Spall Repair Patch Health Monitoring System Using BIM and IoT

Abstract

1. Introduction

2. Materials and Methods

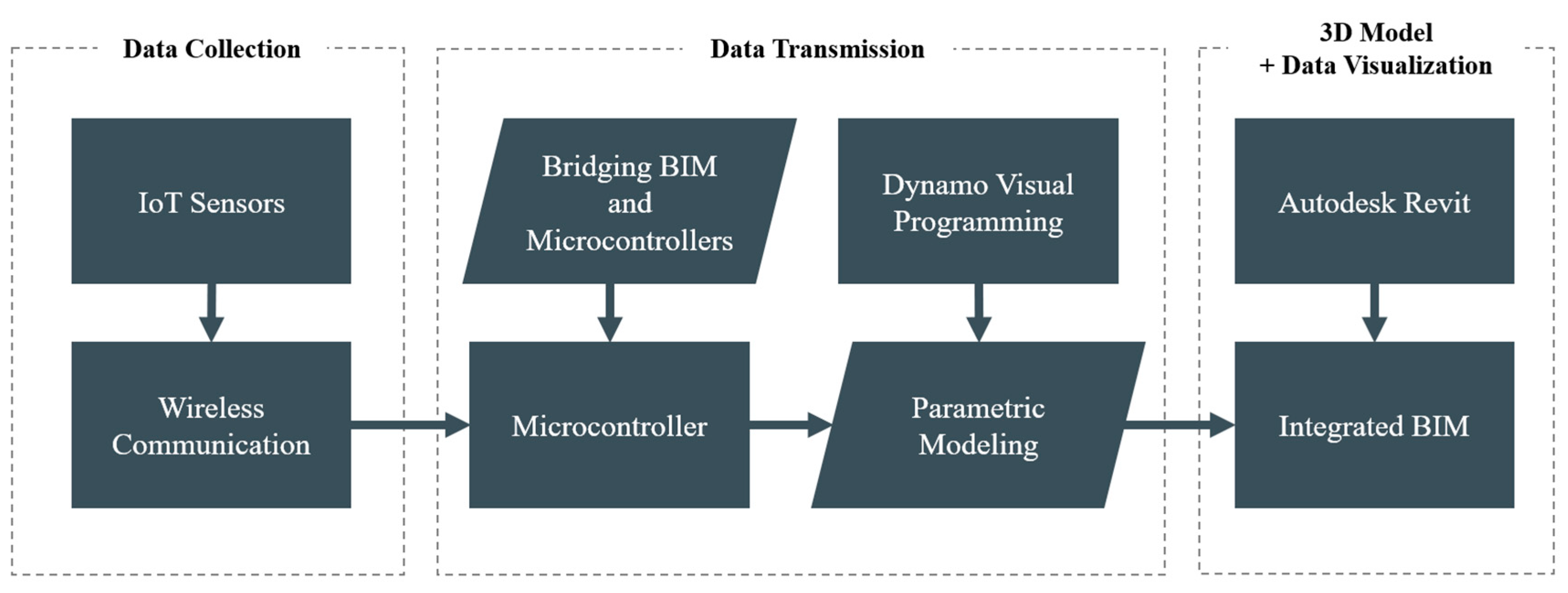

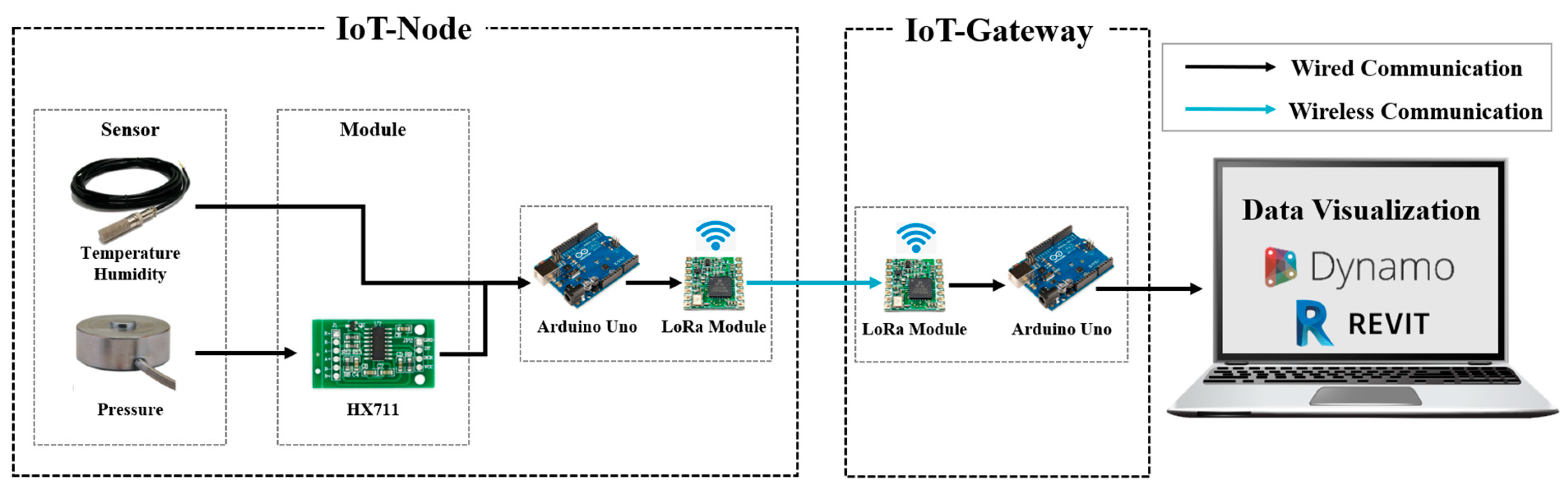

2.1. Monitoring System

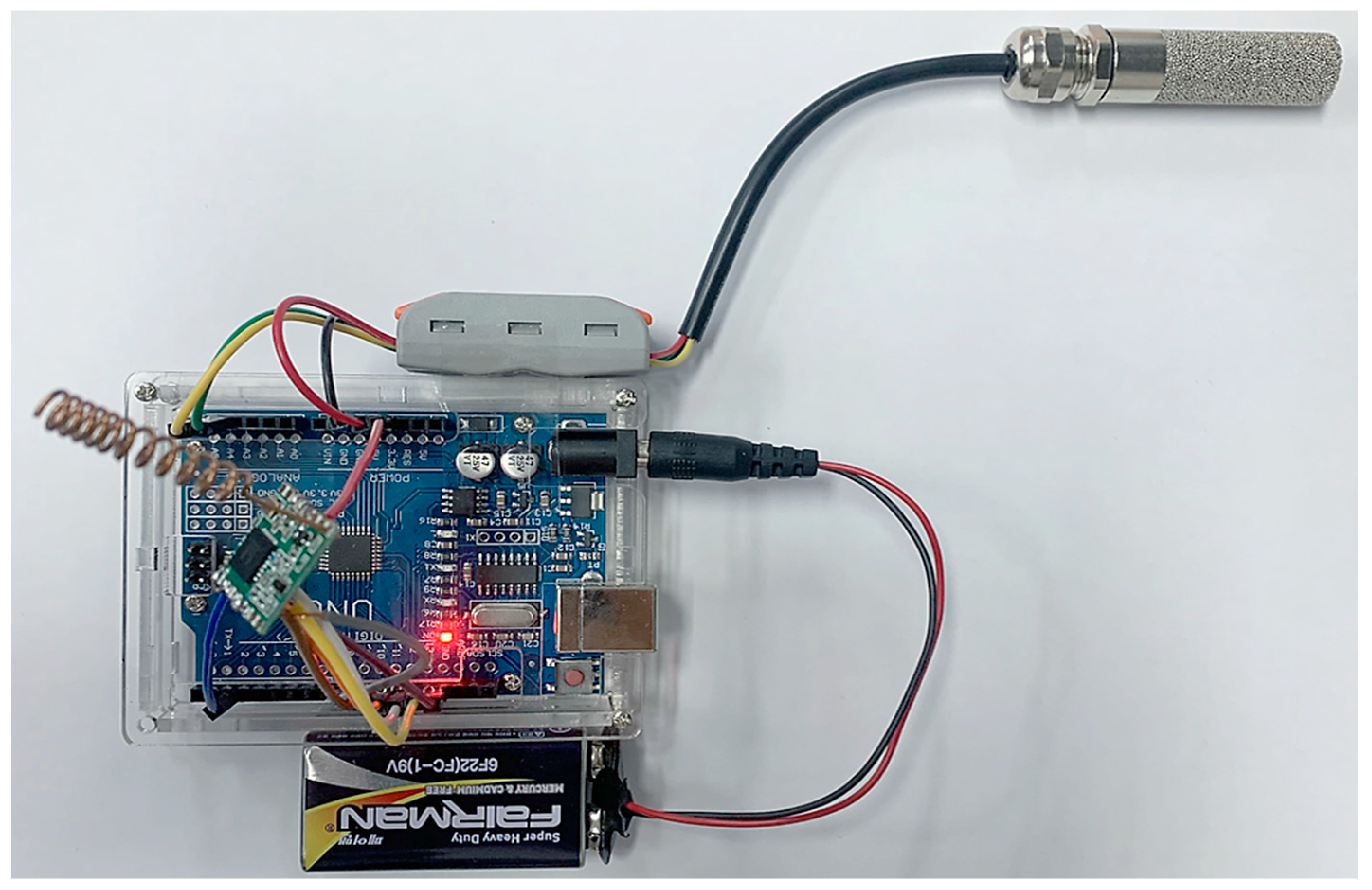

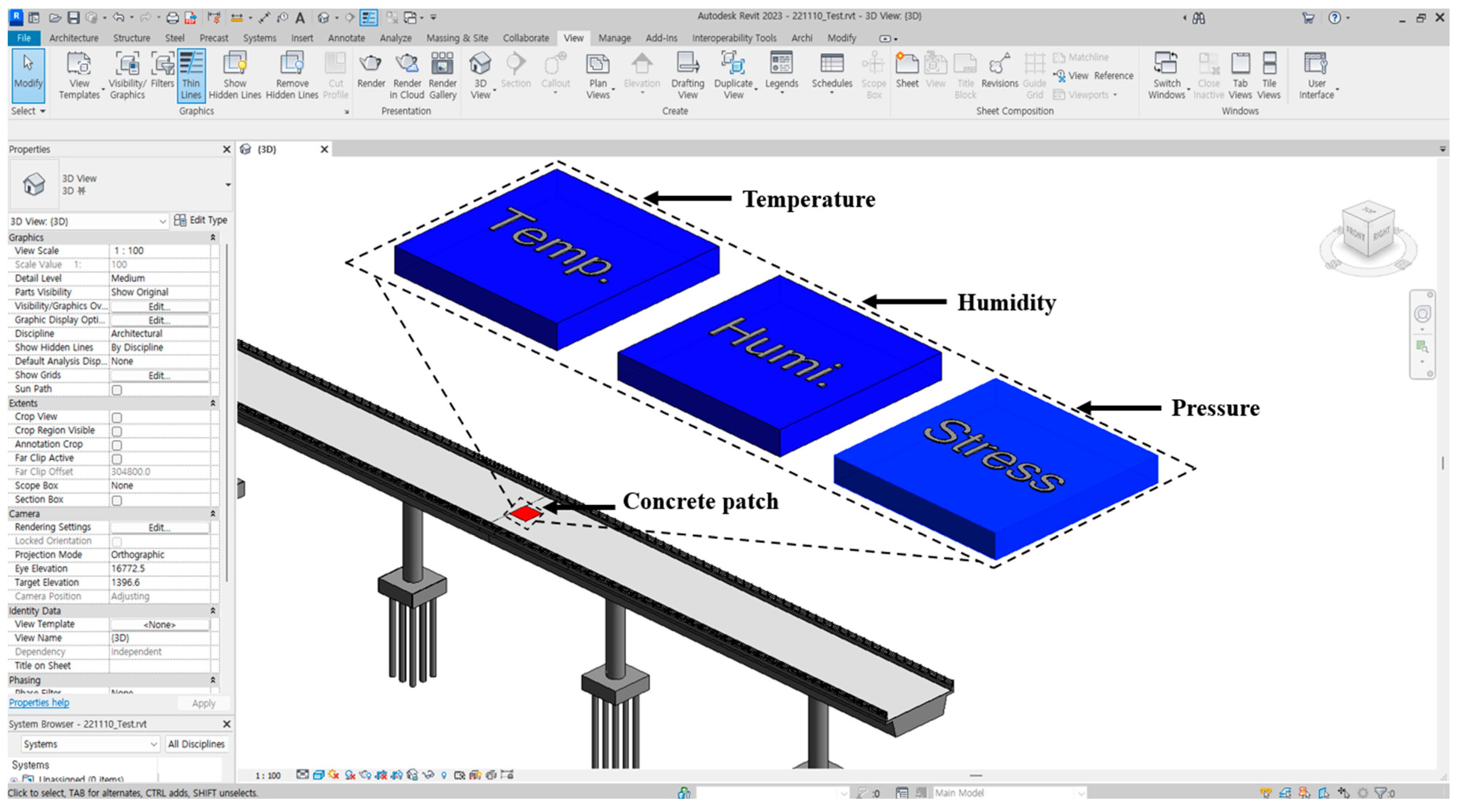

2.1.1. Monitoring System Configuration

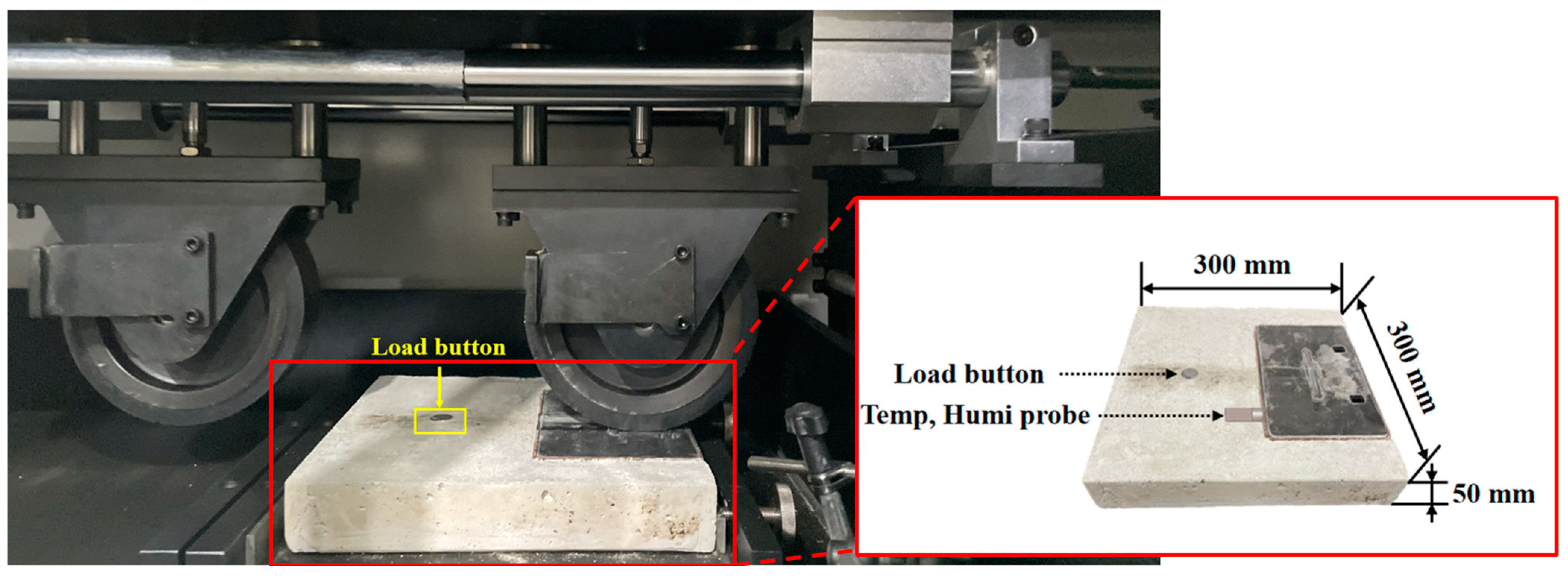

2.1.2. Sensors

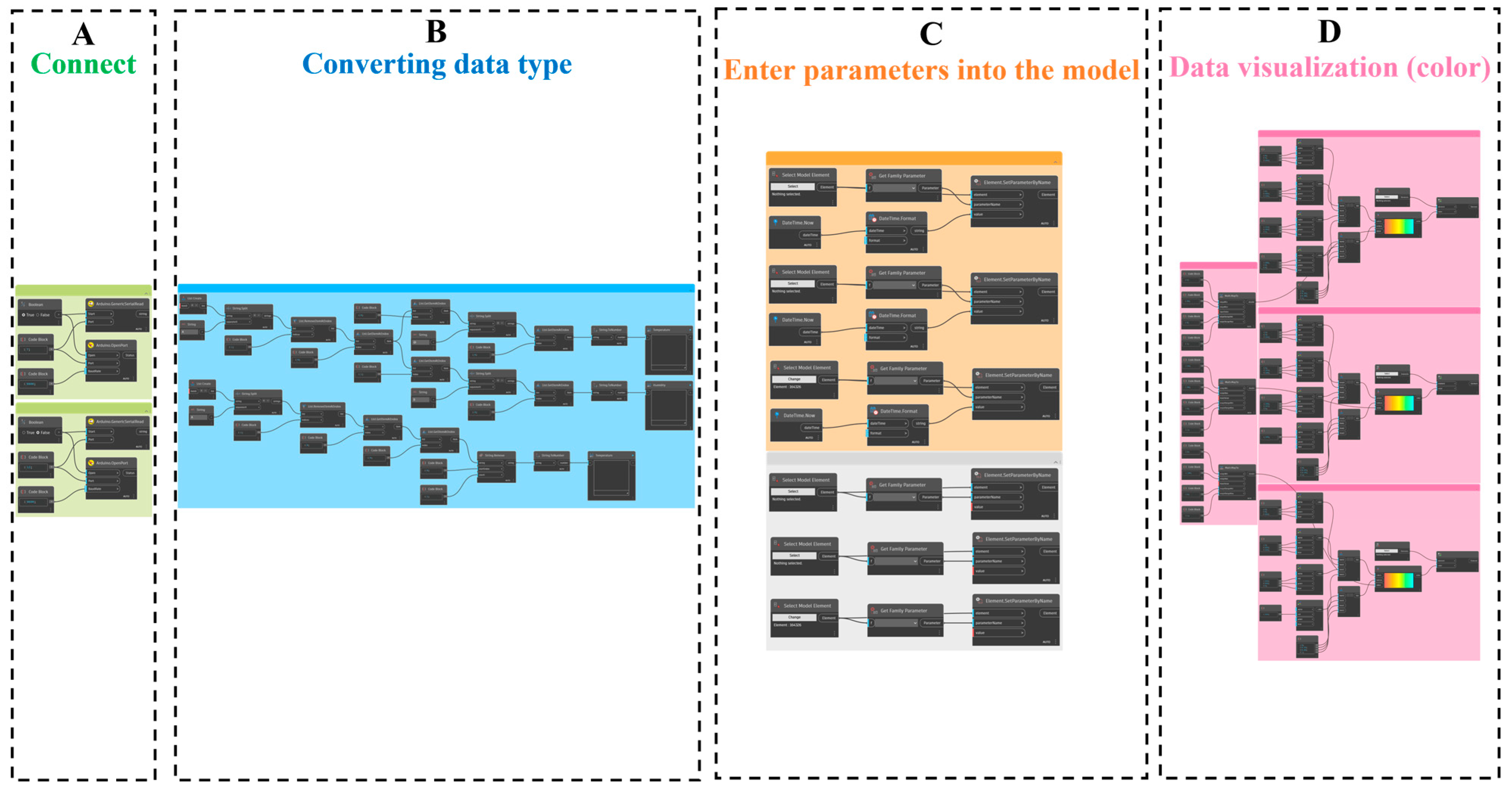

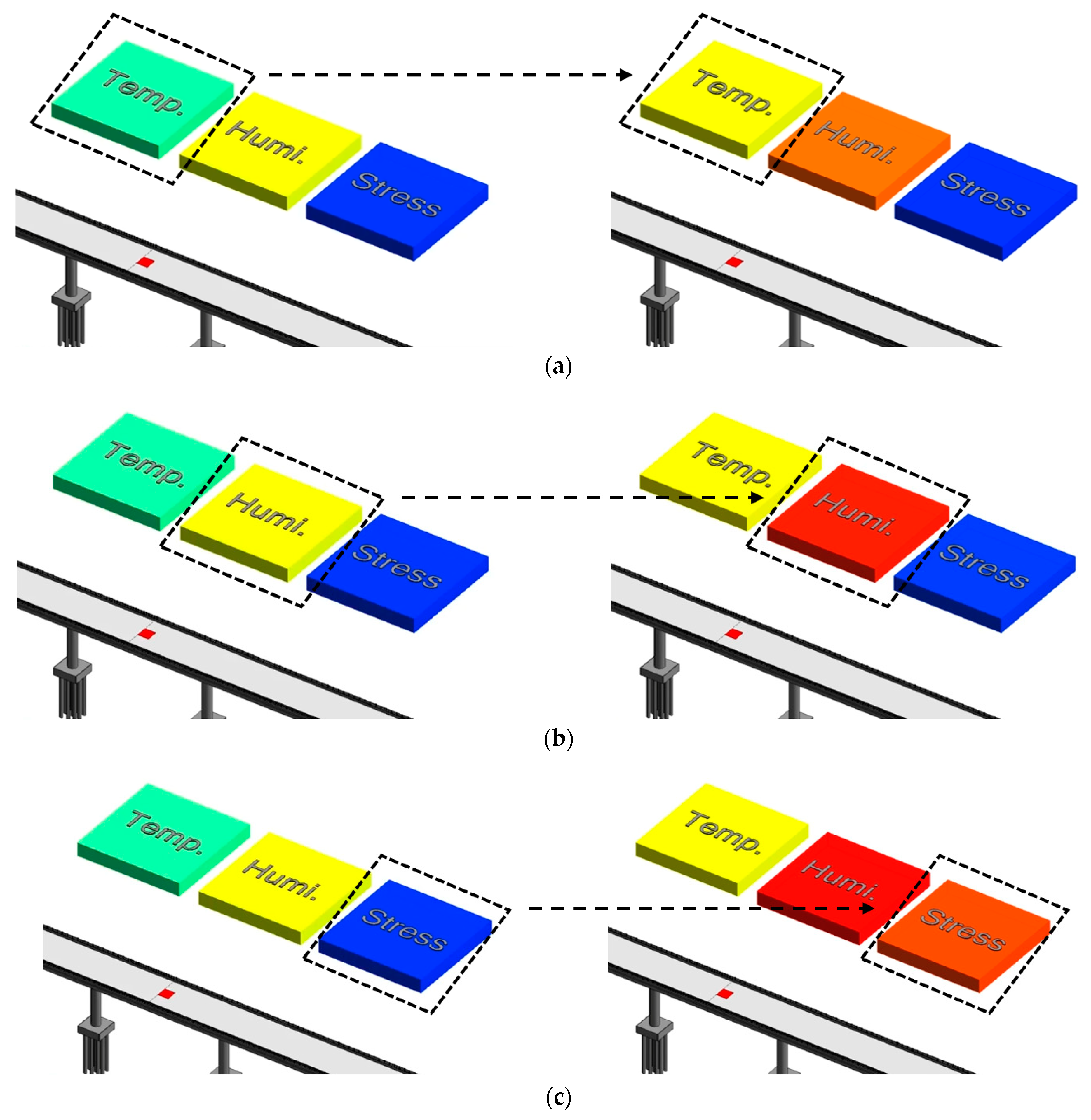

2.2. Development of Dynamo Scripts for Data Visualization

3. Results and Discussion

3.1. Results

3.2. Discussion

3.3. Limitations

4. Conclusions

- This research focused on the development and validation of a monitoring system for concrete repair areas, integrating BIM and IoT technologies. This study’s findings led to several significant conclusions:

- The development of the monitoring system facilitated the measurement of temperature, humidity, and stress changes within a concrete repair area. It enabled a deeper understanding of the effects of core factors like temperature, humidity, and stress change within the concrete repair area.

- The successful integration of BIM and IoT using Dynamo provided data visualization capabilities not previously achievable in traditional BIM software. This integration allowed for the real-time visualization of sensor data within the BIM environment, enhancing the interpretability and utility of the collected data.

- The reliability of the proposed monitoring system was validated through an adapted ASTM D8292 experiment. Originally designed for asphalt, this method was adapted to provide a controlled testing environment for concrete specimens, ensuring consistent temperature settings and sustained load conditions. This adaptation enabled the precise verification of the embedded sensors’ performance.

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.; Minocha, A.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Cao, Y. Laboratory evaluation of magnesium phosphate cement paste and mortar for rapid repair of cement concrete pavement. Constr. Build. Mater. 2014, 58, 122–128. [Google Scholar] [CrossRef]

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P.P. Pervious concrete as an alternative pavement strategy: A state-of-the-art review. Int. J. Pavement Eng. 2020, 21, 1516–1531. [Google Scholar] [CrossRef]

- Jiang, C.; Gu, X.; Huang, Q.; Zhang, W. Carbonation depth predictions in concrete bridges under changing climate conditions and increasing traffic loads. Cem. Concr. Compos. 2018, 93, 140–154. [Google Scholar] [CrossRef]

- Darter, M.I.; Barenberg, E.J.; Yrjanson, W.A. Joint Repair Methods for Portland Cement Concrete Pavements; Transportation Research Board: Washington, DC, USA, 1985. [Google Scholar]

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P. A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure. Adv. Eng. Inform. 2015, 29, 196–210. [Google Scholar] [CrossRef]

- Georgali, B.; Tsakiridis, P. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. 2005, 27, 255–259. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L.; Zayed, T. Infrared thermography model for automated detection of delamination in RC bridge decks. Constr. Build. Mater. 2018, 168, 313–327. [Google Scholar] [CrossRef]

- Hüthwohl, P.; Lu, R.; Brilakis, I. Multi-classifier for reinforced concrete bridge defects. Autom. Constr. 2019, 105, 102824. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Saydam, D.; Kim, S. Maintenance, management, life-cycle design and performance of structures and infrastructures: A brief review. Struct. Infrastruct. Eng. 2012, 8, 1–25. [Google Scholar] [CrossRef]

- Shahin, M.Y. Pavement Management for Airports, Roads, and Parking Lots, 1st ed.; Springer: New York, NY, USA, 1994. [Google Scholar]

- McDaniel, R.; Olek, J.; Behnood, A.; Magee, B.; Pollock, R. Pavement Patching Practices; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar] [CrossRef]

- Karimi, H.R.; Khedri, E.; Aliha, M.; Shaker, H.; Haghighatpour, P.J. Repair efficiency evaluation for cracked asphalt mixture pavement in different ambient temperatures using bitumen and polymer concrete as repair materials. Constr. Build. Mater. 2023, 369, 130556. [Google Scholar] [CrossRef]

- Wilson, T.P.; Romine, A. Materials and Procedures for Repair of Potholes in Asphalt-surfaced Pavements—Manual of Practice; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2001. [Google Scholar]

- Banaeipour, A.; Al Sarfin, M.A.; Thomas, R.J.; Maguire, M.; Sorensen, A.D. Laboratory and Field Evaluation of Commercially Available Rapid-Repair Materials for Concrete Bridge Deck Repair. J. Perform. Constr. Facil. 2022, 36, 04022031. [Google Scholar] [CrossRef]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- Sakr, M.; Sadhu, A. Visualization of structural health monitoring information using Internet-of-Things integrated with building information modeling. J. Infrastruct. Intell. Resil. 2023, 2, 100053. [Google Scholar] [CrossRef]

- Scianna, A.; Gaglio, G.F.; La Guardia, M. Structure monitoring with BIM and IoT: The case study of a bridge beam model. ISPRS Int. J. Geo-Inf. 2022, 11, 173. [Google Scholar] [CrossRef]

- Chang, K.-M.; Dzeng, R.-J.; Wu, Y.-J. An automated IoT visualization BIM platform for decision support in facilities management. Appl. Sci. 2018, 8, 1086. [Google Scholar] [CrossRef]

- Oreto, C.; Massotti, L.; Biancardo, S.A.; Veropalumbo, R.; Viscione, N.; Russo, F. BIM-based pavement management tool for scheduling urban road maintenance. Infrastructures 2021, 6, 148. [Google Scholar] [CrossRef]

- Sofia, H.; Anas, E.; Faïz, O. Mobile mapping, machine learning and digital twin for road infrastructure monitoring and maintenance: Case study of mohammed VI bridge in Morocco. In Proceedings of the 2020 IEEE International conference of Moroccan Geomatics (Morgeo), Casablanca, Morocco, 11–13 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Isailović, D.; Stojanovic, V.; Trapp, M.; Richter, R.; Hajdin, R.; Döllner, J. Bridge damage: Detection, IFC-based semantic enrichment and visualization. Autom. Constr. 2020, 112, 103088. [Google Scholar] [CrossRef]

- Kang, J.-S.; Chung, K.; Hong, E.J. Multimedia knowledge-based bridge health monitoring using digital twin. Multimed. Tools Appl. 2021, 80, 34609–34624. [Google Scholar] [CrossRef]

- Anik, S.M.H.; Gao, X.; Meng, N.; Agee, P.R.; McCoy, A.P. A cost-effective, scalable, and portable IoT data infrastructure for indoor environment sensing. J. Build. Eng. 2022, 49, 104027. [Google Scholar] [CrossRef]

- Desogus, G.; Quaquero, E.; Rubiu, G.; Gatto, G.; Perra, C. Bim and iot sensors integration: A framework for consumption and indoor conditions data monitoring of existing buildings. Sustainability 2021, 13, 4496. [Google Scholar] [CrossRef]

- Avia Semiconductor (Xiamen) HX711. Available online: http://en.aviaic.com/detail/730856.html (accessed on 1 May 2024).

- Arduino Uno Rev3. Available online: https://store.arduino.cc/products/arduino-uno-rev3 (accessed on 1 May 2024).

- Margolis, M.; Jepson, B.; Weldin, N.R. Arduino Cookbook: Recipes to Begin, Expand, and Enhance Your Projects, 3rd ed.; O’Reilly Media: Newton, MA, USA, 2020. [Google Scholar]

- Semtect Product Details SX1276. Available online: https://www.semtech.com/products/wireless-rf/lora-connect/sx1276 (accessed on 1 May 2024).

- Sensirion SHT31-DIS-B. Available online: https://sensirion.com/products/catalog/SHT31-DIS-B (accessed on 1 May 2024).

- Honeywell Model 53 Series. Available online: https://sps.honeywell.com/us/en/products/advanced-sensing-technologies/industrial-sensing/industrial-test-and-measurement/load-cells/miniature-load-cells/model-53-series (accessed on 1 May 2024).

- Fraden, J. Handbook of Modern Sensors; American Institute of Physics; Springer: New York, NY, USA, 1994. [Google Scholar]

- Load Cell Amplifier HX711 Breakout Hookup Guide. Available online: https://learn.sparkfun.com/tutorials/load-cell-amplifier-hx711-breakout-hookupguide/introduction (accessed on 1 May 2024).

- Firefly Experiments. Available online: http://www.fireflyexperiments.com (accessed on 1 May 2024).

- Banzi, M.; Shiloh, M. Getting Started with Arduino; Maker Media Inc.: New York, NY, USA, 2022. [Google Scholar]

- ASTM D8292; Standard Test Methods for Permanent Deformation Behavior and Rutting Resistance of Compacted Asphalt Mix in the Modified Loaded Wheel Tracker Test Utilizing Controlled Confining Pressure. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Taheri, S. A review on five key sensors for monitoring of concrete structures. Constr. Build. Mater. 2019, 204, 492–509. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Mumovic, D.; Greening, P. Life cycle energy efficiency in building structures: A review of current developments and future outlooks based on BIM capabilities. Renew. Sustain. Energy Rev. 2017, 67, 811–825. [Google Scholar] [CrossRef]

- Browne, R.; Blundell, R. The behaviour of concrete in prestressed concrete pressure vessels. Nucl. Eng. Des. 1972, 20, 429–475. [Google Scholar] [CrossRef]

- Yi, Y.; Zhu, D.; Guo, S.; Zhang, Z.; Shi, C. A review on the deterioration and approaches to enhance the durability of concrete in the marine environment. Cem. Concr. Compos. 2020, 113, 103695. [Google Scholar] [CrossRef]

- Hao, H.; Bi, K.; Chen, W.; Pham, T.M.; Li, J. Towards next generation design of sustainable, durable, multi-hazard resistant, resilient, and smart civil engineering structures. Eng. Struct. 2023, 277, 115477. [Google Scholar] [CrossRef]

| Title | Research Gap | Methods | Results and Limitation |

|---|---|---|---|

| Visualization of structural health monitoring information using Internet-of-Things integrated with building information modeling [18] | Lack of visualization of data changes | BIM, IoT sensors | Automatic data collection and BIM visualization/Applicable primarily to lab-scale models |

| Structure monitoring with BIM and IoT: The case study of a bridge beam model [19] | Lack of measurement of internal changes in structures | Arduino Uno, BIM | Real-time BIM visualization of bridge deflections/Accuracy may vary outside lab settings |

| An automated IoT visualization BIM platform for decision support in facilities management [20] | Lack of measurement of internal changes in structures | BIM, Dynamo | Improved decision-making via real-time environmental data in BIM/Limited to university campus settings |

| BIM-based pavement management tool for scheduling urban road maintenance [21] | Lack of real-time monitoring data visualization | BIM | Systematic road maintenance planning with predictive tools/Lack of verification of various environment variables |

| Mobile Mapping, Machine Learning and Digital Twin for Road Infrastructure Monitoring and Maintenance: Case Study of Mohammed VI Bridge in Morocco [22] | Unable to determine cause of internal damage | Point cloud, IoT sensors, DTM | DTM integration with data enables structural health monitoring/Absence of actual field data application |

| Bridge damage: Detection, IFC-based semantic enrichment and visualization [23] | Incapable of identifying source of internal damage | BrIM, UAV, point cloud | BrIM achieves over 70% accuracy in detecting 5 out of 7 types of damage/Only surface damage can be detected |

| Multimedia knowledge-based bridge health monitoring using digital twin [24] | Lack of identification for cause of spalling occurrence | DTM | DTM closely matches real bridge with 0.1% and 5.4% errors/Limited in unpredictable or changing conditions |

| Parameter | Range | Accuracy | Resolution |

|---|---|---|---|

| Temperature | −40 °C~+125 °C | ±0.2 °C | 0.01 °C |

| Humidity | 0~100% (R.H.) | ±2% | 0.01% |

| Range | Operating Temperature | Ø Load Button |

|---|---|---|

| ~200 kN | −54 °C~+121 °C | 19.8 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.; Cho, J.; Kim, J.; Song, Y.; Kang, J.; Yeon, J. Spall Repair Patch Health Monitoring System Using BIM and IoT. Buildings 2024, 14, 1589. https://doi.org/10.3390/buildings14061589

Kim C, Cho J, Kim J, Song Y, Kang J, Yeon J. Spall Repair Patch Health Monitoring System Using BIM and IoT. Buildings. 2024; 14(6):1589. https://doi.org/10.3390/buildings14061589

Chicago/Turabian StyleKim, Chaehyeon, Junhwi Cho, Jinhyo Kim, Yooseob Song, Julian Kang, and Jaeheum Yeon. 2024. "Spall Repair Patch Health Monitoring System Using BIM and IoT" Buildings 14, no. 6: 1589. https://doi.org/10.3390/buildings14061589

APA StyleKim, C., Cho, J., Kim, J., Song, Y., Kang, J., & Yeon, J. (2024). Spall Repair Patch Health Monitoring System Using BIM and IoT. Buildings, 14(6), 1589. https://doi.org/10.3390/buildings14061589