1. Introduction

In the evolution of the construction industry, the advent of green prefabrication, uplifted via digital and smart construction strategies, marks a significant move towards sustainability. Green prefabrication emerges as a leader in construction industry innovation [

1].

Prefabrication has witnessed a paradigm shift while evolving from basic assembly-line production to digitally enabled manufacturing [

2]. Building information modeling (BIM), 3D printing, and the Internet of things (IoT) are the key technologies transforming construction digitally; BIM has helped provide a digital model that streamlines project management, promotes sustainability, optimizes material uses, and minimizes CO

2 emissions and waste [

3]. Digital tools may also offer various solutions to handling labor shortages and skill gaps in the construction industry [

4] by automating and digitizing some aspects of industrial construction processes in which technology mitigates risks of human error and reduces reliance on manual labor [

5]. However, in digitalizing construction and its process in green prefabrication, there are some challenges; for instance, a high initial investment cost, the complexity of technology, safety, and cybersecurity are concerns to look at and resolve [

6]. In terms of sustainability, the green prefabrication and evaluation of digital construction strategies in this context requires focused strategies that reduce the carbon footprints of buildings, enhance efficiency, and promote economic aspects of construction [

7]. Further, the social dimension of sustainability belongs to the categories of health, wellbeing, and inclusivity, which are gaining prominence in the discourse surrounding green prefabrication [

8]. Digital tools enhance design to promote human well-being, air quality, and daylight [

9].

Compared with computer-aided design (CAD), BIM is more advantageous in building design, reducing design construction errors and, later, construction costs [

10]. So far, BIM has contributed well to the industry, while its tools have been developed in the context of traditional non-prefabricated buildings [

11]. The functional features related to prefabricated buildings are not complete in some existing BIM products, where they still need to be improved in terms of prefabricated buildings. The exploration of digital construction strategies within the jurisdiction of green prefabrication represents a journey towards sustainability, as well as efficient and resilient construction manufacturing.

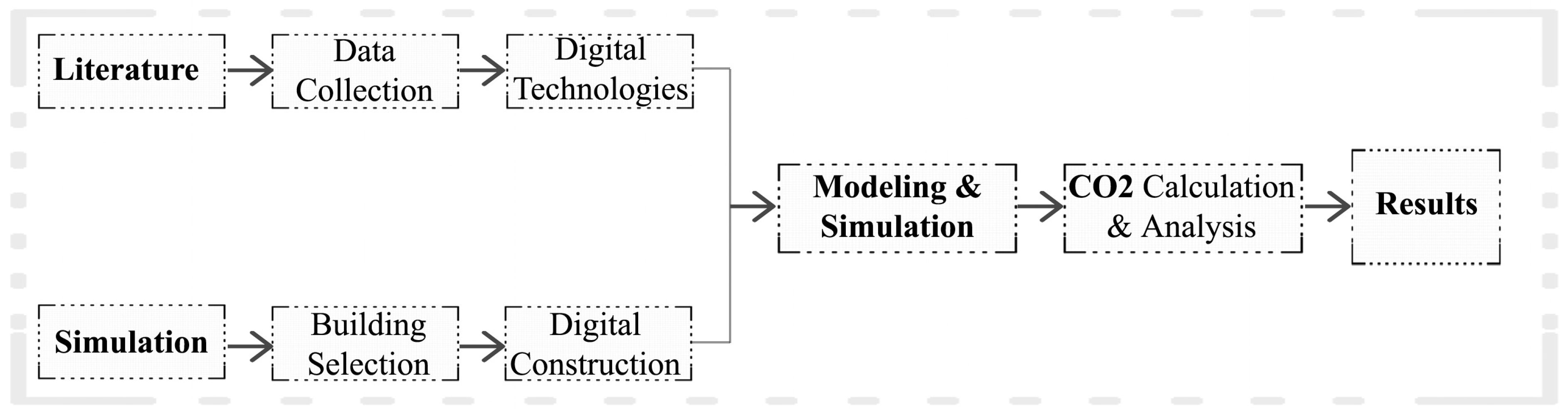

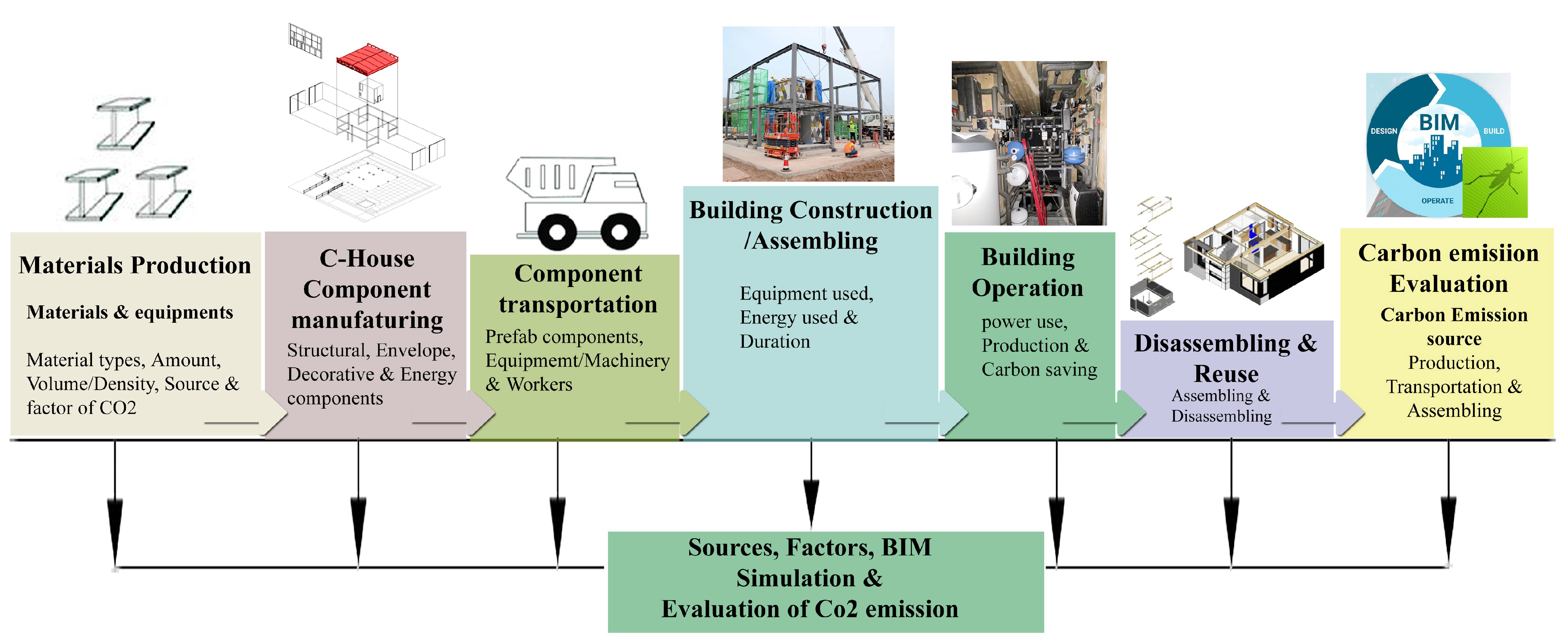

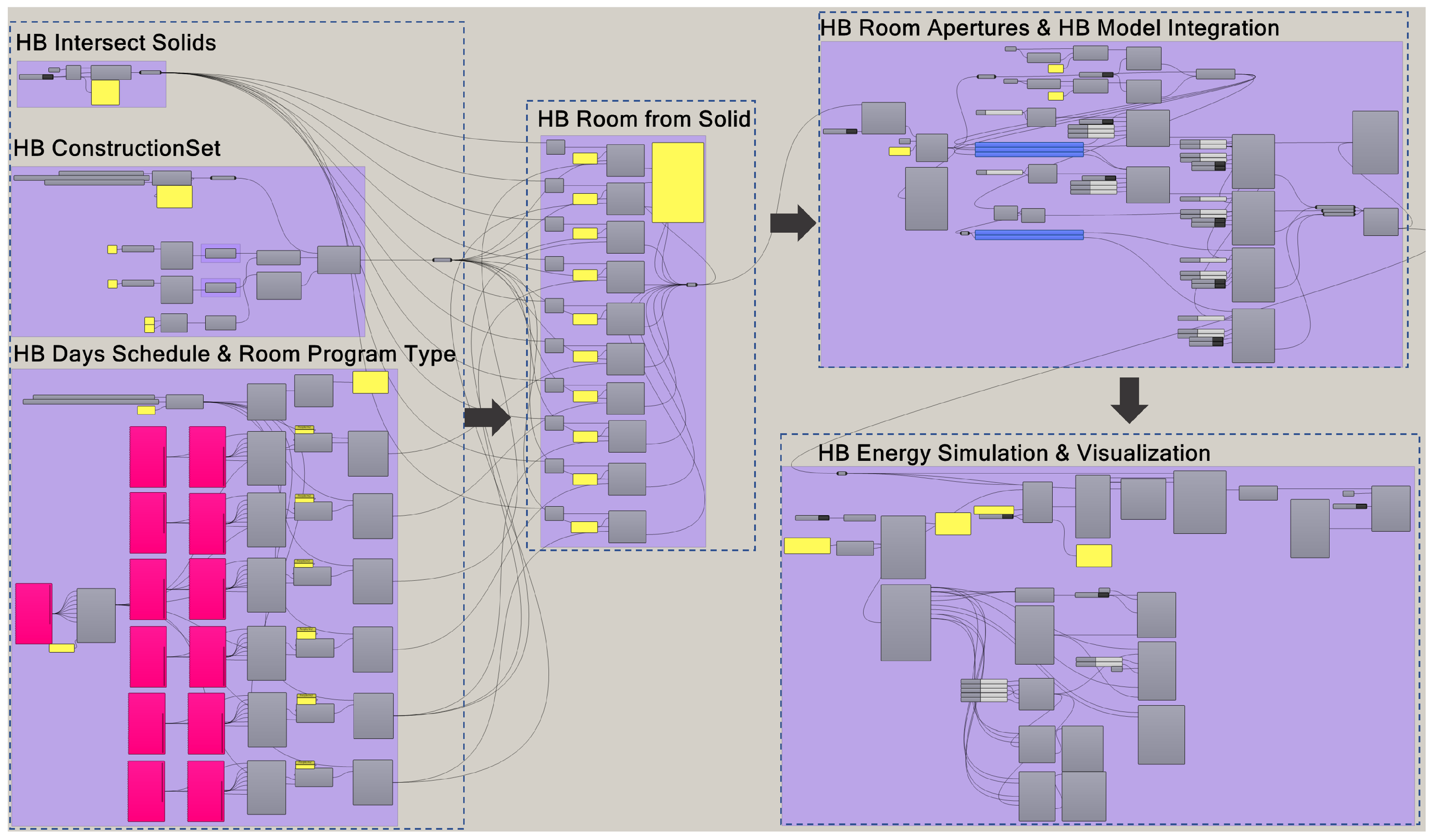

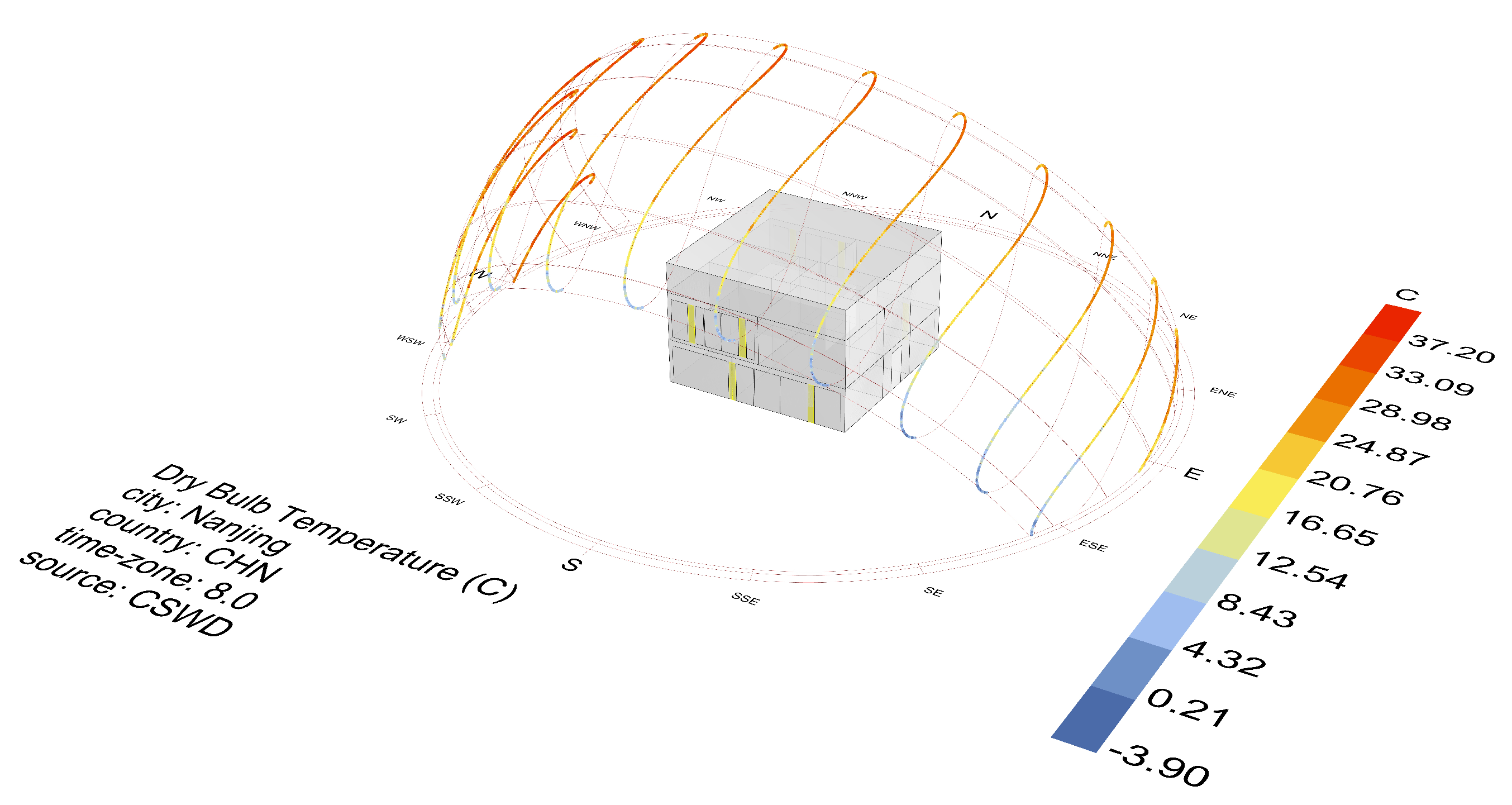

Through an analysis of energy and simulation, this work examines the sustainability of Southeast University’s C-House, a prefabricated building situated in Nanjing, China. This study evaluated carbon emissions by using BIM and investigated methods of optimization, such as passive options like photovoltaic (PV) panels. By integrating intelligent and eco-friendly strategies into digital construction, BIM enabled performance evaluation and resource conservation. To estimate carbon emissions, the life-cycle assessment of C-House was examined, with each stage being assessed by using mathematical formulas and BIM simulation tools. The framework for the project’s future is informed by this study, which gives digital building strategies priority in promoting green prefabrication. The promotion of sustainable practices in the field of green prefabrication requires the adaptation of sustainable policies, improving education in the sector. The evaluation of C-House shows effectiveness in reaching social, economic, and environmental goals. Upcoming frameworks will give priority to scalability, technology integration, and digital strategy refinement. This paper focuses on the synthesis of the latest research in the field of smart and sustainable construction and the prefabrication of green buildings to evaluate their strategies, implementation, and investigation while keeping in mind their potential and challenges in fostering sustainable practices.

This paper critically evaluates these strategies and investigates their core in contemporary research to reveal that digital innovation like BIM is reshaping the domain of prefabrication in alignment with smart and green development [

12]. This study reveals seven stages in the life cycle of the prefabricated C-House, compared with the conventional five stages of a regular structure. C-House is in its third cycle, having finished the first two cycles. Reusing green prefab structures has a positive impact on the environment and can lower carbon emissions when the third cycle is completed.

4. Case Analysis

The selection of C-House, representing a green prefabricated building, aligns with the primary focus on digital construction strategies, analyzing carbon emissions and energy efficiency. The criteria for selection also included project scale, its multifunctional behavior, geographical location, climatic conditions, and the utilization of digital techniques for evacuation, like BIM. This case study offers practical insights into green prefabricated building strategies and their application.

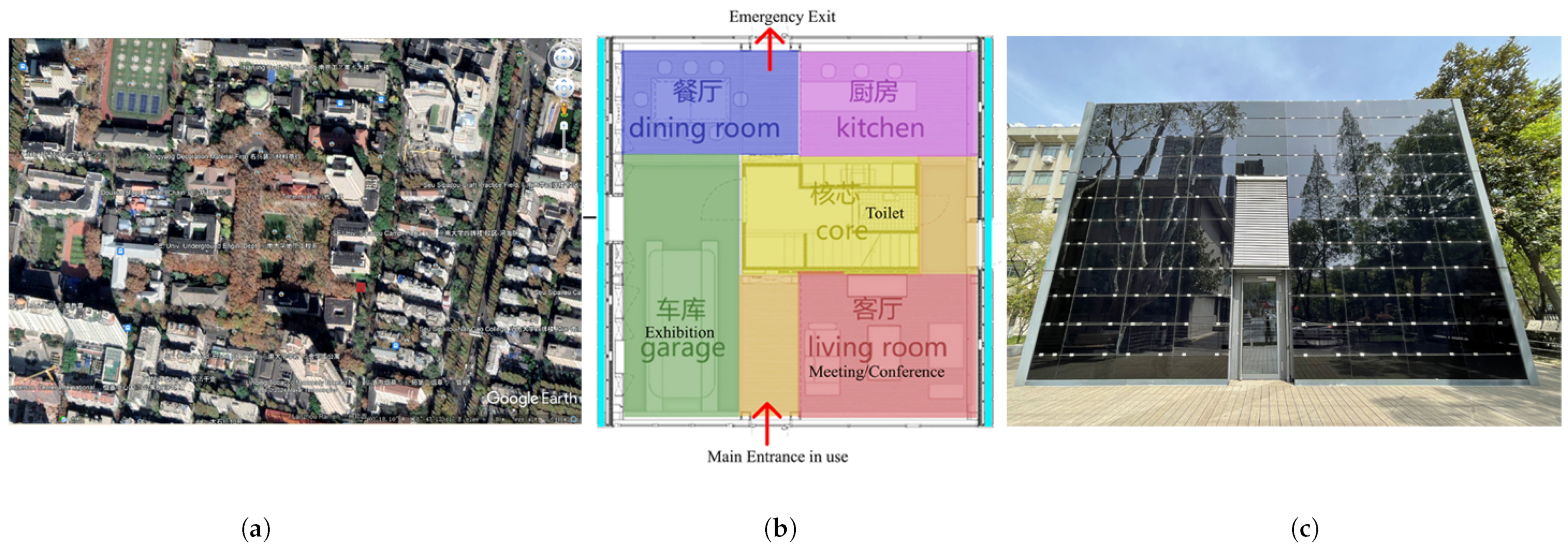

4.1. Geographical Location and Floor Plans of C-House

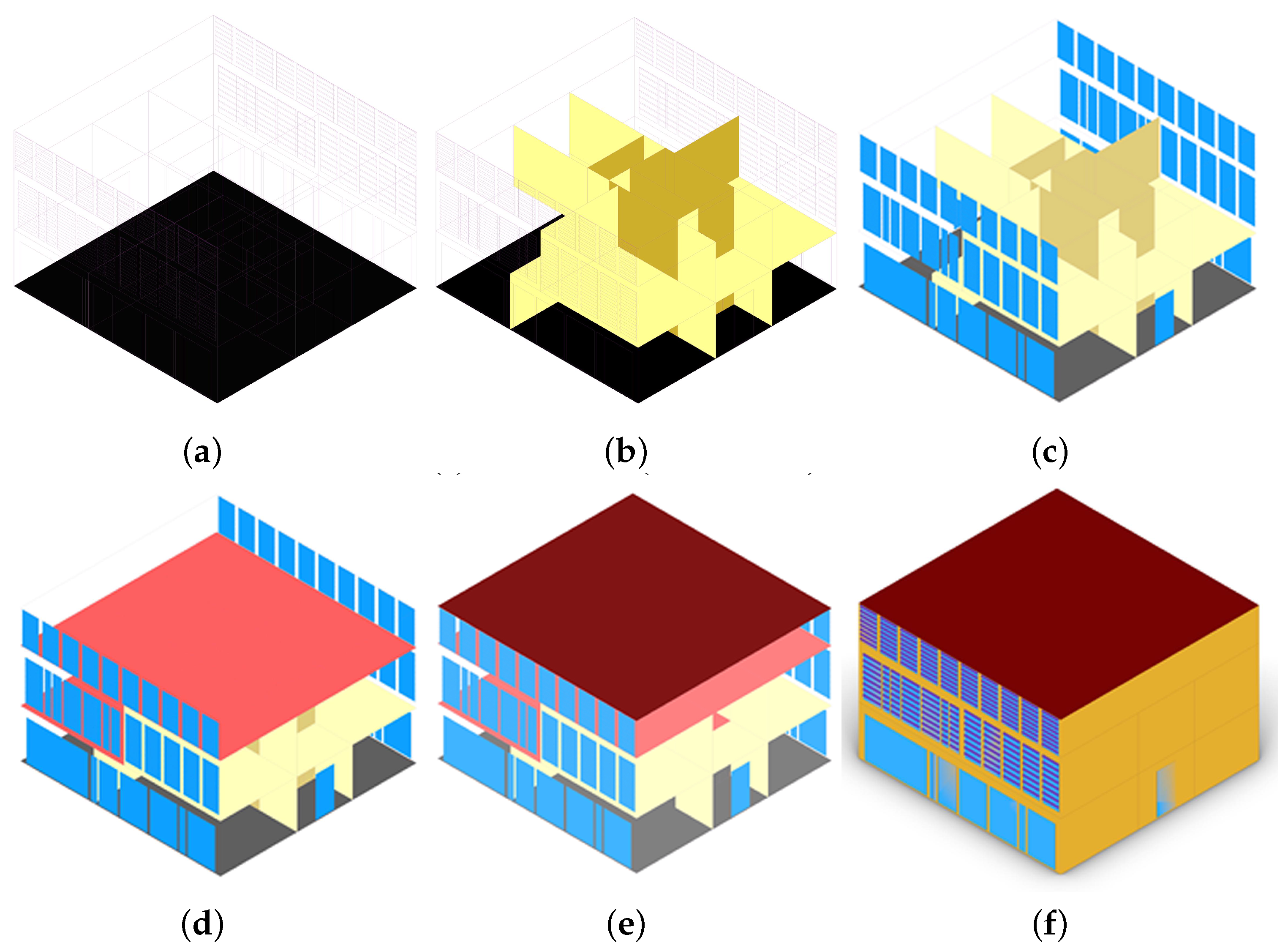

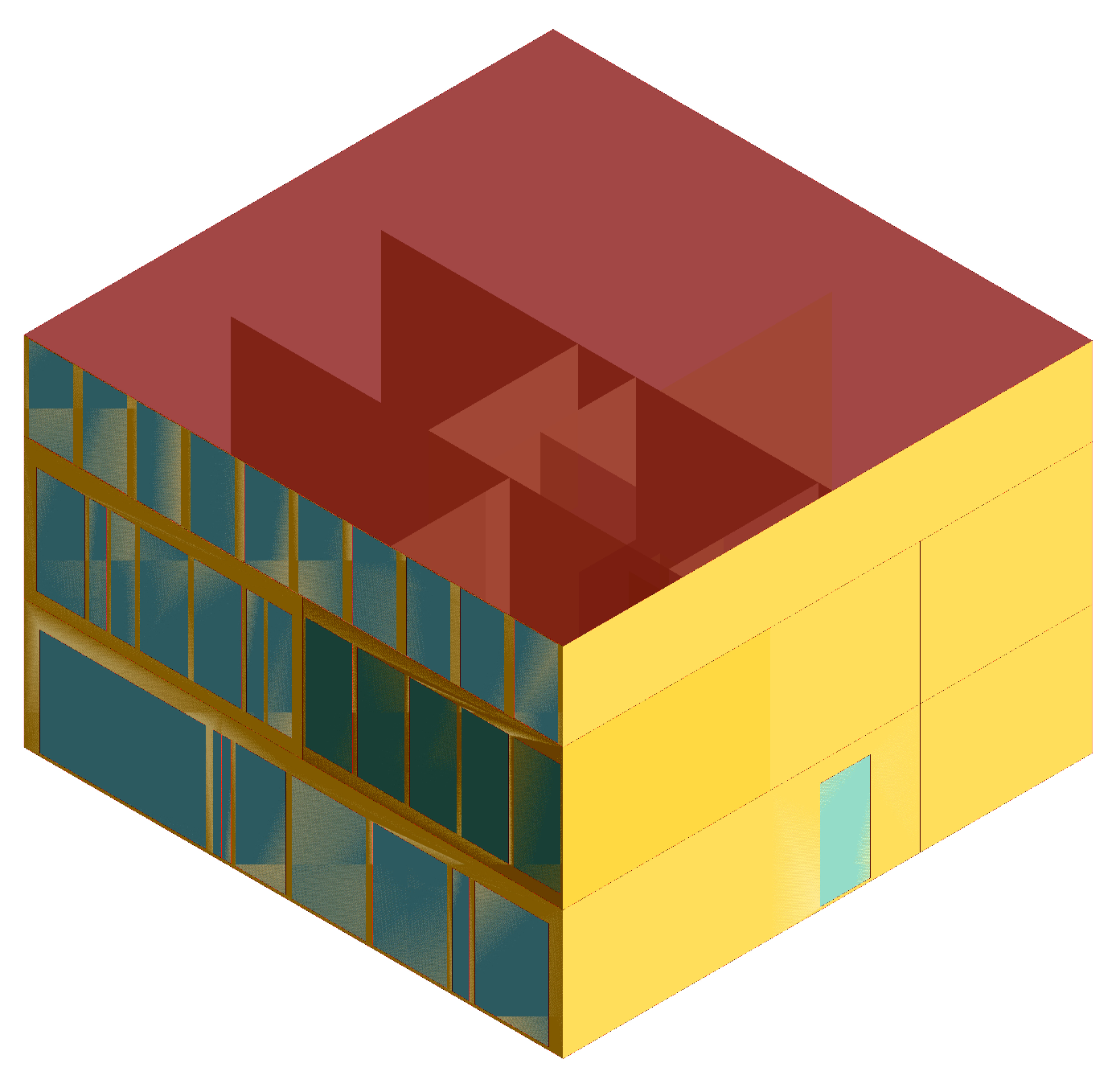

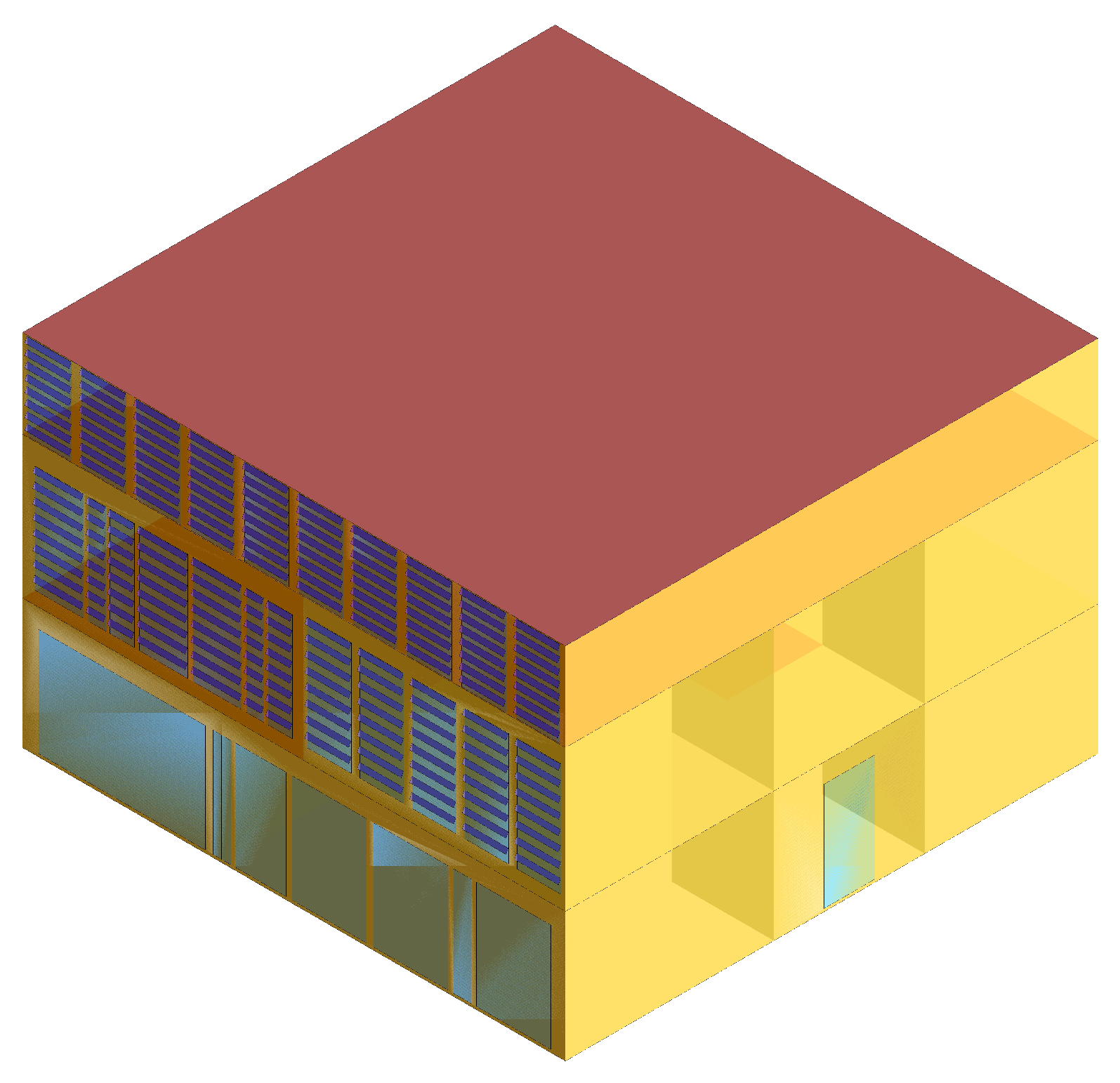

The building was located in the ancient capital of China at Nanjing No. 2 Sipailou, Xuanwu District, Nanjing City, Jiangsu Province, Southeast University (Sipailou Campus), and the spatial arrangement of its floor plan, as well as the exterior view of the building and PV panels, is shown in

Figure 4.

4.2. Prefabricated Building Components of C-House

Each component shown in

Figure A1 was developed and manufactured in a factory before being sent to the assembly site (

Figure A2).

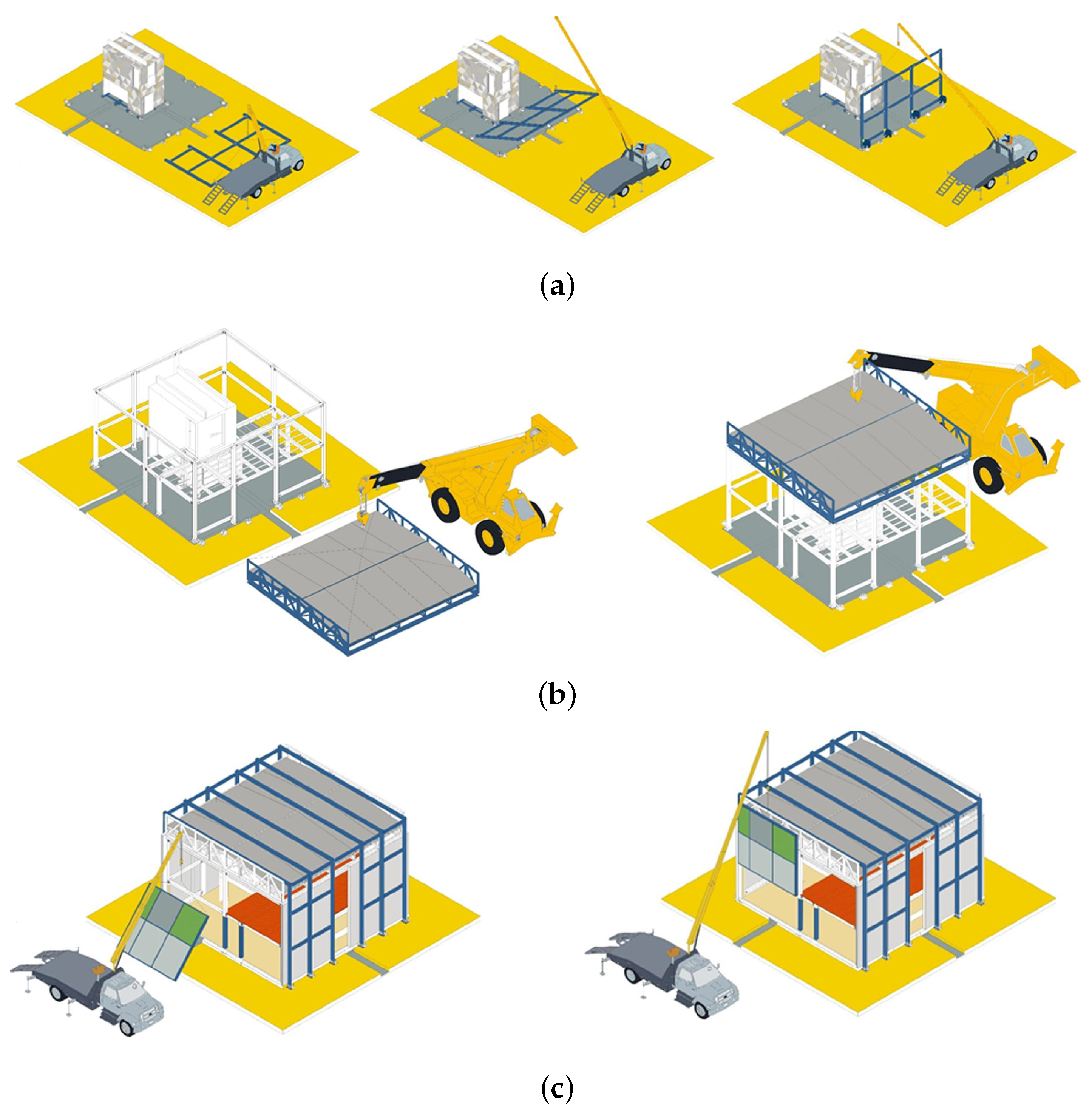

4.3. Assembly of Building on Site along with Its Prefabricated Components

Changing the vertical concept of component installation to horizontal installation on the ground can reduce the time required for a truck crane to repeatedly move up and down, avoid operational work, and significantly improve operational efficiency. For laborers/workers, this methodology can reduce the time working at heights and even eliminate the need for scaffolding when building the main structure, completely avoiding injuries such as falling from heights.

In the case of C-House, the roof components are the largest components in all the prefabricated building construction, with the heaviest weight and the processes with the most numerous requirements. The difference between C-House and normal roof construction is that all roof components from the structure to maintenance to surface layers are completed on the ground; the workers do not need scaffolding while installing the roof due to its low height.

On the ground, the curtain walls and glass panels are firstly installed by using a car crane to form multiple curtain wall units, which are installed separately by using the car crane. This improves the installation speed but also replaces manual labor with the help of a crane.

4.4. Detailed Life-Cycle Assessment of C-House

The types of materials and components used in C-House, their specific production amounts, their carbon emission factors, and their overall carbon emission values are what distinguish the various materials and components. For example, we can discuss the total carbon emissions from various materials. For instance, iron emits more emissions than aluminum. The following tables of materials and component specifications, along with carbon calculation data on each stage, and the final chart of the categorization of carbon emission computation, are available, in addition to the basic mathematical formula of each step by which we may calculate carbon emissions:

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6 in

Appendix A. The total carbon emissions were calculated to streamline the statistical analysis in

Section 4.4, which is focused on the detailed life-cycle assessment of C-House and includes information on material production, component manufacturing, and the detailed seven stages of the life cycle.

4.4.1. Material Production

The total carbon emissions of the material production phase (

) are calculated as

In Equation (

1) [

37],

represents the carbon emissions of the material production phase (kgCO

2e),

is the consumption of the type

i main material (kg), and

is the type i material’s carbon emission factor (kgCO

2e/per unit material consumption).

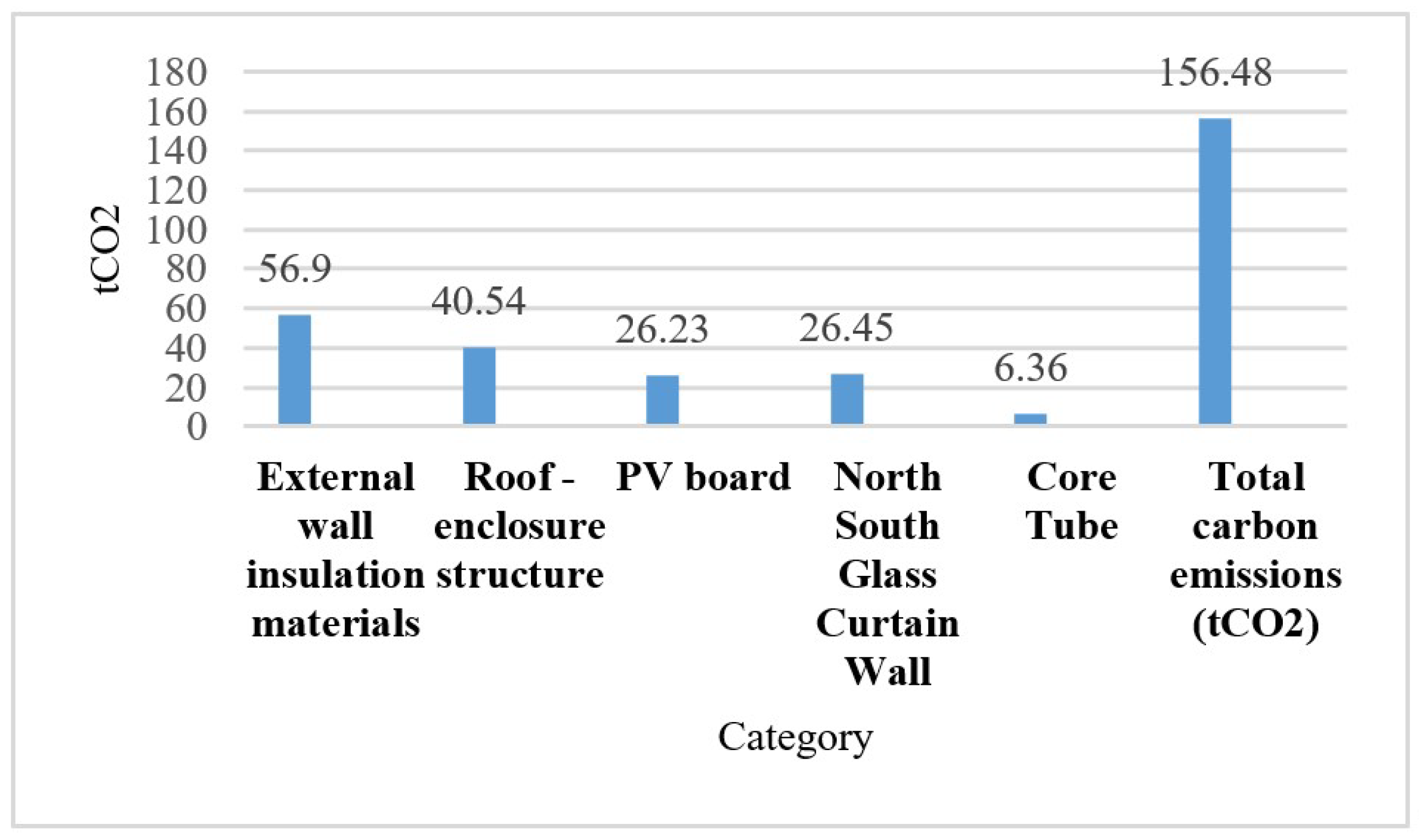

The carbon emissions calculated for the material production stage are further divided into five phases, i.e., external wall insulation materials: 56.90 tCO

2; roof enclosure structure: 40.54 tCO

2; PV board: 26.23 tCO

2; north–south glass curtain wall: 26.45 tCO

2; and core tube multi-category material extraction: 6.36 tCO

2. The total amount of carbon emissions is 156.50 tCO

2, as shown in

Figure 5.

4.4.2. Component Manufacturing

The total carbon emissions of the component manufacturing phase (

) are calculated as

In Equation (

2) [

37],

represents the carbon emissions of the component manufacturing phase (kgCO

2e),

is the consumption of the type

ith main component (kg), and

is the type

ith component’s carbon emission factor (kgCO

2e/per unit component weight).

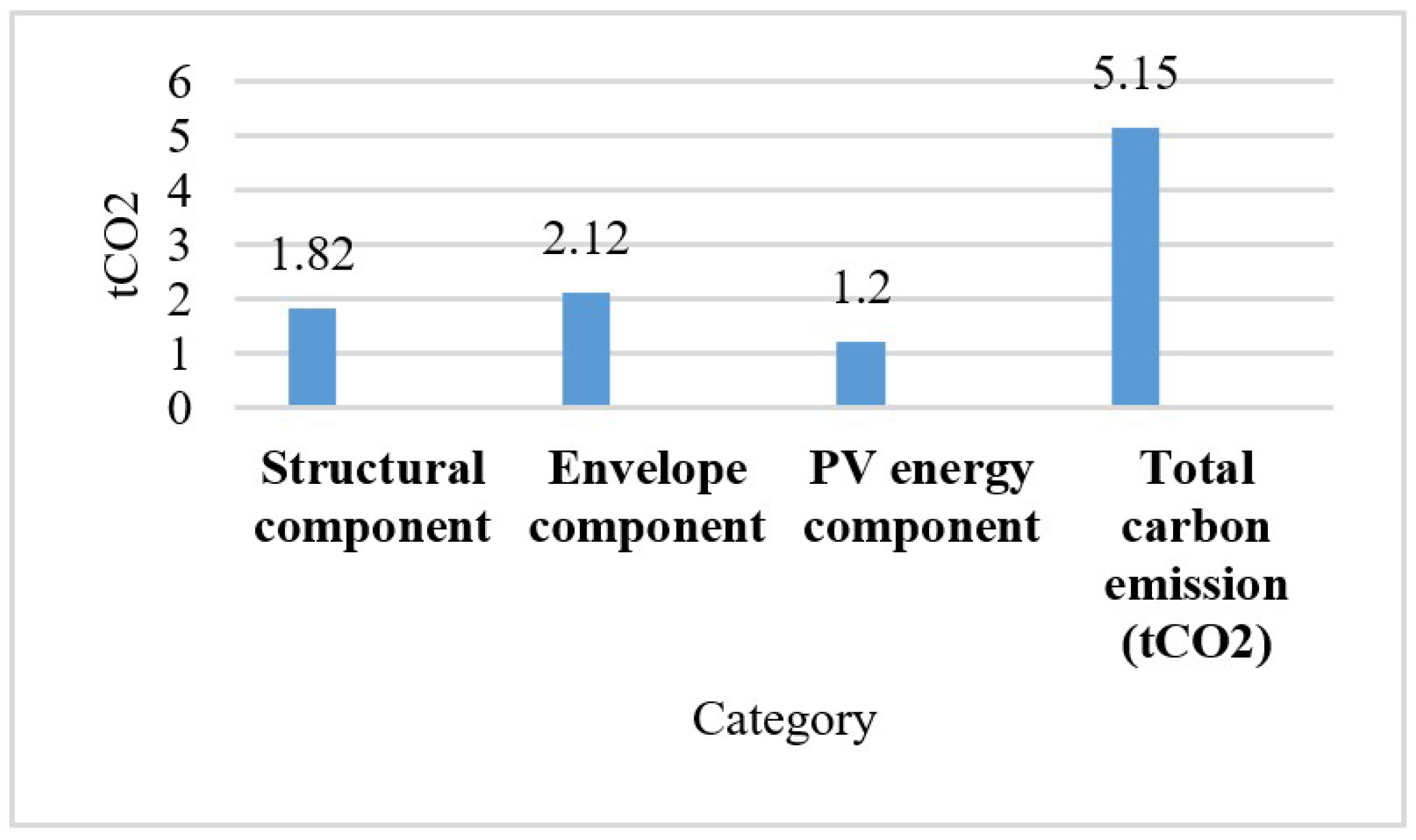

The carbon emissions calculated for the component manufacturing stage are further divided into three phases, i.e., structural components: 1.82 tCO

2; envelope components: 2.12 tCO

2; and PV energy components: 1.20 tCO

2. The total amount of carbon emission is 5.15 tCO

2, as shown in

Figure 6.

4.4.3. Component Transportation

The total carbon emissions during the transportation of the building components (

) are calculated as

In Equation (

3) [

37],

represents the carbon emissions during the transportation of the building components (kgCO

2e),

is the consumption of the type

i main component (kg),

is the average transportation distance of the

ith building component (km), and

is the type

jth transportation mode of the type

ith component’s carbon emission factor [kgCO

2e/(t·km)].

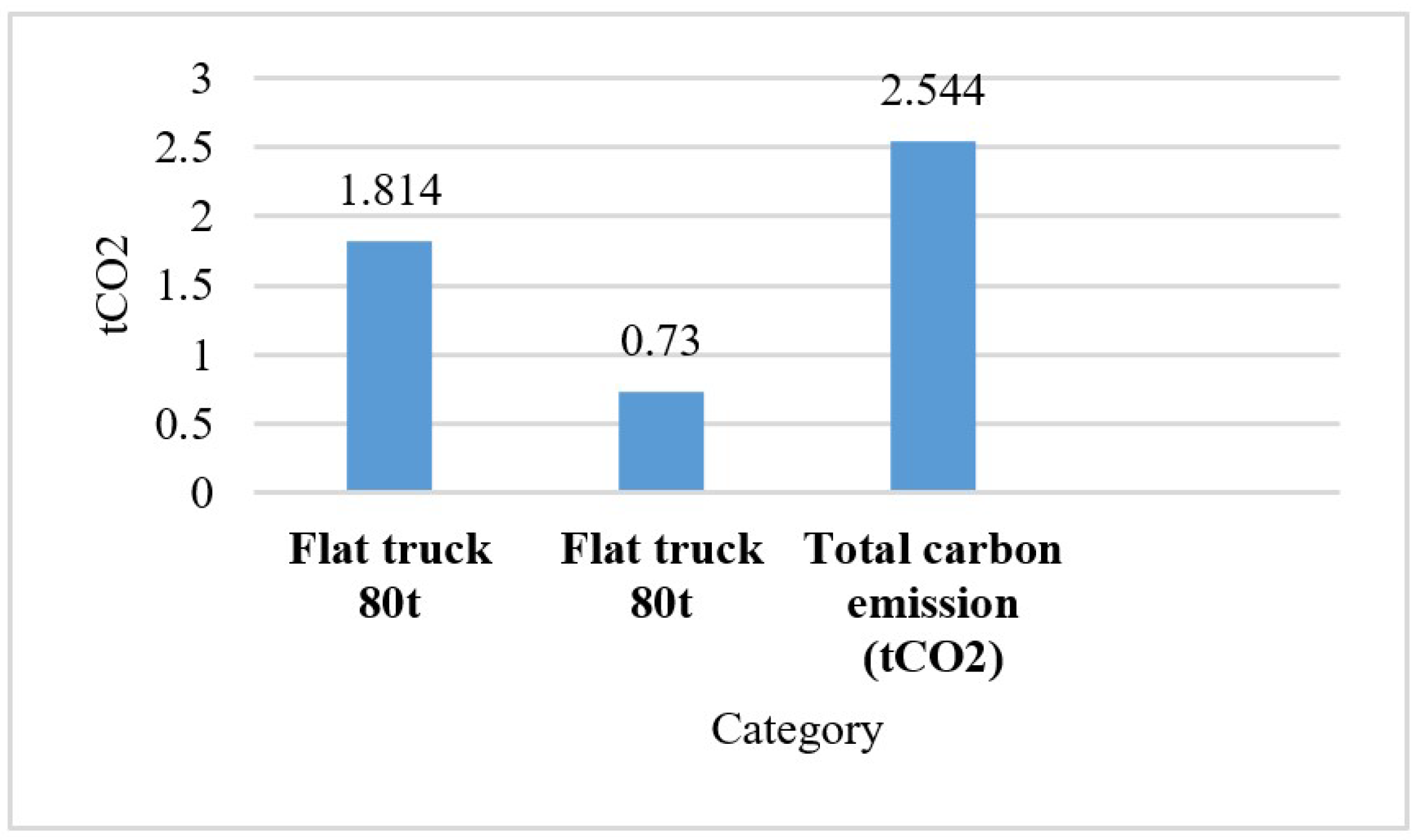

The carbon emissions calculated for the component transportation stage are further divided into two phases, i.e., flatbed truck 80 t: 1.81 tCO

2; and flatbed truck 80 t: 0.73 tCO

2. The total amount of carbon emissions is 2.54 tCO

2, as shown in

Figure 7.

4.4.4. Building Construction/Assembling

The total carbon emissions during the building construction phase (

) are calculated as

In Equation (

4) [

37],

represents the carbon emissions during the building construction phase (kgCO

2e),

is the total consumption of energy in the building construction phase (kWh or kg),

is the type

ith energy’s carbon emission factor (kgCO

2e/kWh or kgCO

2e/kg), and A is the building area (m

2).

The carbon emissions calculated for the assembling stage are further divided into eight phases, i.e., workers: 11.2 tCO

2; 80 t truck crane: 2.04 tCO

2; mobile lifting: 1.92 tCO

2; cutting machine: 0.02 tCO

2; wood work saw: 0.13 tCO

2; AC welding machine: 4.45 tCO

2; electric wrench: 0.32 tCO

2; and electric drill: 0.21 tCO

2. The total amount of carbon emissions is 20.33 tCO

2, as shown in

Figure 8.

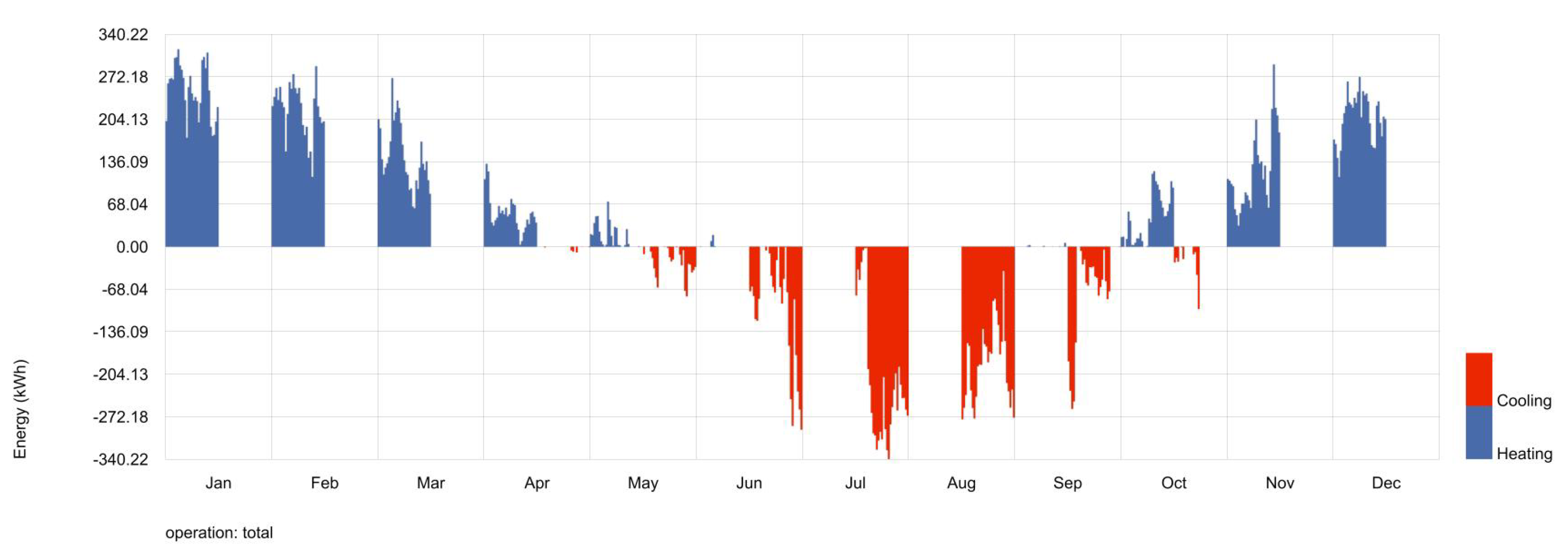

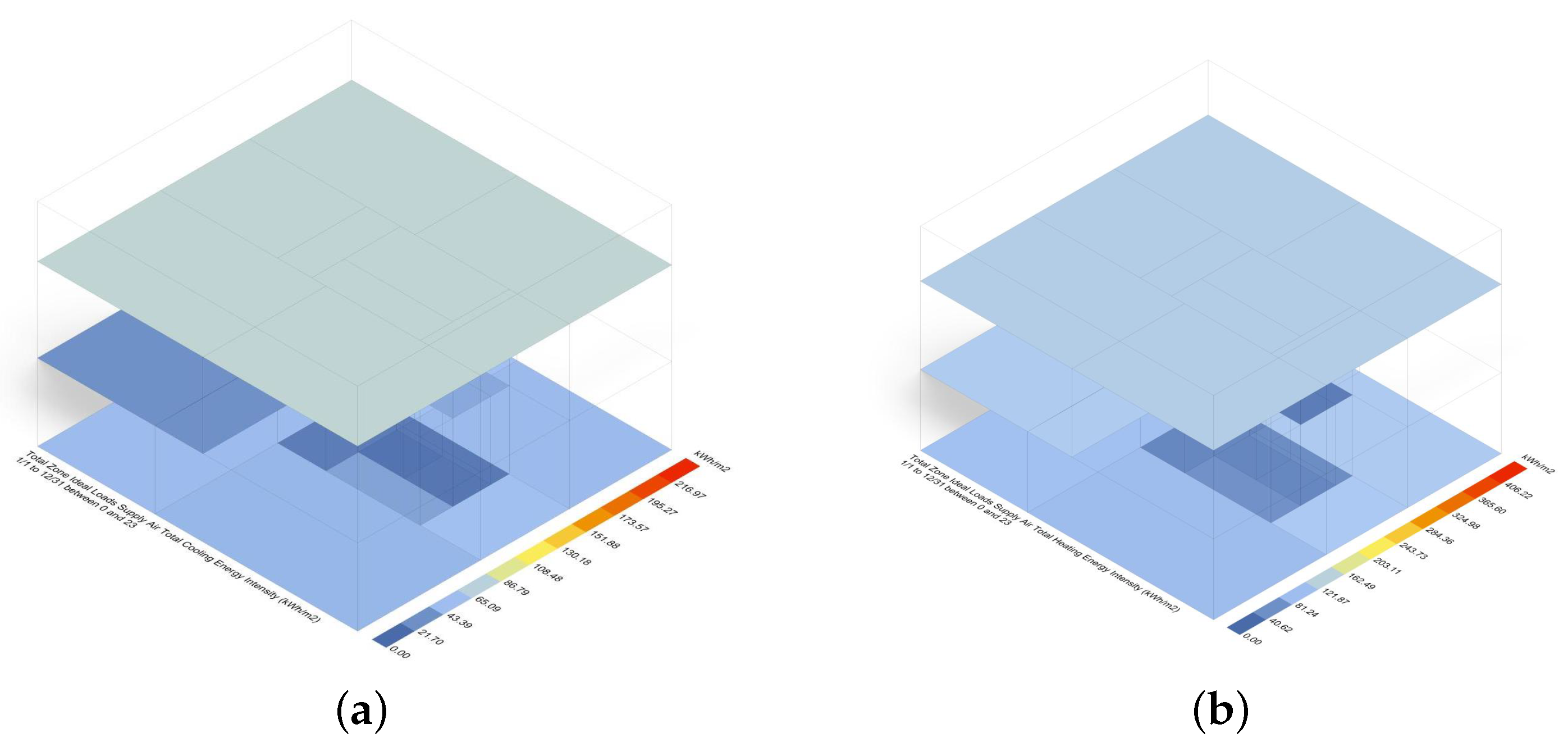

4.4.5. Building Operation

The total carbon emissions per unit building area during the building operation phase (

) are calculated as

In Equation (

5) [

37],

represents the carbon emissions per unit building area during the building operation phase (kgCO

2e/m

),

is the annual consumption of type

ith energy (unit/a),

is the type

i energy’s carbon emission factor (tCO

2/tJ),

y is the design lifetime of the building, and

A is the building area (m

).

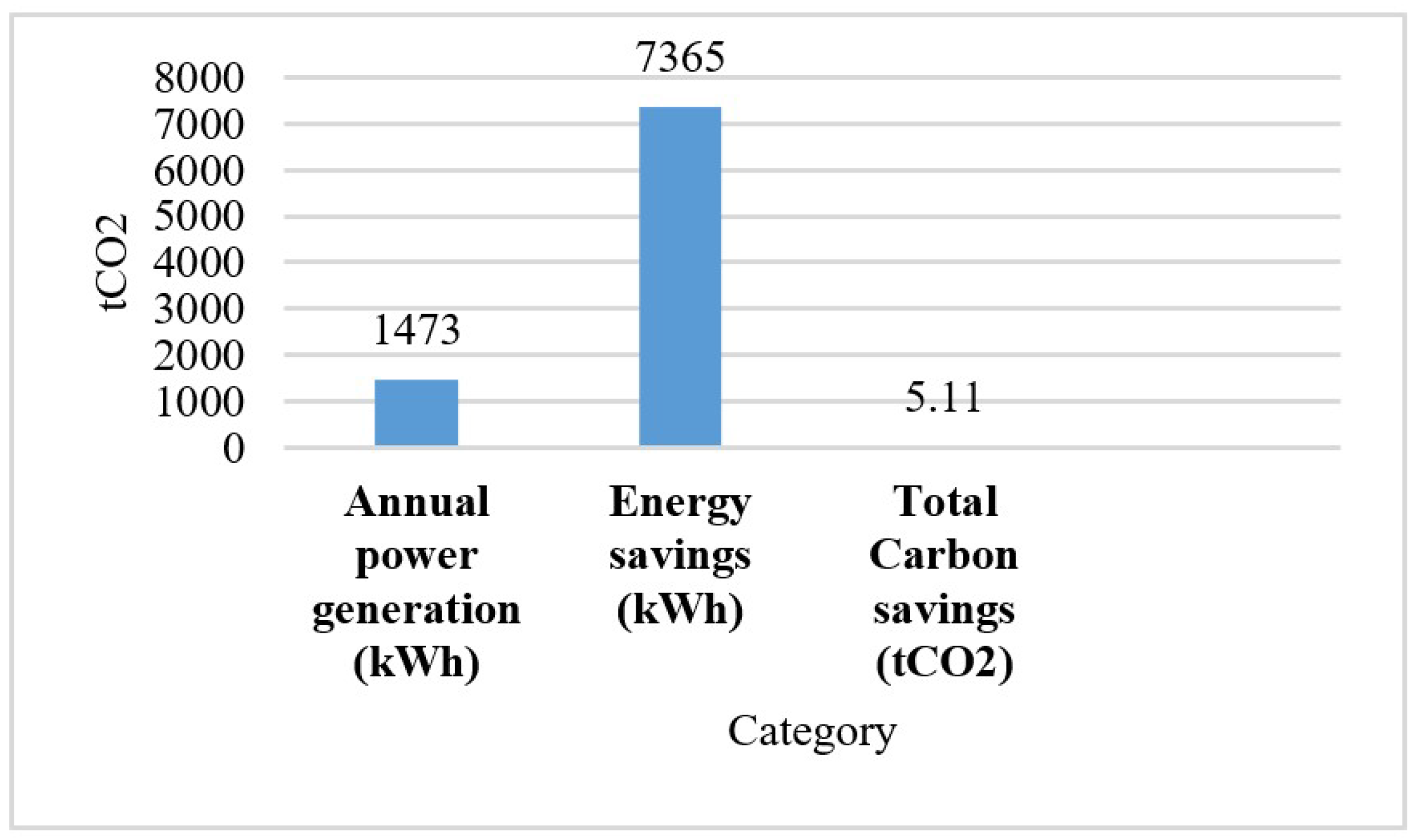

The carbon emissions calculated for the operational stage are further divided into two phases, i.e., average annual power generation (kWh): 1473; and energy savings from 2018 to the present (kWh): 7365. The total amount of carbon emissions in the operation stage is 5.11 tCO

2, as shown in

Figure 9.

The carbon emission inventory provides some indicators for C-House which can improve the emission inventory; to be more precise, we have used PV panels to create energy around the building in addition to using wooden furniture, flooring, and wall cladding for the interior. In addition, the building’s deliberate placement among lush trees has been emphasized to reduce carbon emissions.

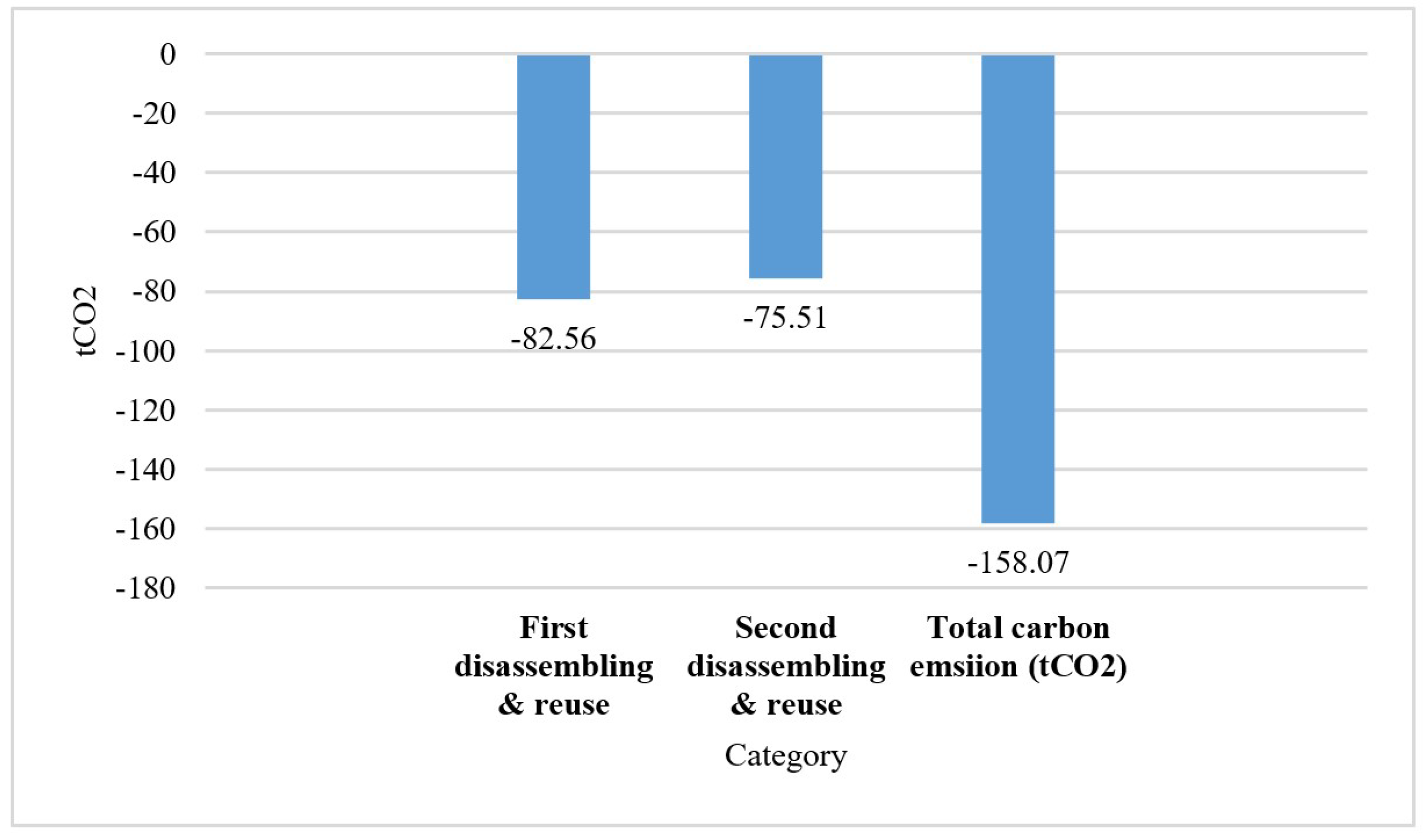

4.4.6. Disassembling and Reuse

The carbon emissions calculated for the disassembling and reuse stage are further divided into two phases, i.e., the first disassembling and reuse: −82.56 tCO

; and the second disassembling and reuse: −75.51 tCO

. The total amount of carbon emission is −158.07 tCO

, as shown in

Figure 10.

4.4.7. Renovation and Reuse

The total carbon emissions per unit building area during the building operation phase (

) are calculated as

In Equation (

6) [

37],

represents the carbon emissions per unit building area during the building operation phase (kgCO

2e/m

),

is the annual consumption of type

ith energy (unit/a),

is the type

i energy’s carbon emission factor (tCO

/tJ),

y is the design lifetime of the building, and

A is the building area (m

).

In both reuse scenarios, C-House’s life cycle did not require a calculation for the renovation stage. As a result, a formula to determine carbon emissions during the stages of renovation and reuse was created. Carbon emissions, however, have not yet been determined for this phase.

4.4.8. Seven-Stage Graph of C-House Life-Cycle Assessment, including Total Carbon Emissions and Its Evaluation

Standard:

Standard for Building Carbon Emission Calculation (GB/T 51366-2019) [

37].

The total carbon emissions of the whole building life cycle are calculated as

In Equation (

7) [

37], the total carbon emissions calculated during the overall life cycle of building are divided into seven phases, i.e., material production: 156.50 tCO

; component manufacturing: 5.15 tCO

; transportation: 2.54 tCO

; assembling: 20.33 tCO

; operation: 5.11 tCO

; two times of disassembling and reuse: −82.56 and −75.51 = −158.07 tCO

; renovation and reuse: not calculated (

Figure 11).

Total first-life-cycle carbon emissions of C-House = 189.66t − 82.56 = 107.10 tCO. Total second-life-cycle carbon emissions of C-House = 107.10t − 75.51 = 31.59 tCO.

6. Result and Discussion

To verify the carbon emission dynamic simulation and calculation method, this paper used the carbon emission calculation model and calculation method specified in the “Standard for Building Carbon Emission Calculation” (GBT 51366-2019) issued by the Ministry of Urban–Rural and Construction of China to carry out carbon emission calculations for the above case.

The definition of the whole life-cycle boundary of the building in the calculation was also derived from the Standard for Building Carbon Emission Calculation (GBT 51366-2019).

The carbon emissions from the production phase of building materials are 156.5023 tCO;

The carbon emissions from the component manufacturing stage are 5.156798 tCO;

The carbon emissions from the construction stage are 20.33562 tCO;

The carbon emissions from the construction stage are 5.118675 tCO;

The carbon emissions from the disassembling and reuse stage are −82.564 tCO (the first disassembling) and −75.514 tCO (the second disassembling and reuse).

6.1. Analysis of Composition of Carbon Emissions in Each Stage of C-House Construction Process

The building construction process consists of the material preparation stage, component manufacturing stage, logistics transfer stage, and assembly construction stage and can also be called the physical process of the building. We calculated that 82.53% of the carbon emissions are produced in the material preparation stage of the construction process of C-House, 2.72% of the carbon emissions in the component manufacturing stage, 1.34% of the carbon emissions in the logistics transfer stage, and 10.72% of the carbon emissions in the assembly construction stage.

C-House, spanning seven stages versus five conventional stages, is in its third cycle and shows a notable 70.57% decrease in carbon emissions in the second cycle and 43.53% in the first one.

So, it has been concluded that the more times a prefab building is reused, the more the life-cycle carbon emissions will be reduced. From the above analysis and data, C-House has completed its second life cycle, and now, it is in its third life cycle.

6.2. Analysis of Carbon Emission Composition of C-House Component System

Due to the complexity of the interior decoration system and the specificity of C-House equipment, the interior decoration component system and the equipment piping system of the building were not included in the calculation of carbon emissions in this case. As a result, among the remaining component groups of C-House, the structural component system emits 1.828445 tCO, accounting for 33.5% of the carbon emissions during component manufacturing; the envelope component system emits 2.121288 tCO, accounting for 41.27% of the carbon emissions during component manufacturing; and the PV component system emits 1.207066 tCO, accounting for 25.23% of the carbon emissions. The reasons for such composition are as follows: Firstly, C-House is only a two-story residence, and its own structural proportion is not too high. Secondly, C-House has a central core layout; in order to let the living space arranged on all sides receive the best lighting and a sense of permeability, the north and south elevations are designed with a glass curtain wall design, and at the same time, in order to improve the thermal performance of the curtain wall, a triple bridge-breaking glass structure is used, so the enclosure components are not designed with a glass curtain wall. Thirdly, to realize the design purpose of the production capacity building, C-House utilizes the east, west, and roof facades of the building with crystalline silicon photovoltaic panels on the roof and thin film photovoltaic panels on the east and west facades, which make up the PV production capacity system of the building, with 176 photovoltaic panels in total. At the same time, to achieve rapid construction and ensure the safety and reliability of the building in the competition, a separate mounting frame was designed for the PV system, which greatly improved the carbon footprint of the PV component system.

6.3. Analysis of Carbon Emission Reduction Potential of Building Ectopic Retrofitting

Although C-House is a specially designed low-rise residential building, from the very beginning of the design, the possibility of the future relocation of the whole building was considered, and a reversible installation design was established for both the components and the component connection structure; so, it can achieve 99% recyclability, and the total carbon emission is only 10% of the physical process after completing one ectopic retrofitting, while it becomes a carbon-negative building directly after the second ectopic retrofitting. But this provides new ideas for the design of zero-carbon buildings. It is well known that in the field of construction, there are many carbon-saving technologies, but there are very few methods to realize carbon-negative ones, usually only carbon sinks, carbon adsorption materials, and new energy sources, so it is quite difficult to realize zero-carbon buildings. However, by building life extension or ectopic retrofitting to obtain negative carbon in the form of carbon substitution, even a building without special design and with a 30% component loss rate can achieve the zero-carbon status after adopting an appropriate carbon-reduction design and carrying out two ectopic retrofittings. While scenarios like ex situ retrofitting are extremely rare, building life extension can be scaled up to a large scale.

7. Conclusions

This study examines building performance optimization strategies based on BIM digital technology, focusing on the possibility of performing carbon emission assessments of prefabricated buildings through digital technology. By modeling the BIM model with high accuracy, the performance simulation of the building in design, production, construction, operation, and maintenance phases can be realized to calculate the carbon emissions of the building and discover the possible factors that increase the carbon emissions. We chose C-House, a case project with very distinctive features, as the building has gone through multiple life-cycle stages (including production, transshipment, three construction, two deconstruction, operation, and maintenance stages), to build a component-based BIM model to fully simulate and calculate the carbon emission values. If the life cycle of the building is extended and the durability of all types of building components is increased, the ability to reduce carbon emissions is particularly obvious, which is important for the subsequent further reduction in carbon emissions to improve building performance.

The pivotal outcomes derived from the seven-stage life cycle, analysis, and subsequent conclusions can be succinctly summarized as follows:

The findings describe the life cycle of C-House, spanning seven stages versus five conventional stages. Now in its third cycle, C-House shows a notable 70.57% decrease in carbon emissions in the second cycle and 43.53% in the first one. This pattern underscores how the extended reuse of prefabricated buildings diminishes emissions over time, highlighting their potential environmental benefits.

The report also highlights important metrics supporting the decrease in carbon emissions: PV panel integration combined with wooden interior accents to generate energy. Strategic positioning among trees additionally diminishes emissions.

This paper emphasizes the crucial role of long-term environmental sustainability in building design decisions. Leveraging digital tools like BIM enables the precise modeling of building performance, promoting smart and green design construction strategies. Future studies should enhance simulation modeling and explore machine learning and IoT sensors for real-time data validation. BIM-based strategies can foster low-carbon, eco-friendly construction practices, yielding energy efficient, socially sustainable buildings.