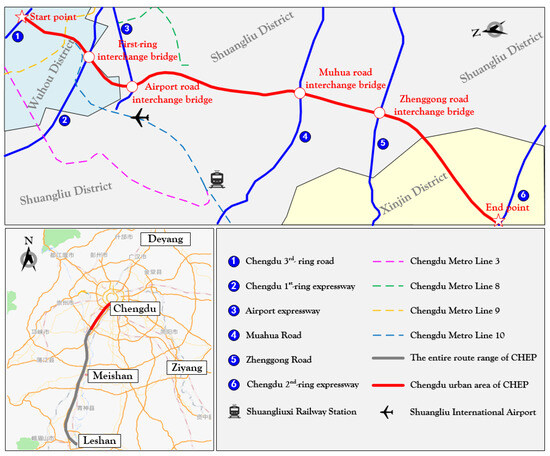

As shown in Figure 1, the Chengle Highway Expansion Project (CHEP), a highway to connect Chengdu and Leshan in the Sichuan province, China, is the first case of a large-scale highway reconstruction and expansion project from four lanes to eight lanes and its completion will greatly promote the urban development of Chengdu, Deyang, Meishan and Ziyang in the Sichuan Province, China. This paper studies the CHEP viaducts within Chengdu, located between the Third-ring Road and the Second-ring Highway. The total length of the viaducts is about 26.7 km, which is composed of five main-line bridges and four interchange bridges, involving 16.7 km main-line bridges and 10 km ramp-line bridges. The total investment of the project is about 4.37 billion RMB (£0.49 billion), which is expected to be completed and opened to traffic in 2025.

Figure 1.

Design range of viaducts within Chengdu urban area. (Remark: the terms in Chinese in the figure refer to the names of various cities near the CHEP in Sichuan province, China).

The initial design criteria included the following:

- ■

- Traffic speed: 120 km/h.

- ■

- Traffic load: Chinese highway-I load.

- ■

- Road layout: dual eight-lane highway with a standard width of 42 m.

- ■

- Service life: 100 years.

- ■

- Earthquake: seismic intensity VII, peak ground acceleration 0.10 g.

- ■

- Standard span of main girder: mostly 30 m (accounting for 75%).

2.2. Environmental Protection and Assembly Demands

Considering the environmental sensitivity and high traffic density of the project area, specific measures for environmental protection and efficient assembly are crucial. As shown in Figure 1, the viaducts project within the Chengdu urban area is located in the urban built-up area and planning area, passing through the Wuhou District, the Shuangliu District and the Xinjin District of Chengdu, with a dense population, concentrated traffic and sensitive environment. The whole design range involves 34 environmental sensitive points, which need to cross multiple underlying roads, operating railways and municipal pipe networks. The houses and factories on both sides of the route line are dense, accompanied by complex construction boundary conditions. The bridge design scheme needs to be forced to adopt a low-carbon structural system and ABC technology with performances of low carbon emissions and rapid assembly so as to reduce the impacts on existing traffic, the surrounding environment and residents.

3. ABC-Oriented LA Composite Bridge Scheme

3.1. Overall Scheme Comparison

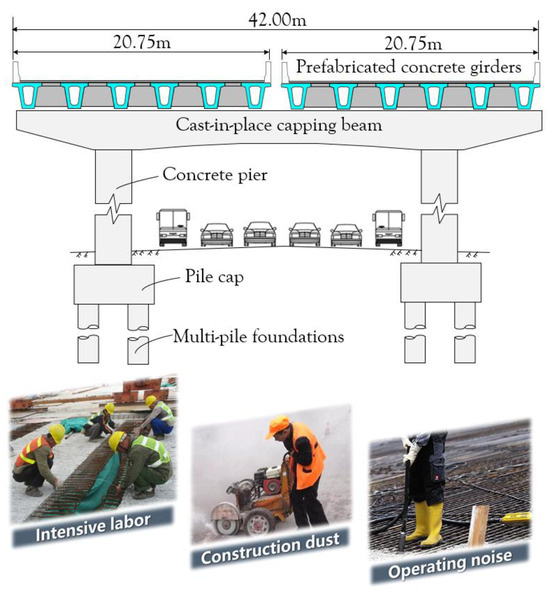

For the construction requirements of CHEP, overall, feasible bridge schemes include concrete bridges, P-ACB and ASB. As shown in Figure 2, for concrete bridges with a span of 20 m~60 m, the superstructure generally adopts a prefabricated box girder or T-shape girder and the superstructure adopts cast-in-place capping beams and piers. This scheme owns good structural integrity and a mature construction procedure, but there are the following problems in using this kind of scheme in CHEP: (1) The concrete consumption is 1.41 million m3; the large consumption of cement and gravel leads to high carbon emissions. The construction period is long due to the low efficiency, accompanied by serious construction noise and dust pollution. (2) A multi-pile foundation has to be used in this scheme to withstand the heavy structural weight from the concrete girders, capping beams and piers and a total of 5388 pile foundations and 1596 pile caps are used, which means more construction links and a longer time consumption. In addition, 3 × 106 m3 of waste soil stacking has a great impact on the environment. (3) To ensure the traffic of the bottom road under the bridge, partial capping beams have to adopt the integral structure with a span of 42 m, a maximum weight of 700 t and a concrete consumption of nearly 300 m3. Building the superstructure using the temporary support method needs much equipment and labor and inevitably causes serious safety risk, environmental impacts and traffic disruption. (4) There are too many assembly interfaces between prefabricated girders, including 60 transverse connections and 70 wet joints, which will lead to a large amount of on-site work and an insufficient assembly degree.

Figure 2.

Concrete bridge scheme.

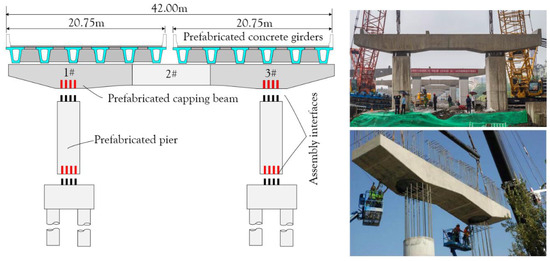

As shown in Figure 3, for the P-ACB scheme, the superstructure generally adopts a prefabricated box girder or T-shape girder and the superstructure adopts precast-assembled concrete capping beams and piers. The components are prefabricated and staged in the factory and transported to the site using large-scale transport equipment for modular assembly. The pre-embedded holes, steel bars or specific connecting devices are designed at the assembly interfaces between the capping beams and piers to realize the connection. This technology can greatly promote ABC, but there are still the following problems for this project: (1) The standard size of the prefabricated capping beam is 42.3 m and the overall weight is 700 t. The lifting weight is more than 200 t even if it is divided into three segments for assembly and the requirements for the trafficability of large-scale transport routes and the hoisting capacity of the equipment are extremely high. (2) The large number of assembly interfaces will bring the problems of the high demand of assembly accuracy, complex connection details and the low reliability of the connection quality. (3) The small number of superstructures and the low degree of standardization will lead to low production efficiency even if using the smart precast field. Moreover, the structure is complex and the construction process is numerous, which means a high construction cost for LA goals.

Figure 3.

P-ACB scheme.

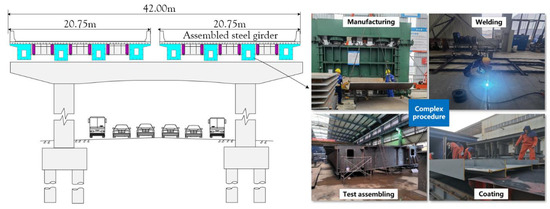

As shown in Figure 4, the ASB scheme generally adopts steel box girder or steel plate girder as the bridge superstructure. The production of the steel girder has to go through multiple complex processes, such as plate unit manufacturing, welding, test pre-assembly and coating, and the production cycle is long, with a high demand for advanced labors and equipment. The steel material consumption of the steel girder is usually greater than 300 kg/m2 and the cost only for processing and manufacturing exceeds 30% of the material cost. Therefore, the cost of the steel bridge is usually unacceptable to the government or investors compared with the concrete scheme and is limited to the application cross-line and cross-obstacles scenes. Furthermore, there is a wide variety of components involving steel boxes, steel plates, stiffened ribs and other components with different sizes and weights, which are of low standardization, and it is difficult to control the accuracy of on-site assembly.

Figure 4.

ASB scheme.

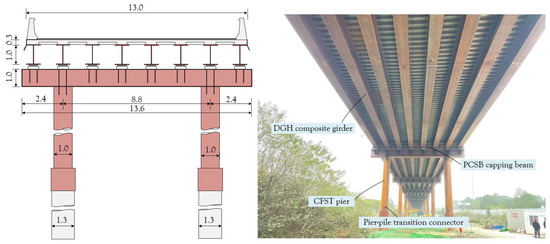

To sum up, the above bridge schemes cannot meet the high requirements of the low-carbon, intelligent and assembled construction for the CHEP. Accordingly, this paper proposes a novel LA composite bridge scheme for ABC, which minimizes the amount of on-site work and reduces the impacts of construction activities on the environment through standardized designs, industrialized prefabrication, assembly construction and the sustainability concept. As shown in Figure 5, the LA composite bridge’s structural system consists of dense-girder–H-shaped (DGH) composite girders, a prestress-assisted concrete-filled steel box (PCSB) capping beam, a concrete-filled steel tube (CFST) pier and a single-pile reinforced concrete (SPRC) pile foundation. The detailed description of the structural system and the application of low-carbon materials are shown in Section 3.2 and Section 3.3, respectively.

Figure 5.

LA composite bridge scheme.

3.2. A Novel LA Composite Bridge Structural System

3.2.1. Dense-Girder–H-Shape Composite Girder

At present, the commonly applied forms of steel plate composite girders in the world are multi-girder and few-girder systems, according to the number of girders. The few-girder system greatly reduces the consumption of steel for a better economy, but requires dense transverse connecting members between girders to maintain structural integrity and stability, and even the need to stretch transverse prestress in the bridge deck brings complex and cumbersome processes. In addition, its safety redundancy under extreme loads is not excessive, and the dynamic performance needs to be focused on. Oppositely, the transverse load distribution coefficient of the multi-girder system is small, showing better stress uniformity for each girder, while the safety redundancy and disaster resilience under the scenario of local component failure can be guaranteed. In addition, its small girder height and light lifting weight make it more suitable for ABC. However, the problem of excessive steel consumption needs to be overcome under today’s low-carbon and sustainable development concept.

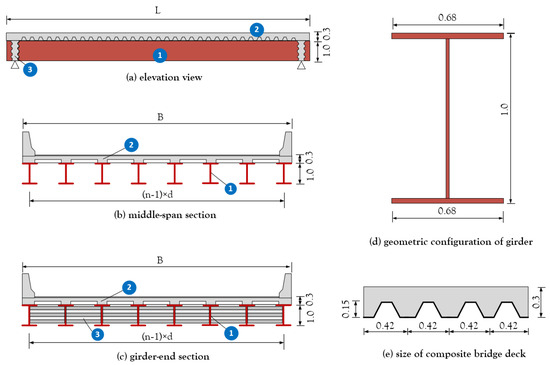

Based on the multi-girder design concept, this paper proposes the DGH composite girder that adapts to the transverse force transmission of vehicle loads, so that any wheel load is borne by at least two girders. Meanwhile, a large number of transverse connection members and stiffened steel plates are innovatively eliminated through structural optimization, which greatly overcomes the problem of the high consumption of steel structures in a multi-girder system. As shown in Figure 6, the DGH composite girder is composed of multiple H-shaped steel girders and a corrugated steel–concrete composite bridge deck, with a girder height of 1.0 m and a deck thickness of 0.3 m. The applicable span of the DGH composite girder is 20–35 m. Specifically, there is no stiffened steel plate arranged on the girders, as well as no intermediate transverse connecting members within the span. Only the corrugated steel–concrete composite end beams filled with concrete are set at both ends, which greatly eliminates the stiffener structure and the number of welds. Only the concrete-filled corrugated steel composite girder-end crossbeams are designed at both ends, which significantly simplifies the stiffener structure and the number of welds and greatly reduces the steel consumption.

Figure 6.

Structural description of the DGH composite girder (unit: m). (Remark: ①: H-shape steel girder, ②: corrugated steel–concrete composite bridge deck, ③: girder-end crossbeam, L and B refer to the span of girder and the width of the deck and n and d refer to the number and spacing of girders).

The elimination of transverse connecting members and stiffeners may imply a need to focus on the integrity, stability and lateral force transmission performance of the structure. The above concerns are ensured by the following multiple design strategies: (1) a girder spacing of less than 1.8 m (wheel spacing of standard vehicles in China) ensures a uniform structural response from an individual girder even under the worst-case scenario and the dense-girder system adaptively increases the lateral stiffness of the superstructure owing to the sectional contribution of multiple girders. (2) The optimal thickness parameter of 0.3 m for the composite bridge deck greatly improves the integrity and stiffness of the deck, with the assistance of the corrugated steel base plate which owns large axial stiffness and out-of-plane stiffness relative to flat steel plates. (3) The optimum width design value of 0.68 m for the top plate and bottom plate of the H-shape steel girder makes it have a greater torsional stiffness than the traditional I-shape steel girder to resist the local instability risk. (4) The girder-end crossbeams are designed using the combination of a corrugated steel shell and concrete, and a larger thickness of 0.46 m (usually about 0.3 m for a concrete box girder or a T-shape girder) improves the stiffness of the girder-end crossbeams to provide strong boundary constraints for the DGH girder, so as to magnify the integrity and stability of the bridge superstructure.

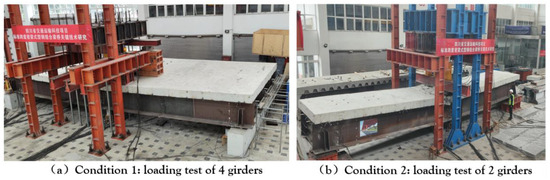

In addition, the dense-girder arrangement increases the transverse force-transmission paths of the structural system and improves the redundancy and robustness of the system when dealing with extreme loads or disaster situations [40]. When local members fail, the stress of the structure be can easily redistributed due to the strong composite bridge deck and girder-end crossbeams and the further spread of damage can be significantly limited by using alternate transmission paths to distribute the loads to other H-shaped girders. The local stability, load lateral distribution and other structural responses of the DGH composite girder have been verified by loading tests. As shown in Figure 7, two testing conditions of two girders and four girders are respectively designed to explore the transverse force-transmission performance of the DGH girder without transverse connecting members. Firstly, the loading test of four girders under Condition 1 (loads are transferred laterally through the composite bridge deck) is carried out, after which the structure is cut in half for the loading test of four girders under Condition 2 (no transverse force-transmission path).

Figure 7.

Mechanical behavior experiment.

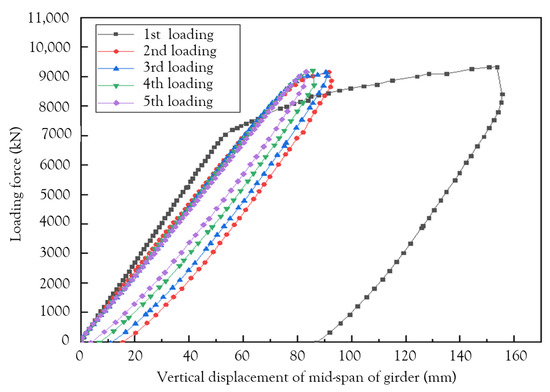

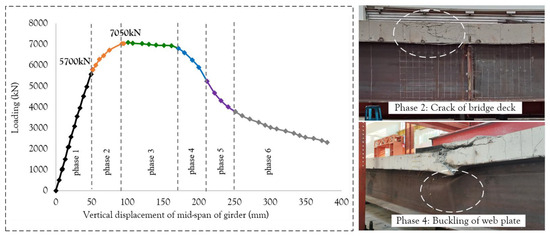

Figure 8 shows the loading-displacement curve of Condition 1 and the ultimate bearing capacity of the structure is 9360 kN. After unloading, the loading test is repeated four times and the bearing capacity remains at the same level, which verifies the structural safety. Figure 9 shows the loading-displacement curve of Condition 2 and the ultimate bearing capacity of the structure is 7050 kN. By comparing the testing results of four girders and two girders, 2310 kN of the loads is transversely transferred through the composite bridge deck, although no transverse connecting members exists. It proves that the transverse force-transmission performance of the composite bridge deck is reliable and the basis for canceling the transverse connecting members between girders is sufficient.

Figure 8.

Loading-displacement curve of the loading test of 4 girders.

Figure 9.

Loading-displacement curve of the loading test of 2 girders.

In addition, from Figure 9, the loading-displacement curve of Condition 2 can be divided into six phases: phase 1 (the elastic working stage), phase 2 (the cracking stage of the bridge deck), phase 3 (the bridge deck is crushed), phase 4 (the buckling of the web plate of the H-shaped girder), phase 5 (the deformation development of the web plate) and phase 6 (the large deformation of the web plate). It can be seen that the first-order failure of the structure is the crushing failure of the bridge deck and the second-order failure is when the local buckling of the web plate occurs. In other words, the failure of the web plate buckling occurs during a long loading process after the elastic working stage, which proves that the web plate without stiffeners has no safety problems in the objective service stage.

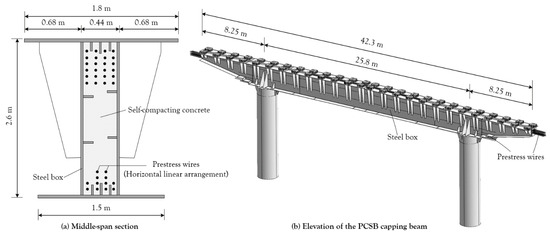

3.2.2. Prestress-Assisted Concrete-Filled Steel Box Capping Beam

The standard width of the capping beam of the CHEP is 42.3 m, which involves technological challenges in the structural design of the extra-large span capping beam. The construction of the extra-large-span capping beam usually adopts the P-ACB scheme (as shown in Figure 10) and its technological limitations are described in detail in Section 3.1. To this end, this paper proposes the PCSB capping beam as one of the solution schemes for the technological challenges in the extra-large-span capping beam design, which is a composite structure formed by stretching prestress on the steel box and then pouring self-compacting concrete (SCC) into the box. The combination of a steel box and concrete fully integrates the advantages of the two materials, that is, the strength of the concrete is significantly improved owing to the constraints from the steel box and the steel box is laterally supported by the concrete, which reduces the instability risk of the steel structure. Meanwhile, the application of prestressed wires reduces the tensile stress level of the steel box and concrete under the objective service stage and improves the service performance during the whole life-cycle. Compared with the concrete capping beam, the toughness is improved while the weight is reduced. Compared with the steel capping beam, less steel consumption and greater stiffness and stability make it more suitable for the application scenarios of extra-large-span capping beams.

Figure 10.

P-ACB scheme for capping beam.

As shown in Figure 11, for the CHEP, the standard width of the capping beam is 42.3 m, which meets the traffic demand of eight lanes in two lines. The spacing between the two piers is 25.8 m and the middle-span section height of the capping beam is 2.6 m. A total of 36 prestressed wires with a horizontal straight line arrangement are installed on the capping beam and the amount of steel structure is 70 t and the amount of concrete is 35.6 m3. The typical construction sequence of the PCSB capping beam is as follows: (1) stretching the prestressed bundles and anchoring them at both ends of the steel box; (2) hoisting the capping beam with the anchored prestressed bundles and welding the bottom plate of the capping beam to the top surface of the pier steel pipe; (3) the SCC is poured into the steel box from one end of the capping beam; and (4) after the concrete strength meets the design requirements, the prestressed bundles are loosened to transfer the prestress to the steel box and concrete, so as to form a composite structure.

Figure 11.

Structural detail of the PCSB capping beam.

The PCSB capping beam is very suitable for the construction scenarios with the ABC requirements and environmentally friendly requirements. The steel box lifting weight of the PCSB capping beam is only 70 t, which shows excellent lightweight characteristics compared with the concrete capping beam, which can accelerate the construction and promote the level of industrial construction, relying on the steel box as the template for concrete pouring with no brackets and template engineering, which can minimize the impacts of the construction process on traffic and the environment. The use of SCC without vibration operation can greatly reduce the impact of construction noise on the environment.

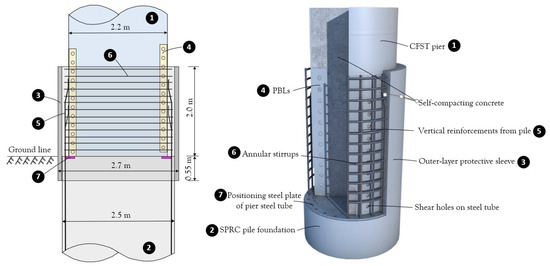

3.2.3. Pier and Pile Structure

As shown in Figure 10, the superstructure of the LA composite bridge structural system adopts CFST piers, and each pier is connected to a SPRC pile foundation through a pier–pile transition connector. As the total weight of the DGH composite girders, PCSB capping beam and CFST piers of the novel bridge scheme is reduced by about 40% compared with that of the traditional concrete bridge scheme, only a single pile can meet the safety demand without the need to design a pile-group foundation, which thus eliminates the huge pile cap structure, greatly saves the amount of concrete, speeds up the construction and also significantly reduces the noise and mud pollution associated with multi-pile drilling operations.

Meanwhile, for the CFST pier, the compressive strength of the concrete is increased by 1.8~2.5 times due to the hoop confinement effect of the steel tube on concrete and the stability of the steel tube is also improved by the support effect of the concrete in the tube. The mutual achievement of the steel and concrete materials makes the CFST pier have better ductility and crashworthiness. During the construction, for the piers with a length of 12 to 20 m, the lifting weight of a single steel pipe is only 10.3 to 17.2 t so that the ordinary lifting equipment can achieve rapid construction. In addition, the steel tube can be used as a support template for concrete pouring without the need to set up any temporary scaffolding, which avoids the interference to the traffic under the bridge.

As shown in Figure 12, a variety of anchorage structures are used to realize the structural safety of the pier–pile transition connector so that the force flow transmission between the two structures of the CFST and reinforced concrete is smooth. The shear holes are set at the bottom of the CFST pier and the PBLs are welded on the inner wall of the steel tube so that the concrete and steel tube in the pier–pile transition area can work together with a good bonding performance and the opening holes on the PBLs can transform the shear force of the steel tube into the concrete. The outer-layer protective sleeve provides an additional hoop confinement effect and increases the cross-sectional area in the pier–pile transition area, thereby improving the bearing capacity and bending performance under the earthquake action. The annular stirrups and vertical reinforcements in the pile foundation extend upward to the CFST pier area and weld with the steel tube, which enhances the anchorage reliability and force transmission uniformity between the two structures. The above measures make the pier–pile transition connector very strong and improve the seismic performance, which can eliminate the tied beam between piles and obtain the beneficial effects of saving materials, simplifying the process and speeding up the construction period.

Figure 12.

Structural detail of the pier–pile transition connector.

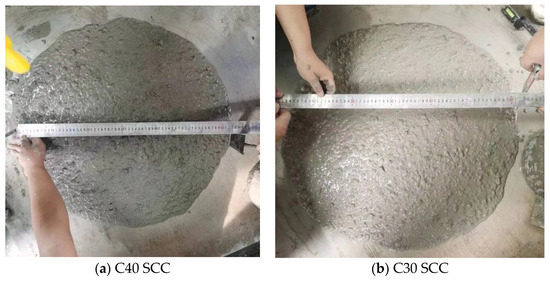

3.3. Large-Scale Application of Low-Carbon Materials and Technologies

3.3.1. Self-Compacting Concrete

SCC is widely used in all the composite structures of the LA composite bridge scheme and the concrete can be quickly poured and compacted by its own gravity (as shown in Table 1 and Figure 13), so the labor intensity of workers can be greatly reduced owing to the elimination of the use of vibrators and the noise pollution to the surrounding environment can be minimized. The multi-objective mixture design of self-compacting concrete is proposed to minimize the amount of slurry material, while satisfying the strength and working performances. Compared with the same-grade concrete, the amount of cement can be reduced by about 25 kg/m3, which can reduce carbon emissions by about 12,500 t for the CHEP.

Table 1.

Working performance of SCC.

Figure 13.

Working condition of SCC.

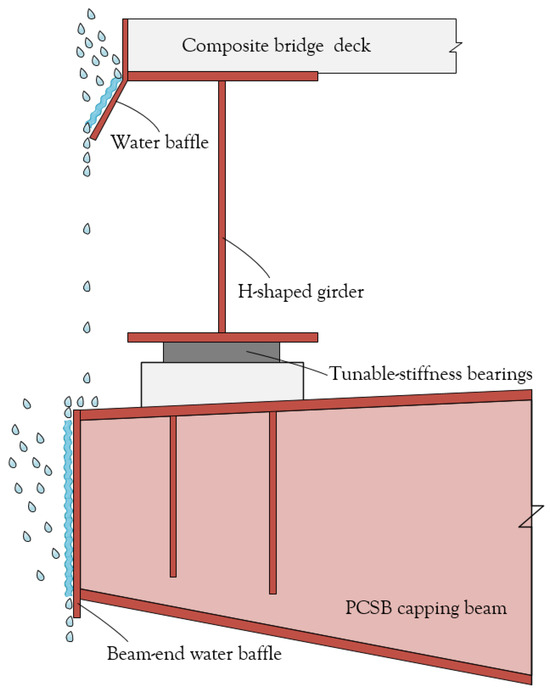

3.3.2. Uncoated Weathering Steel

All steel components in contact with atmospheric environment in CHEP are made of uncoated weathering steel (UWS) and the amount of UWS is 327,000 t. Table 2 shows the list of UWS bridges built in recent years and the CHEP is the first large-scale application of UWS in China; it is also the largest case of UWS consumption in a single project around the world.

Table 2.

UWS bridges built in recent years.

The LA composite bridge scheme using UWS integrates the following advantages: (1) The coating process in the factory is eliminated, so the cost is reduced, the construction speed is accelerated and the labor intensity is reduced. (2) No secondary coating is required, so the maintenance frequency as well as the cost in the life-cycle is observably reduced. (3) The corrosion resistance of the bridge components is improved owing to the atmospheric corrosion resistance of the UWS, which greatly improves the life-cycle durability of the structure.

It should be noted that the use of UWS in wet areas and particularly in contact with rain water may cause the removal of the protective rust layer and then the corrosion can progress over time, reducing the resistance and durability of steel sections [42]. The corrosion resistance performance of UWS is greatly related to the composition of alloying elements and their compounds and the protective effect of the rust layer is closely related to environmental conditions (temperature, humidity, sunlight, salt content, etc.) [43]. Therefore, the designer should choose the alloying element composition of the UWS according to the bridge operating environment (defined by the atmospheric corrosion resistance index I, a larger I means a better weather resistance). For the CHEP, considering the climate environment of Chengdu, China, the value of I is 6.0. In addition, the formation of the protective rust layer on the surface of UWS generally takes about three years, thus yellow rust liquid appears on the surface of UWS in the early stage of use. It is difficult to form a stable rust layer on the surface of UWS under the climate condition with a high salt content [44], which reduces the performance advantage of UWS. Therefore, in the LA composite bridge scheme, the side H-shape girder, the PCSB capping beam and the CFST pier are required to perform the rapid stabilization treatment of the rust layer on the surface of UWS.

In addition, designers are advised to consider a corrosion allowance of 0.5~1.5 mm in the thickness design of the steel plate to reduce the impact of the lost rust layer on the durability of steel sections. More importantly, from the disease analysis of UWS bridges in the United States, a good drainage detail and ventilation structure design are necessary. As shown in Figure 14, an inclined water baffle is arranged on the top flange of the side H-shape girder to avoid the hydrops on the surface of the UWS that affects its weatherability. Meanwhile, the water baffle is also the construction template of the concrete of the bridge deck, as well as the fact that it improves the stability of the top flange of the side H-shape girder. In addition, two beam-end water baffles are arranged on both ends of the PCSB copping beam to prevent rainwater from entering the inclined bottom plate of the PCSB copping beam.

Figure 14.

Structural details of the water baffle.

3.3.3. Tunable-Stiffness Bearings Technology

Equal-stiffness bearings are generally adopted in a multi-span girder bridge, where the horizontal stiffness of each bearing between two expansion joints is the same regardless of the pier height, resulting in significant differences in the mechanical response of the piers with different heights, uneven stress and damage to the bearings. In addition, the length of a single multi-span girder bridge between two expansion joints is less than 150 m and too many expansion joints are designed, resulting in poor driving comfort and a high level of driving noise.

To this end, the tunable-stiffness bearings technology, which has been formed to a local standard [45] in the Sichuan Province, China, is proposed to achieve a long-connected and few-joint structural system through the following strategies:

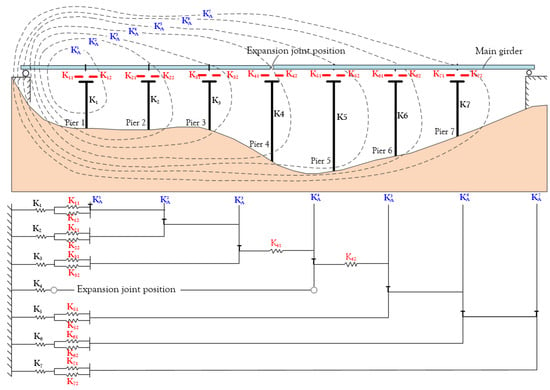

(1) A coordinated matching strategy between the horizontal stiffness of the bearing and the piers is proposed to enhance the total stiffness of the main girder within a long-connected bridge, as well as reduce the horizontal displacement of the main girder under the actions of temperature, braking force and earthquake. As shown in Figure 15, the calculation principle for the aggregative horizontal stiffness of a multi-span girder bridge is as follows:

Figure 15.

Aggregative horizontal stiffness of multi-span girder bridge.

Step 1: the horizontal stiffness of all bearings on the same pier is superimposed

where are the horizontal stiffness of the bearings on both sides of the i-th pier, respectively.

Step 2: The horizontal stiffness of the bearings and the i-th pier are integrated into the aggregative horizontal stiffness of the i-th pier

where is the horizontal stiffness of the i-th pier, which is related to parameters such as the pier height and section size. Then, the total horizontal stiffness of a length-connected bridge composed of n piers is

Equation (3) relates the total horizontal stiffness of the main girder to the horizontal stiffness of the bearings , the horizontal stiffness of the bridge piers and the number of piers . By adjusting and , the group piers can participate in the stiffness contribution to improve the . Moreover, the adjustable horizontal stiffness of the bearings can change the boundary conditions of the piers, thereby regulating the internal forces of each pier and making the mechanical response of all piers uniform regardless of their height.

(2) The calculation method for the optimal length of the main girder between two expansion joints is proposed, where the horizontal stiffness of bearings and the number of piers n are adopted as the optimization design variables D to carry out multi-objective trade-offs between the stress optimality, driving comfort and life-cycle sustainability. The optimization model is established as follows:

where Mi is the bottom bending moment of the i-th pier and is the average bottom bending moment of all piers. The above model ensures structural stiffness and dynamic performance by satisfying the constraint condition that the natural frequency of vibration is greater than 0.2 Hz. f1 is designed to maximize the number of piers to extend the length of the main girder, so as to minimize the number of expansion joints, improve driving comfort and reduce noise pollution during the operation stage. f2 is designed for maximizing the total longitudinal stiffness of the main girder in pursuit of better stiffness and a dynamic performance for better driving comfort. f3 is designed to achieve a uniform stress distribution on bearings and piers in order to enhance the durability and sustainability during the entire bridge life-cycle.

Specifically, for the CHEP, based on the proposed tunable-stiffness bearings technology, the length of the main girder between the two expansion joints is increased to 300 m and the number of expansion joints reduces to 50% of traditional bridges, which can greatly reduce the vehicle operation noise of bridges in urban areas.

4. Sustainability Assessment on the LA Composite Bridge Scheme

4.1. Construction Sustainability Performance

Considering the various influencing factors on construction sustainability, this paper uses an index system by considering the following six aspects: carbon emissions, environmental impacts, traffic disruption, construction time, construction cost and assembly degree. The construction sustainability performances of the concrete bridge scheme, P-ACB scheme, ASB scheme and LA composite bridge scheme are compared in Table 3. The carbon emissions are calculated according to the carbon emissions of various materials in the production process. The construction time is determined according to the construction schedule of various bridge schemes. The construction cost is calculated according to the project budget of various bridge schemes. The assembly degree is measured according to the proportion of materials processed in the factory and assembled on site.

Table 3.

Primary construction sustainability performances’ comparison between several bridge schemes.

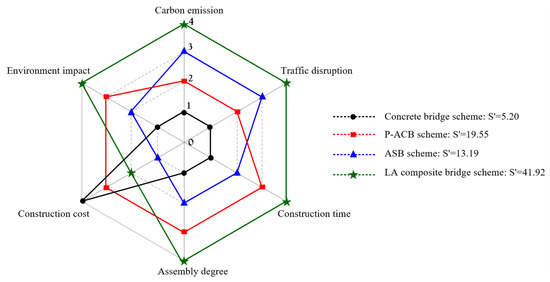

Then, the hierarchical evaluation method based on a rose chart is employed to compare sustainability associated with different bridge schemes. As shown in Figure 16, each performance is scored with 1–4 points according to the merit ranking of the various bridge schemes and the area Si enclosed by connecting lines is taken as the analysis index of the sustainability associated with the bridge schemes. Considering the LA goal, this paper designs the performance enhancement factor to increase the focus on low-carbon emissions and the assembly degree. The final sustainability index of each scheme is:

where refer to the performance enhancement factors considering low-carbon emissions and the assembly degree, respectively. When the carbon emission performance of each scheme is scored 4 points, , then the score is 3 points, . Similarly, when the assembly degree performance of each scheme is scored 4 points, , then the score is 3 points, .

Figure 16.

Construction sustainability performance assessment of bridge schemes.

As seen in Figure 16, the traditional concrete bridge scheme receives the lowest grade (), and it results in not only a serious environment impact and traffic disruption, but also a high onsite construction cost, time and risk. Even if the P-ACB and ASB schemes overcome the problems of the concrete bridge scheme and promote the ABC to a certain extent, there are still many ABC performances that need to be further improved for the LA goals. The LA composite bridge scheme receives the highest grade () since it achieves an excellent balance between the various performance indicators such as low carbon and assembly.

4.2. Comprehensive Economic Performance

4.2.1. Material and Construction Costs

The comparison of the material consumption and construction cost between the concrete bridge scheme and the LA composite bridge scheme is shown in Table 4. Compared with the concrete bridge scheme, although the amount of steel (including uncoated weathering steel, rebar and prestressed wires) increased by 11.79 × 104 t with an increase of about 38.2%, the amount of concrete reduced by about 8.02 × 105 m3 with a great reduction of 56.8% thanks to the lightweight design concept of the LA composite bridge scheme. For the construction cost composed of direct and indirect expenses caused by the installation and disassembly of the support template, equipment investment, hoisting construction and labor input, the LA composite bridge scheme can reduce 123.5 million RMB with a great reduction of 52.4% compared to the concrete bridge scheme, owing to the excellent comprehensive sustainable performance of the LA composite bridge scheme.

Table 4.

Material and construction cost comparison.

Although the amount of steel for the LA composite bridge scheme is increased, the comprehensive unit price is lower than that of the traditional steel bridge because of the simple structure, convenient processing and manufacturing and less welding of the LA composite bridge scheme. Finally, the project investment cost of the composite bridge scheme is 4.37 billion RMB, which is only 7.1% more than that of the concrete bridge scheme.

4.2.2. Life-Cycle Cost

When the project investment cost is further extended to the life-cycle range of the bridge, the life-cycle cost of the two schemes is almost equivalent. Firstly, the tunable-stiffness bearings are adopted in the CHEP, which have the same life as the bridge and do not need to be replaced every 15~20 years like the traditional bearings. Therefore, the tunable-stiffness bearings technology can save a rear bearing replacement cost of about 86.4 million RMB within the 100-year life-cycle of the bridge (as shown in Table 5). Secondly, the uncoated weathering steel is so adopted for all the components of the Chengle project, which does not need to be re-coated every 15~20 years like the traditional steel bridge, so the coating cost can be saved, which is about 66.2 million RMB during the life-cycle of the bridge (as shown in Table 6). Furthermore, at the end of the bridge’s life, the steel material of the LA composite bridge scheme can be reused again and has an additional residual value compared to the concrete bridge scheme. Hence, the LA composite bridge scheme replacing the concrete bridge scheme has good economy and has the potential of large-scale popularization and application.

Table 5.

The cost of replacing bearings during the life-cycle of the bridge.

Table 6.

The cost of re-coating during the life-cycle of the bridge.

4.3. Social Benefit Contribution

The main social benefit contributions of the LA composite bridge scheme are as follows:

- The LA composite bridge scheme is proposed to provide a feasible path for the development of low-carbon bridge technology. Compared with the concrete bridge scheme, the concrete consumption of the LA composite bridge scheme is reduced by 80.2 × 104 m3, and the steel consumption including rebars and prestressed wires increases only by 11.79 × 104 t. The final carbon emissions considering the superposition of various materials are reduced by about 16×104 t (without accounting for other energy consumption reductions), which is equivalent to the carbon dioxide absorption of 1 km2 of forest for 4.3 years.

- The LA composite bridge scheme minimizes the interference of bridge construction activities on the surrounding environment. Any supports and formworks do not need to be erected during the construction, so as not to interrupt traffic and occupy land. The whole bridge adopts self-compacting concrete without vibration operation, reducing the noise during construction. And the number of expansion joints is halved compared with the traditional bridge, meaning the driving comfort associated with driving noise are greatly improved.

- The standardized and simple structure form is applied to the LA composite bridge scheme, which is especially convenient for intelligent processing and manufacturing and can promote the industrialization development of steel-structure bridges. Eighty percent of the workload is performed in the factory, which can liberate the intensive labor input and improve the working environment and work intensity of the workers.

5. Engineering Application

5.1. Structural Description

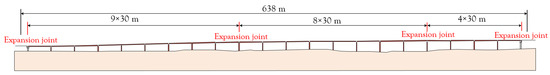

Before the large-scale application of the LA composite bridge scheme in the CHEP, its technical feasibility was tested and verified by the construction of the testing bridge, the Pengshan Qinglong Bridge in Meishan, Sichuan, China. As shown in Figure 17 and Figure 18, in order to achieve a highly standardized design, the span of all the main girders is 30 m, with a total length of 638 m and a standard deck width of 13 m. The maximum length of the main girder between two expansion joints reaches 270 m. The steel structure of the whole bridge is made of UWS and the concrete used for the whole bridge is SCC. The main design parameters of various components are as follows:

Figure 17.

Elevation view of the Pengshan Qinglong Bridge.

Figure 18.

Cross-section view of the Pengshan Qinglong Bridge (unit: m).

- ■

- DGH composite girder: the girder height of 1 m, the deck thickness of 0.3 m and the girder spacing of 1.76 m.

- ■

- PCSB capping beam: the length of 13.6 m and the girder height of 1 m.

- ■

- CFST pier: the diameter of 1.0 m and the average height of 9 m.

- ■

- SPRC pile: the diameter of 1.3 and the average length of 27 m.

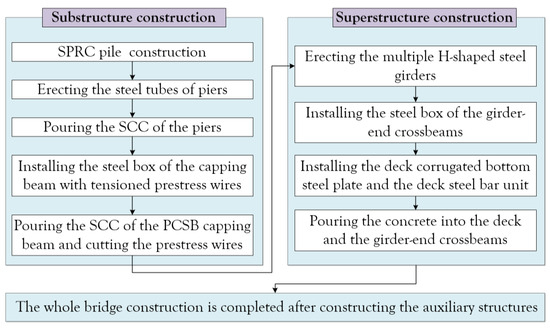

5.2. Construction Procedure

The main components of the LA composite bridge scheme are manufactured in the steel structure factory and only the connection of the assembly interfaces between the components and a small amount of SCC need to be completed on site, which minimizes the amount of on-site work for ABC and shortens the interference time to the surrounding environment and traffic. The Pengshan Qinglong Bridge began construction in July 2022, completed in December 2022 and opened to traffic in February 2023. Excluding the impacts of no labor to carry out construction activities during COVID-19 and the local government’s requirement to suspend construction during periods of heavy air pollution, the effective construction time is only 105 days, which saves more than 30% of the construction time compared with the traditional concrete bridge scheme. As shown in Figure 19 and Figure 20, the main construction procedures of the Pengshan Qinglong Bridge are as follows:

Figure 19.

The main construction procedure of the Pengshan Qinglong Bridge.

Figure 20.

The onsite construction process of the Pengshan Qinglong Bridge.

Step 1: After the construction of the SPRC pile foundation, the steel tube of the CFST pier is lifted to the top of the pile foundation and aligned with the pile foundation and then the pier–pile transition connector is constructed. Finally, the SCC is poured from the top of the pier into the pier–pile transition connector and the interior of the CFST pier until it is poured to 0.6 m away from the top of the pier.

Step 2: The whole segment of the PCSB capping beam is transported from the factory to the site and is lifted to the pier-top area after stretching the prestressed wires on the ground under the bridge so that the PBLs arranged at the bottom of the capping beam can be accurately positioned and inserted into the range of 0.6 m at the top of the pier. Then, the connection between the capping beam and the pier is realized by welding the steel tube of the pier and the bottom plate of the capping beam.

Step 3: The concrete inside the capping beam and within 0.6 m of the pier top is poured. After the concrete strength reaches the design requirements, the prestressed wires are cut to form a composite capping beam structure with the superposition of the steel box, concrete and prestresses.

Step 4: After multiple H-shaped steel main girders are lifted and placed on the PCSB capping beam, the steel boxes of the girder-end crossbeams are installed to realize the temporary transverse connection between the multiple main girders. Then, the deck corrugated bottom steel plates are hoisted and placed on the top surface of the main girder and welded with the main girder. After the prefabricated units of the steel bar of the bridge deck are installed, the concrete for the composite bridge deck and the girder-end crossbeams is poured to complete the construction of the bridge superstructure.

Step 5: the whole bridge construction is completed after constructing the bridge auxiliary structures.

5.3. Real-Scale Bridge Testing

After the completion of the Pengshan Qinglong bridge, the real-scale bridge testing including static and dynamic testing was carried out to verify the safety of the bridge and the rationality of the design and calculation method, mainly involving the strength, stiffness and dynamic performance of the main girder.

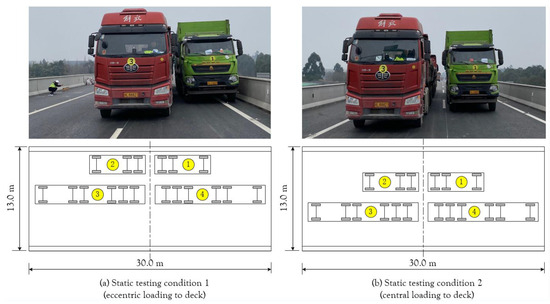

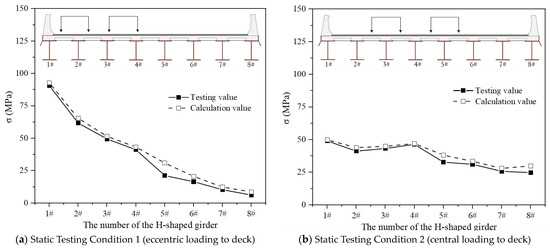

5.3.1. Static Loading Test

The static loading test was carried out on the 10th span of the Qinglong Bridge and two testing conditions of central loading and eccentric loading considering the overload scenario were designed, respectively (as shown in Figure 21). Figure 22 shows the longitudinal stress of the bottom plate of the H-shaped girder under the mid-span section, which reflects the structural strength. Under Static Testing Condition 1 (the worst-case condition), the stress of the 1#-8# girders gradually decreased and the maximum stress of 90.64 MPa existed in the 1# side girder. Meanwhile, the maximum stress of 49.03 MPa existed in the 1# side girder under Static Testing Condition 2. Even under the overload scenario, the maximum stress is less than the allowable stress of the steel after superimposing the dead load. In addition, the measured stress values are less than the calculated values and no residual stress was found in the structure after unloading, which shows that the structural strength meets the relevant specifications.

Figure 21.

Condition design of static testing. (Remarks: each of 1# and 2# vehicle weighs 40 t, while each of 3# and 4# vehicle weighs 55 t).

Figure 22.

Longitudinal stress of the bottom plate of the H-shaped girder under mid-span section.

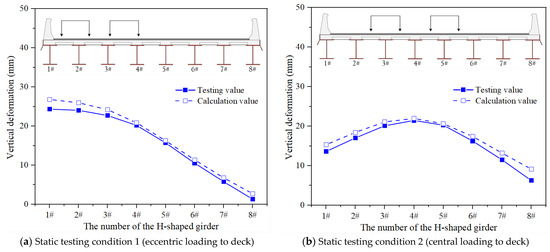

Figure 23 shows the vertical deformation of the H-shaped girder under the mid-span section, which reflects the structural stiffness. The maximum vertical deformation of 24.35 mm exists in the 1# side girder under Static Testing Condition 1, which is less than 1/600 of the span of the girder. Similarly, the measured deformation values are less than the calculated values, which means there is adequate structural stiffness.

Figure 23.

Vertical deformation of the H-shaped girder under mid-span section.

5.3.2. Dynamic Testing

The dynamic testing mainly includes structural natural vibration frequency testing and all of the spans of the Qinglong Bridge are tested. As shown in Table 7, the measured natural vibration frequency of each span is obtained by the spectrum curve of the pulsating signal. The minimum measured frequency is 3.32 Hz, which is 1.10 times that of the calculation value. The average measured frequency is 3.57 Hz, which is 1.19 times that of the calculation value, which means a good structural stiffness and dynamic performance. In addition, to evaluate the dynamic performance objectively, the natural vibration frequencies of the steel truss beam, the T-shaped, I-shaped and box-shaped concrete beams, the continuous concrete beam and the steel–concrete composite box beam are also measured and collected for comparative analysis. As shown in Figure 24, the natural vibration frequency of the proposed LA composite bridge is consistent with the concrete girder bridge and the steel girder bridge of the same scale.

Table 7.

Results of natural vibration frequency testing.

Figure 24.

Testing results of natural vibration frequency for various bridge structural systems.

5.3.3. Long-Term Performance Observation

As of February 2024, the Pengshan Qinglong Bridge has been in normal service for one year. The researchers went to the site for a total of 15 times to inspect and monitor the structural performance of the bridge and no abnormalities were found in the bridge appearance. In addition, the structural strength and stiffness performance were not attenuated. The successful construction of the Pengshan Qinglong Bridge provides strong design, construction and management experience for the construction of the viaducts within the Chengdu urban area of the CHEP.

6. Conclusions

This study proposes a novel LA composite bridge scheme for ABC through the collaborative application of new steel–concrete composite structures, rapid-assembly interface designs and low-carbon material technologies. Compared with the traditional ABC scheme, the proposed scheme has less material consumption, lower carbon emissions, lighter components, reliable structural safety and an acceptable engineering cost.

(1) Based on the urban viaduct project of the CHEP, this paper comprehensively compares the advantages and disadvantages of the concrete bridge scheme, the P-ACB scheme, the ASB scheme and the LA composite bridge scheme in terms of the construction speed, environmental interference, equipment input and labor input and, finally, the LA composite bridge scheme is recommended. In this scheme, the structural design, stress and installation characteristics of the DGH composite girder, PCSB capping beam and CFST pier are described in detail and large-scale low-carbon materials and technologies such as the SCC, the UWS and the tunable-stiffness bearings technology are introduced into the scheme for a better LA goal.

(2) The proposed scheme is evaluated comprehensively from the aspects of the construction sustainability performance, comprehensive economic performance and social benefit contribution. The LA composite bridge scheme achieves an excellent balance between various performance indicators such as low carbon and assembly. In addition, the proposed scheme has a good economic performance owing to less material consumption and no need for coating and bearing replacements during the life-cycle.

(3) The proposed scheme is applied to a real-scale bridge and the whole construction process only experienced 105 days of effective time, accompanied with slight environmental interference and construction noise and a small amount of labor and equipment inputs. The safety of the bridge, the rationality of the design concept and the calculation method are verified by performing the static loading test, dynamic loading tests and long-term performance monitoring.

Author Contributions

Conceptualization: L.K., T.M. and H.W.; Methodology: L.K., T.M. and H.W.; Software: J.X. and P.Z.; Validation: P.Z. and H.W.; Formal analysis: J.X., T.M. and P.Z.; Investigation: L.K. and H.W.; Resources: T.M.; Data curation: J.X.; Writing—original draft: L.K.; Writing—review and editing: T.M., H.W., J.X. and P.Z.; Visualization: L.K., H.W. and P.Z.; Supervision: L.K.; Project administration: J.X.; Funding acquisition: J.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Transportation Scientific and Technology Project of the Sichuan Province, China. [Grant No. 2022-ZL-07, 2022-ZL-08], and the Sichuan Science and Technology Program, China [Grant No. 23JBGOV0009].

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

Authors Ling Kang, Tingmin Mu and Huan Wang are employed by the Sichuan Highway Planning, Survey, Design and Research Institute Ltd. Authors Jinhua Xu and Ping Zhao are employed by the Sichuan Chengle Expressway Co., Ltd.

Abbreviations

| ABC | Accelerated Bridge Construction |

| LA | Low-carbon and Assembled |

| P-ACB | Precast-Assembled Concrete Bridge |

| ASB | Assembled Steel Bridge |

| CHEP | Chengle Highway Expansion Project |

| DGH | Dense-Girders–H-shape |

| PCSB | Prestress-assisted Concrete-filled Steel Box |

| CFST | Concrete-Filled Steel Tube |

| SPCR | Single-Pile Reinforced Concrete |

| SCC | Self-Compacting Concrete |

| UWS | Uncoated Weathering Steel |

References

- Bai, Y.; Wang, X.; Wang, X.; Wang, H.; Tchuente, N.F.C.; Wu, W. Pavement Strategy Optimization of Cable-Stayed Bridges against the Negative Reaction Risks of Auxiliary Piers. Appl. Sci. 2023, 13, 4877. [Google Scholar] [CrossRef]

- Li, H.; Tao, Z.; Han, D. Finite Element Analysis of Axial Compression Behavior of L-Shaped Concrete-Filled Steel Tubular Columns with Different Combinations. Buildings 2024, 14, 730. [Google Scholar] [CrossRef]

- Wang, X.; Fei, P.; Dong, Y.; Wang, C. Accelerated construction of self-anchored suspension bridge using novel tower-girder anchorage technique. J. Bridge Eng. 2019, 24, 05019006. [Google Scholar] [CrossRef]

- Shu, J.; Ma, H.; Ding, W.; Jin, Z. Improved Evidence Fusion Theory for the Safety Assessment of Prestressed Concrete Bridges. Buildings 2024, 14, 1144. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Sun, Y.; Liu, Y.; Liu, Y.; Liang, P.; Bai, Y. Fault-tolerant interval inversion for accelerated bridge construction based on geometric nonlinear redundancy of cable system. Automat. Constr. 2022, 134, 104093. [Google Scholar] [CrossRef]

- Wang, X.; Wang, F.; Zhao, J.; Qi, Z.; Wang, H.; Li, P.; Tao, P. Machine learning-based assembly fault-tolerant interval inversion method for stay cables. J. Harbin Inst. Technol. 2023, 55, 60–69. [Google Scholar]

- Tazarv, M.; Saiidi, M.S. UHPC-filled duct connections for accelerated bridge construction of RC columns in high seismic zones. Eng. Struct. 2015, 99, 413–422. [Google Scholar] [CrossRef]

- Kim, D.; Kwak, Y.; Sohn, H. Accelerated cable-stayed bridge construction using terrestrial laser scanning. Automat. Constr. 2020, 117, 103269. [Google Scholar] [CrossRef]

- Zhang, G.; Su, S.; Han, Q.; Xu, K.; Li, Z.; Du, X. Experimental and numerical investigation of seismic performance of prefabricated double-column piers used in accelerated bridge construction. Eng. Struct. 2023, 293, 116688. [Google Scholar] [CrossRef]

- Kagioglou, P.; Katakalos, K.; Mitoulis, S.A. Resilient connection for accelerated bridge constructions. Structures 2021, 33, 3025–3039. [Google Scholar] [CrossRef]

- Xu, Y.; Wei, K.; Zhang, Z.; Wang, J.; Mao, H.; Fu, W. Seismic Behavior of Precast Bridge Column–Cap Beam Joints with Grouted Corrugated Duct Connections: Experimental and Numerical Study. J. Bridge Eng. 2022, 28, 04022153. [Google Scholar] [CrossRef]

- Jiao, C.; Liu, W.; Li, Y.; Shi, W.; Long, P. Experimental study of CFST embedded precast concrete bridge column-foundation connection with studs. Soil Dyn. Earthq. Eng. 2023, 168, 107826. [Google Scholar] [CrossRef]

- Xia, B.; Xiao, J.; Ding, T.; Guan, X.; Chen, J. Life cycle assessment of carbon emissions for bridge renewal decision and its application for Maogang Bridge in Shanghai. J. Clean. Prod. 2024, 448, 141724. [Google Scholar] [CrossRef]

- Yu, F.; Ma, K.; Yuan, B.; Liu, Z.; Guo, Y.; Wang, Y. Experimental study of a new assembled integral concrete–steel open-web sandwich plate composite bridge. Eng. Struct. 2022, 272, 115018. [Google Scholar] [CrossRef]

- Zhang, C.; Yin, Z.; Qin, R. Attention-Enhanced Co-Interactive Fusion Network (AECIF-Net) for automated structural condition assessment in visual inspection. Automat. Constr. 2024, 159, 105292. [Google Scholar] [CrossRef]

- Nguyen, D.-C.; Jeon, C.-H.; Roh, G.; Shim, C.-S. BIM-based preassembly analysis for design for manufacturing and assembly of prefabricated bridges. Automat. Constr. 2024, 160, 105338. [Google Scholar] [CrossRef]

- Xiao, F.; Hulsey, J.L.; Balasubramanian, R. Fiber optic health monitoring and temperature behavior of bridge in cold region. Struct. Control Health Monit. 2017, 24, e2020. [Google Scholar] [CrossRef]

- Xiao, F.; Hulsey, J.L.; Chen, G.S.; Xiang, Y. Optimal static strain sensor placement for truss bridges. Int. J. Distrib. Sens. N. 2017, 13, 155014771770792. [Google Scholar] [CrossRef]

- Xiao, F.; Chen, G.S.; Hulsey, J.L.; Dolan, J.D.; Dong, Y. Ambient loading and modal parameters for the Chulitna River Bridge. Adv. Struct. Eng. 2016, 19, 660–670. [Google Scholar] [CrossRef]

- Xiao, F.; Chen, G.S.; Hulsey, J.L. Monitoring Bridge Dynamic Responses Using Fiber Bragg Grating Tiltmeters. Sensors 2017, 17, 2390. [Google Scholar] [CrossRef]

- Zheng, H.; Gong, Z.; Cui, C.; Chen, Z.; Ma, X.; Li, H.; Li, Y. Experimental study on oblique-shear performance of splicing joint for precast ultrahigh-performance concrete segmental bridges. Case Stud. Constr. Mat. 2023, 19, e02336. [Google Scholar] [CrossRef]

- Li, X.-X.; Deng, E.; Wang, Y.-W.; Ni, Y.-Q. 3D laser scanning for predicting the alignment of large-span segmental precast assembled concrete cable-stayed bridges. Automat. Constr. 2023, 155, 105056. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Zhao, G.; Zhang, J. Numerical study on seismic behavior of precast bridge columns with large-diameter bars and UHPC grout considering the bar-slip effect. Bull. Earthq. Eng. 2020, 18, 4963–4984. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Investigation of a Detail for Connecting Precast Columns to Precast Cap Beams Using Ultrahigh-Performance Concrete. J. Bridge Eng. 2020, 25, 04020001. [Google Scholar] [CrossRef]

- Li, S.; Zhao, T.; Alam, M.S.; Cheng, Z.; Wang, J.-Q. Probabilistic seismic vulnerability and loss assessment of a seismic resistance bridge system with post-tensioning precast segmental ultra-high performance concrete bridge columns. Eng. Struct. 2020, 225, 111321. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, L.; Zhang, Z.; Cao, X.; Khan, I.; Deng, K.; Xu, T. Effective stress-strain relationship for grouted sleeve connection: Modeling and experimental verification. Eng. Struct. 2020, 210, 110300. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Zheng, X.; Song, Z. Experimental study on seismic response of precast bridge piers with double-grouted sleeve connections. Eng. Struct. 2020, 221, 111023. [Google Scholar] [CrossRef]

- Zhanghua, X.; Jiping, G.; Youqin, L.; Faqiang, Q. Shake table study on precast segmental concrete double-column piers. Earthq. Eng. Eng. Vib. 2020, 19, 705–723. [Google Scholar] [CrossRef]

- Li, S.; He, S.; Jin, Y. Scour Depth Determination of Bridge Piers Based on Time-Varying Modal Parameters: Application to Hangzhou Bay Bridge. J. Bridge Eng. 2017, 22, 04017107. [Google Scholar] [CrossRef]

- Lu, W.J.; Li, B.; Hou, J.F.; Xu, X.W.; Zou, H.F.; Zhang, L.M. Drivability of Large Diameter Steel Cylinders During Hammer-Group Vibratory Installation for the Hong Kong–Zhuhai–Macao Bridge. Engineering 2023, 20, 180–191. [Google Scholar] [CrossRef]

- Tamai, S.; Yagata, Y.; Hosoya, T. New technologies in fabrication of steel bridges in Japan. J. Constr. Steel Res. 2002, 58, 151–192. [Google Scholar] [CrossRef]

- Liu, H.; He, X.; Gao, L.; Li, F. Numerical Simulation of the Wind Field of Assembled Steel Truss Bridge. Appl. Mech. Mater. 2013, 340, 841–847. [Google Scholar] [CrossRef]

- Martínez-Muñoz, D.; García, J.; Martí, J.V.; Yepes, V. Discrete swarm intelligence optimization algorithms applied to steel–concrete composite bridges. Eng. Struct. 2022, 266, 114607. [Google Scholar] [CrossRef]

- Campagne, F.V.L. Efficiently Including Reclaimed Steel Elements in a Truss Bridge Design by Performing a Stock-Constrained Shape and Topology Optimization. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2 December 2022. [Google Scholar]

- Aydın, Z. Size, layout and tendon profile optimization of prestressed steel trusses using Jaya algorithm. Structures 2022, 40, 284–294. [Google Scholar] [CrossRef]

- Hui, J.-Z.; Lei, J.-Y.; Wang, Y.-F.; Zhang, F.-Q.; Ding, K.; Zhang, J.-L. Multiattribute Decision-making Evaluation Method for Highway Steel Bridge Factory Manufacturing. China J. Highw. Transp. 2021, 34, 99–108. [Google Scholar]

- Zhang, C.; Liu, Y.; Liu, J.; Yuan, Z.; Zhang, G.; Ma, Z. Validation of long-term temperature simulations in a steel-concrete composite girder. Structures 2020, 27, 1962–1976. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Z.; Wang, H.; Gao, Y.; Fan, L. Numerical Investigation on Novel Shear Connectors in Prefabricated Composite Beams. Appl. Sci. 2023, 13, 6130. [Google Scholar] [CrossRef]

- Martínez-Muñoz, D.; García, J.; Martí, J.V.; Yepes, V. Deep learning classifier for life cycle optimization of steel–concrete composite bridges. Structures 2023, 57, 105347. [Google Scholar] [CrossRef]

- Wang, X.; Mao, X.; Frangopol, D.M.; Dong, Y.; Wang, H.; Tao, P.; Qi, Z.; Tang, S. Full-scale experimental and numerical investigation on the ductility, plastic redistribution, and redundancy of deteriorated concrete bridges. Eng. Struct. 2021, 234, 111930. [Google Scholar] [CrossRef]

- Standardization, C.A.F.E.C. Technical Specification for Application of Self-Compacting Concrete; China Planning Press: Beijing, China, 2021; pp. 1–67. [Google Scholar]

- Fu, J.-D.; Wan, S.; Yang, Y.; Su, Q.; Han, W.-W.; Zhu, Y.-B. Accelerated corrosion behavior of weathering steel Q345qDNH for bridge in industrial atmosphere. Constr. Build. Mater. 2021, 306, 124864. [Google Scholar] [CrossRef]

- Ji, W.; Li, X.; He, J.; Zhang, X.; Li, J. Research status of monitoring, detection, and intelligent identification of weathering steel bridges. J. Constr. Steel Res. 2024, 220, 108814. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, J.; Kang, J.; Duan, M.; Wang, Y. Rust layer adhesion capability and corrosion behavior of weathering steel under tension during initial stages of simulated marine atmospheric corrosion. Constr. Build. Mater. 2020, 234, 117393. [Google Scholar] [CrossRef]

- Administration for Market Regulation of Sichuan province C. Technical Specification for Variable Stiffness Bearings of Highway Beam Bridge; China Communication Press: Beijing, China, 2019; pp. 1–38. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).