A New Building Information Modelling-Based Approach to Automate Recyclability Rate Calculations for Buildings

Abstract

1. Introduction

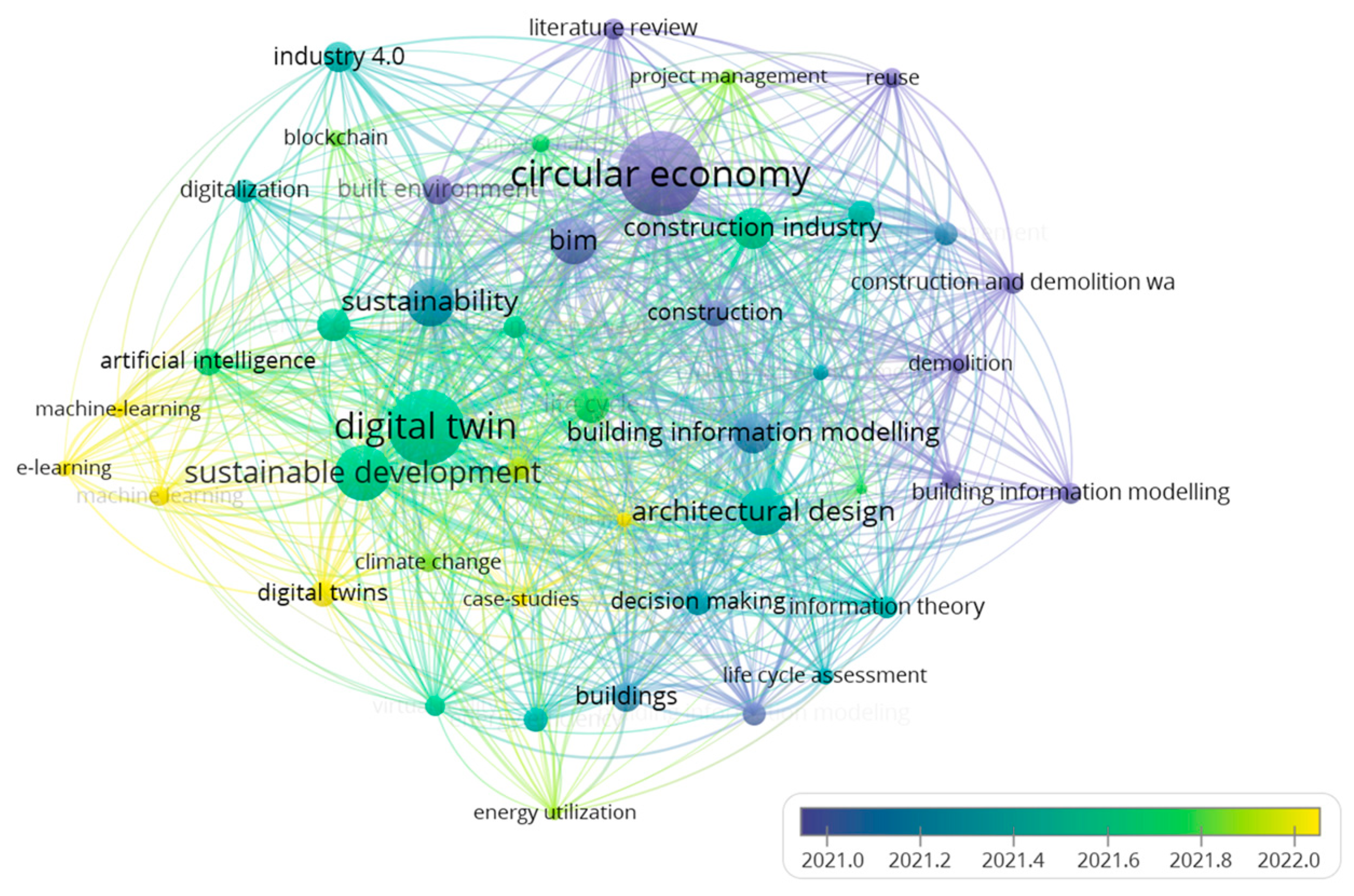

2. Literature Review

2.1. Waste Management and Recyclability in CE

2.2. Circular Indicators of Building Materials

2.3. Application of Digital Technologies in CE

3. Materials and Methods

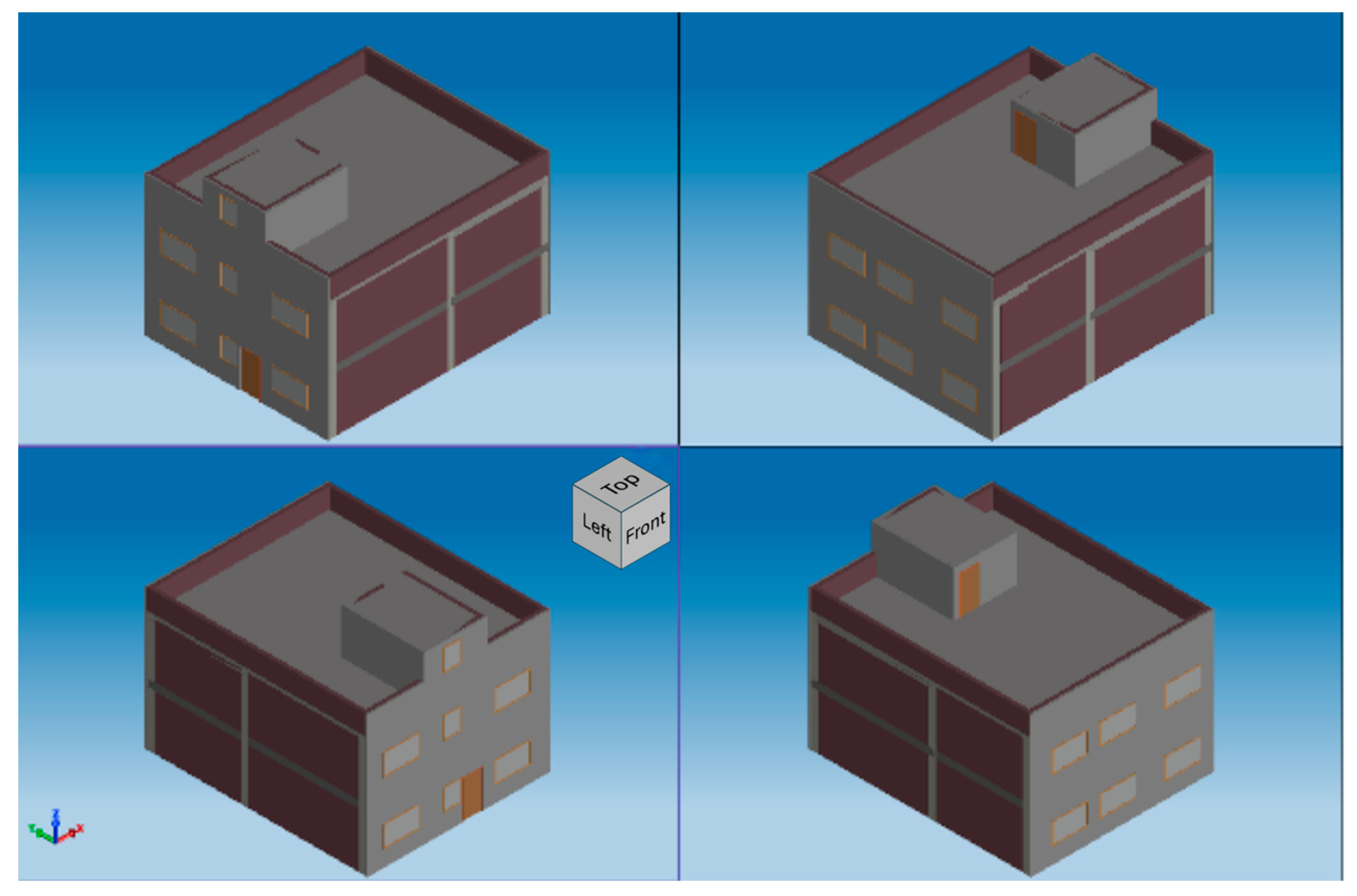

3.1. BIM Model and IFC for Material Inventory

3.2. Inventory Integration with the European Waste Catalogue (EWC)

3.3. Recyclability Rate of Each Material

- Health and safety: Hazardous materials can pose significant risks to human health and the environment if not handled and disposed of properly. By identifying these materials early in the recyclability assessment process, appropriate safety measures can be put in place to protect workers, occupants, and the surrounding community.

- Regulatory compliance: The EWC provides a legal framework to classify and manage waste materials. Buildings that contain hazardous materials are subject to specific regulations regarding their demolition, deconstruction, and recycling in different countries.

- Environmental protection: The improper disposal of hazardous materials can have severe environmental consequences, including contamination of soil, water, and air. By identifying these materials and ensuring their safe disposal or recycling, ecosystems can be protected, and sustainable development is promoted.

3.4. Reference Service Life (RSL)

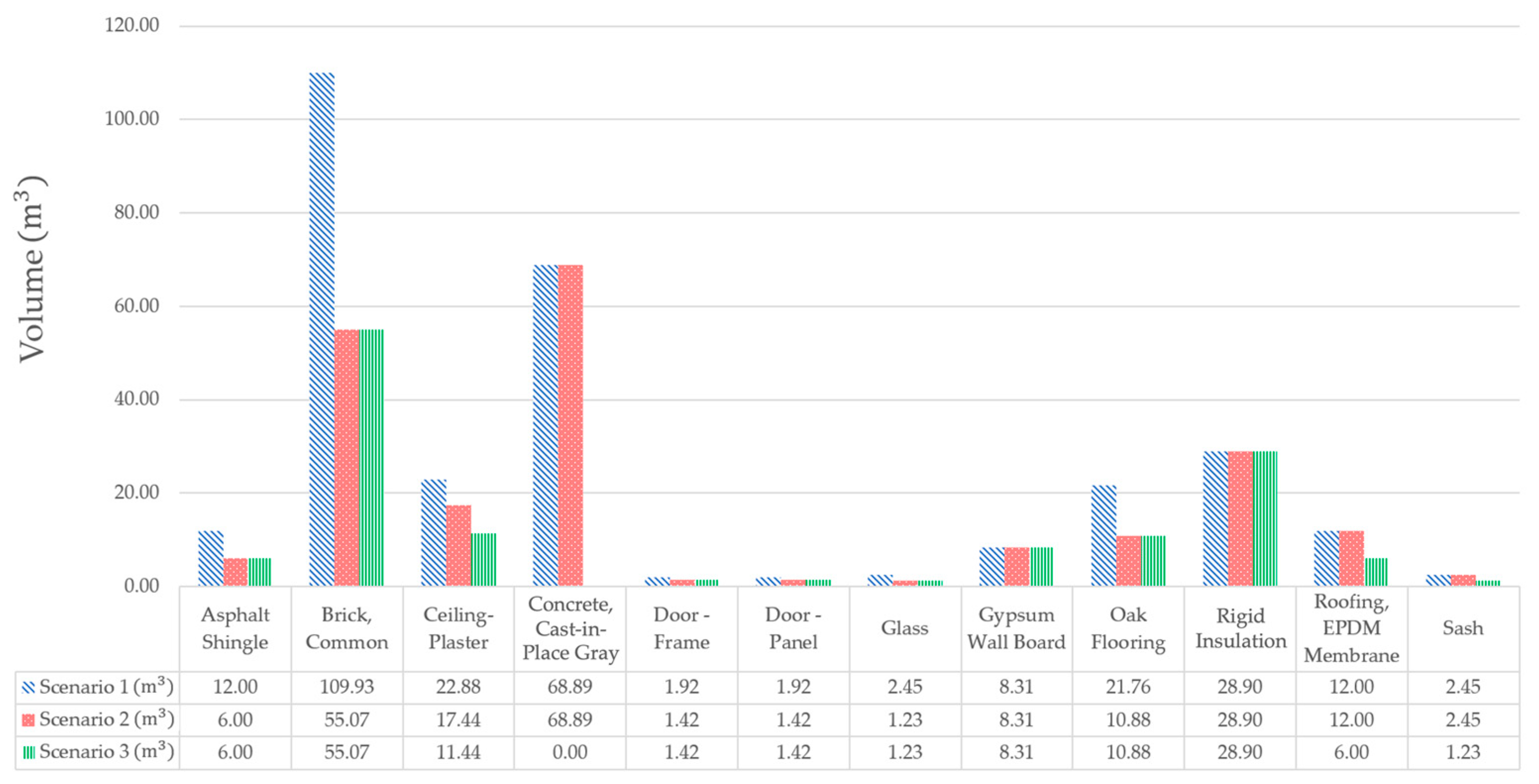

3.5. Scenario Analysis

4. Results and Discussion

4.1. Building Recyclability Rate

4.2. Scenario Analysis

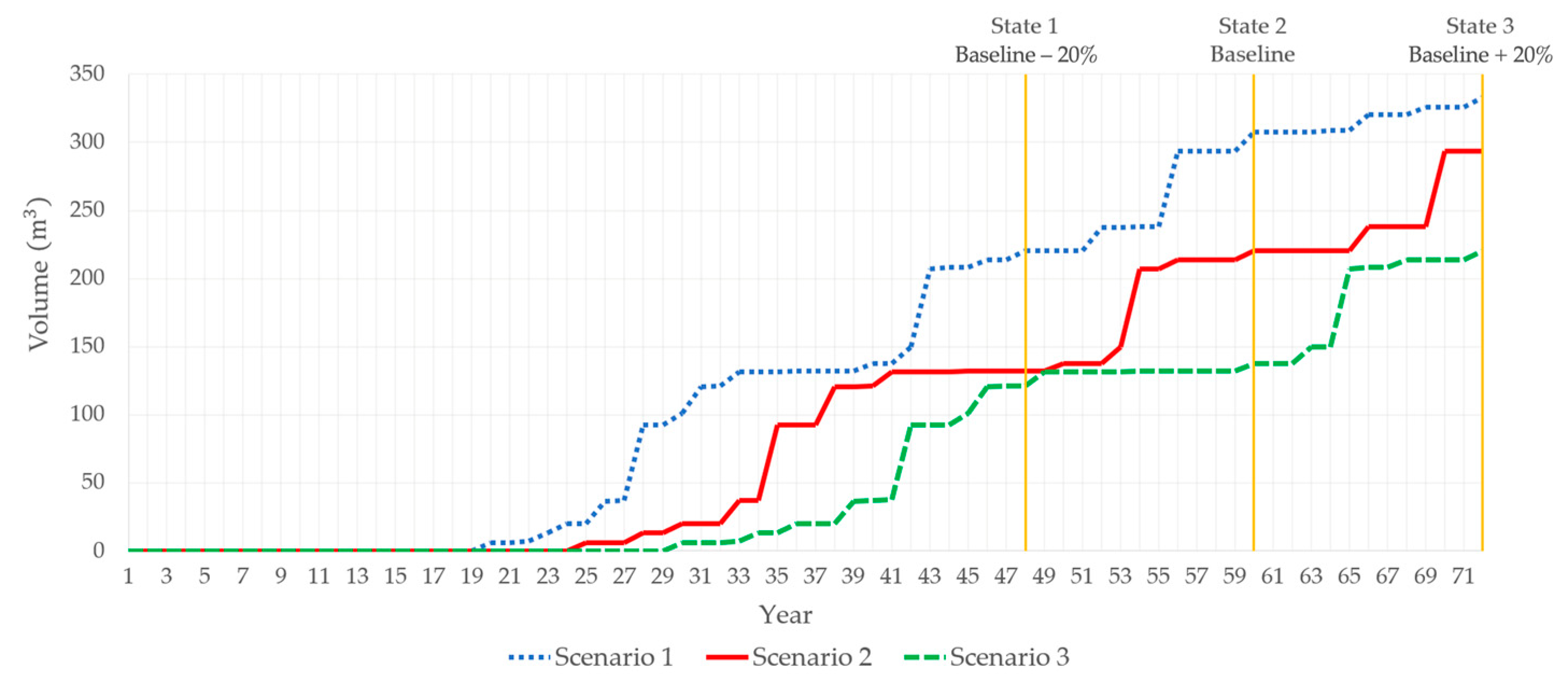

4.3. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, M.I.M. Estimating the sustainability returns of recycling construction waste from building projects. Sustain. Cities Soc. 2016, 23, 78–93. [Google Scholar] [CrossRef]

- Amarasinghe, I.; Hong, Y.; Stewart, R.A. Development of a material circularity evaluation framework for building construction projects. J. Clean. Prod. 2024, 436, 140562. [Google Scholar] [CrossRef]

- Villoria Sáez, P.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- BIO Intelligence Service, Cambridge Econometrics, Directorate-General for Environment (European Commission). Study on Modelling of the Economic and Environmental Impacts of Raw Material Consumption: Final Report. LU: Publications Office of the European Union. 2014. Available online: https://data.europa.eu/doi/10.2779/77904 (accessed on 12 December 2023).

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular material passports for buildings—Providing a robust methodology for promoting circular buildings. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1122. [Google Scholar] [CrossRef]

- Khadim, N.; Agliata, R.; Marino, A.; Thaheem, M.J.; Mollo, L. Critical review of nano and micro-level building circularity indicators and frameworks. J. Clean. Prod. 2022, 357, 131859. [Google Scholar] [CrossRef]

- Charef, R.; Emmitt, S. Uses of building information modelling for overcoming barriers to a circular economy. J. Clean. Prod. 2021, 285, 124854. [Google Scholar] [CrossRef]

- Bellini, A.; Bang, S. Barriers for data management as an enabler of circular economy: An exploratory study of the Norwegian AEC-industry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1122. [Google Scholar] [CrossRef]

- Zanelli, C.; Marrocchino, E.; Guarini, G.; Toffano, A.; Vaccaro, C.; Dondi, M. Recycling Construction and Demolition Residues in Clay Bricks. Appl. Sci. 2021, 11, 8918. [Google Scholar] [CrossRef]

- Caldas, L.R.; Silva, M.V.; Silva, V.P.; Carvalho, M.T.M.; Toledo Filho, R.D. How Different Tools Contribute to Climate Change Mitigation in a Circular Building Environment?—A Systematic Literature Review. Sustainability 2022, 14, 3759. [Google Scholar] [CrossRef]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions a New Circular Economy Action Plan for a Cleaner and More Competitive Europe. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 20 December 2023).

- Delivering the European Green Deal—European Commission. 2021. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal_en (accessed on 18 December 2023).

- European Parliament. Directive (EU) 2018/of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste; European Parliament: Brussels, Belgium, 2018. [Google Scholar]

- Rose, C.M.; Stegemann, J.A. From Waste Management to Component Management in the Construction Industry. Sustainability 2018, 10, 229. [Google Scholar] [CrossRef]

- Sampaio, A.Z. BIM as a Computer-Aided Design Methodology in Civil Engineering. J. Softw. Eng. Appl. 2017, 10, 194–210. [Google Scholar] [CrossRef]

- Jayasinghe, L.B.; Waldmann, D. Development of a bim-based web tool as a material and component bank for a sustainable construction industry. Sustainability 2020, 12, 1766. [Google Scholar] [CrossRef]

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping construction supply chain processes with circular economy strategies: A systematic literature review. J. Clean. Prod. 2022, 335, 130240. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Svennevig, P.R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988. [Google Scholar] [CrossRef]

- Xavier, L.H.; Giese, E.C.; Ribeiro-Duthie, A.C.; Lins, F.A.F. Sustainability and the circular economy: A theoretical approach focused on e-waste urban mining. Resour. Policy 2021, 74, 101467. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef] [PubMed]

- González-Sánchez, M.; Martín-Ortega, J.L. Greenhouse Gas Emissions Growth in Europe: A Comparative Analysis of Determinants. Sustainability 2020, 12, 1012. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Material Circularity Indicator (MCI). 2023. Available online: https://ellenmacarthurfoundation.org/material-circularity-indicator (accessed on 19 March 2023).

- Çetin, S.; Gruis, V.; Straub, A. Digitalization for a circular economy in the building industry: Multiple-case study of Dutch social housing organizations. Resour. Conserv. Recycl. Adv. 2022, 15, 200110. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Selection Criteria for Building Materials and Components in Line with the Circular Economy Principles in the Built Environment—A Review of Current Trends. Infrastructures 2021, 6, 49. [Google Scholar] [CrossRef]

- Cottafava, D.; Ritzen, M. Circularity Indicator for Residential Buildings: Addressing the Gap Between Embodied Impacts and Design Aspects. Resour. Conserv. Recycl. 2021, 164, 105–120. [Google Scholar] [CrossRef]

- Steinmann, Z.J.N.; Huijbregts, M.A.J.; Reijnders, L. How to define the quality of materials in a circular economy? Resour. Conserv. Recycl. 2019, 141, 362–363. [Google Scholar] [CrossRef]

- Zhang, N.; Han, Q.; de Vries, B. Building Circularity Assessment in the Architecture, Engineering, and Construction Industry: A New Framework. Sustainability 2021, 13, 12466. [Google Scholar] [CrossRef]

- Incelli, F.; Cardellicchio, L.; Rossetti, M. Circularity Indicators as a Design Tool for Design and Construction Strategies in Architecture. Buildings 2023, 13, 1706. [Google Scholar] [CrossRef]

- Kovacic, I.; Honic, M.; Sreckovic, M. Digital platform for circular economy in AEC industry. Eng. Proj. Organ. J. 2020, 9, 1–16. [Google Scholar] [CrossRef]

- Kaewunruen, S.; AbdelHadi, M.; Kongpuang, M.; Pansuk, W.; Remennikov, A.M. Digital Twins for Managing Railway Bridge Maintenance, Resilience, and Climate Change Adaptation. Sensors 2023, 23, 252. [Google Scholar] [CrossRef]

- BIM Based Fast Toolkit for Efficient rEnovation in Buildings|BIM4EEB Project|Fact Sheet|H2020. European Commission. Available online: https://cordis.europa.eu/project/id/820660 (accessed on 13 March 2024).

- AlJaber, A.; Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. Life Cycle Cost in Circular Economy of Buildings by Applying Building Information Modeling (BIM): A State of the Art. Buildings 2023, 13, 1858. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O. Integrating construction supply chains within a circular economy: An ANFIS-based waste analytics system (A-WAS). J. Clean. Prod. 2019, 229, 863–873. [Google Scholar] [CrossRef]

- 2014/955/EU: Commission Decision of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council Text with EEA Relevance. OJ L Dec 18. 2014. Available online: http://data.europa.eu/eli/dec/2014/955/oj/eng (accessed on 18 December 2023).

- Bousquin, J. Jobsite Recycling Has Many Challenges. Builder. 2019. Available online: https://www.builderonline.com/building/jobsite-recycling-has-many-challenges_o (accessed on 21 December 2023).

- Brick by Brick, Waste Can Shape the Future of Construction|ArchDaily. Available online: https://www.archdaily.com/1005981/brick-by-brick-waste-can-shape-the-future-of-construction (accessed on 21 December 2023).

- Keller, M. Gypsum Recycling Presents Challenges. American Recycler News, Inc. 2022. Available online: https://americanrecycler.com/gypsum-recycling-presents-challenges/ (accessed on 21 December 2023).

- Recycling—Gypsum Association. Available online: https://gypsum.org/recycling-gypsum-wallboard/ (accessed on 21 December 2023).

- EUMEPS. Available online: http://67.23.254.45/~eumeps/faq/ (accessed on 21 December 2023).

- Wood Recycling for the Construction Industry National Waste Associates: Intelligent National Waste Services Management. Reuse and Recycle Your Waste. Available online: https://www.nationalwaste.com/blog/wood-recycling-for-the-construction-industry-dont-let-your-money-get-hauled-away/ (accessed on 21 December 2023).

- Recycling Wood from Construction Projects|nibusinessinfo.co.uk. Available online: https://www.nibusinessinfo.co.uk/content/recycling-wood-construction-projects (accessed on 23 December 2023).

- Santos, G.; Esmizadeh, E.; Riahinezhad, M. Recycling Construction, Renovation, and Demolition Plastic Waste: Review of the Status Quo, Challenges and Opportunities. J. Polym. Environ. 2024, 32, 479–509. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Sáez-de-Guinoa, A.; Zambrana-Vasquez, D.; Fernández, V.; Bartolomé, C. Circular Economy in the European Construction Sector: A Review of Strategies for Implementation in Building Renovation. Energies 2022, 15, 4747. [Google Scholar] [CrossRef]

- Bellona. Circularity in Cement and Concrete. 2022. Available online: https://bellona.org/news/industry/2022-02-circularity-in-cement-and-concrete (accessed on 23 December 2023).

- End of Life Recycling. Concrete Centre. Available online: https://www.concretecentre.com/Performance-Sustainability/Circular-economy/End-of-life-recycling.aspx (accessed on 23 December 2023).

- Gowtham, R.; Prabhu, S.M.; Gowtham, M.; Ramasubramani, R. A Review on Utilization of Waste Glass in Construction Field. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1130, 012010. [Google Scholar] [CrossRef]

- Glass Recycling—Current Market Trends—Recovery. Available online: https://www.recovery-worldwide.com/en/artikel/glass-recycling-current-market-trends-3248774.html (accessed on 23 December 2023).

- Environmental Responsibility|Rose Collection Sash Windows. Rose Collection. Available online: https://www.sashwindowsuk.com/about/environmental-responsibility (accessed on 23 December 2023).

- Roofing & Recyclability: Metal vs. Shingle vs. EPDM vs. Tile Roofing. Available online: https://sheffieldmetals.com/learning-center/roofing-materials-recyclability/ (accessed on 23 December 2023).

- Asphalt Shingles. CT.gov—Connecticut’s Official State Website. Available online: https://portal.ct.gov/DEEP/Reduce-Reuse-Recycle/Construction-and-Demolition/Asphalt-Shingles (accessed on 23 December 2023).

- Construction and Demolition Waste (CDW). Collectors. Available online: https://www.collectors2020.eu/the-project/scope/construction-demolition-waste-cdw/ (accessed on 23 December 2023).

- Goulouti, K.; Favre, D.; Giorgi, M.; Padey, P.; Galimshina, A.; Habert, G.; Lasvaux, S. Dataset of service life data for 100 building elements and technical systems including their descriptive statistics and fitting to lognormal distribution. Data Brief 2021, 36, 107062. [Google Scholar] [CrossRef] [PubMed]

- Goulouti, K.; Giorgi, M.; Favre, D.; Lasvaux, S. Development of a Service Life Database of Building Elements Based on an International Data Collection. In Proceedings of the XV International Conference on Durability of Building Materials and Components (DBMC 2020), Barcelona, Spain, 20–23 October 2020; Available online: https://www.scipedia.com/public/Goulouti_et_al_2020a (accessed on 13 March 2024).

- Hapm Publications, Ltd. HAPM Component Life Manual; CRC Press: London, UK, 2020; 578p. [Google Scholar]

- BLP Durability Assessment; Building LifePlans Ltd.: London, UK, 2005.

- Nicolella, M. Manutenzione Programmata Degli Edifici; Edizioni Luciano: Naples, Italy, 2021; 210p, Available online: https://www.iris.unina.it/handle/11588/857601 (accessed on 27 February 2024).

- Di Giulio, R. Manuale di Manutenzione Edilizia, 3rd ed.; Ambiente Territorio Edilizia Urbanistica; Maggioli Editore: Pisa, Italy, 2007; 417p. [Google Scholar]

- Re Cecconi, F.; Marcon, F. Manutenzione e Durata Degli Edifici e Degli Impianti; Ambiente Territorio Edilizia Urbanistica; Maggioli Editore: Pisa, Italy, 2012; 200p. [Google Scholar]

- BS 7543:2015; Guide to Durability of Buildings and Building Elements, Products and Components. British Standards Institution: London, UK, 2015. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000030295129 (accessed on 14 March 2024).

- BS ISO 15686-8:2008; Buildings and Constructed Assets—Service-Life Planning. International Organization for Standardization: Geneva, Switzerland, 2008. Available online: https://bsol.bsigroup.com/Bibliographic/BibliographicInfoData/000000000030084862 (accessed on 26 February 2024).

- Municipal Waste Recycling Rates in Europe by Country—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/daviz/municipal-waste-recycled-and-composted-6#tab-chart_7 (accessed on 12 December 2023).

| No. | Material | Recyclability Range | Recyclability Rate Considered for Case Study | Reference |

|---|---|---|---|---|

| 1 | Brick | 0–85% | 36% | [9,37,38] |

| 2 | Gypsum wall | 2–10% | 4% | [39,40] |

| 3 | Rigid insulation | 46% | 46% | [41] |

| 4 | Wood | 10–15% | [42,43] | |

| 5 | PVC | 11–100% | 50% | [44,45] |

| 6 | Steel | 59% | [46] | |

| 7 | Aluminum | 33% | [46] | |

| 8 | Copper | 37% | [46] | |

| 9 | Concrete | 40–98% | 75% | [47,48] |

| 10 | Glass | 35–74% | 70.9% | [49,50] |

| 11 | Sash | 80% | 80% | [44,51] |

| 12 | Asphalt shingle | 10–70% | 70% | [52,53] |

| 13 | EPDM membrane | 70–100% | 96% | [52,54] |

| No. | Material | RSL 1 (Years) [55] | RSL 2 (Years) [56] | RSL 3 (Years) [57] | RSL 4 (Years) [58] | RSL 5 (Years) [59] | RSL 6 (Years) [60] | RSL 7 (Years) [61] | Average (Years) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Brick | N/A | 25 | +35 | +60 | 20 | N/A | 25–40 | 34.5 |

| 2 | Gypsum wall | 40 | 40 | 35 | 60 | 25 | N/A | 20–30 | 37.5 |

| 3 | Rigid insulation (exterior) | 38 | 35 | 35 | 60 | 25 | N/A | 30–40 | 38 |

| 4 | Rigid insulation (interior) | 38 | 35 | 35 | 60 | N/A | N/A | 30–40 | 40.6 |

| 5 | Wood (exterior) | 40 | 40 | 35 | 30 | N/A | 20–30 | 30–40 | 34 |

| 6 | Wood (interior) | 40 | 40 | 35 | 60 | N/A | 20–30 | 30–40 | 39 |

| 7 | Concrete | N/A | 75 | +35 | 60 | N/A | 15–20 | 80 | 53 |

| 8 | Glass | 30 | 30 | 30 | 30 | N/A | N/A | 25–30 | 29.5 |

| 9 | Sash | 30 | 30 | 20 | 30 | N/A | N/A | N/A | 27.5 |

| 10 | Asphalt shingle | 30 | 30 | 30 | 50 | 15–20 | 20–30 | 40–50 | 32.5 |

| 11 | EPDM membrane | 30 | 30 | 35 | 25 | 15–20 | 10–15 | 20 | 24 |

| 12 | Ceiling, plaster | 30 | 35 | N/A | 25 | N/A | 25–30 | 25–40 | 30 |

| 13 | Oak flooring | N/A | 35 | N/A | 60 | N/A | 15–20 | 15–20 | 32.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fereydooni Eftekhari, A.; Khodabakhshian, A.; Iuorio, O.; Re Cecconi, F.; Daniotti, B. A New Building Information Modelling-Based Approach to Automate Recyclability Rate Calculations for Buildings. Buildings 2024, 14, 1521. https://doi.org/10.3390/buildings14061521

Fereydooni Eftekhari A, Khodabakhshian A, Iuorio O, Re Cecconi F, Daniotti B. A New Building Information Modelling-Based Approach to Automate Recyclability Rate Calculations for Buildings. Buildings. 2024; 14(6):1521. https://doi.org/10.3390/buildings14061521

Chicago/Turabian StyleFereydooni Eftekhari, Alireza, Ania Khodabakhshian, Ornella Iuorio, Fulvio Re Cecconi, and Bruno Daniotti. 2024. "A New Building Information Modelling-Based Approach to Automate Recyclability Rate Calculations for Buildings" Buildings 14, no. 6: 1521. https://doi.org/10.3390/buildings14061521

APA StyleFereydooni Eftekhari, A., Khodabakhshian, A., Iuorio, O., Re Cecconi, F., & Daniotti, B. (2024). A New Building Information Modelling-Based Approach to Automate Recyclability Rate Calculations for Buildings. Buildings, 14(6), 1521. https://doi.org/10.3390/buildings14061521