1. Introduction

The reuse of wood elements in architectural projects has gained popularity in recent years due to potential benefits in terms of sustainability and cost-effectiveness. Architects who incorporate reused wood elements into their designs may experience a range of advantages and challenges. From an environmental perspective, reusing wood can reduce waste and carbon footprint while helping to conserve natural resources. Additionally, reuse can be more cost-effective than buying new wood and can add value to a building by creating a rustic or vintage look that appeals to clients.

Circular construction is a design and construction approach that promotes sustainability and resource efficiency by using renewable resources, recycling materials, and reducing waste [

1]. It aligns with the principles of the circular economy and aims to create a closed-loop system where resources are used and reused in a sustainable manner [

2]. Key aspects of circular construction include sustainable material sourcing and use, reusing and repurposing materials, designing for longevity and adaptability, efficient deconstruction and recycling practices, minimizing waste and energy consumption, embracing renewable resources like wood, and promoting a circular economy for construction.

However, incorporating reused wood elements can also present structural challenges for architects. The structural integrity of the reused wood may be compromised, requiring careful evaluation and design adjustments. Despite several challenges (such as health concerns, or special care and maintenance demands), the aesthetic appeal and sustainability-related benefits make the reuse of wood elements a trend in architecture that is likely to continue in the years to come.

The building sector is currently responsible for about 28% of global energy-related carbon dioxide (CO

2) emissions. This share rises to about 40% if CO

2 emissions from the production of building materials are included. Furthermore, construction products have a significant amount of embodied energy, that is, the energy used for their processing. Materials are, therefore, a key to mitigating the embodied emissions of buildings [

3,

4]. At the end of a building’s lifespan, materials with high embodied energy often end up in landfills. In 2018, the member countries of the European Union (EU) collectively produced approximately 2.4 billion tons of waste, underscoring the significant scale of the issue [

5]. Among the various waste streams, construction and demolition waste (C&D waste) emerge as particularly weighty and voluminous, constituting roughly one-quarter of the total generated waste. This category encompasses diverse materials that hold potential for recycling [

6].

The transition towards a circular economy, or circularity, within the built environment is seen as one of the ways forward to cope with the huge amount of construction and demolition waste generated [

7]. Buildings must be viewed as material repositories, and their disassembly must have already been considered during the design stage of a project. In this way, waste will be avoided and materials returned to the cycle repeatedly.

Deconstruction holds the potential to reduce greenhouse gas (GHG) emissions in the construction sector by making reusable construction materials available, and by reducing the need for new materials in construction projects [

8]. Deconstruction can be more cost-effective than demolition when considering the reduction in landfill disposal costs and the revenue from salvage [

9]. Salvaged materials from deconstruction can be reused or recycled [

10].

Boyd et al. [

11] projected that the reuse and recycling of salvaged materials could lower GHG emissions by more than 50% when compared to emissions from demolition activities, thus favorably contributing to the mitigation of global warming. Deconstruction’s environmental benefits encompass decreased GHG emissions through the avoidance of landfill disposal and energy conservation by eliminating transportation to final disposal sites. Additionally, salvaged materials can be repurposed in new construction, building rehabilitation, or remodeling projects, thus avoiding energy consumption and GHG emissions attributed to all processes between raw material extraction and the final stage of product manufacturing [

12]. The European Directive on Waste advocates for the recovery of all waste for material purposes, emphasizing reuse and recycling as pivotal approaches to curbing the utilization of primary resources [

8].

The utilization of wood in construction offers numerous advantages, making it a promising material for environmentally conscious building practices. Arehart et al. [

13] have highlighted that increasing the amount of wood-based building materials is one of the most important and effective ways of storing carbon aboveground. Wood stands out among other materials as a CO

2-neutral material, as throughout its growth period it absorbs the same amount of CO

2 from the environment as it later releases during decomposition or when used for energy generation, regardless of whether it is chipped or utilized differently. Gorgolewski’s [

14] research on salvaged materials following building deconstruction revealed that wood has greater potential for reuse compared to other prevalent building materials like concrete, brick, and glass. In the long term, the reuse or recycling of wood construction products increases carbon storage and potentially reduces CO

2 emissions when substituting non-wood materials [

15]. Moreover, through reuse and recycling, these materials can have an extended lifespan, reducing waste and diminishing the demand for virgin raw materials, along with the associated energy costs of processing [

16].

The reuse of wood elements depends on the ways in which buildings are demolished. In current demolition practices, buildings are crushed using heavy machinery. After demolition, waste materials are sorted into different containers based on their composition for recycling and proper disposal [

17,

18]. This means that the structural elements, including those made of wood, cannot be reused. Chipping wood for particleboard or fiberboard is possible, but it means downcycling the original high-value solid material [

19]. However, studies [

20] have demonstrated that intact wooden beams and columns with larger cross-sections hold significant potential for reuse when they have suitable fixings in place. Glued connections are not suitable because they cannot be separated without damaging the elements. Carpentry joints are sometimes suitable—notches can cause stress concentration if the elements are used in different configurations. Sometimes nails and staples are also suitable; however, they fail in bending and, therefore, are difficult to remove without damaging the element. Screws are mostly suitable because the same connector is not so effective in the same hole. The most suitable are bolts and dowels—the holes and the cracks should be checked [

19]. Sakaguchi et al. [

17] found that the method of demolition and the building’s design influence the feasibility of reuse. As the construction industry moves towards a circular economy, there is growing interest in material reuse within the building sector [

21,

22,

23]. Material reuse has been promoted in the field of urban mining for many years [

24]. The urban mine, housing various anthropogenic stocks, is considered to be a promising source for the supply of secondary materials [

25,

26].

There is a consensus in the literature that the architect plays a decisive role in reducing waste by focusing on waste design. However, the findings show that waste management is not a priority for architects in the planning process. Architects mostly believe that waste is generated during construction site operations and is rarely generated during the planning stages. Osmani at al. showed that approximately one-third of construction waste can be caused by design decisions [

27]. Lack of training and design for flexibility and adaptability were the top barrier and approach to construction waste minimization, respectively [

28].

Kitek Kuzman et al. [

29] investigated and quantified this by surveying the attitudes of public and professional organizations towards prolonging the life cycles of wood products to combat climate change through cascading in Bosnia and Herzegovina, Croatia, Serbia, and Slovenia, finding that it is necessary to improve the quantification of wood usage through material intensity analysis of buildings, and emphasizing the requirement for more comprehensive education and explanations to promote sustainable practices.

Wood’s importance in circular construction lies in its renewable nature, carbon sequestration capabilities, low embodied energy, circular supply chain potential, waste reduction, biophilic design advantages, thermal performance, and positive economic impact. Integrating wood into construction practices can contribute to a more sustainable and resilient built environment.

Figure 1 shows the material flow of wood, addressing the circular construction approach, which involves designing products and processes to minimize waste, maximize recycling and reuse, and preserve materials in use for as long as possible.

The novelty in this research lies in its provision of insights into the challenges and opportunities related to reclaimed wood usage in South–Central Europe. It emphasizes the necessity for support mechanisms and heightened awareness to propel circular construction practices in the region.

2. Research Area and Methods

2.1. South–Central European Countries Encompassed by this Study

In this work, the research on the reuse of wood in the light of circular building construction refers to five South–Central European countries, namely, Slovenia, Serbia, North Macedonia, BiH, and Montenegro.

Our choice of countries, varying in EU affiliation, economic development, and regulatory harmonization in timber-based and circular construction, aims to uncover differences in opinions and knowledge among professional architects residing and working in these diverse contexts. Subsequently, the obtained results and observed differences may be used among relevant national stakeholders as a starting point in defining the actions necessary to intensify the reuse of wood, the benefits of which are described in

Section 1.

The building sector in Slovenia, Serbia, North Macedonia, BiH, and Montenegro varies based on each country’s economic, social, and cultural context. Several factors, such as the forest area and forest utilization rate, dominate the timber production and market both in individual countries and globally. Slovenia has a well-developed and sustainable building sector, while Serbia is only at the beginning of the path to introduce and implement more comprehensive sustainability- and circularity-related principles, following the introduction of a set of laws and regulations to improve the energy efficiency of buildings. North Macedonia is rebuilding its sector after political and economic instability, and BiH [

29] has a mix of traditional and modern practices focusing on sustainability. Montenegro’s sector has experienced significant growth, driven by tourism and foreign investment, yet persistent challenges such as transparency issues remain. Some basic key figures for all five countries are shown in

Table 1.

The five countries of Slovenia, Serbia, North Macedonia, BiH, and Montenegro differ in their use of wood in the building sector. Slovenia prioritizes sustainable and energy-efficient construction as well as passive houses [

32], with significant use of wood [

33]. Serbia is increasing its use of wood due to government incentives for energy-efficient buildings. North Macedonia is exploring the potential of using wood in sustainable building practices. BiH traditionally used wood in construction and now incorporates it into modern sustainable building practices. In Montenegro, wood is used in construction, but stricter regulations are needed to ensure sustainability. Slovenia and Montenegro are among the most forested countries in South–Central Europe, and their expectations are high, yet dependent on each country’s specific policies, priorities, and socioeconomic conditions. The current situation in the field of wood reuse for building practice varies across the European area—they are more actively engaged in Finland, Sweden, Norway, and Denmark [

34], as well as in Germany, while in the southern part of Europe this kind of practice has not yet been detected. The primary objective of this study was to solicit insights regarding the viability of recycling wood products, concerns regarding the durability of wood-based materials over time, the incentives for repurposing wood from existing structures (particularly for structural applications), and the significance of ecological, technical, and economic considerations.

Drawing from the collected data, this study delves into the prospects for cascading practices and examines potential avenues for future development. Furthermore, this research serves as an inaugural step toward conducting distinct case studies on various building construction and furniture scenarios, exploring cascading wood practices in diverse international contexts.

2.2. Methods

To investigate the reuse of wood in construction, a web survey was chosen as a suitable research method. We interviewed architects from all five countries that were included in the research. Surveying architects is a method that is often used in studies. Heltorp et al. [

35] examined the expectations, experiences, and acceptance levels among users, architects, and industry representatives in the context of reused and recycled wooden materials, emphasizing the importance of their opinions. Sieffert et al. [

36] outlined the reasoning behind the reuse of materials and showed how the divide between civil engineering and architectural perspectives has been addressed. Most of the studies giving criteria for decision-making refer to architects and engineers, showing that these are the most important decision-makers in material selection. For example, evaluation tools for supporting material selection for engineers and architects are presented in [

37].

The questionnaire was implemented in five selected countries from Central and Southeast Europe: Slovenia, Serbia, North Macedonia, BiH, and Montenegro. The target population was practicing architects. Lists of members of architectural chambers and associations served as a sampling frame: in Slovenia, the Chamber of Architecture and Spatial Planning of Slovenia; in Serbia, the Alumni Association Database of the University of Priština in Kosovska Mitrovica; in North Macedonia, the Chamber of Certified Architects and Certified Engineers of the Republic of North Macedonia; in BiH, the Association of Architects of Bosnia and Herzegovina, as well as the Alumni Association of the University of Banja Luka and the Faculty of Architecture, Civil Engineering, and Geodesy, whose members work as architects in various companies and studios in Bosnia; and in Montenegro, the Alumni Association of the University of Montenegro and the Association of Architects in Montenegro. An international group of certified architects was involved in the process of questionnaire development to investigate architects’ perspectives and practices regarding the reuse of wood in construction. The respondents were randomly selected from the lists of members.

The online survey software 1KA (Version 21.05.25) [

38] was used to collect the respondents’ data. Requests and a link to participate in the online survey were sent to 1093 e-mail addresses: 200 in Slovenia, 200 in Serbia, 200 in North Macedonia, 293 in BiH, and 200 in Montenegro. The survey took place from late November 2022 to mid-February 2023. Taking into account undeliverable emails due to invalid email addresses or companies that no longer exist, the response rate was 48.0% for Slovenia, 43.5% for Serbia, 50.5% for North Macedonia, 34.5% for BiH, and 49.5% for Montenegro. Based on similar studies [

39,

40,

41,

42], a response rate of 15–35% can be considered reasonable for analysis purposes in business surveys, with the main reasons for non-participation in surveys often being an unattractive survey topic or the length of the questionnaire [

43]. In our study, the overall response rate was 44.3%, which is considered adequate. Not all of the responses were complete, but since all of the respondents answered at least five questions in addition to the general questions, and since the questions are largely independent of one another, we have included them all in the analysis. The main trigger for respondents dropping out of the survey appears to have been switching to a new page in the survey. We received 96 responses from Slovenia, 91 of which were completed, which corresponds to a completion rate of 95%. From Serbia, we received 87 responses, of which 76 were completed, giving a completion rate of 87%. From North Macedonia, 101 responses were received, of which 96 were completed, corresponding to a completion rate of 95%. From BiH, 101 responses were received, of which 99 were completed, corresponding to a completion rate of 98%. From Montenegro, we received 99 responses, 88 of which were completed, which corresponds to a completion rate of 89%. In total, we received 484 responses, of which 450 were complete, which corresponds to a completion rate of 93%.

The questionnaire (see

Appendix A) consisted of four parts:

A general questionnaire that reflected the profile of the respondents who participated in the survey: the industry sector, the company size, and the product type.

Questions about the potential for wood products’ reuse.

Questions related to doubts, motivations, and the potential to use and reuse wood products.

Material/construction choice by investors and architects in their practice.

The statistical software JASP 0.16.4 was used for data analysis. The statistical significance level was set at p < 0.05. Descriptive statistics such as frequency counts and percentages were obtained and presented in bar graphs. Pearson’s chi-squared test for cross-tabulations was used to assess differences between countries and groups of respondents. Spearman’s rank correlation coefficient, a nonparametric measure of dependence, was used to measure the correlation between two ordinal variables. The following abbreviations have been used in all charts: ALL—the data for all five countries combined, SVN—Slovenia, BIH—Bosnia and Herzegovina, SRB—Serbia, MKD—North Macedonia, MNE—Montenegro.

3. Results

3.1. Respondents’ Profiles

Part of the questionnaire consisted of questions reflecting the profile of the architects participating in the survey. The results presented in

Table 2 show that slightly more than half of the respondents were female in all countries except Slovenia, with the highest proportion in BiH. The age of the respondents varied from country to country. In all countries except Slovenia, most of the respondents (63–84%) were between 25 and 44 years old. In Slovenia, this percentage was only 29%, and 62% were between 45 and 64 years old. All of the respondents were certified architects who had completed a professional master’s degree or a university degree. The role of certified architects involves designing and overseeing the construction of buildings, ensuring that they meet safety standards, local codes, and the requirements of their clients.

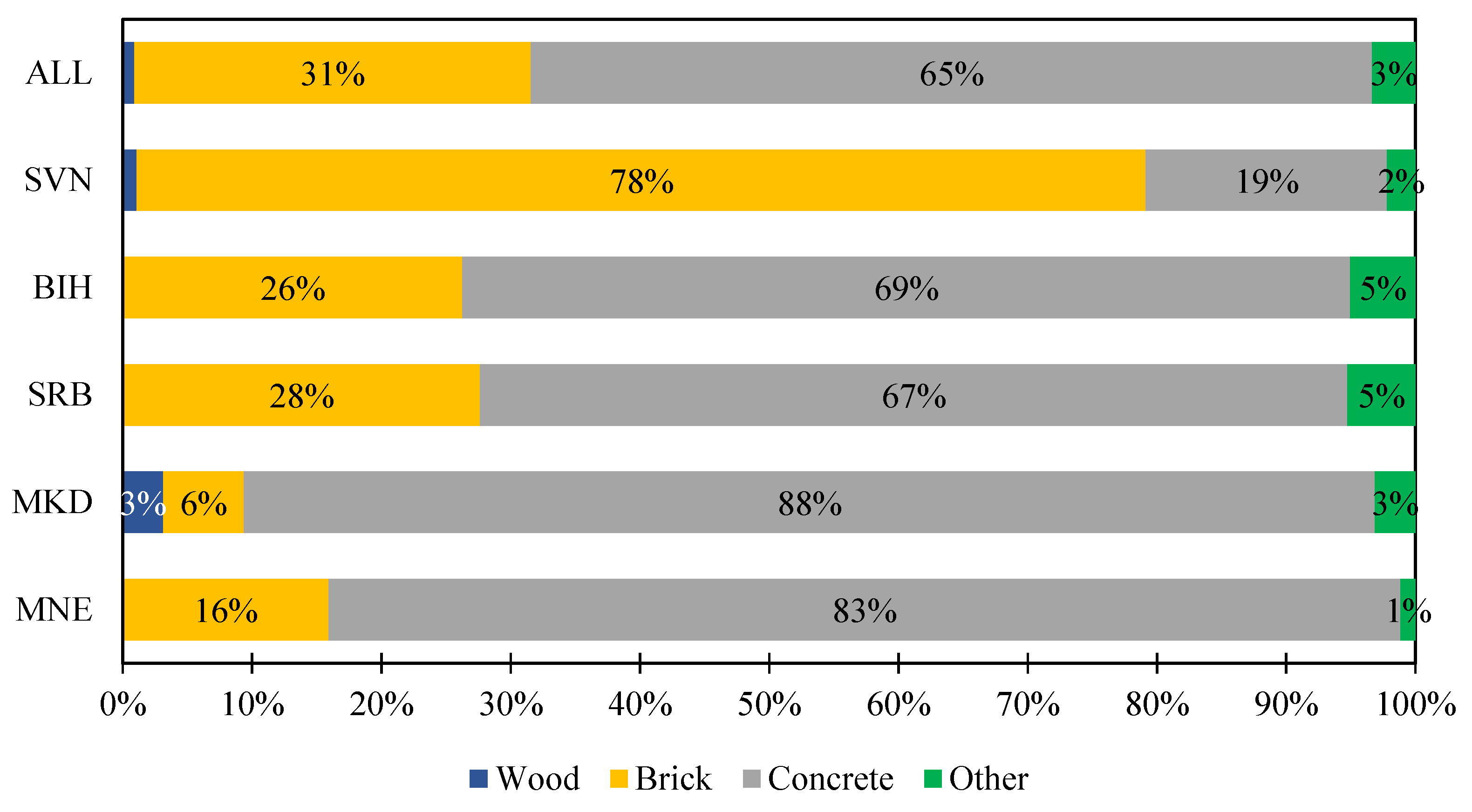

3.2. Material/Construction Choice by Investors and Architects

Architects believe that investors most often choose concrete as a building material. However, there are significant differences between countries (χ

2(12) = 145.521,

p < 0.001) (

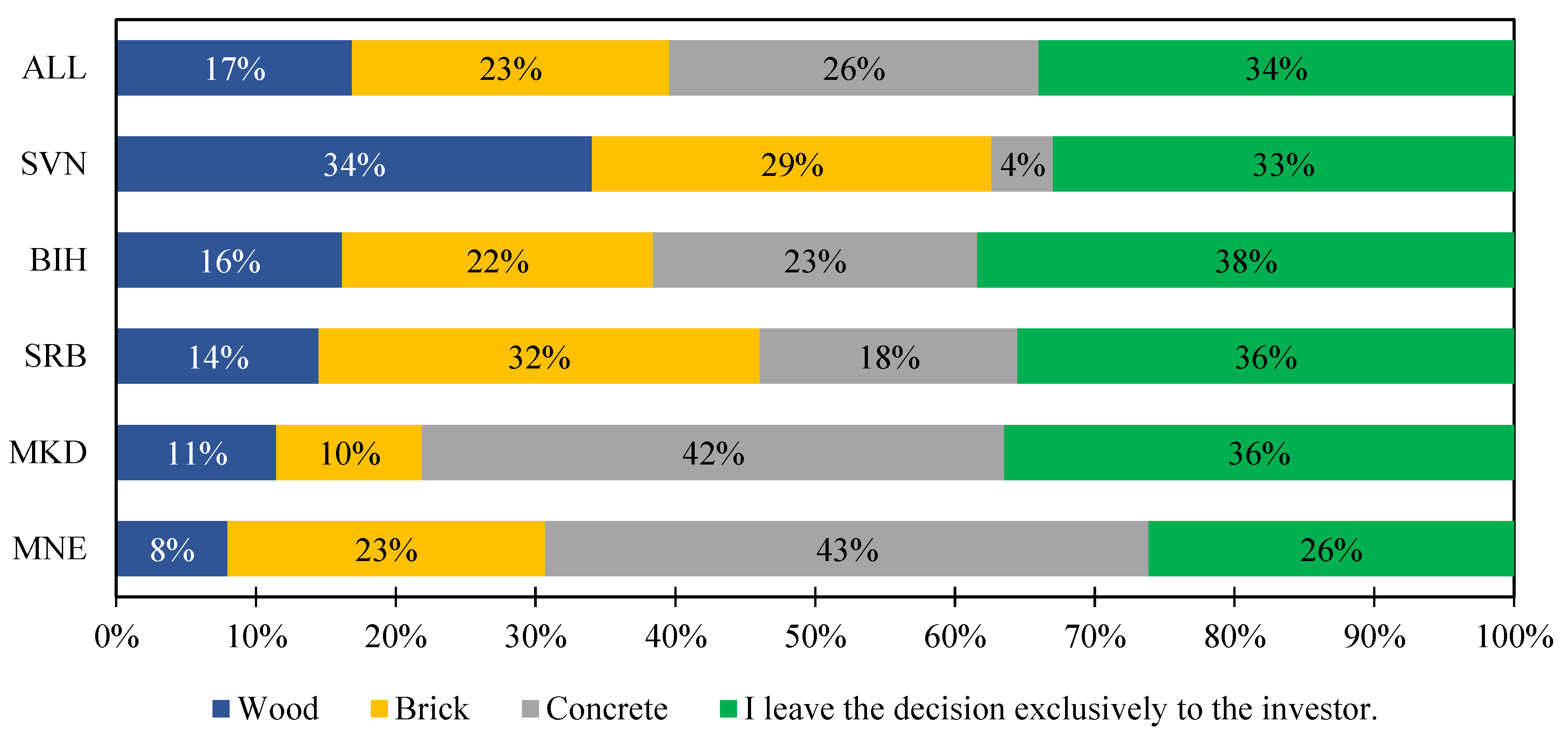

Figure 2). In more than 30% of cases, the architects leave the decision about the building material exclusively to the investors. Recommendations on building materials also differ significantly between countries (χ

2(12) = 71.565,

p < 0.001) (

Figure 3). In North Macedonia (88%) and Montenegro (83%), architects most often recommend concrete to investors (42% and 43%, respectively), and investors use concrete 88% and 83% of the time, respectively. In Serbia, architects most often recommend brick (32%), followed by concrete and wood. In BiH, architects recommend concrete (23%) or brick (22%) and, to a slightly lesser extent, wood (16%). In both countries, most investors use concrete (69% in BiH and 67% in Serbia), followed by brick, while 5% use other materials such as steel, glass, or stone. Slovenia stands out the most; it is the only country where architects mostly recommend wood as a building material (34%), followed by brick (29%) and, very rarely, concrete (4%), which is in alignment with new Slovenian building regulations. Investors, on the other hand, most often choose brick (78%). The survey showed that wood is very rarely chosen as a building material in all countries studied here.

Architects may have varying degrees of confidence in wood as a building material, for several reasons. It is important to note that these perceptions can vary among professionals and are often influenced by a combination of factors, including historical perception, lack of familiarity, misconceptions about wood’s structural capabilities or durability, regulatory constraints (building codes and regulations), aesthetic preferences, market dynamics (availability of material), and the influence of an architect’s educational background.

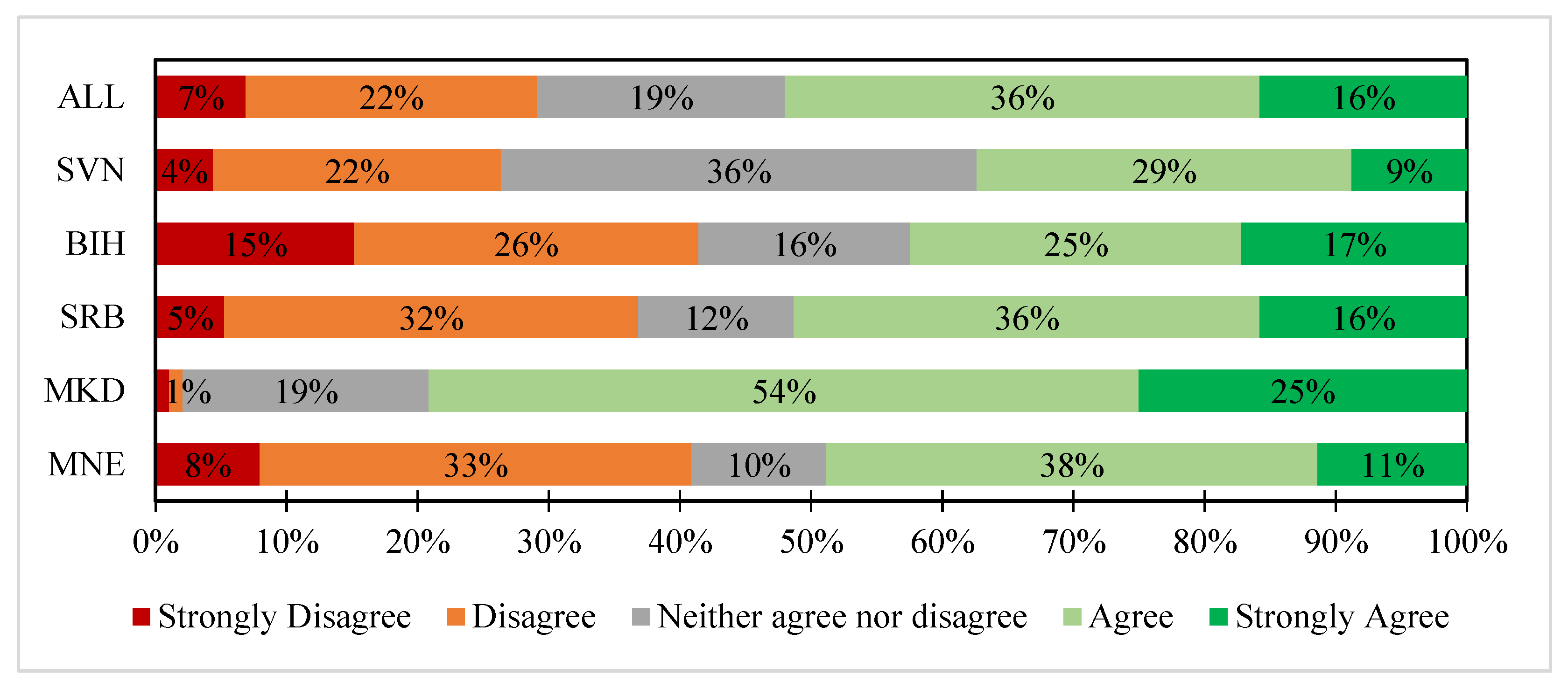

Moreover, architects generally agree or strongly agree with the statement that choosing ecologically friendly materials is an important criterion for investors. However, differences among the countries are significant (χ

2(16) = 86.469,

p < 0.001); the percentage varies between 38% in Slovenia and 79% in North Macedonia (

Figure 4).

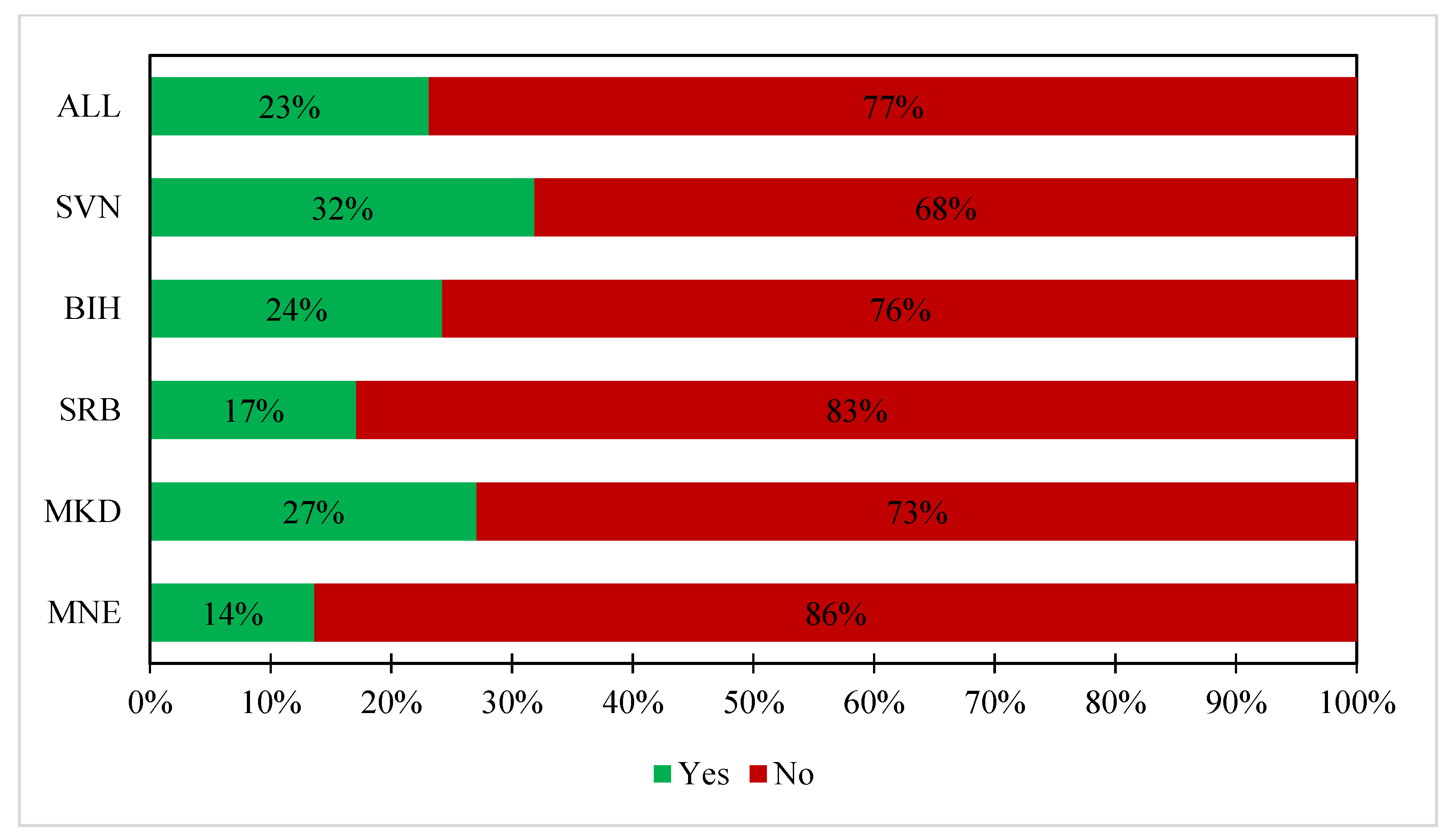

A relatively low percentage of the architects had experience with investors who decided to reuse wood. The percentage differed among the countries (χ

2(4) =10.839,

p = 0.028); the lowest (14%) was in Montenegro, and the highest (32%) in Slovenia (

Figure 5).

Wooden elements (beams and columns) with larger cross-sections can be reused in prefabricated timber roof trusses connected with metal connectors or some other type of mechanical connectors [

44], where the width of the cross-section of the chords and webs ranges from 24 to 60 mm. When the elements of existing timber trusses are reused, the damage at the end of the element caused by the nails [

45] can be removed by shortening that rod. Cross-laminated wood panels are formed with 20–40 mm thick lamellas. Such lamellas can be obtained after deconstructing wooden elements with larger cross-sections. Depending on their quality, these elements can be used in different panel section zones to accept both static and dynamic loads [

46].

The architects mentioned many possible ways to reuse wood elements in their design. More often, the following were reported: flooring—reclaimed wood can be salvaged from old buildings or other structures and can be refinished to create a unique and rustic look; wall paneling to create a feature wall or to add texture and warmth to a space; building facades or furniture to create one-of-a-kind pieces that add warmth and character to a space; doors and windows or staircases can add a unique and rustic charm to a building project while also promoting sustainability by reusing old materials. By following these good practices, architects can benefit from using reclaimed wood in their designs by promoting sustainability, creating unique aesthetics, saving costs, and adding historical context to their projects. Architects should possess comprehensive knowledge of materials, including wood, and be prepared to provide investors with informed recommendations, highlighting the advantages of using wood as a construction material.

3.3. The Potential for Wood Products’ Reuse

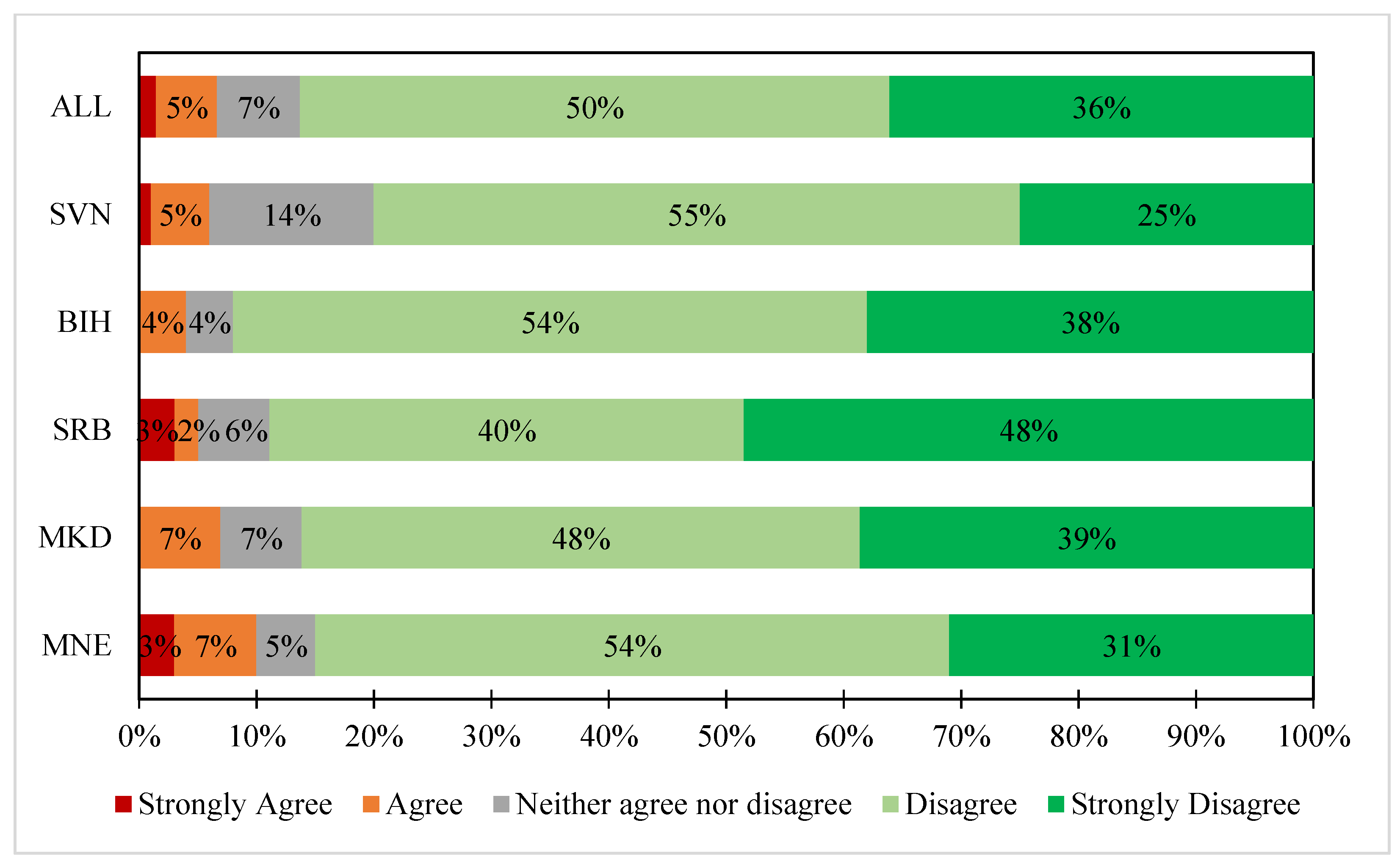

Only a small minority of respondents, ranging from 4% to 10%, agreed or strongly agreed with the statement that wood elements used in construction are made for single use and cannot be recycled, while 80% to 92% of respondents disagreed or strongly disagreed with this statement (

Figure 6). There were statistically significant differences among countries (χ

2(16) = 28.381,

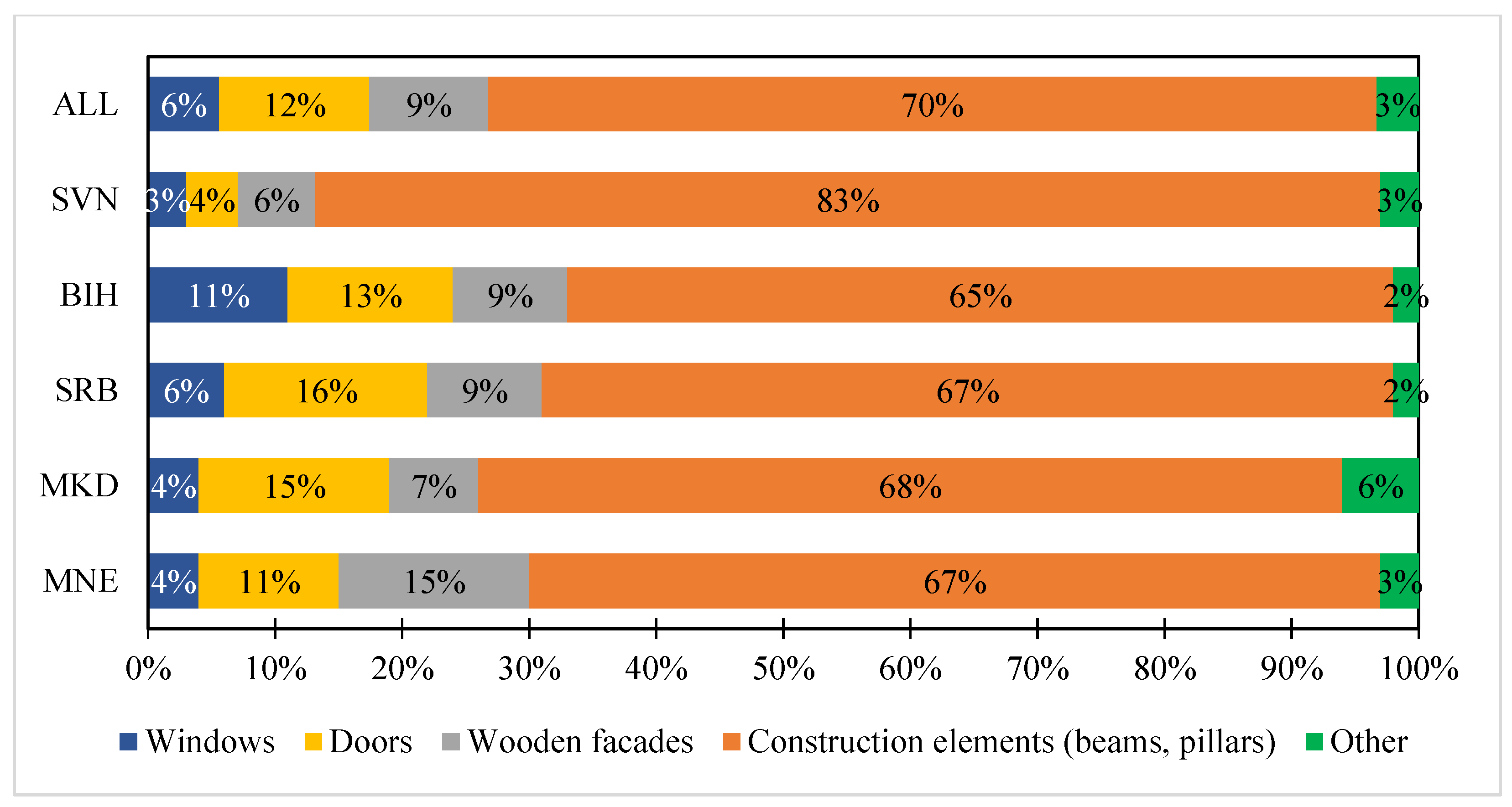

p = 0.028). The highest percentage of undecided respondents was found in Slovenia (14%). Most of the respondents considered construction elements like beams and pillars to be the wood products with the highest reuse potential (

Figure 7). The percentage varied from 65% in BiH to 83% in Slovenia, but the differences were not significant.

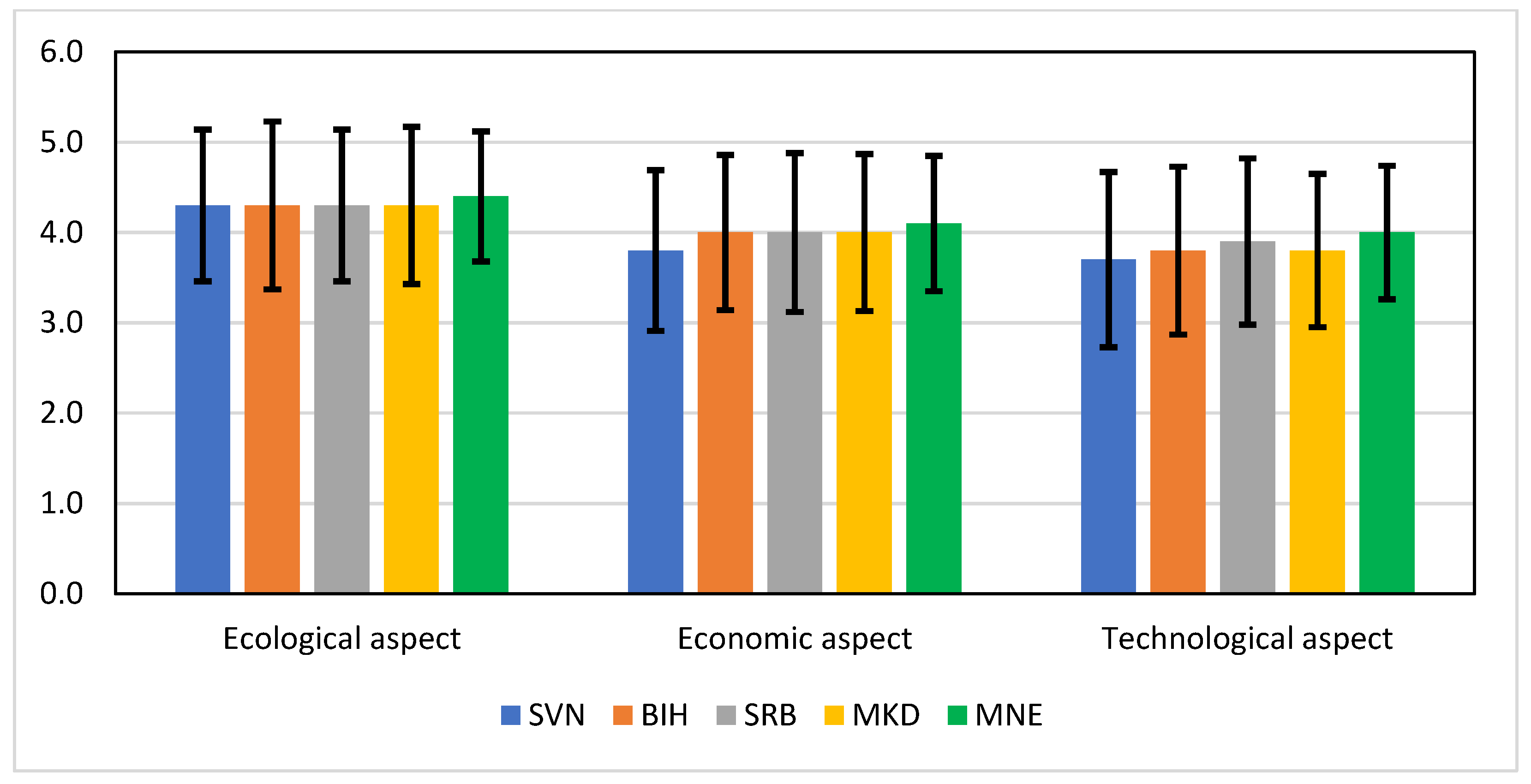

To enrich this study, the architects were asked to rate the importance of ecological, economic, and technological aspects in the reuse of wood products on a scale from not at all important (1) to very important (5).

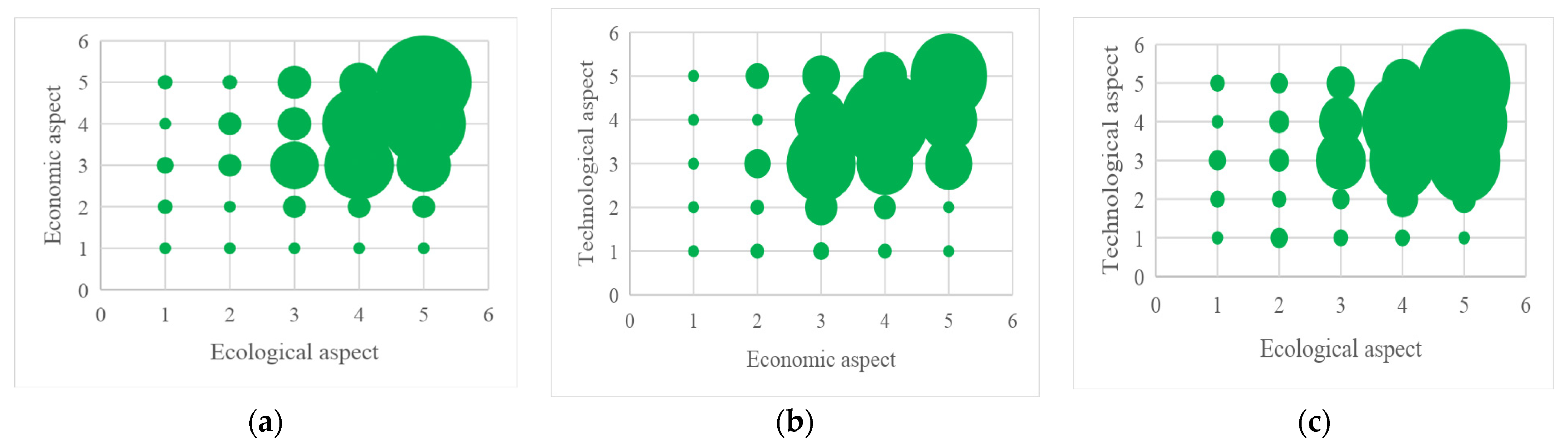

Figure 8 shows that the average scores were similar for all countries. The respondents rated the ecological aspect as the most important, followed by the economic and technological aspects. The differences in importance between the aspects were significant (χ

2(8) = 90.344,

p < 0.001). The ecological aspect was rated as fairly or very important by 84% of respondents, the economic aspect by 69%, and the technological aspect by 65% of respondents. Spearman’s rank-order coefficient confirmed a significant low positive correlation between the importance of the ecological and the economic aspects (r

S(482) = 0.383,

p < 0.001) (

Figure 9), between the importance of the ecological and the technological aspects (r

S(482) = 0.291,

p < 0.001), and between the importance of the economic and the technological aspects (r

S(482) = 0.397,

p < 0.001).

3.4. Doubts, Motivations, and Potential to Use and Reuse Wood Products

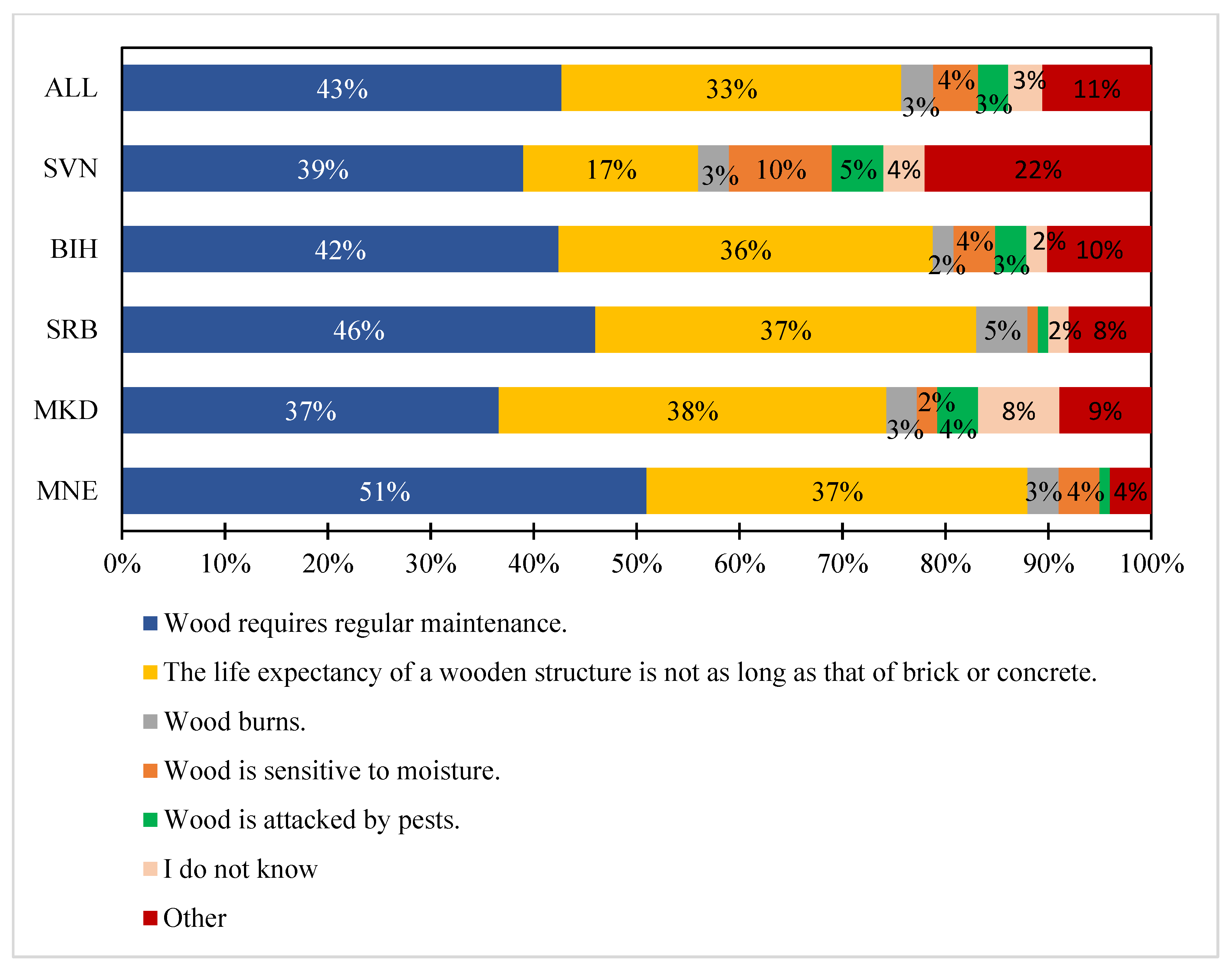

Doubts about the long-term quality of wood products can arise due to several factors. While wood is a popular and versatile material, it is not immune to potential issues that can impact its long-term performance. There are several reasons that discourage investors from choosing a wooden house. The most important for the respondents was the need for regular maintenance of wood and the shorter life expectancy of a wooden structure compared to that of brick or concrete (

Figure 10). The differences among countries were significant (χ

2(24) = 56.501,

p < 0.001). In Slovenia, 39% of respondents cited regular maintenance as the most important reason, followed by other reasons (22%): fire risk—wood is considered to be a combustible material; certain pests, insects, and fungi have the ability to digest wood; wood rot; building code limitations; and other, less significant reasons. In BiH, Serbia, and North Macedonia, the most important reason was regular maintenance (42–51%), followed by shorter life expectancy (36–37%). Respondents from Montenegro cited shorter life expectancy as the most important reason (38%), followed by regular maintenance (37%).

Respondents in all countries agreed (98%) that the profession and government do not adequately support or promote the reuse of wood in the spirit of circular construction.

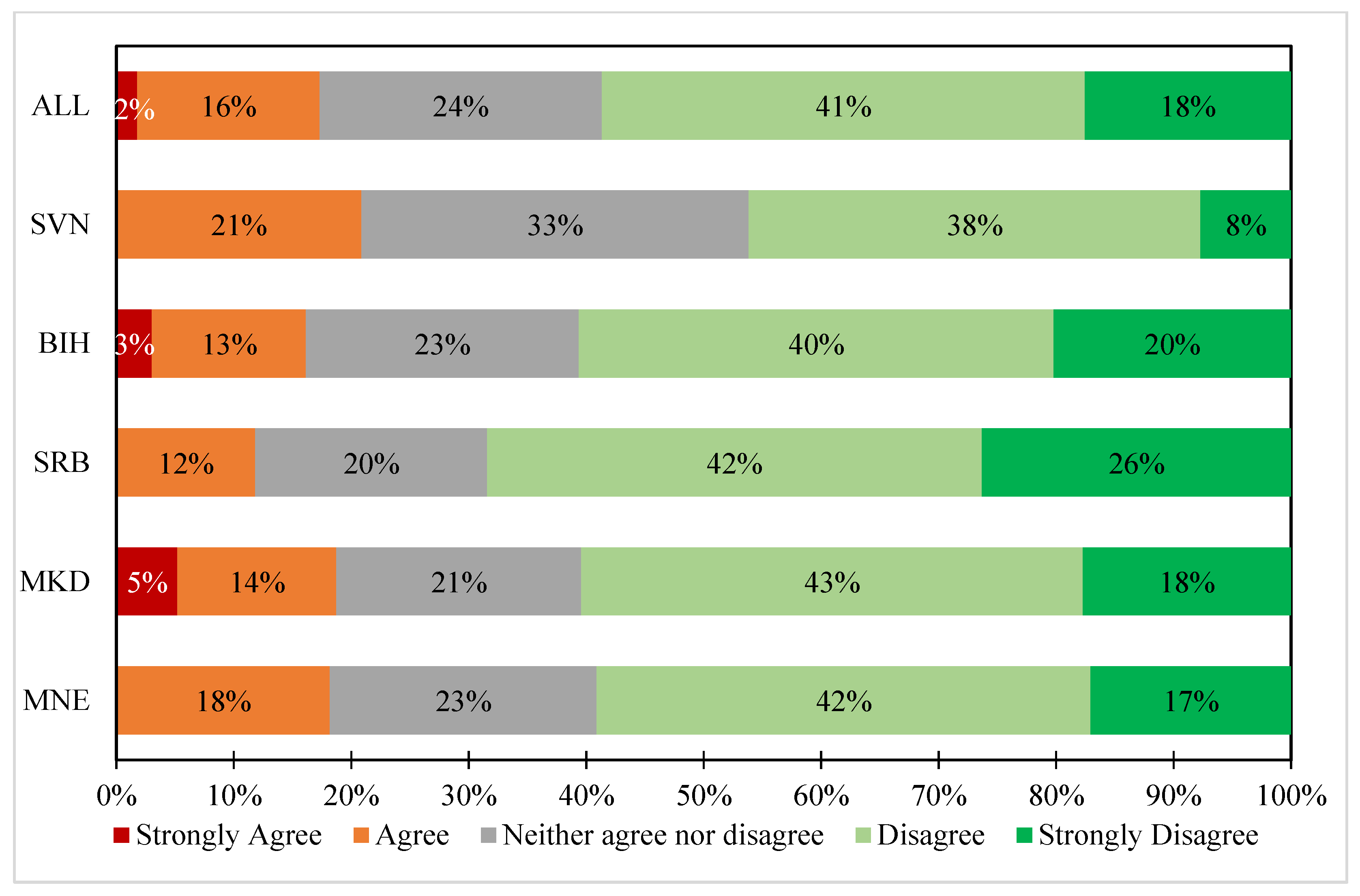

Most respondents disagreed or strongly disagreed that reclaimed wood has a lower value than other construction and demolition waste, such as metals and plastics (

Figure 11). The percentage varied and may have been influenced by cultural, regional, or personal preferences, from 46% in Slovenia to 68% in Serbia. The differences among countries were significant (χ

2(16) = 28.256,

p = 0.029). In Slovenia, 21% agreed with this statement, while another 33% neither agreed nor disagreed. In Serbia, however, only 12% agreed and 20% neither agreed nor disagreed. The majority of architects tended to view the reuse of wood positively, attributing higher rather than lower value compared to other construction and demolition waste products like metals and plastics.

The respondents indicated that previously used wood is reused less than metals or plastics due to a variety of reasons: environmental benefits, unique aesthetics, history and storytelling, quality and durability, sustainability and recycling, artisanal and craftsmanship appeal, value appreciation, and other reasons. Availability is a major factor, as it is not always readily available and salvaging it can be difficult and expensive. Cost is another consideration, as salvaging and processing reclaimed wood can be more expensive than new wood or other materials. Difficulty in processing due to the components’ size, shape, and the presence of hardware is also a concern. Additionally, the durability of reclaimed wood depends on its type and condition, and it may require inspection and testing before use. Regulations and building codes may also limit its use. Finally, location, industry, and cultural factors could also impact the reuse of reclaimed wood.

4. Discussion

Architects are important actors in the construction industry. They are the key drivers of the first life-cycle phase of buildings, that is, the design, i.e., the critical decision-makers whose decisions impact all later phases of the life cycle of buildings and determine the environmental impact through those phases. For example, architects play a decisive role in reducing construction waste by focusing on designing out waste [

27]. Hence, studying architects’ opinions on various topics (e.g., [

28,

47,

48,

49]) is considered to be a relevant research method. To that end, this study offers an insight into architects’ perspectives on wood reuse in construction across five South–Central European countries: Slovenia, Serbia, North Macedonia, Bosnia and Herzegovina, and Montenegro.

Key identified trends were similar among architects from all five encompassed countries, meaning that the national differences in terms of overall development levels did not impact their responses significantly, contrary to our starting research theses.

Objectively, the use of wood in construction varies among the five countries. Slovenia prioritizes sustainable and energy-efficient construction, emphasizing passive houses with substantial wood use. Serbia is increasing its wood usage due to government incentives for energy-efficient buildings. North Macedonia is exploring wood’s potential in sustainable construction, while BiH blends traditional and modern wood practices. In Montenegro, wood is used, but stricter regulations are required for sustainability. Slovenia and Montenegro, highly forested countries in South–Central Europe, differ in their wood reuse practices compared to more active countries.

Questions in the survey were formulated in a way that enabled us to carry out evaluation in several parallel directions. Firstly, the architects’ awareness about the possibilities and significance of wood reuse in the context of sustainable and circular construction was evaluated. The results from the survey demonstrate that architects from all five included South–Central European countries possess general knowledge and awareness about ecological significance of wood reuse, the potential of wood materials to be used more than once or to be recycled, and the value of reclaimed wood materials in comparison to construction waste from other, more frequently recycled materials such as plastics or metals.

On the other hand, specific knowledge about the precise possibilities of recycling and reuse of wood products (e.g., [

50]) seemed to be missing, e.g., most architects from all five studied countries believed that wooden beams and pillars have the largest reuse potential. Likewise, the architects from all five selected countries expressed stereotypical doubts about the long-term quality of wood products.

In all included countries, architects themselves notice that the profession and national governments do not adequately support or promote the reuse of wood in the spirit of circular construction. The investors are another significant constraint: the largest number of surveyed architects never had a chance to be involved in the design or construction of a building with reclaimed wood components, nor had they considered using reclaimed wood products in their work. In fact, on the contrary, even new wood is very rarely chosen as a building material. The investors seem to be main decision-makers in terms of what materials are going to be used in construction, and, when given a chance to propose, architects mainly opt for other conventional materials, apart from in Slovenia, where architects recommend wood more often than in other countries. In the future, more needs to be done to promote the use of wood among architects, including through education about the potential of wood in structurally ambitious architectural designs.

The survey carried out in this research had the limitation of not including the aspect of professional responsibility [

27] in the questions’ design. To further deepen the relevance of this study, subsequent analyses should tackle this aspect.

5. Conclusions

The results obtained through this study and their analysis clearly point at the need to take additional actions and increase the reuse of wood in construction in the five included South–Central European countries. Moreover, this research has shown that there is a need to promote even the use of new wood construction products in all included countries, although Slovenia has made a significant yet insufficient difference by leading the way in the use of new wood in construction. Having considered the identified gaps and constraints for a more comprehensive reuse of wood, the actions needed to change the current unfavorable trends must come from both the top and the bottom.

To systematically address the issue of the environmental quality of construction materials, along with the preference of wood in that context, new policy actions and recommendations are needed in all included countries. New policy interventions will have the greatest potential to tackle all actors in construction chains. In parallel, it is necessary to intensify promotional and informational campaigns to continue raising awareness not only among architects, but also among other actors influencing the development of the construction industry, such as investors, contractors, and construction material manufacturers.

Having observed that the architects who participated in this survey mainly demonstrated the possession of general knowledge, it is necessary to organize educational activities targeting the acquisition of knowledge on specific engineering methods for the application, reuse, maintenance, and disassembly of wood within the building structure. These educative actions could be successfully organized through professional architectural associations. Next to that, it is important to launch campaigns and highlight the economic benefits of the reuse of wood building products, as currently—as the survey shows—this aspect is underestimated. The latter finding, however, might be part of the systematic gap in the knowledge of circular economy, and further research in this domain is therefore needed.

Finally, professional architects from the five South–Central European countries included in this study must be given sufficient possibilities to individually act in accordance with the principles of circular economy, and more specifically to apply reclaimed wood in their projects. In that sense, however, several external circumstances must be changed first, and changing these circumstances may represent new, collaborative business solutions for the South–Central Europe region, e.g., developing the market with reclaimed wood products, or manufacturing wooden building products and components that can be disassembled.