Study on the Effect of Jute CNFs Addition on the Water Absorption and Mechanical Properties of Geopolymer Concrete

Abstract

1. Introduction

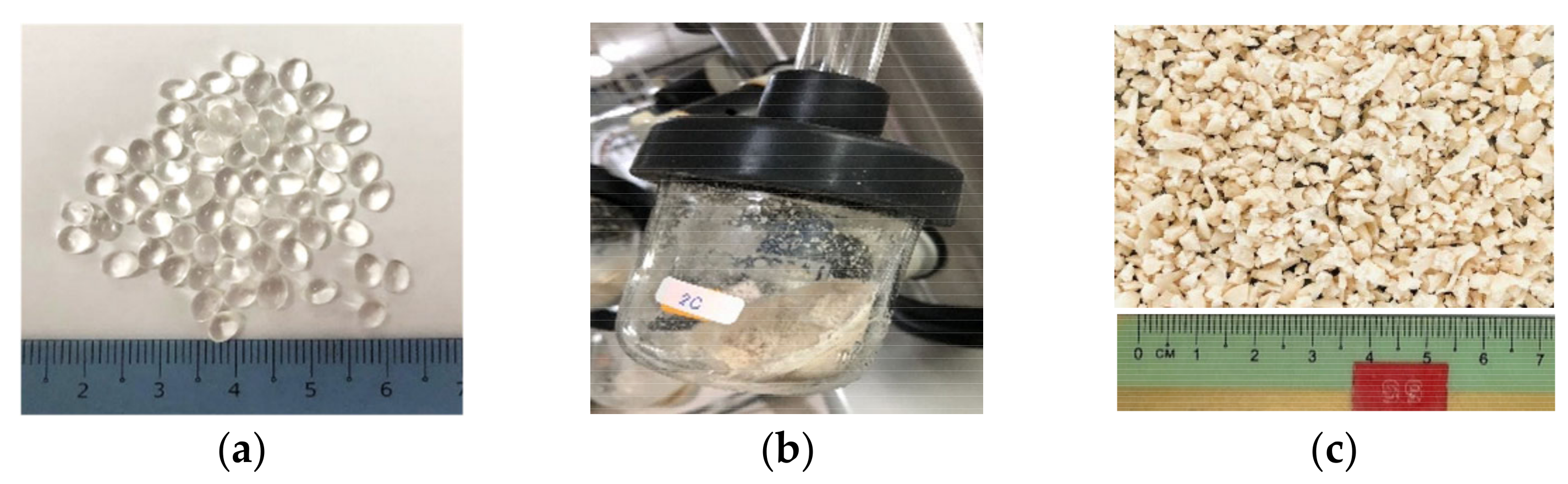

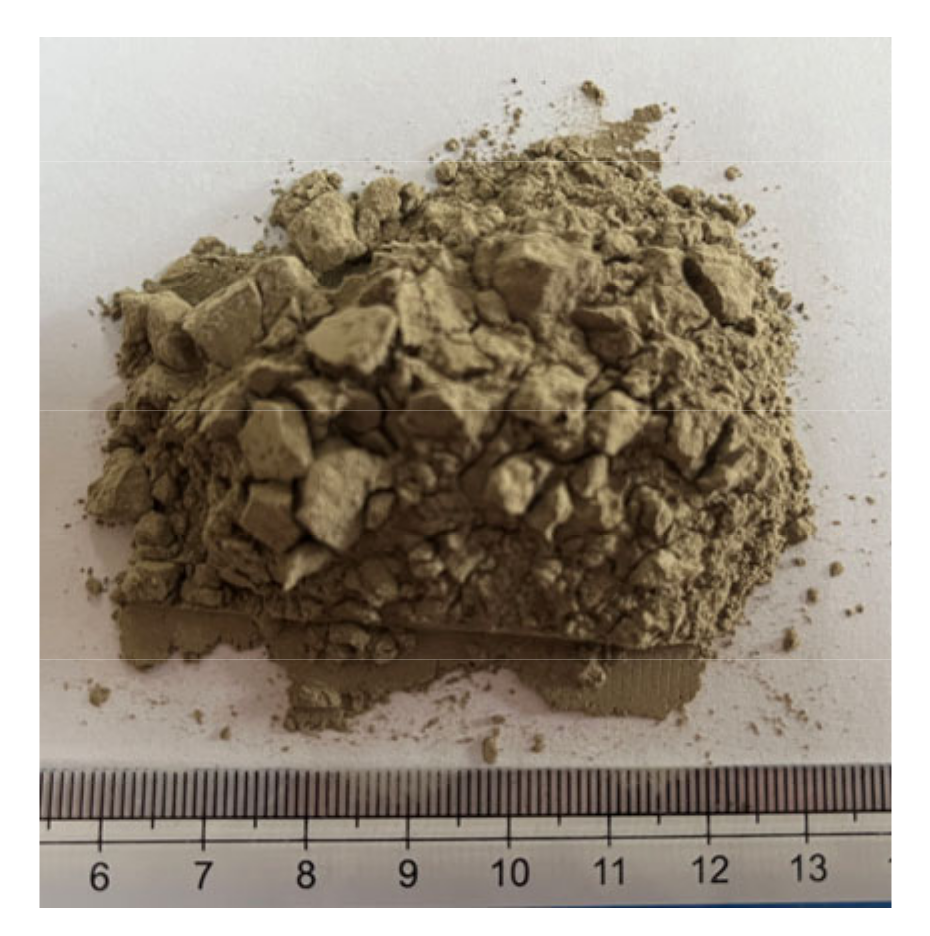

2. Materials and Methods

2.1. Preparation of TPU Nanocomposite

2.2. Preparation of Neat Geopolymer Concrete and TPU/Jute CNF Nanocomposites-Reinforced Geopolymer Concrete

2.3. Preparation for Durability Geopolymer Concrete and TPU/Jute CNFs-Reinforced Geopolymer Concrete

2.4. Mechanical Testing Analysis of Prepared Geopolymer Concrete and TPU/Jute CNFs-Reinforced Geopolymer Concrete

3. Results and Discussion

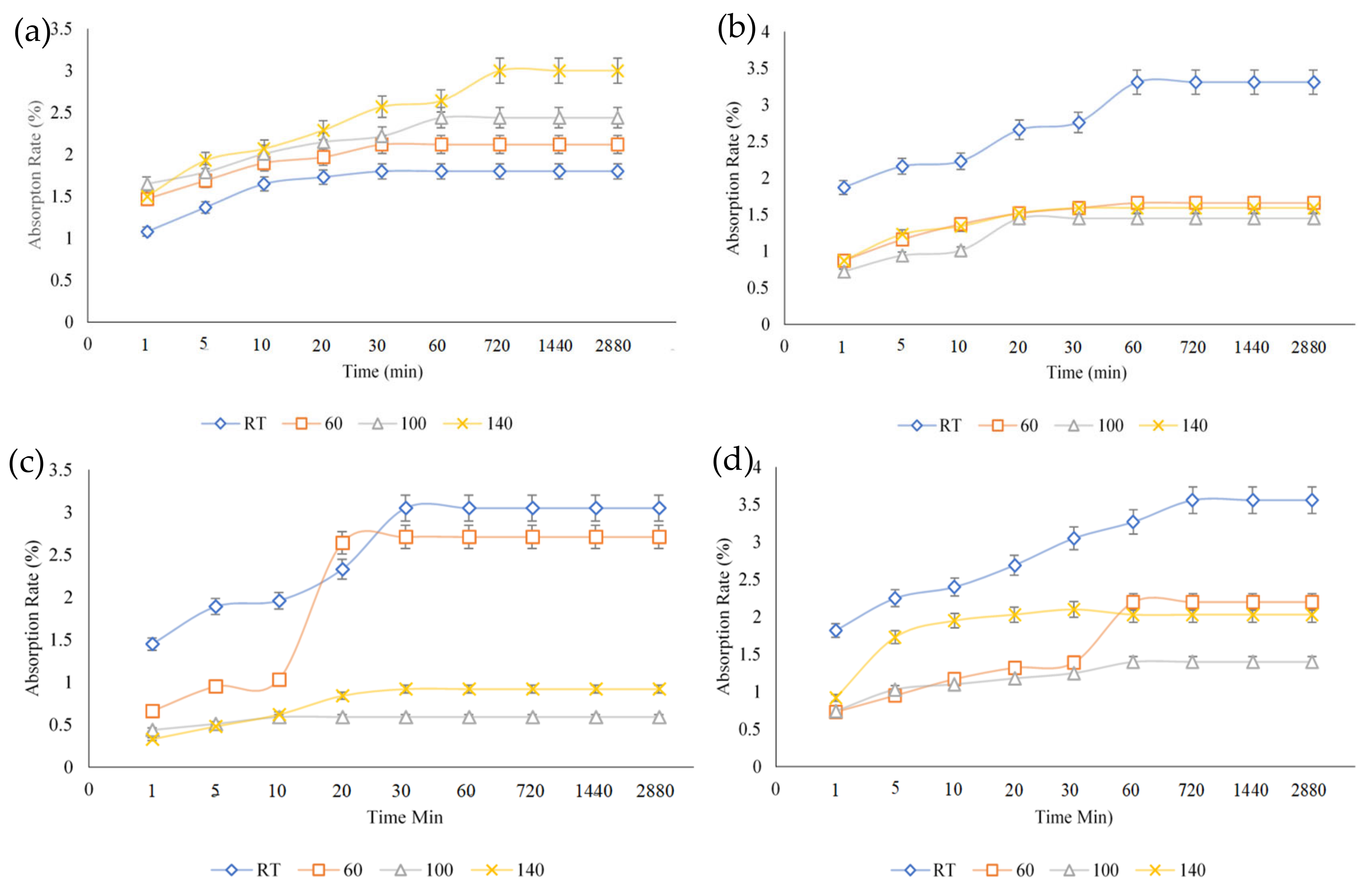

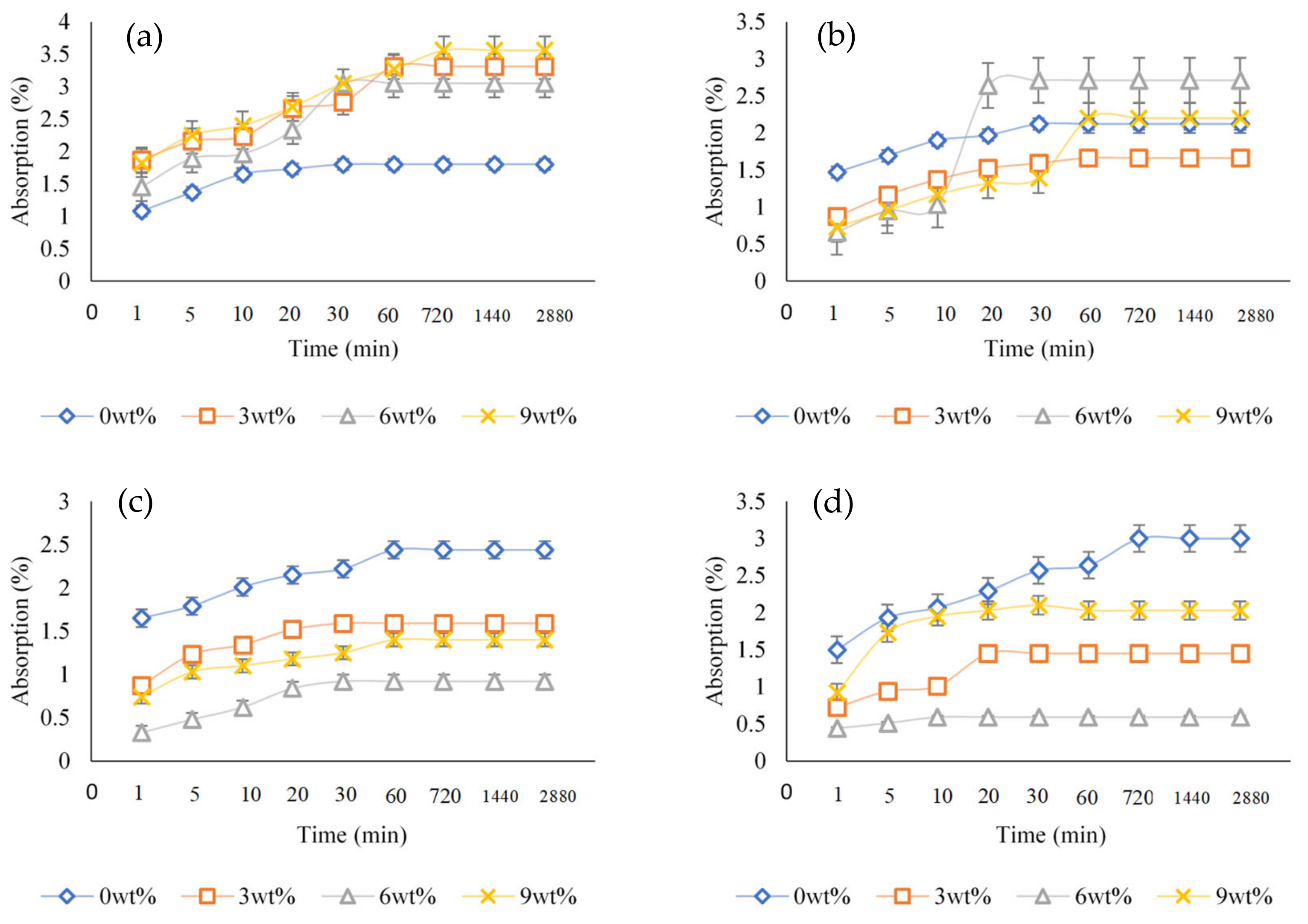

3.1. Durability Analysis of Prepared Geopolymer Concrete and TPU/Jute CNFs-Reinforced Geopolymer Concrete

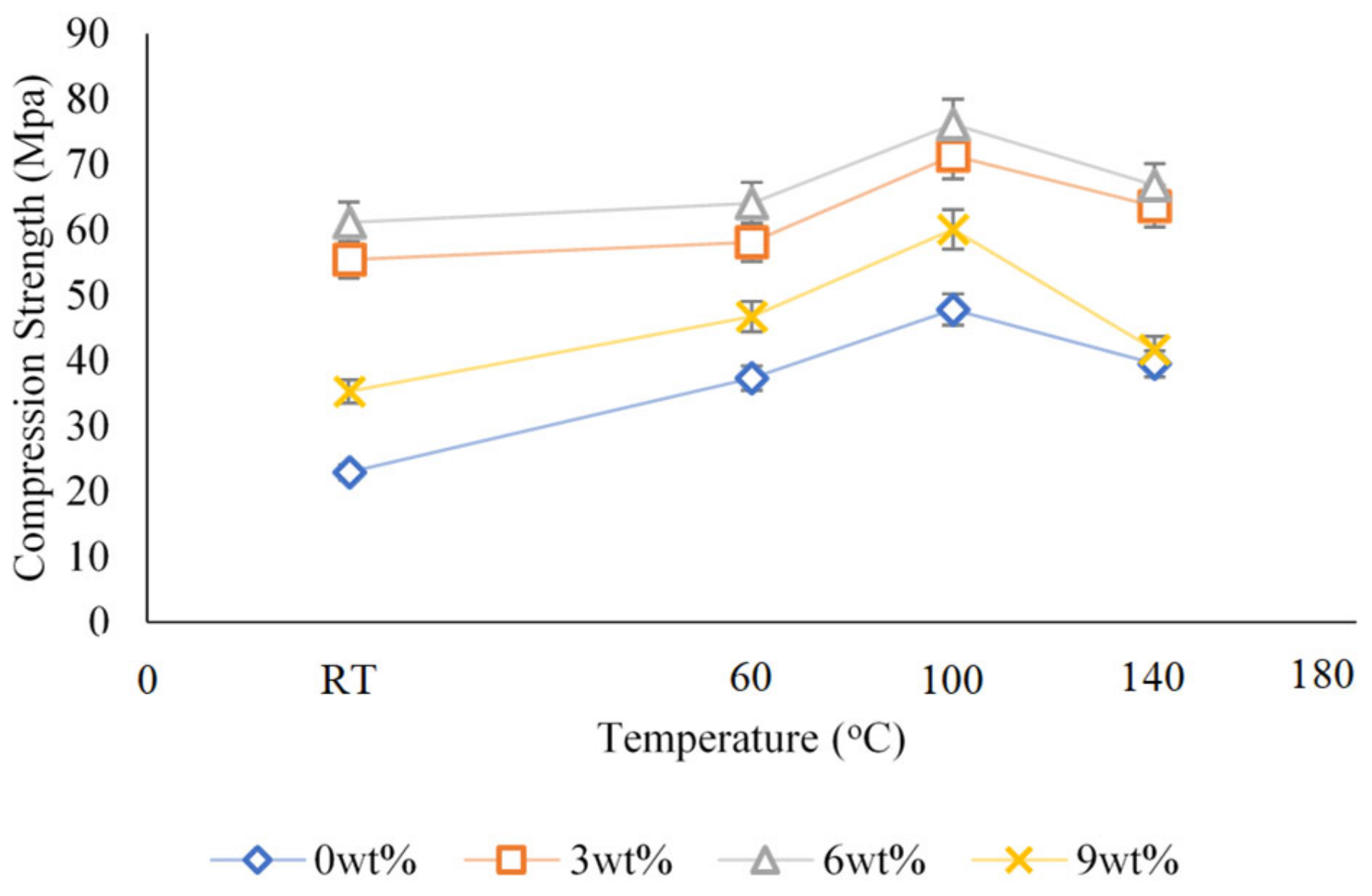

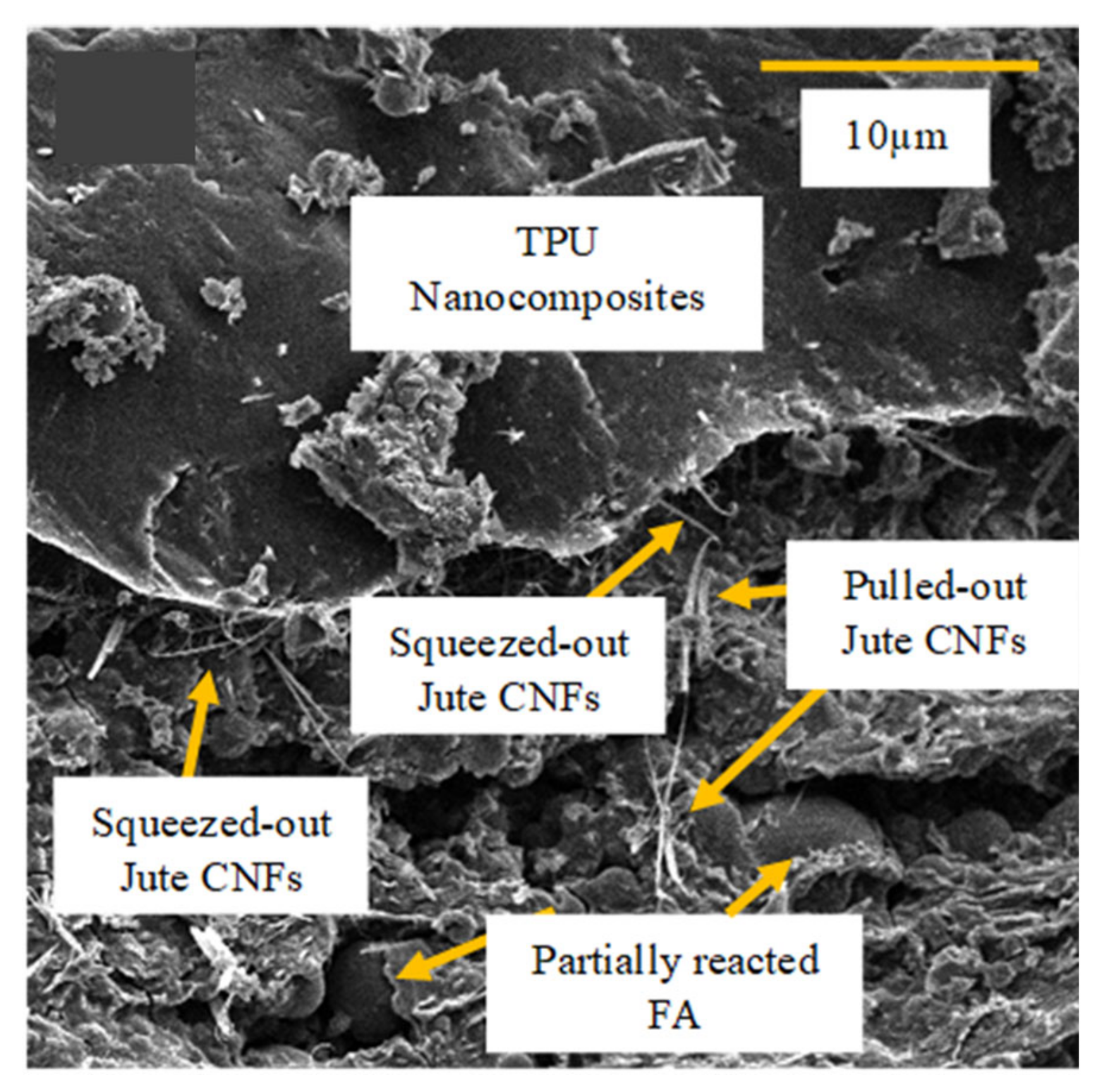

3.2. Compressive Strength Analysis of Prepared Geopolymer Concrete and TPU/Jute CNFs-Reinforced Geopolymer Concrete

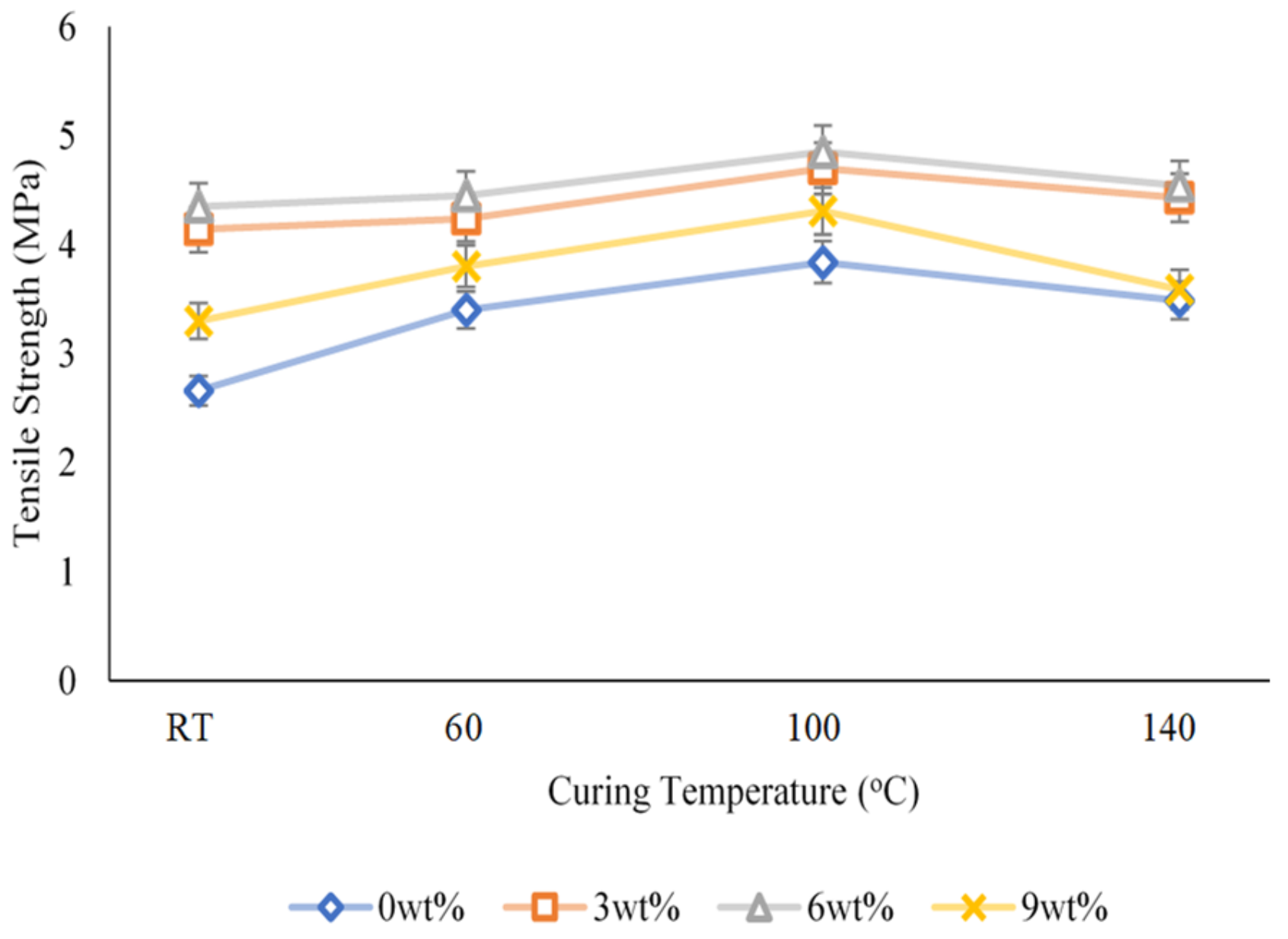

3.3. Splitting Tensile Strength Analysis of Prepared Geopolymer Concrete and TPU/Jute CNFs-Reinforced Geopolymer Concrete

4. Conclusions

5. Limitations of Study and Future Recommendation

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lokuge, W.; Wilson, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Design of fly ash geopolymer concrete mix proportions using multivariate adaptive regression spline model. Constr. Build. Mater. 2018, 166, 472–481. [Google Scholar] [CrossRef]

- Alola, A.A.; Bekun, F.V.; Adebayo, T.S.; Uzuner, G. The nexus of disaggregated energy sources and cement production carbon mission in China. Energy Environ. 2022, 34, 1937–1956. [Google Scholar] [CrossRef]

- Sharma, U.; Bahrami, A.G.N.; Özkılıç, Y.O.; Verma, M.; Berwal, P.; Althaqafi, E.; Khan, M.A.; Islam, S. Behavior of fibers in geopolymer concrete: A comprehensive review. Buildings 2024, 14, 136. [Google Scholar] [CrossRef]

- Hashmi, A.F.; Khan, M.S.; Nila, M.; Shariq, M.; Baqi, A. Green concrete: An eco-friendly alternative to the OPC concrete. Construction 2022, 2, 93–103. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical fundamentals of geopolymers in sustainable construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer concrete: A material for sustainable development in Indian construction industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Kucukgoncu, H.; Ozbayrak, A. Microstructural analysis of low-calcium fly ash based geopolymer concrete with different ratios of activator and binder under high temperatures. Arab. J. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Osamah, M.G.A.K.; Ammar, M. Study the behavior of geopolymer concretes under repeated loadings. J. Eng. Appl. Sci. 2021, 68, 14. [Google Scholar] [CrossRef]

- Huang, H.; Pang, H.; Huang, J.; Zhao, H.; Liao, B. Synthesis and characterization of ground glass fiber reinforced polyurehane-based polymer concrete as cementitious runway repair material. Constr. Build. Mater. 2020, 242, 117221. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Wang, J.; Yuan, J.; Jiang, F.; Yu, X.; Xiao, F. Recent applications and developments of polyurethane materials in pavement engineering. Constr. Build. Mater. 2021, 304, 124639. [Google Scholar] [CrossRef]

- Khan, M.B.; Shafiq, N.; Waqar, A.; Radu, D.; Cismas, C.; Imran, M.; Almujibah, H.; Benjeddou, O. Effects of jute fiber on fresh and hardened characteristics of concrete with environmental assessment. Buildings 2023, 13, 1691. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.M.; Islam, S. Scope of using jute fiber for the reinforcement of concrete material. Text. Cloth. Sustain. 2017, 2, 11. [Google Scholar] [CrossRef]

- Zhu, J.; Zheng, W.Z.; Qin, C.Z.; Xu, Z.Z.; Wu, Y.Q. Effect of different fibers on mechanical properties and ductility of alkali-activated slag cementitious material. IOP Conf. Ser. Mater. Sci. Eng. 2018, 292, 01206. [Google Scholar] [CrossRef]

- Muhd, H.Y.; Meor, A.F.; Mohd, M.A.B.A.; Muhammad, S.I.I.; Rafiza, A.R.; Dumitru, D.B.N.; Diana, P.B.N.; Omrane, B.; Khanh, S.N. Mechanical properties of fly ash-based geopolymer concrete incorporation nylon66 fiber. Materials 2022, 15, 9050. [Google Scholar] [CrossRef]

- Md, K.H.; Mohamed, I.I.; Sukanta, K.S.; Safat, A.D. Mechanical properties of rubberised geopolymer concrete. Materials 2024, 17, 1031. [Google Scholar] [CrossRef]

- Syazwani, S.N.; Ervina, E.M.N.; Nurhidayatullaili, M.J.; Aeslina, A.K. Study on tensile properties and fracture structure analysis: The impact of jute CNFs addition in TPU nanocomposites. Nanomaterials 2024, Submitted. [Google Scholar]

- Nayak, D.K.; Abhilash, P.P.; Sing, R.; Kumar, R.; Kumar, V. Fly ash fo sustainable construction: A review of fly ash concrete and its beneficial use case studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Alomayri, T.; Assaedi, H.; Shaikh, F.U.A.; Low, I.M. Effect of water absorption on the mechanical properties of cotton fabric-reinforced geopolymer composites. J. Asian Ceram. Soc. 2014, 2, 223–230. [Google Scholar] [CrossRef]

- Sherwani, A.F.H.; Younis, K.H.; Arndt, R.W. Fresh, mechaical and durability behavior of fly ash-based self compavted geopolymer concrete: Effect of slag content and various curing conditions. Polymers 2022, 14, 3209. [Google Scholar] [CrossRef]

- Amirreza, K.; Morteza, T.; Abbas, S.; Alireza, A. Evaluation of compressive and splitting tensile strength of slag based aluminosilicate geopolymer reinforced by waste polymeric materials using taguchi method. Mater. Res. Express 2021, 8, 025504. [Google Scholar] [CrossRef]

- Mustafa, M.A.B.A.; Faris, M.A.; Tahir, M.F.M.; Kadir, A.A.; Sandu. A.V.; Mat Isa, N.A.A.; Corbu, O. Performance and characterization of geopolymer concrete reinforced with short steel fiber. IOP Conf. Ser. Mater. Sci. Eng. 2017, 209, 012038. [Google Scholar] [CrossRef]

- Abdullah, A.; Hussin, K.; Abdullah, M.M.A.B.; Yahya, Z.; Sochacki, W.; Razak, R.A.; Błoch, K.; Fansuri, H. The Effects of Various Concentrations of NaOH on the Inter-Particle Gelation of a Fly Ash Geopolymer Aggregate. Materials 2021, 14, 1111. [Google Scholar] [CrossRef] [PubMed]

- ASTM C 642-06; Standard Test Method for Density, Absorption, and Void in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C 109/C 109M-08; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. Or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM C 496/C 496M-04; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C192/C192M; Standard Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2002. [CrossRef]

- Luhar, I.; Luhar, S. Rubberized geopolymer composites: Value-added applications. J. Compos. Sci. 2021, 5, 1–27. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Mechanical and durability properties of fly ash geopolymer concrete containing recycled coarse aggregates. Int. J. Sustain. Built Environ. 2016, 5, 277–287. [Google Scholar] [CrossRef]

- Turkey, F.A.; Beddu, S.B.; Ahmed, A.N.; Suhair, K.A.H. Effect of high temperatures on the properties of lightweight geopolymer concrete based fly ash and glass powder mixture. Case Stud. Constr. Mater. 2022, 17, e01489. [Google Scholar] [CrossRef]

- Syazwani, N.S.; Efzan, M.N.E.; Kok, C.K.; Nurhidayatullaili, M.J. Analysis on extracted jute cellulose nanofibers by Fourier transform infrared and X-ray diffraction. J. Build. Eng. 2022, 48, 103744. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.S.; Kohail, M.; Nasr, E.S.A. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Syazwani, N.S.; Ervina, E.M.N.; Kok, C.K.; Aeslina, A.K.; Sivaraman, V. Microstructure and mechanical properties of thermoplastic polyurethane/jute cellulose nanofibers (CNFs) nanocomposites. In Recent Trends in Manufacturing and Materials Towards Industry 4.0: Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 805–816. [Google Scholar] [CrossRef]

- Rathore, A.; Pradhan, M.K. Hybrid, cellulose bionanocomposite from banana and jute fiber: A review of preparation, properties and applications. Mater. Today Proc. 2017, 4, 3492–3951. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Mohammed, A.A. Engineering properties of geopolymer concrete composites incorporated recycled plastic aggregates modified with nano-silica. J. Build. Eng. 2023, 75, 106942. [Google Scholar] [CrossRef]

- ACI 369.1M-17; Standard Requirements for Seismic Evaluation and Retrofit of Existing Concrete Buildings (ACI 369.1M-17) and Commentary. American Concrete Institute: Michigan, MI, USA, 2018.

| Weight Percent (wt%) | Fly Ash (kg/m3) | Fine Aggregates (kg/m3) | Coarse Aggregates (kg/m3) | TPU/Jute CNF Nanocomposites (kg/m3) | Alkaline Activator (kg/m3) |

|---|---|---|---|---|---|

| 0 | 409.17 | 613.63 | 1350.14 | 0 | 224.98 |

| 3 | 409.17 | 535.69 | 1350.14 | 77.93 | 224.98 |

| 6 | 409.17 | 457.75 | 1350.14 | 155.88 | 224.98 |

| 9 | 409.17 | 379.82 | 1350.14 | 233.81 | 224.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nordin, S.S.; Mhd Noor, E.E.; Muhd Julkapli, N.; Abdul Kadir, A. Study on the Effect of Jute CNFs Addition on the Water Absorption and Mechanical Properties of Geopolymer Concrete. Buildings 2024, 14, 3444. https://doi.org/10.3390/buildings14113444

Nordin SS, Mhd Noor EE, Muhd Julkapli N, Abdul Kadir A. Study on the Effect of Jute CNFs Addition on the Water Absorption and Mechanical Properties of Geopolymer Concrete. Buildings. 2024; 14(11):3444. https://doi.org/10.3390/buildings14113444

Chicago/Turabian StyleNordin, Siti Syazwani, Ervina Efzan Mhd Noor, Nurhidayatullaili Muhd Julkapli, and Aeslina Abdul Kadir. 2024. "Study on the Effect of Jute CNFs Addition on the Water Absorption and Mechanical Properties of Geopolymer Concrete" Buildings 14, no. 11: 3444. https://doi.org/10.3390/buildings14113444

APA StyleNordin, S. S., Mhd Noor, E. E., Muhd Julkapli, N., & Abdul Kadir, A. (2024). Study on the Effect of Jute CNFs Addition on the Water Absorption and Mechanical Properties of Geopolymer Concrete. Buildings, 14(11), 3444. https://doi.org/10.3390/buildings14113444