The Supplier Selection of Prefabricated Component Production Line: A Lean-Based AHP–Improved VIKOR Framework

Abstract

:1. Introduction

2. Literature Review

2.1. Lean Principle

2.2. Supplier Selection in PC Production

2.3. MCDM Methods for Supplier Selection

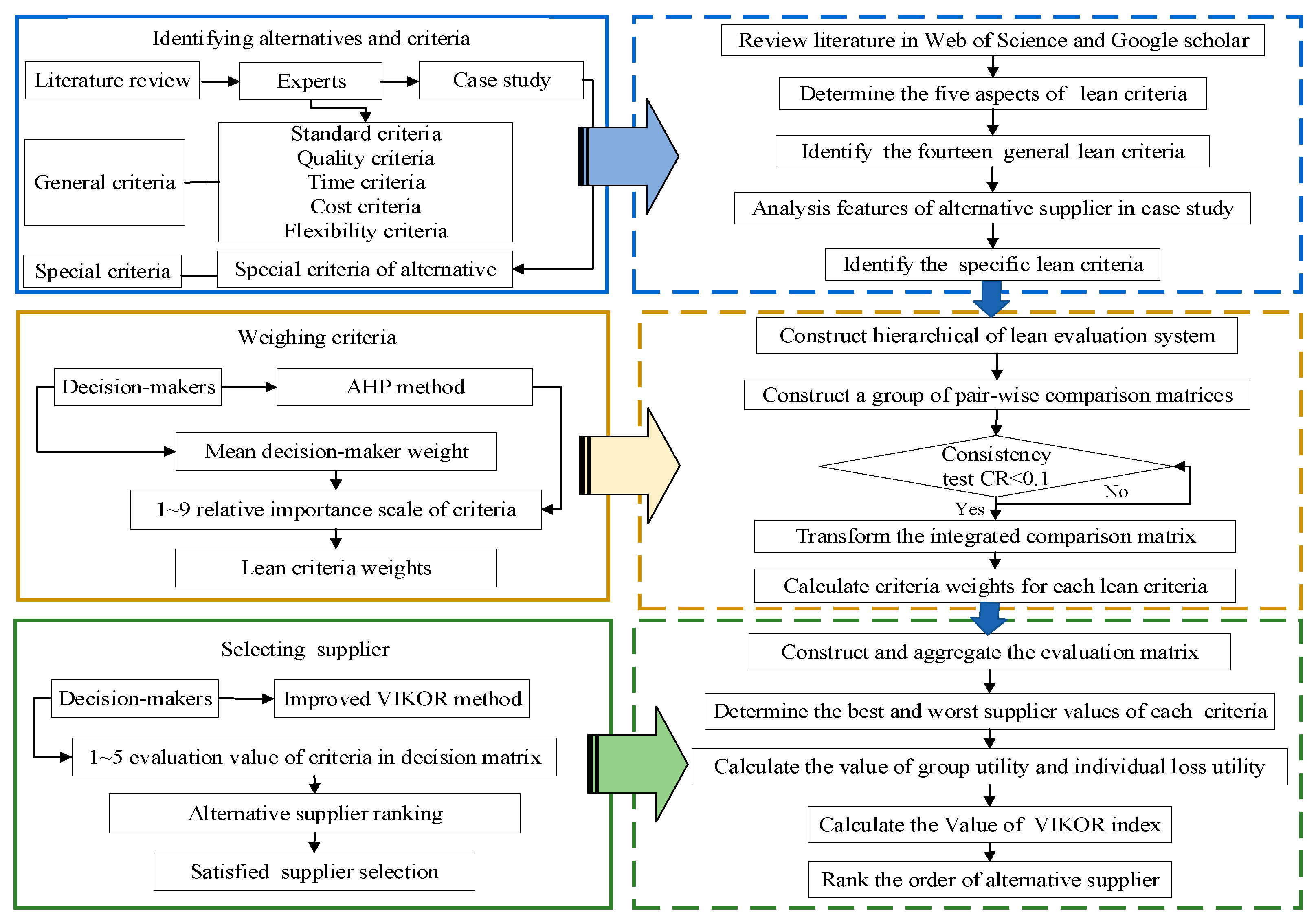

3. Lean-Based AHP–Improved VIKOR Evaluation Framework

3.1. Identifying the Universal Lean Evaluation Criteria

3.2. Weight Criteria Based on AHP

3.2.1. Constructing Pairwise Comparison Matrices

3.2.2. Calculating Priority Vectors

3.2.3. Checking for Consistency

3.2.4. Determining Criterion Weights

3.3. Supplier Evaluation and Selection Based on Improved VIKOR Method

- I.

- Acceptable advantage:

- II.

- Acceptable stability:

4. Case Study

4.1. Case Description

4.2. Data Analysis

4.2.1. Establishing Specific Lean Evaluation Criteria

4.2.2. Calculating Weights of Criteria

4.2.3. Selecting Suppliers

4.3. Case Result

5. Discussion and Conclusions

- For suppliers of PC production lines, it is vital to enhance and develop lean operation capabilities and management strategies based on the evaluation criteria so to improve the efficiency and success of PC production lines.

- For producers of PCs, they should consider the level of automaticity and information technology, and lean production requirements, while selecting the production line.

- For policymakers, it is necessary to formulate industry standards and conduct relevant activities, like adding lean principles into policies for PC development, so to improve the awareness of lean-based PC production lines.

6. Limitations and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Suppliers | The Main Description of the Production Line | Special Characteristic |

|---|---|---|

| Zhongjian | Automated production line with state-of-the-art automated equipment; requires little manual labor; simple equipment operation without the need for technical training; a high level of craftsmanship; strong expandability; extensive visual monitoring means of process control. | High level of automation and digitalization |

| Tianyi | Semi-automatic production line with partial automatic machinery, like a curing kiln and material feeder; well-designed logistics; free technical training provided; a variety of matching mold types, thereby improving the responsiveness to customer demands. | High level of mold utilization and optimization |

| Xindadi | Manual production line with less automatic equipment, with most of the operations carried out manually by workers; minimal fixed asset investment, using natural curing methods, requiring relatively more workers; the common solution without the need for specific criteria. | - |

| 1st-Level Criteria | 2nd-Level Criteria | Suppliers | ||

|---|---|---|---|---|

| ZJ | Y | DD | ||

| A1: Standard | Z1: Production process standardization degree | ✓ | ✓ | ✓ |

| Z2: Customized standard process design level | ✓ | ✓ | ✓ | |

| Z3: The comprehensiveness of differentiated standard operating systems | ✓ | ✓ | ✓ | |

| Z4: Standard operation level | ✓ | ✓ | ✓ | |

| A2: Quality | Z5: Total productive maintained level | ✓ | ✓ | ✓ |

| Z6: Product quality and reliability level | ✓ | ✓ | ✓ | |

| Z7: Equipment reliability or failure rate | ✓ | ✓ | ✓ | |

| Z8: * Automated monitoring level of quality and reliability | ✓ | - | - | |

| A3: Time | Z9: Production Takt and turnround time | ✓ | ✓ | ✓ |

| Z10: Just-in-time and pull level | ✓ | ✓ | ✓ | |

| Z11: Equipment utilization level | ✓ | ✓ | ✓ | |

| Z12: * One-piece flow level and line balance level | ✓ | - | - | |

| Z13: * Mold optimization level for improving the operation efficiency | - | ✓ | - | |

| A4: Cost | Z14: Buying price | ✓ | ✓ | ✓ |

| Z15: Use and maintenance cost level | ✓ | ✓ | ✓ | |

| Z16: Unit production cost | ✓ | ✓ | ✓ | |

| Z17: * Mold utilizing operation | - | ✓ | - | |

| A5: Flexibility | Z18: Mass customization production level of the quick response to customers’ demands | ✓ | ✓ | ✓ |

| The Evaluation Goal | 1st-Level Criteria | Weights of 1st-Level Criteria | 2nd-Level Criteria | Weights Corresponding to 1st-Level Criteria | Weights Corresponding to the Evaluation Goal | ||||

|---|---|---|---|---|---|---|---|---|---|

| ZJ | TY | XDD | ZJ | TY | XDD | ||||

| The lean evaluation and selection of suppliers | A1 | 0.102 | Z1 | 0.125 | 0.125 | 0.125 | 0.013 | 0.013 | 0.013 |

| Z2 | 0.375 | 0.375 | 0.375 | 0.038 | 0.038 | 0.038 | |||

| Z3 | 0.375 | 0.375 | 0.375 | 0.038 | 0.038 | 0.038 | |||

| Z4 | 0.125 | 0.125 | 0.125 | 0.013 | 0.013 | 0.013 | |||

| A2 | 0.245 | Z5 | 0.390 | 0.637 | 0.637 | 0.096 | 0.156 | 0.156 | |

| Z6 | 0.068 | 0.105 | 0.105 | 0.017 | 0.026 | 0.026 | |||

| Z7 | 0.152 | 0.258 | 0.258 | 0.037 | 0.063 | 0.063 | |||

| Z8 | 0.390 | - | - | 0.096 | - | - | |||

| A3 | 0.102 | Z9 | 0.113 | 0.168 | 0.637 | 0.012 | 0.017 | 0.065 | |

| Z10 | 0.064 | 0.075 | 0.258 | 0.007 | 0.008 | 0.026 | |||

| Z11 | 0.411 | 0.570 | 0.105 | 0.042 | 0.058 | 0.011 | |||

| Z12 | 0.411 | - | - | 0.042 | - | - | |||

| Z13 | - | 0.187 | - | - | 0.019 | - | |||

| A4 | 0.504 | Z14 | 0.637 | 0.522 | 0.637 | 0.321 | 0.263 | 0.321 | |

| Z15 | 0.258 | 0.200 | 0.258 | 0.130 | 0.101 | 0.130 | |||

| Z16 | 0.105 | 0.078 | 0.105 | 0.053 | 0.039 | 0.053 | |||

| Z17 | - | 0.200 | - | - | 0.101 | - | |||

| A5 | 0.046 | Z18 | 1 | 1 | 1 | 0.046 | 0.046 | 0.046 | |

| Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 | Z10 | Z11 | Z12 | Z13 | Z14 | Z15 | Z16 | Z17 | Z18 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zhongjian | 4.50 | 3.83 | 4.67 | 3.33 | 3.83 | 3.50 | 3.33 | 4.33 | 4.00 | 3.83 | 3.50 | 4.50 | - | 4.83 | 2.67 | 3.83 | - | 3.50 |

| Tianyi | 4.00 | 3.67 | 4.17 | 4.00 | 4.33 | 3.50 | 3.50 | - | 4.33 | 4.17 | 4.33 | - | 4.33 | 4.00 | 3.50 | 3.83 | 4.00 | 4.17 |

| Xindadi | 3.67 | 3.00 | 3.83 | 4.00 | 4.67 | 3.50 | 4.17 | - | 3.67 | 3.50 | 2.83 | - | - | 2.33 | 4.00 | 4.33 | - | 3.50 |

| Rank | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Zhongjian | Z1 | 1 | 5 | 4.50 | 0.125 | 0.013 | 0.002 | 0.066 | 0.235 | 0.156 | 1 |

| Z2 | 1 | 5 | 3.83 | 0.293 | 0.038 | 0.011 | |||||

| Z3 | 1 | 5 | 4.67 | 0.083 | 0.038 | 0.003 | |||||

| Z4 | 1 | 5 | 3.33 | 0.418 | 0.013 | 0.005 | |||||

| Z5 | 1 | 5 | 3.83 | 0.293 | 0.096 | 0.028 | |||||

| Z6 | 1 | 5 | 3.50 | 0.375 | 0.017 | 0.006 | |||||

| Z7 | 1 | 5 | 3.33 | 0.418 | 0.037 | 0.016 | |||||

| Z8 | 1 | 5 | 4.33 | 0.168 | 0.096 | 0.016 | |||||

| Z9 | 1 | 5 | 4.00 | 0.250 | 0.012 | 0.003 | |||||

| Z10 | 1 | 5 | 3.83 | 0.293 | 0.007 | 0.002 | |||||

| Z11 | 1 | 5 | 3.50 | 0.375 | 0.042 | 0.016 | |||||

| Z12 | 1 | 5 | 4.50 | 0.125 | 0.042 | 0.005 | |||||

| Z14 | 1 | 5 | 4.83 | 0.043 | 0.321 | 0.014 | |||||

| Z15 | 1 | 5 | 2.67 | 0.583 | 0.130 | 0.076 | |||||

| Z16 | 1 | 5 | 3.83 | 0.293 | 0.053 | 0.015 | |||||

| Z18 | 1 | 5 | 3.50 | 0.375 | 0.046 | 0.017 | |||||

| Tianyi | Z1 | 1 | 5 | 4.00 | 0.25 | 0.013 | 0.003 | 0.076 | 0.254 | 0.160 | 2 |

| Z2 | 1 | 5 | 3.67 | 0.333 | 0.038 | 0.013 | |||||

| Z3 | 1 | 5 | 4.17 | 0.208 | 0.038 | 0.008 | |||||

| Z4 | 1 | 5 | 4.00 | 0.250 | 0.013 | 0.003 | |||||

| Z5 | 1 | 5 | 4.33 | 0.168 | 0.156 | 0.026 | |||||

| Z6 | 1 | 5 | 3.5 | 0.375 | 0.026 | 0.010 | |||||

| Z7 | 1 | 5 | 3.5 | 0.375 | 0.063 | 0.024 | |||||

| Z8 | 1 | 5 | 4.33 | 0.168 | 0.017 | 0.003 | |||||

| Z9 | 1 | 5 | 4.17 | 0.208 | 0.008 | 0.002 | |||||

| Z10 | 1 | 5 | 4.33 | 0.168 | 0.058 | 0.010 | |||||

| Z11 | 1 | 5 | 4.33 | 0.168 | 0.019 | 0.003 | |||||

| Z12 | 1 | 5 | 4.00 | 0.250 | 0.263 | 0.066 | |||||

| Z14 | 1 | 5 | 3.50 | 0.375 | 0.101 | 0.038 | |||||

| Z15 | 1 | 5 | 3.83 | 0.293 | 0.039 | 0.012 | |||||

| Z16 | 1 | 5 | 4.00 | 0.250 | 0.101 | 0.025 | |||||

| Z18 | 1 | 5 | 4.17 | 0.208 | 0.046 | 0.010 | |||||

| Xindadi | Z1 | 1 | 5 | 3.67 | 0.333 | 0.013 | 0.004 | 0.214 | 0.384 | 0.299 | 3 |

| Z2 | 1 | 5 | 3.00 | 0.50 | 0.038 | 0.019 | |||||

| Z3 | 1 | 5 | 3.83 | 0.293 | 0.038 | 0.011 | |||||

| Z4 | 1 | 5 | 4.00 | 0.250 | 0.013 | 0.003 | |||||

| Z5 | 1 | 5 | 4.67 | 0.083 | 0.156 | 0.013 | |||||

| Z6 | 1 | 5 | 3.50 | 0.375 | 0.026 | 0.010 | |||||

| Z7 | 1 | 5 | 4.17 | 0.208 | 0.063 | 0.013 | |||||

| Z8 | 1 | 5 | 3.67 | 0.333 | 0.065 | 0.022 | |||||

| Z9 | 1 | 5 | 3.50 | 0.375 | 0.026 | 0.010 | |||||

| Z10 | 1 | 5 | 2.83 | 0.543 | 0.011 | 0.006 | |||||

| Z11 | 1 | 5 | 2.33 | 0.668 | 0.321 | 0.214 | |||||

| Z12 | 1 | 5 | 4.00 | 0.250 | 0.130 | 0.033 | |||||

| Z14 | 1 | 5 | 4.33 | 0.168 | 0.053 | 0.009 | |||||

| Z15 | 1 | 5 | 3.50 | 0.375 | 0.046 | 0.017 |

References

- Lima, L.; Trindade, E.; Alencar, L.; Alencar, M.; Silva, L. Sustainability in the construction industry: A systematic review of the literature. J. Clean. Prod. 2021, 289, 125730. [Google Scholar] [CrossRef]

- Kim, K.; Tiedmann, H.R.; Faust, K.M. Construction industry changes induced by the COVID-19 pandemic. Eng. Constr. Archit. Manag. 2024; ahead of print. [Google Scholar]

- Hassan, N.M.; Alashwal, A. Developing a model for the implementation of designing out waste in construction. Arch. Eng. Des. Manag. 2024, 1, 17. [Google Scholar] [CrossRef]

- Kim, Y.-W.; Rhee, B.-D. Incentive-based coordination for scheduled delivery in prefab construction. Constr. Manag. Econ. 2024, 42, 624–639. [Google Scholar] [CrossRef]

- Sah, T.P.; Lacey, A.W.; Hao, H.; Chen, W. Prefabricated Concrete Sandwich and Other Lightweight Wall Panels for Sustainable Building Construction: State-of-the-Art Review. J. Build. Eng. 2024, 89, 109391. [Google Scholar] [CrossRef]

- Dang, P.; Geng, L.; Niu, Z.; Chan, M.; Yang, W.; Gao, S. A Value-Based Network Analysis for Stakeholder Engagement through Prefabricated Construction Life Cycle: Evidence from China. J. Civ. Eng. Manag. 2024, 30, 49–66. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.P.; Pan, W.; Ye, K.H. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014038. [Google Scholar] [CrossRef]

- Wu, Z.; Luo, L.; Li, H.; Wang, Y.; Bi, G.; Antwi-Afari, M.F. An analysis on promoting prefabrication implementation in construction industry towards sustainability. Int. J. Environ. Res. Public Health 2021, 18, 11493. [Google Scholar] [CrossRef]

- Chippagiri, R.; Bras, A.; Sharma, D.; Ralegaonkar, R.V. Technological and Sustainable Perception on the Advancements of Prefabrication in Construction Industry. Energies 2022, 15, 7548. [Google Scholar] [CrossRef]

- Gao, Y.; Tian, X.-L. Prefabrication policies and the performance of construction industry in China. J. Clean. Prod. 2020, 253, 120042. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Teng, Y.; Dai, L. A dynamic simulation study on the sustainability of prefabricated buildings. Sustain. Cities Soc. 2022, 77, 103551. [Google Scholar] [CrossRef]

- Luo, T.; Xue, X.; Tan, Y.; Wang, Y.; Zhang, Y. Exploring a body of knowledge for promoting the sustainable transition to prefabricated construction. Eng. Constr. Archit. Manag. 2021, 28, 2637–2666. [Google Scholar] [CrossRef]

- Research&Market. Global Prefabricated Construction Industry Report 2023: Prefabricated Construction Startups Are Raising Funding Rounds to Support Their Growth. Available online: https://www.prnewswire.com/news-releases/global-prefabricated-construction-industry-report-2023-prefabricated-construction-startups-are-raising-funding-rounds-to-support-their-growth-301839783.html (accessed on 4 December 2024).

- Zairul, M. The recent trends on prefabricated buildings with circular economy (CE) approach. Clean. Eng. Technol. 2021, 4, 100239. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Mbachu, J. Optimization of the supplier selection process in prefabrication using BIM. Buildings 2019, 9, 222. [Google Scholar] [CrossRef]

- Liang, R.; Li, R.; Yan, X.; Xue, Z.; Wei, X. Evaluating and selecting the supplier in prefabricated megaprojects using extended fuzzy TOPSIS under hesitant environment: A case study from China. Eng. Constr. Archit. Manag. 2023, 30, 1902–1931. [Google Scholar] [CrossRef]

- Darwish, M.; Mohsen, O.; Mohamed, Y.; Al-Hussein, M. Integrated Simulation and Lean Approach for Production Line Improvement in a Prefabricated Panelized Homebuilding Facility. In Proceedings of the 28th Annual Conference of the International Group for Lean Construction (IGLC28), Berkeley, CA, USA, 6–12 July 2020. [Google Scholar]

- Han, Z.; Yu, L.; Li, B.; Qi, Y. Research on prefabricated component production line mold platform combination method. J. Phys. Conf. Ser. 2022, 2187, 012059. [Google Scholar] [CrossRef]

- Liu, C.; Wu, J.; Jiang, X.; Gu, Y.; Xie, L.; Huang, Z. Automatic assembly of prefabricated components based on vision-guided robot. Autom. Constr. 2024, 162, 105385. [Google Scholar] [CrossRef]

- China Construction Association Certification Center. Research Report on the Development of Prefabricated Construction in China’s Building Industry; China Construction Association Certification Center: Beijing, China, 2022. [Google Scholar]

- Martin, H.; Ramjarrie, K. Cloud contractor selection model for design-build open tender. J. Constr. Eng. Manag. 2021, 147, 04021020. [Google Scholar] [CrossRef]

- Nam, S.; Yoon, J.; Kim, K.; Choi, B. Optimization of Prefabricated Components in Housing Modular Construction. Sustainability 2020, 12, 10269. [Google Scholar] [CrossRef]

- Abdollahi, M.; Arvan, M.; Razmi, J. An integrated approach for supplier portfolio selection: Lean or agile? Expert Syst. Appl. 2015, 42, 679–690. [Google Scholar] [CrossRef]

- Barkokebas, B.; Khalife, S.; Al-Hussein, M.; Hamzeh, F. A BIM-lean framework for digitalisation of premanufacturing phases in offsite construction. Eng. Constr. Archit. Manag. 2021, 28, 2155–2175. [Google Scholar] [CrossRef]

- Du, J.; Xue, Y.; Sugumaran, V.; Hu, M.; Dong, P. Improved biogeography-based optimization algorithm for lean production scheduling of prefabricated components. Eng. Constr. Archit. Manag. 2023, 30, 1601–1635. [Google Scholar] [CrossRef]

- Zhang, S.; Zhongfu, L.; Tianxin, L.; Mengqi, Y. A holistic literature review of building information modeling for prefabricated construction. J. Civ. Eng. Manag. 2021, 27, 485–499. [Google Scholar] [CrossRef]

- Akanbi, O.A.; Oyedolapo, O.; Steven, G.J. Lean Principles in Construction. In Sustainable Construction Technologies; Butterworth-Heinemann: Oxford, UK, 2019; pp. 317–348. [Google Scholar] [CrossRef]

- Ho, C.T.T. Application of Optimization to the Production Planning of Construction Prefabrication Supply Chains. Ph.D. Thesis, University of Washington, Seattle, WA, USA, 2019. [Google Scholar]

- Rashidi, K.; Noorizadeh, A.; Kannan, D.; Cullinane, K. Applying the triple bottom line in sustainable supplier selection: A meta-review of the state-of-the-art. J. Clean. Prod. 2020, 269, 122001. [Google Scholar] [CrossRef]

- Lima-Junior, F.R.; Carpinetti, L.C.R. A multicriteria approach based on fuzzy QFD for choosing criteria for supplier selection. Comput. Ind. Eng. 2016, 101, 269–285. [Google Scholar] [CrossRef]

- Chen, C.-H. A novel multi-criteria decision-making model for building material supplier selection based on entropy-AHP weighted TOPSIS. Entropy 2020, 22, 259. [Google Scholar] [CrossRef] [PubMed]

- Dutta, P.; Jaikumar, B.; Arora, M.S. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Ann. Oper. Res. 2022, 315, 1399–1454. [Google Scholar]

- Ecer, F. Multi-criteria decision making for green supplier selection using interval type-2 fuzzy AHP: A case study of a home appliance manufacturer. Oper. Res. 2022, 22, 199–233. [Google Scholar]

- Ghasempoor Anaraki, M.; Vladislav, D.S.; Karbasian, M.; Osintsev, N.; Nozick, V. Evaluation and selection of supplier in supply chain with fuzzy analytical network process approach. J. Fuzzy Ext. Appl. 2021, 2, 69–88. [Google Scholar]

- Göncü, K.K.; Çetin, O. A decision model for supplier selection criteria in healthcare enterprises with dematel ANP method. Sustainability 2022, 14, 13912. [Google Scholar] [CrossRef]

- Hadian, H.; Chahardoli, S.; Golmohammadi, A.-M.; Mostafaeipour, A. A practical framework for supplier selection decisions with an application to the automotive sector. Int. J. Prod. Res. 2020, 58, 2997–3014. [Google Scholar] [CrossRef]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection-A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Amiri, M.; Hashemi-Tabatabaei, M.; Ghahremanloo, M.; Keshavarz-Ghorabaee, M.; Zavadskas, E.K.; Banaitis, A. A new fuzzy BWM approach for evaluating and selecting a sustainable supplier in supply chain management. Int. J. Sustain. Dev. World Ecol. 2021, 28, 125–142. [Google Scholar] [CrossRef]

- Siew, L.W.; Hoe, L.W.; Fai, L.K.; Bakar, M.A.; Xian, S.J. Analysis on the e-Learning Method in Malaysia with AHP-VIKOR Model. Int. J. Inf. Educ. Technol. 2021, 11, 52–58. [Google Scholar] [CrossRef]

- Kilpatrick, J. Lean principles. Utah Manuf. Ext. Partnersh. 2003, 68, 1–5. [Google Scholar]

- Sachdeva, G. Lean, Six Sigma, and Industry 4.0 Technologies Connection and Inclusion. In Lean Six Sigma 4.0 for Operational Excellence Under the Industry 4.0 Transformation; CRC Press: Boca Raton, FL, USA, 2023; pp. 47–57. [Google Scholar]

- Wang, S.; Tang, J.; Zou, Y.; Zhou, Q. Research on production process optimization of precast concrete component factory based on value stream mapping. Eng. Constr. Archit. Manag. 2020, 27, 850–871. [Google Scholar] [CrossRef]

- Potužák, B.J. Utilization of lean construction principles and techniques. Supply Chain Manag. 2017, 1, 38–54. [Google Scholar]

- Rosli, M.F.; Muhammad Tamyez, P.F.; Zahari, A.R. The effects of suitability and acceptability of lean principles in the flow of waste management on construction project performance. Int. J. Constr. Manag. 2023, 23, 114–125. [Google Scholar] [CrossRef]

- Gusmao Brissi, S.; Wong Chong, O.; Debs, L.; Zhang, J. A review on the interactions of robotic systems and lean principles in offsite construction. Eng. Constr. Archit. Manag. 2022, 29, 383–406. [Google Scholar] [CrossRef]

- Elmalky, A.; Mohamed, S.A.; ELDASH, K. Impact of Adopting Lean Principles on Construction Waste in Developing Countries. Eng. Res. J. 2024, 53, 82–93. [Google Scholar] [CrossRef]

- Wang, Y.; Bian, S.; Dong, L.; Li, H. Multiresolution Modeling of a Modular Building Design Process Based on Design Structure Matrix. Buildings 2023, 13, 2330. [Google Scholar] [CrossRef]

- Shabeen, S.R.; Krishnan, K.A. Application of lean manufacturing using value stream mapping (VSM) in precast component manufacturing: A case study. Mater. Today Proc. 2022, 65, 1105–1111. [Google Scholar] [CrossRef]

- Marzouk, M.; Elmaraghy, A. Design for deconstruction using integrated lean principles and bim approach. Sustainability 2021, 13, 7856. [Google Scholar] [CrossRef]

- Goyal, M.; Gao, Z. Integration of building information modeling (BIM) and prefabrication for lean construction. In Proceedings of the International Conference on Construction and Real Estate Management 2018, Charleston, SC, USA, 9–10 August 2018; pp. 78–84. [Google Scholar]

- Fahmy, M. Lean Principles Implementation in Construction Management: A One Team Approach. In Proceedings of the International Conference on Civil Infrastructure and Construction (CIC 2020), Doha, Qatar, 2–5 February 2020. [Google Scholar]

- Zhang, Y. A Framework to Improve Modular Construction Manufacturing Production Line Performance. Master’s Thesis, University of Alberta, Edmonton, AB, USA, 2017. [Google Scholar]

- Song, Y.; Wang, J.; Guo, F.; Lu, J.; Liu, S. Research on supplier selection of prefabricated building elements from the perspective of sustainable development. Sustainability 2021, 13, 6080. [Google Scholar] [CrossRef]

- Mostafa, S.; Tam, V.W.; Dumrak, J.; Mohamed, S. Leagile strategies for optimizing the delivery of prefabricated house building projects. Int. J. Constr. Manag. 2020, 20, 867–881. [Google Scholar] [CrossRef]

- Sahu, A.K.; Sharma, M.; Raut, R.D.; Sahu, A.K.; Sahu, N.K.; Antony, J.; Tortorella, G.L. Decision-making framework for supplier selection using an integrated MCDM approach in a lean-agile-resilient-green environment: Evidence from Indian automotive sector. TQM J. 2023, 35, 964–1006. [Google Scholar] [CrossRef]

- Yang, H.; Yeung, J.F.; Chan, A.P.; Chiang, Y.H.; Chan, D.W. A critical review of performance measurement in construction. J. Facil. Manag. 2010, 8, 269–284. [Google Scholar] [CrossRef]

- Liang, R.; Li, R.; Chong, H.-Y. Sustainable supplier selection for prefabricated megaprojects during COVID-19: A novel large group decision-making model. Build. Res. Inf. 2023, 51, 533–554. [Google Scholar] [CrossRef]

- Wang, H.; Guo, X. Selection of Prefabricated Components Supplier for Prefabricated Building Based on BP Neural Network Model. In Applied Mathematics, Modeling and Computer Simulation; IOS Press: Amsterdam, The Netherlands, 2022. [Google Scholar]

- El Mokadem, M. The classification of supplier selection criteria with respect to lean or agile manufacturing strategies. J. Manuf. Technol. Manag. 2017, 28, 232–249. [Google Scholar] [CrossRef]

- Tsai, W.C. Fuzzy measures of supplier evaluation under lean concepts. J. Oper. Res. Soc. 2017, 60, 1005–1011. [Google Scholar] [CrossRef]

- Rezaei, A.; Rahiminezhad Galankashi, M.; Mansoorzadeh, S.; Mokhatab Rafiei, F. Supplier Selection and Order Allocation with Lean Manufacturing Criteria: An Integrated MCDM and Bi-objective Modelling Approach. Eng. Manag. J. 2020, 32, 253–271. [Google Scholar] [CrossRef]

- Almasi, M.; Khoshfetrat, S.; Galankashi, M.R. Sustainable supplier selection and order allocation under risk and inflation condition. IEEE Trans. Eng. Manag. 2019, 68, 823–837. [Google Scholar] [CrossRef]

- Pamucar, D.; Torkayesh, A.E.; Biswas, S. Supplier selection in healthcare supply chain management during the COVID-19 pandemic: A novel fuzzy rough decision-making approach. Ann. Oper. Res. 2023, 328, 977–1019. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; You, X.-Y.; Liu, H.-C.; Wu, S.-M. An Extended VIKOR Method Using Intuitionistic Fuzzy Sets and Combination Weights for Supplier Selection. Symmetry 2017, 9, 169. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.-H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Jing, S.; Niu, Z.; Chang, P.-C. The application of VIKOR for the tool selection in lean management. J. Intell. Manuf. 2019, 30, 2901–2912. [Google Scholar] [CrossRef]

- Xu, F.; Liu, J.; Lin, S.; Yuan, J. A VIKOR-based approach for assessing the service performance of electric vehicle sharing programs: A case study in Beijing. J. Clean. Prod. 2017, 148, 254–267. [Google Scholar] [CrossRef]

- Rezaie, K.; Ramiyani, S.S.; Nazari-Shirkouhi, S.; Badizadeh, A. Evaluating performance of Iranian cement firms using an integrated fuzzy AHP–VIKOR method. Appl. Math. Model. 2014, 38, 5033–5046. [Google Scholar] [CrossRef]

- Valipour Parkouhi, S.; Safaei Ghadikolaei, A. A resilience approach for supplier selection: Using Fuzzy Analytic Network Process and grey VIKOR techniques. J. Clean. Prod. 2017, 161, 431–451. [Google Scholar] [CrossRef]

- Anvari, A.; Zulkifli, N.; Arghish, O. Application of a modified VIKOR method for decision-making problems in lean tool selection. Int. J. Adv. Manuf. Technol. 2014, 71, 829–841. [Google Scholar] [CrossRef]

- Liu, H.-C.; You, J.-X.; You, X.-Y.; Shan, M.-M. A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method. Appl. Soft Comput. 2015, 28, 579–588. [Google Scholar] [CrossRef]

- Soner, O.; Celik, E.; Akyuz, E. Application of AHP and VIKOR methods under interval type 2 fuzzy environment in maritime transportation. Ocean Eng. 2017, 129, 107–116. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Li, X.K.; Wang, X.M.; Lei, L. The application of an ANP-Fuzzy comprehensive evaluation model to assess lean construction management performance. Eng. Constr. Archit. Manag. 2020, 27, 356–384. [Google Scholar] [CrossRef]

- Barth, K.B.; Formoso, C.T. Requirements in performance measurement systems of construction projects from the lean production perspective. Front. Eng. Manag. 2021, 8, 442–455. [Google Scholar] [CrossRef]

- Ahmad, S.; Soetanto, R.; Goodier, C. Lean approach in precast concrete component production. Built Environ. Proj. Asset Manag. 2019, 9, 457–470. [Google Scholar] [CrossRef]

- Du, J.; Zhang, J.; Castro-Lacouture, D.; Hu, Y. Lean manufacturing applications in prefabricated construction projects. Autom. Constr. 2023, 150, 104790. [Google Scholar] [CrossRef]

- Feldmann, F.G. Towards lean automation in construction—Exploring barriers to implementing automation in prefabrication. Sustainability 2022, 14, 12944. [Google Scholar] [CrossRef]

- Liu, J.K.; Shi, G.S. Quality Control of a Complex Lean Construction Project Based on KanBIM Technology. Eurasia J. Math. Sci. Technol. Educ. 2017, 13, 5905–5919. [Google Scholar] [CrossRef]

- Kong, L.; Li, H.; Luo, H.; Ding, L.; Zhang, X. Sustainable performance of just-in-time (JIT) management in time-dependent batch delivery scheduling of precast construction. J. Clean. Prod. 2018, 193, 684–701. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Framling, K.; Koskela, L. Opportunities for enhanced lean construction management using Internet of Things standards. Autom. Constr. 2016, 61, 86–97. [Google Scholar] [CrossRef]

- Topaktas, R.; Altin, S.; Aydin, C.; Akkoc, A.; Urkmez, A.; Aydin, Z.B. Lean Tools Proposal to mitigate Delays and Cost Overruns in Construction Projects. Cent. Eur. J. Urol. 2020, 73, 336–341. [Google Scholar] [CrossRef]

- Xu, Y.G.; Qian, C. Lean Cost Analysis Based on BIM Modeling for Construction Project. Appl. Mech. Mater. 2014, 457–458, 1444–1447. [Google Scholar] [CrossRef]

- Pheng, L.S.; Gao, S.; Lin, J.L. Converging early contractor involvement (ECI) and lean construction practices for productivity enhancement: Some preliminary findings from Singapore. Int. J. Product. Perform. Manag. 2015, 64, 831–852. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision-making with the AHP: Why is the principal eigenvector necessary. Eur. J. Oper. Res. 2003, 145, 85–91. [Google Scholar] [CrossRef]

- Rahardjo, B.; Wang, F.-K.; Lo, S.-C.; Chou, J.-H. A Hybrid Multi-Criteria Decision-Making Model Combining DANP with VIKOR for Sustainable Supplier Selection in Electronics Industry. Sustainability 2023, 15, 4588. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, B.; Xu, C.; Li, L. Site selection decision framework using fuzzy ANP-VIKOR for large commercial rooftop PV system based on sustainability perspective. Sustain. Cities Soc. 2018, 40, 454–470. [Google Scholar] [CrossRef]

- Prasad, K.G.D.; Prasad, M.V.; Rao, S.V.V.B.; Patro, C.S. Supplier Selection through AHP-VIKOR Integrated Methodology. Int. J. Ind. Eng. 2016, 3, 1–6. [Google Scholar] [CrossRef]

- Chang, C.L. A modified VIKOR method for multiple criteria analysis. Environ. Monit. Assess. 2010, 168, 339–344. [Google Scholar] [CrossRef]

- Yu, T.; Shi, Q.; Zuo, J.; Chen, R. Critical factors for implementing sustainable construction practice in HOPSCA projects: A case study in China. Sustain. Cities Soc. 2018, 37, 93–103. [Google Scholar] [CrossRef]

- Petroutsatou, K.; Ladopoulos, I.; Nalmpantis, D. Hierarchizing the criteria of construction equipment procurement decision using the AHP method. IEEE Trans. Eng. Manag. 2021, 70, 3271–3282. [Google Scholar] [CrossRef]

- Falch, L.; de Silva, C.W. Improvement of VIKOR method with application to Multi-Objective design problems. Int. J. Inf. Technol. Decis. Mak. 2023, 22, 777–802. [Google Scholar] [CrossRef]

| 1st-Level Criteria | 2nd-Level Criteria | Main Sources |

|---|---|---|

| A1: Standardization | Z1: Production process standardization degree | [77] |

| Z2: Customized standard process design level | [78] | |

| Z3: The comprehensiveness of differentiated standard operating systems | [77] | |

| Z4: Standard operation level | [76] | |

| A2: Quality | Z5: Total productive maintenance level | [17] |

| Z6: Product quality and reliability level | [79] | |

| Z7: Equipment reliability or failure rate | [80] | |

| A3: Time | Z8: Production Takt and turnround time | [81] |

| Z9: Just-in-time and pull level | [82] | |

| Z10: Equipment utilization level | [77] | |

| A4: Cost | Z11: Buying price | [83] |

| Z12: Use and maintenance cost level | [84] | |

| Z13: Unit production cost | [83] | |

| A5: Flexibility | Z14: Mass customization production level of the quick response to customers’ demands | [85] |

| Score | Relative Importance |

|---|---|

| 1 | Criteria i and j are of equal importance. |

| 3 | Criteria i is weakly more important than j. |

| 5 | Criteria i is strongly more important than j. |

| 7 | Criteria i is very strongly more important than j. |

| 9 | Criteria i is absolutely more important than j. |

| Z1 | Z2 | Z3 | Zn | ||

|---|---|---|---|---|---|

| No. Expert | Stakeholder Group | No. | Main Position | Education Level | Experience |

|---|---|---|---|---|---|

| 1 | Tianjin University | 3 | Professor | Master’s | 5≤ |

| 2 | Tianjin University | 2 | Senior scholar | Bachelor’s | 5≤ |

| 3 | Yizhong | 1 | Universal manager | Master’s | 5≤ |

| 4 | Yizhong | 4 | Vice-Universal manager | Master’s | 5≤ |

| 5 | Yizhong | 5 | Project manager | Bachelor’s | 5≤ |

| 6 | Yuanda Factory | 2 | Factory director | Master’s | 5≤ |

| 7 | Other Factories | 3 | Universal manager | Master’s | 5≤ |

| 1st-Level Criteria | A1 | A2 | A3 | A4 | A5 |

|---|---|---|---|---|---|

| A1 | 1 | 1/3 | 1 | 1/5 | 3 |

| A2 | 3 | 1 | 3 | 1/3 | 5 |

| A3 | 1 | 1/3 | 1 | 1/5 | 3 |

| A4 | 5 | 3 | 5 | 1 | 7 |

| A5 | 1/3 | 1/5 | 1/3 | 1/7 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, P.; Gao, H.; Niu, Z.; Geng, L.; Hui, F.K.P.; Sun, C. The Supplier Selection of Prefabricated Component Production Line: A Lean-Based AHP–Improved VIKOR Framework. Buildings 2024, 14, 4018. https://doi.org/10.3390/buildings14124018

Dang P, Gao H, Niu Z, Geng L, Hui FKP, Sun C. The Supplier Selection of Prefabricated Component Production Line: A Lean-Based AHP–Improved VIKOR Framework. Buildings. 2024; 14(12):4018. https://doi.org/10.3390/buildings14124018

Chicago/Turabian StyleDang, Pei, Hui Gao, Zhanwen Niu, Linna Geng, Felix Kin Peng Hui, and Chao Sun. 2024. "The Supplier Selection of Prefabricated Component Production Line: A Lean-Based AHP–Improved VIKOR Framework" Buildings 14, no. 12: 4018. https://doi.org/10.3390/buildings14124018

APA StyleDang, P., Gao, H., Niu, Z., Geng, L., Hui, F. K. P., & Sun, C. (2024). The Supplier Selection of Prefabricated Component Production Line: A Lean-Based AHP–Improved VIKOR Framework. Buildings, 14(12), 4018. https://doi.org/10.3390/buildings14124018