Shear Performance of Demountable High-Strength Bolted Connectors: An Experimental and Numerical Study Based on Reverse Push-Out Tests

Abstract

1. Introduction

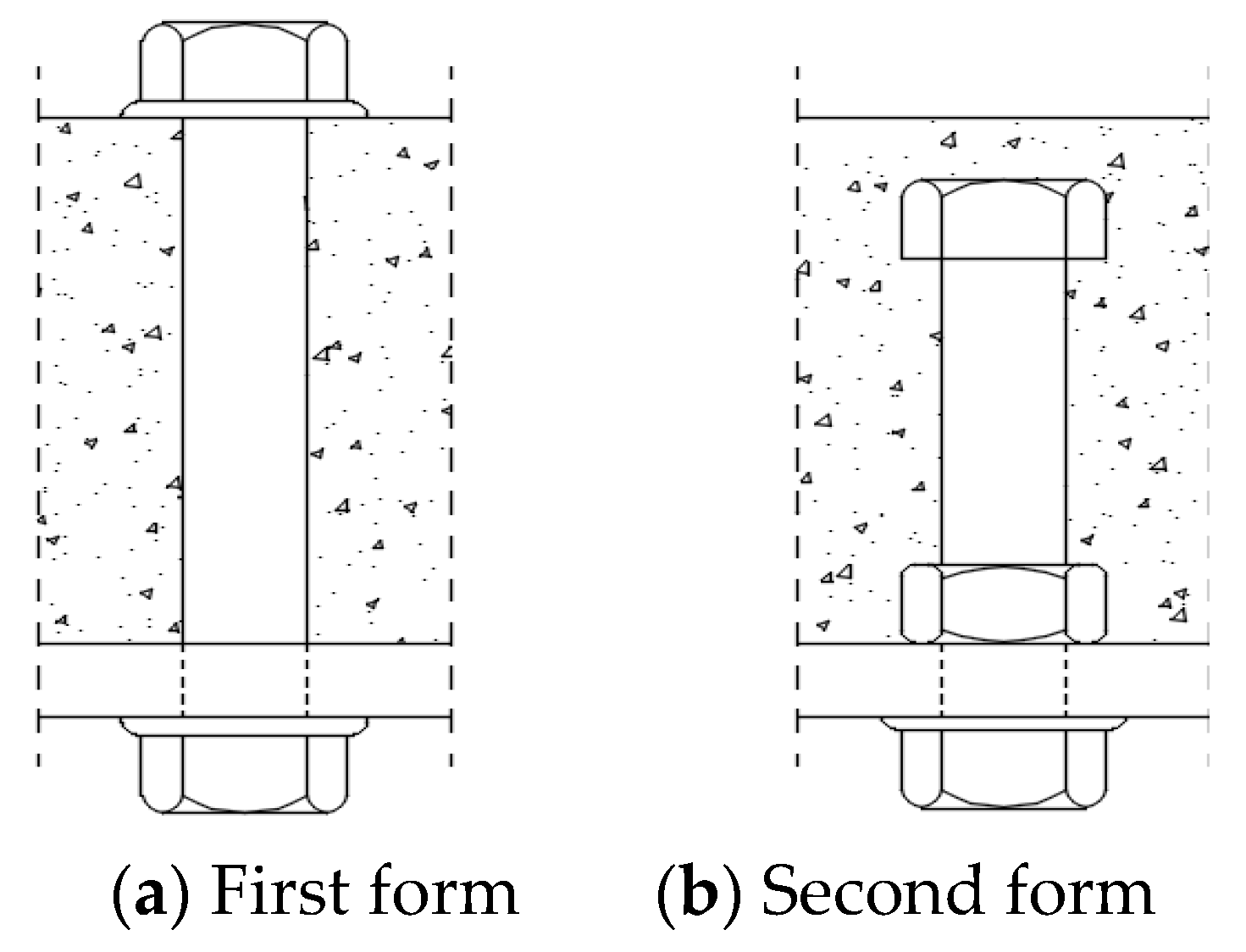

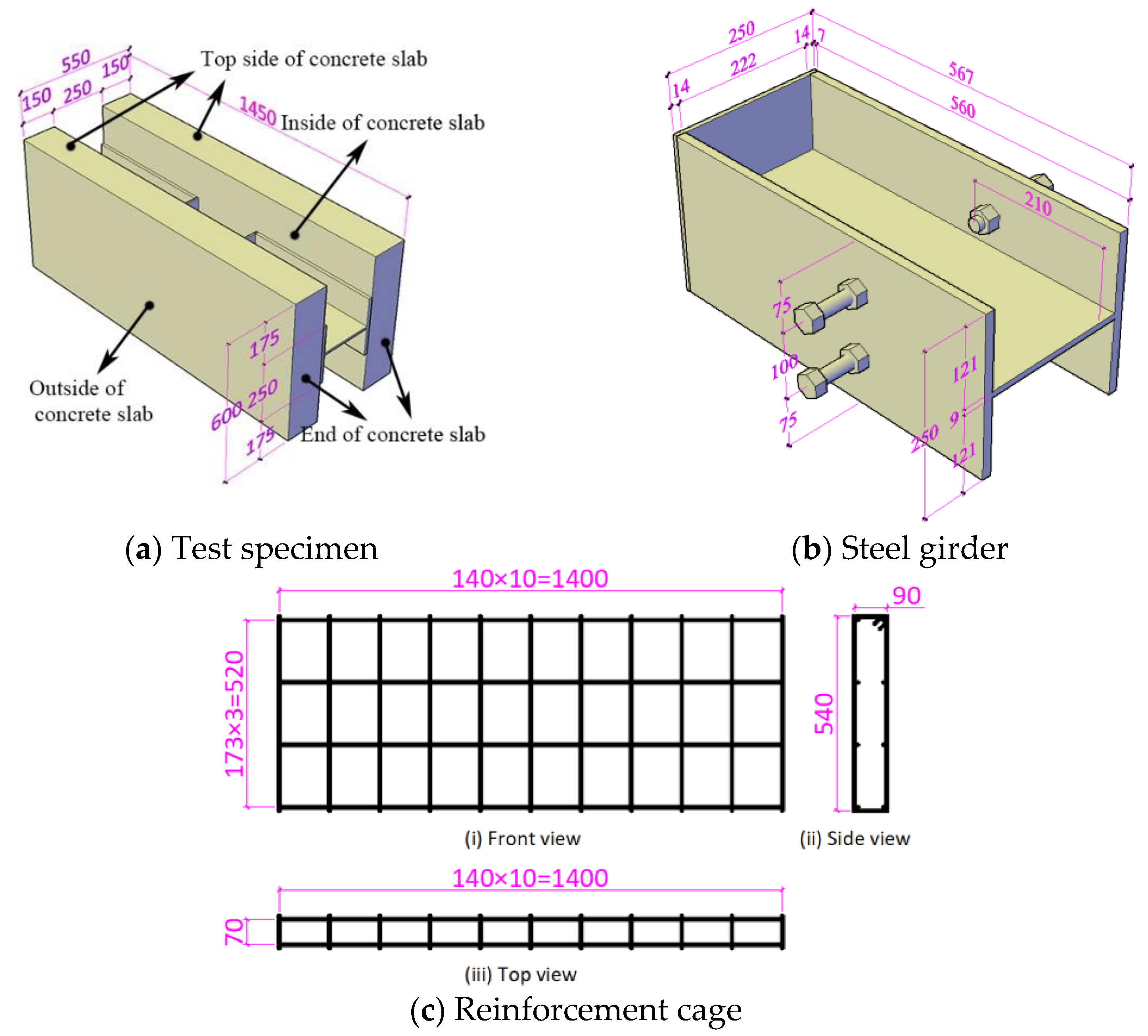

2. Reverse Push-Out Tests

2.1. Geometrical Dimension and Material Properties

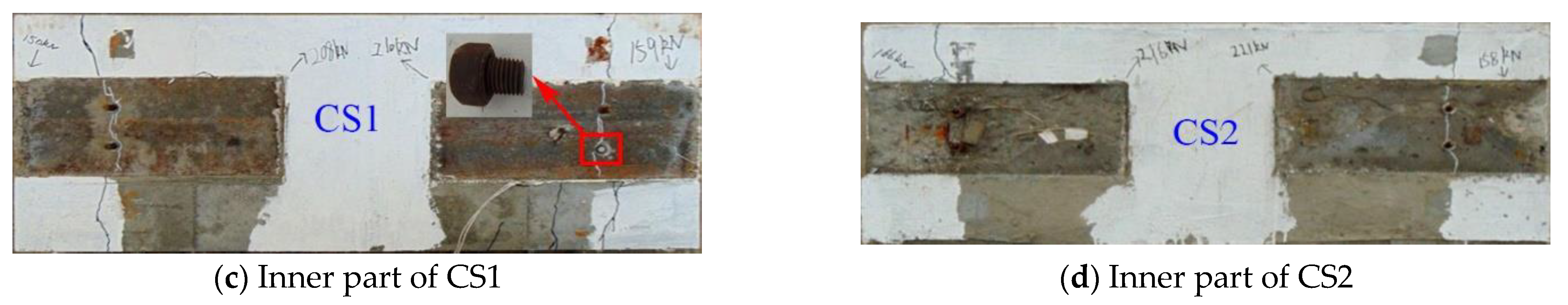

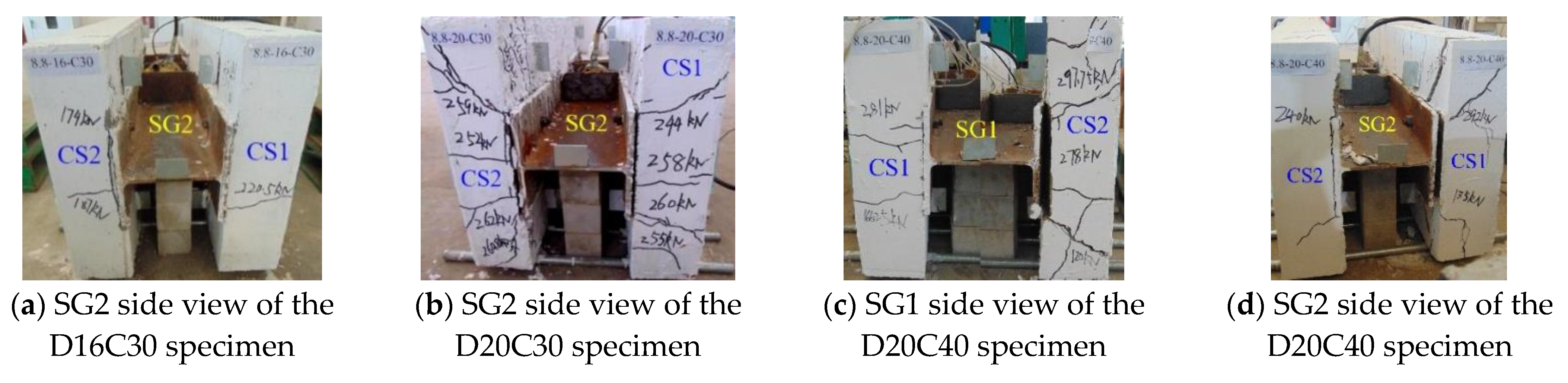

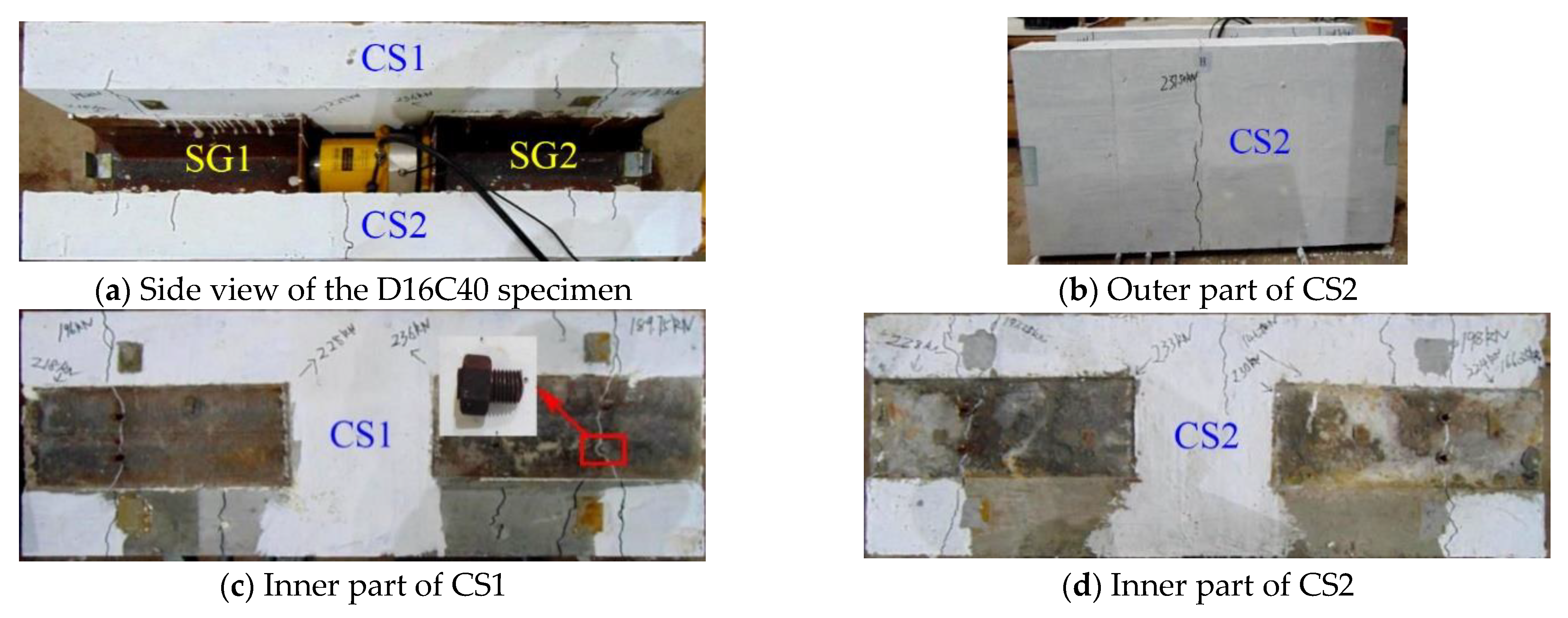

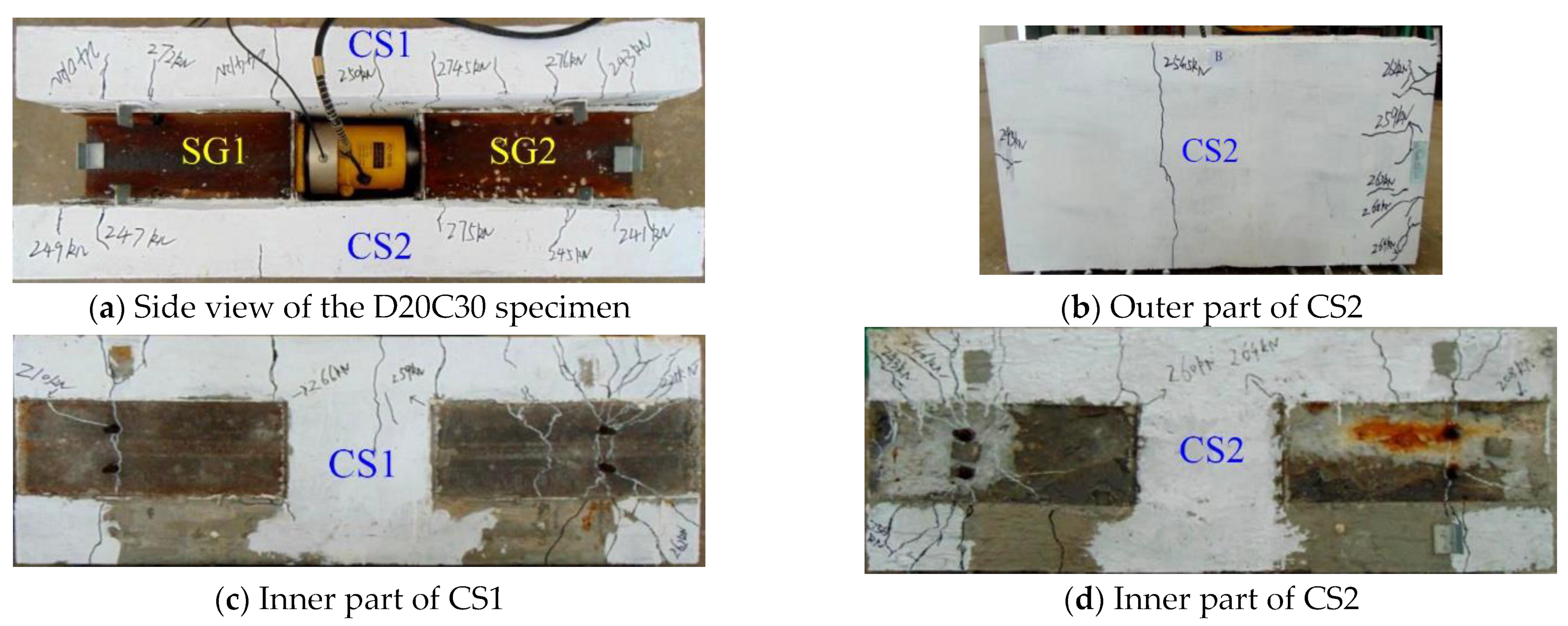

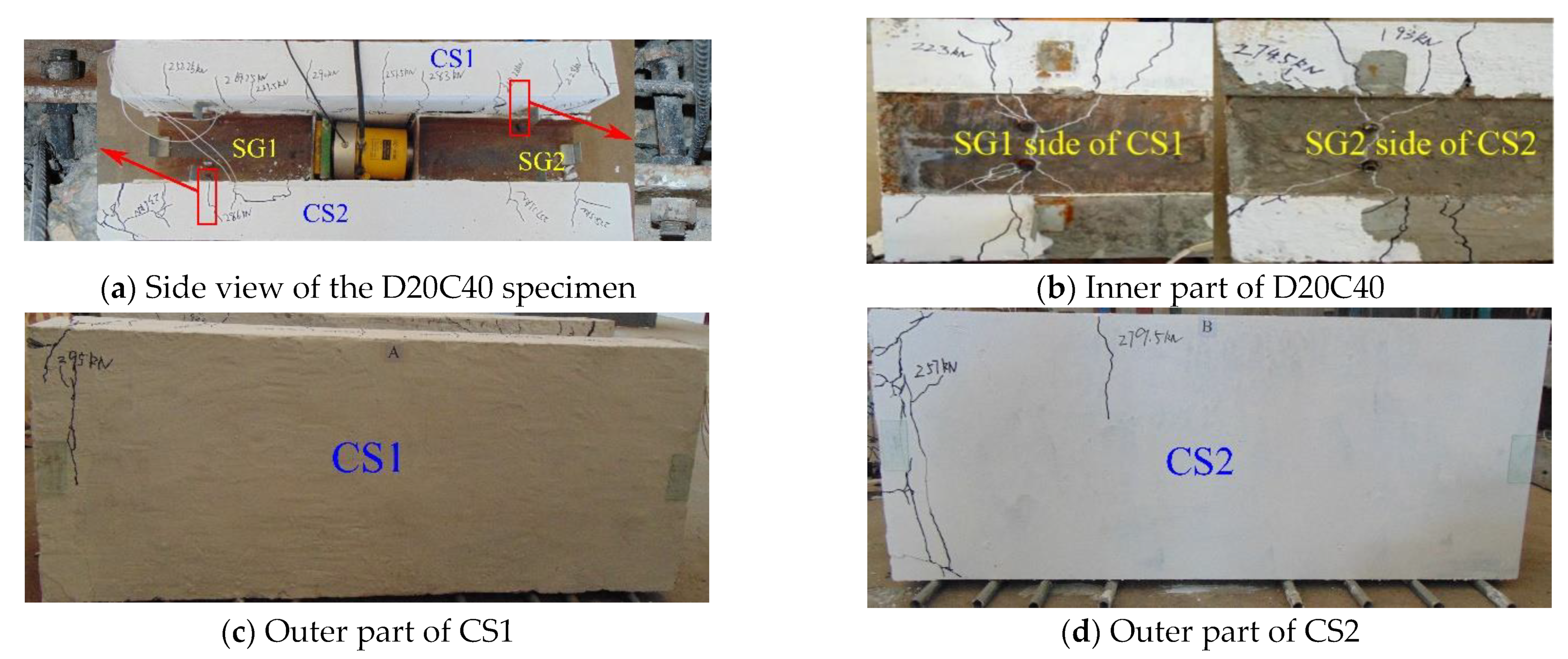

2.2. Test Program and Phenomena

2.3. Load–Slip Response

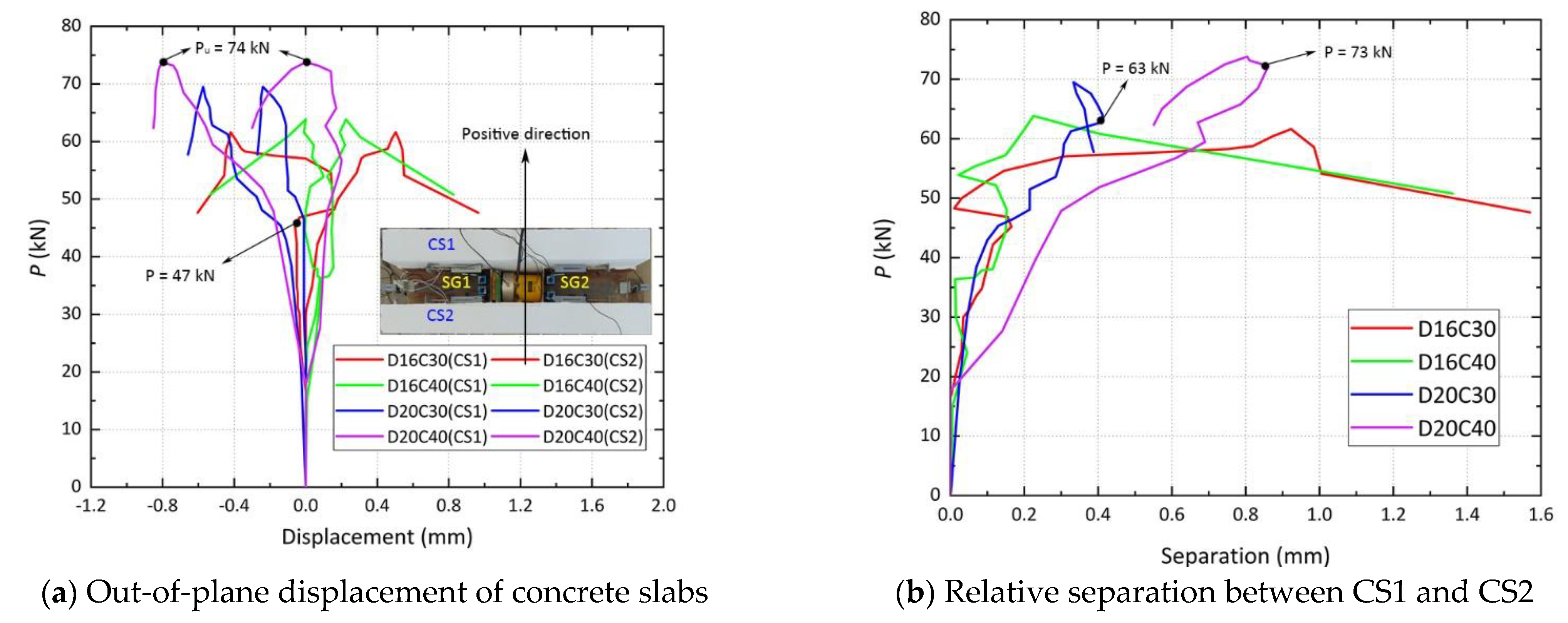

2.4. Out-of-Plane Displacement Results

3. Numerical Modeling and Analysis

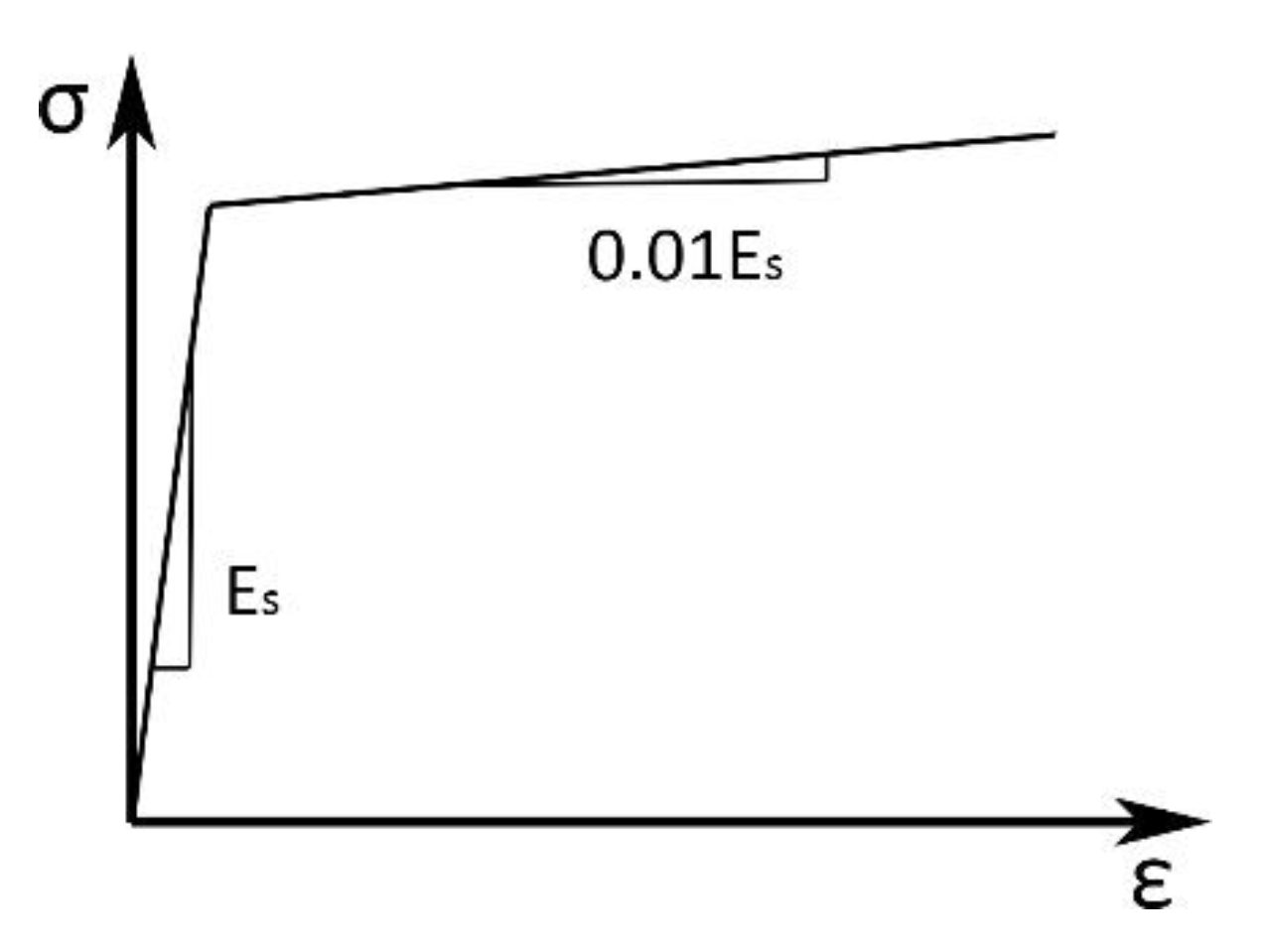

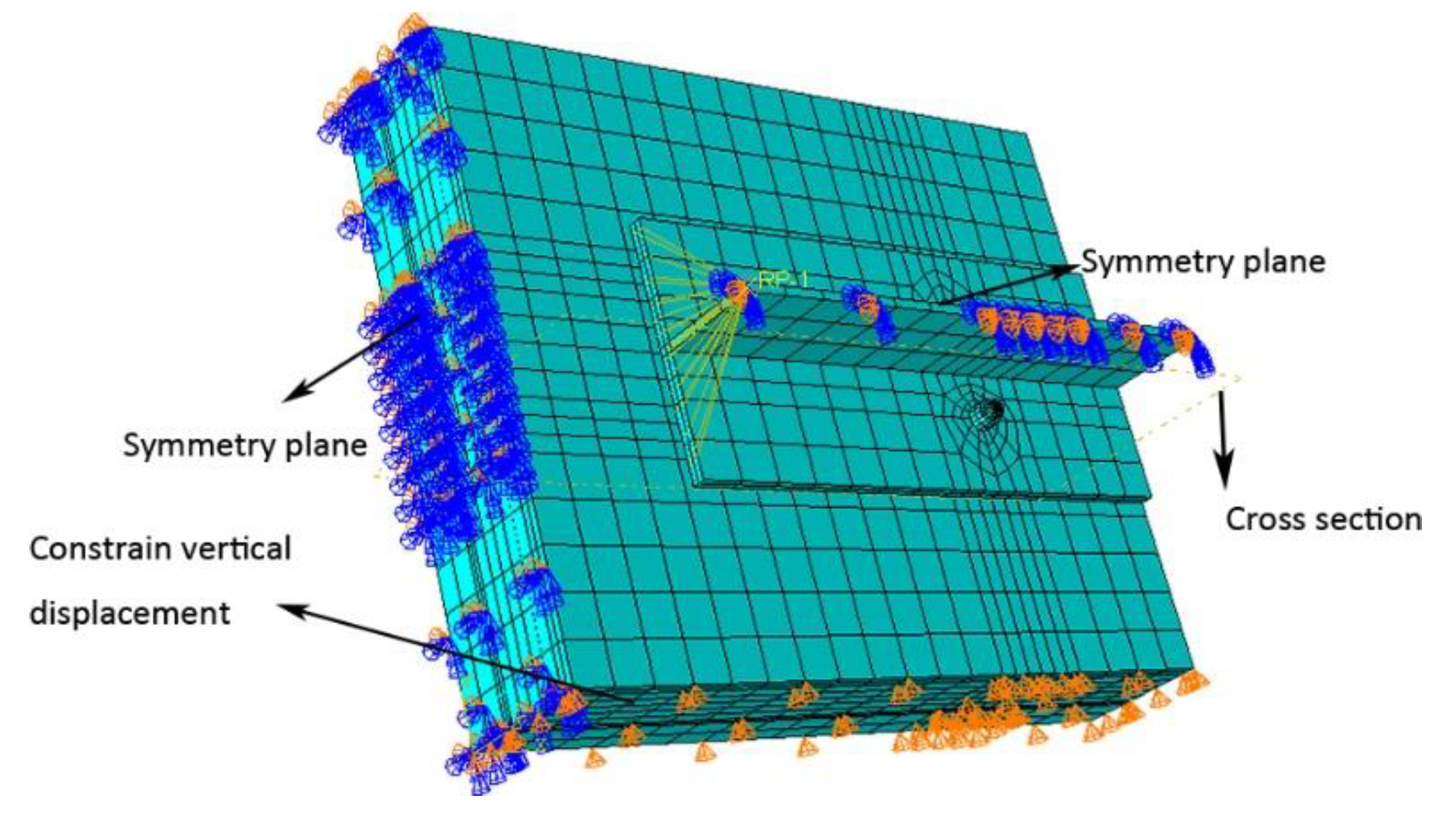

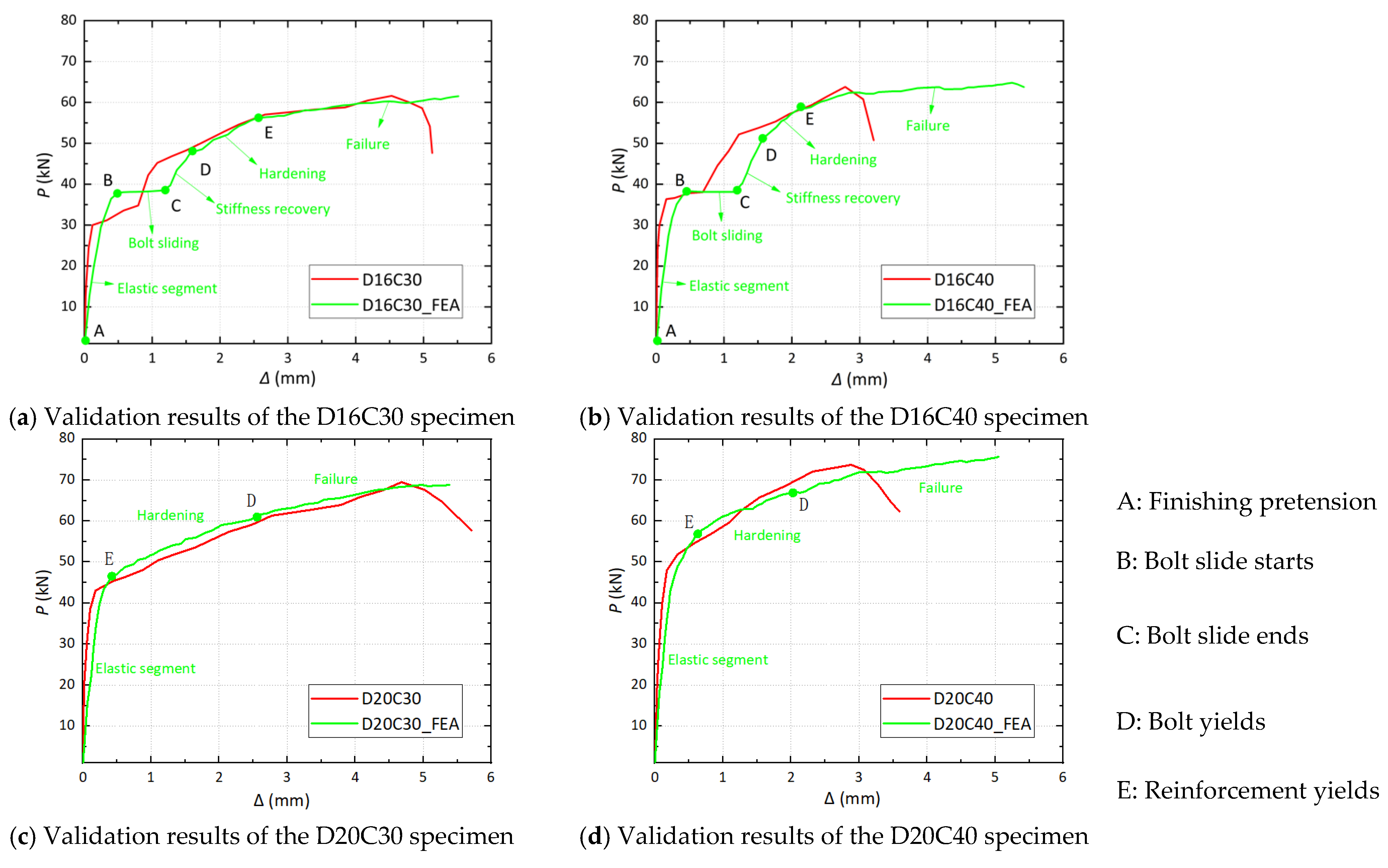

3.1. FE Model and Validation

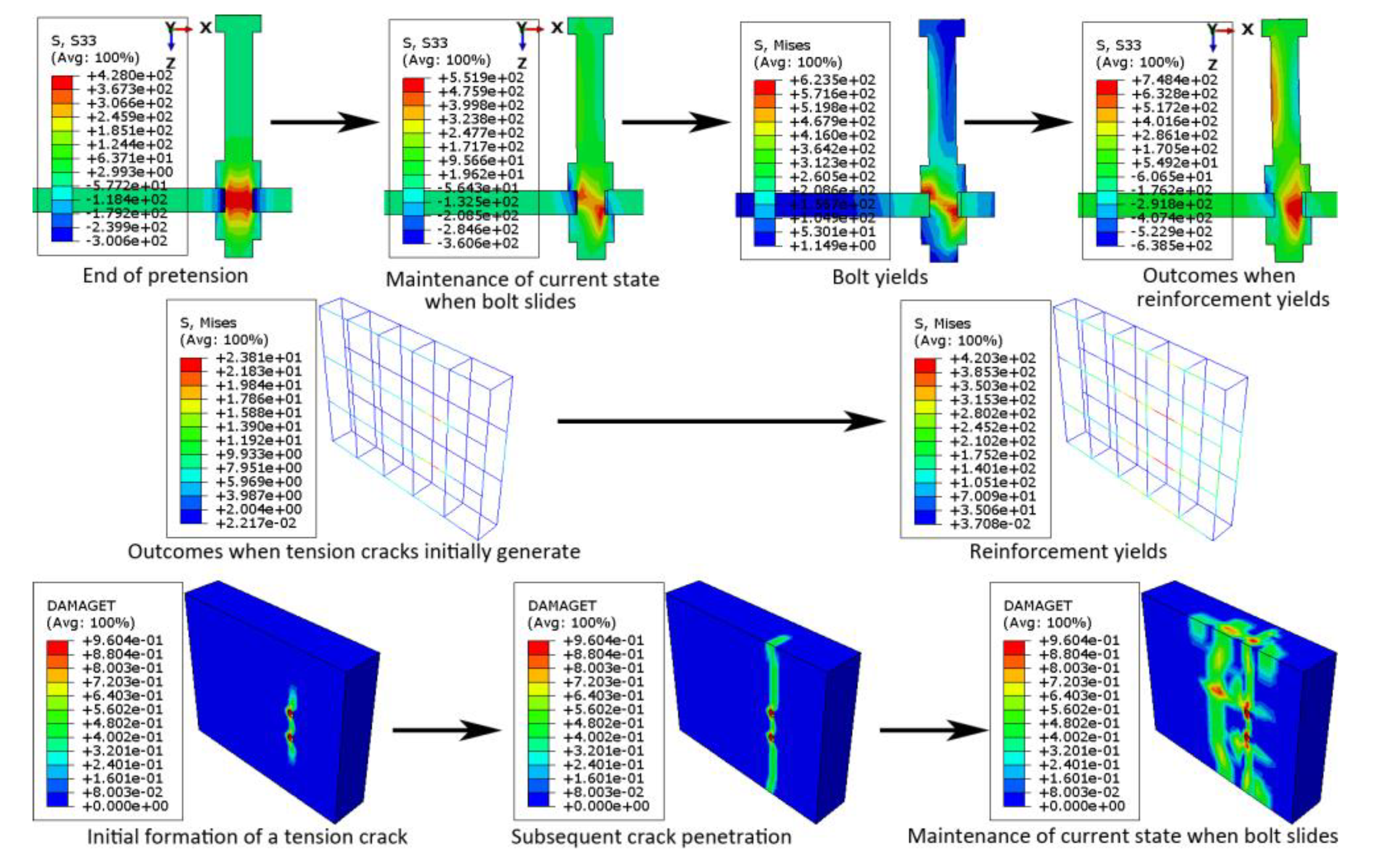

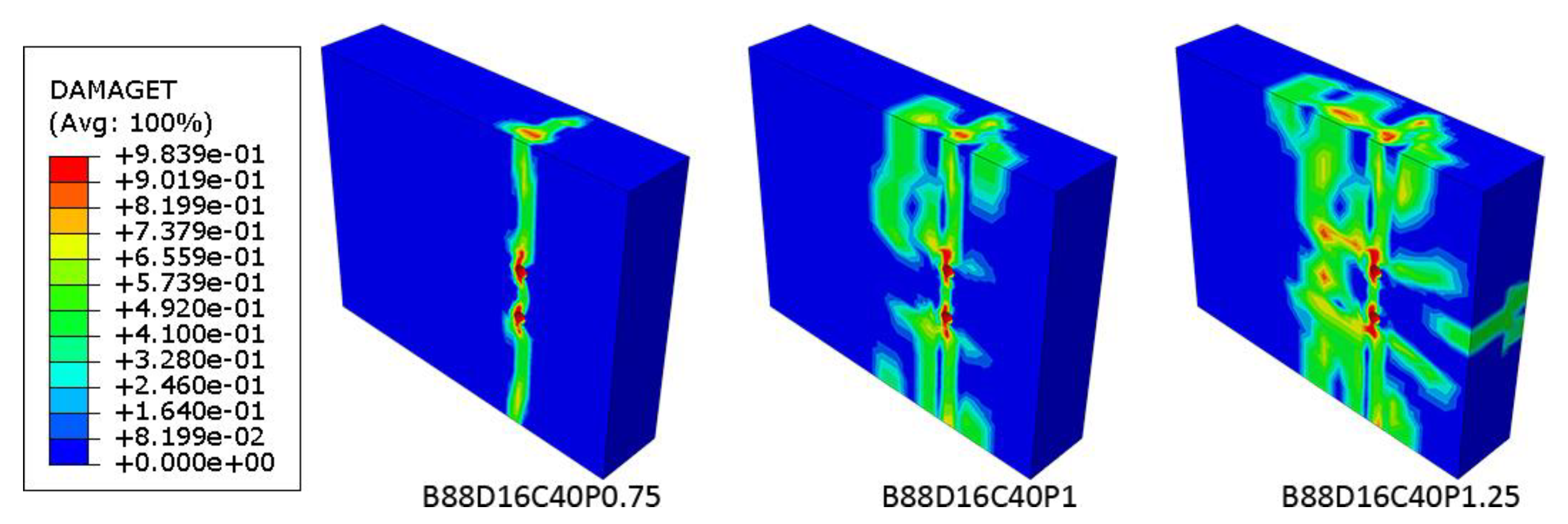

3.2. Evolution of Stress and Damage

4. Parametric Studies

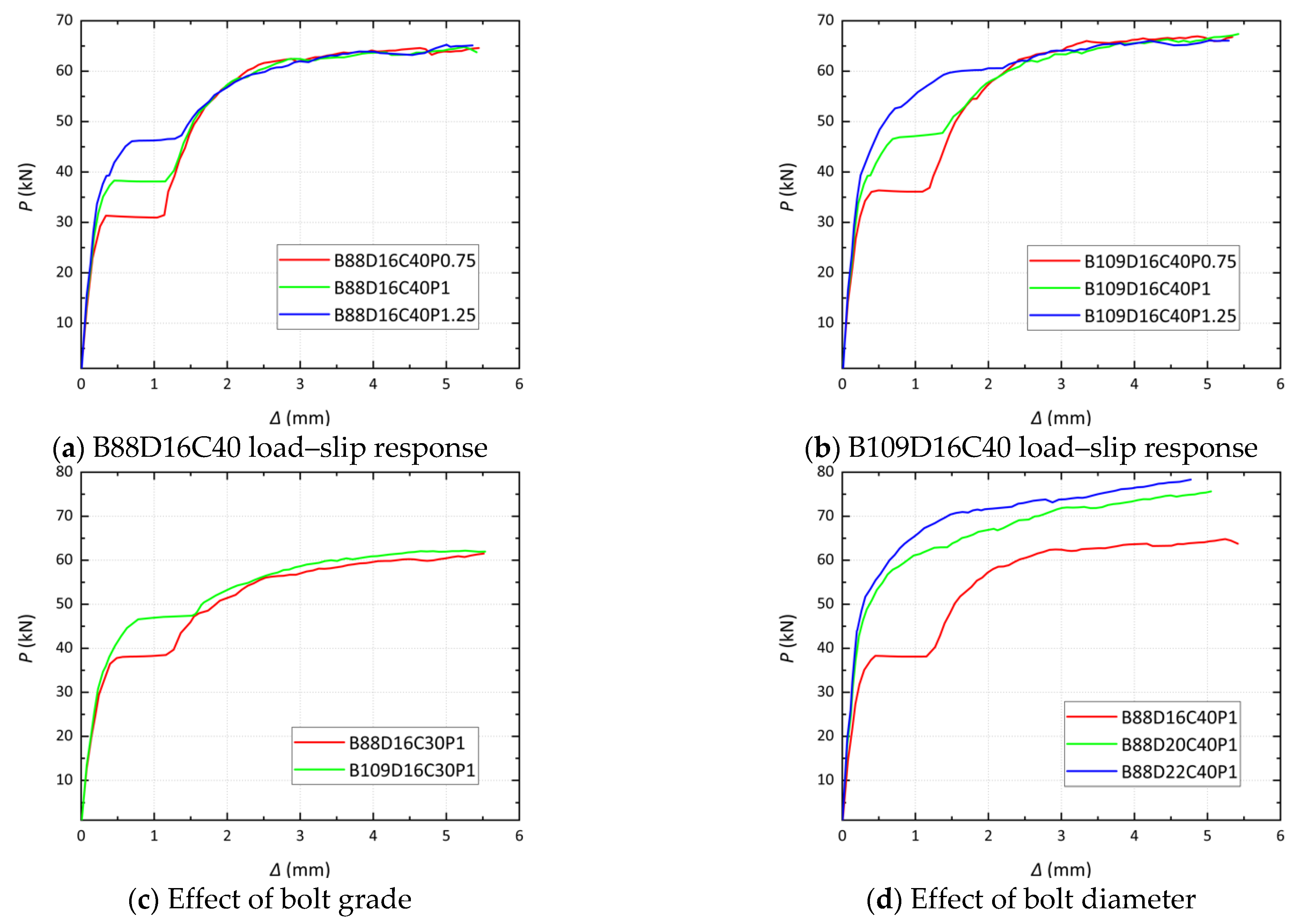

4.1. Effects of Bolt Properties

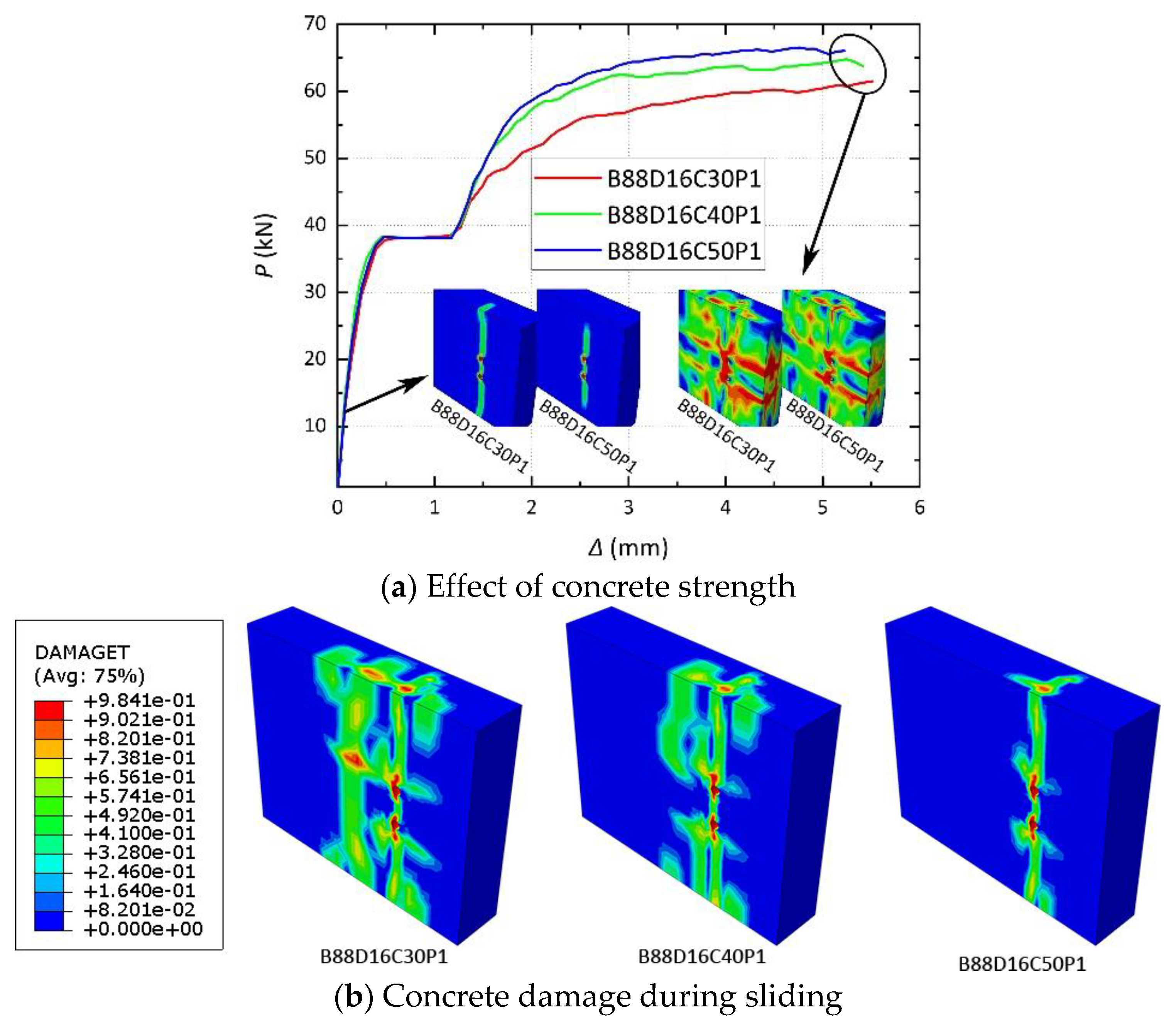

4.2. Effects of Concrete Strength

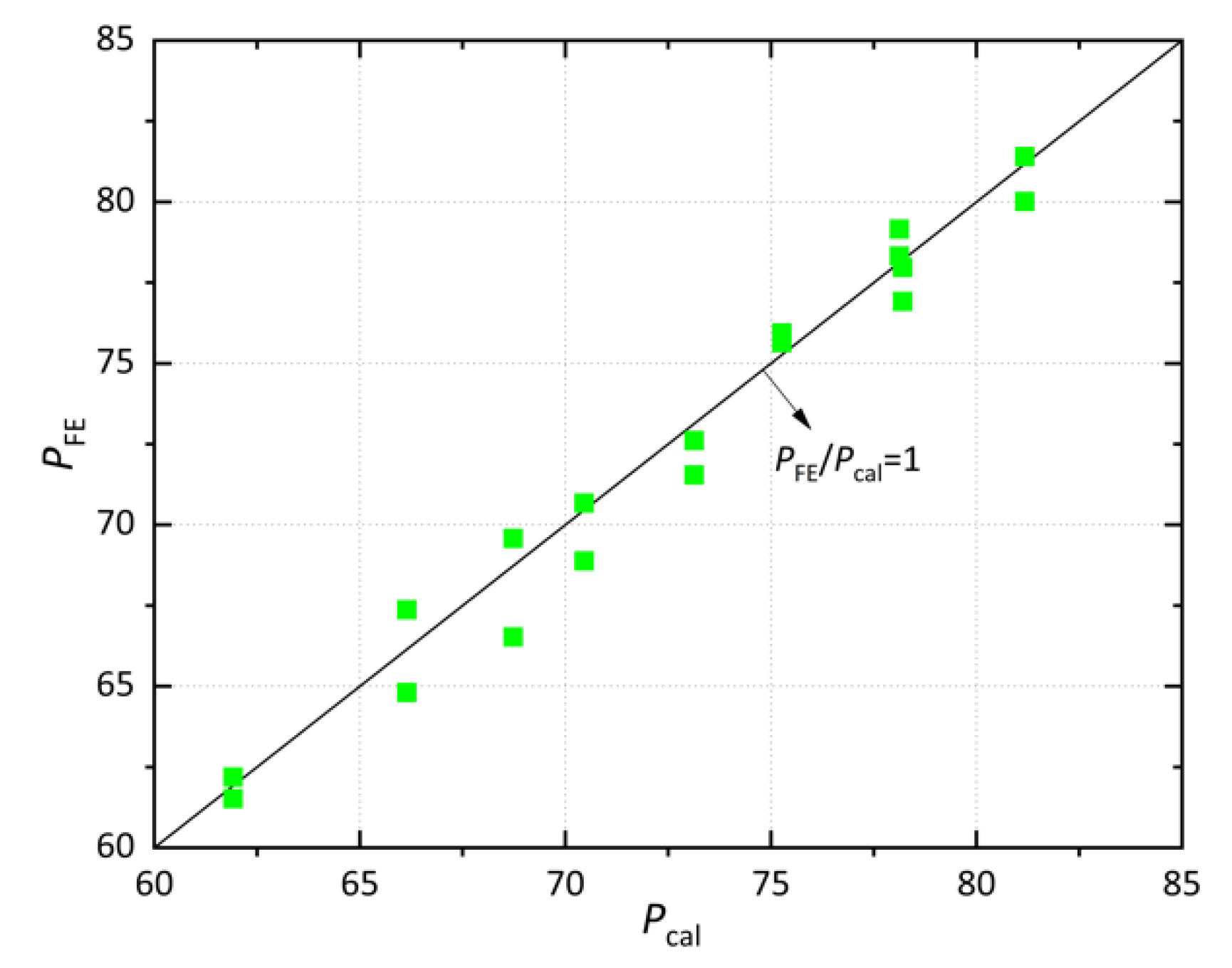

5. Shear Resistance of Single Bolt

6. Conclusions

- (1)

- During the loading process, tensile and splitting cracks were produced in the concrete, the distribution of which became denser with decreasing concrete strength and increasing bolt diameter.

- (2)

- When the concrete strength increased from 30 to 40, the ultimate strength with 16 mm and 20 mm bolts increased by 3.6% and 6.2%, respectively.

- (3)

- When the diameter of the bolts increased from 16 to 20 mm, the ultimate strength with C30 and C50 concrete increased by 12.8% and 15.6%, respectively.

- (4)

- The concrete slabs tended to separate from each other, but this was mitigated when splitting cracks occurred.

- (1)

- The load–slip responses of the specimens with 16 mm bolts could be divided into five phases, i.e., elastic segment, bolt sliding, stiffness recovery, hardening, and failure.

- (2)

- The load–slip responses of the specimens with 20 mm bolts could be divided into three phases, i.e., elastic segment, hardening, and failure. The fact that bolt slip was not observed does not mean that it did not occur; instead, it occurred simultaneously with the concrete deformation and failure, rendering it difficult to be reflected in the load–slip response.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sánchez, B.D.; Tamayo, J.P.; Morsch, I.B.; Miranda, M.P. A nonlinear geometric model for pre-stressed steel-concrete composite beams. J. Braz. Soc. Mech. Sci. 2021, 43, 233. [Google Scholar] [CrossRef]

- Radnic, J.; Markic, R.; Glibic, M.; Cubela, D.; Grgic, N. Experimental testing of concrete beams with different levels of prestressing. Proc. Inst. Mech. Eng. Part. L-J. Mater. Des. Appl. 2016, 230, 760–779. [Google Scholar] [CrossRef]

- Rezaie, F.; Bayat, A.M.; Farnam, S.M. Sensitivity analysis of pre-stressed concrete sleepers for longitudinal crack prorogation effective factors. Eng. Fail. Anal. 2016, 66, 385–397. [Google Scholar] [CrossRef]

- Mohammadi, T.; Wan, B.L.; Harries, K.A. Bond-slip behavior of fiber-reinforced polymer/concrete interface in single shear pull-out and beam tests. J. Reinf. Plast. Comp. 2016, 35, 375–386. [Google Scholar] [CrossRef]

- Asaduzzaman, S.M.; Islam, G.M.S. Using Jute Fiber to Improve Fresh and Hardened Properties of Concrete. J. Nat. Fibers 2023, 20, 2204452. [Google Scholar] [CrossRef]

- Hamoda, A.; Hossain, K.M.A.; Sennah, K.; Shoukry, M.; Mahmoud, Z. Behaviour of composite high performance concrete slab on steel I-beams subjected to static hogging moment. Eng. Struct. 2017, 140, 51–65. [Google Scholar] [CrossRef]

- Arafa, A.; Farghaly, A.S.; Ahmed, E.A.; Benmokrane, B. Laboratory testing of GFRP-RC panels with UHPFRC joints of the Nipigon River cable-stayed bridge in Northwest Ontario, Canada. J. Bridge. Eng. 2016, 21, 05016006. [Google Scholar] [CrossRef]

- El-Khoriby, R.S.; Taher, S.E.; Ghazy, M.F.; Abd-Elaty, M.A. Performance of pre-cracked beams exposed to corrosion environment cast with ultra-high performance concrete. Ain Shams Eng. J. 2023, 14, 102171. [Google Scholar] [CrossRef]

- Wan, Z.Y.; Fang, Z.; Liang, L.N.; He, S.H.; Sun, X.D. Structural performance of steel–concrete composite beams with UHPC overlays under hogging moment. Eng. Struct. 2022, 270, 114866. [Google Scholar] [CrossRef]

- Nie, J.G.; Tao, M.X.; Nie, X.; Fan, J.S.; Zhang, Z.X.; Tang, H.Y.; Zhu, L.; Li, Y.X. New technology and application of uplift-restricted and slip-permitted connection. Civ. Eng. J. 2015, 48, 4. [Google Scholar] [CrossRef]

- Li, C.; Nie, J.G.; Zhou, X.Y.; Liu, X.W. Anti-cracking design for hogging moment regions of steel-concrete continuous composite beam bridges. J. Build. Struct. 2022, 43, 3. [Google Scholar] [CrossRef]

- Su, H.; Su, Q.T.; Xu, C.; Zhang, X.L.; Lei, D.Y. Shear performance and dimension rationalization study on the rubber sleeved stud connector in continuous composite girder. Eng. Struct. 2021, 240, 112371. [Google Scholar] [CrossRef]

- Su, H.; Su, Q.T.; Casas, J.R.; Xu, C.; Tang, J.; Jiang, C. Influence mechanism of steel-concrete interlayer partial shear connections on mechanical properties of composite girders. Structures 2022, 46, 503–520. [Google Scholar] [CrossRef]

- Guo, J.Y.; Wang, J.Y.; Wang, Y.B.; Gao, X.L.; Bian, C. Experimental study on demountable steel ultra-high performance concrete composite slabs under hogging moment. Arch. Civ. Mech. Eng. 2022, 22, 137. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, S.K.; Zhu, Y.P.; Fan, L.; Shao, X.D. Flexural responses of steel-UHPC composite beams under hogging moment. Eng. Struct. 2020, 206, 110134. [Google Scholar] [CrossRef]

- Dai, X.H.; Lam, D.; Saveri, E. Effect of concrete strength and stud collar size to shear capacity of demountable shear connectors. J. Struct. Eng. 2015, 141, 04015025. [Google Scholar] [CrossRef]

- Ataei, A.; Bradford, M.A.; Liu, X.P. Experimental study of composite beams having a precast geopolymer concrete slab and deconstructable bolted shear connectors. Eng. Struct. 2016, 114, 1–13. [Google Scholar] [CrossRef]

- Kwon, G.; Engelhardt, M.D.; Klingner, R.E. Behavior of post-installed shear connectors under static and fatigue loading. J. Construct. Steel Res. 2010, 66, 532–541. [Google Scholar] [CrossRef]

- Lee, M.S.S.; Bradford, M.A. Sustainable composite beam behaviour with deconstructable bolted shear connectors. In Proceedings of the Composite Construction in Steel and Concrete VII, North Queensland, Australia, 28–31 July 2013. [Google Scholar]

- Liu, X.P.; Bradford, M.A.; Lee, M.S.S. Behavior of high-strength friction-grip bolted shear connectors in sustainable composite beams. J. Struct. Eng. 2015, 141, 04014149. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Chen, B.C.; Liu, A.R.; Pi, Y.L.; Zhang, J.P.; Wang, Y.; Zhong, L.C. Experimental study on shear behavior of high strength bolt connection in prefabricated steel-concrete composite beam. Compos. Part B-Eng. 2019, 159, 481–489. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Liu, A.R.; Chen, B.C. Experimental study on shear behavior of high-strength bolt connection in steel-concrete composite beam. J. Build. Struct. 2019, 40, 054. [Google Scholar] [CrossRef]

- GB 50017-2017; Standard for Design of Steel Structures. China Architecture & Building Press: Beijing, China, 2017.

- EN1994-2-2008; Eurocode 4: Design of Composite Steel and Concrete Structures—Part 2: General Rules and Rules for Bridges. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Du, H.; Hu, X.M.; Meng, Y.F.; Han, G.H.; Guo, K.K. Study on composite beams with prefabricated steel bar truss concrete slabs and demountable shear connectors. Eng. Struct. 2020, 210, 110419. [Google Scholar] [CrossRef]

- Du, H.; Zhang, B.; Hu, X.M.; Kou, L.Y.; Xia, Y. Experimental study on shear performance of bolted connections in steel-concrete composite beams. J. Build. Struct. 2017, 38, 043. [Google Scholar] [CrossRef]

- Chen, J.; Wang, W.; Ding, F.X.; Xu, F.; Long, S.G.; Yang, C.Q. Shear bearing capacity of high-strength bolt connectors in steel-concrete composite beams. J. Railw. Sci. Eng. 2019, 16, 10. [Google Scholar] [CrossRef]

- Pavlović, M.; Markovic, Z.; Veljkovic, M.; Budevac, D. Bolted shear connectors vs. headed studs behaviour in push-out tests. J. Construct. Steel Res. 2013, 88, 134–149. [Google Scholar] [CrossRef]

- Zhou, A.; Dai, H.; Liu, Q.W.; Ding, F.; Dai, J.P. Experimental study on shear-bearing-bearing capacity of stud connectors within tension concrete. J. Highw. Transp. Res. Develop. 2008, 3, 70–74. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2015.

- Sidoroff, F. Physical Non-Linearities in Structural Analysis; Springer: Heidelberg/Berlin, Germany, 1981; pp. 237–244. [Google Scholar]

- Karalar, M.; Dicleli, M. Effect of pile orientation on the fatigue performance of jointless bridge H-piles subjected to cyclic flexural strains. Eng. Struct. 2023, 276, 115385. [Google Scholar] [CrossRef]

- Du, Q.Z.; Luo, G.Q.; Wang, X.; Wang, T.; Fu, G.Q.; Lu, C.J. Fast optimization method of flexible support structure based on mathematical model. Arch. Adv. Eng. Sci. 2023, 1–11. [Google Scholar] [CrossRef]

- Cao, Y.; Wakil, K.; Alyousef, R.; Jermsittiparsert, K.; Ho, L.S.; Alabduljabbar, H.; Alaskar, A.; Alrshoudi, F.; Mohamed, A.M. Application of extreme learning machine in behavior of beam to column connections. Structures 2020, 25, 861–867. [Google Scholar] [CrossRef]

- Purohit, J.; Dave, R. Leveraging deep learning techniques to obtain efficacious segmentation results. Arch. Adv. Eng. Sci. 2023, 1, 11–26. [Google Scholar] [CrossRef]

- Wei, Y.S.; Wang, J.F.; Wang, J.X.; Xu, Q.Y.; Lloret, J. Iteration dependent interval based open-closed-loop iterative learning control for time varying systems with vector relative degree. CAAI Trans. Intell. Technol. 2023, 8, 645–660. [Google Scholar] [CrossRef]

- Tao, Z.H.; Ouyang, C.P.; Liu, Y.B.; Chung, T.L.E.; Cao, Y.X. Multi-head attention graph convolutional network model: End-to-end entity and relation joint extraction based on multi-head attention graph convolutional network. CAAI Trans. Intell. Technol. 2023, 8, 468–477. [Google Scholar] [CrossRef]

- Zhao, L.M.; Sun, Z.B.; Liu, K.P.; Zhang, J.L. The dynamic relaxation form finding method aided with advanced recurrent neural network. CAAI Trans. Intell. Technol. 2023, 8, 635–644. [Google Scholar] [CrossRef]

- Poudel, Y.K.; Bhandari, P. Control of the BLDC Motor Using Ant Colony Optimization Algorithm for Tuning PID Parameters. Archives of Advanced Engineering Science. Arch. Adv. Eng. Sci. 2023, 1–12. [Google Scholar] [CrossRef]

| Specimen | Concrete Grade | Bolt Diameter (mm) | Inner Diameter of Reserved Holes (mm) | (kN) | Preload (kN) |

|---|---|---|---|---|---|

| D16C30 | C30 | 16 | 18 | 80 | 14 |

| D16C40 | C40 | 16 | 18 | 80 | 14 |

| D20C30 | C30 | 20 | 22 | 125 | 25 |

| D20C40 | C40 | 20 | 22 | 125 | 25 |

| Materials | Yield Strength (MPa) | Ultimate or Compressive Strength (MPa) | (MPa) | (MPa) | Young’s Modulus (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 1 | No. 2 | No. 3 | ||||

| Girder | 242.66 | 237.21 | 239.08 | 385.48 | 392.59 | 396.24 | 239.65 | 391.44 | 204.2 |

| Bolt | 637.19 | 615.73 | 620.94 | 789.26 | 773.25 | 784.32 | 624.62 | 782.28 | 204.8 |

| Reinforcement | 419.63 | 417.09 | 424.97 | 557.35 | 555.47 | 561.63 | 420.56 | 558.15 | 205.0 |

| C30 | — | — | — | 32.9 | 33.5 | 33.8 | — | 33.4 | — |

| C40 | — | — | — | 41.7 | 43.1 | 43.6 | — | 42.8 | — |

| Specimen | P When Bolts Slide (kN) | Py (kN) | Δy (mm) | Pu (kN) | Δu (mm) | Py/Pu |

|---|---|---|---|---|---|---|

| D16C30 | 30.008 | 45.214 | 1.075 | 61.622 | 4.529 | 0.734 |

| D16C40 | 36.373 | 52.170 | 1.218 | 63.841 | 2.785 | 0.817 |

| D20C30 | — | 42.962 | 0.185 | 69.504 | 4.673 | 0.618 |

| D20C40 | — | 47.876 | 0.171 | 73.787 | 2.887 | 0.649 |

| Concrete Grade | Bolts Diameter (mm) | Increase Rate of Py | Increase Rate of Δy | Increase Rate of Pu | Increase Rate of Δu |

|---|---|---|---|---|---|

| C30 C40 | 16 | 15.4% | 13.3% | 3.6% | −38.5% |

| 20 | 11.4% | −7.6% | 6.2% | −38.2% | |

| C30 | 16 20 | −5.0% | — | 12.8% | — |

| C40 | −8.2% | — | 15.6% | — |

| No. | Shear Capacity Pu in Experiment (kN) | Shear Capacity Pu-FE in Finite Element Simulations (kN) | Aberration (|Pu-FE − Pu|/Pu) |

|---|---|---|---|

| D16C30 | 61.622 | 61.519 | 0.17% |

| D16C40 | 63.841 | 64.810 | 1.52% |

| D20C30 | 69.504 | 68.883 | 0.89% |

| D20C40 | 73.787 | 75.642 | 2.51% |

| No. | Ps (kN) | (kN) | Pu (kN) | No. | Pu (kN) | No. | Ps (kN) | (kN) | Pu (kN) | No. | Pu (kN) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| B88D16C30P0.75 | 30.87 | 29.33 | 60.00 | B88D20C30P1 | 68.88 | B109D16C30P0.75 | 36.20 | 36.67 | 60.77 | B109D20C30P1 | 70.67 |

| B88D16C30P1 | 38.22 | 39.11 | 61.52 | B88D20C40P1 | 75.64 | B109D16C30P1 | 47.28 | 48.89 | 62.19 | B109D20C40P1 | 75.94 |

| B88D16C30P1.25 | 48.41 | 48.89 | 61.25 | B88D20C50P1 | 76.92 | B109D16C30P1.25 | — | 61.11 | 61.74 | B109D20C50P1 | 77.97 |

| B88D16C40P0.75 | 31.15 | 29.33 | 64.60 | B88D22C30P1 | 71.54 | B109D16C40P0.75 | 36.25 | 36.67 | 66.92 | B109D22C30P1 | 72.61 |

| B88D16C40P1 | 38.17 | 39.11 | 64.81 | B88D22C40P1 | 78.32 | B109D16C40P1 | 47.28 | 48.89 | 67.37 | B109D22C40P1 | 79.16 |

| B88D16C40P1.25 | 46.33 | 48.89 | 65.25 | B88D22C40P1 | 80.01 | B109D16C40P1.25 | — | 61.11 | 66.11 | B109D22C40P1 | 81.40 |

| B88D16C50P0.75 | 30.89 | 29.33 | 66.65 | B109D16C50P0.75 | 36.17 | 36.67 | 68.70 | ||||

| B88D16C50P1 | 38.17 | 39.11 | 66.53 | B109D16C50P1 | 47.26 | 48.89 | 69.58 | ||||

| B88D16C50P1.25 | 46.18 | 48.89 | 66.68 | B109D16C50P1.25 | — | 61.11 | 67.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, P.; Niu, Z.-W.; Shi, Y.-H.; Liu, Y.; Wang, W.-L. Shear Performance of Demountable High-Strength Bolted Connectors: An Experimental and Numerical Study Based on Reverse Push-Out Tests. Buildings 2024, 14, 1052. https://doi.org/10.3390/buildings14041052

Deng P, Niu Z-W, Shi Y-H, Liu Y, Wang W-L. Shear Performance of Demountable High-Strength Bolted Connectors: An Experimental and Numerical Study Based on Reverse Push-Out Tests. Buildings. 2024; 14(4):1052. https://doi.org/10.3390/buildings14041052

Chicago/Turabian StyleDeng, Peng, Zhi-Wei Niu, Yu-Hao Shi, Yan Liu, and Wen-Long Wang. 2024. "Shear Performance of Demountable High-Strength Bolted Connectors: An Experimental and Numerical Study Based on Reverse Push-Out Tests" Buildings 14, no. 4: 1052. https://doi.org/10.3390/buildings14041052

APA StyleDeng, P., Niu, Z.-W., Shi, Y.-H., Liu, Y., & Wang, W.-L. (2024). Shear Performance of Demountable High-Strength Bolted Connectors: An Experimental and Numerical Study Based on Reverse Push-Out Tests. Buildings, 14(4), 1052. https://doi.org/10.3390/buildings14041052