Nonlinear Dynamic Response of Galfenol Cantilever Energy Harvester Considering Geometric Nonlinear with a Nonlinear Energy Sink

Abstract

1. Introduction

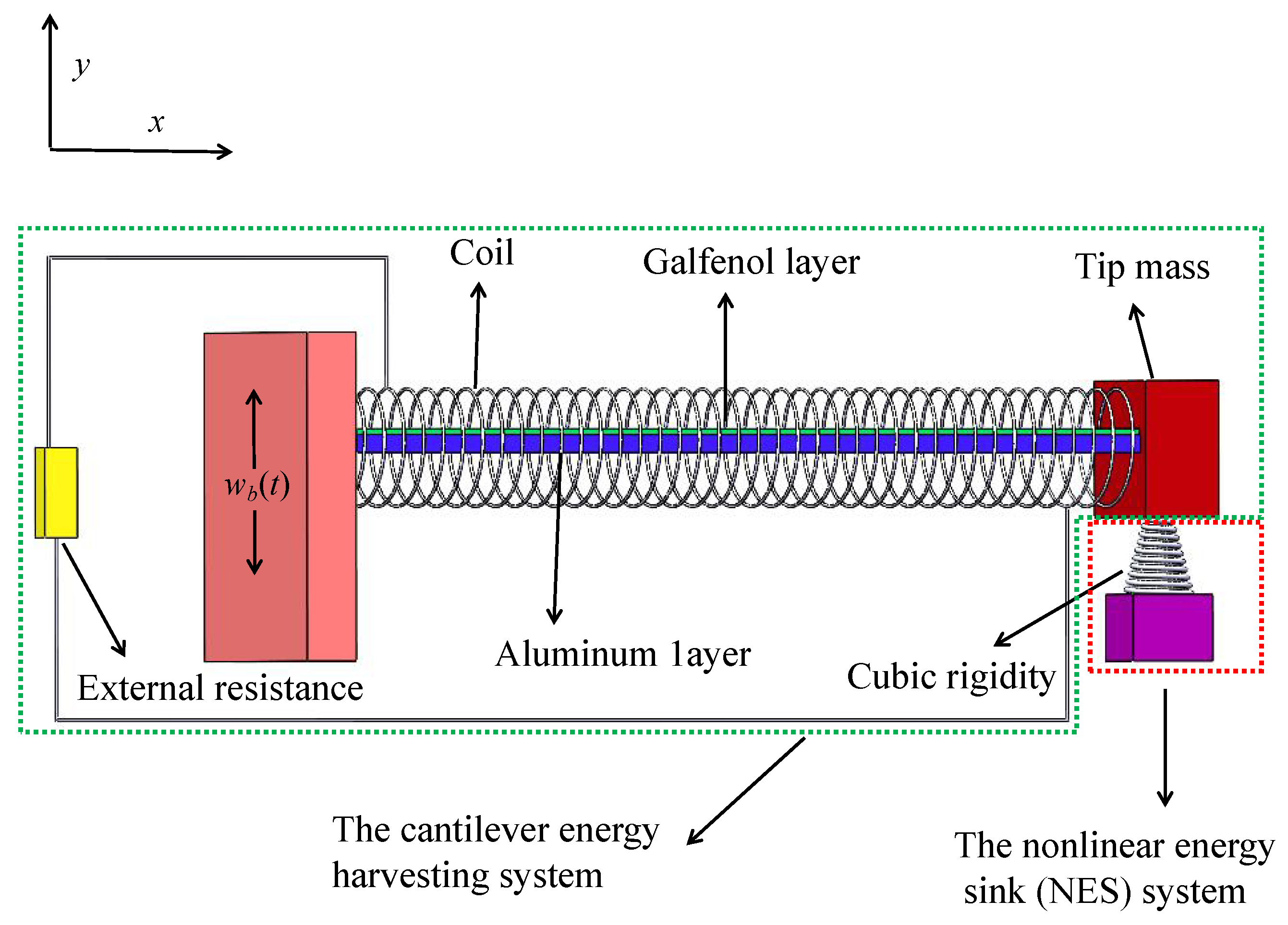

2. Mathematical Model

2.1. Coupled Mechanical Equations of the Cantilever Energy Harvesting System

2.2. Coupled Electrical Circuit Equations of the Cantilever Energy Harvesting System

2.3. Coupled Mechanical Equations of the NES System

3. Representative Model of Output Responses for the Coupled System

4. Results and Discussion

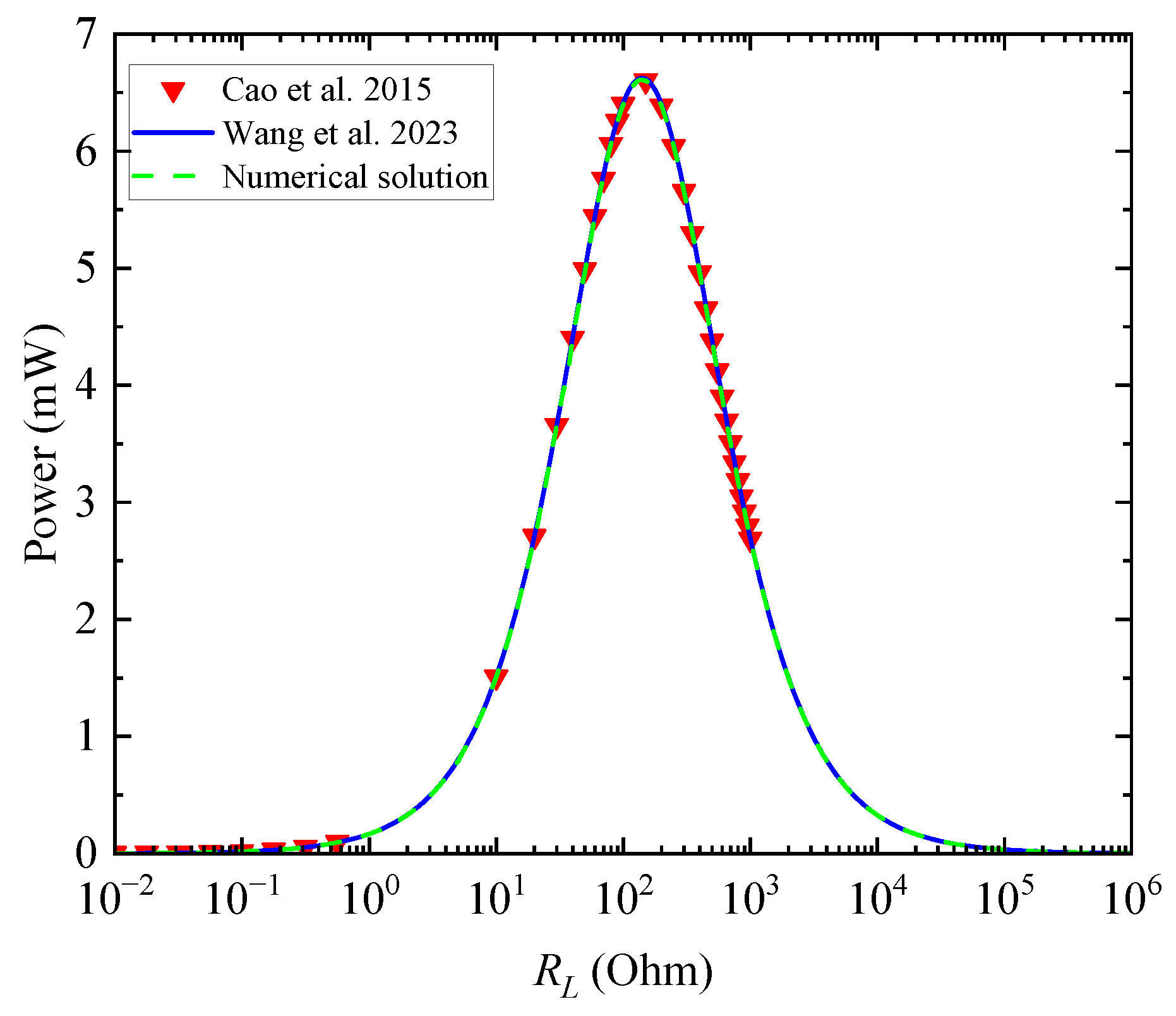

4.1. Model Validation

4.2. Comparison between the Linear and Nonlinear Systems

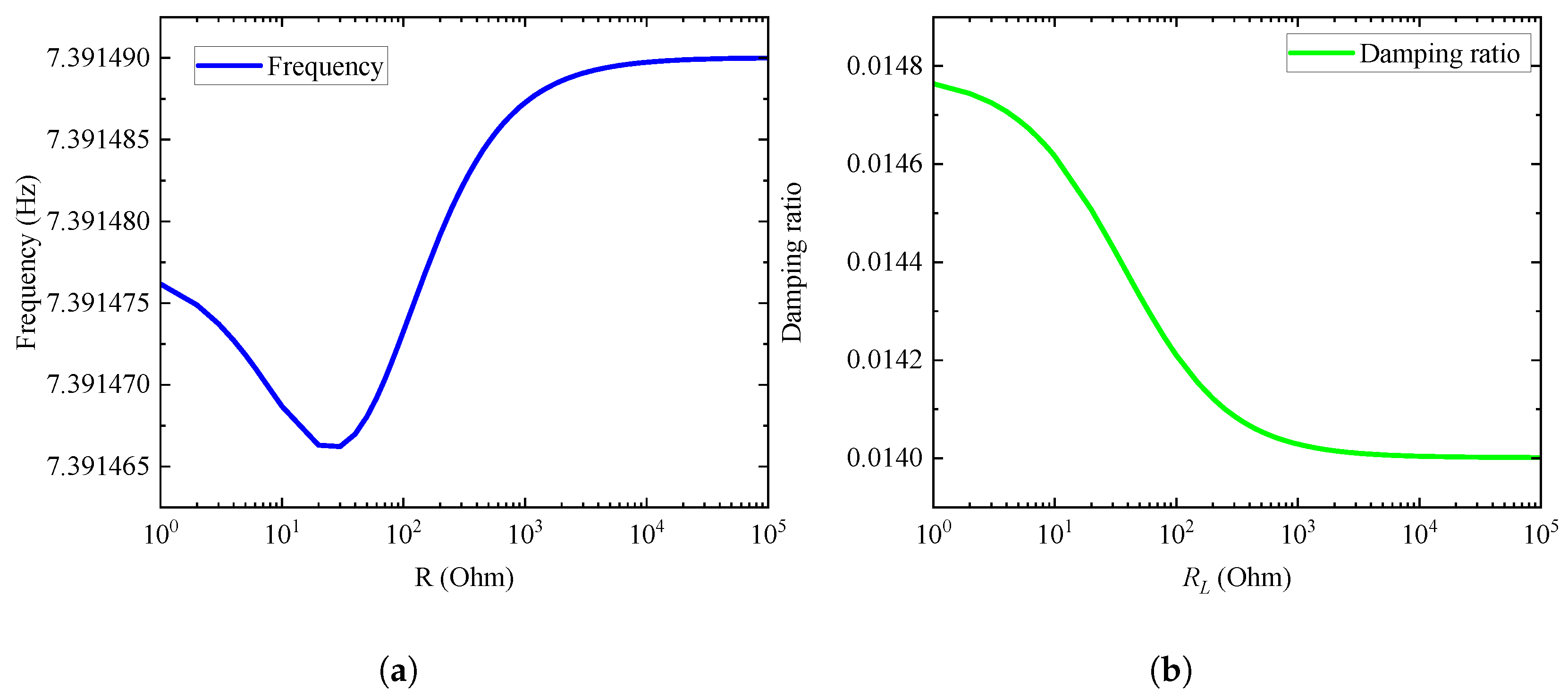

4.3. Effect of External Load Resistance on Global Damping and Frequency

4.4. Parametric Analysis

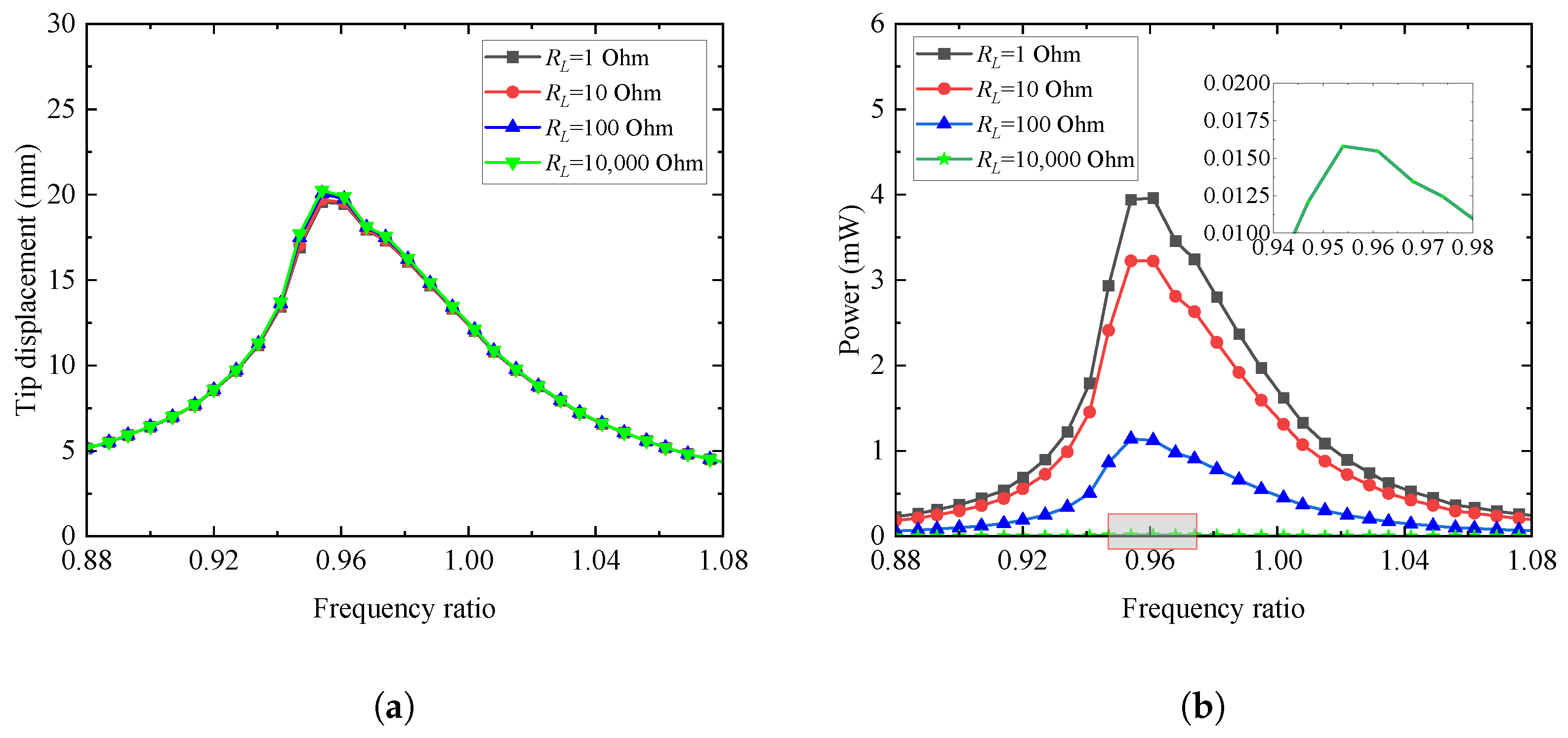

4.4.1. Effects of External Resistance and Excitation Frequency Ratio

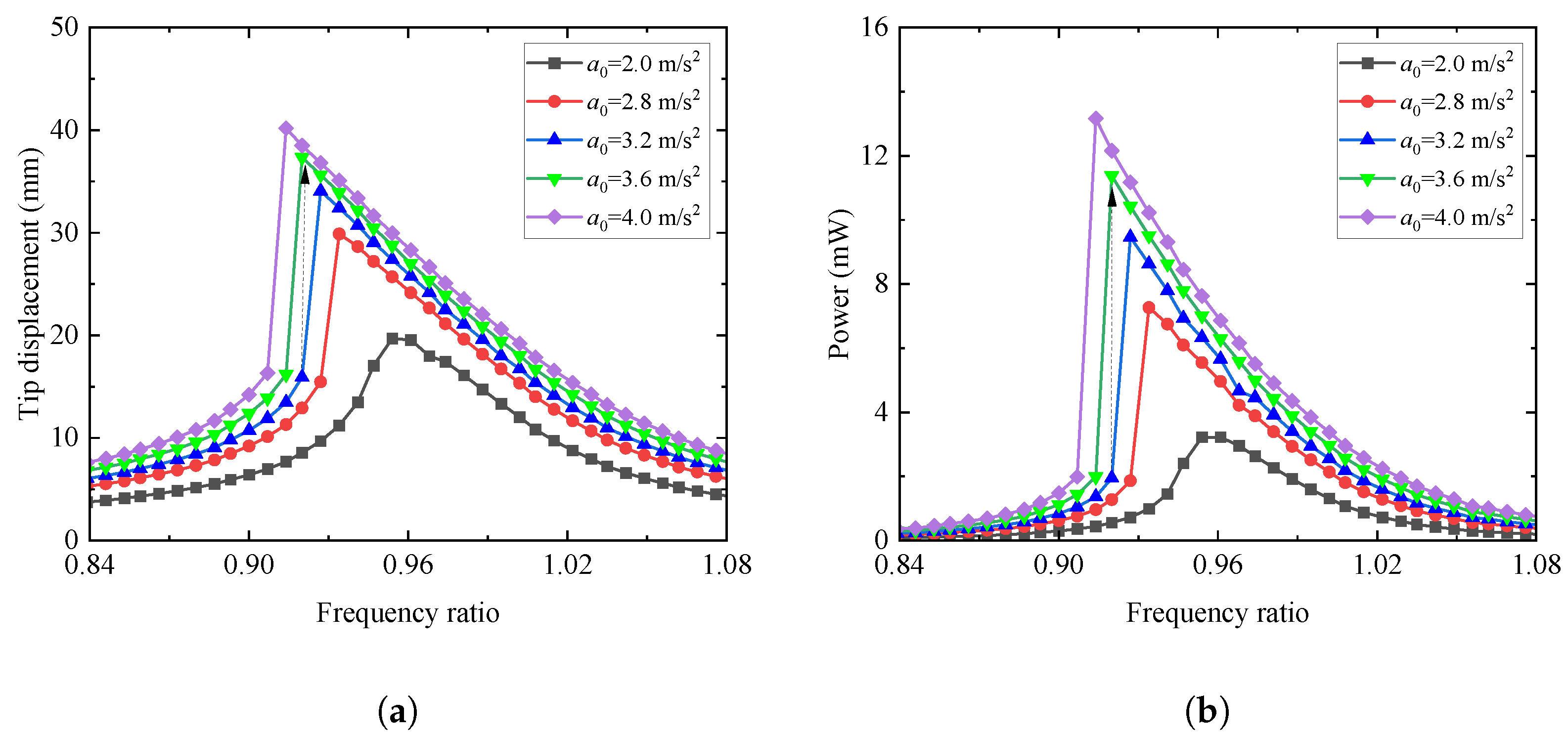

4.4.2. Effects of Excitation Acceleration Amplitude and Excitation Frequency Ratio

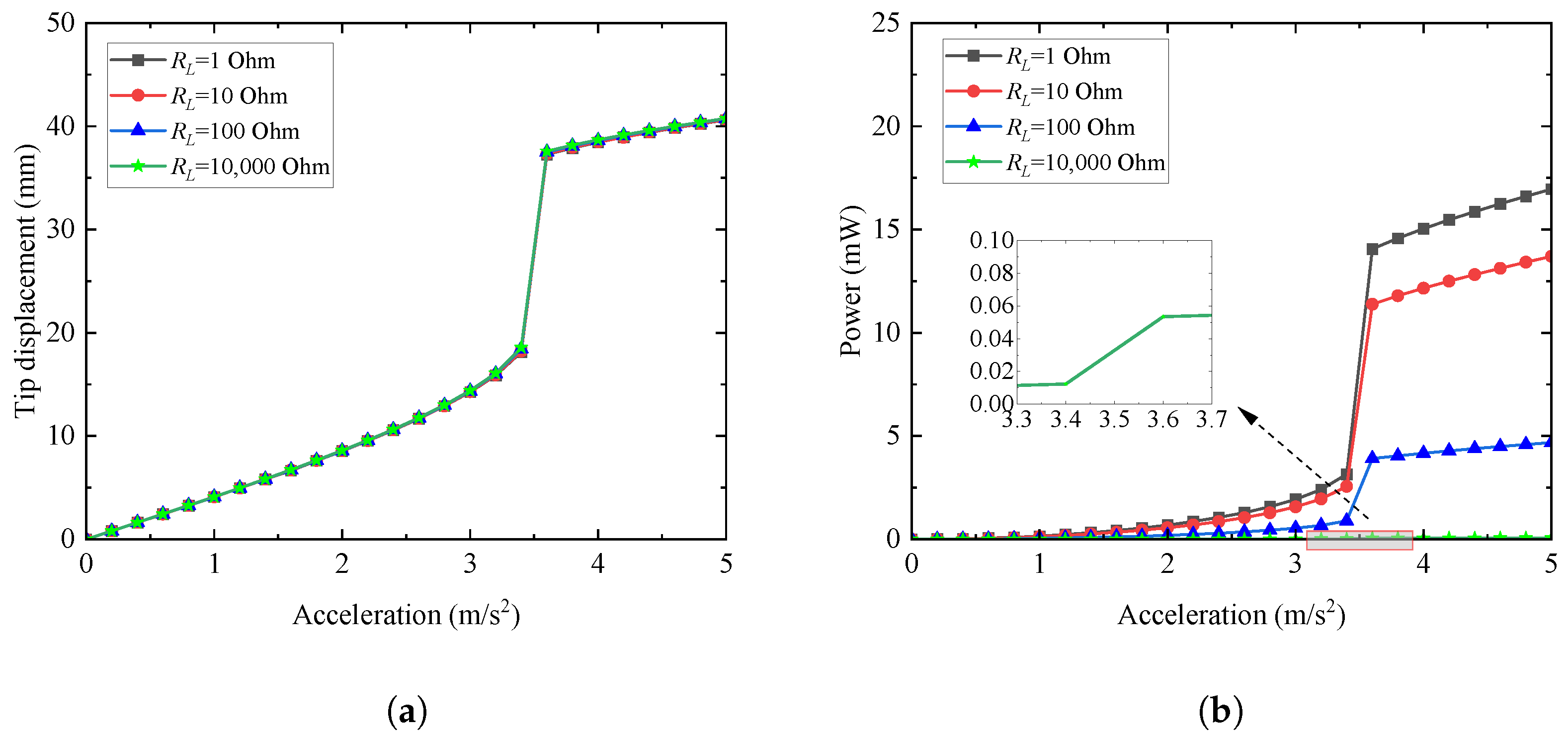

4.4.3. Effects of External Resistance and Excitation Acceleration Amplitude

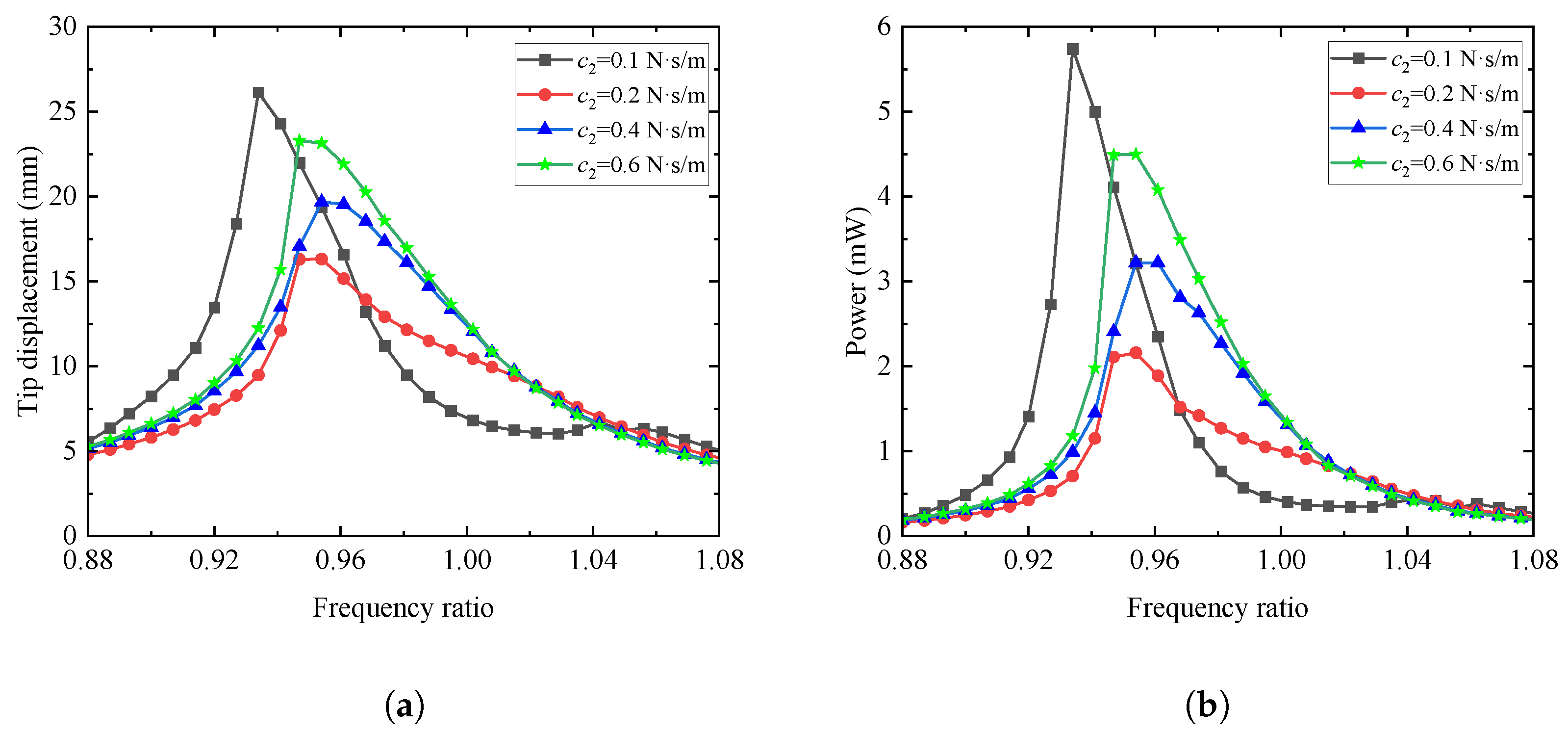

4.4.4. Effects of the Damping and Nonlinear Stiffness for the NES

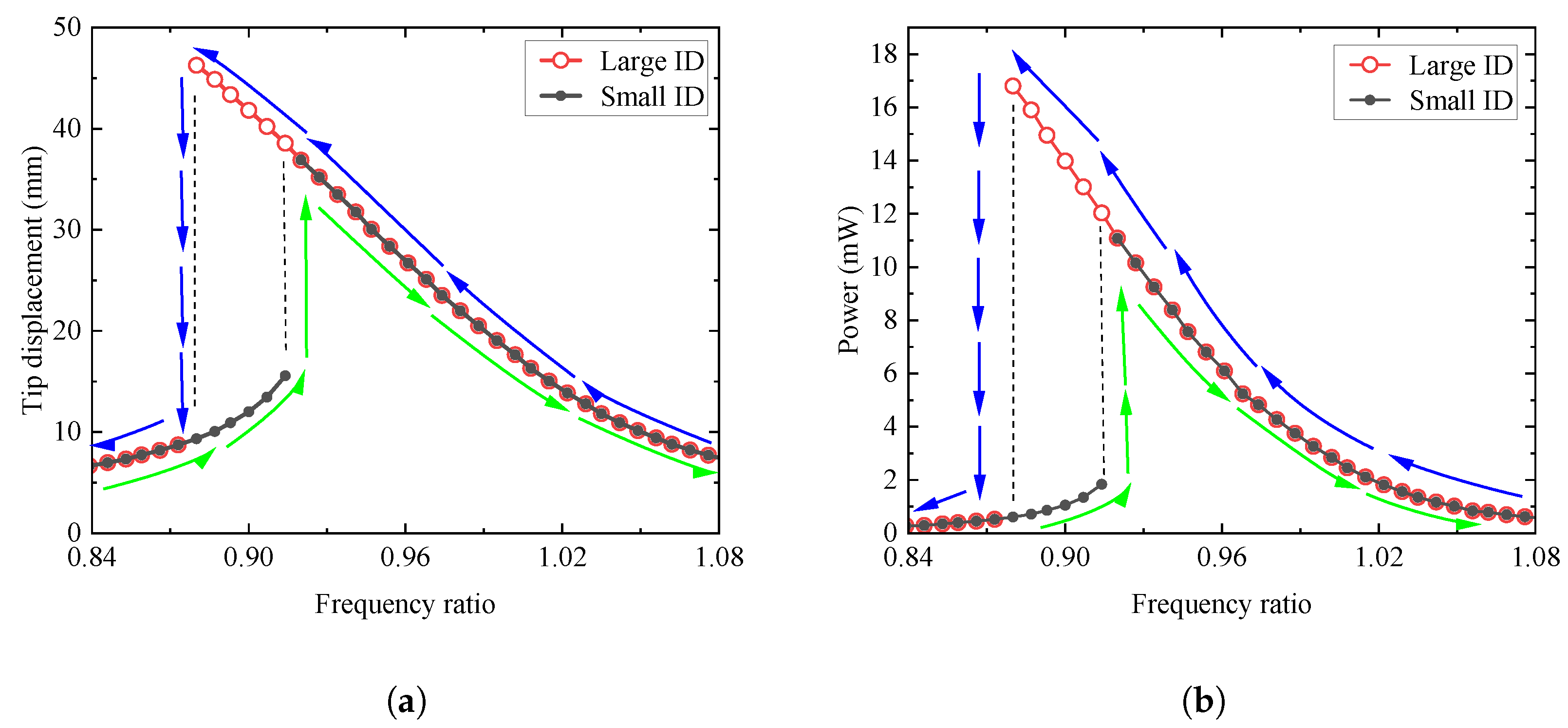

4.4.5. Effects of the Initial Excitation Condition

5. Conclusions

- (1)

- The numerical calculation solutions of the proposed coupling system reveal that the addition of an NES can effectively reduce the vibration behaviors of the cantilever Galfenol energy harvesting system. After considering the geometric nonlinearity of the cantilever beam, the jumping phenomenon will occur relative to the linear system.

- (2)

- For any fixed external load resistance, excitation acceleration amplitude, NES damping, or NES nonlinear stiffness, the corresponding optimal range of the excitation frequency ratio, around 0.96, could be identified to maximize the harvested power.

- (3)

- When the external excitation acceleration, NES damping, and nonlinear stiffness exceed a certain threshold, the system output responses will exhibit a jumping phenomenon, namely the nonlinear softening phenomenon. In the nonlinear softening range, two branching curves exist, corresponding to the responses of small and large initial conditions, respectively. In the non-softening range, there is only one branching curve. This means that the output response of the coupled system is independent of the initial conditions when the excitation is outside the jumping region.

- (4)

- In summary, to achieve better energy harvesting characteristics, the external resistance should be taken as small (such as Oom) and the external excitation amplitude should be larger (such as m/s2). The NES damping should be taken as a smaller or larger value (such as = 0.1 N· s/m or > 0.4 N· s/m), and the stiffness of the NES should be as large as possible (such as > 106 N/m3). Then the appearance of the nonlinear softening phenomenon will occur and effectively expand the vibration energy-capturing frequency bandwidth of the proposed coupling system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alavi, A.H.; Hasni, H.; Lajnef, N.; Chatti, K.; Faridazar, F. An intelligent structural damage detection approach based on self powered wireless sensor data. Automat. Constr. 2016, 62, 24–44. [Google Scholar] [CrossRef]

- Clemente, C.S.; Mahgoub, A.; Davino, D.; Visone, C. Multiphysics circuit of a magnetostrictive energy harvesting device. J. Intel. Mat. Syst. Str. 2017, 28, 2317–2330. [Google Scholar] [CrossRef]

- Wang, L.Z.; Tan, T.; Yan, Z.M.; Yan, Z.T. Tapered galloping energy harvester for power enhancement and vibration reduction. J. Intel. Mat. Syst. Str. 2019, 30, 2853–2869. [Google Scholar] [CrossRef]

- Dragunov, V.P.; Ostertak, D.I.; Sinitskiy, R.E. New modifications of a Bennet doubler circuit-based electrostatic vibrational energy harvester. Sens. Actuat. A-Phys. 2020, 302, 111812. [Google Scholar] [CrossRef]

- Tan, Y.; Dong, Y.; Wang, X. Review of MEMS Electromagnetic Vibration Energy Harvester. J. Microelectromech. Syst. 2017, 26, 1–16. [Google Scholar] [CrossRef]

- Budhathoki, S.; Sapkota, A.; Law, K.M.; Nepal, B.; Ranjit, S.; Kc, S.; Mewes, T.; Hauser, A.J. Low Gilbert damping and linewidth in magnetostrictive FeGa thin films. J. Magn. Magn. Mater. 2020, 496, 165906. [Google Scholar] [CrossRef]

- Moradian, K.; Sheikholeslami, T.F.; Raghebi, M. Investigation of a spherical pendulum electromagnetic generator for harvesting energy from environmental vibrations and optimization using response surface methodology. Energ. Convers. Manag. 2022, 266, 115825. [Google Scholar] [CrossRef]

- Jin, Y.; Xiao, S.; Zhang, Y. Enhancement of tristable energy harvesting using stochastic resonance. J. Stat. Mech. Theory Exp. 2018, 23, 123–211. [Google Scholar] [CrossRef]

- Yang, T.; Cao, Q. Novel multi-stable energy harvester by exploring the benefits of geometric nonlinearity. J. Stat. Mech. Theory Exp. 2019, 7, 033405. [Google Scholar] [CrossRef]

- Wang, W.; Cao, J.; Wei, Z.H.; Litak, G. Approximate Fokker-Planck-Kolmo-gorovequation analysis for asymmetric multistable energy harvesters excited by white noise. J. Stat. Mech. Theory Exp. 2021, 3, 023407. [Google Scholar] [CrossRef]

- Chand, R.R.; Tyagi, A. Investigation of the Effects of the Piezoelectric Patch Thickness and Tapering on the Nonlinearity of a Parabolic Converging Width Vibration Energy Harvester. J. Vib. Eng. Technol. 2021, 10, 1–18. [Google Scholar] [CrossRef]

- Ghouli, Z.; Litak, Z. Effect of High-Frequency Excitation on a Bistable Energy Harvesting System. J. Vib. Eng. Technol. 2023, 11, 99–106. [Google Scholar] [CrossRef]

- Lin, C.H.; Lin, Y.Z. Analysis of nonlinear piezomagnetism for magnetostrictive terfenol-D composites. J. Magn. Magn. Mater. 2021, 540, 168490. [Google Scholar] [CrossRef]

- Nakajima, K.; Tanaka, S.; Mori, K.; Kurita, H.; Narita, F. Effects of Heat Treatment and Cr Content on the Microstructures, Magnetostriction, and Energy Harvesting Performance of Cr-Doped-Fe-Co Alloys. Adv. Eng. Mater. 2021, 24, 2101036. [Google Scholar] [CrossRef]

- Wang, L.Z.; Lian, C.L.; Shu, D.L.; Yan, Z.T.; Nie, X.C. Analytical solution and optimal design for the output performance of Galfenol cantilever energy harvester considering electromechanical coupling effect. Sci. Rep. 2023, 13, 12857. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Tan, Y.; Zu, J. A multi-impact frequency up-converted magnetostrictive transducer for harvesting energy from finger tapping. Int. J. Mech. Sci. 2017, 126, 235–241. [Google Scholar] [CrossRef]

- Wu, J.; Hu, Z.; Gao, X.; Cheng, M.; Zhao, X.; Su, W.; Li, X.; Wang, Z.; Zhou, Z.; Dong, S.; et al. Electrode shape dependence of the barbell-shaped magneto-mechano-electric energy harvester for low-frequency applications. Sens. Actuat. A-Phys. 2019, 297, 111535. [Google Scholar] [CrossRef]

- Yoo, J.H.; Flatau, A.B. A bending-mode galfenol electric power harvester. J. Intell. Mater. Syst. Struct. 2012, 23, 647–654. [Google Scholar] [CrossRef]

- Atulasimha, J.; Flatau, A.B. A review of magnetostrictive iron-gallium alloys. Smart. Mater. Struct. 2011, 20, 043001. [Google Scholar] [CrossRef]

- Davino, D.; Giustiniani, A.; Visone, C.; Adly, A.A. Energy Harvesting Tests With Galfenol at Variable Magneto-Mechanical Conditions. IEEE Trans. Magn. 2012, 48, 3096–3309. [Google Scholar] [CrossRef]

- Clark, A.E.; Hathaway, K.B.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A.; Keppens, V.M.; Petculescu, G.; Taylor, R.A. Extraordinary magnetoelasticity and lattice softening in bcc Fe-Ga alloys. J. Appl. Phys. 2003, 93, 8621–8623. [Google Scholar] [CrossRef]

- Javed, A.; Morley, N.A.; Gibbs, M.R.J. Structure, magnetic and magnetostrictive properties of as-deposited Fe-Ga thin films. J. Magn. Magn. Mater. 2009, 321, 2877–2882. [Google Scholar] [CrossRef]

- Cao, S.; Zheng, J.; Guo, Y.; Li, Q.; Sang, J.; Wang, B.; Yan, R. Dynamic Characteristics of Galfenol Cantilever Energy Harvester. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Cao, S.Y.; Sun, S.S.; Zheng, J.J.; Wang, B.; Wan, L.L.; Pan, R.Z.; Zhao, R.; Zhang, C.G. Modeling and analysis of Galfenol cantilever vibration energy harvester with nonlinear magnetic force. AIP Adv. 2018, 8, 056718. [Google Scholar] [CrossRef]

- Clemente, C.S.; Davino, D.; Loschiavo, V.P. Analysis of a Magnetostrictive Harvester With a Fully Coupled Nonlinear FEM Modeling. IEEE Trans. Magn. 2021, 57, 4001201. [Google Scholar] [CrossRef]

- Jin, S.; Meng, A.; Li, M.; Xu, Z.; Wu, S.; Chen, Y. Modeling and Analysis of Wave Energy Harvester with Symmetrically Distributed Galfenol Cantilever Beams. Materials 2023, 16, 5585. [Google Scholar] [CrossRef] [PubMed]

- Vakakis, A.F.; Manevitch, L.I.; Gendelman, O.; Bergman, L. Dynamics of linear discrete systems connected to local essentially nonlinear attachments. J. Sound. Vib. 2003, 264, 559–577. [Google Scholar] [CrossRef]

- Panagopoulos, P.N.; Vakakis, A.F.; Tsakirtzis, S. Transient resonant interactions of linear chains with essentially nonlinear end attachments leading to passive energy pumping. Int. J. Solids. Struct. 2004, 41, 6505–6528. [Google Scholar] [CrossRef]

- Vakakis, A.F. Inducing passive nonlinear energy sinks in vibrating systems. J. Vib. Acoust. 2001, 123, 324–332. [Google Scholar] [CrossRef]

- Gendelman, O.V.; Manevitch, L.I.; Vakakis, A.F.; Closkey, R.M. Energy pumping in nonlinear mechanical oscillators: Part I-Dynamics of the underlying Hamiltonian systems. J. Appl. Mech. 2001, 68, 34–41. [Google Scholar] [CrossRef]

- Georgiades, F.; Vakakis, A.F. Dynamics of a linear beam with an attached local nonlinear energy sink. Commun. Nonlinear. Sci. 2007, 12, 643–651. [Google Scholar] [CrossRef]

- Gendelman, O.V.; Sapsis, T.; Vakakis, A.F.; Bergman, L.A. Enhanced passive targeted energy transfer in strongly nonlinear mechanical oscillators. J. Sound. Vib. 2011, 330, 1–8. [Google Scholar] [CrossRef]

- Kani, M.; Khadem, S.E.; Pashaei, M.H.; Dardel, M. Vibration control of a nonlinear beam with a nonlinear energy sink. Nonlinear Dynam. 2016, 83, 1–22. [Google Scholar] [CrossRef]

- Parseh, M.; Dardel, M.; Ghasemi, M.H.; Pashaei, M.H. Steady state dynamics of a non-linear beam coupled to a non-linear energy sink. Int. J. Nonlin. Mech. 2016, 79, 48–65. [Google Scholar] [CrossRef]

- Ahmadabadi, Z.N.; Khadem, S.E. Nonlinear vibration control and energy harvesting of a beam using a nonlinear energy sink and a piezoelectric device. J. Sound. Vib. 2014, 333, 4444–4457. [Google Scholar] [CrossRef]

- Kremer, D.; Liu, K. A nonlinear energy sink with an energy harvester: Transient responses. J. Sound. Vib. 2014, 333, 4859–4880. [Google Scholar] [CrossRef]

- Kremer, D.; Liu, K. A nonlinear energy sink with an energy harvester: Harmonically forced responses. J. Sound. Vib. 2017, 410, 287–302. [Google Scholar] [CrossRef]

- Xiong, L.; Tang, L.; Liu, K.; Mace, B.R. Broadband piezoelectric vibration energy harvesting using a nonlinear energy sink. J. Phys. D Appl. Phys. 2018, 51, 185502. [Google Scholar] [CrossRef]

- Tian, W.; Li, Y.M.; Yang, Z.C.; Li, P.; Zhao, T. Suppression of nonlinear aeroelastic responses for a cantilevered trapezoidal plate in hypersonic airflow using an energy harvester enhanced nonlinear energy sink. Int. J. Mech. Sci. 2020, 172, 105417. [Google Scholar] [CrossRef]

- Fang, Z.W.; Zhang, Y.W.; Li, X.; Ding, H.; Chen, L.Q. Integration of a nonlinear energy sink and a giant magnetostrictive energy harvester. J. Sound. Vib. 2017, 391, 35–49. [Google Scholar] [CrossRef]

- Wang, Z.J.; Zang, J.; Zhang, Y.W. Method for Controlling Vibration and Harvesting Energy by Spacecraft: Theory and Experiment. AIAA J. 2022, 60, 6097–6115. [Google Scholar] [CrossRef]

- Xu, K.F.; Zhang, Y.W.; Niu, M.Q.; Zang, J.; Xue, J.; Chen, L.Q. An improved nonlinear energy sink with electromagnetic damping and energy harvesting. Int. J. Appl. Mech. 2022, 14, 2250055. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Gao, C.Q.; Zhang, Z.; Zang, J. Dynamic Analysis of Vibration Reduction and Energy Harvesting Using a Composite Cantilever Beam with Galfenol and a Nonlinear Energy Sink. Int. J. Mech. Sci. 2021, 13, 2150089. [Google Scholar] [CrossRef]

- Xue, J.R.; Zhang, Y.W.; Niu, M.Q.; Chen, L.Q. Harvesting electricity from random vibrations via a nonlinear energy sink. J. Vib. Control 2023, 29, 5398–5412. [Google Scholar] [CrossRef]

- Xu, K.F.; Zhang, Y.W.; Zang, J.; Niu, M.Q.; Chen, L.Q. Integration of vibration control and energy harvesting for whole-spacecraft: Experiments and theory. Mech. Syst. Signal. Process. 2021, 161, 107956. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Su, C.; Ni, Z.Y.; Zang, J.; Chen, L.Q. A multifunctional lattice sandwich structure with energy harvesting and nonlinear vibration control. Compos. Struct. 2019, 221, 110875. [Google Scholar] [CrossRef]

- Li, J.; He, X.; Yang, X.; Liu, Y. A consistent geometrically nonlinear model of cantilevered piezoelectric vibration energy harvesters. J. Sound. Vib. 2020, 486, 115614. [Google Scholar] [CrossRef]

- Tan, T.; Yan, Z.M.; Lei, H.; Sun, W.P. Geometric nonlinear distributed parameter model for cantilever beam piezoelectric energy harvesters and structural dimension analysis for galloping mode. J. Intell. Mater. Syst. Struct. 2017, 28, 3066–3078. [Google Scholar] [CrossRef]

- Shooshtari, A.; Hoseini, S.M.; Mahmoodi, S.N.; Kalhori, H. Analytical solution for nonlinear free vibrations of viscoelastic microcantilevers covered with a piezoelectric layer. Smart. Mater. Struct. 2012, 21, 075015. [Google Scholar] [CrossRef]

- Li, H.S.; Sun, H.X.; Song, B.Y.; Zhang, D.; Shang, X.C.; Liu, D.H. Nonlinear dynamic response of an L-shaped beam-mass piezoelectric energy harvester. J. Sound. Vib. 2021, 499, 116004. [Google Scholar] [CrossRef]

- Nie, X.C.; Tan, T.; Yan, Z.M.; Yan, Z.T.; Hajj, M.R. Broadband and high-efficient L-shaped piezoelectric energy harvester based on internal resonance. Int. J. Mech. Sci. 2019, 159, 287–305. [Google Scholar] [CrossRef]

- Nie, X.C.; Tan, T.; Yan, Z.M.; Yan, Z.T.; Zhang, W.M. Ultra-wideband piezoelectric energy harvester based on Stockbridge damper and its application in smart grid. Appl. Energ. 2020, 267, 114898. [Google Scholar] [CrossRef]

- Nie, X.C.; Gao, X.; Wang, L.Z.; Tan, T.; Yan, Z.T.; Yan, Z.M.; Liu, X. Nonlinear analysis of the internal resonance response of an L-shaped beam structure considering quadratic and cubic nonlinearity. J. Stat. Mech. Theory Exp. 2022, 2, 023204. [Google Scholar] [CrossRef]

- Nie, X.C.; Tan, T.; Yan, Z.M.; Yan, Z.T.; Wang, L.Z. Revised method of multiple scales for 1:2 internal resonance piezoelectric vibration energy harvester considering the coupled frequency. Commun. Nonlinear Sci. 2023, 118, 107018. [Google Scholar] [CrossRef]

- Han, Q.K.; Li, X.L.; Chu, F.L. Skidding behavior of cylindrical roller bearings under time-variable load conditions. Int. J. Mech. Sci. 2018, 135, 203–214. [Google Scholar] [CrossRef]

- Han, Q.K.; Chu, F.L. Nonlinear dynamic model for skidding behavior of angular contact ball bearings. J. Sound. Vib. 2015, 354, 219–235. [Google Scholar] [CrossRef]

- Wang, H.; Han, Q.K.; Zhou, D. Nonlinear dynamic modeling of rotor system supported by angular contact ball bearings. Mech. Syst. Signal. Process. 2017, 85, 16–40. [Google Scholar] [CrossRef]

- Liu, W.R.; Bai, X.; Yang, H.; Bao, R.X.; Liu, J.Q. Tendon driven bistable origami flexible gripper for high-speed adaptive grasping. IEEE Robot. Autom. Lett. 2024, 9, 5417–5424. [Google Scholar] [CrossRef]

- Clemente, C.; Davino, D. Modeling and characterization of a kinetic energy harvesting device based on galfenol. Materials 2019, 12, 3199. [Google Scholar] [CrossRef] [PubMed]

- Erturk, A.; Inman, D.J. Piezoelectric Energy Harvesting-Base Excitation Problem for Cantilevered Structures and Correction of the Lumped-Parameter Electromechanical Model; John Wiley and Sons: Hoboken, NJ, USA, 2011; pp. 19–48. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D. An experimentally validated bimorph cantilever model for piezoelectric energy harvesting from base excitations. Smart Mater. Struct. 2009, 18, 025009. [Google Scholar] [CrossRef]

- Erturk, A.; Hoffmann, J.; Inman, D.J. A piezomagnetoelastic structure for broadband vibration energy harvesting. Appl. Phys. Lett. 2009, 94, 254102. [Google Scholar] [CrossRef]

- Bibo, A.; Abdelkefi, A.; Daqaq, M.F. Modeling and characterization of a piezoelectric energy harvester under combined aerodynamic and base excitations. J. Vin. Acoust. 2015, 137, 031017. [Google Scholar] [CrossRef]

- Khazaee, M.; Rezaniakolaei, A.; Rosendahl, L. An experimental study to determine damping of piezoelectric harvesters using transient analysis of unified electromechanical voltage equation. Energ. Convers. Manag. 2021, 227, 113567. [Google Scholar] [CrossRef]

- Cao, S.; Sang, J.; Zheng, J.; Wang, B. Electromechanical coupling dynamic model of galfenol cantilever energy harvester. Proc. CSEE 2015, 35, 5623–5631. (In Chinese) [Google Scholar]

- Zhang, H.; Xiang, X.; Huang, B.; Wu, Z.F.; Chen, H. Static homotopy response analysis of structure with random variables of arbitrary distributions by minimizing stochastic residual error. Comput. Struct. 2023, 288, 107153. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Li, W. Probabilistic time series forecasting with deep non-linear state space models. CAAI Trans. Intell. Technol. 2023, 8, 3–13. [Google Scholar] [CrossRef]

- Wang, G.; Hao, Z.H.; Li, H.S.; Zhang, B. An activated variable parameter gradient-based neural network for time-variant constrained quadratic programming and its applications. CAAI Trans. Intell. Technol. 2023, 8, 670–679. [Google Scholar] [CrossRef]

| Parameter | Description | Value |

|---|---|---|

| L | Length of the aluminum layer and Galfenol layer(mm) | 130 |

| , | Width of the aluminum layer and Galfenol layer (mm) | 20 |

| Thickness of the aluminum layer and (mm) | ||

| Thickness of the Galfenol layer (mm) | ||

| Young’s Modulus of the aluminum layer (GN/m2) | 68 | |

| Young’s Modulus of the Galfenol layer (GN/m2) | 70 | |

| Density of the aluminum layer (kg/m3) | 2700 | |

| Density of the Galfenol layer (kg/m3) | 7496 | |

| Mechanical damping ratio of the first modal | ||

| M | Mass of the tip lumped mass (g) | 70 |

| magnetic permeability(H/m) | ||

| Piezomagnetic coefficient (T/Gpa) | 34 | |

| bias magnetic field strength (kA/m) | ||

| N | number of the coil | 1000 |

| Internal resistance of the coil (Ohm) | ||

| Mass of the NES (g) | 4 | |

| damping of the NES (N·s/m) | ||

| elastic stiffness of the NES (N/m3) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Liu, C.; Liu, W.; Yan, Z.; Nie, X. Nonlinear Dynamic Response of Galfenol Cantilever Energy Harvester Considering Geometric Nonlinear with a Nonlinear Energy Sink. Buildings 2024, 14, 1482. https://doi.org/10.3390/buildings14051482

Wang L, Liu C, Liu W, Yan Z, Nie X. Nonlinear Dynamic Response of Galfenol Cantilever Energy Harvester Considering Geometric Nonlinear with a Nonlinear Energy Sink. Buildings. 2024; 14(5):1482. https://doi.org/10.3390/buildings14051482

Chicago/Turabian StyleWang, Lingzhi, Chao Liu, Weidong Liu, Zhitao Yan, and Xiaochun Nie. 2024. "Nonlinear Dynamic Response of Galfenol Cantilever Energy Harvester Considering Geometric Nonlinear with a Nonlinear Energy Sink" Buildings 14, no. 5: 1482. https://doi.org/10.3390/buildings14051482

APA StyleWang, L., Liu, C., Liu, W., Yan, Z., & Nie, X. (2024). Nonlinear Dynamic Response of Galfenol Cantilever Energy Harvester Considering Geometric Nonlinear with a Nonlinear Energy Sink. Buildings, 14(5), 1482. https://doi.org/10.3390/buildings14051482