Numerical Simulation of Nuclear Power Plant Pile Foundation Damage Under Earthquake Action

Abstract

1. Introduction

2. Materials and Methods

2.1. Macro Experimental Phenomena

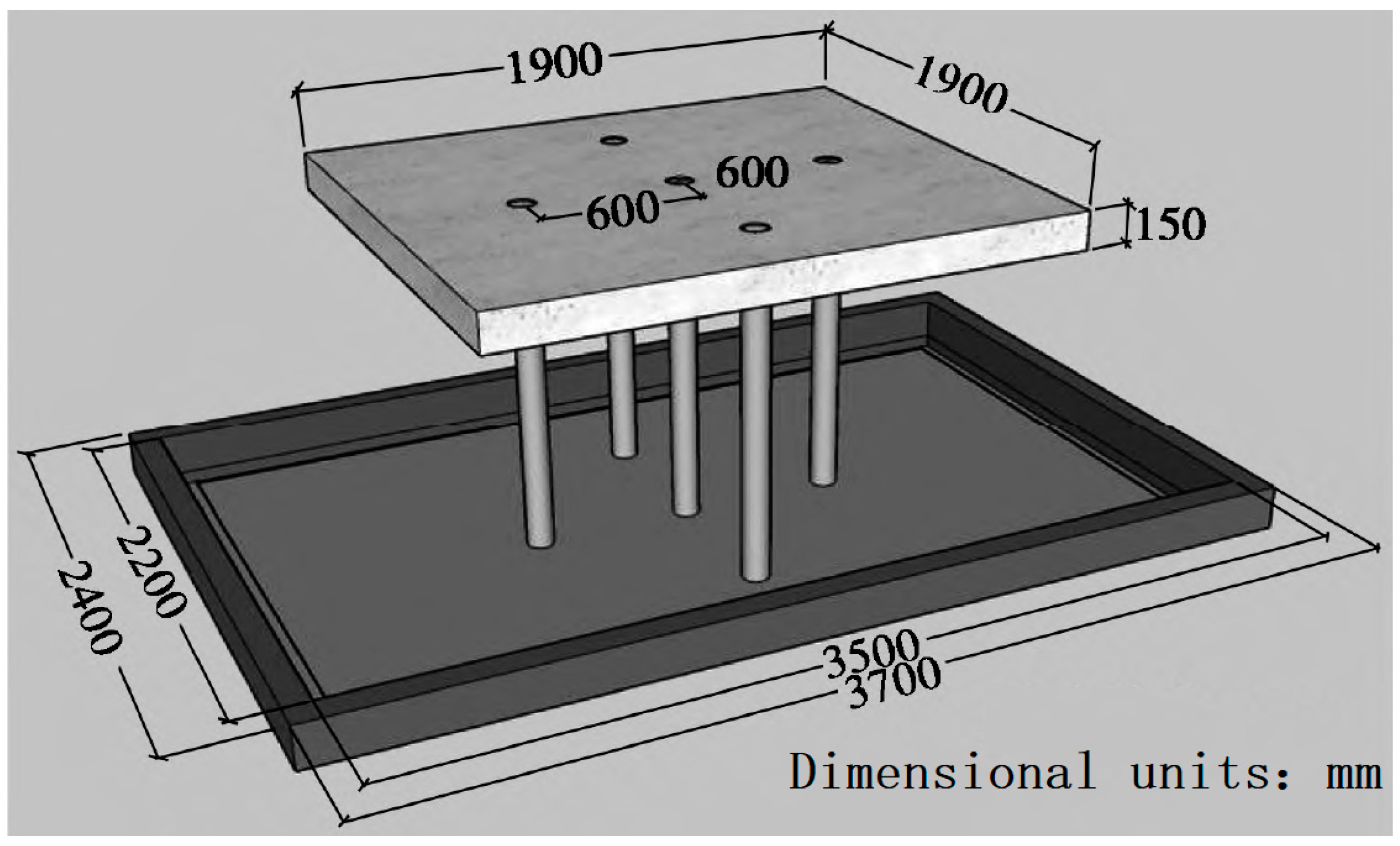

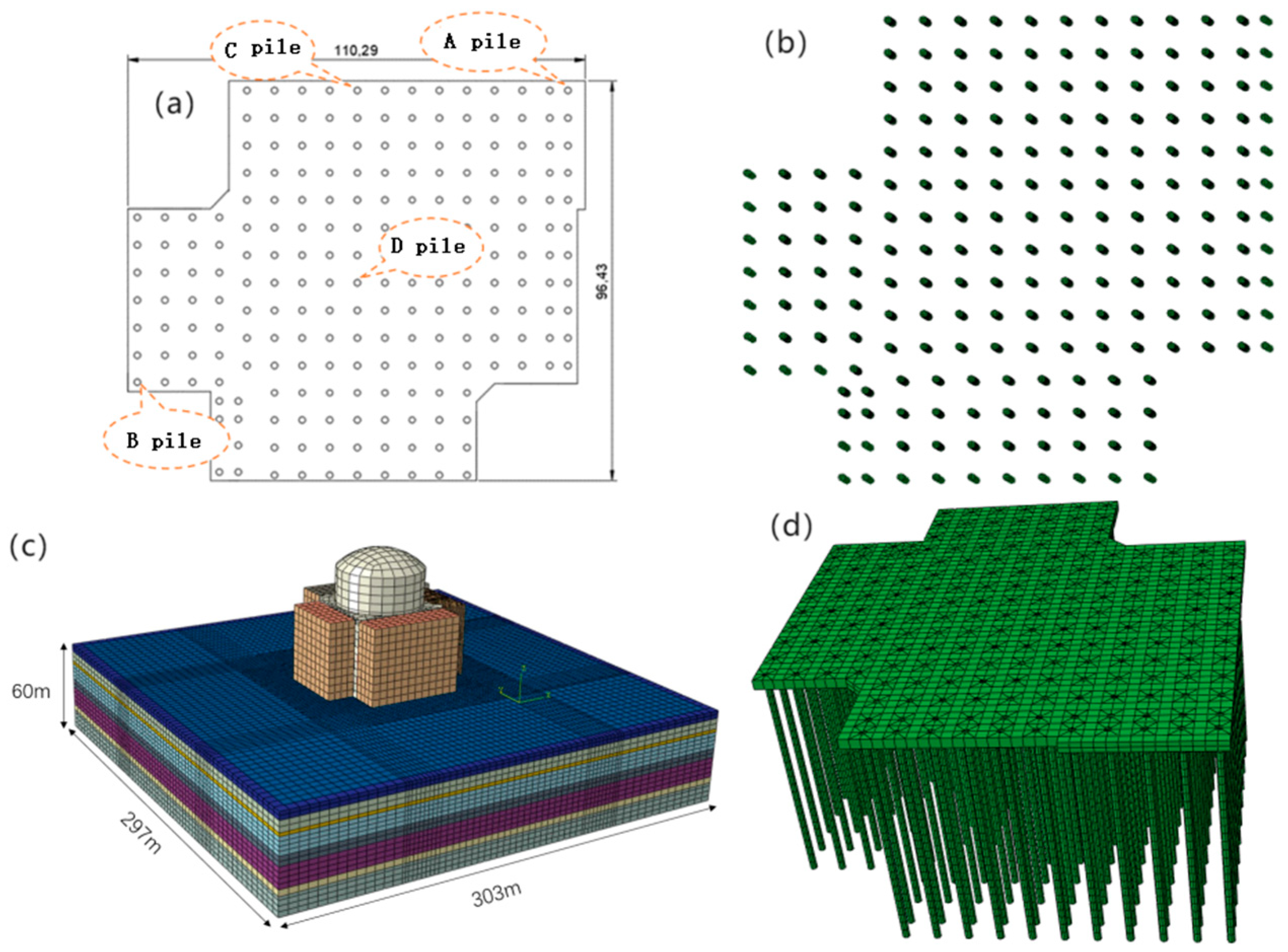

2.2. Computational Model

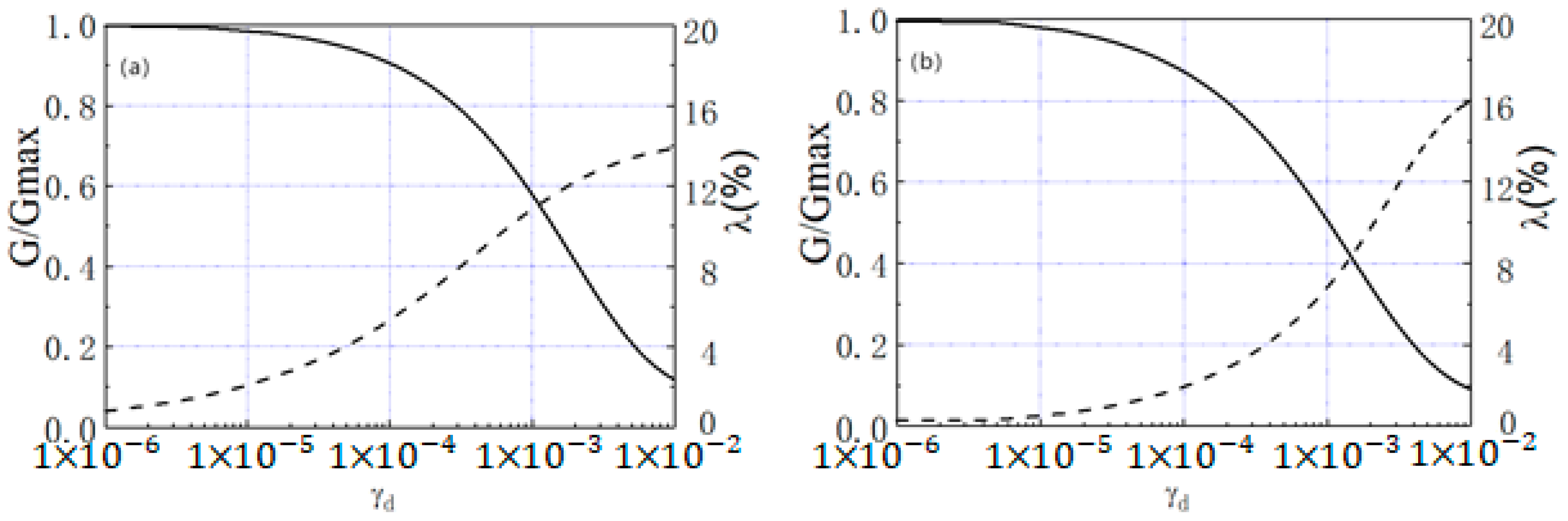

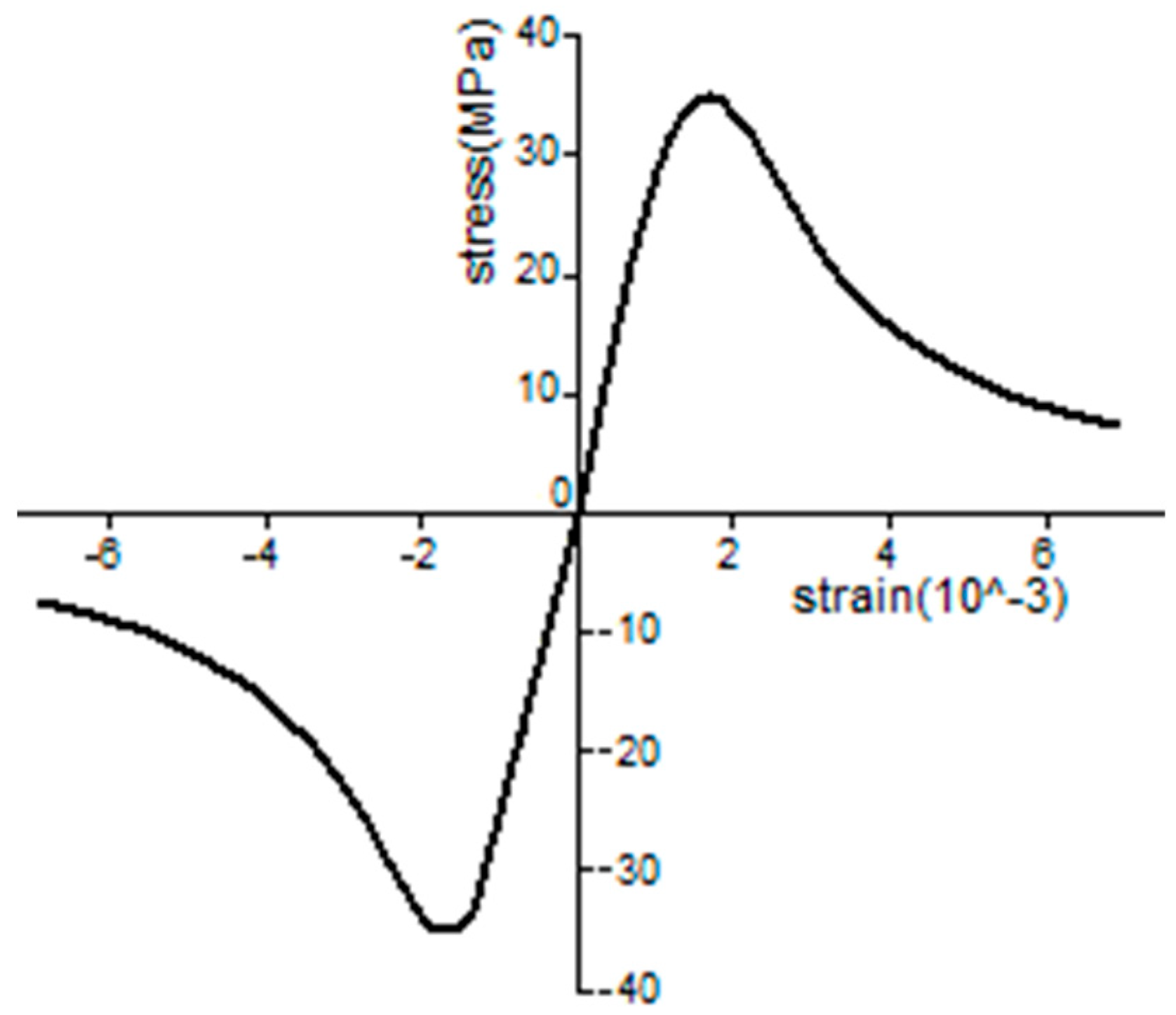

2.3. Calculation Parameters

2.4. Finite Element Model

2.5. Input Ground Motion Time History

3. Results and Discussion

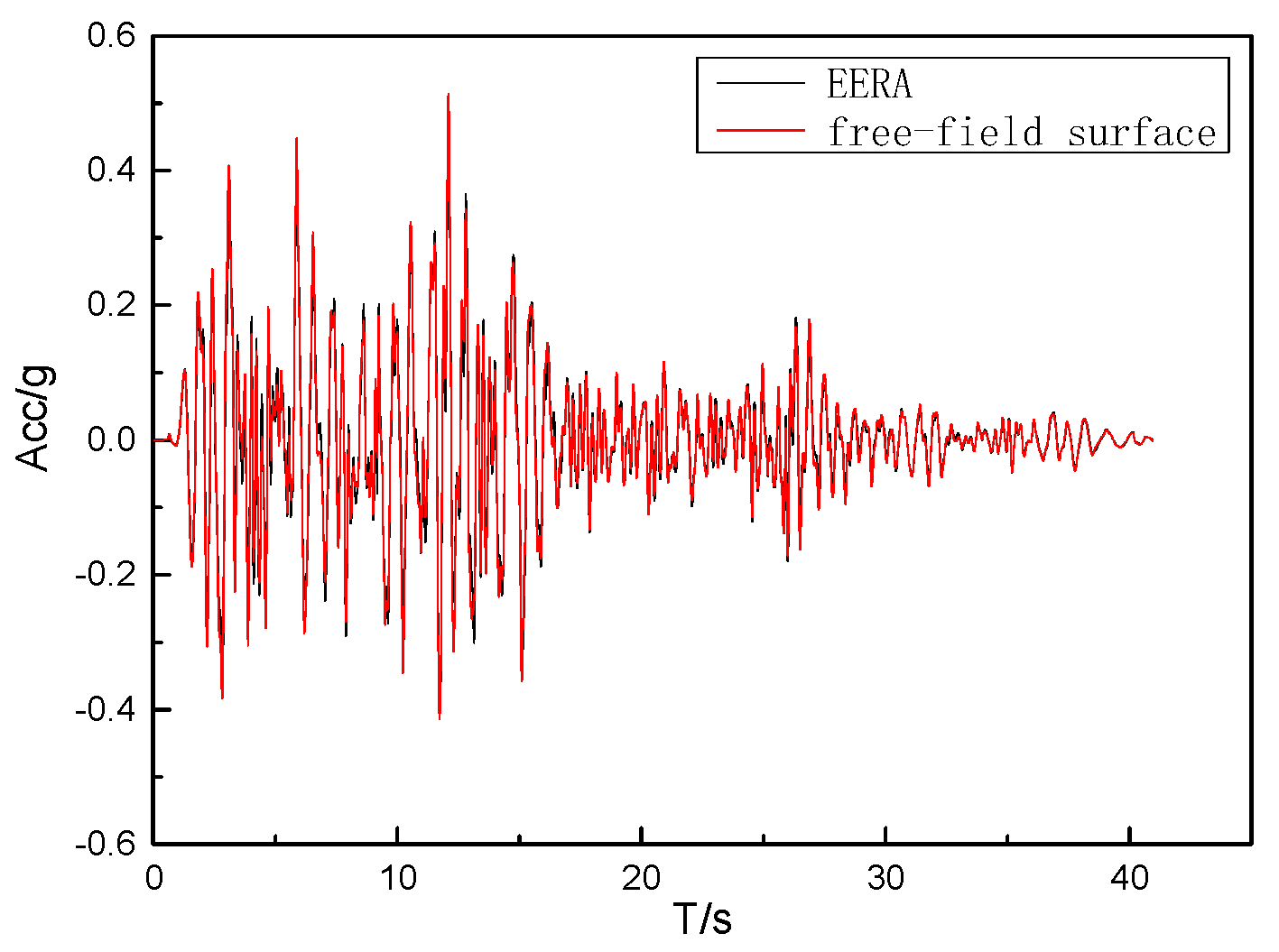

3.1. Free-Field Verification

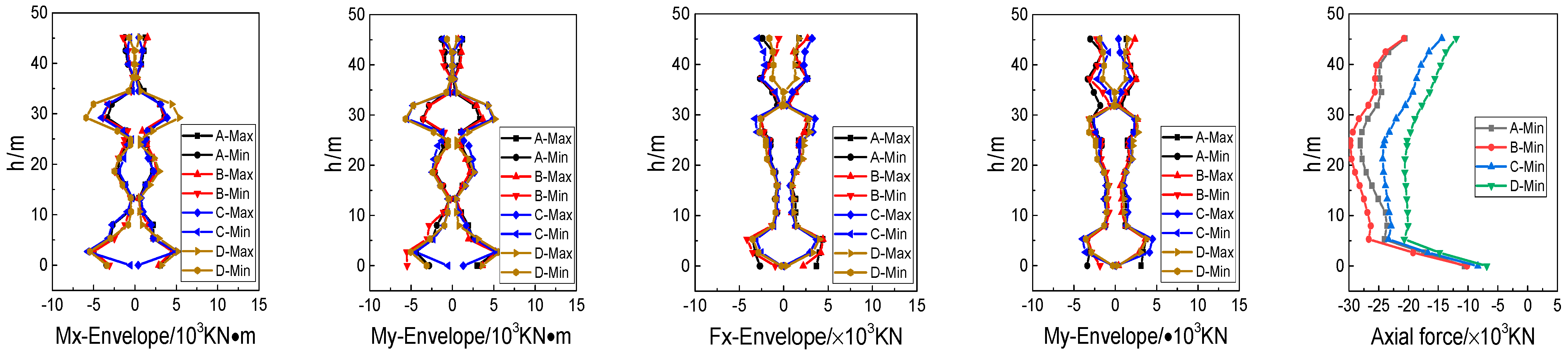

3.2. Distribution of Internal Forces in Pile Body

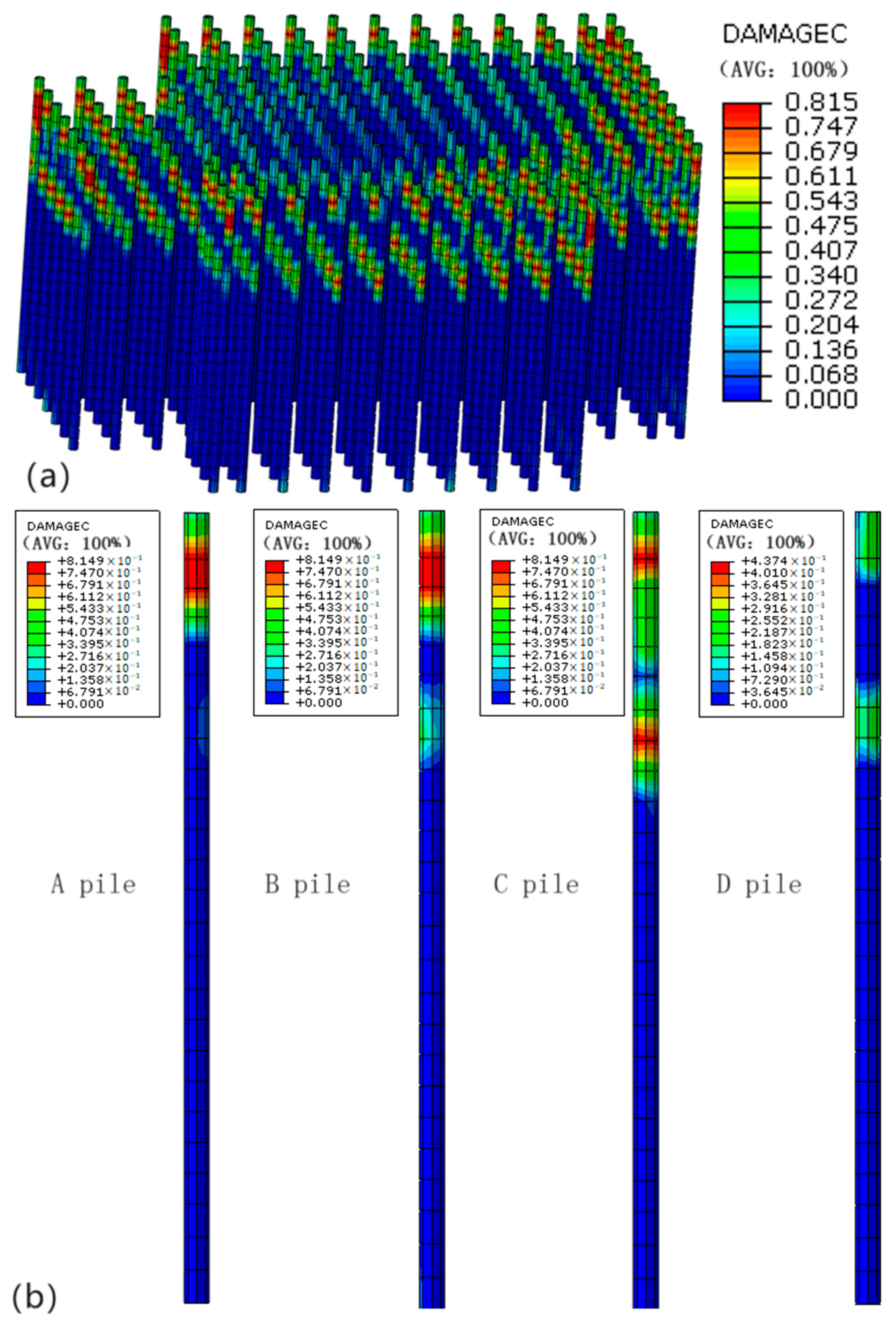

3.3. Pile Damage Distribution

4. Seismic Response Analysis of Pile Foundation After Soil Reinforcement

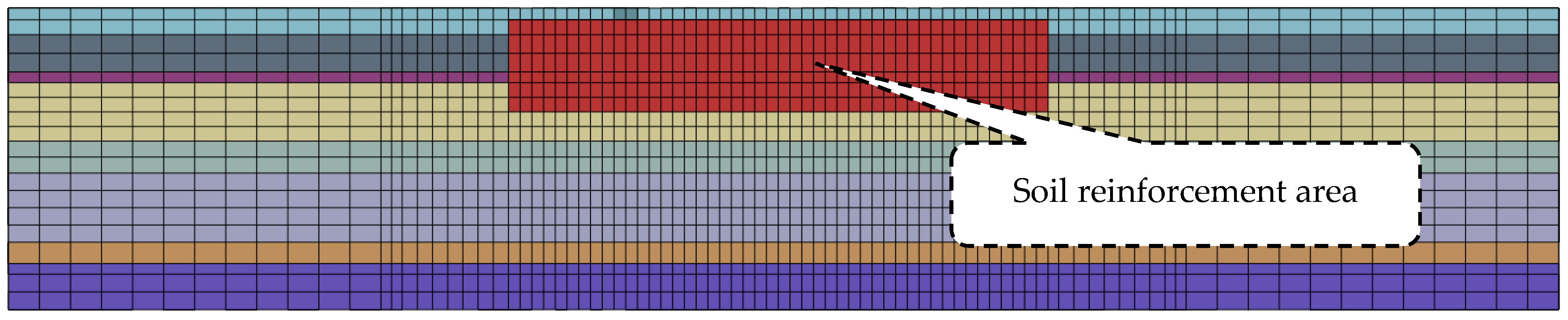

4.1. Soil Reinforcement Scheme

4.2. Internal Force Distribution of Pile Body After Reinforcement

4.3. Pile Damage Distribution After Soil Reinforcement

4.4. Discussion

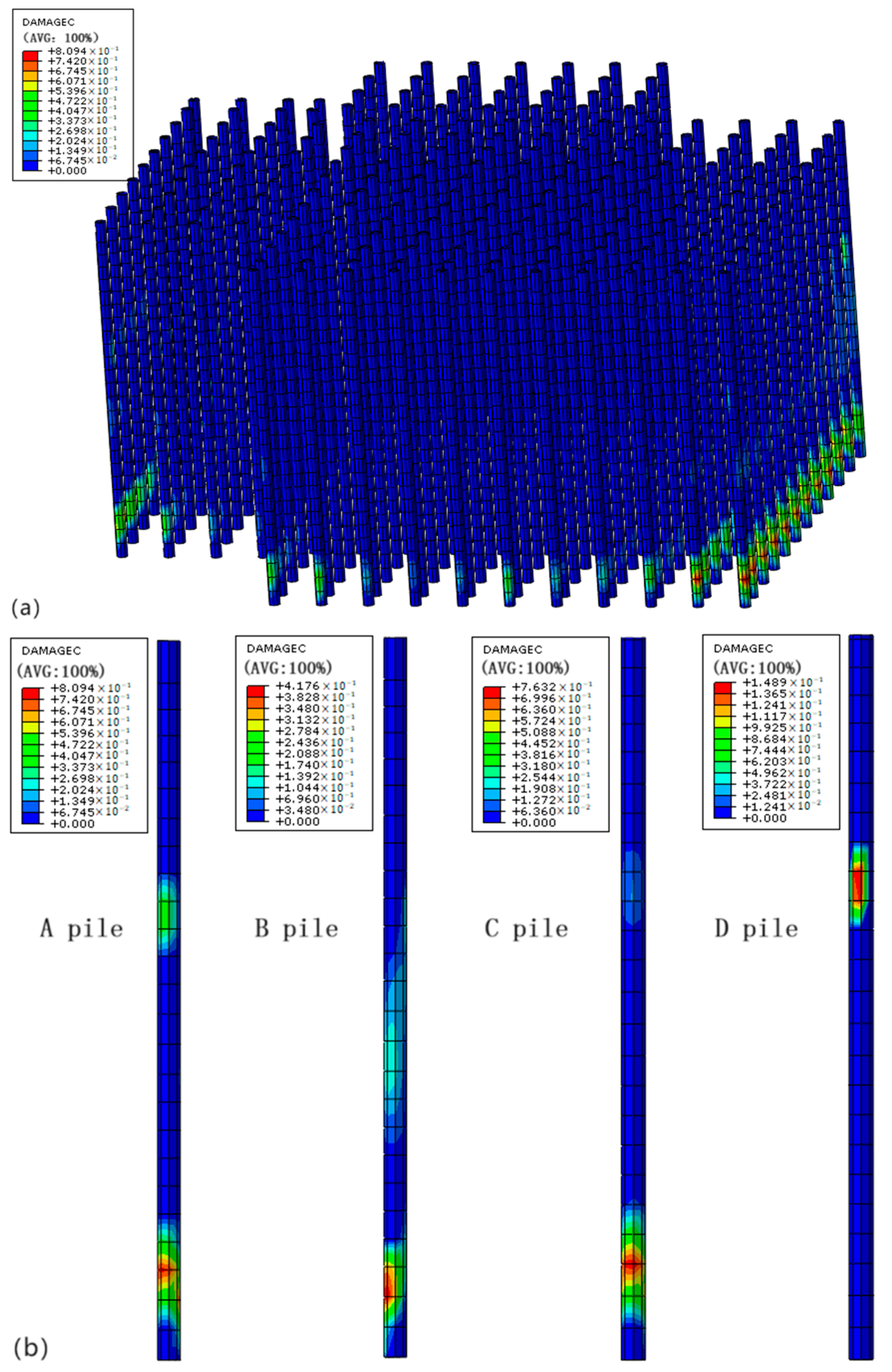

- The numerical calculations of the nuclear island pile group, along with the shaking table test results by Jing Liping [34], indicate that:

- (1)

- The shear force in the piles is greatest at the pile–cap connection and decreases with depth, while the bending moments are larger at the pile tops and in the upper-middle regions;

- (2)

- Damage to the nuclear island plie group occurs at the pile tops and in the lower one-third of the pile length;

- (3)

- The extent of the damage is greatest in the corner piles, followed by the edge piles, with the center piles sustaining the least damage. The primary reason for these results is that the mass and stiffness of the nuclear island structure are significantly greater than those of the pile foundation, creating weak points near the pile–cap connection, especially at the corner piles, making them more prone to damage under seismic loading.

- This paper utilizes numerical methods to investigate the seismic response of the nuclear island pile foundation after reinforcing the surrounding soil within a certain range. Appropriate reinforcement can significantly alter the stress state at the pile tops under seismic loads, thus reducing damage to the group piles. However, determining the most economical type of soil reinforcement and the optimal range requires more detailed numerical simulations and indoor shaking table tests to provide recommendations with greater engineering application value.

- The viscoelastic boundary used in this study is detailed in Wang Zhan’s [41] paper. This boundary condition effectively mitigates the influence of excessive deformation in boundary elements on the computational results, while also considering the relationship between the dimensions of the boundary elements and their potential maximum deformations. This approach maintains computational accuracy and simplifies the pre-processing of the software.

- This paper assumes that concrete exhibits symmetric tensile/compressive properties, which may lead to an underestimation of concrete damage. In reality, the initial development of cracks in the concrete may be greater than assumed, resulting in a higher level of early damage. As damage progresses to a certain stage, the surrounding concrete may fail, but the steel reinforcement can still sustain some tensile forces. Consequently, the damage estimated based on this assumption may be less than the actual results, with later concrete damage being lower. The simplification of the model is reasonably valid, adequately reflecting the performance of reinforced concrete while significantly enhancing the computational efficiency of the software.

5. Conclusions

- The results of the numerical simulation for a pile foundation in a nuclear power plant indicate that the section of the pile foundation coupled with the bearing platform in a medium-soft soil site experiences the greatest force under seismic loading, making it prone to damage. These results align with the macroscopic phenomena observed in the shaking table model tests.

- The numerical simulation results reveal that the bending moment and the shear force of the pile foundation group are primarily distributed in the upper one-third of the pile foundation. The pile head exhibits significant damage, with the side piles and corner piles in the direction of vibration being the most severely damaged.

- Numerical methods were utilized to reinforce the soil in a specific area around the pile foundation. This reinforcement process can improve the stress state of the pile foundation to some extent, reduce the degree of damage, and provide valuable guidance for the seismic design of pile foundations.

- The research findings of this paper on the soil–pile–nuclear island system and the methods for reinforcing pile foundations provide a reference for the design of nuclear power plant foundations and serve as a basis for ensuring the seismic safety of nuclear structures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Shu, X.; Ye, W.; Tang, Y. Recent studies on seismic resistance of pile foundation. Ind. Constr. 2002, 32, 50–53. (In Chinese) [Google Scholar]

- Liu, H.X. Tangshan Earthquake Damage; Seismological Press: Beijing, China, 1986. (In Chinese) [Google Scholar]

- Mendoza, M.J.; Auvinet, G. The mexico earthquake of september 19, 1985—Behavior of building foundations in Mexico city. Earthq. Spectra 1988, 4, 835–853. [Google Scholar] [CrossRef]

- Jiang, X.M. Investigation and Research on Earthquake Damage of Wenchuan Earthquake Foundation. Master’s Thesis, Tongji University, Shanghai, China, 2009. (In Chinese). [Google Scholar]

- Bhattacharya, S.; Madabhushi, S.P.G.; Bolton, M.D. An alternative mechanism of pile failure in liquefiable deposits during earthquakes. Geotechnique 2004, 54, 203–213. [Google Scholar] [CrossRef]

- Green, R.A.; Cox, B.R.; Rathje, E.; Olson, S.M.; Rix, G.J.; Bachhuber, J.; French, J.; Lasley, S.; Martin, N. Geotechnical aspects of failures at Port-au-Prince Seaport during the 12 January 2010 Haiti Earthquake. Earthq. Spectra 2011, 27, 43–65. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Tamura, S.; Suzuki, H.; Katsumata, K. Building damage associated with geotechnical problems in the 2011 Tohoku Pacific Earthquake. Soils Found. 2012, 52, 956–974. [Google Scholar] [CrossRef]

- Tian, Z.Y. Study on Pile Negative Friction Caused by Soft Soil Seismic Settlement. Master’s Thesis, Institute of Disaster Prevention, Langfang, China, 2020. (In Chinese). [Google Scholar]

- Castelli, F.; Maugeri, M. Simplified approach for the seismic response of a pile foundation. J. Geotech. Geoenviron. Eng. 2009, 135, 1440–1451. [Google Scholar] [CrossRef]

- Thavaraj, T.; Liam Finn, W.D.; Wu, G. Seismic response analysis of pile foundations. Geotech. Geol. Eng. 2010, 28, 275–286. [Google Scholar] [CrossRef]

- Bradley, B.A.; Cubrinovski, M.; Dhakal, R.P.; MacRae, G.A. Intensity measures for the seismic response of pile foundations. Soil Dyn. Earthq. Eng. 2009, 29, 1046–1058. [Google Scholar] [CrossRef]

- Kimura, M.; Zhang, F. Seismic evaluations of pile foundations with three different methods based on three-dimensional elasto-plastic finite element analysis. Soils Found. 2000, 40, 113–132. [Google Scholar] [CrossRef]

- Garala, T.K.; Madabhushi, G.S.P. Role of pile spacing on dynamic behavior of pile groups in layered soils. J. Geotech. Geoenvironmental Eng. 2021, 147, 04021005. [Google Scholar] [CrossRef]

- Hökelekli, E.; Bayraktar, A.; Şermet, F. Seismic Failure Mechanisms of Concrete Pile Groups in Layered Soft Soil Profiles. Buildings 2024, 14, 177. [Google Scholar] [CrossRef]

- Stacul, S.; Squeglia, N. Simplified assessment of pile-head kinematic demand in layered soil. Soil Dyn. Earthq. Eng. 2020, 130, 105975. [Google Scholar] [CrossRef]

- López Jiménez, G.A.; Dias, D.; Jenck, O. Effect of the soil–pile–structure interaction in seismic analysis: Case of liquefiable soils. Acta Geotech. 2019, 14, 1509–1525. [Google Scholar] [CrossRef]

- Avcil, F.; Işık, E.; İzol, R.; Büyüksaraç, A.; Arkan, E.; Arslan, M.H.; Aksoylu, C.; Eyisüren, O.; Harirchian, E. Effects of the February 6, 2023, Kahramanmaraş earthquake on structures in Kahramanmaraş city. Nat. Hazards 2024, 120, 2953–2991. [Google Scholar] [CrossRef]

- Zhao, X.G.; Gao, W.S. Experimental study on seismic response of pile group foundation with high-cap by shaking table. Build. Struct. 2019, 49, 120–129. (In Chinese) [Google Scholar]

- Xie, W.; Sun, L. Experimental studies on seismic response characteristics of dynamic interaction system of pile-soil-cable-stayed bridges. Chin. J. Geotech. Eng. 2019, 41, 1319–1328. (In Chinese) [Google Scholar]

- Xu, C.-S.; Dou, P.-F.; Du, X.-L.; Su, C.; Li, X. Shaking table test study on dynamic response of non liquefiable soil pile group foundation structure system. J. Build. Struct. 2022, 43, 185–194. (In Chinese) [Google Scholar]

- Wolf, J.; Von Arx, G. Impedance functions of a group of vertical piles. In Proceeding of the ASCE Conference in Earthquake Engineering and Soil Dynamics, Pasadena, CA, USA, 19–21 June 1978; Volume 2, pp. 1024–1041. [Google Scholar]

- Yang, X.-W. Numerical Analysis of Pile-Soil-Structure Dynamic Interaction. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2006. (In Chinese). [Google Scholar]

- Kumar, A.; Choudhury, D.; Katzenbach, R. Effect of earthquake on combined pile-raft foundation. Int. J. Geomech. 2016, 16, 04016013. [Google Scholar] [CrossRef]

- Wang, X.; Shafieezadeh, A.; Ye, A. Optimal EDPs for post-earthquake damage assessment of extended pile-shaft–supported bridges subjected to transverse spreading. Earthq. Spectra 2019, 35, 1367–1396. [Google Scholar] [CrossRef]

- Pan, R.; Sun, F.; Zhang, Q. Discussion on 3 Issues Related to Structure Safety in Nuclear Safety Regulation. Nucl. Saf. 2013, 12 (Suppl. S1), 81–87. (In Chinese) [Google Scholar]

- Zou, D.; Sui, Y.; Chen, K. Plastic damage analysis of pile foundation of nuclear power plants under beyond-design basis earthquake excitation. Soil Dyn. Earthq. Eng. 2020, 136, 106179. [Google Scholar] [CrossRef]

- Wolf, J.P.; Von Arx, G.A.; De Barros, F.C.P.; Kakubo, M. Seismic analysis of the pile foundation of the reactor building of the NPP Angra 2. Nucl. Eng. Des. 1981, 65, 329–341. [Google Scholar] [CrossRef]

- Bhaumik, L.; Raychowdhury, P. Seismic response analysis of a nuclear reactor structure considering nonlinear soil-structure interaction. Nucl. Eng. Des. 2013, 265, 1078–1090. [Google Scholar] [CrossRef]

- Patil, G.; Choudhury, D.; Mondal, A. Interactive iterative methodology for seismic analysis of pile-raft supported nuclear power plant structure in a conventional framework. Soil Dyn. Earthq. Eng. 2023, 173, 108109. [Google Scholar] [CrossRef]

- Firoj, M.; Maheshwari, B.K. Effect of CPRF on nonlinear seismic response of an NPP structure considering raft-pile-soil-structure-interaction. Soil Dyn. Earthq. Eng. 2022, 158, 107295. [Google Scholar] [CrossRef]

- Zou, D.; Sui, Y.; Zhou, C.; Zhou, Y.; Pan, R.; Liu, X.; Li, J. Nonlinear Dynamic Analysis of Soil-Pile Interactions of Nuclear Island with Nonlithological Foundation. Nucl. Power Eng. 2020, 41, 59–65. (In Chinese) [Google Scholar]

- Qi, Y.; Yin, X.; Wang, G. Dynamic Interaction Analysis of Water Intake Structure of Nuclear Power Plant under Complex Foundation Condition. Struct. Eng. 2021, 37, 151–158. (In Chinese) [Google Scholar]

- Chen, S.-I.; Zhang, J.; Guo, Q.-C.; Zhou, G.-L.; Liu, Q.-F.; Wang, J.-Q. Time-domain soil-structure interaction analysis of nuclear facilities on non-horizontal layered site. Chin. J. Geotech. Eng. 2020, 42, 308–316. (In Chinese) [Google Scholar]

- Jing, L.-P.; Wang, G.; Li, J.-R.; Sun, Y.-L.; Zhou, Z.-Y.; Qi, W.-H. Shaking table tests and numerical simulations of dynamic interaction of soil-pile-nuclear island system. Chin. J. Geotech. Eng. 2022, 44, 163–172. (In Chinese) [Google Scholar]

- Systèmes, D. ABAQUS 6.14 Analysis User’s Manual; Dassault Systemes, Inc.: Waltham, DC, USA, 2014. [Google Scholar]

- Bardet, J.P.; Ichii, K.; Lin, C.H. EERA—A Computer Program for Equivalent-Linear Earthquake Site Response Analyses of Layered Soil Deposits; University of Southern California, Department of Civil Engineering: Los Angeles, CA, USA, 2000. [Google Scholar]

- Song, Z.F.; Yang, X.G.; Zhang, H.D. Finite Element Calculation and Analysis for the Integrity Strength Test of Containment Structure of “HPR-1000”. In Proceedings of the 2022 Industrial Building Academic Exchange Conference, Chengdu, China, 19 August 2022; Volume 1. (In Chinese). [Google Scholar]

- GB50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- Gu, Y.; Liu, J.-B. 3D Consistent Viscous-Spring Artificial Boundary And Viscous-Spring Boundary Element. Eng. Mech. 2007, 24, 31–37. (In Chinese) [Google Scholar]

- Liu, J.; Tan, H.; Bao, X.; Wang, D.; Li, S. Seismic wave input method for three-dimensional soil-structure dynamic interaction analysis based on the substructure of artificial boundaries. Earthq. Eng. Eng. Vib. 2019, 18, 747–758. [Google Scholar] [CrossRef]

- Wang, Z.; Jing, L.-P. Lu, X.-U.; Qi, W.-H. Comparative study of viscous-spring boundary element and methods of seismic motion input. World Earthq. Eng. 2023, 39, 167–177. (In Chinese) [Google Scholar]

- Chen, G.X. Geotechnical Seismic Engineering; Science Press: Beijing, China, 2007. (In Chinese) [Google Scholar]

| Soil Description | Soil Thickness (m) | Poisson’s Ratio | Density (kg/m3) | Shear Wave Velocity After Discounting (m/s) | Damping Ratio (%) |

|---|---|---|---|---|---|

| Silty clay | 5 | 0.45 | 1950 | 75.08 | 11.66 |

| Silt | 7 | 0.48 | 2010 | 110.76 | 10.31 |

| Silty clay | 2 | 0.42 | 1880 | 123.53 | 11.07 |

| Silty clay | 11 | 0.48 | 1980 | 158.49 | 11.96 |

| Silty clay | 6 | 0.42 | 1910 | 137.37 | 12.94 |

| Silty clay | 13 | 0.42 | 1980 | 200.40 | 11.99 |

| Silt | 4 | 0.38 | 2030 | 189.36 | 10.73 |

| Basalt | 10 | 0.28 | 2450 | 1569.00 | 5 |

| Concrete Grade | Modulus of Elasticity (MPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|

| C35 | 31500 | 0.2 | 2350 |

| C80 | 38000 | 0.2 | 2550 |

| Parameter | Value Ranges | Recommendation Coefficient | |

|---|---|---|---|

| two-dimensional | 0.35–0.65 | 1/2 | |

| 0.8–1.2 | 2/2 | ||

| three-dimensional | 0.5–1.0 | 2/3 | |

| 1.0–2.0 | 4/3 |

| Density (kg/m3) | Poisson’s Ratio | Elastic Modulus (MPa) | Shear Modulus (MPa) | Shear Wave Velocity (m/s2) |

|---|---|---|---|---|

| 2100 | 0.3 | 500 | 192.3 | 302.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, F.; Qi, W.; Jing, L.; Wang, Z.; Lu, X. Numerical Simulation of Nuclear Power Plant Pile Foundation Damage Under Earthquake Action. Buildings 2024, 14, 3617. https://doi.org/10.3390/buildings14113617

Xia F, Qi W, Jing L, Wang Z, Lu X. Numerical Simulation of Nuclear Power Plant Pile Foundation Damage Under Earthquake Action. Buildings. 2024; 14(11):3617. https://doi.org/10.3390/buildings14113617

Chicago/Turabian StyleXia, Feng, Wenhao Qi, Liping Jing, Zhan Wang, and Xinyu Lu. 2024. "Numerical Simulation of Nuclear Power Plant Pile Foundation Damage Under Earthquake Action" Buildings 14, no. 11: 3617. https://doi.org/10.3390/buildings14113617

APA StyleXia, F., Qi, W., Jing, L., Wang, Z., & Lu, X. (2024). Numerical Simulation of Nuclear Power Plant Pile Foundation Damage Under Earthquake Action. Buildings, 14(11), 3617. https://doi.org/10.3390/buildings14113617