Abstract

This work presents the types of waste of Armenian volcanic aluminosilicate tuff rocks extraction, as a component of the raw material of non-cement, artificial stone materials, the technical possibilities of their use, and the results of experiments for meeting the indicators of physical and mechanical characteristics of natural stone. Preliminary orientational experimental studies have specified the proportions of the raw materials in the compositions, the connections between the preparation of mixtures, the compaction of samples, and the shortest possible heat treatment regimes at temperatures up to 200 °C. Non-cement artificial stones were developed using tuff waste, with filler–composite binder ratios of 75/25 and 70/30, and a water/solid mass ratio of 0.10-to-0.12%. After 9 h of heat treatment, the density, water absorption, and compressive strength of non-cement artificial stone materials were determined. The results showed that these materials outperformed natural stone materials from the same deposits, in terms of the same physical and mechanical characteristics. The use of tuff waste resulted in increased densities, from 10.5 to 39%, decreased water absorption by 2 to 2.5 times, and increased compressive strength of non-cement artificial stone materials, from 15 to 30% compared to natural tuff stones. X-ray diffraction and SEM image studies were also carried out for the obtained non-cement artificial stones. The novelty in the developed technology of obtaining stone materials primarily revolves around the mixture preparation technology by using tuff waste materials and low-temperature heat treatment.

1. Introduction

It is well known that the production of building materials and natural stones (at quarries) does not produce toxic emissions compared to the chemical and metallurgical industries. However, the extraction of raw materials necessary for structures and buildings generates such a vast amount of waste that it significantly harms the environment: this causes economic and environmental problems such as the disruption of underground water supply, the degradation of land usable for agricultural purposes, air pollution with dust particles, and the rapid consumption of natural stone volumes in mines. The waste can serve as raw materials for new building materials, lowering environmental pollution and production costs compared to natural resources.

Hence, the primary objective of modern materials science is to innovate new construction materials. Enhancing the chemical stability, mechanical properties, and durability of these materials involves optimizing their composition. Notably, these factors do not significantly affect the overall cost of the materials [1,2,3,4,5].

Along with population growth, industrial and civil construction volumes are increasing on Earth. The predominant building material in modern construction is concrete, in which traditional Portland cement is used as the main binder. The production of Portland cement is well known as a highly material- and energy-intensive process, resulting in significant CO2 emissions that contribute to environmental pollution and various associated problems [6,7,8]. Therefore, the search for ways to effectively use mineral industrial waste in the production of building materials and the search for ways to produce new construction materials with improved properties is an urgent problem today, the answer to which will provide a wide variety of construction materials, expand the raw material base for their production, improve and develop technologies, and reduce costs. Volcanic slag and pumice, perlite rocks, volcanic tuffs, and tuff lavas of the minings of Armenia, as well as mineral and metallurgical industry wastes, can be used as raw materials for the production of building materials, such as non-cement stones [9,10,11,12].

Rocks containing volcanic glass, endowed with excess energy that has not been realized during the formation of structural bonds, exhibit high hydraulic properties. Such rocks are widely distributed in the territory of RA, thanks to which they can serve as an effective raw material for solving complex construction challenges by reducing energy consumption, particularly for non-cement stone production [13,14,15]. Since ancient times, the main building blocks in Armenia have been the multi-type and multi-colored volcanic tuffs spread across different regions of the country. Since antiquity, mainly as a masonry stone, tuffs have been widely used in various spiritual, residential, bridge-building, and defense (and many other) structures, due to which the country is distinguished by its unique architectural signature [16,17,18,19,20].

In this work, we carried out investigations of tuff waste compositions’ mixture preparation, compaction, heat treatment, and other solutions for the technology advancement in non-cement stone materials.

2. Materials and Methods

2.1. Raw Materials

The tuffs of Armenia belong to sintered stone materials. According to petrographic and physical–mechanical parameters, the tuffs of Armenia are divided into five types: Ani, Artik, Yerevanian, Byurakan, and Felsite.

In this research, as a raw material, the wastes of Artik, Ani, and Byurakan types of tuff stone extraction were included, from the Artik, Ani, and Agarak mines, respectively. It should be noted that the specific types of tuffs included in this research are just test samples of preliminary studies. Armenia has a variety of tuffs, which can provide a realistic possibility of obtaining artificial stones.

The mentioned ones have a low density, high strength, low thermal conductivity and radioactivity, higher durability, and a variety of colors [21,22,23]. The averaged data on the chemical compositions of the mentioned raw materials are given in Table 1, which were determined in the Laboratory of Construction Chemistry of the National University of Architecture and Construction of Armenia, according to the standard [24].

Table 1.

Average data on the chemical composition of the raw materials.

The main physical and mechanical properties of waste fillers were determined according to the standards [25,26,27] and are presented in Table 2 and Table 3.

Table 2.

Average values of physical and mechanical characteristics of raw aluminosilicate rocks.

Table 3.

Grain size composition of fillers obtained from tuff wastes.

The results of the sieve analysis of tuff wastes from mines, their particle size composition, and the degree of fineness for dust particles (d < 16) were determined according to the European standard [28], and are presented in Table 3.

Sodium silicate blocks (Na2O∙mSiO2), which are a semi-finished product of liquid glass, were used as a binding component in the compositions of artificial stone materials, which provided sufficient physico-mechanical properties of the final product and a color equivalent to the color of natural stones [29,30,31,32]. The sodium silicate blocks with an n = 2.5 silica modulus were used in this research. The average chemical composition, specific surface area, and degree of fineness are presented in Table 4.

Table 4.

Average chemical composition and specific surface area of sodium silicate.

2.2. Mixing and Sample Preparation

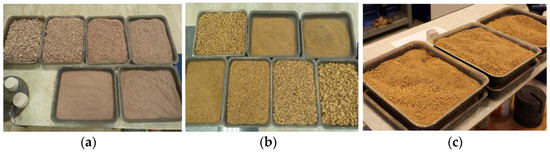

The mixtures were prepared in the following order: the composite binder was added to sand of a pre-selected grain size (Figure 1), obtained from tuff waste (Table 3). The composite binder was obtained by co-grinding tuff powder and sodium silicate in a ball mill for 10 min (ball milling machine A091-02 Matest, Treviolo, Italy). Co-grinding of the components made it possible to obtain powdered masses with a specific surface area between 3000 cm2/g and 3500 cm2/g, which has binding properties in aqueous mixtures.

Figure 1.

Characteristic images of used tuff sands: (a) Artik, (b) Ani, and (c) Agarak mines.

The tuff sand and the composite binder were mixed for 2 min using a laboratory mortar mixer. After that, water was added and mixed for no less than six minutes. The total duration of mixing was 8 min.

Molding and densification of the resulting mixtures were performed by pressing with a hydraulic compression machine under the influence of a force that was up to 25 MPa at a speed of 0.3 MPa/s, resulting in test samples with smooth, dense, and shiny surfaces.

The prepared cube-shaped test samples with dimensions of 50 mm × 50 mm × 50 mm were immediately demolded and transferred to a muffle furnace (Muffle furnace 1100 °C high capacity, A023 Matest, Treviolo, Italy), where they were subjected to heat treatment. The heat treatment was performed at a maximum temperature of 200 °C.

The quantity of water required for homogenization, hydration, and structural formation of the prepared mixtures was assessed by considering the indicators of each type of tuff filler, such as water absorption and surface water retention capacity, grain composition, and specific surface area. The water/solid mass ratio in the developed compositions is within 0.10–0.12 [33]. Figure 1 shows the sieving sands from the tuff wastes used in the developed compositions.

For each type of tuff filler, two percentage ratios of the filler/composite binder quantity by mass were developed: 75/25 (Table 5 № 1, 3, and 5 components) and 70/30 (Table 5 № 2, 4, and 6 components).

Table 5.

Compositions of cementitious artificial stone materials with fillers obtained from tuff waste and composite binder.

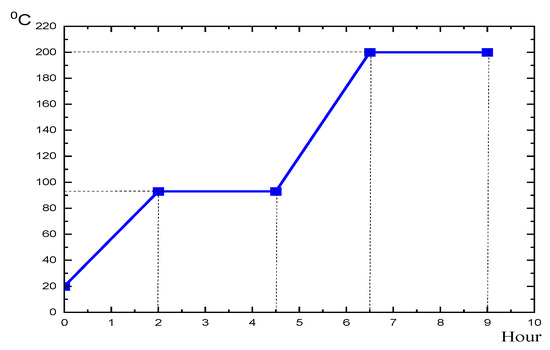

The test samples prepared with the developed components were subjected to heat treatment for 9 h (Figure 2).

Figure 2.

Heat treatment mode of artificial stone materials.

According to Figure 2, heat treatment was performed in the following order: temperature rise from 20 to (90 ± 5) °C for 2 h, keeping at a specified temperature for 2 h and 30 min, followed by a temperature rise to 200 °C for 2 h, keeping at a specified temperature for 2 h and 30 min, and gradual cooling to a room temperature.

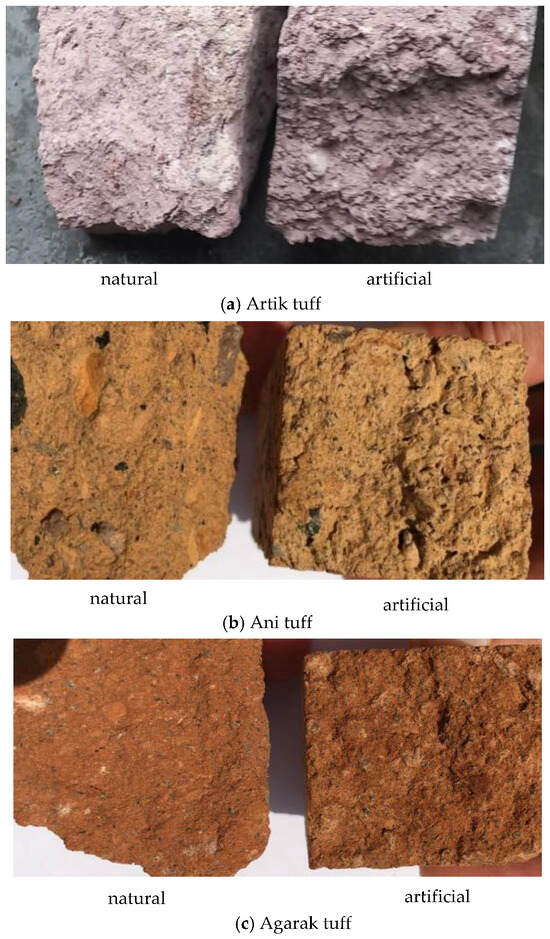

Figure 3 shows the characteristic features of the artificial stone materials processed on the basis of natural stones and their waste from Artik, Ani, and Agarak deposits.

Figure 3.

Natural tuff stones of (a) Artik, (b) Ani, and (c) Agarak deposits and images of cementitious artificial stones made with compounds processed with industrial waste and the composite binder.

2.3. Methods

2.3.1. Physical Characterizations

The density of non-cement artificial stone was determined according to the EN 1936:2006 [26] standard after 9 h of heat treatment and curing at room temperature.

After 48+1 h of water saturation, the water absorption of non-cement artificial stone was determined according to the AST 100-94 [34] standard.

To determine the density and water absorption, for the laboratory tests we used Italian “Matest” manufacturer equipments, such as measuring calipers with 0.01 mm accuracy and V073-01 balance with 0.1 g accuracy.

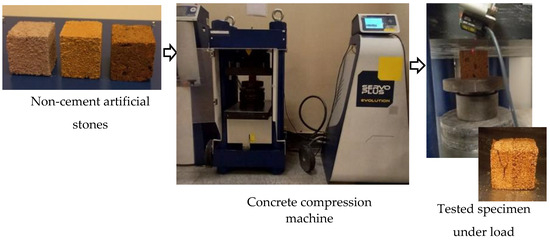

2.3.2. Mechanical Characterization

The 50 mm × 50 mm × 50 mm dimensions cube samples compressive strength test was defined by AST 100-94 and EN 1926:2006 [34,35] standards using a hydraulic compression testing machine with a measuring range of 2000 kN (the Italian Matest (Treviolo, Italy) C089, 2000 kN automatic Servo-Plus Progress Concrete compression machine was used to determine the compressive strength of samples with an accuracy of 0.001 kN). After placing the specimen on the machine’s lower baseplate in a coaxial position, it was subjected to a compressive load (P) until failure by smoothly lifting the lower support. For natural stone materials, the standard speed is 0.3–0.5 MPa/s.

2.3.3. X-ray Diffraction

X-ray diffraction analysis (XRD) was carried out on a URD-63 diffractometer, produced in Germany by the “Carl Zeiss” company. X-ray wavelength is λ = 1.542 Å; d = 0.77/sin θ (reflection order: n = 1). The copper anode with an intense emission Cu, K, Ni filter was used as an internal standard. It provided information about the crystallographic structure and chemical composition.

2.3.4. Scanning Electron Microscopy (SEM)

SEM (VEGA TS 5130 MM “TESCAN” scanning electron microscope, an SE detector, produced in the Czech Republic) was used to investigate the microstructure on non-perturbed fractured specimens attained after the compressive strength tests. Throughout all SEM measurements, a high accelerating voltage of 14.0 kV was used.

3. Results and Discussion

3.1. Density

For the artificial stone materials that have undergone the intended heat treatment regime, the densities were determined according to the formula (EN 1936:2006) [26]

where —is the density of the sample, kg/m3,

m—is the mass of the sample, kg,

V0—is the volume of the sample, m3.

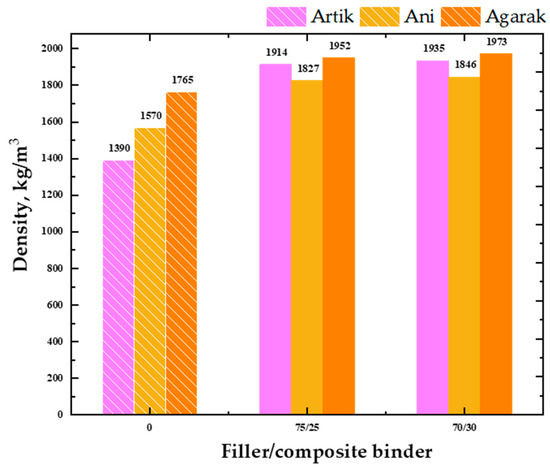

The obtained results were compared with the density indicators of natural stones taken from the same deposits.

The density indicators of the test samples made with tuffs from the Artik mine waste were = 1914 kg/m3 with the 75/25 filler/composite binder composition (№1), = 1935 kg/m3 with the 70/30 filler/composite binder composition (№2), and the density of natural stone material from the same deposit (Artik) is: = 1390 kg/m3.

With tuff waste from the Ani mine, with 75/25 aggregate/composite binder composition (№3), = 1827 kg/m3, with 70/30 aggregate/composite binder composition (№4), = 1846 kg/m3, and with the natural stone material (Ani), = 1570 kg/m3.

And with the 75/25 filler/composite binder composition (№5) made with tuff waste of the Agarak mine, = 1952 kg/m3, with the 70/30 filler/composite binder composition (№6), = 1973 kg/m3, and with the natural stone material of the same mine (Agarak), = 1765 kg/m3.

In Figure 4, a comparison of the density indicators of natural stone from the Artik, Ani, and Agarak mines (with a dashed line) and artificial stone materials made from waste from the same mines (without a dashed line) is presented.

Figure 4.

Natural stones of Artik, Ani, and Agarak mines and the density indicators of artificial stone materials made from waste.

By examining the data, it is clear that, with tuffs extracted from all three deposits, the densities of the test samples made by using the pressing method are higher than those of the natural stones taken from the same deposits.

3.2. Water Absorption

For the produced artificial and natural stone materials, water absorption indicators (AST 100-94) [34] were determined and compared with each other. They were dried at 105 °C until a constant mass and weighed under air conditions (m1). The test samples were then hydrated by inserting a container filled with water at a temperature of (20 ± 2) °C and weighed (m2) after 48+1 h. Water adsorption is determined by the equation

where W—is the water absorption of the sample, %,

m1—is the mass of the dried sample weighed with an accuracy of 0.01 g,

m2—is the mass of the water-saturated sample, g.

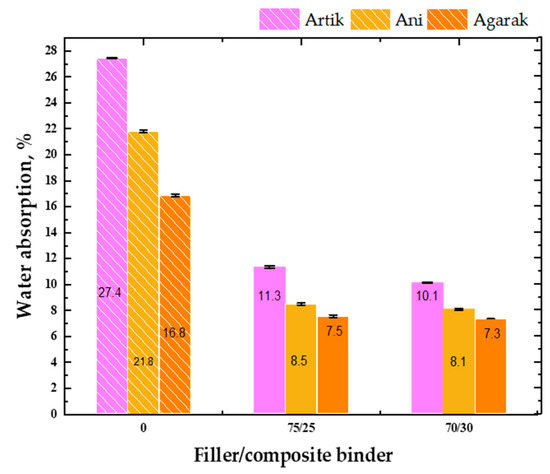

The water absorption of artificial stone materials made with composition №1 developed with tuff stones from the Artik mine was 11.3%, that of stone materials made with composition №2 was 10.1%, and the water absorption of natural stones from the same mine was 27.4%.

With the tuffs of the Ani mine, the water absorption of the artificial stone materials made with composition №3 was 8.5%, №4 was 8.1%, and the natural stone of the same mine was 21.8%. The water absorption of artificial stone materials processed with waste from the Agarak mine with composition №5 was 7.5%, with №6 it was 7.3%, and the water absorption of natural stone from the Agarak mine was 16.8%.

Figure 5 presents a water absorption indicator comparison of natural stone from the Artik, Ani, and Agarak mines and artificial stone materials made of waste from the same mines.

Figure 5.

Natural stones of Artik, Ani, and Agarak deposits and their water absorption indicators for waste-based artificial stone materials.

Analyzing the obtained results, it becomes clear that the water absorption indicators of artificial stone materials made with tuff stones brought from all three mines have decreased more than twice compared with the water absorption indicators of natural stones from the same mines, and as a result they have become more water resistant.

3.3. Compressive Strength

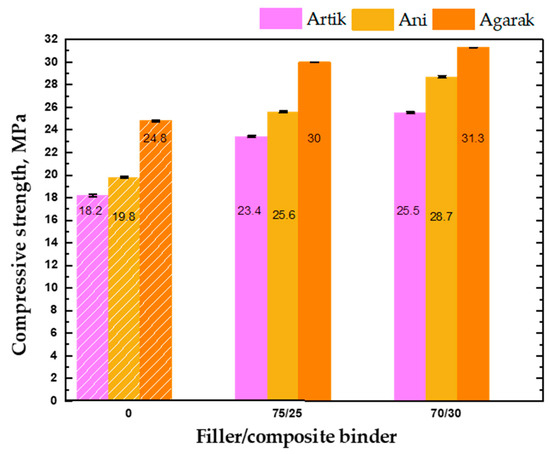

The compressive strengths of the artificial stone materials made with Artik tuff compositions №1 and №2 were 23.4 MPa and 25.5 MPa, respectively, and 18.2 MPa of the natural stone from the same mine (Figure 6). With tuff deposits from the Ani mine, the following values were obtained: the artificial stone materials made with composition №3 and №4 had compressive strengths of 25.6 MPa and 28.7 MPa, respectively, and the natural stone of the Ani mine had a compressive strength of 19.8 MPa. In addition, with compositions №5 and №6 made with Agarak tuffs, the compressive strengths were 30.0 MPa and 31.3 MPa, respectively, and 24.8 MPa for natural stone from the same mine. Figure 7 compares the compressive strength indicators of natural stone from the Artik, Ani, and Agarak mines with those of artificial stone materials made of waste from the same mines.

Figure 6.

Diagram of the test procedure for non-cement artificial stone materials.

Figure 7.

Natural stones of Artik, Ani, and Agarak deposits and compressive strength indicators of artificial stone materials made from waste.

Analyzing the obtained results, the compressive strength indicators of artificial stone materials increased from 15% up to 30% compared with those of natural stones.

Because the strength indicators of artificial stone materials made with 75/25 and 70/30 filler/composite binder percentages are not significantly different from each other with the waste taken from the three mines, preference was given to economically more profitable compositions, and 25% was chosen as the optimal composite binder (sodium silicate lumps and tuff powder) and 75% tuff filler for the compositions.

Regardless of the type of tuff waste used, the sodium silicate component in the processed N1-6 compositions does not exceed the limit of 8%, which ensures the necessary compressive strength of the non-cement artificial stone materials.

After studying the literature, it was found that incorporating up to 9% silicate lump and drying the material resulted in increased strength.

Otherwise, the adhesive contacts exceed the optimal amount and the monolithic concrete is transformed into a unified volumetric system. The intergranular porous area of the material will be almost filled with the adhesive, which negatively affects the strength indicators.

Too much content of silicate lump is also undesirable because of the formation of a large amount of alkalis, which leads to a significant deterioration in water resistance and other vital operational properties of artificial stone materials [19,20,36,37,38].

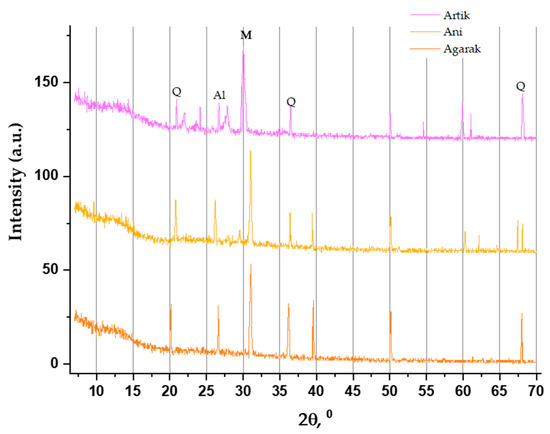

3.4. X-ray Diffraction

An XRD study was carried out for non-cement artificial stone materials prepared with the optimal composition of 70/30 filler/composite binder, and is illustrated in Figure 8 (Agarak, Ani, and Artik). After the compressive strength test, the required number of samples for X-ray examination were taken and dried at 105 °C until constant mass. Then, they were crushed in ceramic tare until able to pass through a 63 μm sieve mash with square holes.

Figure 8.

X-ray analysis results of non-cement artificial stone materials of Artik, Ani, and Agarak tuff wastes. (Q—quartz, Al—Albite, M—Muscovite).

The peak under 20.8°2θ corresponds to quartz (SiO2), which is commonly found in tuff and can also be present in sodium silicate. A peak under 26.65°2θ is associated with sodium feldspar (albite) NaAlSi3O8, which is formed in the presence of sodium silicate and improves the mechanical strength of the products. Peaks under 32.1°2θ correspond to muscovite, which is often present in tuff. The presence of sodium in the sodium silicate could influence the formation of specific clay minerals [39,40,41].

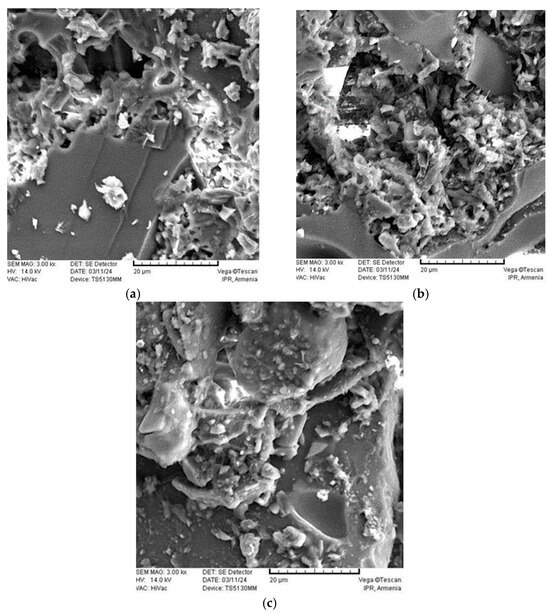

3.5. SEM Analysis

Scanning electron microscopy (SEM) is the best way to study the morphology of the resulting materials on a scale increased several times. SEM images taken at 3000× magnification of non-cement artificial stone samples treated with composite binder and tuff sands are shown in Figure 9a–c.

Figure 9.

SEM image of non-cement artificial stones with tuff wastes of Artik (a), Ani (b), and Agarak (c).

SEM of samples prepared from Artik (a) and Ani (b) tuff waste and a composite binder (tuff powder + sodium silicate) shows that the resulting structure contains flat lamellar surfaces. In the case of Artik tuff waste, these lamellar surfaces are quite small, and there are also agglomerates of fine powders. In the case of Ani tuff waste, there are both small and large lamellar surfaces. In the structure of samples made of Agarak tuff waste, small spherical surfaces can be seen․ The composite binder was able to fill the voids of the resulting matrix, which to some extent improved the mechanical properties of the resulting artificial stone materials [42,43].

In this work, the possibilities of using tuff wastes that have accumulated in stone mining deposits for many years in the composition of non-cement artificial stone materials as the main raw material have been studied. For this purpose, first of all, the physical and mechanical properties of tuff waste were investigated in accordance with the existing interstate standards, six compositions of non-cement artificial stone materials were developed with two compositions of each type of tuff waste with a percentage ratio of 75/25 and 70/30 filler/composite binder. The 50 mm × 50 mm × 50 mm test cube samples have been made with the developed compositions, which have been compacted by pressing, demolded, and undergone heat treatment. The density, water absorption, and compressive strength data have been determined for the obtained artificial stone materials and compared with the density, water absorption, and compressive strength data of natural tuff stones from the same deposits. The obtained results are presented in Table 6.

Table 6.

Comparative data of the physical and mechanical properties of natural stones and non-cement artificial stone materials on their basis.

Analyzing the data presented in Table 6, the following conclusions can be drawn:

- ✓

- Densities of non-cemented artificial stone materials made with tuff wastes of Artik mine increased from 37% up to 39% compared to the density of natural stones, in the case of Ani tuff wastes from 16% up to 18%, and in the case of Agarak tuff wastes from 10.5% up to 12%. In other words, non-cement artificial stone materials with a denser structure were obtained.

- ✓

- The water absorption data of non-cement artificial stone materials made with tuff waste from Artik, Ani, and Agarak mines have decreased by 2 to 2.5 times, which means that compared to natural stone materials, artificial stones a lower amount of water due to the resulting dense structure and therefore they can be used as facing materials.

- ✓

- The compressive strength data of non-cemented artificial stone materials, compared to the compressive strength data of natural stones, increased from 22% up to 27% in the case of tuff deposits of Artik, from 25% up to 30% in the case of Ani, and from 15% up to 20% in the case of Agarak deposits.

In the result of experimental research work and theoretical analysis it becomes clear that non-cement artificial stone materials with higher physical and mechanical properties, comparing natural stones with the same properties, can be obtained. Non-cement artificial stone materials are based on the tuff waste accumulated in mines as filler and sodium silicate as binder in a ratio of 75/25 and 70/30. Based on the compressive strength data, 70/30 filler/composite binder compositions have been selected as optimal for the tuff waste of the three mines.

Non-cement artificial stone materials obtained with the developed components can be used in industrial and civil construction for various architectural designs of structures, as well as internal facing slabs, wall blocks, etc.

4. Conclusions

The possibility of using tuff waste to produce non-cement artificial stone material has been investigated. The influencing factors of physical and mechanical properties to reveal the possibilities of using tuff waste from a microscopic point of view were investigated with X-ray diffraction and SEM methods. After mixtures compaction by pressing and heat treatment for 9 h, the densities of non-cement artificial stones increased from 10.5% to 39% compared to the densities of the natural stones. Non-cement artificial stones with a denser structure have been formed, where the water absorption is 2 to 2.5 times less, and the compressive strengths are higher, from 15% to 30% compared to the same properties of natural tuffs.

In the future works, it is planed to study the frost resistance, thermal conductivity, and permeability of non-cement artificial stones.

Author Contributions

Conceptualization, A.A. (Avetik Arzumanyan) and N.M.; methodology, A.A. (Avetik Arzumanyan), N.M., D.L., and M.B.; validation, N.M.; formal analysis, all authors; investigation, A.A. (Avetik Arzumanyan), N.M․, and A.A. (Arusyak Arzumanyan); resources, A.A. (Avetik Arzumanyan) and M.B.; data curation, N.M.; writing, all authors; visualization, N.M., A.A. (Avetik Arzumanyan), and A.A. (Arusyak Arzumanyan); supervision, M.B. and D.L.; project administration, M.B.; funding acquisition, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge the financial support of the Science Committee of the Republic of Armenia (Project no. 21AG-1C008).

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mehta, P.K. Reducing the environmental impact of concrete. Concr. Int. 2002, 10, 61–66. Available online: http://ecosmartconcrete.com/docs/trmehta02.pdf (accessed on 24 July 2002).

- Alex, A.G.; Jose, P.A.; Saberian, M.; Li, J. Green Pervious Concrete Containing Diatomaceous Earth as Supplementary Cementitous Materials for Pavement Applications. Materials 2023, 16, 48. [Google Scholar] [CrossRef] [PubMed]

- Dietz, A.; Ramroth, H.; Urban, T.; Ahrens, W.; Becher, H. Exposure to cement dust, related occupational groups, and laryngeal cancer risk: Results of a population-based case-control study. Int. J. Cancer 2004, 108, 907–911. [Google Scholar] [CrossRef] [PubMed]

- Al-Neaimi, Y.I.; Gomes, J.; Lloyd, O.L. Respiratory illnesses and ventilatory function among workers at a cement Factory in a rapidly developing country. Occup. Med. 2001, 51, 367–373. [Google Scholar] [CrossRef] [PubMed]

- Gehlot, M.R.; Shrivastava, S. Utilization of stone waste in the development of sustainable mortar: A state of the art review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kurdowski, W. New Concretes. (Chapter). In Cement and Concrete Chemistry; Springer Science & Business: Berlin/Heidelberg, Germany, 2014; pp. 369–532. [Google Scholar] [CrossRef]

- Hendriks, C.A.; Worrell, E.; De Jager, D.; Blok, K.; Riemer, P. Emission reduction of greenhouse gases from the cement industry. In Proceedings of the Fourth International Conference on Greenhouse Gas Control Technologies, Interlaken, Switzerland, 30 August–2 September 1998; pp. 939–944. Available online: http://geomimicry.net/files/sustainability%20documents/EmissionReductionofGreenhouseGasesfromtheCementIndustry.pdf (accessed on 4 May 2024).

- Imbabi, M.; Carriran, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- Arzumanyan, A.; Tadevosyan, V.; Muradyan, N.; Navasardyan, H. Study of “Saralsk” Deposit for Practical Applications in Construction. J. Archit. Eng. Res. 2021, 1, 3–6. [Google Scholar] [CrossRef]

- Muradyan, N.G. Determination of technological characteristics of cementless stone production from the waste of volcanic rock extraction. NUACA Bull. 2020, 2, 92–108. [Google Scholar]

- Játiva, A.; Ruales, E.; Etxeberria, M. Volcanic Ash as a Sustainable Binder Material: An Extensive Review. Materials 2021, 14, 1302. [Google Scholar] [CrossRef]

- Gum, S.R.; Young, B.L.; Kyung, T.K.; Young, S.C. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Capasso, I.; D’Angelo, G.; Fumo, M.; del Rio Merino, M.; Caputo, D.; Liguori, B. Valorisation of Tuff and Brick Wastes by Alkali Activation for Historical Building Remediation. Materials 2023, 16, 6619. [Google Scholar] [CrossRef] [PubMed]

- Cobîrzan, N.; Thalmaier, G.; Balog, A.A.; Constantinescu, H.; Ceclan, A.; Nasui, M. Volcanic Tuff as Secondary Raw Material in the Production of Clay Bricks. Materials 2021, 14, 6872. [Google Scholar] [CrossRef] [PubMed]

- Badalyan, M.M.; Chobanyan, D.A.; Sardaryan, M. Mining waste is a valuable raw material for the production of silicate materials. Bull. Build. Armen. 2005, 3, 40. [Google Scholar]

- Sahakyan, E.; Arzumanyan, A.; Muradyan, N. Physical and chemical processes of volcanic rock hardening with alkaline silicates. IOP Conf. Ser. Mater. Sci. Eng. 2019, 698, 022078. [Google Scholar] [CrossRef]

- Badalyan, M.; Karapetyan, A.; Muradyan, N.; Ratevosyan, S. Possibility of Tuff Waste Application in the production of Thermal Insulation Materials. J. Archit. Eng. Res. 2021, 1, 7–12. [Google Scholar] [CrossRef]

- Cheng, B.; Xiaowei, G.; Haoyue, H.; Kong, Y.; Huang, P. The Mechanical Properties and Mechanisms in Contact-Hardening Behavior of Silica-Alumina Mine Solid Waste. Buildings 2024, 14, 922. [Google Scholar] [CrossRef]

- Badalyan, M.; Muradyan, N.; Shainova, R.; Arzumanyan, A.; Kalantaryan, M.; Sukiasyan, R.; Yeranosyan, M.; Laroze, D.; Vardanyan, Y.; Barseghyan, M. Effect of Silica Fume Concentrarion and Water-Cement Ratio on the Compressive Strength of Cement-based Mortars. Buildings 2024, 14, 757. [Google Scholar] [CrossRef]

- Muradyan, N.; Arzumanyan, A.; Kalantaryan, M.; Vardanyan, Y.; Yeranosyan, M.; Ulewicz, M.; Laroze, D.; Barseghyan, M. The Use of Biosilica to Increase the Compressive Strength of Cement Mortar: The Effect of the Mixing Method. Materials 2023, 16, 5516. [Google Scholar] [CrossRef] [PubMed]

- Arzumanyan, A.A.; Gevorgyan, H.; Arzumanyan, A.; Muradyan, N.G. Investigation of the Heat Resistance of Volcanogenic Tuffs of Armenia for Assessment of their Suitability as Fillers for Refractory Lightweight Concretes. NUACA Bull. 2018, 4, 31–40. [Google Scholar]

- Arzumanyan, A.; Arzumanyan, A.; Muradyan, N. Heat-Acid-Resistant Light Concretes on the Base of Volcanic Tuff Lava and Pumise Aggregates of Armenia, Submitting to “Materials science Forum” “Construction and Architecture: Theory and Practice of the industrial development”. Key Eng. Mater. 2019, 828, 141–145. [Google Scholar] [CrossRef]

- Wang, X.; Wenhua, Z.; Yunsheng, Z.; Hongxia, Q.; Cuizhen, X.; Mubita, M.; Baofeng, A. Research on the green preparation of manufactured sand by tuff produced in Gansu China and its influence on the properties of concrete. Constr. Build. Mater. 2023, 409, 133794. [Google Scholar] [CrossRef]

- GOST 8269.1-97; Crushed Stone and Gravel from Dense Rocks and Industrial Waste for Construction Work. Chemical Analysis Methods. RussianGost: Moscow, Russia, 1998. Available online: https://www.russiangost.com/p-19914-gost-82691-97.aspx (accessed on 1 July 1998).

- GOST 12730.3-2020; CONCRETE Method for Determining Water Absorption. RussianGost: Moscow, Russia, 2021. Available online: https://www.expertnk.ru/en/library/?code=342 (accessed on 1 September 2021).

- BS EN 1936:2006; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. BSI: London, UK, 2007. Available online: https://www.scribd.com/document/425684492/BS-EN-1936-2006-pdf (accessed on 31 January 2007).

- GOST 8736-2014; Sand for Construction Works. Specifications. RussianGost: Moscow, Russia, 2015. Available online: https://docs.cntd.ru/document/1200114239 (accessed on 1 April 2015).

- EN 196-6:2018; Methods of Testing Cement—Part 6: Determination of Fineness. BSI: London, UK, 2018. Available online: https://www.en-standard.eu/bs-en-196-6-2018 (accessed on 14 January 2019).

- Overview of the Silicate Block and Liquid Glass Market in the CIS. Moscow. 2017, 164p. Available online: https://www.infomine.ru/research/27/176 (accessed on 19 May 2022).

- Matinfar, M.; Nychka, J.A. A review of sodium silicate solutions: Structure, gelation, and syneresis. Adv. Colloid Interface Sci. 2023, 322, 103036. [Google Scholar] [CrossRef]

- Korneev, V.I.; Danilov, V.V. Soluble and liquid glass. SPb Stroyizdat. 1996, p. 216. Available online: http://booksshare.net/index.php?id1=4&category=chem&author=korneev-vi&book=1996 (accessed on 9 December 2012).

- Vinai, R.; Soutsos, M. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2019, 116, 45–56. [Google Scholar] [CrossRef]

- Arzumanyan, A.; Muradyan, N. Development of composite binders based on volcanic tuff waste. Int. J. Appl. Sci. Eng. 2023, 21, 2022347. [Google Scholar] [CrossRef]

- AST 100-94; Building Stones from Tuff, Basalt and Travertine: Specifications. Armstandard: Yrevan, Armenia, 1995.

- BS EN 1926:2006; Natural Stone Test Methods. Determination of Uniaxial Compressive Strength. BSI: London, UK, 2006.

- Ponomar, V.; Luukkonen, T.; Yliniemi, J. Revisiting alkali-activated and sodium silicate-based materials in the early works of Glukhovsky. Constr. Build. Mater. 2023, 398, 132474. [Google Scholar] [CrossRef]

- Qingwei, Z.; Gao, P.; Li, K.; Dong, G.; Jin, G.; Sun, X.; Zhao, J.; Chen, L. Experimental Research on the Properties and Formulation of Fly Ash Based Geopolymer Grouting Material. Buildings 2022, 12, 503. [Google Scholar] [CrossRef]

- Sahakyan, E.R.; Arzumanyan, A.A.; Muradyan, N.G. Inorganic Polymeric Materials Based on Natural Silicate and Aluminosilicate Raw Materials. Key Eng. Mater. 2022, 906, 1–6. [Google Scholar] [CrossRef]

- Nikolova, A.; Rostovskya, I.; Nugteren, H. Geopolymer materials based on natural zeolite. Case Stud. Constr. Mater. 2017, 6, 198–205. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, T.; Deng, Y.; Han, Y.; Zhang, T.; Hou, P.; Zhang, G. Microstructure and mechanical performance of alkali-activated tuff-based binders. Cem. Concr. Compos. 2023, 139, 105030. [Google Scholar] [CrossRef]

- Liu, S.; Fang, P.; Wang, H.; Kong, Y.; Ouyang, L. Effect of tuff powder on the hydration properties of composite cementitious materials. Powder Technol. 2021, 380, 59–66. [Google Scholar] [CrossRef]

- Chen, Y.; Xiuqi, W.; Weisong, Y.; Tang, S.; Yan, G. Effects of Waste Glass Powder on Rheological and Mechanical Properties of Calcium Carbide Residue Alkali-Activated Composite Cementitious Materials System. Materials 2023, 16, 3590. [Google Scholar] [CrossRef] [PubMed]

- Zawrah, M.F.; Gado, R.A.; Feltin, N.; Ducourtieux, S.; Devoille, L. Recycling and utilization assessment of waste fired clay bricks (Grog) with granulated blast-furnace slag for geopolymer production. Process Saf. Environ. Prot. 2016, 103, 237–251. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).