Abstract

There is an increase in decoration and renovation activities in the construction industry, and waste generation rates (WGRs) play a crucial role in guiding the management of demolition waste in decoration and renovation projects (DWDRPs). However, there has been little systematic research on this type of waste. Based on site surveys and a document review of 26 projects, this study offers insights into DWDRP wastes, from their initial generation to their final disposal. The results revealed that the WGRs for DWDRPs ranged from 30.96 kg/m2 to 629.96 kg/m2 and that the key components of DWDRPs included mortar, concrete, timber, tile, and metal; these five types of waste contributed 75.02% of the total waste. Although these findings deviate slightly from those of previous studies, these variations are attributed to diverse waste management practices, awareness levels, and employed construction technologies. Despite its importance, in China, the management of DWDRPs faces challenges, such as limited public awareness, inadequate collection and sorting guidance, and insufficient legislation. To counter these issues, we recommend a set of strategies, including stringent regulations, enhanced supervision, government incentives, improved collection and sorting methods, and the adoption of innovative technologies. This study not only sheds light on the specific challenges in decoration and demolition waste management in rapidly urbanizing areas but also proposes a comprehensive approach for improving waste management practices.

1. Introduction

With the increasing demand for an improved quality of life, decoration and renovation activities have witnessed a surge in frequency over the past decade. Based on data from Statista, the global revenue of the decoration industry in 2023 amounted to 28 billion US dollars. Within this total, Europe contributed 6 billion US dollars, the United States contributed 4 billion US dollars, and China contributed 8 billion US dollars. The Chinese decoration and renovation industry has experienced remarkable expansion, reaching an impressive production value of 101 billion US dollars in 2017 [1] and the total value of completed projects reaching 655.8 billion US dollars in 2018, marking substantial increases from 2008 [2]. This growth has led to an increase in decoration and renovation project wastes (DWDRPs), which account for 13–15% of construction and demolition wastes (CDWs), significantly impacting urban solid waste management [3,4]. DWDRPs contain a variety of harmful substances, posing challenges for environmental sustainability [5].

Despite the acknowledged impacts of DWDRPs, there is a notable lack of standardized definitions and comprehensive research on this waste category, especially in the context of China’s rapid urbanization. In Europe and the United States, DWDRPs are broadly classified under CDWs, but such a classification overlooks the unique compositions and disposal challenges of DWDRPs in China [6,7].

In this context, our study aims to bridge this gap by providing a comprehensive investigation into the compositions and waste generation rates (WGRs) of DWDRPs in China, enhancing the understanding of their environmental impacts and proposing effective management practices. However, it is important to note that the projects covered in our study typically encompass elements of both renovation and decoration, which complicates the clear categorization into purely “renovation projects” or “decoration projects”.

In developed countries, the recovery rates of DWDRPs have been effectively utilized, such as in Japan, Germany, and the United States, with recovery rates reaching 96%, 88%, and 76%, respectively. In contrast, in China, the best-performing cities, such as Shanghai and Shenzhen, achieve recovery rates below 15%, significantly lower than the levels observed in developed countries [8]. It is evident that there has been a lack of comprehensive research dedicated to exploring DWDRPs in China. Cities are taking proactive measures to enhance waste management. For instance, being a prominent megacity in southern China, Shenzhen, akin to numerous major urban centers in emerging economies, is currently experiencing a phase of rapid urban development while simultaneously grappling with the multifaceted challenges associated with sustainable progress. Shenzhen has embarked on an innovative urban development initiative, setting an exemplary model for what is commonly referred to as a “zero-waste” city. The primary objectives of this endeavor are to significantly curtail the requirement for landfill space and mitigate the environmental repercussions linked to solid waste management (GOSC, 2019) [9]. As a part of this process, there is an urgent necessity to comprehend the generation of DWDRPs within the rapidly developing decoration and renovation sectors. Islam et al. (2019) highlighted that a critical facet of effective waste management involved the precise estimation of building-related waste quantities [10]. The accurate estimation of DWDRPs within China and the implementation of corresponding regulatory measures represent crucial steps toward the attainment of the “zero-waste” city’s objective. Essential factors in this endeavor encompass the meticulous consideration of waste quantities, compositions, and flow, all of which play a pivotal role in the development and execution of waste management strategies in pursuit of this goal.

This study aims to address these gaps by comprehensively investigating the compositions and WGRs for DWDRPs in China. It seeks to enhance the understanding of DWDRPs’ environmental impacts and propose effective management practices. The research unfolds in four stages, starting with an in-depth literature review, followed by an investigation of WGRs through site visits and a project document analysis, leading to data analysis and the presentation of the findings.

2. Literature Review

2.1. Compositions of DWDRPs

As previously mentioned, when examining DWDRPs, there is currently no universally accepted definition worldwide. It is impressive to establish a precise definition of this term. DWDRPs are typically categorized as a type of construction waste. According to Chinese regulations, DWDRPs pertain to materials, such as wasted concrete, wasted bricks, wasted wood, and other byproducts, resulting from the decoration and demolition activities of walls, floors, ceilings, and similar components [11]. The geographical distribution of DWDRPs exhibits a tendency for concentration, primarily observed at construction sites, in urban areas, and at various other locations [12].

DWDRPs encompass a combination of materials, including both inert substances and non-inert hazardous elements, generated during the processes of the decoration and demolition of buildings. Typically, DWDRPs comprise predominantly inert materials, like concrete and bricks (blocks), which generally entail a lower environmental risk compared to hazardous wastes [13]. Non-inert materials utilized in interior decoration activities include elements that contain toxic substances, such as heavy metals [8]. The inert material category encompasses both soft inert materials, such as soil, earth, silt, and slurry, as well as hard inert materials, including rocks and fragmented concrete. In contrast, non-inert materials consist of metals, timber, plastics, and packaging wastes [4,14]. According to the literature, the contamination of soil and water can occur because of pollutants, like heavy metals and brominated flame retardants [14]. Polybrominated diphenyl ethers and hexabromocyclododecane, among other substances, pose significantly higher potential risks [15]. In China, it is worth noting that, in most cases, no construction permit is required during the building decoration and demolition stages. Largely unregulated and decentralized decoration and demolition activities, coupled with the lack of effective waste management oversight, have resulted in low recycling rates and an increased potential for environmental pollution [4]. DWDRPs are typically disposed of through simple landfilling or dumping procedures, often without adequate environmental safeguards [8]. This rudimentary disposal method not only occupies extensive land areas but also poses the risks of soil and groundwater contamination when non-inert DWDRPs leach toxic substances following rain events [16]. Recognizing its substantial role in shaping the living environment, the decoration industry has also been associated with adverse effects on the natural environment [8]. Decoration, inherently, is environmentally unfriendly as it generates substantial DWDRPs as byproducts of diverse decoration activities. Statistical data underscore the considerable environmental impacts of decoration activities across different nations [17,18]. Through the characterization of metal concentrations in DWDRPs, this study unveiled significantly higher metal levels in non-inert wastes. This underscores the critical importance for implementing effective waste management practices [19]. By investigating the leaching behaviors of potential heavy metals under conditions of acid rain and landfill leachates, Yu et al. (2019) revealed that household waste leachates exerted a more pronounced influence on the migration of heavy metals [20].

2.2. Overview of DWDRP Management

The relentless expansion of urban landscapes has been paralleled by a commensurate rise in the wastes generated from construction, decoration, and demolition activities [21]. Yu et al. (2018) contend that as a distinct component of the broader CDW category, DWDRPs encompass a heterogeneous mix of materials [19]. These include inert substances, like concrete, bricks, and tiles, as well as hazardous constituents, such as heavy metals and organic pollutants, which pose significant environmental and public health risks when not managed appropriately [4,8,19,22,23]. The challenge for managing these wastes is further compounded by the varying natures of decoration and demolition practices influenced by a matrix of economic, cultural, and technological factors, underscoring the critical role of WGRs as an essential metric for effective waste management [4,8,22].

Methodologies for quantifying DWDRPs reflect this complexity, ranging from simple empirical estimates to sophisticated analyses tailored to specific building types and demolition activities [8]. Accurate WGRs are dependent on data regarding a building’s use, age, and renovation frequency, which are essential for informing the development of policy and regulation; however, such data are not always readily available or robust, leading to a reactive rather than a proactive stance in legislative development [4]. Current regulatory measures in China, such as Shanghai’s waste management provisions and those by the Ministry of Housing and Urban–Rural Development of the People’s Republic of China, exhibit gaps that need to be filled to capture the full spectrum of DWDRP management needs [6,24].

The ecological impacts of DWDRP management practices are a growing concern, with previous studies, highlighting the long-term contamination risks associated with non-inert wastes [20]. These risks are exacerbated by disposal methods that lack the sophistication needed to prevent the leaching of toxic substances into the environment [25]. Consequently, there is an exigent need for innovative waste treatment technologies that can neutralize or segregate hazardous elements effectively [26].

In response to these challenges, some regions in China have begun to adopt innovative waste management practices [27]. The urban model advocating for a more integrated approach proposes the use of technology for waste tracking and the promotion of sustainable treatment technologies [28]. Building information modeling (BIM) and prefabrication are recognized as effective strategies for reducing waste at the source, which can lead to significant reductions in the environmental footprints of construction-related activities [29]. These techniques align with global sustainability objectives, highlighting the need for concerted efforts that emphasize resource efficiency and waste minimization.

In the EU, the EU’s Waste Framework Directive outlines fundamental waste management principles emphasizing the protection of human health and the environment by minimizing risks to water, air, soil, plants, and animals and avoiding nuisance through noise and odors and introduces the waste hierarchy, which prioritizes waste prevention and considers landfilling as the last resort [30]. The forecast method anticipates a notable surge in construction and demolition wastes in Norway, particularly with concrete/bricks and wood, offering pivotal insights for addressing future waste management capacities and challenges [31]. The study on CDW management in Italy, underscores the environmental and social benefits of selective demolition and best practices, highlighting the economic barriers to their adoption in the construction sector and the need for incentives to foster a circular economy transition [32]. Usman et al. (2021) conducted a case study to examine the effectiveness of construction and demolition waste management practices in Malaysia’s construction sector, particularly highlighting the potential for reuse and recycling within residential and high-rise buildings [33]. Through research on CDW management in Kuwait, it has been identified that existing practices are misaligned with circular construction principles, leading to the recommendation for enhanced recycling initiatives and strengthened legislative enforcement to significantly improve waste management efficiency [34].

2.3. Waste Generation Rates (WGRs)

WGRs serve as the critical indicator for comprehending the current state of waste management [22]. Consequently, scholars have conducted extensive investigations into WGRs [4,21,35,36,37,38,39,40,41].

Several methodologies for measuring WGRs have been illustrated. After Skoyles’s investigation, which involved distinguishing between 37 materials, such as steel, cement, concrete, mortar, timber, and more, many subsequent studies have employed a similar methodology [35]. Nonetheless, other studies have established comprehensive WGRs by calculating the volume (in cubic meters) or quantity (in tons) of the waste generated per square meter of the gross floor area (GFA) without distinguishing between materials [4,22,28,39,41]. GFA is a universally accepted and commonly used metric that allows for straightforward calculations and easy data acquisition, making it highly accessible for researchers and practitioners alike.

Various approaches have been employed to quantify waste, utilizing either weight measurements (in kilograms or tons) or volume measurements (in cubic meters). Subsequently, WGRs are calculated based on factors such as the quantity purchased per square meter of the gross floor area (GFA) or the quantity required according to the design specifications. As previously demonstrated, these methods for calculating WGRs have been utilized in various countries [4,21,35,36,37,38,39,40,41]. In addition, some scholars have compared WGRs across different regions [42,43]. Although it can be debated whether waste management knowledge developed in one country is directly applicable to another, cross-country comparisons can provide valuable insights for recognizing and adopting effective waste management practices.

Lifetime analysis offers another method for estimating WGRs and is feasible at a regional level. It encompasses two approaches: the life cycle analysis of buildings and material flow analyses (MFAs). Cochran and Townsend utilized the MFA method to assess CDW generation and composition in the US [44]. This method proves particularly valuable for estimating waste at regional levels where data on demolition areas are lacking [45].

In summary, previous research on WGRs has employed a range of methodologies, including direct observation, surveys, on-site investigation, and consultations, which can be broadly classified as either ‘hard’ or ‘soft’ approaches.

As discussed above, waste WGRs have been applied in various countries and regions. Nevertheless, there is a significant dearth of research on DWDRP generation rates in China. Given the pivotal roles of WGRs in forecasting waste generation and facilitating waste management, this study focuses on investigating WGRs for DWDRPs in different types of buildings. Taking into consideration the advantages and disadvantages of the various methods introduced above, the WGRs for DWDRPs in different types of buildings were calculated using the waste generation rate per unit of construction area method through on-site surveys and by studying project documents.

3. Methods

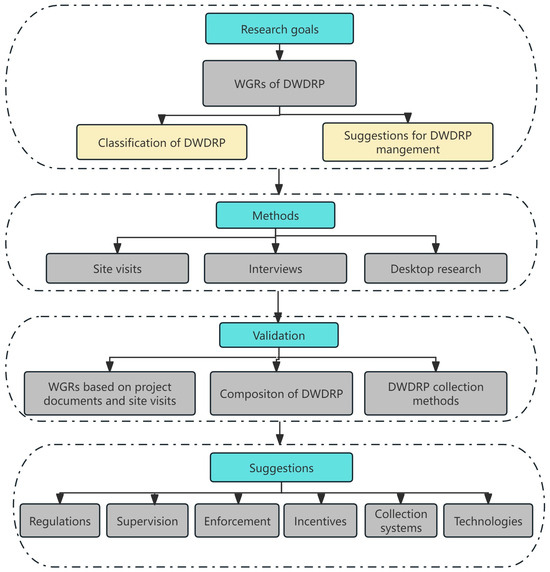

To elucidate the compositions and WGRs for DWDRPs, as well as to propose sound recommendations for DWDRP management, a research framework has been adopted, as shown in Figure 1.

Figure 1.

Research framework.

3.1. Scope of the Study

The constituent materials of DWDRPs encompass concrete, mortar, bricks, metals, timber, gypsum, paint, glass, tiles, etc. As previously mentioned, in this study, demolition wastes refer to the wastes generated during the demolition of interior decorations; exterior curtain wall decorations were excluded from this study because of the inability to obtain available data. DWDRPs are inherently complex; however, most of them can be recycled and reused after undergoing sorting procedures [4]. DWDRPs that are not amenable to be recycled are subsequently disposed of in landfills; therefore, the development of effective waste management systems for DWDRPs is indispensable to ensure the safe and environmentally responsible recycling and disposal of these wastes [8].

All the research buildings in this study were civil buildings. As per the guidelines stipulated in the Uniform Standards for Civil Building Design [24], civil buildings are classified as either residential or public buildings. Public buildings are subsequently categorized into two groups: commercial buildings, which include retail and office buildings, and civic buildings, encompassing buildings related to tourism and education, as expounded upon in this study [8].

3.2. The Foundation for Quantifying Demolition Wastes

For estimating the quantities of DWDRPs, many researchers utilize approaches such as on-site weighing and questionnaire surveys [4,22,38,41]. Nonetheless, these methods demand significant investments in terms of labor and time.

When quantifying DWDRPs, material consumption refers to the standardized quantity of materials reasonably consumed to complete the decoration task under specific conditions [4]. Demolition processes typically involve mechanical or manual methods. Although there may be some loss of materials during usage, this impact is considered negligible in the context of the entire building. Hence, the generation of demolition wastes closely approximates the actual material consumption during the decoration process [46]. This pivotal factor forms the foundation for quantifying DWDRPs.

3.3. Calculation Model

This study utilized the waste generation per unit of area (WGA) method, considering the building types and purposes (as mentioned in Section 3.1), and this approach was subsequently validated through site visits.

Data from the project documents were added together using the formula shown in Equation (1) to obtain the quantities of the demolition wastes in this study as follows:

where W refers to the total weight of all the waste generated during the decoration demolition, Wt refers to the weight of the type t waste during the demolition, and n is the total number of waste types.

Using the formula shown in Equation (2) below, the WGRs for various waste materials were calculated as follows:

where GFA refers to the gross floor area of these projects. When calculating the WGRs for different types of waste, W should be replaced with Wt.

3.4. Data Acquisition

The primary methods employed for the data acquisition for the inventory analysis included site visits, semi-structured interviews, and desk research. Notably, specific details concerning the types and consumptions of building decoration materials were extracted from the decoration material manuals of the projects, construction organization designs, and the bills of quantities. Site visits were conducted to gather raw data from the real environment to enable the systemic analysis [47]. Site visits offer exceptional flexibility, boasting a high success rate and providing access to intricate, authentic, and highly specific information [48]. In this study, during on-site surveys, the compositions of the DWDRPs were validated, and the waste disposal methods were examined. The project documents provided a comprehensive list, with detailed descriptions and quantities of the work, specifying both the precise amounts of materials and compositions of materials required for each individual subitem. Subsequently, according to the principles of the “Standard Method of Measurement for Building Construction and Fitting-out Works” (GB 50854-2013), the accurate material quantities can be obtained through the project documents [49]. According to the compositions of the materials that were used, as described in the project documents, the classifications of DWDRPs can be determined. Importantly, during these on-site visits, we conducted tracking of DWDRPs within specific sections of the projects and performed immediate on-site classifications to ensure the accuracy of the project documents regarding the types of DWDRPs. The data obtained from the project documents and the quantities calculated using the methods outlined in GB 50854-2013 are intended to serve as estimated quantities. These estimations are based on a systematic review of the available information and adhere to the prescribed methodological framework.

3.5. Case Description

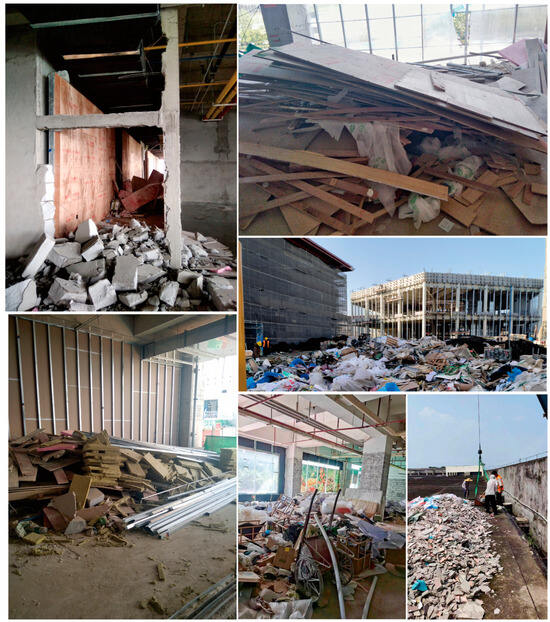

All the projects investigated in this study are ongoing initiatives. These projects span a spectrum of cities across China, encompassing urban landscapes from the bustling metropolis of Shenzhen in the south to the dynamic hub of Beijing in the north. Nestled in between, they include influential urban centers, like Zhuhai, Chongqing, Xiamen, Hefei, Yancheng, Chengdu, Huaibei, Quanzhou, and Xi’an (Table 1). Within these diverse projects, the decoration areas exhibit a wide range, varying from 600 m2 to 35,000 m2, highlighting the substantial geographical and architectural heterogeneity covered by this study. The on-site conditions of the projects are illustrated in Figure 2, showing the collected wastes without proper sorting. The architectural categories represented in these endeavors encompass residential, commercial, and public buildings, providing a comprehensive cross-sectional view of China’s urban development spanning the nation from its southern reaches to the northern territories.

Table 1.

Inventory and geographic distribution of projects.

Figure 2.

The on-site conditions of the projects showing the wastes without proper sorting.

3.6. Data Limitations

In investigating DWDRPs, it is crucial to recognize the intricate and diverse nature of real-world project situations. The data involved in this research are complex and multifaceted, encompassing a broad spectrum of calculations with inherent intricacies. Additionally, the data range is limited given the dynamic nature of the field. The data used for this research were collected from a limited number of projects in specific regions of China, which may not be fully representative of the entire country. Therefore, the generalizability of the findings to other regions should be made with caution. The accuracy of the data heavily relies on the quality of the project documents. In cases where these documents were incomplete or inaccurate, it may have impacted the precision of the waste generation rates calculated in this study. It is imperative to emphasize that the foundational premise of this research hinges upon a certain level of trust in the diligence and accuracy of the personnel responsible for recording and documenting this information.

4. Results and Discussion

In this research, the validation was primarily conducted through site surveys and the review of the project documentation (Section 3.4, Data Acquisition). Specifically, we utilized detailed information from construction organization manuals, design drawings, and bills of quantities, combined with data collected from site visits, to verify the compositions and WGRs for DWDRPs.

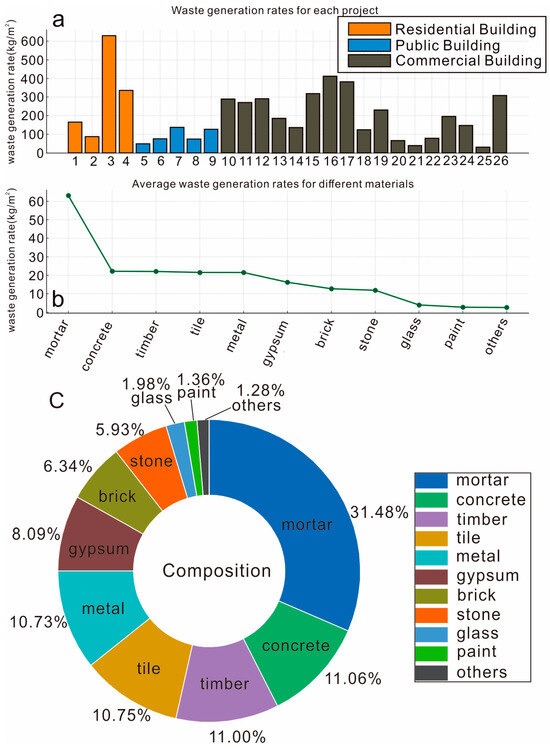

4.1. Compositions of DWDRPs

The compositions and percentages of DWDRPs by weight in this study are based on the calculation model in Section 3.3 and data acquisition in Section 3.4. DWDRPs encompass various materials, including mortar, concrete, timber, gypsum, metal, tile, stone, glass, brick, paint, and others. The amounts of DWDRPs generated in this study and their compositions and contributions are shown in Figure 3c. Among the primary components, mortar waste comprises the most significant portion at 31.48%, while concrete and timber contribute 11.06% and 11.00% of the total demolition waste, respectively. Furthermore, tile and metal also constitute a substantial portion of the demolition waste, accounting for 10.75% and 10.73%, respectively. Statistically, those five types of waste contribute 75.02% of the total waste. This finding is inconsistent with the percentages of wastes in CDWs as well as decoration and renovation wastes [8,46]. Additionally, gypsum, brick, and stone are large parts of demolition wastes, accounting for 8.09%, 6.34%, and 5.93%, respectively. Glass, paint waste, and other non-inert materials account for 4.62% of the total waste. It is worth noting that based on on-site observations, the paint waste is found in mixed fragments at the construction site. It is important to point out that the contents of bricks in DWDRPs, as revealed by this study, are lower in comparison to their proportions in CDWs as well as decoration and renovation wastes [8,46]. This is because all the projects under investigation are not brick–concrete structures but are framed structures and frame–shear structures, resulting in a significant reduction in the use of bricks.

Figure 3.

(a) Waste generation rates for projects; (b) waste generation rates for different materials; (c) compositions and percentages of DWDRPs.

4.2. Waste Generation Rates (WGRs) for DWDRPs

We employed the mean average in our analysis as it provides a concise overview and reflects the central tendency of all the cases. Therefore, the mean average effectively represents the overall situation. These findings revealed that the WGRs for DWDRPs ranged from 30.96 kg/m2 to 629.96 kg/m2, as shown in Figure 3a. The overall mean value was 200.38 kg/m2. With respect to the compositions, it was found that a significant amount of mortar was generated during demolition activities, and we used a mean value of 63.08 kg/m2, constituting approximately 31% of the total amount because of its extensive utilization across various building types. The second largest contributor is concrete, which accounts for 11% of the total amount (mean: 22.15 kg/m2), followed by timber, tile, and metal, with mean values of 22.04 kg/m2, 21.53 kg/m2, and 21.49 kg/m2, respectively, as shown in Figure 3b. These five types of waste accounted for more than 70% of the total amount.

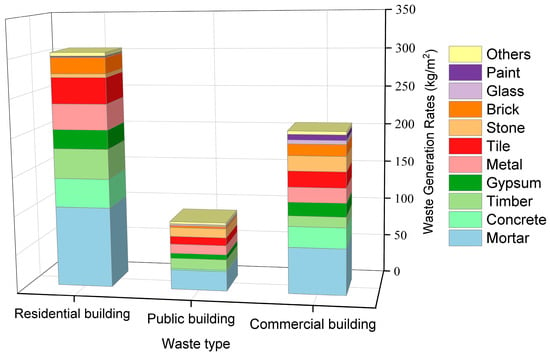

The WGRs varied according to the building category. The WGRs observed in the residential category had an average value of 305.00 kg/m2, followed by the commercial category, which had the second highest WGRs, with a mean value of 207.39 kg/m2. The lowest waste generation rate is found in the public category, with an average value of 88.76 kg/m2. These findings are different from those in previous research, which had suggested that the WGRs for residential buildings were the highest and that the WGRs for commercial buildings were the lowest [8]. This could be attributed to the fact that residential buildings typically involve more interior walling and floor installations, which often necessitate the use of mortar as a decoration material. Furthermore, public buildings often employ simplified decoration techniques and accommodate shorter construction periods, thereby reducing WGRs. The details of the WGRs and the compositions of demolition wastes for different building types are shown in Figure 4.

Figure 4.

Waste generation rates and compositions of DWDRPs for different building types, based on project documents and field investigations.

4.3. Implications of the Waste Generation Rates (WGRs) in This Study

These findings, as illustrated in Figure 3c, delineate the material compositions of DWDRPs, with mortar, concrete, timber, metal, and tiles being predominant. This composition suggests a targeted approach for waste reduction efforts by contractors, especially given the significant variability in WGRs across different building types. The pronounced waste generation in residential buildings, as opposed to non-residential ones, corroborates earlier research [8,46], underscoring the need for sector-specific waste management strategies and offering new insights that enrich the theoretical understanding of construction and demolition waste dynamics.

Table 2 shows that the WGRs for the DWDRPs observed in this study slightly deviate from previous research findings [23,31,39,46,50,51]. However, it is important to note that the primary objective for including these comparisons was to emphasize the variability and range of WGRs observed in different geographical and constructional contexts rather than to draw direct equivalences. The large variation in WGRs can likely be ascribed to contrasting waste management methodologies, varying levels of waste management awareness, and diverse construction technologies employed by different contractors [22]. These WGRs serve a dual function: First, they facilitate the categorization of waste into distinct groups, enabling in-depth examinations of specific waste types based on their characteristics and underlying factors (e.g., construction technologies and waste management and material management procedures); second, when considering waste in its entirety, they facilitate the comprehension of the overall volume of waste generated by a single project or multiple projects [4]. Utilizing WGRs, project managers can quantify the production of waste and formulate waste management and disposal strategies [8]. For example, in cases where the estimated demolition waste is substantial, architects and designers can, during the initial phases, modify the design to minimize the waste generation; furthermore, when WGRs are notably high, project managers can emphasize reuse and waste recycling, aligning with the best practices for sustainability [4,22].

Table 2.

WGRs for demolition wastes in different regions.

These findings have provided valuable insights into the implications for policymakers within DWDRP management sectors, thereby informing policy formulation. This includes recommendations for the development of regulations, standards, and guidelines aimed at minimizing DWDRPs. These findings also offer evidence-based insights that could guide policy formulation toward more sustainable construction practices [22].

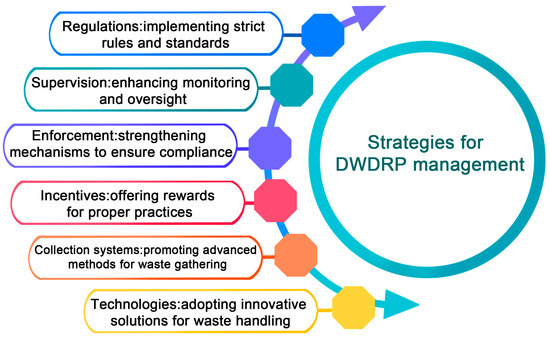

4.4. Strategies for DWDRP Management

The burgeoning growth of urban areas has magnified the challenges for managing DWDRPs, necessitating a strategic approach that is both inclusive and enforceable. This study, through site visits and interviews, identifies a major trend: the predominant disposal of DWDRPs in municipal landfills without proper segregation [25,52,53]. This reflects the broader issue of inadequate legal frameworks and underdeveloped technological practices in rapidly urbanizing areas, particularly in China.

Effective DWDRP management intersects legal, technological, and financial sectors. It necessitates overhauling traditional practices for sustainable methodologies. Developed nations, such as Germany and Japan, contrasting with China’s practices, employ advanced waste treatment technologies [4,54,55].

Considering legal reforms, China needs to establish a robust regulatory framework that not only incentivizes waste classification but also prioritizes waste reduction and the reuse of materials before recycling [43,56]. Furthermore, compliance through clear guidelines and penalties for non-adherence is essential [57]. Capacity building within regulatory bodies is crucial for effective enforcement. This involves equipping these bodies with tools and human capital for rigorous inspections and ensuring compliance with waste management guidelines [50]. Additionally, developing infrastructure for DWDRP management, such as dedicated sorting facilities, is vital. These facilities would facilitate the segregation of materials, like concrete and metals, for recycling, conserving resources and reducing landfill wastes [58]. A proposal for a centralized regulatory and monitoring system, inspired by Japan’s ‘slip system’, would enforce accountability and transparency [22]. This system should be complemented by a strong enforcement mechanism with the authority to impose fines for non-compliance.

The financial aspect involves reorienting economic incentives to favor waste minimization and the reuse of materials, thereby reducing DWDRPs’ environmental impacts [56,59]. This includes subsidies, tax reliefs, and enhanced loan facilities to stimulate growth and innovation in waste treatment methodologies [56,59].

Improvements in waste collection and sorting at the source are necessary. This field research indicates the current inadequacy of DWDRP collection, with valuable materials lost because of ineffective segregation [38]. Implementing training programs for workers and strategically placing labeled bins for different waste types can significantly improve waste separation efficiency [8,22].

An equally important strategy is the cultivation of a culture of environmental responsibility among all the stakeholders. Education and awareness programs, targeting industry professionals and the public, are crucial in altering perceptions and practices regarding DWDRPs [4]. These programs should focus on the environmental impacts of improper waste management and the benefits of waste reduction, reuse, and recycling.

By synthesizing these findings with practices from developed countries, it is evident that a concerted effort is needed to reform China’s DWDRP management systems. The integration of legal, technological, and financial strategies is imperative for addressing these challenges effectively. This comprehensive approach can pave the way for sustainable urban development and environmental conservation in China. The proposed strategies provide a roadmap for action, potentially transforming DWDRP management in China and setting an example for other developing nations facing similar issues (Figure 5).

Figure 5.

Strategies for DWDRP management.

5. Conclusions

This study investigates WGRs for DWDRPs within the context of DWDRP management in rapidly urbanizing areas, particularly focusing on the Chinese urban development landscape. Through a detailed examination of 26 diverse projects, we have identified a significant variation in WGRs, reflecting the complex interplay of waste management practices, technological adoption, and awareness levels among stakeholders. This variation, with WGRs ranging from 30.96 kg/m2 to 629.96 kg/m2, and the predominance of materials, like mortar, concrete, timber, tile, and metal, which, together, constitute 75.02% of the total waste, highlight the need for a nuanced approach to waste management.

These findings reveal that the variability in the waste generation is not merely a function of the types of buildings or the scope of decorations and renovations that are undertaken but also reflects the broader socioeconomic and technological milieu within which these projects are situated. This nuanced understanding contributes significantly to the field by highlighting the need for tailored waste management strategies that account for the unique contexts of urban development in rapidly growing economies, like China.

Furthermore, the proposed strategies, if implemented effectively, can lead to substantial improvements in the sustainability, efficiency, and organization of waste management systems, aligning with environmental protection goals and fostering sustainable urban development. The multifaceted approaches advocated for in this study collectively advance the discourse on DWDRP management, offering actionable insights for policymakers, practitioners, and researchers alike.

6. Limitations and Future Directions

The intricate and diverse natures of building decoration processes, coupled with the inclusion of various building types, inevitably lead to fluctuations in WGRs associated with decoration activities. Hence, the WGRs derived from this study for these projects are specifically relevant to projects undergoing similar decoration styles. Furthermore, owing to the limited number of projects that were studied, high concentrations of certain materials may also be attributed to their excessive use in specific projects.

Although researchers diligently conducted on-site investigations and reviewed project documents to classify decoration waste, it is inevitable that some waste may have been mixed with others, leading to inaccuracies in both the on-site investigations and project documentations. Therefore, stricter on-site classification methods should be implemented in the future to categorize and weigh different waste materials accurately, along with ensuring the precision of project documentations. These measures aim to enhance the accuracy of the waste generation rate calculations.

Author Contributions

Conceptualization, data curation, methodology, and writing—original draft preparation, L.Z.; supervision, project administration, and writing—review and editing, H.W.; resources, writing—review and editing, and validation, X.W. (Xin Wang); supervision and writing—review and editing, F.W.; supervision and writing—review and editing, Z.D.; resources and validation. X.R.; data curation and visualization, L.S.; validation and investigation, X.W. (Xin Wen); supervision and data curation, J.L.; data curation and validation, P.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (Grant No. 72304187).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Authors Lianxiang Zhang, Xin Wang, Fugui Wu, Lei Song, Xin Rong, Xin Wen, Jing Liu and Ping Zhong were employed by the company Shenzhen Architectural Decoration (Group) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- National Bureau of Statistics of the People’s Republic of China. China Real Estate Statistics Yearbook. 2018. Available online: https://www.stats.gov.cn/sj/ndsj/2018/indexch.htm (accessed on 4 February 2024). (In Chinese)

- Ge, D.; Liu, X.; Zhang, Y. Blue Book of Building Decoration—Annual Report on the Development of Chinese Building Dec-oration Industry 2018; Social Sciences Academic Press: Beijing, China, 2018. [Google Scholar]

- Wang, J.; Wu, H.; Duan, H.; Zillante, G.; Zuo, J.; Yuan, H. Combining life cycle assessment and Building Information Modelling to account for carbon emission of building demolition waste: A case study. J. Clean. Prod. 2017, 172, 3154–3166. [Google Scholar] [CrossRef]

- Ding, Z.; Gong, W.; Tam, V.W.; Illankoon, I.C.S. Conceptual framework for renovation waste management based on renovation waste generation rates in residential buildings: An empirical study in China. J. Clean. Prod. 2019, 228, 284–293. [Google Scholar] [CrossRef]

- Li, G.J. Urban Waste Treatment Project; Chinese Academy of Sciences: Beijing, China, 2007. (In Chinese) [Google Scholar]

- Shanghai Municipal People’s Government. The Regulations of C&D Waste Management in Shanghai. 2017. Available online: https://www.shanghai.gov.cn/nw41492/20200823/0001-41492_53766.html (accessed on 4 February 2024). (In Chinese)

- Wang, G.; Li, D.; Hou, X.; Ling, Q. X-ray fluorescence spectrometry analysis of heavy metals in the construction waste. Nucl. Electron. Detect. Technol. 2013, 33, 873–875. Available online: https://kns.cnki.net/kcms2/article/abstract?v=p7sfyaWOx3NnOoWCszeMHfa4H7Ms-kU1QyLQBmbesHBXJQeccEAMNxNmcBEss5h4hi9PsMCCPp1LVECVXAS4w6tRJPPYdpnQOFV_1rR_OqvoRby_OBnvBfxHU4NRnDzA&uniplatform=NZKPT&flag=copy (accessed on 4 February 2024).

- Sun, P.; Zhang, N.; Zuo, J.; Mao, R.; Gao, X.; Duan, H. Characterizing the generation and flows of building interior decoration and renovation waste: A case study in Shenzhen City. J. Clean. Prod. 2020, 260, 121077. [Google Scholar] [CrossRef]

- General Office of the State Council of the People’s Republic of China. A Notice Issued by the General Office of the State Council on the Workplan for the Pilot Construction of “Zero-Waste” Cities. 2019. Available online: http://www.gov.cn/zhengce/content/2019-01/21/content_5359620.htm (accessed on 1 August 2020). (In Chinese)

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Urban Construction Waste Management Regulations. 2005. Available online: https://www.gov.cn/zhengce/2022-09/27/content_5712655.htm (accessed on 4 February 2024). (In Chinese)

- Niu, D.J.; Wei, Y.M.; Zhao, Y.C. Municipal Solid Waste Management; China City Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Wang, J.; Huang, Q. Encouraging the environmentally sound management of C&D waste in China: An integrative review and research agenda. Renew. Sustain. Energy Rev. 2015, 43, 611–620. [Google Scholar] [CrossRef]

- Duan, H.; Yu, D.; Zuo, J.; Yang, B.; Zhang, Y.; Niu, Y. Characterization of brominated flame retardants in construction and demolition waste components: HBCD and PBDEs. Sci. Total. Environ. 2016, 572, 77–85. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Wang, J.; Duan, H.; Ouyang, L.; Huang, W.; Zuo, J. An innovative approach to managing demolition waste via GIS (geographic information system): A case study in Shenzhen city, China. J. Clean. Prod. 2016, 112, 494–503. [Google Scholar] [CrossRef]

- Reddrop, A.; Ryan, C. Housing Construction Waste; Commonwealth Department of Industry, Science & Tourism: Canberra, Australia, 1997.

- Wang, J.Y.; Touran, A.; Christoforou, C.; Fadlalla, H. A systems analysis tool for construction and demolition wastes management. Waste Manag. 2004, 24, 989–997. [Google Scholar] [CrossRef]

- Yu, D.; Duan, H.; Song, Q.; Li, X.; Zhang, H.; Zhang, H.; Liu, Y.; Shen, W.; Wang, J. Characterizing the environmental impact of metals in construction and demolition waste. Environ. Sci. Pollut. Res. 2018, 25, 13823–13832. [Google Scholar] [CrossRef]

- Yu, D.; Li, X.; Duan, H.; Huo, P. Leaching characteristics of heavy metals from urban building-demolition and renovation wastes. Environ. Eng. 2019, 37, 153–158. Available online: https://kns.cnki.net/kcms2/article/abstract?v=p7sfyaWOx3O8IA36VsXFnCk0iUVglTsOTFns40YZbHb1eUrLv4YLXJpSjLaRSyr-ShKHPWD5Op7tFDQG4nh2bTSRxu-6QA7ELL4kFNmGUdD64qqrQ1uiEWi6eZ3npreLwFmuZrA9Abs=&uniplatform=NZKPT&flag=copy (accessed on 14 January 2024). (In Chinese).

- Lu, W.; Webster, C.; Peng, Y.; Chen, X.; Zhang, X. Estimating and calibrating the amount of building-related construction and demolition waste in urban China. Int. J. Constr. Manag. 2017, 17, 13–24. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H.; Li, J.; Hao, J.J.; Mi, X.; Ding, Z. An empirical investigation of construction and demolition waste generation rates in Shenzhen city, South China. Waste Manag. 2011, 31, 680–687. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Waste generation, composition, and handling in building-related construction and demolition in Hanoi, Vietnam. Waste Manag. 2020, 117, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Uniform Standards for Civil Building Design (Draft). 2019. Available online: https://www.mohurd.gov.cn/gongkai/zhengce/zhengcefilelib/201905/20190530_240715.html (accessed on 4 February 2024). (In Chinese)

- Li, Z.; Deng, Q.; Bai, J.; Li, Y.; Wang, Y.; Liu, N.; Gong, Y. Management system for engineering and decoration waste: An exploratory study in Shenzhen. J. Environ. Manag. 2022, 314, 115085. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.X.; Tam, V.W.Y.; Le, K.N.; Li, W.G. Challenges in current construction and demolition waste recycling: A China study. Waste Manag. 2020, 118, 610–625. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Lin, Z.W. Model Development for Estimating the Quantity of a Single Building’s Demolition Waste 2006; National Central University: Taoyuan City, Taiwan, 2006. [Google Scholar]

- Tam, V.W.; Tam, C.; Zeng, S.; Ng, W.C. Towards adoption of prefabrication in construction. J. Affect. Disord. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total. Environ. 2021, 803, 149892. [Google Scholar] [CrossRef]

- Bergsdal, H.; Bohne, R.A.; Brattebø, H. Projection of Construction and Demolition Waste in Norway. J. Ind. Ecol. 2007, 11, 27–39. [Google Scholar] [CrossRef]

- Iodice, S.; Garbarino, E.; Cerreta, M.; Tonini, D. Sustainability assessment of Construction and Demolition Waste management applied to an Italian case. Waste Manag. 2021, 128, 83–98. [Google Scholar] [CrossRef] [PubMed]

- Umar, U.A.; Shafiq, N.; Ahmad, F.A. A case study on the effective implementation of the reuse and recycling of construction & demolition waste management practices in Malaysia. Ain Shams Eng. J. 2020, 12, 283–291. [Google Scholar] [CrossRef]

- Al-Raqeb, H.; Ghaffar, S.H.; Al-Kheetan, M.J.; Chougan, M. Understanding the challenges of construction demolition waste management towards circular construction: Kuwait Stakeholder’s perspective. Clean. Waste Syst. 2023, 4, 100075. [Google Scholar] [CrossRef]

- Skoyles, E.R. Materials wastage—A misuse of resources. Batim. Int. Build. Res. Pract. 1976, 4, 232. [Google Scholar] [CrossRef]

- Bossink, B.A.G.; Brouwers, H.J.H. Construction Waste: Quantification and Source Evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef]

- Forsythe, P.; Marsden, P. Modelling construction waste performance—An arising procurement issue. Profitab. Partn. Constr. Procure 1999, 427, 679–688. Available online: https://ascelibrary.org/doi/abs/10.1061/%28ASCE%290733-9364%282002%29128%3A4%28316%29 (accessed on 15 January 2024). [CrossRef]

- Poon, C.S.; Yu, T.W.; Ng, L.H. A Guide for Managing and Minimizing Building and Demolition Waste; Department of Civil & Structural Engineering, Hong Kong Polytechnic University: Hong Kong, China, 2001. [Google Scholar]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Construction and demolition waste generation rates for high-rise buildings in Malaysia. Waste Manag. Res. J. A Sustain. Circ. Econ. 2016, 34, 1224–1230. [Google Scholar] [CrossRef] [PubMed]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-based automated construction waste estimation algorithms: The case of concrete and drywall waste streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Zhao, Y.; Lei, G.; Wang, Q. Reflections and suggestions on the management and disposal of decoration waste for Wuhan. Environ. Prot. 2020, 48, 53–56. Available online: https://kns.cnki.net/kcms2/article/abstract?v=p7sfyaWOx3PwViHjPN55Vv0rQWYL8QWdPtpWYTfEK9fXQjCQuOrTH8ApdA1StMdH9HtiJckkot4Fu2Vru3EgWlG8feZAqPR9nSpmCt369B1z6QIlPyXo14unKqDbCkTf2qp4RWRzKV8x9xYy-p7XIA==&uniplatform=NZKPT&language=CHS (accessed on 6 January 2024). (In Chinese).

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. J. A Sustain. Circ. Econ. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Umar, U.A.; Shafiq, N.; Malakahmad, A.; Nuruddin, M.F.; Khamidi, M.F. A review on adoption of novel techniques in construction waste management and policy. J. Mater. Cycles Waste Manag. 2016, 19, 1361–1373. [Google Scholar] [CrossRef]

- Cochran, K.M.; Townsend, T.G. Estimating construction and demolition debris generation using a materials flow analysis ap-proach. Waste Manag. 2010, 30, 2247–2254. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.W.; Shen, L.; Liu, G. Quantifying construction and demolition waste: An analytical review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef]

- Wu, H.; Duan, H.; Zheng, L.; Wang, J.; Niu, Y.; Zhang, G. Demolition waste generation and recycling potentials in a rapidly developing flagship megacity of South China: Prospective scenarios and implications. Constr. Build. Mater. 2016, 113, 1007–1016. [Google Scholar] [CrossRef]

- Edmondson, A.C.; Mcmanus, S.E. Methodological fit in management field research. Acad. Manag. Rev. 2007, 32, 1246–1264. [Google Scholar] [CrossRef]

- DeHoratius, N.; Rabinovich, E. Field research in operations and supply chain management. J. Oper. Manag. 2010, 29, 371–375. [Google Scholar] [CrossRef]

- GB 50854-2013; Standard Method of Measurement for Building Construction and Fitting-Out Works. China Planning Press: Beijing, China, 2014. Available online: https://www.mohurd.gov.cn/gongkai/zhengce/zhengcefilelib/201301/20130105_224600.html (accessed on 6 January 2024). (In Chinese)

- EPA. Estimating 2003 Building-Related Construction and Demolition Materials Amounts; Retrieved from USA; EPA: Washington, DC, USA, 2015.

- Metro Vancouver. Demolition, Land Clearing and Construction Waste Management Toolkit; Retrieved from Vancouver Canada; Metro Vancouver: Vancouver, BC, Canada, 2008; Available online: http://www.metrovancouver.org/services/solid-waste/SolidWastePublications/DLCToolkit.pdf (accessed on 23 December 2023).

- Bai, Z.C. Analysis on construction technology management of architectural decoration. Create Liv. 2015, 22, 150–152. (In Chinese) [Google Scholar]

- Zheng, G.Q. The research of using composite fittings in housing decoration projects. J. Wuhan Univ. Technol. (Inf. Manag. Eng.) 2001, 23, 40–43. Available online: https://kns.cnki.net/kcms2/article/abstract?v=p7sfyaWOx3P7dSxPC7n0lBHFcGqn0Zz7L_M-Y4htW2FVHRvGI2y81LNUwvhHYYjIrH9KE5_3I3VhcI5IkFDLq3hoO73jYPlC8-jNTMVwOWqBy9QOeJrRWPTBi3KtavkjXPR5MD7uMSw=&uniplatform=NZKPT&language=CHS (accessed on 25 December 2023). (In Chinese).

- Policy Research on Construction Waste Recycling and Reutilization. City Building Energy Conservation and Wall Materials Innovation Office. 2015, pp. 38–44. Available online: https://www.efchina.org/Reports-en/report-20140630-en (accessed on 14 December 2023).

- Liang, B. Countermeasures for the recycling and utilization of construction waste in our country based on the comprehensive utilization of foreign construction waste. Shanghai Build. Mater. 2015, 4, 12–16. [Google Scholar]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Ye, B.; Yuan, H. An Overview of C&D Waste Management Regulations in Central China. In Proceedings of the 2014 International Conference on Construction and Real Estate Management, Kunming, China, 27–28 September 2014. [Google Scholar]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996–2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).