A Review on the Effect of Synthetic Fibres, Including Macro Fibres, on the Thermal Behaviour of Fibre-Reinforced Concrete

Abstract

1. Introduction

1.1. Thermal Performance of Concrete

1.2. Fibre-Reinforced Concrete

1.2.1. Steel Fibre-Reinforced Concrete

1.2.2. Polymer Fibre-Reinforced Concrete

1.2.3. Glass Fibre-Reinforced Concrete

1.2.4. Natural Fibre-Reinforced Concrete

1.2.5. Basalt-Reinforced Concrete

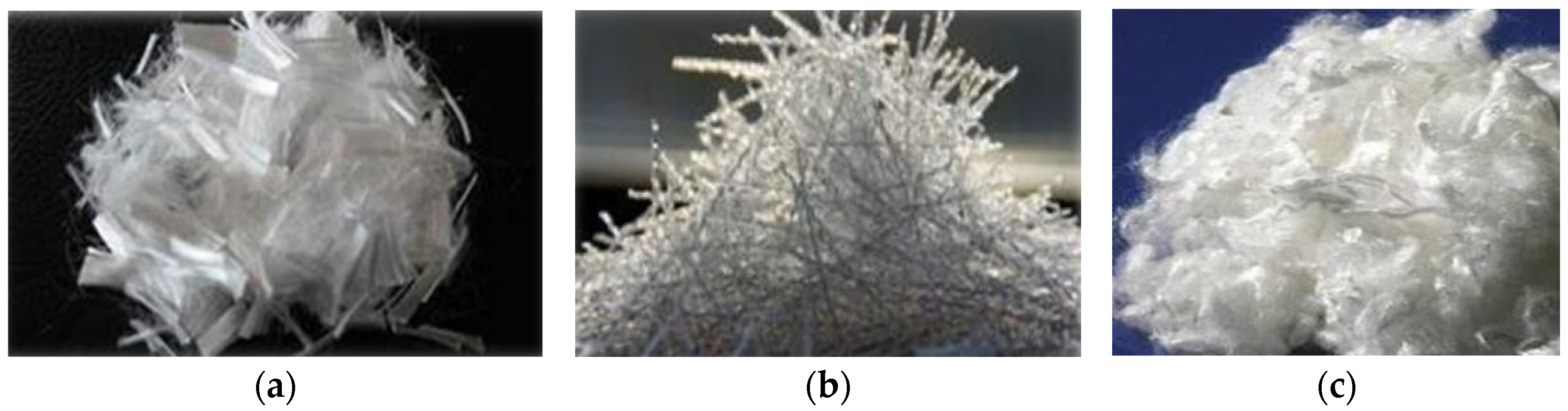

2. Properties of Synthetic Polymer Fibres

| Types of Fibres | Tensile Strength (MPa) | MOE (GPa) | Relative Density (kg/m3) | Acid/Alkali Resistance | Elongation at Break (%) | Approx. Cost ($ /kg) |

|---|---|---|---|---|---|---|

| PP fibres [14,42,43] | 240–900 | 1.5–12 | 910 | High | 15–80 | 1–2.5 |

| PVA fibres [44,45,46] | 1000–1600 | 20–42.8 | 1290–1300 | High | 6–7 | 1–15 |

| PE fibres [47,48] | 80–600 | 5–100 | 920–960 | High | 4–100 | 2–20 |

| Steel fibres as comparison [49] | 500–2000 | 200 | 7840 | Low to High | 0.5–3.5 | 1–8 |

3. Thermal Performance of Different Synthetic Fibres in Concrete Composites

3.1. Thermal Performance of PP Fibre-Reinforced Concrete

3.2. Thermal Efficiency of PE Fibre-Reinforced Concrete

3.3. Thermal Performance of PVA Fibre-Reinforced Concrete

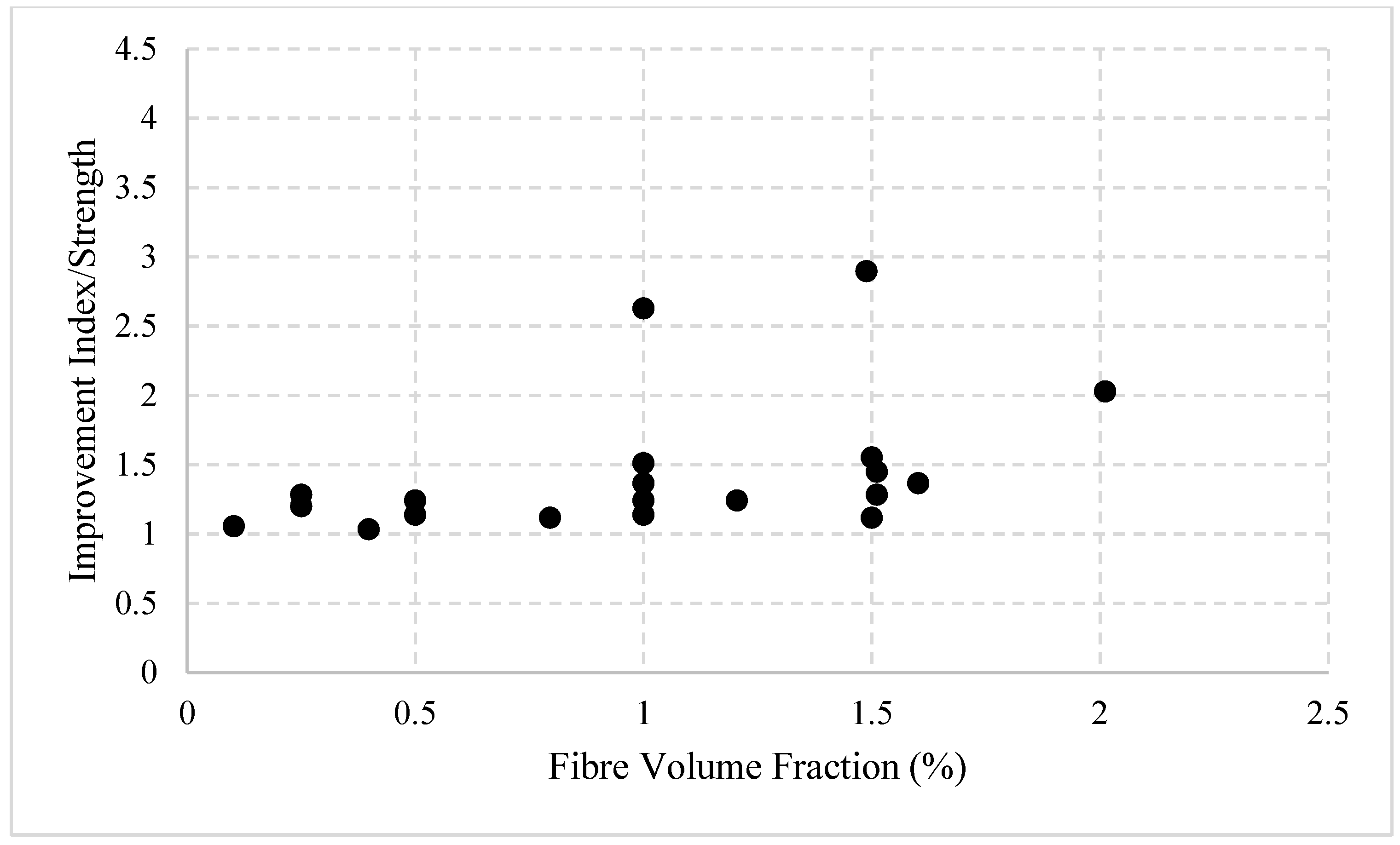

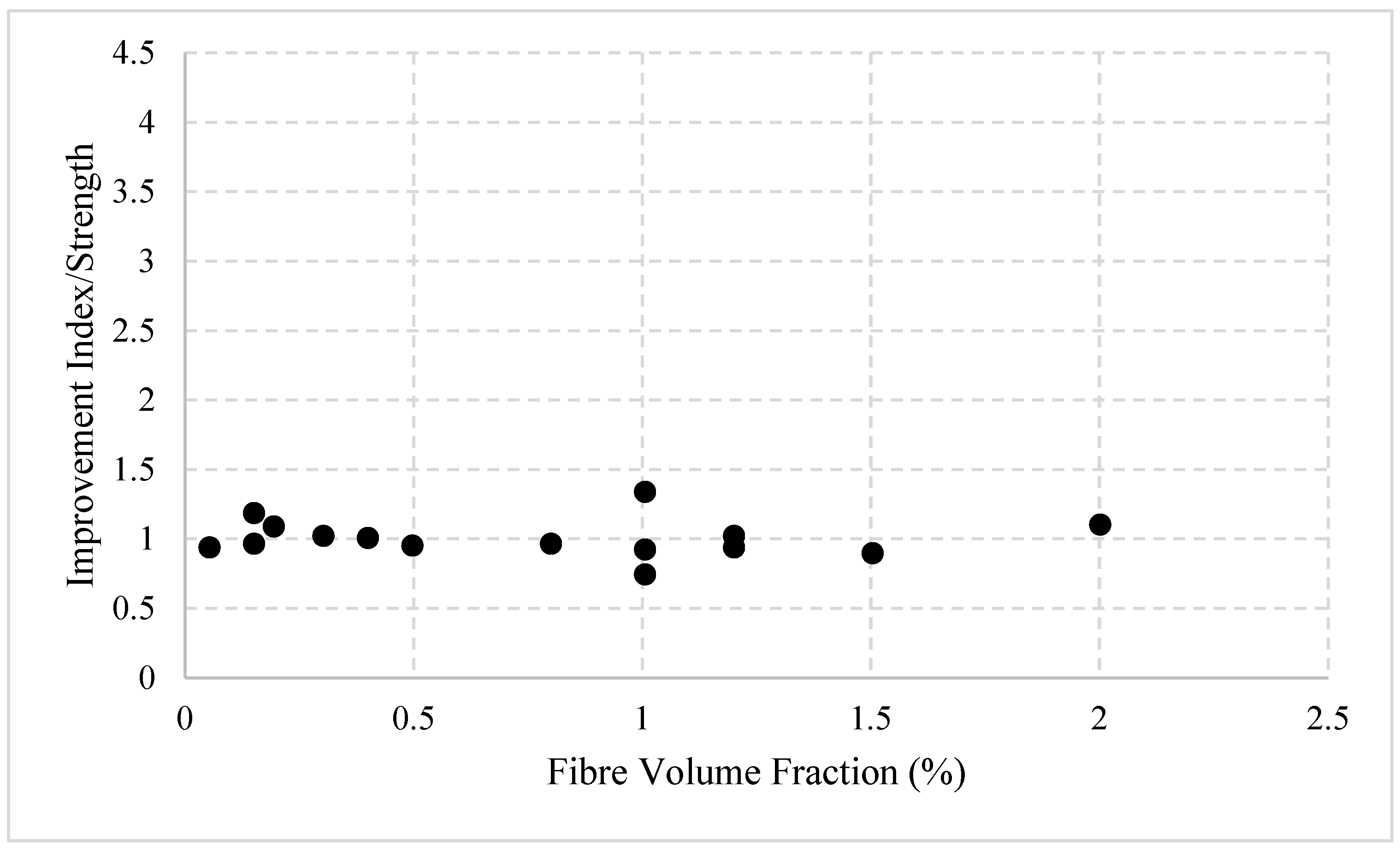

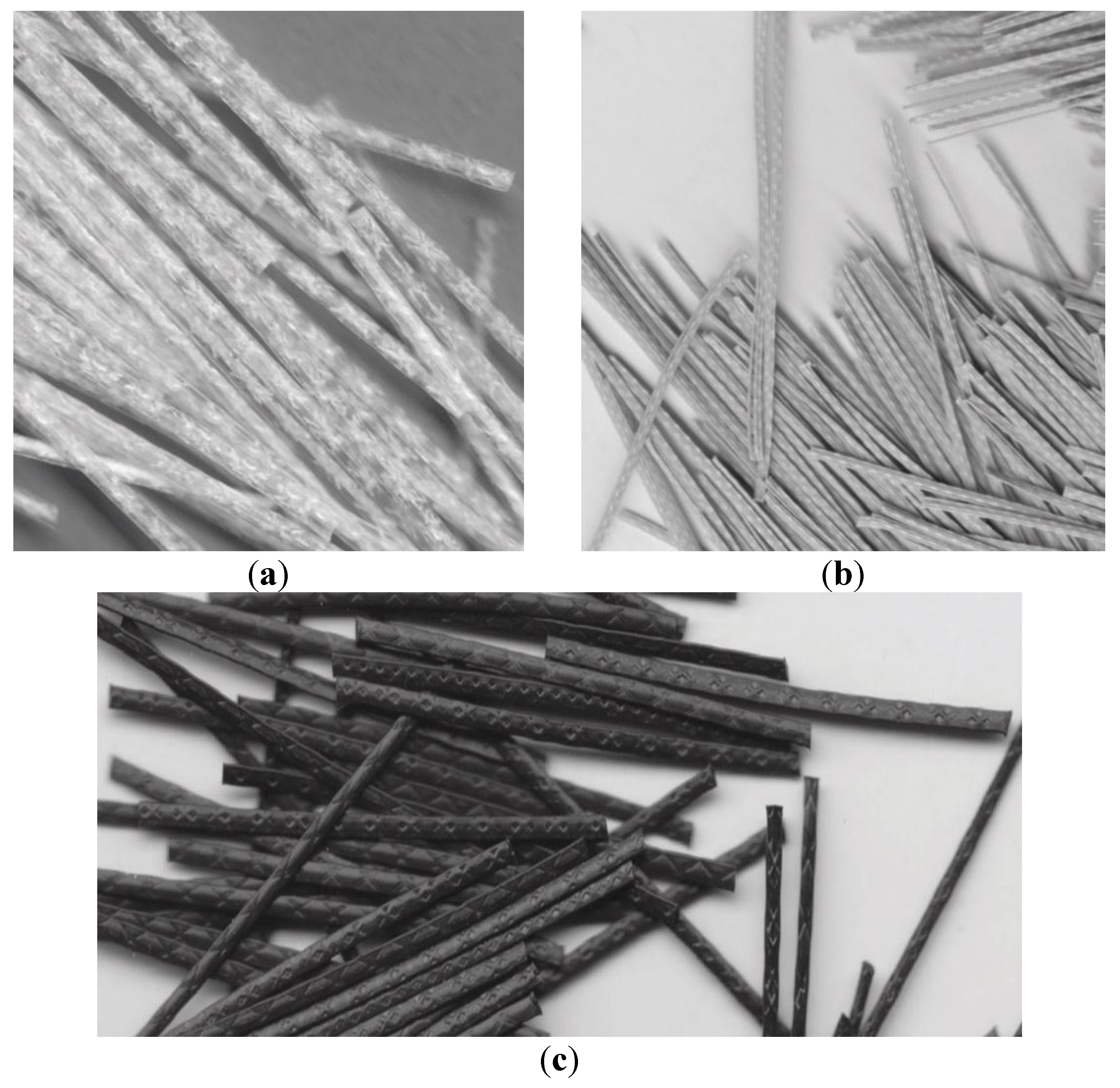

3.4. Thermal Efficiency of Macro Fibre-Reinforced Concrete

3.5. Summary of Material Properties and Thermal Efficiency of Fibre-Reinforced Concrete

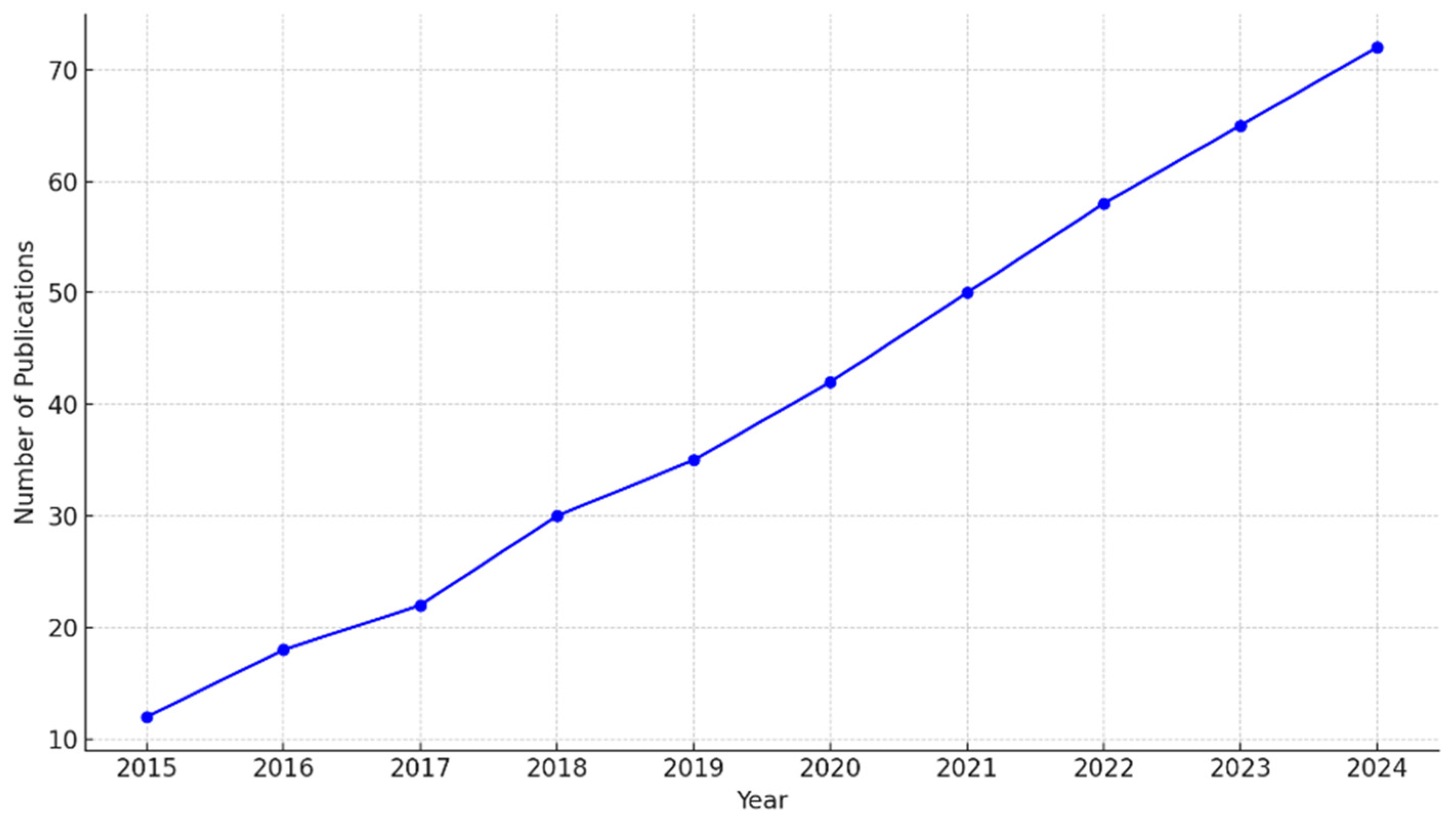

3.6. Bibliometric Analysis

4. Recycling Synthetic Fibre-Reinforced Concrete: End-of-Life Solutions

5. Role of Fibres in Zero-Cement and 3D-Printed Concrete

6. Temperature Effects on Bond Performance and Post-Fire Characteristics of Fibres in Concrete

6.1. Variation in Bond Performance at Various Temperatures

- Steel Fibres: Steel fibres have a higher thermal expansion coefficient compared to concrete. At elevated temperatures, steel fibres expand more than the surrounding matrix, which can enhance the mechanical interlock up to a certain temperature. However, excessive temperatures may cause micro-cracking in the concrete, reducing the bond strength. Studies have shown that bond strength decreases significantly beyond 300 °C due to the degradation of both the fibre and the matrix [21,42].

- Polypropylene Fibres: Polypropylene fibres have a low melting point (~160 °C). When exposed to high temperatures, they soften and melt, leading to a loss in bond and mechanical reinforcement. However, the melting of these fibres can create additional porosity, which may help in relieving internal pressures caused by steam during heating, potentially reducing spalling in concrete [54,55,56,57,58,59,60,61].

- Basalt and Carbon Fibres: Basalt fibres maintain their properties up to about 600 °C, while carbon fibres can withstand even higher temperatures. The bond performance of these fibres at elevated temperatures is influenced by the stability of the concrete matrix and the integrity of the fibre–matrix interface. Thermal mismatch can still lead to bond deterioration, but these fibres generally perform better under high-temperature conditions compared to synthetic fibres [74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89].

6.2. Post-Fire Characteristics of Fibres in Concrete

- Steel Fibres: Post-fire, steel fibres may retain some mechanical properties if temperatures did not exceed critical thresholds. However, oxidation and scaling can occur, reducing cross-sectional area and bond strength. The surrounding concrete is often weakened due to dehydration and micro-cracking, further diminishing the composite action [21,45].

- Basalt and Carbon Fibres: These fibres exhibit better retention of mechanical properties after fire exposure. Basalt fibres can maintain structural integrity up to 400–500 °C, while carbon fibres can endure even higher temperatures. However, the degradation of the concrete matrix at extreme temperatures can still adversely affect the overall composite performance [76,77,78,79,80,81].

6.3. Implications for Design and Future Research

- Material Selection: Choosing fibres with appropriate thermal properties can enhance high-temperature performance. For structures exposed to elevated temperatures, fibres like basalt or carbon may be more suitable.

- Design Considerations: Engineers should account for potential reductions in bond strength due to temperature effects when designing FRC elements, especially in fire-prone environments.

- Future Research: Further studies are needed to develop fibres and concrete matrices with compatible thermal expansions, improve high-temperature bond performance, and establish standardized testing methods for assessing thermal effects on FRC.

7. Application Scenarios for Synthetic Fibres in Concrete

- Polypropylene (PP) fibres are highly effective in mitigating explosive spalling, making them particularly suitable for high-rise buildings and tunnels that are at high risk of fire exposure. The ability of PP fibres to create micro-channels for vapour release at elevated temperatures helps reduce spalling and protect structural integrity during fire events.

- Polyvinyl alcohol (PVA) fibres, with their higher tensile and flexural strength, are ideal for critical infrastructure that is exposed to combined thermal and mechanical stresses, such as bridges and industrial facilities. Their superior modulus of elasticity also contributes to the durability of these structures, even under fire conditions.

- Macro fibres, with their enhanced corrosion resistance and high modulus of elasticity, are well suited for infrastructure exposed to aggressive environments, such as marine structures or chemical plants. Their unique properties help improve thermal stability, reduce cracking, and extend the service life of these structures. By highlighting these specific application scenarios, the practical utility and unique advantages of synthetic fibres in various contexts become clearer.

8. Conclusions

- Synthetic fibre reinforcement reduces spalling at elevated temperatures due to the lower melting point of the fibres, which allows for vapour release, preventing explosive spalling. PP fibres, in particular, are effective in mitigating explosive spalling.

- Concrete with synthetic fibres demonstrates low sensitivity to corrosion effects, chemical reactions, and other harsh environmental factors, making it suitable for alkali environments. Synthetic fibres help protect rebars against chloride penetration, thereby delaying corrosion.

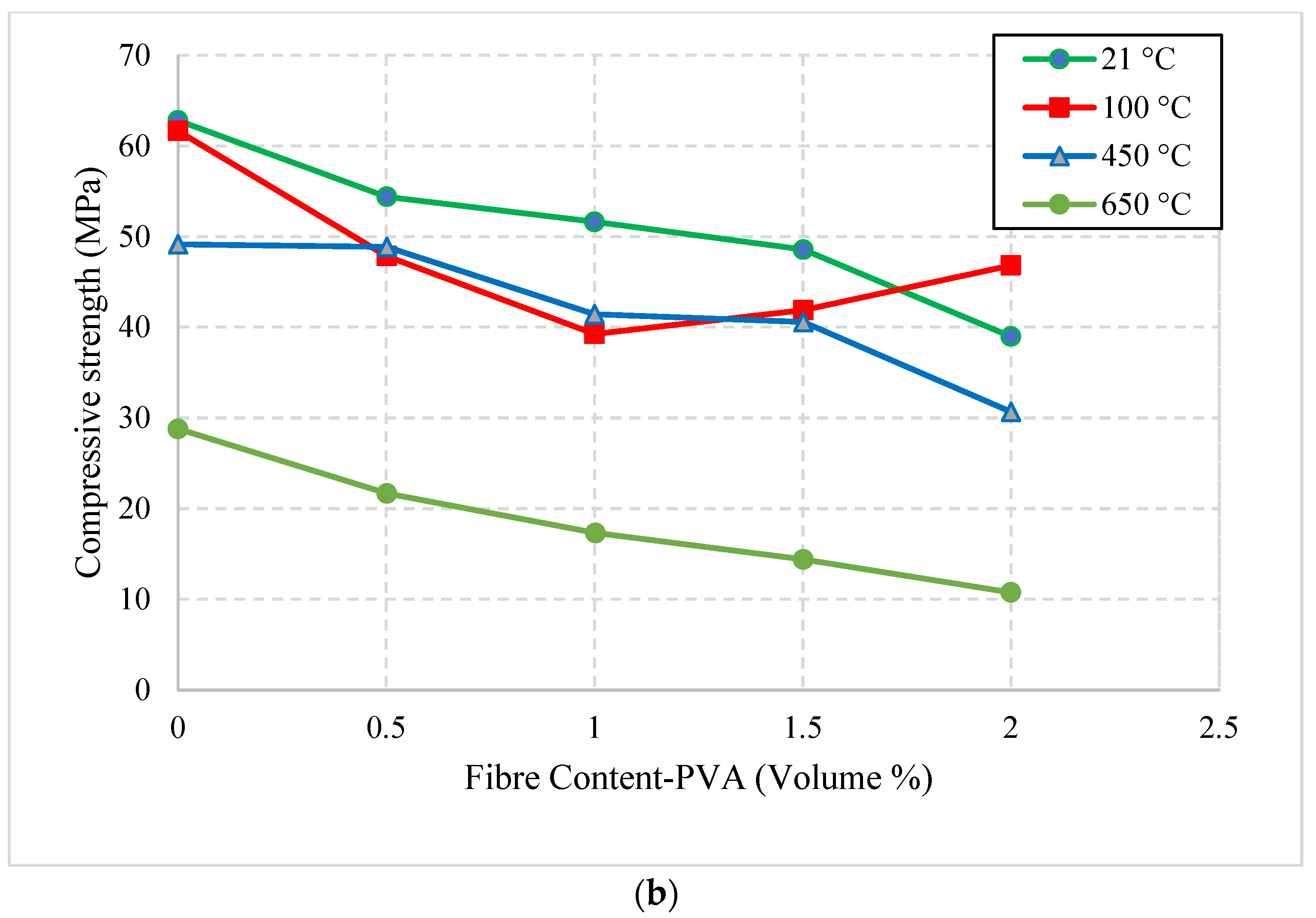

- Despite their benefits, synthetic fibres generally decrease the compressive strength of the composite material.

- PP fibres are effective in enhancing crack resistance and reducing spalling at elevated temperatures, but significant losses in modulus of elasticity, compressive strength, and tensile strength are observed at high temperatures.

- PE fibres are less effective at mitigating fire-induced damage, as continuous spalling occurs at higher temperatures.

- PE and PVA fibres contribute to greater improvements in tensile and flexural strength compared to PP fibres, due to their higher strength and modulus of elasticity.

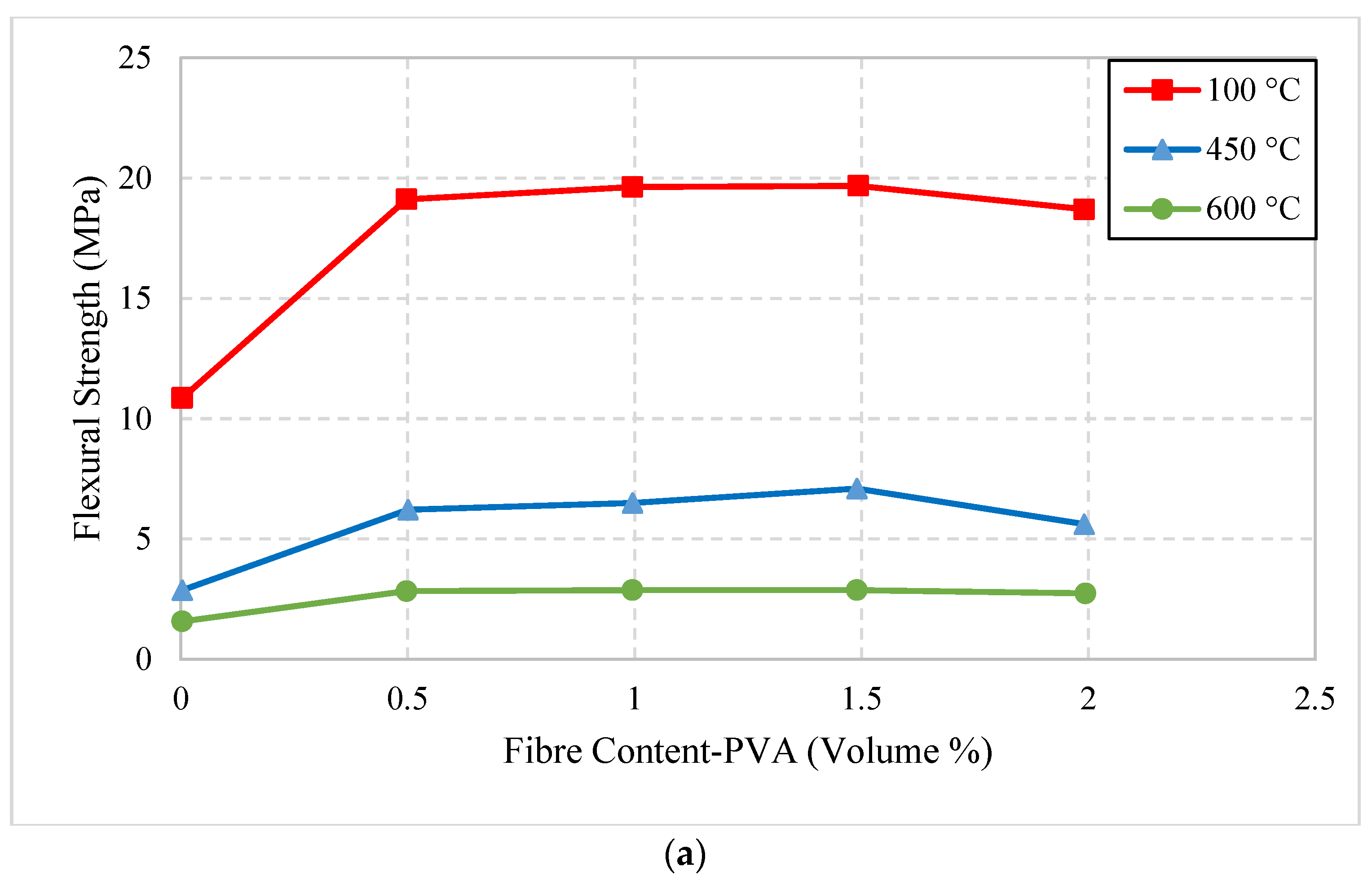

- While PVA fibres exhibit a reduction in compressive strength at higher temperatures, they also reduce micro-cracking and improve flexibility and flexural strength. When used within specific load limits, PVA fibres can serve as primary reinforcement.

- Macro fibres significantly reduce cracking potential and mitigate spalling, and they have beneficial effects on modulus of elasticity, corrosion resistance, and thermal stability. However, they do not substantially improve compressive and flexural strengths. Macro fibres present an appealing alternative to current synthetic fibres such as PP, PE, and PVA due to their many advantages. However, in-depth studies on the thermal characteristics of macro fibre-reinforced concrete at elevated temperatures are still lacking. More research is needed to evaluate the impact of these fibres on thermal conductivity, physical damage (spalling), and the residual mechanical properties of macro fibre-reinforced concrete during and after fire exposure.

- PP fibres have been shown to reduce explosive spalling by up to 80% when incorporated at dosages of 2 kg/m3 in concrete exposed to temperatures above 600 °C [5]. Compared to PVA fibres, which improve tensile strength by 30% [55], PP fibres are particularly effective in mitigating spalling but result in a significant decrease in compressive strength at high temperatures.

- Çavdar [86] found that PVA fibres increased flexural strength by 45%, outperforming PP fibres, which showed a 20% improvement. This indicates that, while PP fibres are effective for reducing spalling, PVA fibres provide superior mechanical enhancement.

Funding

Data Availability Statement

Conflicts of Interest

References

- Lou, C.; Qi, A.; Ye, J.; Lin, S. Experimental study on mechanical properties of high strength concrete with solid waste. IOP Conf. Ser. Mater. Sci. Eng. 2018, 392, 042012. [Google Scholar] [CrossRef]

- Hassan, A.M. Behavior of Continuous Flat Slab Exposed to Fire. World Appl. Sci. J. 2013, 23, 788–794. [Google Scholar]

- Werner, S.; Rogge, A. The effect of various fire-exposed surface dimensions on the spalling of concrete specimens. Fire Mater. 2015, 39, 545–556. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Code provisions for high strength concrete strength-temperature relationship at elevated temperatures. Mater. Struct. 2003, 36, 91–98. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. On residual strength of high-performance concrete with and without polypropylene fibres at elevated temperatures. Fire Saf. J. 2006, 41, 115–121. [Google Scholar] [CrossRef]

- Ulm, F.-J.; Coussy, O.; Bažant, Z.P. The “Chunnel” fire. I: Chemoplastic softening in rapidly heated concrete. J. Eng. Mech. 1999, 125, 272–282. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Kaplan, M.F.; Bazant, Z.P. Concrete at High Temperatures: Material Properties and Mathematical Models; Longman Group Limited: Essex, UK, 1996. [Google Scholar]

- Gawin, D.; Pesavento, F.; Castells, A.G. On reliable predicting risk and nature of thermal spalling in heated concrete. Arch. Civ. Mech. Eng. 2018, 18, 1219–1227. [Google Scholar] [CrossRef]

- Sabtu, H.B.; Stewart, M.G. The Effect of Reinforcement Confinement on Concrete Cover Cracking in Reinforced Concrete Structures. In Materials to Structures: Advancement Through Innovation; CRC Press: Boca Raton, FL, USA, 2012; p. 351. [Google Scholar]

- Kodur, V.K. Innovative strategies for enhancing fire performance of high-strength concrete structures. Adv. Struct. Eng. 2018, 21, 1723–1732. [Google Scholar] [CrossRef]

- Kodur, V.; Bhatt, P. A numerical approach for modeling response of fiber reinforced polymer strengthened concrete slabs exposed to fire. Compos. Struct. 2018, 187, 226–240. [Google Scholar] [CrossRef]

- AzariJafari, H.; Amiri, M.J.T.; Ashrafian, A.; Rasekh, H.; Barforooshi, M.J.; Berenjian, J. Ternary blended cement: An eco-friendly alternative to improve resistivity of high-performance self-consolidating concrete against elevated temperature. J. Clean. Prod. 2019, 223, 575–586. [Google Scholar] [CrossRef]

- Hasan, M.; Afroz, M.; Mahmud, H. An experimental investigation on mechanical behavior of macro synthetic fiber reinforced concrete. Int. J. Civ. Environ. Eng. 2011, 11, 19–23. [Google Scholar]

- Deng, Z.; Li, J. Mechanical behaviors of concrete combined with steel and synthetic macro-fibers. Int. J. Phys. Sci 2006, 1, 57–66. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, J.A.; Toptan, F. An experimental study on the corrosion susceptibility of Recycled Steel Fiber Reinforced Concrete. Cem. Concr. Compos. 2019, 96, 138–153. [Google Scholar] [CrossRef]

- Aslani, F.; Sun, J.; Bromley, D.; Ma, G. Fiber-reinforced lightweight self-compacting concrete incorporating scoria aggregates at elevated temperatures. Struct. Concr. 2019, 20, 1022–1035. [Google Scholar] [CrossRef]

- Moghadam, M.A.; Izadifard, R. Evaluation of shear strength of plain and steel fibrous concrete at high temperatures. Constr. Build. Mater. 2019, 215, 207–216. [Google Scholar] [CrossRef]

- Lau, A.; Anson, M. Effect of high temperatures on high performance steel fibre reinforced concrete. Cem. Concr. Res. 2006, 36, 1698–1707. [Google Scholar] [CrossRef]

- Purkiss, J. Steel fibre reinforced concrete at elevated temperatures. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 179–184. [Google Scholar] [CrossRef]

- Lie, T.; Kodur, V. Thermal and mechanical properties of steel-fibre-reinforced concrete at elevated temperatures. Can. J. Civ. Eng. 1996, 23, 511–517. [Google Scholar] [CrossRef]

- Çavdar, A. Investigation of freeze–thaw effects on mechanical properties of fiber reinforced cement mortars. Compos. Part B Eng. 2014, 58, 463–472. [Google Scholar] [CrossRef]

- Liu, L.; Yang, G.; He, J.; Liu, H.; Gong, J.; Yang, H.; Yang, W.; Joyklad, P. Impact of fibre factor and temperature on the mechanical properties of blended fibre-reinforced cementitious composite. Case Stud. Constr. Mater. 2022, 16, e00773. [Google Scholar] [CrossRef]

- Kasagani, H.; Rao, C. Effect of graded fibers on stress strain behaviour of Glass Fiber Reinforced Concrete in tension. Constr. Build. Mater. 2018, 183, 592–604. [Google Scholar] [CrossRef]

- Kavitha, S.; Kala, T.F. A review on natural fibres in the concrete. Int. J. Adv. Eng. Technol. 2017, 1, 1–4. [Google Scholar]

- Reis, J.; Ferreira, A. Assessment of fracture properties of epoxy polymer concrete reinforced with short carbon and glass fibers. Constr. Build. Mater. 2004, 18, 523–528. [Google Scholar] [CrossRef]

- Reis, J.; Ferreira, A. The influence of notch depth on the fracture mechanics properties of polymer concrete. Int. J. Fract. 2003, 124, 33–42. [Google Scholar] [CrossRef]

- Soroushian, P.; Ravanbakhsh, S. Control of plastic shrinkage cracking with specialty cellulose fibers. Mater. J. 1998, 95, 429–435. [Google Scholar]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jyothsna, G.; Sofi, A.; Shanmugam, V.; Thomas, B. A comprehensive review on the use of natural fibers in cement/geopolymer concrete: A step towards sustainability. Case Stud. Constr. Mater. 2023, 19, e02244. [Google Scholar] [CrossRef]

- Llorens, J.; Julián, F.; Gifra, E.; Espinach, F.X.; Soler, J.; Chamorro, M.À. An Approach to Understanding the Hydration of Cement-Based Composites Reinforced with Untreated Natural Fibers. Sustainability 2023, 15, 9388. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Sustainable Reuse of Waste Tire Textile Fibers (WTTF) as Reinforcements. Polymers 2022, 14, 3933. [Google Scholar] [CrossRef]

- Ren, W.; Xu, J.; Su, H. Dynamic compressive behavior of basalt fiber reinforced concrete after exposure to elevated temperatures. Fire Mater. 2016, 40, 738–755. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Thong, C.; Teo, D.; Ng, C. Application of polyvinyl alcohol (PVA) in cement-based composite materials: A review of its engineering properties and microstructure behavior. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Khatana, S. A review on the use of fibers in reinforced cementitious concrete. J. Ind. Text. 2015, 45, 239–264. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Alberti, M.; Enfedaque, A.; Gálvez, J. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Daniel, J.; Ahmad, S.; Arockiasamy, M.; Ball, H.; Batson, G.; Criswell, M.; Dorfmueller, D.; Fernandez, A.; Gale, D.; Antonio, J. State-of-the-art report on fiber reinforced concrete reported by ACI Committee 544. ACI J. 2002, 96, 1–66. [Google Scholar]

- Ivorra, S.; Garcés, P.; Catalá, G.; Andión, L.G.; Zornoza, E. Effect of silica fume particle size on mechanical properties of short carbon fiber reinforced concrete. Mater. Des. 2010, 31, 1553–1558. [Google Scholar] [CrossRef]

- Hsie, M.; Tu, C.; Song, P. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. From straw in bricks to modern use of microfibers in cementitious composites for improved autogenous healing–A review. Constr. Build. Mater. 2015, 95, 774–787. [Google Scholar] [CrossRef]

- Arisoy, B.; Wu, H.-C. Material characteristics of high performance lightweight concrete reinforced with PVA. Constr. Build. Mater. 2008, 22, 635–645. [Google Scholar] [CrossRef]

- Sun, W.; Chen, H.; Luo, X.; Qian, H. The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem. Concr. Res. 2001, 31, 595–601. [Google Scholar] [CrossRef]

- Banyhussan, Q.S.; Yıldırım, G.; Bayraktar, E.; Demirhan, S.; Şahmaran, M. Deflection-hardening hybrid fiber reinforced concrete: The effect of aggregate content. Constr. Build. Mater. 2016, 125, 41–52. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Ahmed, S.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Poorsaheli, H.B.; Behravan, A.; Aghda, S.T.T.; Gholami, A. A study on the durability parameters of concrete structures reinforced with synthetic fibers in high chloride concentrated shorelines. Constr. Build. Mater. 2019, 200, 578–585. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, Q. Microscopic, physical and mechanical analysis of polypropylene fiber reinforced concrete. Mater. Sci. Eng. A 2009, 527, 198–204. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Tosun, K.; Baradan, B. Effects of fibre type and matrix structure on the mechanical performance of self-compacting micro-concrete composites. Cem. Concr. Res. 2009, 39, 1023–1032. [Google Scholar] [CrossRef]

- Bangi, M.R.; Horiguchi, T. Effect of fibre type and geometry on maximum pore pressures in fibre-reinforced high strength concrete at elevated temperatures. Cem. Concr. Res. 2012, 42, 459–466. [Google Scholar] [CrossRef]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Said, S.H.; Razak, H.A. The effect of synthetic polyethylene fiber on the strain hardening behavior of engineered cementitious composite (ECC). Mater. Des. 2015, 86, 447–457. [Google Scholar] [CrossRef]

- Ohtsu, M.; Uddin, F.A.; Tong, W.; Murakami, K. Dynamics of spall failure in fiber reinforced concrete due to blasting. Constr. Build. Mater. 2007, 21, 511–518. [Google Scholar] [CrossRef]

- Choi, J.; Zi, G.; Hino, S.; Yamaguchi, K.; Kim, S. Influence of fiber reinforcement on strength and toughness of all-lightweight concrete. Constr. Build. Mater. 2014, 69, 381–389. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Bazli, M.; Oskouei, A.V.; Zhao, X.-L. The effect of elevated temperatures on the compressive section capacity of pultruded GFRP profiles. Constr. Build. Mater. 2020, 249, 118725. [Google Scholar] [CrossRef]

- Sarvaranta, L.; Mikkola, E. Fibre mortar composites under thermal exposure. In Nordic Concrete Research Meeting, August 1993; Norsk Betongforening: Göteborg, Sweden, 1993; pp. 157–159. [Google Scholar]

- Pardon, D. Comportement au feu des BHP Additionnés de Fibres Organiques. Formulations Fibrées. Essais sur éléments en Grandeur; Centre Scientifique et Technique du Batiment, le Portail du Système d’Information du Développement Durable et de l’Environnement (SIDE): Marne-la-Vallée, France, 2003. [Google Scholar]

- Lennon, T.; Clayton, N. Fire tests on high grade concrete with polypropylene fibres. In Proceedings of the 5th International Symposium on the Utilisation of High Strength/High Performance Concrete, Savdejord, Norway, 20–24 June 1999. [Google Scholar]

- Liu, J.-C.; Tan, K.H. Fire resistance of ultra-high performance strain hardening cementitious composite: Residual mechanical properties and spalling resistance. Cem. Concr. Compos. 2018, 89, 62–75. [Google Scholar] [CrossRef]

- Kalifa, P.; Chene, G.; Galle, C. High-temperature behaviour of HPC with polypropylene fibres: From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Davoodnabi, S.M. Behavior of steel-concrete composite beam using angle shear connectors at fire condition. Steel Compos. Struct. Int. J. 2019, 30, 141–147. [Google Scholar]

- Shahabi, S.; Sulong, N.; Shariati, M.; Shah, S. Performance of shear connectors at elevated temperatures-A review. Steel Compos. Struct 2016, 20, 185–203. [Google Scholar] [CrossRef]

- Sinaei, H.; Jumaat, M.Z.; Shariati, M. Numerical investigation on exterior reinforced concrete Beam-Column joint strengthened by composite fiber reinforced polymer (CFRP). Int. J. Phys. Sci 2011, 6, 6572–6579. [Google Scholar]

- Uysal, M.; Tanyildizi, H. Estimation of compressive strength of self compacting concrete containing polypropylene fiber and mineral additives exposed to high temperature using artificial neural network. Constr. Build. Mater. 2012, 27, 404–414. [Google Scholar] [CrossRef]

- Tanyildizi, H. Statistical analysis for mechanical properties of polypropylene fiber reinforced lightweight concrete containing silica fume exposed to high temperature. Mater. Des. 2009, 30, 3252–3258. [Google Scholar] [CrossRef]

- Khoury, G. Polypropylene fibres in heated concrete. Part 2: Pressure relief mechanisms and modelling criteria. Mag. Concr. Res. 2008, 60, 189–204. [Google Scholar] [CrossRef]

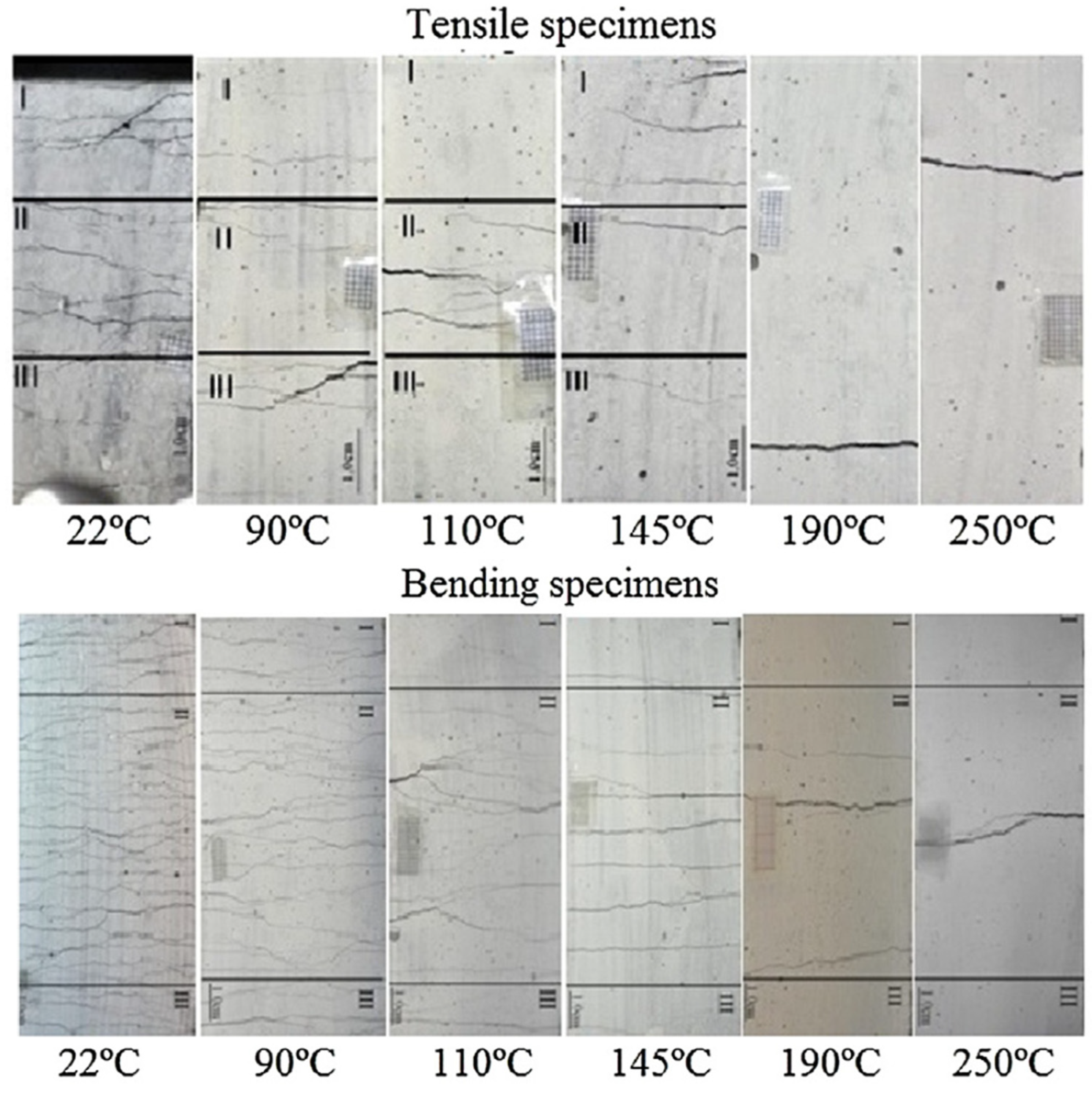

- Zhang, Q.; Li, V.C. Development of durable spray-applied fire-resistive Engineered Cementitious Composites (SFR-ECC). Cem. Concr. Compos. 2015, 60, 10–16. [Google Scholar] [CrossRef]

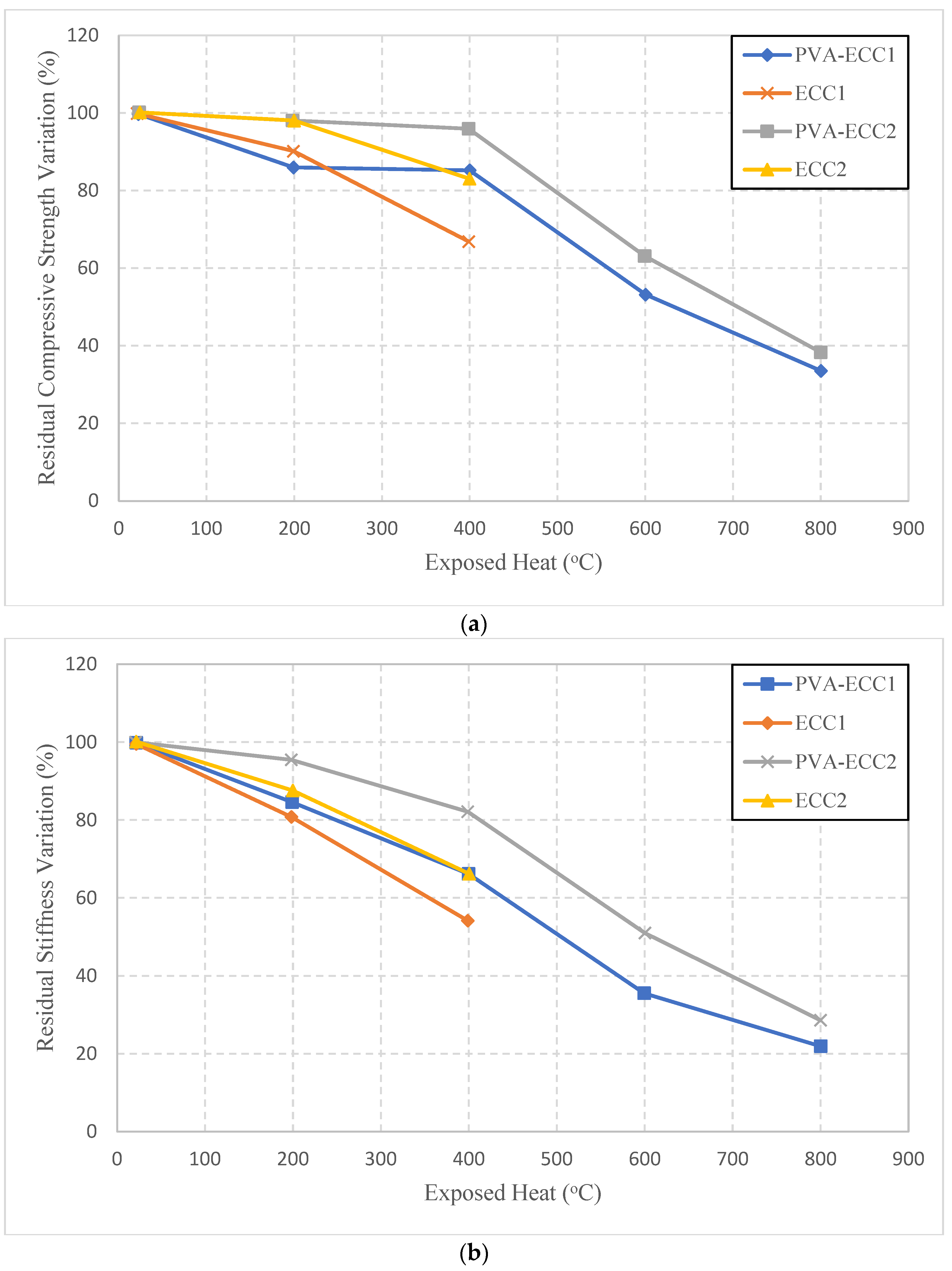

- Şahmaran, M.; Özbay, E.; Yücel, H.E.; Lachemi, M.; Li, V.C. Effect of fly ash and PVA fiber on microstructural damage and residual properties of engineered cementitious composites exposed to high temperatures. J. Mater. Civ. Eng. 2011, 23, 1735–1745. [Google Scholar] [CrossRef]

- Pliya, P.; Beaucour, A.; Noumowé, A. Contribution of cocktail of polypropylene and steel fibres in improving the behaviour of high strength concrete subjected to high temperature. Constr. Build. Mater. 2011, 25, 1926–1934. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Lim, N.H.A.S.; Sam, A.R.M.; Samadi, M. Effects of Elevated Temperatures on Residual Properties of Concrete Reinforced with Waste Polypropylene Carpet Fibres. Arab J. Sci. Eng. 2018, 43, 1673–1686. [Google Scholar] [CrossRef]

- Hiremath, P.N.; Yaragal, S.C. Performance evaluation of reactive powder concrete with polypropylene fibers at elevated temperatures. Constr. Build. Mater. 2018, 169, 499–512. [Google Scholar] [CrossRef]

- Aslani, F.; Kelin, J. Assessment and development of high-performance fibre-reinforced lightweight self-compacting concrete including recycled crumb rubber aggregates exposed to elevated temperatures. J. Clean. Prod. 2018, 200, 1009–1025. [Google Scholar] [CrossRef]

- Varona, F.; Baeza, F.J.; Bru, D.; Ivorra, S. Evolution of the bond strength between reinforcing steel and fibre reinforced concrete after high temperature exposure. Constr. Build. Mater. 2018, 176, 359–370. [Google Scholar] [CrossRef]

- Varona, F.; Baeza, F.J.; Bru, D.; Ivorra, S. Influence of high temperature on the mechanical properties of hybrid fibre reinforced normal and high strength concrete. Constr. Build. Mater. 2018, 159, 73–82. [Google Scholar] [CrossRef]

- Xargay, H.; Folino, P.; Sambataro, L.; Etse, G. Temperature effects on failure behavior of self-compacting high strength plain and fiber reinforced concrete. Constr. Build. Mater. 2018, 165, 723–734. [Google Scholar] [CrossRef]

- Hou, X.; Ren, P.; Rong, Q.; Zheng, W.; Zhan, Y. Comparative fire behavior of reinforced RPC and NSC simply supported beams. Eng. Struct. 2019, 185, 122–140. [Google Scholar] [CrossRef]

- Hou, X.; Ren, P.; Rong, Q.; Zheng, W.; Zhan, Y. Effect of fire insulation on fire resistance of hybrid-fiber reinforced reactive powder concrete beams. Compos. Struct. 2019, 209, 219–232. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Yang, E.-H.; Tan, K.H. Effects of geometry and fraction of polypropylene fibers on permeability of ultra-high performance concrete after heat exposure. Cem. Concr. Res. 2019, 116, 168–178. [Google Scholar] [CrossRef]

- Zhang, D.; Dasari, A.; Tan, K.H. On the mechanism of prevention of explosive spalling in ultra-high performance concrete with polymer fibers. Cem. Concr. Res. 2018, 113, 169–177. [Google Scholar] [CrossRef]

- Ozawa, M.; Parajuli, S.S.; Uchida, Y.; Zhou, B. Preventive effects of polypropylene and jute fibers on spalling of UHPC at high temperatures in combination with waste porous ceramic fine aggregate as an internal curing material. Constr. Build. Mater. 2019, 206, 219–225. [Google Scholar] [CrossRef]

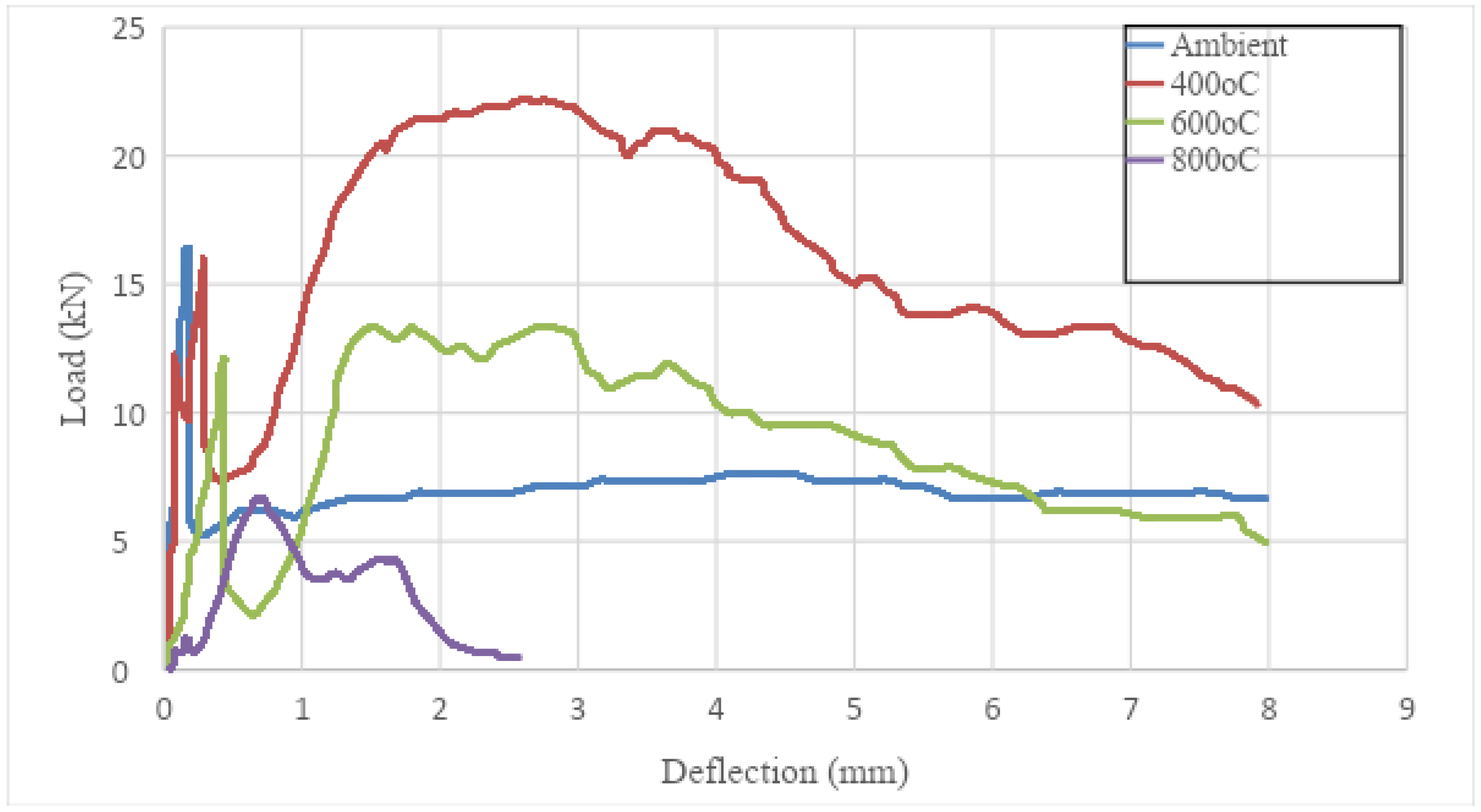

- Sukontasukkul, P.; Pomchiengpin, W.; Songpiriyakij, S. Post-crack (or post-peak) flexural response and toughness of fiber reinforced concrete after exposure to high temperature. Constr. Build. Mater. 2010, 24, 1967–1974. [Google Scholar] [CrossRef]

- Çavdar, A. The effects of high temperature on mechanical properties of cementitious composites reinforced with polymeric fibers. Compos. Part B Eng. 2013, 45, 78–88. [Google Scholar] [CrossRef]

- Shuai, F.; Zhu, H.; Lam, Y.K.; Sham, M.L.; Poon, C.S.; Li, F.; Ng, P.L. High Performance Fire Resistant Concrete Containing Hybrid Fibers and Nano Particles. U.S. Patent 10,071,934, 11 September 2018. [Google Scholar]

- da Silva Magalhães, M.; Toledo Filho, R.D.; Fairbairn, E.d.M.R. Thermal stability of PVA fiber strain hardening cement-based composites. Constr. Build. Mater. 2015, 94, 437–447. [Google Scholar] [CrossRef]

- Yu, J.; Lin, J.; Zhang, Z.; Li, V.C. Mechanical performance of ECC with high-volume fly ash after sub-elevated temperatures. Constr. Build. Mater. 2015, 99, 82–89. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Effect of different fibers on the mechanical properties of concrete containing fly ash. Constr. Build. Mater. 2007, 21, 1486–1491. [Google Scholar] [CrossRef]

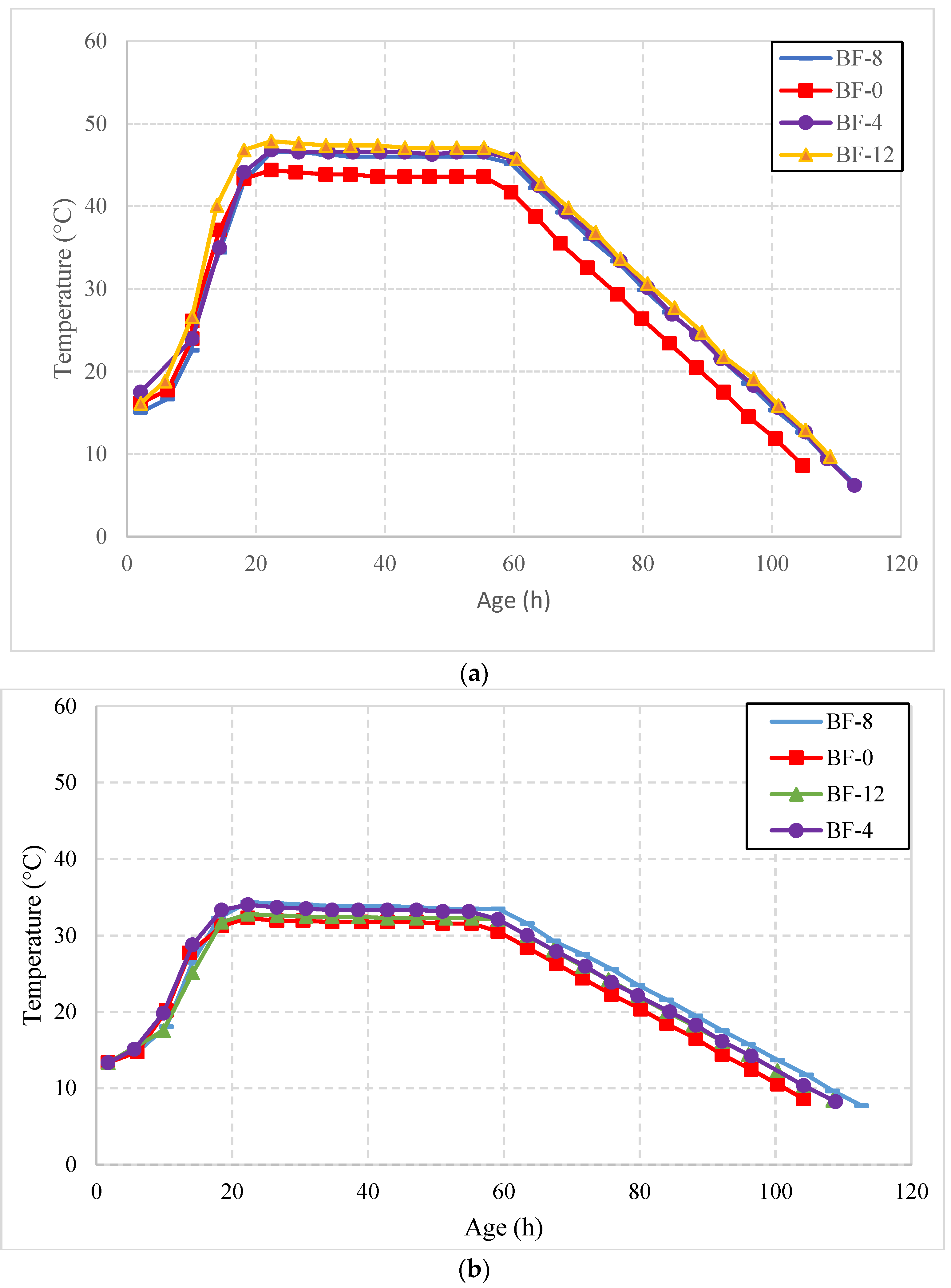

- Shen, D.; Wang, W.; Liu, J.; Zhao, X.; Jiang, G. Influence of Barchip fiber on early-age cracking potential of high performance concrete under restrained condition. Constr. Build. Mater. 2018, 187, 118–130. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. An experimental study on mechanical properties of HPP fiber reinforced concrete (Barchip fibers). In Proceedings of the 4th International Conference on Concrete and Development, Tehran, Iran, 29 April–1 May 2013. [Google Scholar]

- Dawood, E.T.; Ramli, M. Mechanical properties of high strength flowing concrete with hybrid fibers. Constr. Build. Mater. 2012, 28, 193–200. [Google Scholar] [CrossRef]

- Chen, B.; Liu, Q. Recent Advances in the Use of Synthetic Fibres for Concrete Reinforcement: A Comprehensive Review. J. Adv. Concr. Technol. 2024, 32, 45–67. [Google Scholar]

- Zhang, W.; Huang, H.; Yuan, Y. The Role of Macro Fibres in Concrete: Trends, Challenges, and Opportunities. Constr. Mater. Rev. 2024, 28, 90–110. [Google Scholar]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 1–12. [Google Scholar] [CrossRef]

- Tošić, N.; Martinez, D.P.; Hafez, H.; Reynvart, I.; Ahmad, M.; Liu, G.; de la Fuente, A. Multi-recycling of polypropylene fibre reinforced concrete: Influence of recycled aggregate properties on new concrete. Constr. Build. Mater. 2022, 346, 128458. [Google Scholar] [CrossRef]

- Anike, E.E.; Saidani, M.; Olubanwo, A.O.; Tyrer, M.; Ganjian, E. Effect of mix design methods on the mechanical properties of steel fibre-reinforced concrete prepared with recycled aggregates from precast waste. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; pp. 664–672. [Google Scholar]

- Butt, F.; Ahmad, A.; Ullah, K.; Zaid, O.; Shah, H.A.; Kamal, T. Mechanical performance of fiber-reinforced concrete and functionally graded concrete with natural and recycled aggregates. Ain Shams Eng. J. 2023, 14, 102121. [Google Scholar]

- Prasanna, P.; Lingeshwaran, L.; Murthy, R.; Srinivasu, S. Investigation on performance of GGBS concrete by incorporating steel fibers. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2023. [Google Scholar]

- Kaya, Y.; Biricik, Ö.; Bayqra, S.H.; Mardani, A. Effect of fibre type and utilisation rate on dimensional stability and frost resistance of pavement mortar mixture. Int. J. Pavement Eng. 2023, 24, 2154351. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Kaplan, G.; Shi, J.; Benli, A.; Bodur, B.; Turkoglu, M. The effect of steel fiber aspect-ratio and content on the fresh, flexural, and mechanical performance of concrete made with recycled fine aggregate. Constr. Build. Mater. 2023, 368, 130497. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property Assessment of High-Performance Concrete Containing Three Types of Fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- He, L.; Chen, B.; Liu, Q.; Chen, H.; Li, H.; Chow, W.T.; Tang, J.; Du, Z.; He, Y.; Pan, J. A quasi-exponential distribution of interfacial voids and its effect on the interlayer strength of 3D printed concrete. Addit. Manuf. 2024, 89, 104296. [Google Scholar] [CrossRef]

- Zhou, X.; Lu, D.; Du, X.; Wang, G.; Meng, F. A 3D non-orthogonal plastic damage model for concrete. Comput. Methods Appl. Mech. Eng. 2020, 360, 112716. [Google Scholar] [CrossRef]

| Fibre Type | Equivalent Diameter (µm) | Specific Weight (g/cm3) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Final Elongation (%) | Ignition Temperature (°C) | Melting, Decay, or Oxidation Heat Point (°C) | Water Absorption (%) |

|---|---|---|---|---|---|---|---|---|

| Acrylic | 12.7–104.1 | 1.16–1.18 | 269–1000 | 13.79–19.31 | 7.5–50 | - | 221–235 | 1–2.5 |

| Aramid I | 11.94 | 1.44 | 2930 | 62.06 | 4.4 | High | 482 | 4.3 |

| Aramid II | 10.16 | 1.44 | 2344 | 117.2 | 2.5 | High | 482 | 1.2 |

| Carbon (Pan-HM) | 7.62 | 1.6–1.7 | 2482–3034 | 379.9 | 0.5–0.7 | High | 400 | - |

| Carbon (Pitch-GP) | 9.91–12.95 | 1.6–1.7 | 483–793 | 27.58–34.48 | 2–2.4 | High | 400 | 3.7 |

| Carbon (Pitch-HP) | 8.89–17.78 | 1.8–2.15 | 1517–3103 | 151.7–482.7 | 0.5–1.1 | High | 500 | - |

| Nylon | 22.86 | 1.14 | 965 | 5.17 | 20 | - | 200–221 | 2.8–5 |

| Polyester | 19.81 | 1.34–1.39 | 228–1103 | 17.24 | 12–150 | 593 | 257 | 0.4 |

| Polyethylene | 25.4–116 | 0.92–0.96 | 76–586 | 5 | 3–80 | - | 134 | - |

| Polypropylene | - | 0.9–0.91 | 138–690 | 3.54–4.83 | 15 | 593 | 166 | - |

| Research Study | Number of Research Papers on Polymeric Fibres (and Applications) in Concrete | Notes | ||

|---|---|---|---|---|

| PP | PE | PVA | ||

| Afroughsabet et al. [32] | 26 (10) | 2 (2) | 8 (6) | Review study on the use of fibres in high-performance concrete. |

| Thong et al. [33] | - | - | 6 (4) | Review on PVA fibres in concrete. |

| Mukhopadhyay and Khatana [34] | 10 (2) | 8 (3) | 2 (2) | Experimental review study on fibres, including natural, SFRC, and polymer fibres, in concrete. |

| Yin et al. [35] | 8 (4) | - | - | Review on virgin and recycled fibres in reinforced concrete. |

| Gu and Ozbakkaloglu [36] | 26 (13) | 1 (1) | 1 (1) | Review of aggregates, as well as virgin and recycled plastic fibres, in concrete. |

| Base Material | Tensile Strength (MPa) | Geometry | Colour | Specific Density | Length (mm) | Ignition Point (°C) | Chemical Resistance | Elastic Modulus (GPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|---|---|---|

| Modified Olefin | 640 | Continuously Embossed | White | 0.9–0.92 | 54 | >410 | Excellent | 10 | 159–179 |

| Polyolefin | 550 | Continuously Embossed | White | 0.9–0.92 | 48 | >450 | Fair | 10 | 150–165 |

| Polypropylene | 550 | Continuously Embossed | Transparent | 0.85–0.93 | 30 | >380 | Fair | 8.2 | 150–165 |

| Study | PP Fibre Volume (%) | Temperature Range (°C) | Key Findings |

|---|---|---|---|

| Uysal and Tanyildizi [68] | 0.1%, 0.2% | Up to 800 | - Melting of PP fibres creates micro-channels. - Lower residual compressive strength compared to unreinforced concrete. - Mineral compound type does not impact compressive strength decrease. |

| Tanyildizi [69] | 0.5%, 1.0%, 2.0% | Up to 800 | - Temperatures above 400 °C decrease flexural and compressive strength of lightweight concrete. - Higher fibre volume ratios lead to larger strength reductions. |

| Pliya et al. [73] | 0.1%, 0.2% | 150–600 | - Porosity increases significantly with temperature rise. - At 300 °C, fibre-reinforced concrete has 152% more relative porosity than non-fibre concrete. - Splitting tensile strength, compressive strength, and elastic modulus decrease steadily with increasing temperature. |

| Hiremath and Yaragal [75] | 0.1%, 0.5% | 200–800 | - A fibre dosage of 0.1% PP is most effective in mitigating explosive spalling up to 800 °C. - Strength increases up to 400 °C and abruptly decreases after 600 °C. - For durability features like water absorption and sorptivity, 0.5% fibre content performs better. |

| Aslani and Kelin [76] | Not specified | Up to 900 | - Mixtures with steel and PP fibres show a considerable decrease in elasticity modulus at high temperatures. - Residual compressive strength is about 20% after exposure to 900 °C compared to controls at 25 °C. |

| Varona et al. [77] | Hybrid fibres | High temperatures | - High-strength concrete with calcareous aggregates and hybrid fibres (PP and steel) experiences minor spalling at higher temperatures. - Hybrid fibres mitigate spalling effectively. |

| Xargay et al. [79] | PP and steel fibres | Not specified | - Fibre integration enhances structural integrity and force distribution. - Use of PP fibres caused some explosive cracking, requiring further analysis. |

| Hou et al. [80,81] | 0.2% PP, 2% steel | Not specified | - RPC beams with PP and steel fibres exhibit least spalling. - Normal strength concrete beams are more fire-resistant compared to RPC beams. - Fire insulation combined with fibres retains sufficient flexural strength post-fire. |

| Li et al. [82] | Not specified | Not specified | - PP fibres increase residual permeability of concrete. - Important effect on mitigating spalling in ultra-high-performance concrete when exposed to elevated temperatures. |

| Ozawa et al. [84] | 0.5% jute fibres | Not specified | - Incorporating internal curing material and PP fibres decreases autogenous shrinkage and specific density, and increases porosity. - In total, 0.5% jute fibre addition is optimal for mitigating spalling. |

| Macro Fibre Type | Geometry | Tensile Strength (MPa) | Base Material | Specific Weight (kg/m3) | Length (mm) | Alkali Resistance | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| Macro fibre 48 (fibre class II) | Continuously Embossed | 640 | Virgin Polypropylene | 2.5–5 | 48 | Excellent | 12 |

| Macro fibre 54 (fibre class II) | Continuously Embossed | 640 | Virgin Polypropylene | 3–6 | 54 | Excellent | 12 |

| Macro fibre 60 (fibre class II) | Continuously Embossed | 640 | Virgin Polypropylene | 4–6 | 60 | Excellent | 12 |

| Macro fibre MQ58 (fibre class II) | Continuously Embossed | 640 | Bi-Component Polymer | 2.5–5 | 58 | Excellent | 10 |

| Macro fibre R65 (fibre class II) | Continuously Embossed | 610 | Polypropylene | 4–6 | 65 | Excellent | 10 |

| Fibres | Material Characteristics | Other Features | |

|---|---|---|---|

| Advantages | Disadvantages | ||

| Steel fibres | Improved residual strength at elevated temperatures compared to non-fibrous concrete [16]. | Increased vulnerability to chloride corrosion, leading to fibre breakages, strength reduction and concrete spalling. | The length-to-diameter ratio of steel fibres has a major impact on the cohesion quality, with fibre lengths varying from 6.4 to 76 mm. |

| Decreased fire-induced damage at temperatures up to 1200 °C [18]. | |||

| Improved corrosion-resistivity due to the presence of copper (Cu) and the formation of a rust layer [15]. | |||

| High ductility, increased self-weight, and high cost. | |||

| PP fibres | PP fibres are the most effective type of fibre to considerably reduce spalling in concrete exposed to elevated temperatures, including explosive spalling [5,60,63,75]. | Significant loss in modulus of elasticity and strength when subjected to elevated temperatures [70,76]. | For the residual mechanical properties (e.g., tensile strength and compressive strength), an increase in strength up to 400 °C was observed; however, after 600 °C, there was a sudden drop in strength [75]. |

| Increased residual permeability [82]. | With increasing temperature, the splitting tensile and compressive strengths of PP fibre-reinforced concrete reduce steadily [63]. | The melting of PP fibres at high temperatures leads to water evaporation and the subsequent release of vapour pressure [5]. | |

| Improved shrinking resistance due to reduced concrete cracking at early ages [37,38,39]. | Less residual strength at elevated temperatures compared to plain concrete [69]. | PP fibres have been the most widely used and studied type of fibre in comparison to PE and PVA fibres. | |

| Improved corrosion resistivity, crack resistance, and ductility. | Increased porosity [84]. | ||

| PE fibres | Superior performance on spalling and residual compressive strength degradation compared to steel and nanotube fibre concrete [86]. | Decrease in compressive strength and continuous spalling at elevated temperatures [63]. | Increased stiffness for temperatures up to 400 °C due to enhanced bonding of the composite material at high temperatures [74]. |

| Contribution to the interconnectivity of the concrete matrix [50,52]. | Low tensile and impact strength [40]. | ||

| PVA fibres | Improved flexural and compressive strength of concrete [21,89]. | Reduction in compressive strength for composites with high PVA fibre content for temperatures up to 600 °C [21]. | Longer fibres with smaller diameters perform better than shorter fibres with larger diameters [54]. |

| Prevention of spalling for temperatures up to 800 °C [73]. | Larger deflection of PVA fibre composites at elevated temperatures [53]. | Compared to PP fibres, PE and PVA fibres lead to a larger improvement in tensile and flexural strength due to their higher strength and modulus of elasticity. | |

| Improved shrinkage control, abrasion resistance, and protection from thermal expansion and contraction. | Tensile strength, ductility, and cracking potential are negatively affected by high temperatures [88]. | ||

| Reduced number of micro-cracks when exposed to increasing temperatures above 250 °C [88]. | |||

| Macro fibres | Improved corrosion resistivity, toughness, tensile strength, flexural strength, energy absorption, durability, and serviceability [42,92]. | Compressive strength is similar to steel fibre-reinforced concrete [92] | Improved flexural toughness and tensile strength when adding a hybridisation of macro fibres, steel fibres, and palm fibres to high-strength flowing concrete. With an increase in the content of the hybrid fibres, the resistance to impact pressure and first-crack and post-crack strength further improves [93]. |

| Significant reduction in cracking potential in high-performance concrete [75,91]. | |||

| Partial load tolerance of fibres before the onset of cracking [91]. | |||

| High modulus of elasticity and lightweight strings [42,50,93]. | |||

| Macro Fibre Type | Number of Publications | Focus Area |

|---|---|---|

| 2015 | 12 | PP and PE fibre applications |

| 2016 | 18 | PVA fibre properties |

| 2017 | 22 | Fire resistance of fibre composites |

| 2018 | 30 | Hybrid fibre use in construction |

| 2019 | 35 | Long-term durability studies |

| 2020 | 42 | Emerging macro-synthetic fibres |

| 2021 | 50 | Sustainability and eco-friendly fibres |

| 2022 | 58 | Application in high-performance concrete |

| 2023 | 65 | Advances in fibre-reinforced composites |

| 2024 | 72 | Novel applications and hybrid systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehrabi, P.; Dackermann, U.; Siddique, R.; Rashidi, M. A Review on the Effect of Synthetic Fibres, Including Macro Fibres, on the Thermal Behaviour of Fibre-Reinforced Concrete. Buildings 2024, 14, 4006. https://doi.org/10.3390/buildings14124006

Mehrabi P, Dackermann U, Siddique R, Rashidi M. A Review on the Effect of Synthetic Fibres, Including Macro Fibres, on the Thermal Behaviour of Fibre-Reinforced Concrete. Buildings. 2024; 14(12):4006. https://doi.org/10.3390/buildings14124006

Chicago/Turabian StyleMehrabi, Peyman, Ulrike Dackermann, Rafat Siddique, and Maria Rashidi. 2024. "A Review on the Effect of Synthetic Fibres, Including Macro Fibres, on the Thermal Behaviour of Fibre-Reinforced Concrete" Buildings 14, no. 12: 4006. https://doi.org/10.3390/buildings14124006

APA StyleMehrabi, P., Dackermann, U., Siddique, R., & Rashidi, M. (2024). A Review on the Effect of Synthetic Fibres, Including Macro Fibres, on the Thermal Behaviour of Fibre-Reinforced Concrete. Buildings, 14(12), 4006. https://doi.org/10.3390/buildings14124006