Study on Impact Resistance of Alkali-Activated Slag Cementitious Material with Steel Fiber

Abstract

1. Introduction

2. Test Survey

2.1. Experimental Design

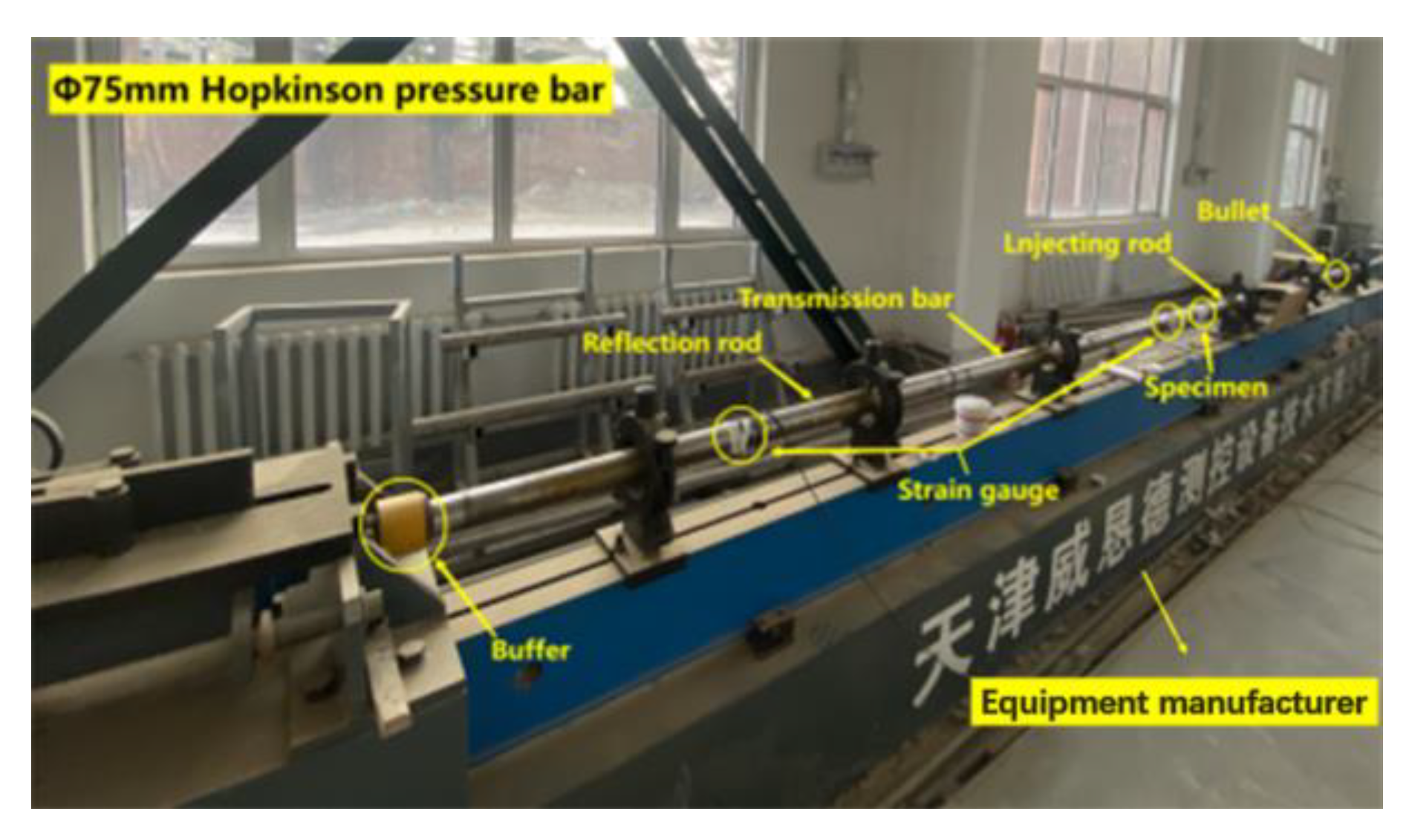

2.2. SHPB Test

3. Result and Discussion

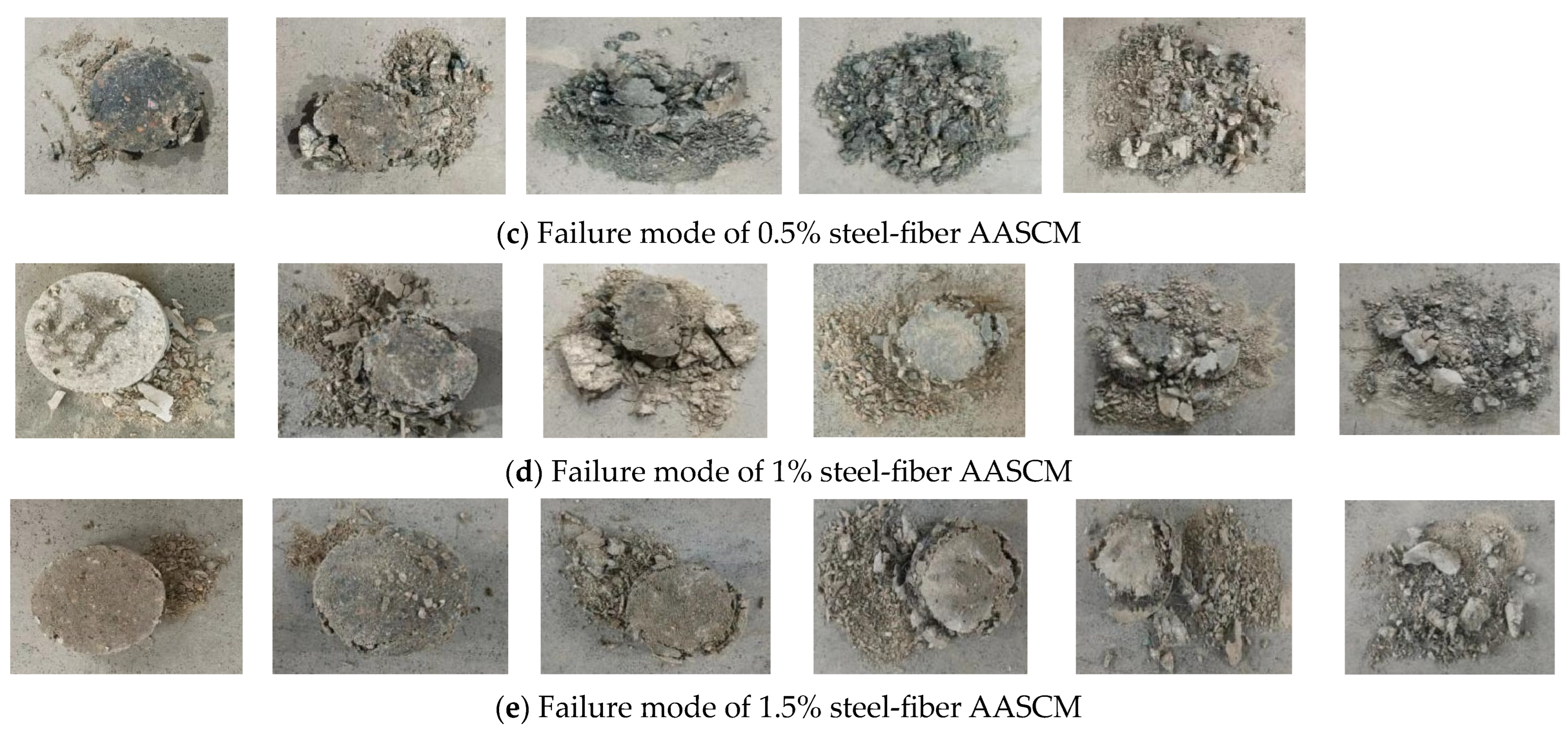

3.1. Impact Failure Mode of AASCMs

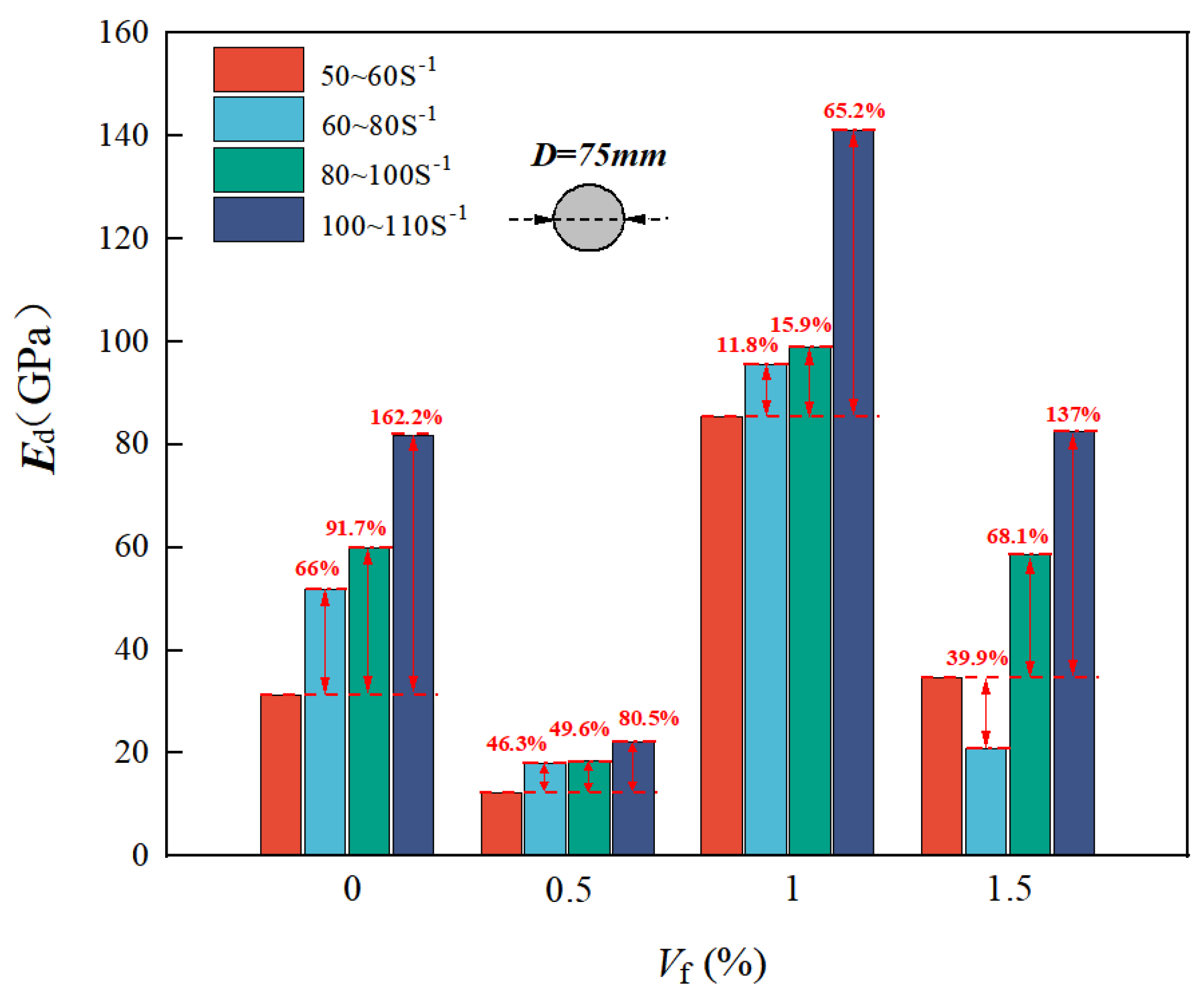

3.2. Dynamic Elastic Modulus

3.2.1. Effect of Strain Rate on Dynamic Elastic Modulus

3.2.2. Influence of Steel-Fiber Content on Dynamic Elastic Modulus

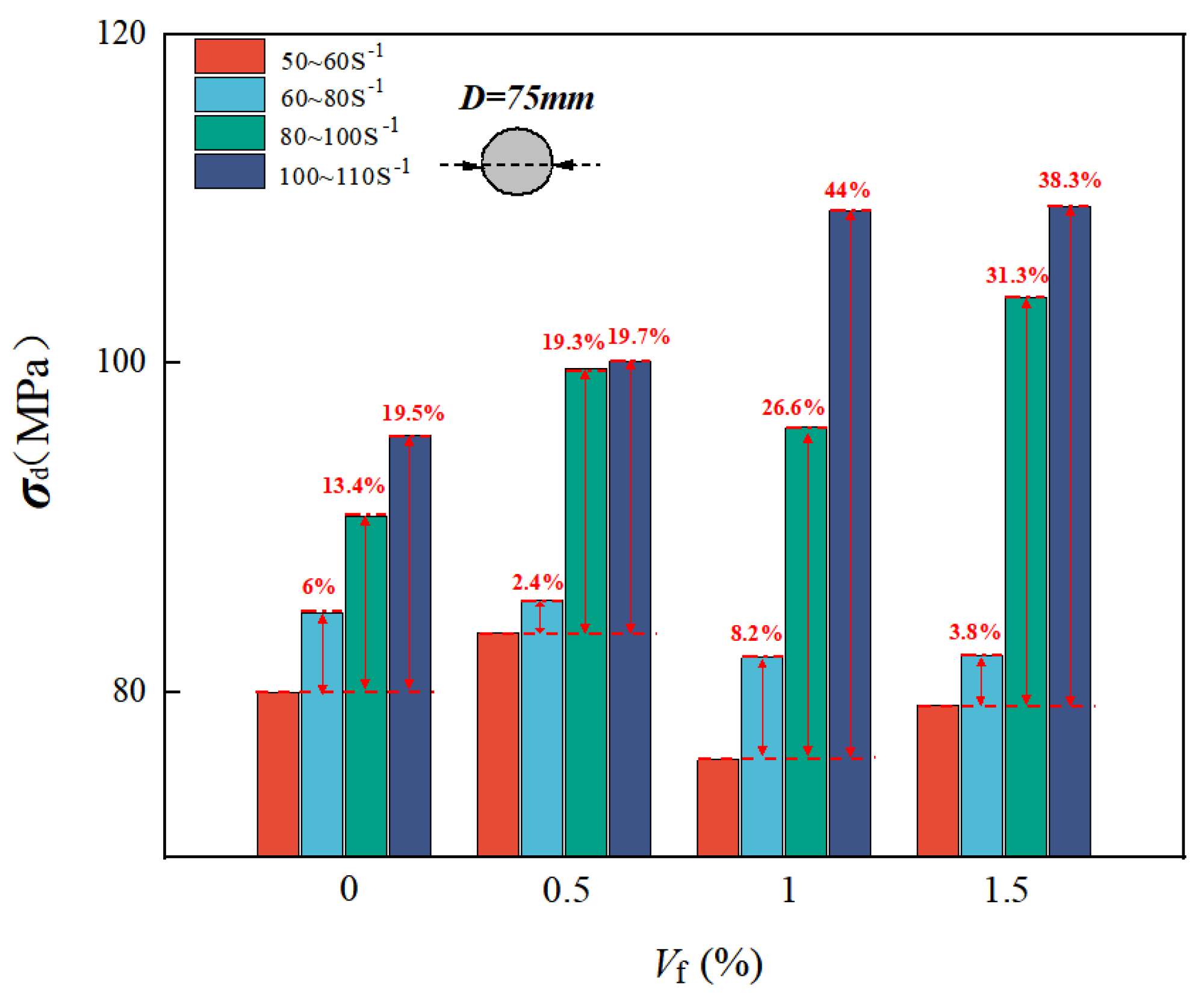

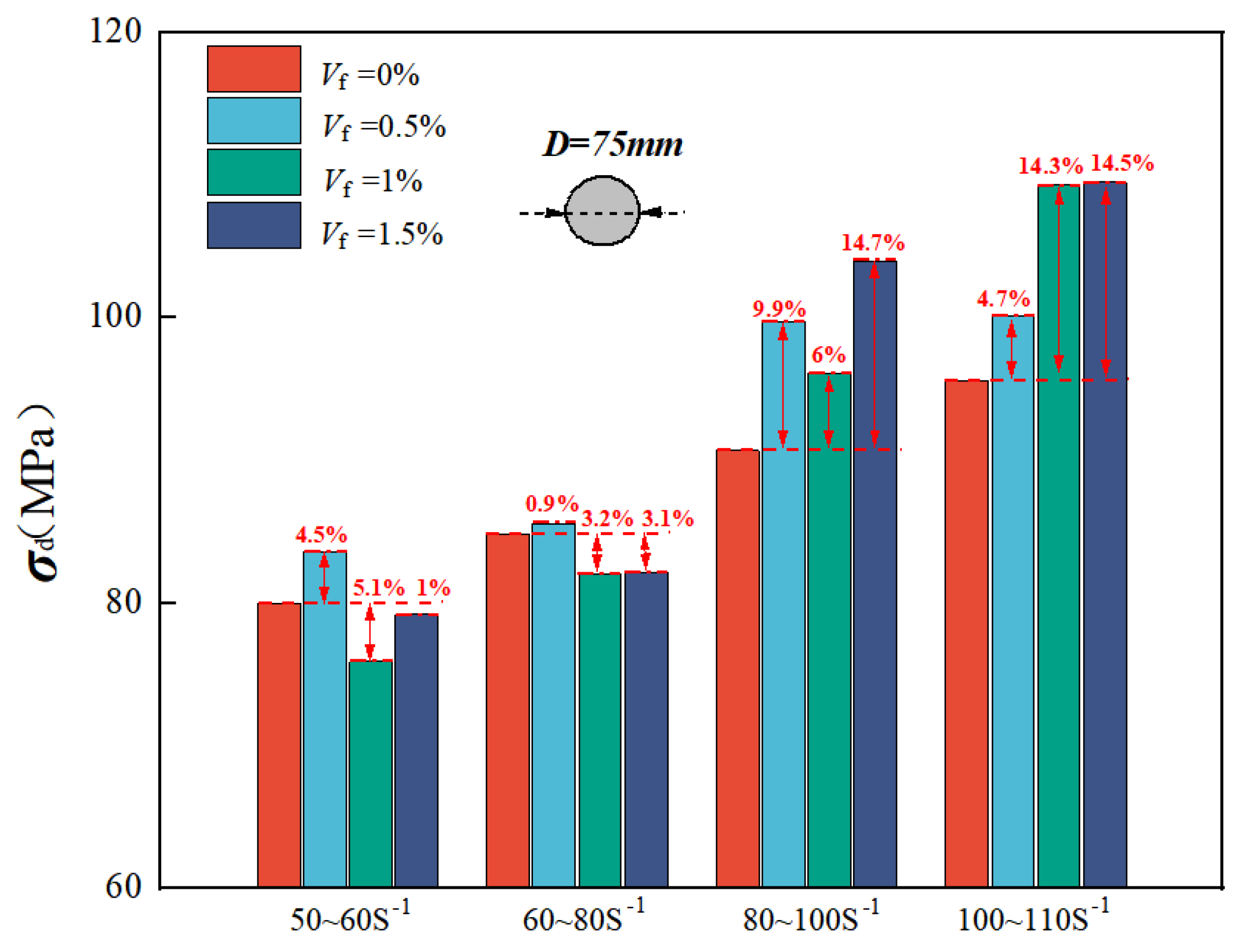

3.3. Dynamic Compressive Strength

3.3.1. Effect of Strain Rate on Dynamic Compressive Strength

3.3.2. Effect of Steel-Fiber Content on Dynamic Compressive Strength

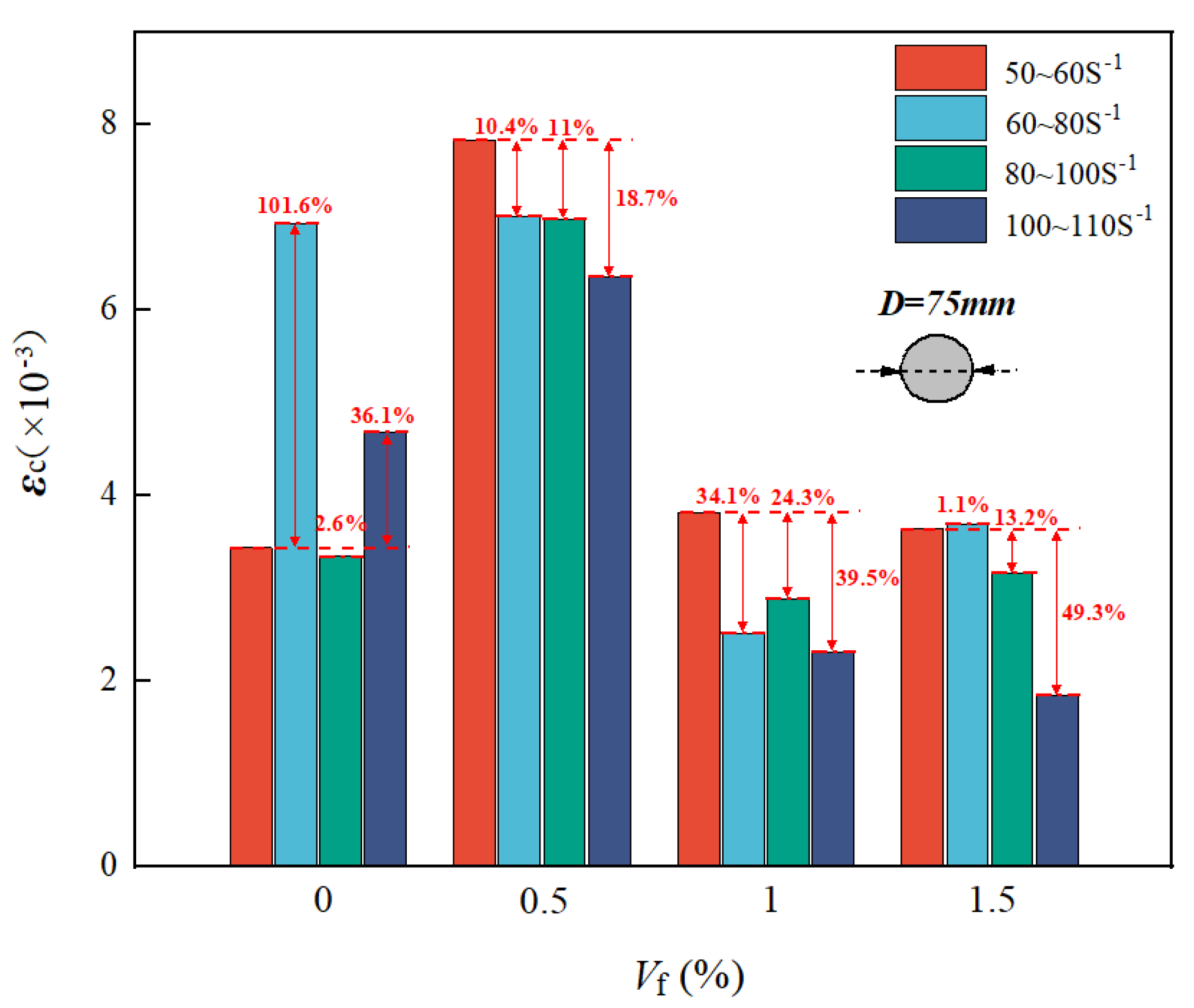

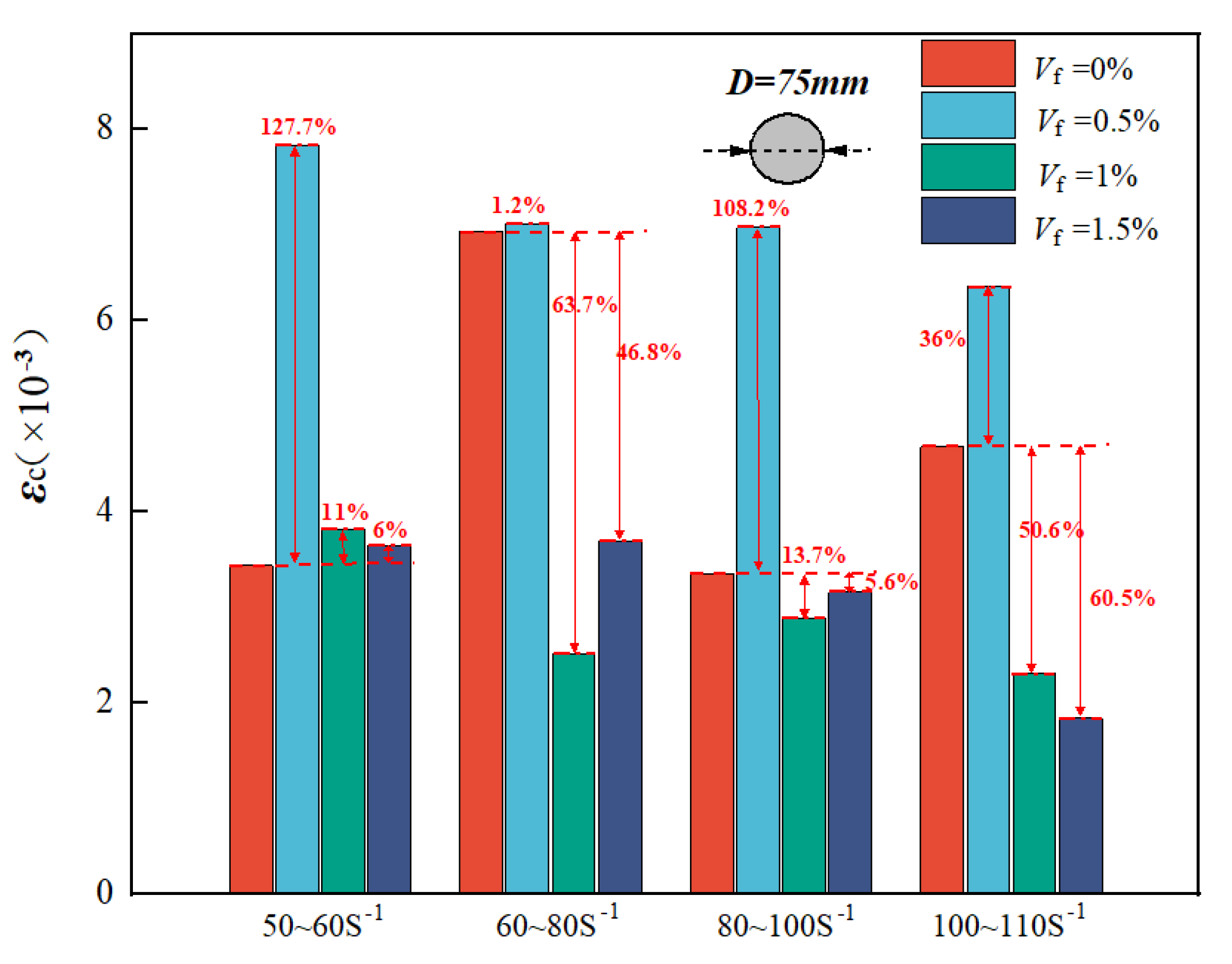

3.4. Dynamic Peak Compressive Strain

3.4.1. Effect of Strain Rate on Dynamic Peak Compressive Strain

3.4.2. Effect of Steel-Fiber Content on Dynamic Peak Compressive Strain

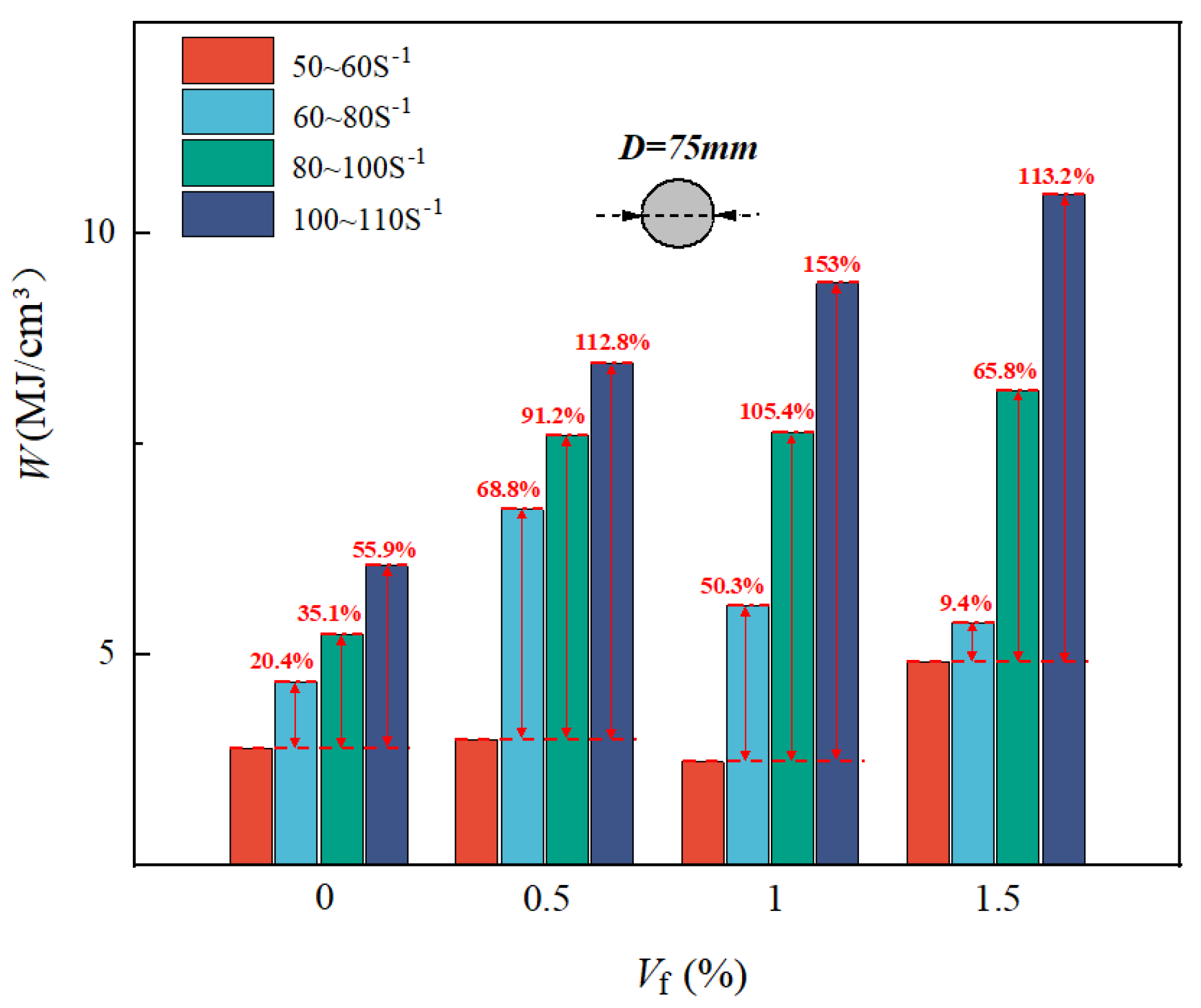

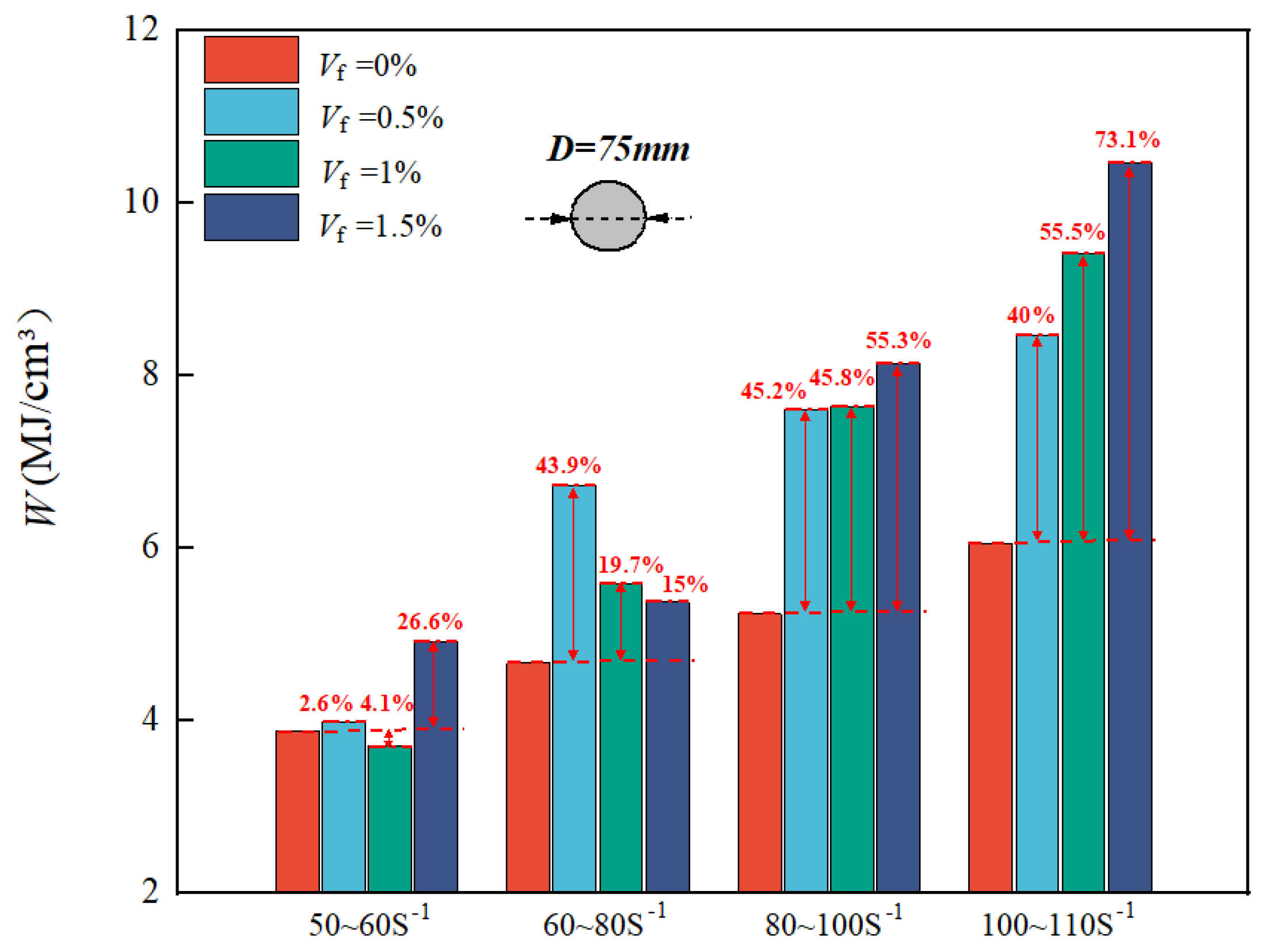

3.5. Energy Absorption

3.5.1. Energy Absorption and Calculation

3.5.2. Effect of Strain Rate on Energy Absorption

3.5.3. Effect of Steel Fiber Content on Energy Absorption

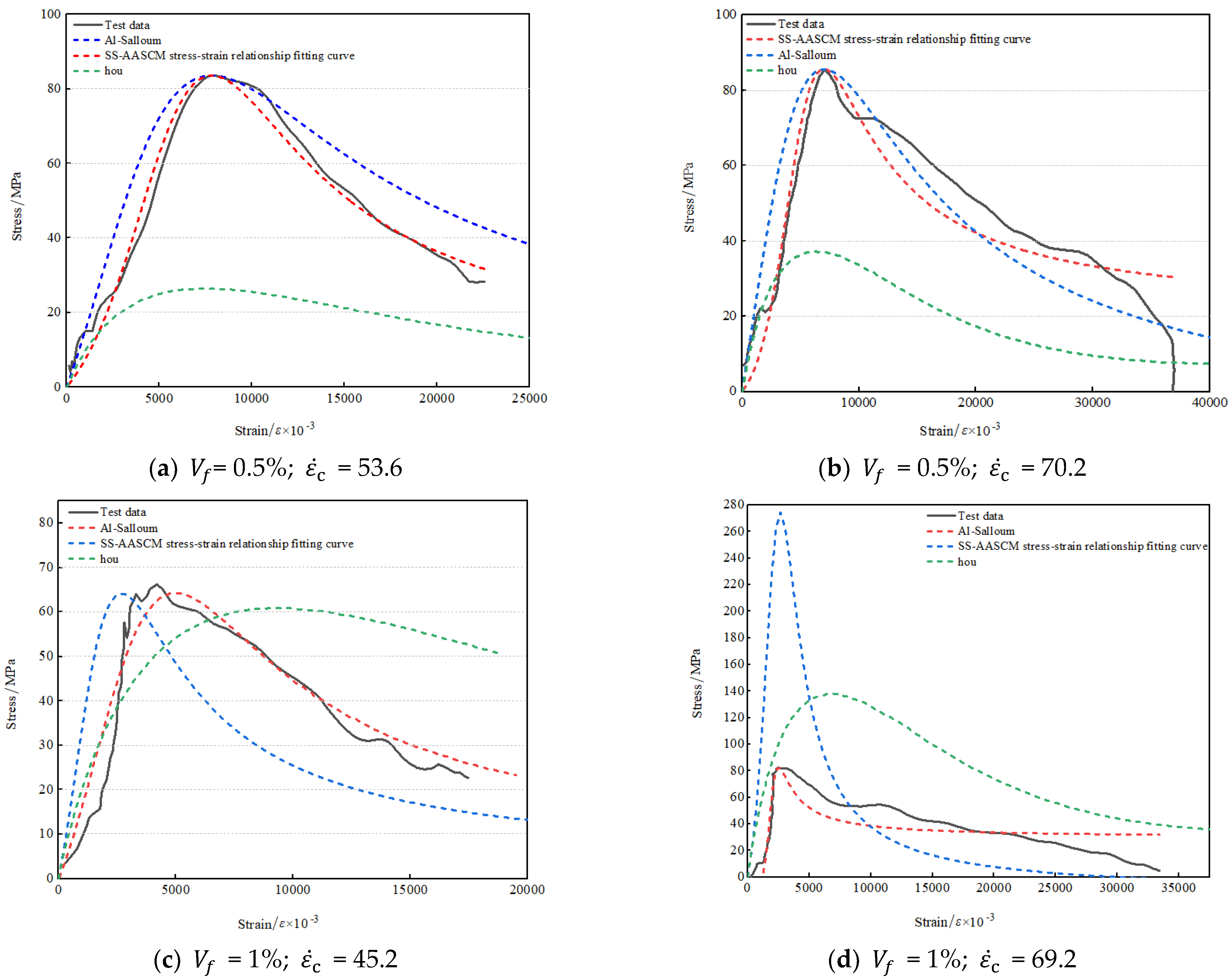

4. Dynamic Constitutive Model of Steel-Fiber Reinforced Alkali Slag Cementitious Material

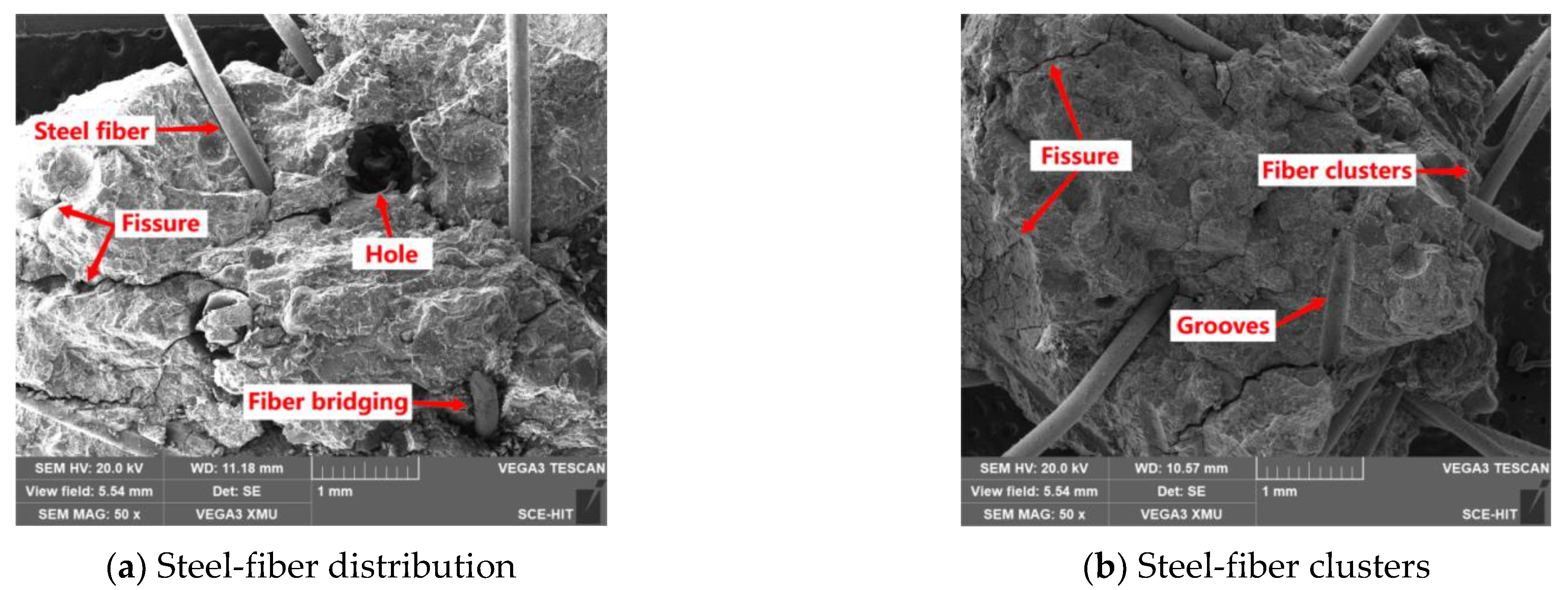

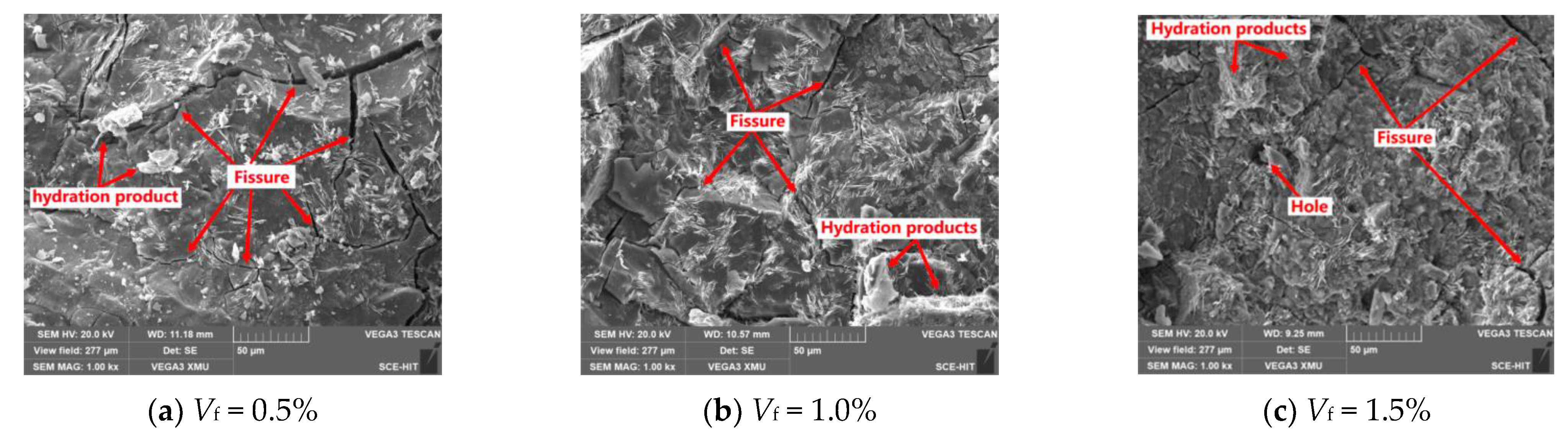

5. Micro-Analysis

6. Conclusions

- (1)

- The dynamic elastic modulus and dynamic compressive strength of the AASCMs increases with the increase of the strain rate. Steel fibers can improve the dynamic elastic modulus and dynamic compressive of AASCMs. The dynamic elastic modulus of AASCMs can be increased by 65.6–173.7%, and increase the dynamic compressive strength of AASCMs by 2.4–44% by adding a 1.0% volume fraction of steel fiber.

- (2)

- The dynamic peak compressive strain of AASCMs without steel fiber is the greatest at a strain rate of 60–80 s−1. An appropriate amount of steel fibers can improve the dynamic peak compressive strain of the AASCMs. With an increase in steel-fiber volume content, the dynamic peak compressive strain of AASCMs increases first and then decreases, reaching a maximum at 0.5% content.

- (3)

- The energy absorption capacity of AASCMs increases with the increase the strain rate. Steel fibers can significantly improve the impact toughness of AASCMs. At high strain rates, the larger the fiber volume content, the stronger the energy absorption capacity of AASCMs; the steel fiber can increase the energy absorption capacity of AASCMs by 9.4–153%.

- (4)

- The existing constitutive model has a high prediction accuracy for the FR-AASCM stress–strain curve; and the correlation coefficient was greater than 0.85. A dynamic constitutive model of the FR-AASCM was established based on the Al-Salloum model with a correlation coefficient was 0.91.

- (5)

- Through SEM microanalysis, it was found that with an increase in the steel-fiber volume content, the number of microcracks generated after the specimen is destroyed decreases, the width of the microcracks decreases, and the degree of damage gradually decreases, thereby improving the impact resistance of the AASCMs.

- (6)

- In addition, the work can be also extended under several directions in the future. First, introduce hybrid fiber systems (e.g., a mix of steel and synthetic fibers) may further optimize both ductility and energy absorption of AASCMs. Second, the combination of Split Hopkinson Pressure Bar test and soundness test can be considered to explore the delayed expansion resistance of the AASCM. Finally, the toughening efficiency of steel fibers can be further improved by controlling the orientation of steel fibers in AASCMs through the magnetic field orientation method, and the effect of the setting speed of AASCMs on the orientation of fibers can be explored.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Yang, S.; Dong, K.; Nepal, R. Assessing embodied carbon emission and its drivers in China’s ICT sector: Multi-regional input-output and structural decomposition analysis. Energy Policy 2024, 186, 114008. [Google Scholar] [CrossRef]

- Ganesh, A.C.; Muthukannan, M. Development of high performance sustainable optimized fiber reinforced geopolymer concrete and prediction of compressive strength. J. Clean. Prod. 2021, 282, 124–543. [Google Scholar] [CrossRef]

- Yuan, X.; Shi, Y.; Lu, F.; Zhang, X.; Wang, J. Study on the effect of activator type on the properties of alkali slag cementitious materials. J. Xinyang Norm. Univ. (Nat. Sci. Ed.) 2021, 34, 667–672. [Google Scholar]

- Nedunuri, A.S.S.S.; Muhammad, S. The role of zinc sulphate as a retarder for alkali activated binders and its influence on the rheological, setting and mechanical behaviour. Constr. Build. Mater. 2022, 344, 128128. [Google Scholar] [CrossRef]

- Yu, L. Preparation and Properties of Alkali-Activated Slag Cementitious Materials. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2011. [Google Scholar]

- Zheng, W.; Chen, W.; Wang, Y. High temperature resistance of alkali slag cementitious materials. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2009, 37, 96–99. [Google Scholar] [CrossRef]

- Chen, P.; Tian, F.; Zhang, J.; Li, Y.; Wei, Y. Effect of nano-silica on mechanical properties and shrinkage of alkali-activated slag cementitious material. Dev. Built Environ. 2024, 19, 100–525. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Zhang, J.; Zhang, Z.; Wang, D. Influence of interface agent and form on the bonding performance and impermeability of ordinary concrete repaired with alkali-activated slag cementitious material. J. Build. Eng. 2024, 94, 110043. [Google Scholar] [CrossRef]

- Sun, J.; Hou, S.; Guo, Y.; He, W.; Cui, Y.; Zhang, P. Effects of high-temperature curing on hydration and microstructure of alkali-activated typical steel slag cementitious material. Dev. Built Environ. 2024, 17, 100–314. [Google Scholar] [CrossRef]

- Vo, D.H.; Thi, K.D.; Hwang, C.L.; Liao, M.C.; Hsu, W.L.; Yehualaw, M.D. Mechanical properties of concrete produced with alkali-activated slag-fly ash and recycled concrete aggregate and designed using the densified mixture design algorithm (DMDA) method: Effects of recycled aggregate content and alkaline solution. Dev. Built Environ. 2023, 14, 100–125. [Google Scholar] [CrossRef]

- Kabir, H.; Hooton, R.; Popoff, N. Evaluation of cement soundness using the ASTM C151 autoclave expansion test. Cem. Concr. Res. 2020, 136, 106–159. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, G.; Chen, P.; Wang, D. Effect of activator composition on deformation and mechanical properties of alkali-activated slag cement mortar. New Build. Mater. 2017, 44, 1–4+17. [Google Scholar]

- Jin, L.; Zhang, R.; Tian, Y.; Dou, G.; Du, X. Experimental investigation on static and dynamic mechanical properties of steel fiber reinforced ultra-high-strength concretes. Constr. Build. Mater. 2018, 178, 102–111. [Google Scholar]

- Zheng, Y.; Zhang, W.; Zheng, L.; Zheng, J. Mechanical properties of steel fiber-reinforced geopolymer concrete after high temperature exposure. Constr. Build. Mater. 2024, 439, 137–394. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.; Wang, Q.; Luo, Y. Research progress on dynamic mechanical properties and blast resistance and impact resistance of engineering cement-based composites. Silic. Bull. 2021, 40, 2485–2496. [Google Scholar]

- Luo, Z.; Li, X.; Ling, T. Study on the strengthening mechanism and fracture mechanics model of steel fiber reinforced concrete. Min. Res. Dev. 2003, 23, 18–22. [Google Scholar]

- Wang, H.T.; Wang, L.C. Experimental study on static and dynamic mechanical properties of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Ye, P.; Chen, Z.; Su, W. Mechanical properties of fully recycled coarse aggregate concrete with polypropylene fiber. Case Stud. Constr. Mater. 2022, 17, e01352. [Google Scholar] [CrossRef]

- Liu, J.; Dai, X.; Yu, X.; Yao, C.; Zhao, X.; Kong, D. Tensile behaviour and full-field strain of reactive powder concrete under dynamic loading: Effects of fibre length and content. Constr. Build. Mater. 2024, 416, 135008. [Google Scholar] [CrossRef]

- Abubakr, A.; Soliman, A. Impact Behaviour of Steel-Fibre-Reinforced Alkali-Activated Slag Concrete Exposed to Elevated Temperatures. Materials 2023, 16, 4096. [Google Scholar] [CrossRef]

- Soufeiani, L.; Raman, S.N.; Bin Jumaat, M.Z.; Alengaram, U.J.; Ghadyani, G.; Mendis, P. Influences of the volume fraction and shape of steel fibers on fiber-reinforced concrete subjected to dynamic loading—A review. Eng. Struct. 2016, 124, 405–417. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Engineering properties of ambient cured alkali-activated fly ash-slag concrete reinforced with different types of steel fiber. Mater. Civ. 2018, 117, 29–40. [Google Scholar]

- Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z.; Bu, C.H. Impact resistance of hybrid fibre-reinforced oil palm shell concrete. Constr. Build. Mater. 2014, 50, 499–507. [Google Scholar]

- Li, W.M.; Xu, J.Y.; Zhai, Y.; Li, Q. Mechanical properties of carbon fiber reinforced concrete under impact load. J. Civ. Eng. 2009, 42, 24–30+38. [Google Scholar]

- Zhang, X.; Yao, A. Study on elastic modulus of slag cementitious material mortar. Silic. Bull. 2011, 30, 950–954. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Xu, W.; Chen, L.; Li, D.; He, J.; Kou, H.; Li, H. Comparative analysis of dynamic constitutive response of hybrid fibre-reinforced concrete with different matrix strengths. Int. J. Impact Eng. 2021, 148, 103763. [Google Scholar]

- Jiao, C.-J.; Sun, W.; Gao, P.-Z.; Zhou, Y. Experimental study on impact resistance of steel fiber reinforced concrete. J. Sun Yat-Sen Univ. (Nat. Sci. Ed.) 2005, 44, 41–44. [Google Scholar]

- Xu, J.; Li, W.; Fan, F.; Bai, E. SHPB experimental study of carbon fiber reinforced geopolymer concrete. J. Build. Mater. 2010, 13, 435–440. [Google Scholar]

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2022, 316, 125896. [Google Scholar]

- Dilger, W.H.; Koch, R.; Kowalczyk, R. Ductility of plain and confined concrete under different strain rates. ACI J. 1984, 81, 73. [Google Scholar]

- Cheng, H.; Chen, P.; Cao, S.; Li, Y. Stress-strain model of steel fibre-reinforced alkali-activated slag cementitious material after high-temperature exposure. J. Build. Eng. 2023, 79, 107743. [Google Scholar] [CrossRef]

- Miyoshi, T.; Itoh, M.; Mukai, T.; Kanahashi, H.; Kohzu, H.; Tanabe, S.; Higashi, K. Enhancement of energy absorption in a closed-cell aluminum by the modification of cellular structures. Scr. Mater. 1999, 41, 1055–1060. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zheng, K.; Bakura, T.J.; Totakhil, P.G. Research on compressive impact dynamic behavior and constitutive model of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 584–595. [Google Scholar] [CrossRef]

- Tai, Y.S. Uniaxial compression tests at various loading rates for reactive powder concrete. Theor. Appl. Fract. Mech. 2009, 52, 14–21. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Sun, H.; Wu, S. Transient dynamic behavior of polypropylene fiber reinforced mortar under compressive impact loading. Constr. Build. Mater. 2016, 111, 30–42. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Zhong, C.; Ye, Z.; Wang, Y. Mechanism and mechanical analysis of impact dynamic strengthening and toughening of steel fiber reinforced concrete. J. Shanxi Energy Coll. 2018, 31, 143–146. [Google Scholar]

- Liu, Y. Study on Mechanical Properties and Anti-Penetration Mechanism of Steel Fiber Reinforced Concrete. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2006. [Google Scholar]

- Al-Salloum, Y.; Almusallam, T.; Ibrahim, S.M.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on SHPB experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar] [CrossRef]

- Hou, X.; Cao, S.; Rong, Q.; Zheng, W.; Li, G. Effects of steel fiber and strain rate on the dynamic compressive stress-strain relationship in reactive powder concrete. Constr. Build. Mater. 2018, 170, 570–581. [Google Scholar] [CrossRef]

- Xie, Y.-T.; Wang, J.-X.; Wang, Y.-Z.; Zhang, B.-J.; Wang, S.-Y. Axial compressive behavior of partially encased composite reactive powder concrete columns after high-temperature exposure. Case Stud. Constr. Mater. 2024, 21, e03625. [Google Scholar] [CrossRef]

- Su, D.Y.; Pang, J.Y.; Huang, X.W. Mechanical and dynamic properties of hybrid fiber reinforced fly-ash concrete. Adv. Civ. Eng. 2021, 2021, 3145936. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Chen, M.; Chen, W.; Zhong, H.; Chi, D.; Wang, Y.; Zhang, M. Experimental study on dynamic compressive behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2019, 98, 95–112. [Google Scholar] [CrossRef]

- Murakami, S.; Ichikawa, H. Utilization of svm in the soundness evaluation of reinforced concrete slab bridge. J. JSCE 2020, 8, 59–70. [Google Scholar]

| Component | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | Miscellaneous |

|---|---|---|---|---|---|---|

| Content/% | 41.17 | 33.94 | 13.16 | 7.28 | 0.66 | 3.79 |

| Density (kg/m3) | Diameter (µm) | Length (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| 7800 | 210 | 12 | 2969 | 200 |

| Groups | Vf (%) | Size (mm) | Mineral Fines (kg/m3) | Sodium Silicate (kg/m3) | Sodium Hydroxide (kg/m3) | Water (kg/m3) | River Sand (kg/m3) | Trial Amount |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | Φ75 × 36.5 | 625 | 164 | 27.8 | 152 | 833 | 6 |

| 2 | 0.5 | Φ75 × 36.5 | 625 | 164 | 27.8 | 152 | 833 | 6 |

| 3 | 1.0 | Φ75 × 36.5 | 625 | 164 | 27.8 | 152 | 833 | 6 |

| 4 | 1.5 | Φ75 × 36.5 | 625 | 164 | 27.8 | 152 | 833 | 6 |

| References | Constitutive Model | Scope of Application |

|---|---|---|

| Al-Salloum [35] | Ordinary concrete | |

| Hou [16] | Fiber-reinforced concrete | |

| This paper proposes | Steel-fiber toughened alkali slag cementitious material |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Chen, G.; Liu, G.; Liu, H.; Zhang, J.; Chen, P.; Su, Y. Study on Impact Resistance of Alkali-Activated Slag Cementitious Material with Steel Fiber. Buildings 2024, 14, 3442. https://doi.org/10.3390/buildings14113442

Liu P, Chen G, Liu G, Liu H, Zhang J, Chen P, Su Y. Study on Impact Resistance of Alkali-Activated Slag Cementitious Material with Steel Fiber. Buildings. 2024; 14(11):3442. https://doi.org/10.3390/buildings14113442

Chicago/Turabian StyleLiu, Pan, Guangjing Chen, Gang Liu, Hao Liu, Jia Zhang, Pang Chen, and Yumeng Su. 2024. "Study on Impact Resistance of Alkali-Activated Slag Cementitious Material with Steel Fiber" Buildings 14, no. 11: 3442. https://doi.org/10.3390/buildings14113442

APA StyleLiu, P., Chen, G., Liu, G., Liu, H., Zhang, J., Chen, P., & Su, Y. (2024). Study on Impact Resistance of Alkali-Activated Slag Cementitious Material with Steel Fiber. Buildings, 14(11), 3442. https://doi.org/10.3390/buildings14113442