Abstract

Over 50% of nuclear power plants (NPPs) worldwide have operated for over three decades, leading to a surge in decommissioning projects. This study addresses the gap in current guidelines by analyzing risks in nuclear decommissioning. Using the fuzzy-AHP technique, tasks within dismantling radioactive concrete structures are prioritized. Findings reveal structural and human-related risks across five main cutting tasks. Collision emerges as a significant concern, particularly during wire saw installation and concrete block hoisting hole creation. Subcategory risk priorities highlight variations in risk across tasks, with jamming, falling, and falling objects identified as top concerns during wire saw transportation. This study emphasizes the importance of comprehensive risk assessment in enhancing safety during decommissioning. It underscores the need to consider both physical risks and risks to personnel throughout the process. By prioritizing safety, stakeholders can ensure worker safety and operational efficiency while minimizing hazards. This research contributes to standardized safety protocols for nuclear decommissioning worldwide, aligning with sustainable energy practices. The outcomes offer practical insights for safety manual development and decision-making processes. This study represents progress in ensuring safety during nuclear decommissioning, paving the way for further refinement of safety protocols and guidelines tailored to decommissioning sites.

1. Introduction

The subject of nuclear decommissioning is gaining more significance among governments, regulators, and industries because many nuclear power plants (NPP) will reach their end of life in the next 2 decades [1]. More than half of the world’s NPPs are getting older and are passing 30 years old. The details vary by country or specific plant, but generally, these plants run for 30 to 60 years [2]. Some might be shut down because of problems like aging facilities, technical safety challenges, economic issues, or political and social reasons. After shutting down, there are plans for activities like recovering nuclear fuel, getting rid of coolant, and cleaning up contamination before taking apart the reactor [3,4]. Dismantling, according to the International Atomic Energy Agency (IAEA), means doing all the necessary technical and managerial tasks safely to completely remove an NPP that is no longer useful and to take apart or modify the rules that applied to it [5]. The process involves several steps, like easing site regulations. Originally, “decommissioning” meant closing a nuclear facility, but nowadays we mostly use this term in accordance with current safety laws [6]. According to the Electric Power Research Institute (EPRI) in the United States, NPP decommissioning has four stages: 1-planning how to decommission, 2-changing the organization’s setup, 3-transitioning the facility, and 4-completing the decommissioning [7]. This breakdown shows that having a proactive plan for dismantling is crucial for successfully decommissioning an NPP.

The implementation of strong risk management procedures becomes increasingly essential as project complexity increases. These procedures involve identifying and assessing potential hazards, executing suitable responses to manage these risks, and monitoring project progress following the implementation of risk reduction measures [8]. Better and more precise risk assessments for different steps of the decommissioning can help leaders in charge of these projects to understand the dangers that may threaten an employee. This understanding allows them to take the right steps to identify, prioritize, and lessen the impact of these risks. In this regard, previous studies have attempted to identify and rank many risks including waste management, safety, radiological, etc. [9,10,11,12] However, there has not been an extensive study that systematically ranks (prioritizes) the elements of risks to assist in making decisions regarding both the structural aspects and the safety of workers involved. Previous research by [13] emphasized the importance of systematic risk assessment in nuclear decommissioning projects, highlighting that such projects involve numerous hazards and complexities that must be carefully managed. Without a systematic approach to prioritize these risks, decision-makers may overlook critical factors, leading to potential accidents or delays in project completion [14].

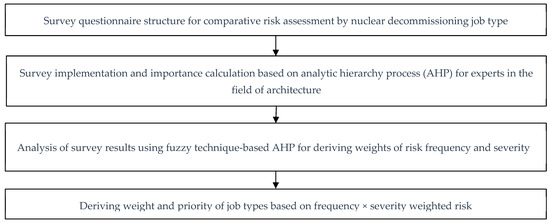

The process begins with a thorough review of existing literature and global standards, particularly referencing guidelines from the International Atomic Energy Agency (IAEA). Expert consultations are conducted through group meetings and face-to-face interviews with professionals and experts in the field, ensuring comprehensive insight into the complexities of nuclear decommissioning. Through these consultations, a risk classification system is established, identifying specific risk factors for each cutting operation. The fuzzy analytic hierarchy process (fuzzy-AHP) methodology is then applied to enhance decision-making precision, accommodating uncertainties and subjective judgments inherent in the assessment process. This involves a series of steps including pairwise comparisons, judgment aggregation, weight determination, risk assessment, and defuzzification, ensuring a transparent and robust analysis of decommissioning risks. The methodology is validated through rigorous scrutiny of expert judgments, ensuring the integrity and reliability of the findings.

2. Literature Review

Building upon the limitations identified in the existing literature, the objective of this study is to conduct a comprehensive risk assessment for NPP decommissioning, encompassing factors related to both structural dismantling and worker safety. This research employs a fuzzy-AHP methodology to systematically evaluate and prioritize these risks, considering their uncertainties and interdependencies. To integrate fuzzy logic with AHP, the study aims to provide a detailed understanding of risk factors and derive priority rankings. The ultimate goal is to develop practical guidelines and recommendations to enhance safety measures and decision-making processes in NPP decommissioning projects, thus addressing the identified gaps in the literature and contributing to improved safety outcomes.

While previous studies have made efforts to identify and rank various risks associated with nuclear decommissioning projects [9,10,11,12], there remains a notable gap in the literature concerning the systematic prioritization of these risks to aid decision-making regarding both structural aspects and worker safety. The absence of a systematic approach to risk assessment in prior research raises significant concerns regarding the effectiveness and comprehensiveness of risk management strategies in nuclear decommissioning projects. One key aspect for this gap is that previous studies have primarily focused on identifying and categorizing risks without systematically assessing and prioritizing them. This lack of systematic risk assessment not only weakens the safety and efficiency of decommissioning efforts but also obstructs the ability to proactively address risks and ensure the well-being of workers involved. Without a structured framework for prioritizing risks, decision-makers may face challenges in adequately addressing critical factors, potentially leading to overlooked hazards, accidents, or project delays [13,14]. Considering the aforementioned gaps in the literature surrounding systematic risk assessment in nuclear decommissioning projects, it is imperative to bridge this deficiency by consolidating existing knowledge and insights. To address this need, Table 1 synthesizes previous research efforts focused specifically on the identification and evaluation of structural and safety risks associated with nuclear decommissioning.

Table 1.

Literature review table.

As explained in Table 1 prior studies have attempted to tailor risk factors and develop methodologies, yet they have encountered challenges such as insufficient scope, inaccuracies in risk classification systems, and a lack of comprehensive analysis of regulatory factors. Moreover, while efforts have been made to enhance worker safety through frameworks and evaluation systems, there is a noticeable absence of integrated approaches that simultaneously address both structural and worker-related risks. These gaps underscore the necessity for further research aimed at conducting a comprehensive risk assessment for nuclear decommissioning operations.

3. Research Methodology

3.1. Risk Assessment Model Framework

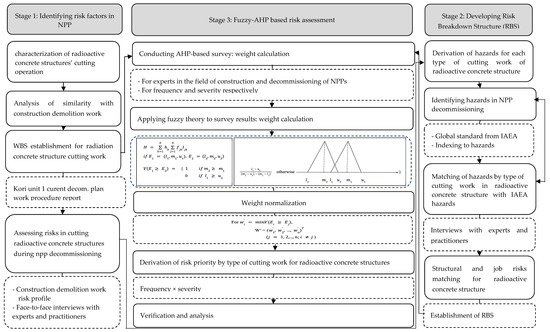

This section explains the methodology employed in our research, which consists of three key stages aimed at comprehensively assessing risks in NPP decommissioning. The first stage involves identifying risk factors inherent in NPP decommissioning. Subsequently, a work breakdown structure (WBS) is established to systematically organize tasks, laying the groundwork for subsequent analysis. The second stage encompasses the development of a risk breakdown structure (RBS), tailored specifically for the decommissioning process, focusing on the identification and correlation of hazards with global standards and real-world operational dynamics. Finally, the third stage entails applying a fuzzy-AHP methodology to calculate risk priorities and weights, utilizing expert judgments synthesized through fuzzy logic-based approaches. All the stages in detail are shown in Figure 1.

Figure 1.

Risk assessment model.

3.2. Identifying Risk Factors in NPP Decommissioning

The process begins with the identification of characteristics of radioactive concrete structures’ cutting operations. This step is followed by an analysis of similarity with construction demolition work to leverage existing knowledge and insights. Subsequently, a WBS is established for radiation concrete structure cutting work, providing a systematic framework for organizing tasks and activities. The establishment of the WBS serves as a foundation for subsequent steps, including conducting a fuzzy-AHP-based survey for weight calculation. This survey involves quantifying the relative importance of criteria and alternatives using fuzzy sets, contributing to the overall risk assessment process. The study focused on the decommissioning process of Kori Unit 1, a nuclear power plant located in Busan, Korea. Constructed in 1972, the site’s rich history provided a robust foundation for the analysis of decommissioning risks and associated methodologies. The Kori Unit 1 Current Decommissioning Plan Work Procedure Report serves as a reference point for understanding specific tasks and procedures involved in decommissioning activities at the Kori Unit 1 plant. Using this information, risks associated with cutting radioactive concrete structures during NPP decommissioning are assessed. This assessment includes comparing the risk profile with that of construction demolition work and conducting face-to-face interviews with experts and practitioners to gather additional insights and validate findings.

The Project Management Institute (PMI) defines a WBS as “a hierarchical decomposition of the total scope of work to be carried out by the project team to accomplish the project objectives and create the required deliverables. The WBS organizes and defines the total scope of the project and represents the work specified in the current approved project scope statement” [22]. In other words, WBS is breaking down all the work that a project team needs to do to reach its goals and create the necessary outcomes. Due to limited cases and data available on NPP decommissioning, expert opinions were sought for consultation and validation of the WBS. Through this process, a structural risk classification system for various tasks in nuclear decommissioning was identified, along with similarities observed with construction demolition work. Particularly challenging and obscure major decommissioning tasks and operations were subsequently modified and improved. Unlike typical construction demolition processes, nuclear decommissioning operations cannot always proceed in a top-down direction due to the structural uniqueness of a reactor. Due to the presence of radioactive elements in the concrete [23], a detailed sequence and method of dismantling must be applied differently for each section that is being dismantled [24]. Additionally, to secure the narrow space around the radioactive concrete inside the reactor, openings for operations should be installed [25]. Furthermore, pathways and channels should be installed to hedge against structural and personnel-related risks in advance.

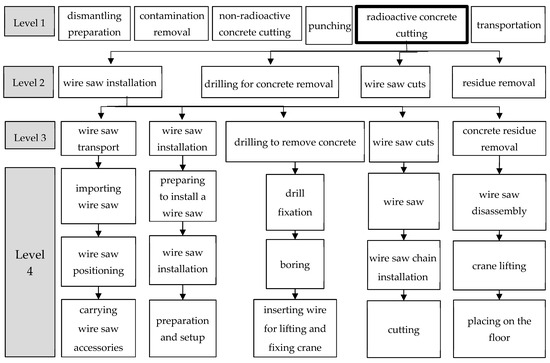

A work classification system was developed (Figure 2) with a total of four classification levels. In this study, the cutting operations were further refined based on Levels 3 and 4, and from this, structural and personnel risks were derived to identify risk factors for each cutting operation. Structural risk refers to the structural requirements for the lead support structure [26] and the potential risks that can lead to direct damage to the structure itself, equipment, and facilities due to various potential hazards that may occur in the construction demolition process. Work-related risks represent harm to the human body or injuries that may occur as a result of structural risks at work [27]. The structural and personnel risks derived in this study were analyzed based on the risk profiles for each operation specified in the construction demolition work. To clearly identify the derivation of structural and personnel risks that may occur in nuclear decommissioning operations based on the similarity between construction demolition work and nuclear decommissioning, group meetings and face-to-face interviews were conducted with individuals with more than ten years of experience in the field and seven experts from research institutions. Through group meetings and face-to-face interviews with professionals in the field of nuclear decommissioning projects and structures, overlapping elements were integrated and removed, and the concept of risk for each cutting operation was concretized and refined. Through this series of processes, structural and personnel risks that may occur during the dismantling of radioactive concrete structures in NPPs were derived and the results are shown in Table 2.

Figure 2.

NPP decommissioning work classification system (WCS).

Table 2.

Structural and personnel risks.

3.3. Developing RBS

A comprehensive description of the development of RBS, specifically tailored for the decommissioning process of cutting radioactive concrete structures in NPPs, was provided. Beginning with the derivation of hazards for each type of cutting work, we systematically identified structural risks, operational challenges, and human-related factors. These hazards were then correlated with global standards from organizations to ensure alignment with industry norms. Through interviews with experts and practitioners, we refined the RBS to reflect real-world operational dynamics and challenges. The RBS was further enriched by mapping hazards to specific cutting tasks, enabling targeted risk mitigation strategies throughout the decommissioning process. Ultimately, the establishment of the RBS served as a foundational tool for guiding risk assessment, decision-making, and resource allocation, enhancing safety and operational efficiency in NPP decommissioning endeavors.

The International Atomic Energy Agency (IAEA) defines preparation guidelines for the establishment of decommissioning plans to protect citizens, workers, and the environment, and to prevent accidents and damages [28]. Most advanced countries in the nuclear field have established safety management systems based on these guidelines and standards provided by IAEA (United States Guidelines [29,30,31]). However, there is diversity in decommissioning technology and related practices, and uncertainties are inherent in specific items, necessitating additional development. Consequently, this study conducted expert consultations while referencing and utilizing international standards to derive risk factors for each nuclear decommissioning operation.

This study, based on the global standards set forth by the International Atomic Energy Agency (IAEA), assigned indices to the decommissioning risks of NPPs (Table 3) and, in collaboration with experts, matched them with the cutting operations of radioactive concrete to derive the specific risks associated with each cutting operation.

Table 3.

Identified hazards in NPP decommissioning (modified from IAEA, 2013).

Based on information matched to each cutting operation from the IAEA’s nuclear decommissioning risk factors, interviews were conducted with professionals in the field of NPP decommissioning projects and structures. This led to the derivation of risk factors for cutting operations involving radioactive concrete structures, as shown in Table 3. By adding the drilling process to the cutting operations, this study demonstrated that the results are suitable for reflecting the characteristics of nuclear decommissioning compared to previous research.

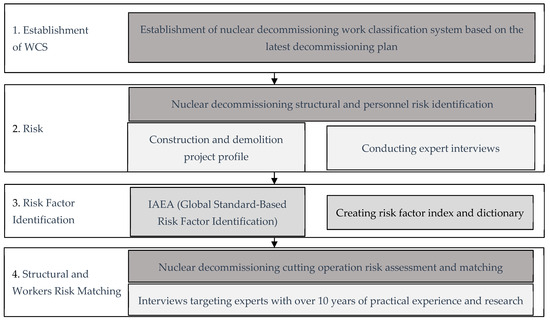

Based on an analysis of potential risk factors associated with cutting operations in NPP decommissioning projects, structural and personnel risks specific to each cutting operation were identified and matched. This matching process involved conducting interviews with professionals and experts in the field with over ten years of experience. These identified risk factors were meticulously aligned with completed cutting operations involving radioactive concrete structures. This systematic approach ensured that each cutting operation’s structural and personnel risks were accurately classified, culminating in the development of a comprehensive risk classification system, as depicted in Figure 3. To guarantee the reliability and objectivity of our study, precise measures were implemented in the selection of experts and the data collection process. Experts were carefully chosen based on clear criteria, encompassing their years of experience in the field, specific roles related to nuclear decommissioning, and demonstrated expertise in risk assessment methodologies. This evaluation process ensured a balanced representation across diverse dimensions of expertise. Moreover, the data collection process was conducted with meticulous attention to detail and transparency. Standardized protocols were employed during interviews and surveys to minimize biases, with clear instructions provided to participants. Efforts were made to avoid leading or biased questioning techniques, thereby fostering an environment conducive to objective data collection. To validate the integrity of the data collected, responses from multiple experts were cross-referenced, and pilot studies were undertaken to refine the survey instruments. Additionally, the obtained results were precisely compared with existing literature and industry standards to ensure consistency and reliability, further enhancing the credibility of our findings. In the data collection process, maintaining objectivity was essential, with strict adherence to standardized procedures and protocols. Participants were encouraged to freely express their perspectives, and no attempts were made to influence their responses. Any potential biases were transparently acknowledged and addressed, underscoring our commitment to maintaining the integrity of the study. While exhaustive efforts were made to mitigate biases and ensure representativeness, it is imperative to acknowledge the inherent limitations of any sampling methodology.

Figure 3.

Risk classification system establishment process.

First, based on the profiling of construction demolition work, group meetings and face-to-face interviews were conducted with seven professionals and experts in the field for over ten years to extract the structural and personnel risks that may occur in the nuclear decommissioning process. Second, based on the global standards presented by the International Atomic Energy Agency (IAEA), indices were assigned to the identified nuclear decommissioning risks, and a basic framework for matching risk factors to cutting operations was established. Third, based on face-to-face interviews with professionals in the field of nuclear decommissioning projects and structures, the process of matching risk factors to cutting operations was further refined. Next, the risk factors for cutting operations involving radioactive concrete were derived based on the classification system. These were then matched with the indices obtained from Table 3. Fourth, utilizing the risk factor indices, structural and personnel risks were matched in Table 4 to derive the structural and personnel risks specific to each cutting operation. This process facilitated the construction of the risk classification system. Through this, the structural and personnel risks for cutting operations involving radioactive concrete structures within the NPP were presented as shown in Table 5. Based on the risk classification system derived in this chapter, the fuzzy-AHP technique was applied for risk assessment, and the prioritization of structural and operational risks was conducted.

Table 4.

Risk classification for NPP decommissioning cutting tasks based on IAEA hazards.

Table 5.

Structural and human risk classification system for NPP decommissioning cutting tasks.

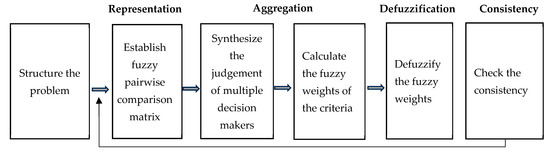

3.4. Fuzzy-AHP Based Risk Assessment

Fuzzy-AHP involves structuring a problem into a hierarchy of goals, criteria, and alternatives, followed by the establishment of a fuzzy pairwise comparison matrix wherein fuzzy sets represent the relative importance of criteria. Expert judgments are synthesized to aggregate opinions, and specialized methods are applied to calculate fuzzy weights of criteria, accounting for uncertainty. A unique step in Fuzzy-AHP involves defuzzification to map fuzzy sets to crisp values for comparison. Furthermore, consistency checks ensure logical coherence among pairwise comparisons, facilitating reliable decision-making amidst uncertainty and vagueness [32,33]. Fuzzy-AHP, introduced by Chang after the research by Laarhoven and Pedryez, uses a triangular fuzzy function as a new complementary method called the expert analysis method [34,35]. This method has been used to complement the shortcomings of AHP by calculating absolute importance. The purpose of adopting the combined fuzzy-AHP method is to address the subjectivity and impracticality limitations of expert judgments in AHP-based pairwise comparisons. Fuzzy-AHP is commonly divided into five phases: (1) pairwise comparison using fuzzy numbers, (2) calculation of the fuzzy synthetic extent value, (3) degree of possibility of the extent value, (4) weight calculation, and (5) weight normalization [36].

Our study utilizes fuzzy logic within the AHP framework to determine risk priorities and calculate weights for various factors involved in nuclear decommissioning. Fuzzy logic offers a reliable methodology for handling the inherent uncertainty and imprecision in expert judgments, crucial in the context of nuclear decommissioning where empirical data may be limited. Through a structured process, expert judgments are aggregated using fuzzy logic-based approaches, converting linguistic terms into numerical values known as fuzzy numbers. These fuzzy numbers are then used in pairwise comparisons to prioritize risks, ensuring a comprehensive understanding of the relative importance of each factor. The transparency in weight calculation is maintained by detailing the criteria used for determining weights based on AHP judgments and fuzzy logic methodology. Specifically, criteria for judgment aggregation and weight determination are clearly outlined, providing insight into the rationale behind the assigned weights. Moreover, the robustness of the fuzzy logic results is ensured through validation and sensitivity analyses, demonstrating the consistency and reliability of the methodology. Any limitations or assumptions associated with the fuzzy logic approach are openly discussed, along with strategies employed to address them, ensuring the validity of the results. Overall, our study provides a transparent and rationale-driven approach to risk assessment in nuclear decommissioning, leveraging fuzzy logic to enhance decision-making processes and safety protocols in the industry.

In comparing the fuzzy-AHP method with other potential approaches for nuclear decommissioning risk assessment, it becomes evident that each method offers unique advantages and limitations. Probabilistic risk assessment (PRA), a quantitative technique, excels in providing a rigorous analysis of risk likelihoods and consequences, yet may struggle with uncertainties and imprecise data inherent in subjective judgments. Similarly, multi-criteria decision analysis (MCDA) offers a structured approach to decision-making by evaluating alternatives based on multiple criteria, but may lack the ability to effectively handle the vagueness and ambiguity present in subjective assessments. However, fuzzy-AHP stands out for its ability to integrate fuzzy logic with the analytic hierarchy process (AHP), enabling decision-makers to represent imprecise information and subjective judgments in a structured manner. This approach not only ensures transparency and consistency in the decision-making process but also enhances the robustness of the analysis by accommodating uncertainties and preferences. Thus, while PRA and MCDA have their merits, fuzzy-AHP emerges as a more suitable option for nuclear decommissioning risk assessment due to its flexibility, transparency, and adaptability to the complexities of real-world decision contexts.

After surveying experts and identifying risks for tasks that are involved in the process, fuzzy-AHP is used to calculate the weight of risks of each task. Figure 4 shows the process of fuzzy-AHP’s calculation.

Figure 4.

The calculation process of fuzzy-AHP [35].

- Structure the problem: breaking down the decommissioning process into a structured hierarchy.

- Establish fuzzy pairwise comparison matrix: quantify the relative importance of criteria and alternatives using fuzzy sets. In another words, compare the importance of tasks (k) with respect to worker risk level (H) using pairwise comparisons in Formula (1).

- H = worker risk level.

- Expected number of days of worker disability due to accidents during demolition work.

- fjk = the frequency or probability of the occurrence of risk j for task k.

- Ijk = the severity of risk j for event (task) k.

- hk = the weight of event (task) k, WBS Level 3 and 4 shown in Figure 2, fuzzy-AHP.

- Synthesize the judgements: assess the frequency and severity of risks (fjk and Ijk) associated with each task (k).

- Calculate the fuzzy weights of the criteria: aggregating the fuzzy sets in the pairwise comparison matrix to derive overall weights for each criterion. Determine the weights (hk) in Formula (1) of each event (or task) based on the AHP judgments and fuzzy logic methodology.

- Defuzzify the fuzzy weights: defuzzification is necessary to map fuzzy sets (representing the relative importance of criteria) to crisp values for comparison. This step enables us to rank criteria based on their overall importance in the decommissioning process. Convert assessed frequency evaluated by a fuzzy number into a single value using the defuzzification Formula (2).

- Fuzzy number = (I, m, U).

- I (infimum): the lower bound or minimum value of the fuzzy number. It represents the smallest possible value within the fuzzy set.

- M (modal value): the value of the fuzzy number at which its membership function reaches its maximum value. In other words, it is the peak or center of the fuzzy set.

- U (supremum): the upper bound or maximum value of the fuzzy number. It represents the largest possible fuzziness.

- Check the consistency: finally, consistency checks ensure the reliability of judgments and the coherence of pairwise comparisons.

The process of risk assessment based on fuzzy-AHP is structured in the following order: establishing a risk classification system based on expert AHP surveys, followed by the application of fuzzy techniques. In this study, to address the difficulty in obtaining data due to the characteristics of NPPs, a risk derivation and classification system based on expert interviews was established. To overcome the lack of empirical data due to subjective assessments, the fuzzy-AHP technique was applied to complement the existing evaluation method with a probabilistic and statistical approach. A survey was conducted based on the analytic hierarchy process (AHP) targeting experts in the field of architecture. Importance was calculated through the survey. For assessing the importance of structural and human risks, a two-step hierarchical paired comparison was conducted for a total of 42 items (21 each for frequency and severity). The survey participants were professionals with over 10 years of experience in the field of architecture, and a total of 27 experts (Table 6) responded to the survey for analysis. The applied process is shown in Figure 5.

Table 6.

Summary of survey respondents.

Figure 5.

Fuzzy-AHP-based risk assessment process.

Fuzzy logic was chosen as the preferred method for determining the risk assessment model for NPP radioactive concrete structure decommissioning due to its ability to handle uncertainties and imprecisions inherent in expert judgments. While there are various tools available such as statistical analysis, machine learning, and artificial intelligence and used by others [1,37], fuzzy logic offers a well-established framework for capturing and processing linguistic uncertainties, which are common in risk assessment processes. Moreover, fuzzy logic allows for the integration of expert knowledge and subjective assessments, crucial in domains like nuclear decommissioning where empirical data may be scarce or difficult to obtain. Additionally, research studies have demonstrated the effectiveness of fuzzy logic in risk assessment applications, as highlighted in references such as [38].

The risk assessment was conducted based on fuzzy techniques, analyzing the AHP survey results. The study focused on the decommissioning process of Kori Unit 1, an NPP located in Busan, Korea. Constructed in 1972, the site’s rich history provided a robust foundation for the analysis of decommissioning risks and associated methodologies. Focusing on the target construction work of radioactive concrete cutting, a pairwise comparison was carried out for both structural and personnel risks for each type of work. In the first step, frequency was assessed, and in the second step, the potential severity of more serious consequences in the event of an accident. At the end, a total of 27 surveys were utilized to calculate the weights. Fuzzy-AHP, utilizing fuzzy numbers defined by multiple values rather than a single value, determined the weights based on the 9-point triangular fuzzy numbers applied by Kaya [39]. By mixing works of [39,40,41] we developed Table 7. The evaluation of attribute weights commenced with the development of a comprehensive questionnaire, followed by the administration of surveys and expert interviews. The precise determination of attribute weights holds paramount significance in the extraction of analogous cases from the case base. Nonetheless, the potential for improved precision in these weights through increased expert involvement highlights a limitation stemming from the inadequacy in the number of experts engaged in the evaluation process. Attribute weight computations were executed by seasoned experts with substantial experience in nuclear decommissioning. Additionally, rigorous scrutiny of received surveys was undertaken to mitigate potential misunderstandings and errors. Notably, the response rate was exemplary, with all 27 distributed questionnaires being returned, resulting in a response rate of 100%. The received surveys were checked for consistency, and 27 passed the consistency test (CR < 0.1). Based on the surveys, weights among the attributes were determined.

Table 7.

Nine-point scale triangular fuzzy number.

4. Results and Discussion

The risk evaluation was conducted for the risks identified by work type. The risks for the major construction types in the dismantling of nuclear radiation concrete structures, along with their detailed subtypes, were derived as follows Table 8 and Table 9. Based on this, a fuzzy-AHP pairwise comparison survey was constructed and conducted.

Table 8.

Wire saw transport risk derivation.

Table 9.

Risk priorities for tasks.

Risk priorities for cutting work types were derived as the final result of the research. Table A2 explains all risks mentioned in the below tables in detail. Weights represent the importance or significance of each risk factor within the context of wire saw transportation. The weights were calculated and normalized based on expert assessments and represent the relative importance of each risk. Priority indicates the order of importance or urgency of addressing each risk factor. It was determined based on the calculated weights, with higher weights indicating higher priority.

After deriving the parameter “H” based on the frequency (fjk) and severity (Ijk) of each risk factor associated with specific tasks in the nuclear decommissioning process, these values were used to calculate weights for each risk factor. These weights were then scaled onto a range from 0 to 1 using a fuzzy-AHP technique shown as “Risks” in Table 9. This scaling process provided a clearer understanding of the priorities for each task by standardizing the weights and allowing for direct comparison between different risk factors. By bringing the weights onto a uniform scale, project managers and stakeholders could more effectively assess and prioritize the structural and personnel risks associated with each task, enabling informed decision-making and resource allocation to mitigate potential hazards and ensure the safety and success of the decommissioning project.

Table 10 summarizes the top three highest risks for each main cutting task involved in the decommissioning of radioactive concrete structures. Overall, the most significant risk across tasks is “Collision”, indicating the potential for equipment clashes or impact with surrounding structures or objects. The highest degree of carefulness should be exercised during concrete block lifting hole creation and wire saw installation, where collision poses a substantial risk. Specifically, careful attention should be paid during drilling machine fixation and wire saw installation preparation, where collision, falling, and electrocution are prevalent risks. Similarly, during wire saw cutting and removal of cut concrete, collision remains a significant concern, requiring thorough planning and execution to mitigate potential accidents.

Table 10.

Summary of the results and showing the three highest risks for each task.

The risk analysis conducted for decommissioning activities involving the dismantling of radioactive concrete structures revealed a comprehensive understanding of the structural and human-related risks associated with five main cutting tasks. These tasks encompassed wire saw transportation, wire saw installation, concrete block hoisting hole creation, wire saw cutting, and removal of cut concrete. Structural risks during wire saw transportation and installation predominantly centered on collisions, conduction, electrical issues, and falling objects, while concrete block hoisting hole creation presented risks of collisions, conduction, and falling objects. Wire saw cutting posed structural risks such as collapse, collisions, electrical issues, falling objects, and fire, whereas removal of cut concrete primarily involved risks of collisions and falling objects. Moreover, human-related risks observed across all cutting tasks included collisions, cutting, falling, jamming, and exposure to radioactive contamination. Additionally, specific risks like electric shock and dislocation were identified in certain tasks. Detailed subcategory risk priorities were confirmed within each main cutting task, providing a nuanced understanding of the prioritization of risks. For example, during wire saw transportation, the prioritization of risks varied across subcategories, with jamming, falling, and falling objects emerging as top concerns. These findings offer valuable insights for stakeholders engaged in the planning and execution of decommissioning operations. By identifying and prioritizing risks at both the structural and human levels, stakeholders can develop targeted mitigation measures to enhance worker safety and operational efficiency during nuclear decommissioning endeavors. This comprehensive risk assessment serves as a crucial resource for guiding decision-making processes and ensuring the successful execution of decommissioning projects while minimizing potential hazards and maximizing safety protocols.

In addition to providing insights into the specific risks associated with decommissioning tasks, it is imperative to outline how these findings can be effectively applied to real-world scenarios and adapted for use in various nuclear decommissioning projects, both within the current site and in similar contexts internationally. The practical application of these risk assessments lies in their ability to inform decision-making processes and guide the development of tailored mitigation strategies. For instance, stakeholders can utilize the identified risk priorities to allocate resources efficiently, implement targeted safety measures, and design comprehensive training programs for workers involved in decommissioning activities. Moreover, the utilization of this risk assessment extends beyond immediate operational considerations; it can also serve as a valuable reference for regulatory authorities and policymakers in formulating guidelines and standards aimed at enhancing safety protocols across the nuclear industry. By illustrating specific methodologies for applying these findings in practice, such as integrating them into project planning frameworks or incorporating them into training curricula, the effectiveness and relevance of the risk assessment are further emphasized, ensuring its practical value in safeguarding both workers and the surrounding environment. Stakeholders can employ these insights to develop robust safety protocols, allocate resources efficiently, and ensure compliance with regulatory standards, thereby enhancing worker safety and environmental protection throughout the decommissioning process.

This study thoroughly examines the structural and personnel risks associated with the decommissioning of radioactive concrete structures. It is crucial to explore the complex connections between these risks and how they can affect each other. Decommissioning operations are constantly changing, and risks often mix together in complicated ways, leading to a series of effects that can make risks worse or better. For example, if there is a problem with moving a wire saw, it might not just be dangerous for the workers, but it could also make other risks worse, like releasing radioactive material, damaging equipment, or causing delays. Understanding these connections is very important for managing risks effectively. It helps stakeholders predict and deal with possible chain reactions before they become bigger problems. Additionally, it is important to consider external factors, like changes in environmental rules or advances in decommissioning technology, to keep the findings relevant over time. These outside factors can introduce new risks or change how serious existing risks are, so it is necessary to keep updating risk management plans to deal with these changes. Including discussions about risk connections and outside factors in the analysis gives a better understanding of the changing risk landscape during nuclear decommissioning. This helps stakeholders make smart choices and put strong safety measures in place to protect workers and the environment.

5. Conclusions

With the increasing number of aging NPPs worldwide and the growing nuclear decommissioning market, there is a pressing need for pre-identification and response strategies for risks during the decommissioning phase. This study has provided insight into the many risks involved in dismantling old nuclear structures made of concrete and managing radiation exposure. By using a systematic method to identify and rank these risks, this study has laid the groundwork for improved safety measures.

- Key findings and analysis:

- o

- Both physical risks (e.g., falling objects, machinery malfunctions) and risks to personnel (e.g., injuries, radiation exposure) must be considered throughout the decommissioning process.

- o

- Specific tasks such as moving wire saws, installing saws, creating holes for lifting concrete blocks, cutting concrete, and removing cut concrete present unique dangers.

- o

- Attention must be paid to potential hazards such as jamming, overheating, collapses, release of harmful particles, and collisions during these tasks.

Understanding these specific risks enables the development of targeted safety plans. By prioritizing the most critical risks, safety can be ensured while maintaining operational efficiency. While this study represents progress in ensuring safety during nuclear decommissioning, further work is needed.

- Recommendations for further work:

- o

- Further testing of safety measures in real-world scenarios is necessary.

- o

- Continued collaboration with experts is essential to refine safety protocols.

- o

- The creation of clear safety guidelines tailored to the challenges of decommissioning sites is crucial.

It is important to note that the findings of this study represent a context-specific assessment and it may not be directly applicable to all nuclear decommissioning situations. Variations in site conditions, technologies used, and local regulations can significantly impact the generalizability of the results. Authors should highlight this aspect to ensure that stakeholders interpret the findings within the appropriate context. Additionally, while the fuzzy-AHP model was employed to assess and prioritize risks, further verification and validation are needed to ensure its suitability and accuracy in different scenarios.

Future work involves comprehensive statistical analysis to validate the model’s efficiency. Empirical data will be collected, subjected to statistical scrutiny, and compared with traditional methods to demonstrate superiority. Leveraging statistical techniques aims to enhance the model’s strength and applicability in real-world scenarios, advancing safety protocols and decision-making processes.

Author Contributions

Conceptualization, H.M. and Y.A.; methodology, N.K. and H.M.; validation, Y.J., N.K. and S.M.; investigation, Y.J. and H.M.; resources, Y.A.; writing—original draft preparation, H.M. and S.M.; writing—review and editing, S.M., Y.J. and Y.A.; supervision, N.K., Y.J. and Y.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by North Carolina Agricultural and Technical State University and the research fund of Hanyang University (HY-2024-3734).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Partial example of AHP survey.

Table A1.

Partial example of AHP survey.

| Comparison Items | Very Important | Equal | Very Important | Comparison Item | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wire saw cutting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Wire saw installation |

| Wire saw cutting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Perforation for hoisting concrete blocks |

| Wire saw cutting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting using a wire saw |

| Wire saw cutting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Removing cut concrete |

| Wire saw installation | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Perforation for hoisting concrete blocks |

| Wire saw installation | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting using a wire saw |

| Wire saw installation | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting and removing concrete |

| Concrete perforation for hoisting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting using a wire saw |

| Concrete perforation for hoisting | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting and removing concrete |

| Cutting using a Wire saw | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | Cutting and removing concrete |

Table A2.

Explanation of risks.

Table A2.

Explanation of risks.

| Risk | Description |

|---|---|

| Falling | This risk pertains to the potential of workers or equipment falling during the transportation or introduction of wire saw equipment. It could result from improper handling or unstable conditions. |

| Collision | The risk of collisions occurring during transportation, which could lead to damage to equipment or injury to workers. |

| Conduction | Concerns related to electrical conduction, which could pose a risk of electric shock during transportation. |

| Drop/Falling | This risk involves the possibility of equipment or materials being dropped or falling during transportation. |

| Cutting | Risks associated with the cutting process itself, which could lead to injuries or accidents. |

| Constriction | Risks related to tight or confined spaces during positioning. |

| Jamming | The risk of pinch points occurring during transportation, which could lead to injuries to workers or damage to equipment. |

| Electric shock | Potential for workers to suffer electric shock due to power-related hazards such as power failure or equipment malfunction during decommissioning activities. |

| Fracture | Possibility of workers sustaining bone fractures or breaks from falls, being struck by falling objects, or accidents involving heavy machinery. |

| Collapsing | Danger of structures or components unexpectedly collapsing during decommissioning, posing hazards such as crushing or trapping workers. |

| Respiratory protection | Risk of respiratory system harm from exposure to hazardous airborne contaminants generated during concrete demolition, necessitating the use of appropriate respiratory protective equipment. |

References

- Heo, Y.; Lee, C.; Kim, H.R.; Lee, S.J. Framework for the development of guidelines for nuclear power plant decommissioning workers based on risk information. Nucl. Eng. Des. 2022, 387, 111624. [Google Scholar] [CrossRef]

- Fthenakis, V.; Kim, H.C. Land use and electricity generation: A life-cycle analysis. Renew. Sustain. Energy Rev. 2009, 13, 1465–1474. [Google Scholar] [CrossRef]

- Ahmad, A.; Covatariu, A.; Ramana, M. A stormy future? Financial impact of climate change-related disruptions on nuclear power plant owners. Util. Policy 2023, 81, 101484. [Google Scholar] [CrossRef]

- Yamamoto, D.; Greco, A. Cursed forever? Exploring socio-economic effects of nuclear power plant closures across nine communities in the United States. Energy Res. Soc. Sci. 2022, 92, 102766. [Google Scholar] [CrossRef]

- Glenn, J.C.; Gordon, T.J. The Millennium Project: Challenges We Face at the Millennium. Technol. Forecast. Soc. Change 2001, 66, 129–312. [Google Scholar] [CrossRef]

- Laraia, M. Chapter 5—Stakeholder case studies. In Nuclear Decommissioning Case Studies; Laraia, M., Ed.; Academic Press: Cambridge, MA, USA, 2022; pp. 21–199. [Google Scholar] [CrossRef]

- Choi, J.; Kim, C.; Cho, Y.; Kwon, H.; Song, K. Utilization of EPRI ChemWorks tools for PWR shutdown chemistry evolution modeling. Nucl. Eng. Technol. 2023, 55, 3543–3548. [Google Scholar] [CrossRef]

- Mariani, C.; Mancini, M. Selection of projects’ primary and secondary mitigation actions through optimization methods in nuclear decommissioning projects. Nucl. Eng. Des. 2023, 407, 112284. [Google Scholar] [CrossRef]

- Awodi, N.J.; Liu, Y.; Ayo-Imoru, R.M.; Ayodeji, A. Fuzzy TOPSIS-based risk assessment model for effective nuclear decommissioning risk management. Prog. Nucl. Energy 2023, 155, 104524. [Google Scholar] [CrossRef]

- Kim, G.L.; Kim, H.; Seo, H.W.; Yu, J.H.; Son, J.W. Classification and consideration for the risk management in the planning phase of NPP decommissioning project. Nucl. Eng. Technol. 2022, 54, 4809–4818. [Google Scholar] [CrossRef]

- Vitázková, J.; Cazzoli, E. Common Risk Target for severe accidents of nuclear power plants based on IAEA INES scale. Nucl. Eng. Des. 2013, 262, 106–125. [Google Scholar] [CrossRef]

- Kim, H.; Lee, D.; Lee, C.W.; Kim, H.R.; Lee, S.J. Safety Assessment Framework for Nuclear Power Plant Decommissioning Workers. IEEE Access 2019, 7, 76305–76316. [Google Scholar] [CrossRef]

- Ok, C.I.L.; Kim, C.L.; Moon, S.R.; Koo, H.S.; Yun, K.H.; Lee, S.K. Prioritization of radiological accident scenarios during decommissioning of nuclear power plants by risk matrix and AHP method. Ann. Nucl. Energy 2022, 175, 109239. [Google Scholar] [CrossRef]

- Hale, A.R.; Ale BJ, M.; Goossens, L.H.J.; Heijer, T.; Bellamy, L.J.; Mud, M.L.; Roelen, A.; Baksteen, H.; Post, J.; Papazoglou, I.A.; et al. Modeling accidents for prioritizing prevention. Reliab. Eng. Syst. Saf. 2007, 92, 1701–1715. [Google Scholar] [CrossRef]

- Moon, H.; Kim, B.; Lee, J.; Cho, H.; Hwang, S.; Ahn, Y. Developing risk breakdown structure for nuclear power plant decommissioning projects in Korea focusing on radioactive concrete dismantle. Int. J. Sustain. Build. Technol. Urban Dev. 2020, 11, 269–280. [Google Scholar] [CrossRef]

- Awodi, N.J.; Liu, Y.K.; Ayodeji, A.; Adibeli, J.O. Expert judgement-based risk factor identification and analysis for an effective nuclear decommissioning risk assessment modeling. Prog. Nucl. Energy 2021, 136, 103733. [Google Scholar] [CrossRef]

- Kudo, S.; Sugihara, T. Basic concept of safety evaluation method for decommissioning of nuclear power plants by applying a graded approach. Nucl. Eng. Des. 2021, 379, 111212. [Google Scholar] [CrossRef]

- Hyun, D.; Kim, I.; Joo, S.; Ha, J.; Lee, J. Remote dismantling system using a digital manufacturing system and workpiece localization for nuclear facility decommissioning. Ann. Nucl. Energy 2024, 195, 110182. [Google Scholar] [CrossRef]

- Li, M.-K.; Liu, Y.-K.; Peng, M.-J.; Xie, C.-L.; Yang, L.-Q. The digital simulation and fuzzy evaluation to reduce the likelihood of unsafe behavior in nuclear decommissioning. Ann. Nucl. Energy 2018, 119, 331–341. [Google Scholar] [CrossRef]

- van de Walle, B.; de Baets, B.; Kerre, E.E. Fuzzy multi-criteria analysis of cutting techniques in a nuclear reactor dismantling project. Fuzzy Sets Syst. 1995, 74, 115–126. [Google Scholar] [CrossRef]

- Sun, H.; Qu, J.; Wang, P.; Kang, J. Application of the Analytic Hierarchy Process in the Selection of Nuclear Power Plant Decommissioning Strategy. In Proceedings of the 2016 24th International Conference on Nuclear Engineering, Charlotte, NC, USA, 26–30 June 2016; Volume 5. [Google Scholar] [CrossRef]

- Torkanfar, N.; Rezazadeh Azar, E. Quantitative similarity assessment of construction projects using WBS-based metrics. Adv. Eng. Inform. 2020, 46, 101179. [Google Scholar] [CrossRef]

- Oh, M.; Jeon, M.K.; Lee, K.; Foster, R.I.; Lee, C.H. Assessment of chlorination technique for decontamination of radioactive concrete waste using simulated concrete waste. Prog. Nucl. Energy 2022, 154, 104458. [Google Scholar] [CrossRef]

- Sow, M.; Leblois, Y.; Bodiot, C.; Motzkus, C.; Ritoux, S.; Gensdarmes, F. Aerosol release fraction by concrete scarifying operations and its implications on the dismantling of nuclear facilities. J. Hazard. Mater. 2020, 400, 123077. [Google Scholar] [CrossRef] [PubMed]

- Amgarou, K.; Aspe, F.; Idoeta, R.; Herranz, M. Recommendations for the selection of in situ measurement techniques for radiological characterization in nuclear/radiological installations under decommissioning and dismantling processes. Prog. Nucl. Energy 2021, 137, 103761. [Google Scholar] [CrossRef]

- Polo López, C.S.; Lucchi, E.; Leonardi, E.; Durante, A.; Schmidt, A.; Curtis, R. Risk-Benefit Assessment Scheme for Renewable Solar Solutions in Traditional and Historic Buildings. Sustainability 2021, 13, 5246. [Google Scholar] [CrossRef]

- Nascimento, J.M.R.e.S.; Bispo, L.G.M.; Silva, J.M.N.d. Risk factors for work-related musculoskeletal disorders among workers in Brazil: A structural equation model approach. Int. J. Ind. Ergon. 2024, 99, 103551. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Decommissioning of Nuclear Power Plants, Research Reactor Facilities and Other Nuclear Fuel Cycle Facilities: A Compendium of Guidance. Vienna, Austria: Author. 2021. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/PUB2023_web.pdf (accessed on 17 April 2024).

- Consolidated Decommissioning Guidance: Decommissioning Process For Materials Licensees (NUREG-1757, Volume 1, Revision 2) | NRC.gov. (n.d.). Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr1757/v1/index.html (accessed on 15 March 2024).

- Consolidated Decommissioning Guidance: Characterization, Survey, And Determination of Radiological Criteria Consolidated Decommissioning Guidance: Characterization, Survey, And Determination of Radiological Criteria—Final Report (NUREG-1757, Volume 2, Revision 2) | NRC.gov. (n.d.). Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr1757/v2/index.html (accessed on 15 March 2024).

- Consolidated NMSS Decommissioning Guidance—Financial Assurance, Recordkeeping, And Timeliness (NUREG-1757, Volume 3, Revision 1) | NRC.gov. (n.d.). Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr1757/v3/index.html (accessed on 15 March 2024).

- Tennakoon, S.; Apan, A.; Maraseni, T.; Altarez, R.D.D. Decoding the impacts of space and time on honey bees: GIS based fuzzy AHP and fuzzy overlay to assess land suitability for apiary sites in Queensland, Australia. Appl. Geogr. 2023, 155, 102951. [Google Scholar] [CrossRef]

- Liu, Y.; Eckert, C.M.; Earl, C. A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Wątróbski, J.; Bączkiewicz, A.; Rudawska, I. A Strong Sustainability Paradigm based Analytical Hierarchy Process (SSP-AHP) method to evaluate sustainable healthcare systems. Ecol. Indic. 2023, 154, 110493. [Google Scholar] [CrossRef]

- Jorge-García, D.; Estruch-Guitart, V. Comparative analysis between AHP and ANP in prioritization of ecosystem services—A case study in a rice field area raised in the Guadalquivir marshes (Spain). Ecol. Inform. 2022, 70, 101739. [Google Scholar] [CrossRef]

- Nahyun, K.; Jongwoo, C.; Lee Hyun-Soo Inseok, Y.; Moonseo, P. Compensation Cost Estimation Model for Construction Noise Claims Using Case-Based Reasoning. J. Constr. Eng. Manag. 2019, 145, 04019047. [Google Scholar] [CrossRef]

- Byun, H.; Park, J.D.; An, S.; Kim, J.; Kim, J.; Lee, D.Y.; Lee, B. Intelligent nuclear decommissioning solution: Code for site characterization and management of overall surveys. Ann. Nucl. Energy 2024, 196, 110212. [Google Scholar] [CrossRef]

- Palanci, M. Fuzzy rule based seismic risk assessment of one-story precast industrial buildings. Earthq. Eng. Eng. Vib. 2019, 18, 631–648. [Google Scholar] [CrossRef]

- Kaya, T.; Kahraman, C. Multicriteria renewable energy planning using an integrated fuzzy VIKOR & AHP methodology: The case of Istanbul. Energy 2010, 35, 2517–2527. [Google Scholar]

- Seier, M.; Zimmermann, T. Environmental impacts of decommissioning nuclear power plants: Methodical challenges, case study, and implications. Int. J. Life Cycle Assess. 2014, 19, 1919–1932. [Google Scholar] [CrossRef]

- Lee, J.; Cho, Y. Economic value of the development of nuclear power plant decommissioning technology in South Korea. Energy Policy 2023, 181, 113695. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).