Abstract

The growing interest in digitalization signals a need for technology-oriented supply chain operations in the construction industry. Electronic procurement (e-procurement) aims to convert traditional procurement approaches into web-based/online platforms. Even though e-procurement is an effective tool that may improve supply chain management, the extent of e-procurement implementation has been slow to date. This study investigates the barriers that hinder e-procurement implementation in construction supply chains with the aim of prioritizing solutions to the identified barriers relative to time, cost, quality, and construction owner satisfaction. A comprehensive literature survey was performed, and a focus group discussion was organized for the purpose of the study, which resulted in the identification of 28 barriers. Then, a total of 131 construction practitioners were contacted to evaluate the barriers through a questionnaire survey. The responses were analyzed using the fuzzy Technique for Order Preference by Similarities to Ideal Solution (fuzzy TOPSIS) for prioritization. Finally, 15 semi-structured interviews were conducted to gain a deeper insight into the transformation process from the conventional procurement route to the e-procurement solution. Findings highlight that issues related to unexpected order cancellations, large variations in material costs, and the uncertain nature of the industry that requires a large number of changes are ranked as the most significant barriers. Given the highly competitive environment and the high demand for advanced technologies in the construction industry, a new paradigm can enhance the efficiency of supply chain operations. Exploring and eliminating the potential difficulties of adopting e-procurement in the procurement process may be a good start. Overall, this research is expected to facilitate the transformation of the procurement process by addressing the critical barriers identified by practitioners.

1. Introduction

There is a growing interest in information and communication technologies (ICTs)-based tools [1,2] as a result of the digitalization of the processes in the construction industry. ICT is the integration of hardware, software, and networks to improve the quality of information flow, promote effective communication, and eventually facilitate the decision-making process [3]. Robust ICT implementations can enhance the effectiveness of many organizational processes, including tendering and awarding, project monitoring and controlling, and material purchasing and storage [1,4]. Although various obstacles have often been encountered in the application of these technologies across the industry [5], successful implementations of ICT offer a chance to explore new models, procedures, and products, particularly in logistics and supply chain management [6].

Robust supply chain management initiatives have become increasingly important in the construction industry due to the industry’s project-based environment and multi-stakeholder process [7,8]. Collaborative relationships among the involved parties improve efficiency and quality in coordinating supply chain activities and improving the production process [7,9]. In other words, effective material flow management reduces cost overrun, time escalation, and quality defects [10]. However, it must also be noted that several adversities have been reported in supply chain management and have been recognized as a significant burden in achieving the targeted objectives in construction projects [11]. For instance, past research addressed problems such as project managers usually having significant concerns about inefficient payment practices, lack of trust between supply chain partners, and site layout/material handling issues that hamper supply chain performance [10,12,13,14]. Here, the setbacks in the improvement of supply chain processes can be attributed to three sector-related issues: (1) the temporary nature of construction projects [15], (2) variations in design and inadequate production processes [16], and (3) the multiple and different needs of the many stakeholders in construction projects [17]. Given the high level of uncertainty in the industry, innovative supply chain activities that introduce more connected, secure, transparent, and flexible solutions [18] may have a critical role both in facilitating supply–demand connections and in improving overall supply chain performance [14,19].

One of these innovative applications involves using electronic supply chain (e-supply chain) processes, which has drawn significant attention among researchers [20,21]. The e-supply chain can be defined as an integration of Internet technologies across all processes in the supply chain, such as production, planning, procurement, inventory management, distribution, and logistics [21,22,23]. Among a plethora of e-supply chain processes, e-procurement (that is, an electronically performed set of procurement activities), is an indispensable element [24] since issues encountered in traditional procurement might incur hidden risks that can pose threats to the subsequent processes of supply chain management [25]. E-procurement platforms present important opportunities for industry practitioners to minimize a wide range of issues, such as order errors, conflicts between stakeholders, and timeouts in material delivery, beyond traditional procurement operations [26,27]. Despite the strategic and operational advantages of electronic applications [28,29], industry stakeholders usually raise concerns about the use of electronic applications in supply chain management [30,31]. Indeed, companies report experiencing challenges relative to capacity, cost, quality, and customer service under competitive market conditions [32]. As a result, procurement systems may have a significant impact not only on cost and time but also on dispute propensity in construction projects [26,33].

The main research focus of this study is to understand the barriers and challenges during the integration of e-procurement procedures into construction supply chains. Accordingly, the aim is to identify and evaluate the barriers to using the e-procurement process in the context of time, cost, quality performance, and construction owner satisfaction. To accomplish this objective, (1) a comprehensive literature review was conducted to establish a list of e-procurement barriers; (2) a focus group discussion (FGD) was undertaken to revise and finalize the list of barriers; (3) a questionnaire survey was performed to collect data about the final list of barriers; (4) fuzzy TOPSIS was used to prioritize the barriers; and (5) semi-structured interviews were performed to understand the underlying reasons of continuing to use traditional procurement practices. Overall, the findings of this study are expected to inform not only researchers but also practitioners about the importance and advantages of using e-procurement practices in the construction industry. It is expected that the practical implications of this study will include (1) identifying the barriers to e-procurement adoption and implementation, (2) ranking these barriers by importance relative to project performance criteria, and (3) allowing practitioners to overcome these barriers and achieve a smooth transition from traditional procurement to e-procurement.

2. Literature Review

2.1. The Role of E-Procurement in Digital Supply Chains

A supply chain is defined as a network of organizations that are involved in executing different operational processes and activities to add value (through upstream and downstream relationships) in delivering products and/or services to customers [34,35]. Having a robust supply chain network is very important for construction companies [36] since delivery on time, cost reduction, and managerial efficiency are ensured by effective supply chain practices [37,38]. Innovative technologies in supply chain management lead to rapid improvements in handling supply chains and allow companies to gain a competitive edge and satisfy the rising demands of customers [39]. In the digitalization era, the “e-supply chain” is regarded as a key innovative element of a company’s business model designed to improve supply chain management [23]. The concept of the “e-supply chain” has significant potential not only in ensuring decision making and process efficiency [40,41] but also in monitoring and controlling business operations [42].

Digital transformation and automation in the procurement process in the construction supply chain can be achieved via Internet-based technologies such as e-procurement or e-commerce [28,43]. As an inseparable part of data-driven supply chain management [44], e-procurement can be defined as a web-based application enhancing packages, tools, workflow systems, and procedures, aiming to automate procurement processes [45]. The Internet/web-based technologies can further provide companies and their supply chain partners with various opportunities and ways to develop new e-business models [46]. Implementations of e-procurement can enable faster delivery of orders, elimination of errors, and healthy exchange of information [47]. Hence, according to Atluri et al. [48], establishing web-based, data-driven, and technology-enabled practices in supply chain operations is likely to offer more responsive, agile, and resilient business models. Overall, Pourmorshed and Durst [49] claim that companies with digitalized supply chains can increase long-term organizational sustainability and continuity.

2.2. Past Studies on E-Procurement Implementation

There has been extensive research focusing on multiple aspects of electronic systems used to improve procurement processes. The impacts of e-procurement systems on supply chain performance were specifically investigated in many of the studies. For instance, Pattanayak and Punyatoya [14] employed structural equation modelling (SEM) to delineate the impacts of e-procurement and supply chain technology internalization on supply chain performance in the construction industry. The researchers found that e-procurement implementation had a significant impact on supply chain performance. A similar research question was also raised by Wijaya [50] to assess whether there is a positive association between e-procurement implementation and supply chain performance for small and medium-sized enterprises (SMEs). They found a positive and significant link between the two concepts and highlighted the role of transparency and effectiveness of the system in the successful implementation of e-procurement practices. For SMEs, Madzimure et al. [47] examined the relationships among diverse forms of e-procurement (e-sourcing, e-design, e-informing, e-negotiation, and e-evaluation), supplier integration, and tangible and intangible aspects of supply chain performance. The researchers discovered that e-sourcing, e-evaluation, and e-informing did not improve supplier integration within SMEs but increased overall supply chain performance significantly. Similarly, Chang et al. [51] investigated the contribution of e-procurement to supply chain performance (in terms of cost and capacity utilization) through partner relationships, information sharing, and supply chain integration. Other researchers underscored the positive impact of e-procurement on firm performance, in addition to supply chain performance [52,53].

Even though e-procurement is considered to be one of the instruments boosting firm performance, understanding the issues and/or hindrances of adopting e-procurement is essential for companies [19]. As in traditional procurement systems, practitioners may encounter issues such as data security, poor integration with existing systems, and transparency in supply chain operations [54]. The literature highlights that, unlike e-procurement in other industries, such as manufacturing, e-procurement in construction involves highly complex and challenging system operations [55]. While Eadie et al. [31] investigated how drivers and barriers to construction e-procurement vary from country to country, Eadie et al. [27] examined the drivers and barriers to e-procurement and their perceived differences between public and private organizations. In both studies, it was found that the importance of drivers of and barriers to an e-procurement system depends on the subjective perceptions of the individuals who participated in the study. Although past efforts examined e-procurement implementations in construction as well as their effects on the performance of the supply chain, none of the past studies ranked the barriers to e-procurement on the basis of project performance criteria such as time, cost, quality, and construction owner satisfaction. Studies that specifically focused on barriers to e-procurement are discussed in the following sub-section.

2.3. Studies on Barriers to E-Procurement Adoption/Implementation

Several studies have been conducted to identify the barriers that hinder e-procurement implementation in the construction industry [27,30,56]. In one of the studies, Yevu et al. [56] performed a systematic literature review to discover the nature of the relationships among barriers to e-procurement in the construction industry and found that organizational/individual resistance to change, which was found as one of the critical barriers, was strongly associated with lack of trust and inadequate technical capability. Similarly, the findings by Isikdag [30], who investigated e-procurement barriers grouped into four categories, namely technological, organizational strategy, marketing, and human and process factors in the Turkish construction industry, also underlined the barrier of “lack of trust”. Yevu et al. [26] pursued a different research direction and compared barriers to and strategies for e-procurement in the construction industry in developed and emerging economies. The researchers concluded that practitioners in both developed and emerging economies had similar views on the importance of barriers related to unethical practices (electronic authentication issues), financial concerns, and technical capabilities.

Investment in e-procurement includes initial cost, maintenance cost, hiring cost, training cost, and Internet service cost [56]. The high cost of using e-procurement systems causes organizations to focus on cost rather than performance gains, which, in turn, leads to cost/benefit concerns [24]. Aduwo et al. [43] and Farzin and Nezhad [57] considered high investment costs to be a key economic/financial barrier. Other studies examining barriers to e-procurement highlighted a variety of issues, such as potential cyber-attacks on the supply network [28], security concerns [24], cultural attitudes [58], insufficient ICT infrastructure [43,55], and unreliable power supply [43,55].

Although multi-criteria decision-making (MCDM) methods can be powerful for evaluating several and sometimes conflicting criteria, such as benefits and/or barriers related to a particular issue, there have been only a few attempts to adopt MCDM tools in the pertinent literature. For instance, the ICT-related risks of e-procurement were ranked by Ramkumar [59] by means of a modified fuzzy analytical network process (fuzzy ANP). Similarly, Ramkumar et al. [60] identified the risks of e-procurement by using SWOT analysis, and they then used a modified fuzzy ANP to assess the risks of e-procurement in manufacturing industries. In another study, fuzzy analytical hierarchy process (AHP) [61] was used to rank the factors affecting green e-procurement through a cloud model in hospitals [62]. MCDM tools were not used in any study to rank e-procurement barriers by their relative importance in the construction industry. In this study, fuzzy MCDM is performed to rank the barriers affecting the adoption of e-procurement in the construction industry based on their importance relative to several project performance criteria.

3. Methodology

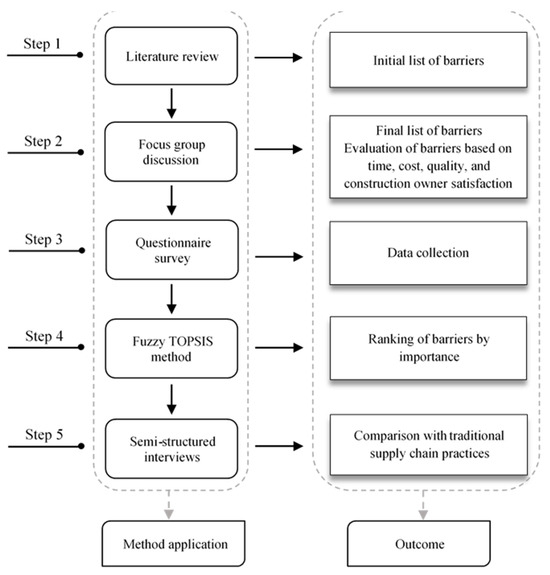

The research methodology consists of five steps (literature review, focus group discussions, questionnaire survey, fuzzy TOPSIS method, and semi-structured interviews) as explained in the following sections (Figure 1).

Figure 1.

Flowchart of the research.

3.1. Literature Review

Initially, a systematic literature review was conducted to generate a list of barriers to e-supply chain and e-procurement. Relevant studies were identified using the Scopus search engine due to its well-established, effective, dependable search tools as well as extensive coverage [33,63]. The following three query strings were searched in the “Title/Abstract/Keywords” field of Scopus to limit the scope of the review, resulting in 65 research papers:

- String: TITLE-ABS-KEY (“e-supply” OR “e-procurement” OR “electronic supply” OR “electronic procurement”) AND

- String: TITLE-ABS-KEY (“barrier” OR “risk” OR “challenge” OR “enabler” OR “driver”) AND

- String: TITLE-ABS-KEY (“construction”)

In the next step, the collected materials were restricted to include only journal articles, which yielded 33 research papers published between 2001 and 2022. In the final step, the papers that are not directly related to e-procurement barriers or risks and that focus on technology rather than its implementation were eliminated, as a result of which 13 studies were found to be suitable for this study in the first search.

To achieve a more comprehensive understanding of the barriers to e-procurement, the third query string consisting of the keyword “construction” was excluded from the search, which resulted in 538 studies. Then, the type of publication was limited to “article” (search result: 255 studies), and irrelevant subject areas such as chemistry, medicine, and energy were removed from the search space (search result: 213 studies). The full papers of these 213 studies were carefully screened. After removing the duplicates between this search and the first search, 20 papers were found to be relevant to this study in addition to the original 13 papers identified in the first search. In total, 33 papers that addressed barriers affecting e-procurement were reviewed.

3.2. Focus Group Discussion (FGD)

A focus group discussion is an exploratory approach aiming to generate knowledge by means of dynamic interactions among experts [64]. After a comprehensive literature review, 79 barriers were identified in the 33 studies considered in this study. These 79 barriers were examined by a group of experts in a focus group discussion. Some of the 79 barriers were straightforward and accepted, some were irrelevant and rejected, some were merged to consolidate ideas and avoid duplication, and some were split to discriminate better. In addition, the experts were encouraged to add barriers that were overlooked in the literature. This method was used to (1) elicit the perspectives of the experts relative to the barriers [65], (2) assess the appropriateness of the barriers for use in the study [66], and (3) establish the synthesized and revised final list of barriers to e-procurement [67].

Ajayi and Oyedele [68] suggested between 5 and 25 experts with a proper background in the subject to perform effective focus group discussion, whereas Nyumba et al. [69] recommended between 3 and 21 experts. While a large number of participants (e.g., 20 to 50) may increase the complexity of the operation, a low number of participants (e.g., 2 to 5) may hinder the generation of creative ideas and solutions [70,71]. In this study, seven eligible construction professionals agreed to share their opinions, knowledge, and experiences in the focus group discussions. Participants were selected based on their educational background and their position in the construction industry and supply chain management. Experts were selected from companies at random. All participants had between 12 and 35 years of experience in both the construction industry and supply chain management. The profiles of the seven professionals who participated in the focus group discussions are presented in Table 1, marked by an asterisk.

Table 1.

Profiles of the participants who contributed to semi-structured interviews.

There were mainly three outputs of the focus group discussions: (1) removing the irrelevant barriers from the list made after the literature review, (2) merging similar barriers to improve clarity and eliminate duplication, and (3) including additional barriers that are considered to be important by the experts. The list of the final 28 barriers identified at the end of group discussions is presented in Table 2.

Table 2.

List of barriers affecting e-procurement.

3.3. Questionnaire Survey

A questionnaire survey was conducted to assess the importance of 28 barriers identified after the focus group discussions. The participants were asked to evaluate the importance of 28 barriers relative to time, cost, quality, and construction owner satisfaction using a seven-point Likert scale (1 = least important and 7 = extremely important). The reason for using the seven-point Likert scale was its higher measurement precision compared to the five-point Likert scale [80].

The questionnaire was sent to 198 construction professionals, and a total of 162 questionnaires were received. Of them, 131 valid responses were obtained after excluding questionnaires with incomplete data, resulting in a response rate of 66%. The profiles of the respondents are provided in Table 3.

Table 3.

Profile of the participants to focus group discussions (n = 131).

The reliability of the collected data was checked by calculating the Cronbach alpha coefficient, which turned out to be α = 0.98. Cronbach’s alpha coefficient needs to be above the threshold of 0.70, and a Cronbach’s alpha coefficient greater than 0.90 indicates excellent internal consistency [81].

3.4. Fuzzy TOPSIS

In this study, TOPSIS was used alongside fuzzy set theory (i.e., fuzzy TOPSIS) to identify the most important e-procurement barriers. TOPSIS was adopted in this study due to (1) its high performance in one-tier decision trees, (2) its wide use in a variety of research fields for ranking problems, and (3) its similarity to the principles of the human decision-making process [82,83]. TOPSIS was developed by Hwang and Yoon [84] and offers a solution based on the minimum distance to the positive ideal solution and the longest distance to the negative ideal solution [85]. The working principle of fuzzy TOPSIS, which is well-suited for the rankings of various alternatives under different subjective criteria, is the main reason for researchers to adopt this method [82]. This approach was also selected due to its simplicity, enabling easy conversion of the triangular fuzzy numbers into crisp values [86,87]. In fuzzy TOPSIS, time, cost, quality, and construction owner satisfaction were recognized as the four criteria and were used to rank the 28 barriers. Construction projects often experience cost overruns, delays, quality failures, and owner dissatisfaction, making cost, time, quality, and owner satisfaction the major factors influencing project success in the construction industry, more so than in other industries [88,89]. The linguistic expressions of the responses and the corresponding triangular fuzzy numbers used in this study are provided in Table 4 [85].

Table 4.

Linguistic scale used in Fuzzy TOPSIS.

The procedure to conduct fuzzy TOPSIS analysis was as follows [90]:

Step 1: The crisp judgments of the experts were transformed into appropriate triangular fuzzy numbers (Table 4). Crisp values (such as 6 for very important) were used in the data collection process and then converted to corresponding triangular fuzzy numbers (such as (7, 9, 10)). The ratings of the barriers are aggregated for each criterion by using Equation (1).

In this equation, = is a triangular fuzzy number, k is the number of respondents, m is the number of barriers (28), and n is the number of criteria (4).

Step 2: A normalized fuzzy decision matrix is obtained by using a linear scale transformation by using Equations (2) and (3). Here, normalized values were computed by dividing each element in the triangular fuzzy numbers to the maximum possible value in the corresponding matrix [91].

Step 3: A weighted normalized fuzzy decision matrix is calculated by using Equation (6), where denotes the relative weight of criteria (Cj). In this step, the corresponding matrix was calculated by multiplying criteria weights and the values in the normalized decision matrix, as the weights of the criteria differ from each other [92].

Step 4: The fuzzy positive ideal reference point (FPIRP, ) and fuzzy negative ideal reference point (FNIRP, ) are determined using Equations (7) and (8), respectively.

The distance of each barrier from and are calculated by using Equations (9) and (10), respectively.

where is the distance of barrier i from FPIRP, and is the distance of barrier i from FNIRP. On the other hand, the distance between two fuzzy numbers can be calculated by using Equation (11) [85].

Step 5: The closeness coefficient ( of each criterion is calculated by using Equation (12). It means that the distance of each criterion from the fuzzy negative ideal solution was divided by the sum of its distance from the fuzzy positive and negative ideal solutions [93].

The barrier with the highest closeness coefficient () is the closest to the FPIRP and farthest from the FNIRP. Thus, the ranking of the barriers to the adoption and implementation of e-procurement can be determined by comparing the closeness coefficients ().

3.5. Semi-Structured Interviews

The information on traditional e-procurement practices in construction projects was examined via semi-structured interviews comprising four open-ended questions asked to 15 construction professionals.

- What kind of procurement process is currently used in your company?

- What are the underlying challenges that you encounter in the traditional procurement process?

- What are your observations about the major advantages of the traditional procurement process?

- Would you like to use an e-procurement system? Do you have any ideas or opinions about e-procurement that you would like to add?

The major reasons for using semi-structured interviews include (1) to collect qualitative data that could enhance the reliability and validity of the study [94,95]; (2) to provide participants with the freedom to express their views and thoughts on a specific topic, namely e-procurement [94,96]; and (3) to provide flexibility for participants to move beyond the core question and answers to uncover hidden patterns [96,97].

According to Bahadorestani et al. [98], semi-structured interviews should be conducted with 10 to 20 experts with appropriate backgrounds in the subject in question. In this study, the participants in the semi-structured interviews included 15 construction professionals who also participated in the questionnaire survey. The following criteria were used to evaluate the eligibility of the participants for this task: (1) working in different positions for construction companies (e.g., purchasing director, project manager, site engineer, and contract administrator), (2) having at least 15 years of experience in the construction industry, (3) having a high educational level, and (4) having at least five years of experience in supply chain management. The profiles of the interviewees are shown in Table 1.

4. Results

The responses were analyzed by using fuzzy TOPSIS, and Table 5 shows the closeness coefficients () and the rankings of the barriers to the adoption and implementation of e-procurement in construction. The results indicate that the top three barriers include issues related to unexpected order cancellations (B28) with a of 0.5538, large variations in material costs (B3) with a of 0.5502, and the uncertain nature of the industry that requires high number of changes (B16) with a of 0.5482.

Table 5.

Results of fuzzy TOPSIS.

Concerning the four assessment criteria, the barrier of greatest importance relative to the cost criterion was B3, high variations in material costs with a CC of 5.504, followed closely by B4, high competitiveness which may result in quality issues relative to the quality criterion with a CC of 5.397, and B28, issues related to unexpected order cancellations relative to the time criterion with a CC of 5.260, while B3 was found to have the greatest importance relative to the cost criterion. Regarding the quality and construction owner satisfaction criteria, high competitiveness which may result in quality issues (B4), was the most critical barrier.

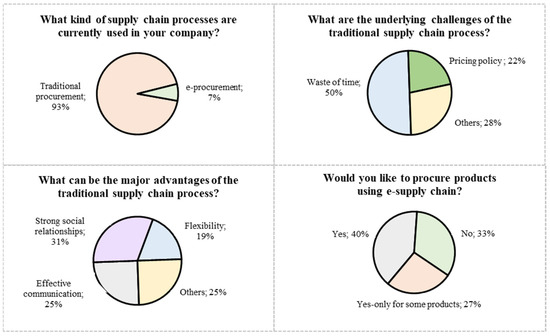

Figure 2 presents the answers of the semi-structured interview participants. The overwhelming majority of them (93%) pointed out that the traditional procurement method was used in their company (Figure 2). An interviewee defined this process as follows: “(1) to propose a purchase request, (2) to study a proposal for selecting a suitable supplier among different alternatives, (3) to pick a firm that meets their expectations in terms of both price and other needs, and (4) to sign a contract with the selected firm”. On the other hand, another interviewee stated that they usually integrated digital support tools into the traditional procurement process in their supply chain operations.

Figure 2.

Summary of collected data from semi-structured interviews (n = 15).

According to Figure 2, half of the interviewees considered the traditional system to be time-consuming due to the lengthy procedures in the purchasing processes, the late feedback and reactions, and the slowness of the decision-making mechanism. Additionally, 22% of the participants pointed out that a pricing policy that involves ever-increasing prices at consistently large increments could hinder the supply process. Moreover, they also mentioned several other challenges in using traditional procurement, such as planned budget overrun, difficulty of communication between parties, inability to react to problems in a timely manner, and issues in conflict resolution (Others (28%) in Figure 2).

Despite the above-mentioned challenges of the traditional procurement method, several advantages were also articulated (Figure 2). The opportunity in traditional procurement to establish strong social/informal relationships with the suppliers was considered by 31% of the participants as a distinct advantage, as close personal relationship often creates a relaxed environment to discuss and resolve issues with mutual satisfaction. For example, an interviewee stated that “since in traditional procurement there is more dialogue with the supplier, it can be more effective in bargaining and in dealing with extraordinary conditions (e.g., the urgency of the purchase, the quick supply of samples to potential customers, and the shipping of sample products). By-products of strong relationships were identified by 25% of the interviewees as effective communications and by 19% as flexibility in decision making.

Concerning the transition from traditional procurement to e-procurement, only 40% of the interviewees expressed their willingness to do so (Figure 2), whereas many interviewees (33%) answered that they were not ready to switch to e-procurement, emphasizing that close bilateral relations were important and that manual processes were more reliable. Interestingly, 27% of them stated that they could use e-procurement only for some specific products and/or services.

5. Discussion

The opportunities presented by web-based platforms have enabled companies to improve their supply chain performance relative to efficiency, cost, and time [14]. Companies can shift their operations from traditional procurement to e-procurement to leverage the many benefits of digitalization and to gain a competitive advantage over their competitors in the long run [99]. The construction industry undergoes compelling transformations to adapt to changes [100], and the digitalization of the supply chain in construction operations is critical in modernizing the existing business management strategies [101]. Although several studies have indicated that the rate of adaptation to the rapidly changing construction industry is slow, it is even slower when it comes to adopting digital technologies [102]. The ability of construction firms to adjust to changes is recognized as a fundamental competency for remaining competitive in the market [103]. A change in the procurement process can also be considered to be one of the major changes occurring in the construction industry, as evidenced by the finding presented in Table 5 that the uncertain nature of the industry that requires a large number of changes (B16) was ranked by focus group participants in this study as one of the most important barriers to adopting and implementing e-procurement in construction firms.

Competitiveness, which drives various efforts on the part of construction companies and project teams, is another distinctive feature of the construction sector [104]. To survive and thrive in a highly competitive market amid the changing expectations of stakeholders, construction companies usually seek to diversify their products and operations [105] and to improve their management practices, including digitizing the supply chain management [106]. It must be noted, however, that efforts to remain competitive can give rise to quality trade-offs [107], leading to numerous claims and sometimes legal disputes [108]. Indeed, according to the focus group participants in this study, a shift from traditional procurement to e-procurement to remain competitive in the marketplace may come at a cost since, according to the information in Table 5, high competitiveness may result in quality issues (B4), a barrier to e-procurement that was identified by the respondents as having the greatest importance in construction quality and construction owner satisfaction in Table 5. Due to a lack of interaction and poor communication between the stakeholders in e-procurement [30], the severity and frequency of quality issues observed during supply chain operations can lead to numerous claims/disputes and a loss of trust between the parties [109,110]. In the e-procurement environment, firms tend to focus primarily on the purchasing cost of products and services rather than the established quality standards, resulting in a lower quality of project deliverables [111]. In this regard, open and transparent communications between construction companies and suppliers are of vital importance in dealing with quality deficits [112] and avoiding legal disputes [113].

It was found in this study that large variations in material costs (B3) are the second most critical barrier to adopting and implementing e-procurement. It was also the most important barrier affecting the cost of construction. Several researchers reported that severe fluctuations in material prices significantly affect delivering projects on time, within budget, and with expected quality standards [111,114]. The reason for large price variations can be related to the digital pricing mechanisms adopted by many companies that may generate an uncontrolled widening of the gap between supply and demand. This glitch in some e-procurement platforms may cause significant and rapid changes in material prices in response to changing market conditions, which makes trading in such high uncertainty challenging for many firms [115].

Information and communication technologies constitute a foundation for the development of online purchasing systems for construction firms to use [116]. However, the actual stocks of the suppliers and the volume of buyers’ orders cannot be known precisely in e-commerce business models such as business-to-business and business-to-consumer. When inventory verification for a purchase order is performed after an existing order is completed, a decrease in demand can sometimes in demand, resulting in unexpected order cancellations [117]. Among the 28 barriers cited in Table 5, issues related to unexpected order cancellations (B28) were found to be the most important barrier overall and the most important barrier relative to the time criterion. The lack of appropriate contracts outlining the rights and responsibilities of the contractors and suppliers, as well as the inadequate administrative procedures for settling conflicts between contractors and suppliers, may create problems when cancellations are requested. Just-in-time purchasing is advised by Liu and Nishi [118] to minimize issues that may arise due to order cancellations. Ouyang et al. [119] claim that just-in-time purchasing can contribute to the performance of supply chains by shortening the lead time between order and delivery, removing extra expenditures, and enhancing service quality of the customers, while according to other researchers (e.g., Abbasi et al. [120], Abbasi et al. [121]), just-in-time purchasing increases the likelihood of large delays in deliveries and consequently may cause large delays in project completion resulting in the contractor paying liquidated damages to the construction owner.

It is important to note that construction companies are usually reluctant to adopt new technologies [122]. As a result, as seen in Figure 2 and asserted by [123], construction companies’ procurement operations have chiefly been conducted using traditional procurement methods. Unfortunately, this process is prone to fluctuations in price depending on the type of product, the volume of the demand, and the level of urgency in the delivery [124]. In addition, as shown in Figure 2, the time-consuming process of traditional procurement is an important challenge. This challenge is usually conducive to errors in the procurement procedure, including mistakes made in orders, mistakes made in delivery, return of products to the supplier, and long waits for replacements [125]. Construction supply chains inherently require building trust as well as a strong relationship and effective communication between contractors and suppliers. According to the information in Figure 2, this practice is considered by the members of the focus group to be the most important advantage of traditional procurement in overcoming potential difficulties that may occur during the procurement process [126]. Overall, Figure 2 indicates that the number of respondents who do not wish to use e-procurement is not low (33%), possibly because these responses are associated with the perceived dramatic reductions in human activities and interactions [56].

This study confirms the findings of some past studies on e-procurement barriers but also points out some differences relative to the findings in some other research studies. For example, the finding that unexpected order cancellations (B28) are one of the most critical barriers to the adoption and implementation of e-procurement confirms the findings of [78]. Some of the barriers found to be important, such as large variations in material costs (B3), highly competitive marketplace that may result in quality issues (B4), and uncertain nature of the industry that may necessitate frequent change orders (B16), were also found to be important in some other studies [43,56,58].

The investigation of technology-supported supply chain implementations has become more prominent in recent years in the literature. For instance, Joshi and Sharma [127] found that digital supply chains have a variety of functions and advantages, such as dynamic fulfilment capability, decision-making support, and high-transparency digital procurement. Zilin et al. [128] performed semi-structured interviews to explore participants’ experiences with blockchain in construction supply chain and highlighted the increasing transparency, trust, and security in supply networks. Zekhnini et al. [129] performed a literature review to explore the impact of different technologies on supply chain processes and developed a roadmap for future practice.

From the methodological lens, one of the distinctive features of this study is the use of fuzzy TOPSIS to rank the e-procurement barriers by their importance. Most of the extant literature on e-performance involves simple statistical analysis [26,74,130], even though statistical analysis is based on determinate principles that do not reflect real-life conditions since human judgments are uncertain and most real-life questions require consideration of multiple and conflicting criteria. In this study, fuzzy TOPSIS is used where each expert’s linguistic expression is converted to its triangular fuzzy equivalence [131], and the overall ranking is conducted by considering several performance criteria.

6. Managerial Implications

In this study, the barriers to the adoption and implementation of e-procurement in construction are identified and evaluated for the purpose of easing the transition from traditional procurement to e-procurement. Ranking barriers to e-procurement by importance to practitioners helps supply chain administrators and project managers focus on the key barriers that need to be overcome. Therefore, the conditions under which supply chain processes can be digitalized more effectively are examined in this study. It is expected that the uncertainties and deficiencies of traditional procurement can be reduced, thereby boosting supply chain efficiency and eventually improving project performance. The results of this study can assist managers in developing appropriate supply chain strategies to promote better project performance since the proposed ranking framework offers a linkage between the barriers and the critical project success factors. This can also allow managers to focus on the key barriers for specific performance criteria. E-procurement is expected to provide enhanced real-time information sharing, improved communication, and long-lasting, trust-based, data-driven relationships between contractors and suppliers.

7. Conclusions

E-procurement plays a critical role for construction companies in adapting to the rapidly changing business environment. However, contractors and suppliers in the construction industry have encountered substantial challenges and barriers to e-procurement adoption and implementation. In this study, the barriers to adopting and implementing e-procurement were identified by conducting a comprehensive literature review and focus group discussions. These barriers were investigated using a questionnaire survey administered to practitioners to assess their impact on project outcomes, including time, cost, quality, and construction owner satisfaction, followed by the use of fuzzy TOPSIS to rank the barriers by relative importance. The major findings and corresponding contributions of the current research can be stated as follows:

- Although there are studies that investigated how to improve supply chain management in both developed and developing countries, this study investigated the barriers to the adoption and implementation of e-procurement in the construction industry with a particular emphasis on project performance criteria, including time, cost, quality, and construction owner satisfaction. The paradigm developed in this study improves the viability of e-procurement by reducing the negative impacts of the most important barriers and by supporting data-driven real-time supply chain management, collaborative relationships between contractors and suppliers, and streamlined and efficient procurement processes.

- The highly competitive and uncertain nature of the marketplace causes quality issues, material price fluctuations, order cancellations, and a large number of change orders. This situation was found to instigate the key barriers to the adoption and use of e-procurement. The barriers mentioned in the literature were identified and refined by seven practitioners who participated in focus group discussions by contributing with their extensive knowledge and experience in the industry and in supply chain management. The resulting list of barriers was organized as a questionnaire that was administered to 131 professionals. This was followed by a series of fifteen semi-structured interviews. It can be stated with confidence that identifying the most critical barriers to the use of e-procurement by using this thorough and comprehensive analysis is expected to have a significant positive impact on the efficiency of supply chain management.

- Semi-structured interviews showed that traditional procurement relies on contractors and suppliers being able to develop trust between them and appreciate manual labor rather than technology-driven solutions. However, minimizing the effects of the barriers to the use of e-procurement can not only create trust between contractors and suppliers but also facilitate the inevitable digital transformation of supply chain management in the construction industry.

Like any research study, this study too has some limitations. One of the limitations is that the interview and questionnaire survey findings were based on the participants’ perceptions of working in the Turkish construction industry. Since their opinions may be affected by the conditions specific to Türkiye, the barriers investigated in the study and the rankings of the barriers may be different in other countries. Another limitation is that even though all participants in the survey and the subsequent interviews were very familiar with supply chain management, only a few of them had used e-procurement. Hence, some of the barriers may have been overlooked by the participants. It would be desirable to survey and interview two distinct groups of participants in future research, one group composed of traditional procurement managers and the other of e-procurement managers. Finally, the barriers were ranked based on four performance criteria, including time, cost, quality, and construction owner satisfaction. Further studies could evaluate additional performance criteria such as communication, productivity, data security, and competitiveness. In addition, the research can also be extended by considering potential opportunities for digital tools, similar to other studies [132,133]. Despite these limitations, this study provides guidance for construction companies aiming to enhance e-procurement practices by addressing essential issues to promote successful transition routes. Overall, given that digitalization is inevitable and underway in many construction companies, the findings of this study are expected to help practitioners smoothly transition from traditional procurement to e-procurement, providing an opportunity to implement real-time information sharing and data-driven supply chain operations.

Author Contributions

Conceptualization, A.P.G. and K.K.; Methodology, K.K. and H.K.; Validation, D.A., A.P.G., K.K. and H.K.; Formal Analysis, K.K.; Investigation, K.K. and H.K.; Writing—Original Draft Preparation, A.P.G., K.K., S.A. and H.K.; Writing—Review and Editing, A.P.G., K.K., D.A. and S.A.; Visualization, K.K. and H.K.; Supervision, A.P.G. and D.A.; Project Administration, D.A., A.P.G., K.K., S.A. and H.K. All authors have read and agreed to the published version of the manuscript.

Funding

The work described in this paper was supported by the Coordinatorship of Scientific Research Projects of the Yildiz Technical University (Project ID: FBA-2023-5472).

Data Availability Statement

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sukanthan Rajendra, D.; Hon, C.K.H.; Manley, K.; Lamari, F.; Skitmore, M. Key Dimensions of the Technical Readiness of Small Construction Businesses That Determine Their Intention to Use ICTs. J. Manag. Eng. 2022, 38, 04022055. [Google Scholar] [CrossRef]

- Camngca, V.P.; Amoah, C.; Ayesu-Koranteng, E. Underutilisation of information communication and technology in the public sector construction project’s implementation. J. Facil. Manag. 2022, 22. [Google Scholar] [CrossRef]

- Vatovec Krmac, E. Modern information communication technologies and tools for supply chain management. Promet Traffic Traffico 2005, 17, 303–309. [Google Scholar]

- Hadaya, P.; Pellerin, R. Determinants of construction companies’ use of web-based interorganizational information systems. Supply Chain Manag. 2010, 15, 371–384. [Google Scholar] [CrossRef]

- Dixit, S.; Stefańska, A.; Musiuk, A.; Singh, P. Study of enabling factors affecting the adoption of ICT in the Indian built environment sector. Ain Shams Eng. J. 2021, 12, 2313–2319. [Google Scholar] [CrossRef]

- Fernandez-Vazquez, S.; Rosillo, R.; de la Fuente, D.; Puente, J. Blockchain in Sustainable Supply Chain Management: An Application of the Analytical Hierarchical Process (AHP) Methodology. Bus. Process Manag. J. 2022, 28, 1277–1300. [Google Scholar] [CrossRef]

- Xue, X.; Wang, Y.; Shen, Q.; Yu, X. Coordination mechanisms for construction supply chain management in the Internet environment. Int. J. Proj. Manag. 2007, 25, 150–157. [Google Scholar] [CrossRef]

- Segerstedt, A.; Olofsson, T. Supply chains in the construction industry. Supply Chain Manag. Int. J. 2010, 15, 347–353. [Google Scholar] [CrossRef]

- Mei, T.; Qin, Y.; Li, P.; Deng, Y. Influence Mechanism of Construction Supply Chain Information Collaboration Based on Structural Equation Model. Sustainability 2023, 15, 2155. [Google Scholar] [CrossRef]

- Heaton, R.; Martin, H.; Chadee, A.; Milling, A.; Dunne, S.; Borthwick, F. The Construction Materials Conundrum: Practical Solutions to Address Integrated Supply Chain Complexities. J. Constr. Eng. Manag. 2022, 148, 04022071. [Google Scholar] [CrossRef]

- Yoon, J.H.; Pishdad-Bozorgi, P. State-of-the-Art Review of Blockchain-Enabled Construction Supply Chain. J. Constr. Eng. Manag. 2022, 148, 03121008. [Google Scholar] [CrossRef]

- Nanayakkara, S.; Perera, S.; Senaratne, S.; Weerasuriya, G.T.; Bandara, H.M.N.D. Blockchain and smart contracts: A solution for payment issues in construction supply chains. Informatics 2021, 8, 36. [Google Scholar] [CrossRef]

- Tezel, A.; Febrero, P.; Papadonikolaki, E.; Yitmen, I. Insights into Blockchain Implementation in Construction: Models for Supply Chain Management. J. Manag. Eng. 2021, 37, 04021038. [Google Scholar] [CrossRef]

- Pattanayak, D.; Punyatoya, P. Effect of supply chain technology internalization and e-procurement on supply chain performance. Bus. Process Manag. J. 2020, 26, 1425–1442. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Law, K.H.; Bjornsson, H.; Jones, A.; Sriram, R. A service oriented framework for construction supply chain integration. Autom. Constr. 2010, 19, 245–260. [Google Scholar] [CrossRef]

- Bankvall, L.; Bygballe, L.E.; Dubois, A.; Jahre, M. Interdependence in supply chains and projects in construction. Supply Chain Manag. 2010, 15, 385–393. [Google Scholar] [CrossRef]

- Aloini, D.; Dulmin, R.; Mininno, V.; Ponticelli, S. Supply chain management: A review of implementation risks in the construction industry. Bus. Process Manag. J. 2012, 18, 735–761. [Google Scholar] [CrossRef]

- Gharaibeh, L.; Eriksson, K.M.; Lantz, B.; Matarneh, S.; Elghaish, F. Toward digital construction supply chain-based Industry 4.0 solutions: Scientometric-thematic analysis. Smart Sustain. Built Environ. 2022, 13, 42–62. [Google Scholar] [CrossRef]

- Charpin, R.; Lee, M.K.; Wu, T. Mobile procurement platforms: Bridging the online and offline worlds in China’s restaurant industry. Int. J. Prod. Econ. 2021, 241, 108256. [Google Scholar] [CrossRef]

- Siddiqui, A.W.; Raza, S.A. Electronic supply chains: Status & perspective. Comput. Ind. Eng. 2015, 88, 536–556. [Google Scholar]

- Valverde, R.; Saadé, R.G. The effect of E-supply chain management systems in the North American electronic manufacturing services industry. J. Theor. Appl. Electron. Commer. Res. 2015, 10, 79–98. [Google Scholar] [CrossRef]

- Ab.Aziz, N.; Ahmad, R.; Dhanapal Durai, D. B2B collaboration method through trust values for e-supply chain integrator: A case study of Malaysian construction industry. In Proceedings of the 4th International Conference on Machine Vision (ICMV 11), Singapore, Singapore, 9–10 December 2011; p. 835031. [Google Scholar]

- Sambasivan, M.; Abidin Mohamed, Z.; Nandan, T. Performance measures and metrics for e-supply chains. J. Enterp. Inf. Manag. 2009, 22, 346–360. [Google Scholar] [CrossRef]

- Toktaş-Palut, P.; Baylav, E.; Teoman, S.; Altunbey, M. The impact of barriers and benefits of e-procurement on its adoption decision: An empirical analysis. Int. J. Prod. Econ. 2014, 158, 77–90. [Google Scholar] [CrossRef]

- Hong, Z.; Lee, C.K.M.; Zhang, L. Procurement risk management under uncertainty: A review. Ind. Manag. Data Syst. 2018, 118, 1547–1574. [Google Scholar] [CrossRef]

- Yevu, S.K.; Yu, A.T.W.; Nani, G.; Darko, A.; Tetteh, M.O. Electronic Procurement Systems Adoption in Construction Procurement: A Global Survey on the Barriers and Strategies from the Developed and Developing Economies. J. Constr. Eng. Manag. 2022, 148, 04021186. [Google Scholar] [CrossRef]

- Eadie, R.; Perera, S.; Heaney, G. A cross discipline comparison of rankings for e-procurement drivers and barriers within UK construction organisations. Electron. J. Inf. Technol. Constr. 2010, 15, 217–233. [Google Scholar]

- Yevu, S.K.; Yu, A.T.W.; Darko, A.; Nani, G.; Edwards, D. Modeling the influence patterns of barriers to electronic procurement technology usage in construction projects. Eng. Constr. Archit. Manag. 2022, 30, 5133–5159. [Google Scholar] [CrossRef]

- Cardoso, A.L.; Biazzin, C. What is the value of e-Procurement for suppliers The drivers, barriers and opportunities for engaging MRO suppliers. Int. J. Procure. Manag. 2020, 13, 1. [Google Scholar] [CrossRef]

- Isikdag, U. An evaluation of barriers to E-Procurement in Turkish construction industry. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 252–259. [Google Scholar]

- Eadie, R.; Perera, S.; Heaney, G. Identification of e-procurement drivers and barriers for UK construction organisations and ranking of these from the perspective of quantity surveyors. Electron. J. Inf. Technol. Constr. 2010, 15, 23–43. [Google Scholar]

- Huang, Y.-S.; Ho, R.-S.; Fang, C.-C. Quantity discount coordination for allocation of purchase orders in supply chains with multiple suppliers. Int. J. Prod. Res. 2015, 53, 6653–6671. [Google Scholar] [CrossRef]

- Koc, K.; Gurgun, A.P. Stakeholder-Associated Life Cycle Risks in Construction Supply Chain. J. Manag. Eng. 2021, 37, 04020107. [Google Scholar] [CrossRef]

- Deng, Y.; Gan, V.J.L.; Das, M.; Cheng, J.C.P.; Anumba, C. Integrating 4D BIM and GIS for Construction Supply Chain Management. J. Constr. Eng. Manag. 2019, 145, 04019016. [Google Scholar] [CrossRef]

- Zhu, H. Consumers Risk Control in a Collaborative Supply Chain. In Proceedings of the IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 1145–1149. [Google Scholar]

- Wen, S.; Tang, H.; Ying, F.; Wu, G. Exploring the Global Research Trends of Supply Chain Management of Construction Projects Based on a Bibliometric Analysis: Current Status and Future Prospects. Buildings 2023, 13, 373. [Google Scholar] [CrossRef]

- Niu, Y.; Lu, W.; Liu, D.; Chen, K.; Anumba, C.; Huang, G.G. An SCO-Enabled Logistics and Supply Chain–Management System in Construction. J. Constr. Eng. Manag. 2017, 143, 04016103. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Y. The Co-evolution between Companies within E-Supply Chain Management in the Era of Digital Economy. In Proceedings of the International Conference on Business Intelligence and Financial Engineering, Beijing, China, 24–26 July 2009; pp. 84–87. [Google Scholar]

- Deepu, T.S.; Ravi, V. A review of literature on implementation and operational dimensions of supply chain digitalization: Framework development and future research directions. Int. J. Inf. Manag. Data Insights 2023, 3, 100156. [Google Scholar] [CrossRef]

- Akyuz, G.A.; Rehan, M. Requirements for forming an “e-supply chain”. Int. J. Prod. Res. 2009, 47, 3265–3287. [Google Scholar] [CrossRef]

- Pant, S.; Sethi, R.; Bhandari, M. Making sense of the e-supply chain landscape: An implementation framework. Int. J. Inf. Manag. 2003, 23, 201–221. [Google Scholar] [CrossRef]

- Masvosvere, D.J.E.; Venter, H.S. Using a standard approach to the design of next generation e-Supply Chain Digital Forensic Readiness systems. SAIEE Afr. Res. J. 2016, 107, 104–120. [Google Scholar] [CrossRef]

- Aduwo, E.B.; Ibem, E.O.; Uwakonye, O.; Tunji-Olayeni, P.; Ayo-Vuaghan, E.K. Barriers to the uptake of E-procurement in the Nigerian building industry. J. Theor. Appl. Inf. Technol. 2016, 89, 115–129. [Google Scholar]

- Addy, M.N.; Addo, E.T.; Kwofie, T.E.; Yartey, J.E. Predicting the adoption of e-procurement in construction project delivery in Sub-Saharan Africa: An application of UTAUT2. Constr. Innov. 2022, 23, 1038–1053. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Ngai, E.W.T. Adoption of e-procurement in Hong Kong: An empirical research. Int. J. Prod. Econ. 2008, 113, 159–175. [Google Scholar] [CrossRef]

- Mukhtar, M.; Jailani, N.; Abdullah, S.; Yahya, Y.; Abdullah, Z. A Framework for Analyzing e-Supply Chains. Eur. J. Sci. Res. 2009, 25, 649–662. [Google Scholar]

- Madzimure, J.; Mafini, C.; Dhurup, M. E-procurement, supplier integration and supply chain performance in small and medium enterprises in South Africa. South Afr. J. Bus. Manag. 2020, 51, 1–12. [Google Scholar] [CrossRef]

- Atluri, R.C.; Pathak, P.; Bhatt, V. Implementation of Blockchain Technologies to Avoid Fraud in Supply Chain. In Proceedings of the International Conference on Innovation and Intelligence for Informatics, Computing, and Technologies (3ICT), Sakheer, Bahrain, 20–21 November 2022; pp. 687–692. [Google Scholar]

- Pourmorshed, S.; Durst, S. The Usefulness of the Digitalization Integration Framework for Developing Digital Supply Chains in SMEs. Sustainability 2022, 14, 14352. [Google Scholar] [CrossRef]

- Wijaya, O.Y.A. The effect of digital procurement and supply chain innovation on SMEs performance. Int. J. Data Netw. Sci. 2022, 6, 1625–1630. [Google Scholar] [CrossRef]

- Hsin Chang, H.; Tsai, Y.; Hsu, C. E-procurement and supply chain performance. Supply Chain Manag. Int. J. 2013, 18, 34–51. [Google Scholar] [CrossRef]

- Hung, W.H.; Lin, C.P.; Tai, Y.M.; Ho, C.F.; Jou, J.J. Exploring the impact of Web-based e-procurement on performance: Organisational, interorganisational, and systems perspectives. Int. J. Logist. Res. Appl. 2014, 17, 200–215. [Google Scholar] [CrossRef]

- Kim, M.; Suresh, N.C.; Kocabasoglu-Hillmer, C. A contextual analysis of the impact of strategic sourcing and E-Procurement on performance. J. Bus. Ind. Mark. 2015, 30, 1–16. [Google Scholar] [CrossRef]

- Gunasekara, H.G.; Sridarran, P.; Rajaratnam, D. Effective use of blockchain technology for facilities management procurement process. J. Facil. Manag. 2022, 20, 452–468. [Google Scholar] [CrossRef]

- Eadie, R.; Perera, S.; Heaney, G.; Carlisle, J. Drivers and barriers to public sector E-procurement within northern ireland’s construction industry. Electron. J. Inf. Technol. Constr. 2007, 12, 103–120. [Google Scholar]

- Yevu, S.K.; Yu, A.T.W.; Darko, A. Barriers to electronic procurement adoption in the construction industry: A systematic review and interrelationships. Int. J. Constr. Manag. 2021, 23, 964–978. [Google Scholar] [CrossRef]

- Farzin, S.; Nezhad, H.T. E-procurement, the golden key to optimizing the supply chains system. World Acad. Sci. Eng. Technol. 2010, 66, 518–524. [Google Scholar]

- Ibem, E.O.; Laryea, S. E-Procurement use in the South African construction industry. J. Inf. Technol. Constr. 2015, 20, 364–384. [Google Scholar]

- Ramkumar, M. A modified ANP and fuzzy inference system based approach for risk assessment of in-house and third party e-procurement systems. Strateg. Outsourcing 2016, 9, 159–188. [Google Scholar] [CrossRef]

- Ramkumar, M.; Schoenherr, T.; Jenamani, M. Risk assessment of outsourcing e-procurement services: Integrating SWOT analysis with a modified ANP-based fuzzy inference system. Prod. Plan. Control 2016, 27, 1171–1190. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Ho, W. Fuzzy Analytic Hierarchy Process; CRC Press: Boca Raton, FL, USA, 2017; Chapman and Hall/CRC. [Google Scholar]

- Fu, H.P.; Chang, T.S.; Yeh, H.P.; Chen, Y.X. Analysis of factors influencing hospitals’ implementation of a green e-procurement system using a cloud model. Int. J. Environ. Res. Public Health 2019, 16, 5137. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A.P.C. Critical Review of Labor Productivity Research in Construction Journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef]

- Chan, I.Y.S.; Leung, M.; Yu, S.S.W. Managing the Stress of Hong Kong Expatriate Construction Professionals in Mainland China: Focus Group Study Exploring Individual Coping Strategies and Organizational Support. J. Constr. Eng. Manag. 2012, 138, 1150–1160. [Google Scholar] [CrossRef]

- Gurgun, A.P.; Koc, K. Administrative risks challenging the adoption of smart contracts in construction projects. Eng. Constr. Archit. Manag. 2022, 29, 989–1015. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Q.; Li, S.; He, W.; Yang, J. Bayesian Monte Carlo Simulation–Driven Approach for Construction Schedule Risk Inference. J. Manag. Eng. 2021, 37, 04020115. [Google Scholar] [CrossRef]

- Hall, A.T.; Durdyev, S.; Koc, K.; Ekmekcioglu, O.; Tupenaite, L. Multi-criteria analysis of barriers to building information modeling (BIM) adoption for SMEs in New Zealand construction industry. Eng. Constr. Archit. Manag. 2022, 30, 3798–3816. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Policy Imperatives for Diverting Construction Waste from Landfill: Experts’ Recommendations for UK Policy Expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar] [CrossRef]

- Nyumba, T.O.; Wilson, K.; Derrick, C.J.; Mukherjee, N. The use of focus group discussion methodology: Insights from two decades of application in conservation. Methods Ecol. Evol. 2018, 9, 20–32. [Google Scholar] [CrossRef]

- Koc, K.; Ekmekcioğlu, Ö.; Özger, M. An Integrated Framework for the Comprehensive Evaluation of Low Impact Development Strategies. J. Environ. Manag. 2021, 294, 113023. [Google Scholar] [CrossRef] [PubMed]

- Budayan, C.; Okudan, O.; Dikmen, I. Identification and prioritization of stage-level KPIs for BOT projects—Evidence from Turkey. Int. J. Manag. Proj. Bus. 2020, 13, 1311–1337. [Google Scholar] [CrossRef]

- Angeles, R.; Nath, R. Business-to-business e-procurement: Success factors and challenges to implementation. Supply Chain Manag. 2007, 12, 104–115. [Google Scholar] [CrossRef]

- Eadie, R.; Perera, S.; Heaney, G. Key process area mapping in the production of an e-capability maturity model for UK construction organisations. J. Financ. Manag. Prop. Constr. 2011, 16, 197–210. [Google Scholar] [CrossRef]

- Gupta, M.; Narain, R. Investigation into barriers to adoption of e-procurement and measures of performance. Int. J. Procure. Manag. 2012, 5, 567. [Google Scholar] [CrossRef]

- Hawking, P.; Stein, A.; Wyld, D.C.; Foster, S. E-procurement: Is the ugly duckling actually a swan down under? Asia Pac. J. Mark. Logist. 2004, 16, 3–26. [Google Scholar] [CrossRef]

- Nasrun Mohd Nawi, M.; Roslan, S.; Salleh, N.A.; Zulhumadi, F.; Harun, A.N. The Benefits and Challenges of E-procurement Implementation: A Case Study of Malaysian Company. Int. J. Econ. Financ. Issues 2016, 6, 329–332. Available online: https://www.econjournals.com/index.php/ijefi/article/view/3627 (accessed on 14 September 2023).

- Nawi, M.N.M.; Deraman, R.; Bamgbade, J.A.; Zulhumadi, F.; Riazi, S.R.M. E-procurement in Malaysian construction industry: Benefits and challenges in implementation. Int. J. Supply Chain Manag. 2017, 6, 209–213. [Google Scholar]

- Kumar, A.; Garg, R.K.; Garg, D. Development of a Structural Model of Risk Issues Involved in E-Supply Chain Adoption in Indian Mechanical Industries. Int. J. Supply Oper. Manag. 2020, 7, 242–260. [Google Scholar]

- Alshurideh, M.T.; Alquqa, E.K.; Alzoubi, H.M.; Kurdi, B.A.; Hamadneh, S. The effect of information security on e-supply chain in the UAE logistics and distribution industry. Uncertain Supply Chain Manag. 2023, 11, 145–152. [Google Scholar] [CrossRef]

- Gao, Y.; Guo, Q.; Zhang, S.; Zhang, J. Understanding the Effect of BIM Capability Imbalance on Opportunistic Behavior: The Case of the Chinese Construction Market. J. Manag. Eng. 2022, 38, 04022005. [Google Scholar] [CrossRef]

- Zhang, X. Concessionaire’s Financial Capability in Developing Build-Operate-Transfer Type Infrastructure Projects. J. Constr. Eng. Manag. 2005, 131, 1054–1064. [Google Scholar] [CrossRef]

- Ertuǧrul, I.; Karakaşoǧlu, N. Comparison of fuzzy AHP and fuzzy TOPSIS methods for facility location selection. Int. J. Adv. Manuf. Technol. 2008, 39, 783–795. [Google Scholar] [CrossRef]

- Ekmekcioğlu, Ö.; Koc, K.; Özger, M. Stakeholder perceptions in flood risk assessment: A hybrid fuzzy AHP-TOPSIS approach for Istanbul, Turkey. Int. J. Disaster Risk Reduct. 2021, 60, 102327. [Google Scholar] [CrossRef]

- Hwang, C.I.; Yoon, K. Multiple Attribute Decision Making; Springer-Verlag: Berlin, Germany, 1981. [Google Scholar]

- Chen, C.T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Seresht, N.G.; Fayek, A.R. Computational method for fuzzy arithmetic operations on triangular fuzzy numbers by extension principle. Int. J. Approx. Reason. 2019, 106, 172–193. [Google Scholar] [CrossRef]

- Koc, K.; Kunkcu, H.; Gurgun, A.P. A Life Cycle Risk Management Framework for Green Building Project Stakeholders. J. Manag. Engineering 2023, 39, 04023022. [Google Scholar] [CrossRef]

- Andary, E.G.; Abi Shdid, C.; Chowdhury, A.; Ahmad, I. Integrated project delivery implementation framework for water and wastewater treatment plant projects. Eng. Constr. Archit. Manag. 2019, 27, 609–633. [Google Scholar] [CrossRef]

- Koc, K.; Budayan, C.; Ekmekcioğlu, Ö.; Tokdemir, O.B. Predicting Cost Impacts of Nonconformances in Construction Projects Using Interpretable Machine Learning. J. Constr. Eng. Manag. 2024, 150, 1–16. [Google Scholar] [CrossRef]

- Wang, T.C.; Chang, T.H. Application of TOPSIS in evaluating initial training aircraft under a fuzzy environment. Expert Syst. Appl. 2007, 33, 870–880. [Google Scholar] [CrossRef]

- Koc, K.; Gurgun, A.P. Drivers for Construction Stakeholders to Adopt Smart Contracts. J. Constr. Eng. Manag. Innov. 2020, 3, 101–112. [Google Scholar] [CrossRef]

- Koc, K.; Gurgun, A.P. Ambiguity factors in construction contracts entailing conflicts. Eng. Constr. Archit. Manag. 2022, 29, 1946–1964. [Google Scholar] [CrossRef]

- Koc, K.; Durdyev, S.; Tleuken, A.; Ekmekcioglu, O.; Mbachu, J.; Karaca, F. Critical success factors for construction industry transition to circular economy: Developing countries’ perspectives. Eng. Constr. Archit. Manag. 2023. [Google Scholar] [CrossRef]

- Xia, B.; Chan, A.P.C. Key competences of design-build clients in China. J. Facil. Manag. 2010, 8, 114–129. [Google Scholar] [CrossRef]

- Darlow, G.; Rotimi, J.O.B.; Shahzad, W.M. Automation in New Zealand’s offsite construction (OSC): A status update. Built Environ. Proj. Asset Manag. 2022, 12, 38–52. [Google Scholar] [CrossRef]

- McLaren, M.; Loosemore, M. Swift trust formation in multi-national disaster project management teams. Int. J. Proj. Manag. 2019, 37, 979–988. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Hu, J.; Papadonikolaki, E. Integrated Approaches to Design for Manufacture and Assembly: A Case Study of Huoshenshan Hospital to Combat COVID-19 in Wuhan, China. J. Manag. Eng. 2021, 37, 1–9. [Google Scholar] [CrossRef]

- Bahadorestani, A.; Karlsen, J.T.; Motahari Farimani, N. A Comprehensive Stakeholder-Typology Model Based on Salience Attributes in Construction Projects. J. Constr. Eng. Manag. 2019, 145, 04019048. [Google Scholar] [CrossRef]

- Singh, P.K.; Chan, S.W. The Impact of Electronic Procurement Adoption on Green Procurement towards Sustainable Supply Chain Performance-Evidence from Malaysian ISO Organizations. J. Open Innov. Technol. Mark. Complex. 2022, 8, 61. [Google Scholar] [CrossRef]

- Xu, S.; Lin, B.; Zou, P.X.W. Examining construction group’s safety attitude resilience under major disruptions: An agent-based modelling approach. Saf. Sci. 2023, 161, 106071. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. Modelling of interrelationships amongst enterprise and inter-enterprise information system barriers affecting digitalization in electronics supply chain. Bus. Process Manag. J. 2022, 28, 178–207. [Google Scholar] [CrossRef]

- Maali, O.; Kepple, N.; Lines, B. Strategies to Achieve High Adoption of Organizational Change Initiatives within the AEC Industry. J. Manag. Eng. 2022, 38, 1–10. [Google Scholar] [CrossRef]

- Lines, B.C.; Reddy Vardireddy, P.K. Drivers of Organizational Change within the AEC Industry: Linking Change Management Practices with Successful Change Adoption. J. Manag. Eng. 2017, 33, 1–10. [Google Scholar] [CrossRef]

- Flanagan, R.; Lu, W.; Shen, L.; Jewell, C. Competitiveness in construction: A critical review of research. Constr. Manag. Econ. 2007, 25, 989–1000. [Google Scholar] [CrossRef]

- Jang, Y.; Kwon, N.; Ahn, Y.; Lee, H.-S.; Park, M. International Diversification and Performance of Construction Companies: Moderating Effect of Regional, Product, and Industry Diversifications. J. Manag. Eng. 2019, 35, 1–11. [Google Scholar] [CrossRef]

- Filho, N.G.; Rego, N.; Claro, J. Supply chain flows and stocks as entry points for cyber-risks. Procedia Comput. Sci. 2021, 181, 261–268. [Google Scholar] [CrossRef]

- Zhao, C.; Song, J. Coordination of dual-channel supply chain considering differential pricing and loss-aversion based on quality control. J. Ind. Manag. Optim. 2023, 19, 2507–2527. [Google Scholar] [CrossRef]

- Shash, A.A.; Habash, S.I. Disputes in Construction Industry: Owners and Contractors’ Views on Causes and Remedies. J. Eng. Proj. Prod. Manag. 2021, 11, 37–51. [Google Scholar]

- Luo, L.; Qiping Shen, G.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-Associated Supply Chain Risks and Their Interactions in a Prefabricated Building Project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Manu, E.; Ankrah, N.; Chinyio, E.; Proverbs, D. Trust influencing factors in main contractor and subcontractor relationships during projects. Int. J. Proj. Manag. 2015, 33, 1495–1508. [Google Scholar] [CrossRef]

- Gadisa, B.; Zhou, H. Exploring influential factors leading to the poor performance of public construction project in Ethiopia using structural equation modelling. Eng. Constr. Archit. Manag. 2020, 28, 1683–1712. [Google Scholar] [CrossRef]

- Pinandhita, G.; Latief, Y. Implementation strategy of total quality management and quality culture to increase the competitiveness of contractor companies in Indonesia. IOP Conf. Ser. Mater. Sci. Eng. 2020, 930, 012012. [Google Scholar] [CrossRef]

- Abubakar, M.E.; Hasan, A.; Jha, K.N. Delays and Financial Implications of COVID-19 for Contractors in Irrigation Projects. J. Constr. Eng. Manag. 2022, 148. [Google Scholar] [CrossRef]

- Mahamid, I. Factors contributing to poor performance in construction projects: Studies of Saudi Arabia. Aust. J. Multi-Discip. Eng. 2016, 12, 27–38. [Google Scholar] [CrossRef]

- Yong, Z.; Yingjin, L.; Xianglan, J. Research on dynamic pricing of supply chain products based on channel advantages. Kybernetes 2012, 41, 1377–1385. [Google Scholar] [CrossRef]

- Deraman, R.; Wang, C.; Yap, J.B.H.; Li, H.; Mohd-Rahim, F.A. Developing Internet Online Procurement Frameworks for Construction Firms. Future Internet 2019, 11, 136. [Google Scholar] [CrossRef]

- Goldman, C.V.; Kraus, S.; Shehory, O. On experimental equilibria strategies for selecting sellers and satisfying buyers. Decis. Support Syst. 2004, 38, 329–346. [Google Scholar] [CrossRef]

- Liu, Z.; Nishi, T. Analyzing just-in-time purchasing strategy in supply chains using an evolutionary game approach. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0070. [Google Scholar] [CrossRef]

- Ouyang, L.-Y.; Wu, K.-S.; Ho, C.-H. An integrated vendor–buyer inventory model with quality improvement and lead time reduction. Int. J. Prod. Econ. 2007, 108, 349–358. [Google Scholar] [CrossRef]

- Abbasi, O.; Noorzai, E.; Gharouni Jafari, K.; Golabchi, M. Exploring the Causes of Delays in Construction Industry Using a Cause-and-Effect Diagram: Case Study for Iran. J. Archit. Eng. 2020, 26, 05020008. [Google Scholar] [CrossRef]

- Abbasi, S.; Taghizade, K.; Noorzai, E. BIM-Based Combination of Takt Time and Discrete Event Simulation for Implementing Just in Time in Construction Scheduling under Constraints. J. Constr. Eng. Manag. 2020, 146, 04020143. [Google Scholar] [CrossRef]

- Huang, Z.; Mao, C.; Wang, J.; Sadick, A.M. Understanding the key takeaway of construction robots towards construction automation. Eng. Constr. Archit. Manag. 2022, 29, 3664–3688. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Le, P.L. Twenty-year application of logistics and supply chain management in the construction industry. Constr. Manag. Econ. 2022, 40, 796–834. [Google Scholar] [CrossRef]

- Yadav, S.; Prakash Singh, S. Modelling procurement problems in the environment of blockchain technology. Comput. Ind. Eng. 2022, 172, 108546. [Google Scholar] [CrossRef]

- Hewamulla, K.; Jayasena, H.; Guruge, K. The impact of procurement method on construction time waste. In Proceedings of the 10th World Construction Symposium 2022, Colombo, Sri Lanka, 24–26 June 2022; pp. 909–920. [Google Scholar]

- Strahorn, S.; Gajendran, T.; Brewer, G. The Influence of Trust in Traditional Contracting: Investigating the “Lived Experience” of Stakeholders. Constr. Econ. Build. 2015, 15, 81–101. [Google Scholar] [CrossRef]

- Joshi, S.; Sharma, M. Sustainable Performance through Digital Supply Chains in Industry 4.0 Era: Amidst the Pandemic Experience. Sustainability 2022, 14, 16726. [Google Scholar] [CrossRef]

- Zhou, Z.; Khoo, T.J.; Ha., C.Y.; Deng, Z.; Li, Y. Blockchain Technology in Construction Supply Chain Management: Enhance Transaction Speed, Cost Effectiveness And Security. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 32, 400–420. [Google Scholar]

- Zekhnini, K.; Cherrafi, A.; Bouhaddou, I.; Benghabrit, Y.; Garza-Reyes, J.A. Supply chain management 4.0: A literature review and research framework. Benchmarking 2021, 28, 465–501. [Google Scholar] [CrossRef]

- Li, X.; Pillutla, S.; Zhou, H.; Yao, D.Q. Drivers of Adoption and Continued Use of E-Procurement Systems: Empirical Evidence from China. J. Organ. Comput. Electron. Commer. 2015, 25, 262–288. [Google Scholar] [CrossRef]

- Singh, R.K.; Benyoucef, L. A consensus based group decision making methodology for strategic selection problems of supply chain coordination. Eng. Appl. Artif. Intell. 2013, 26, 122–134. [Google Scholar] [CrossRef]

- Sanders, N.R.; Boone, T.; Ganeshan, R.; Wood, J.D. Sustainable Supply Chains in the Age of AI and Digitization: Research Challenges and Opportunities. J. Bus. Logist. 2019, 40, 229–240. [Google Scholar] [CrossRef]

- Eswaran, M.; Bahubalendruni, M.V.A.R. Challenges and opportunities on AR/VR technologies for manufacturing systems in the context of industry 4.0: A state of the art review. J. Manuf. Syst. 2022, 65, 260–278. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).