Research on Coordinated Relationship Between Deformation and Force in Shaft Foundation Pit Support Structures

Abstract

1. Introduction

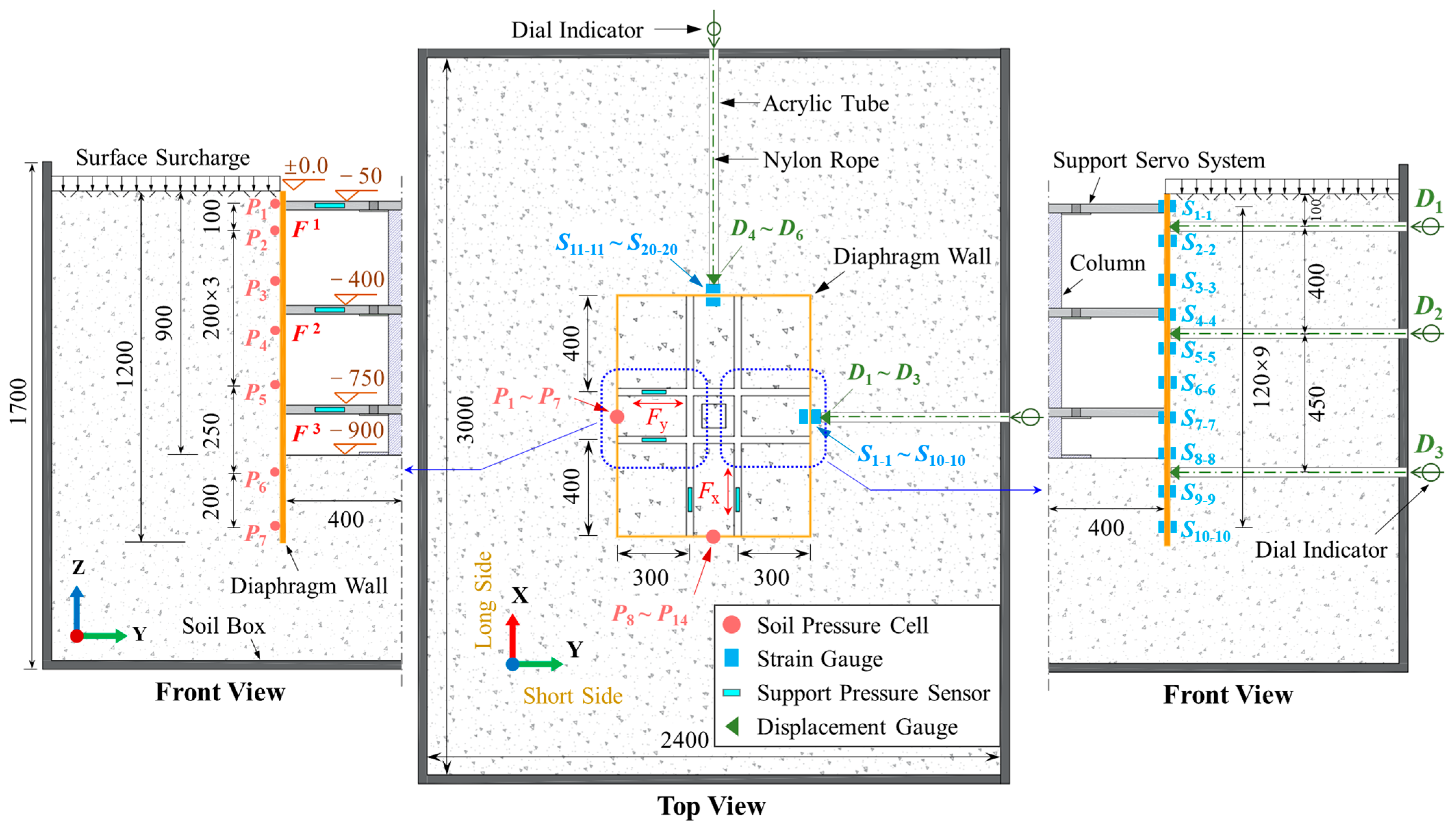

2. Scaled Model Test Design

2.1. Model Test Components

2.2. Test Schemes and Test Conditions

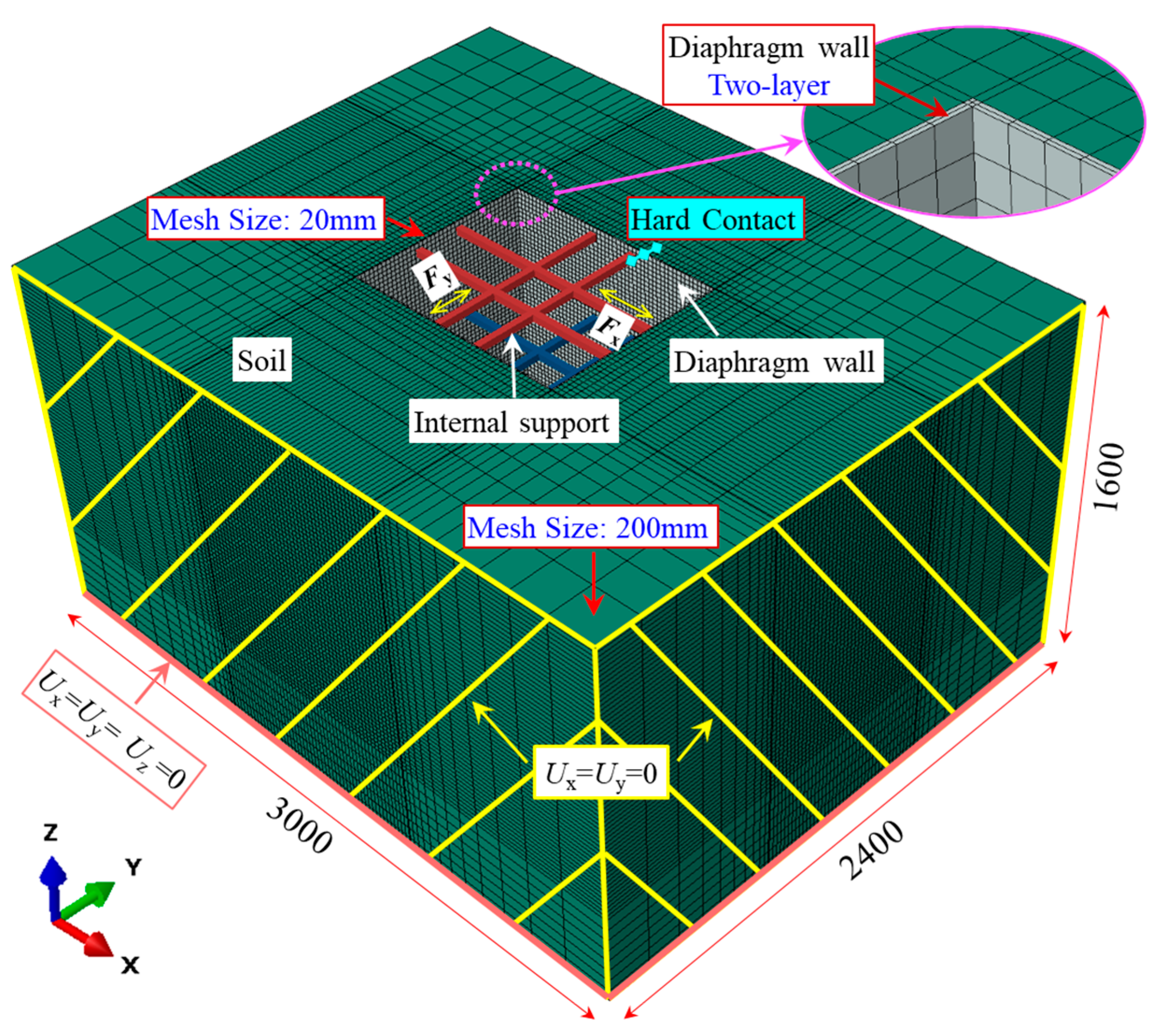

3. Numerical Investigations

3.1. Numerical Model

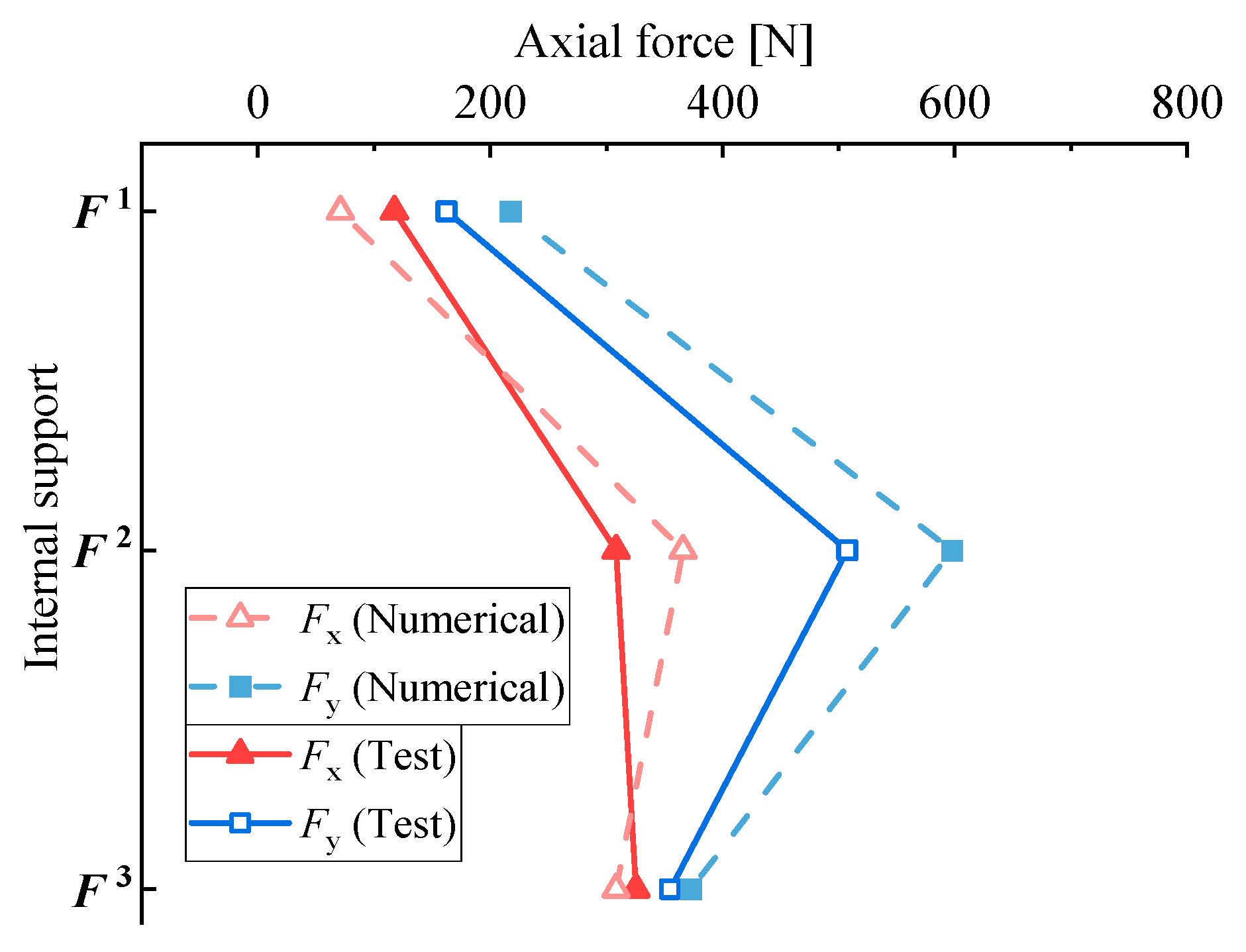

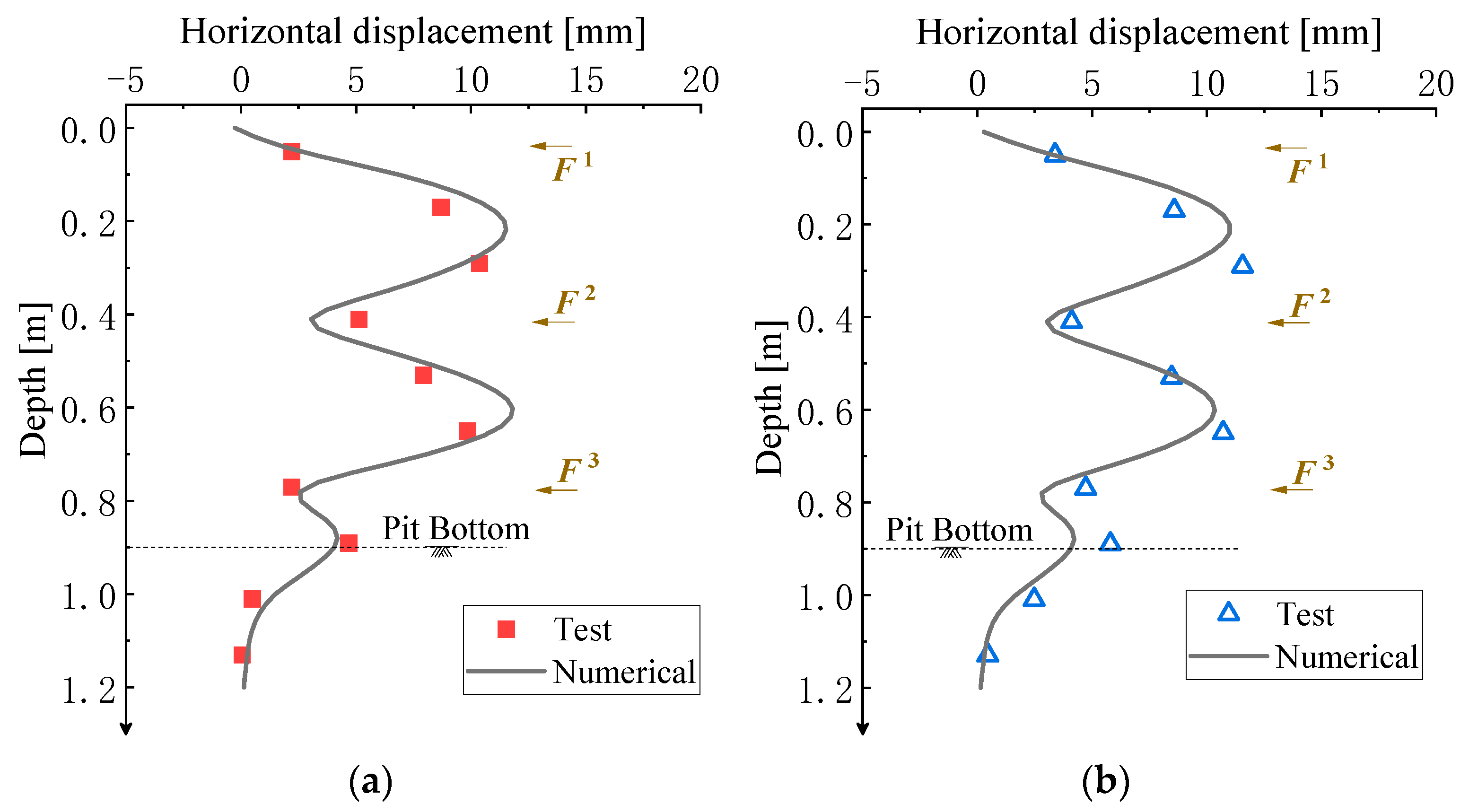

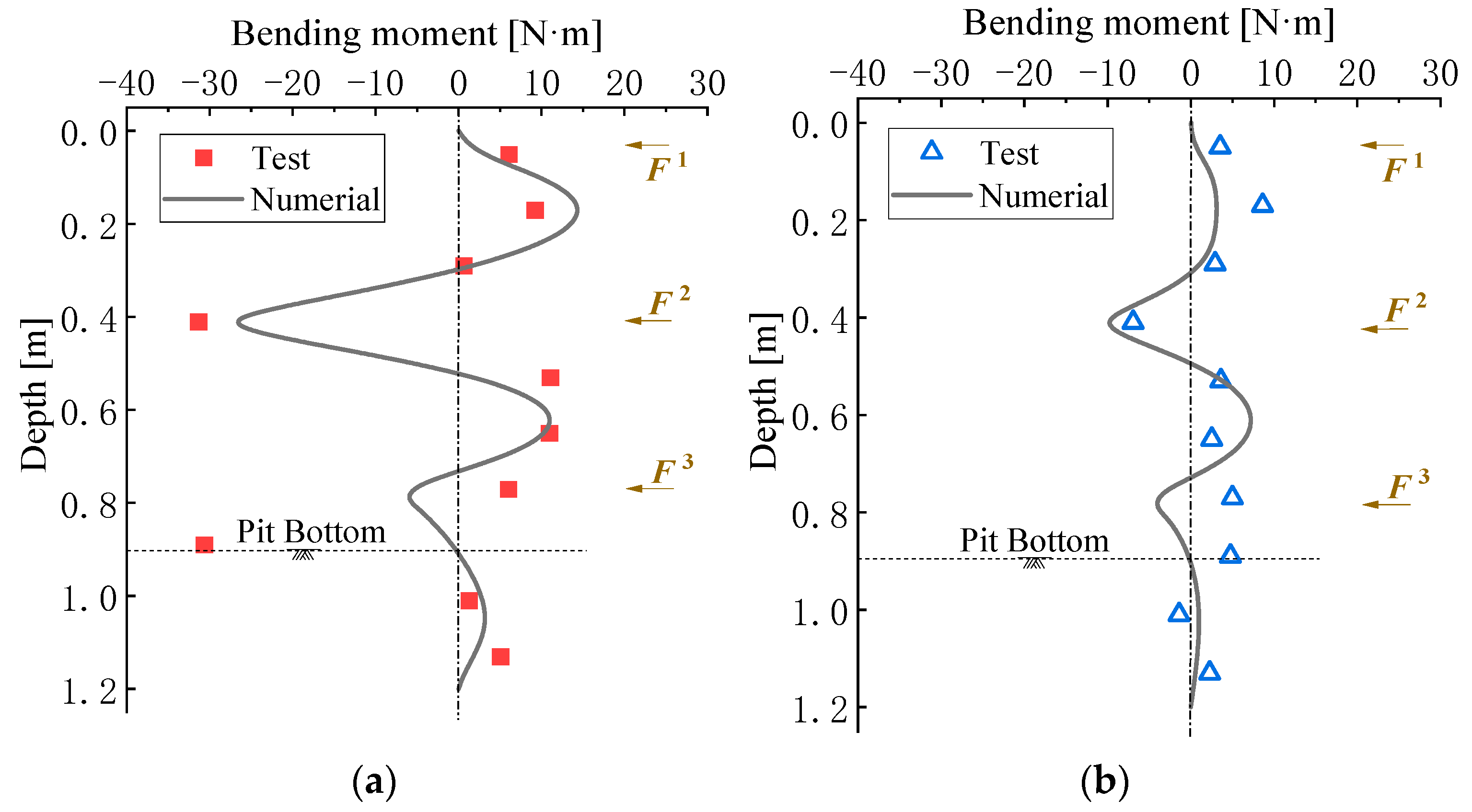

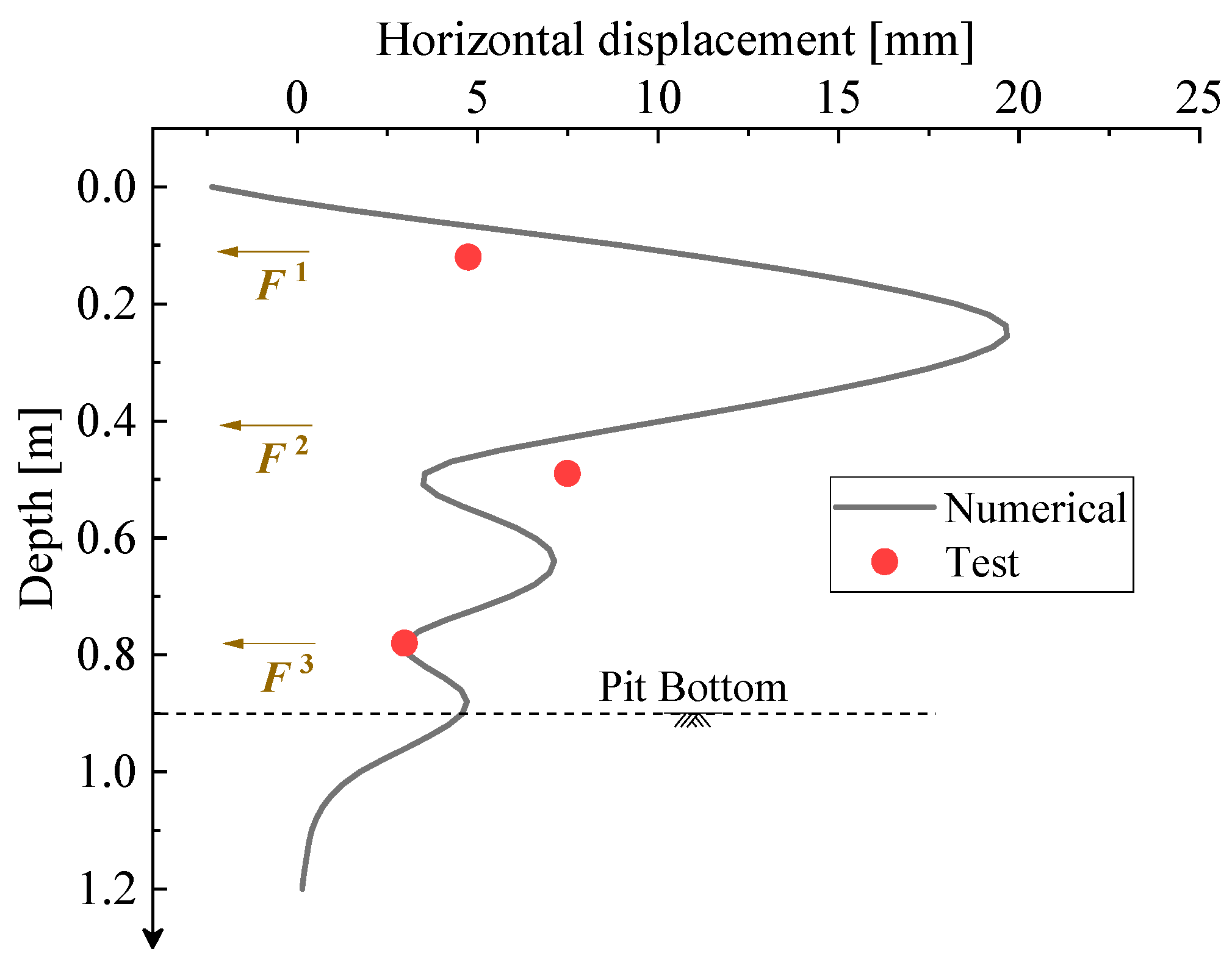

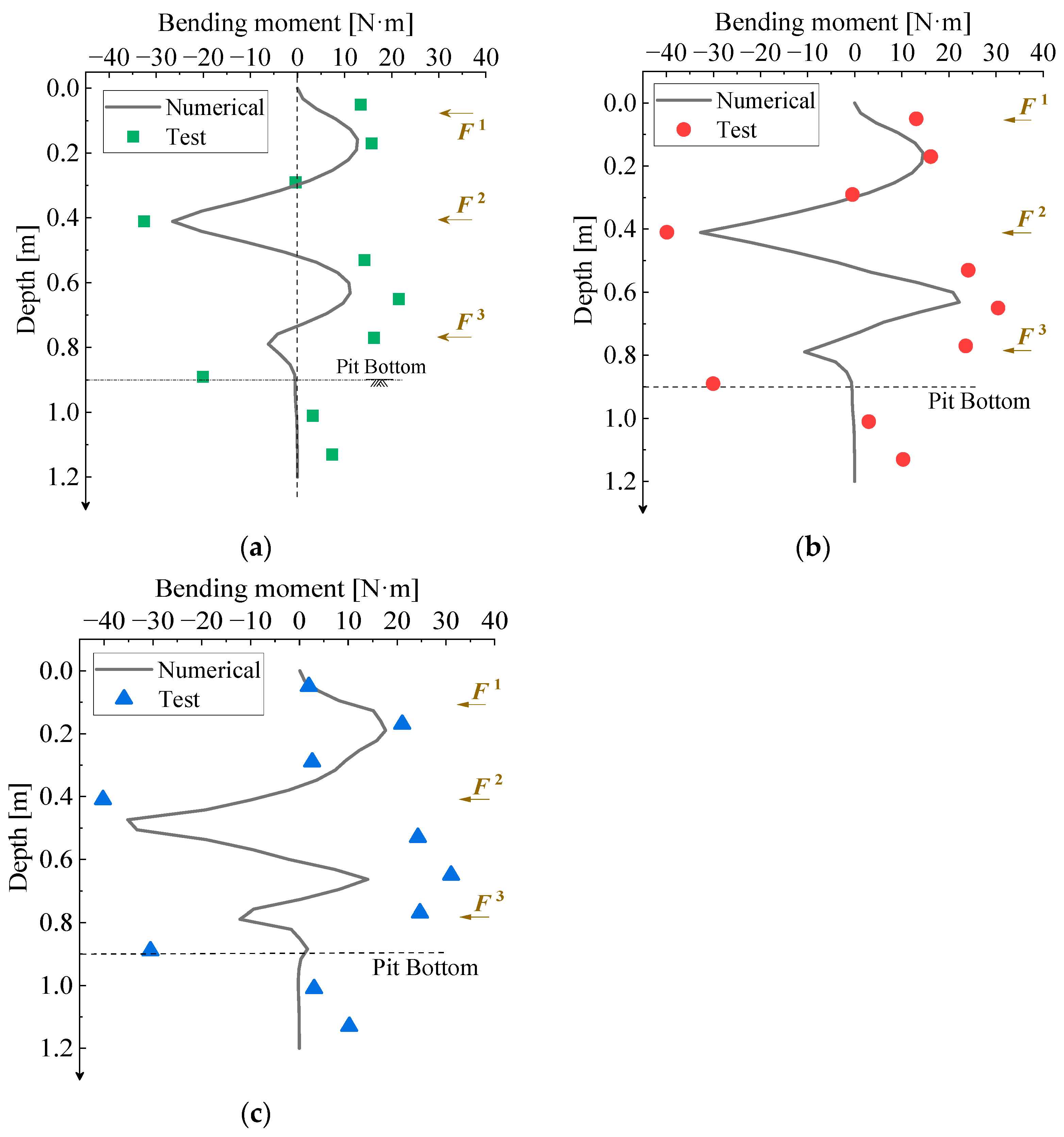

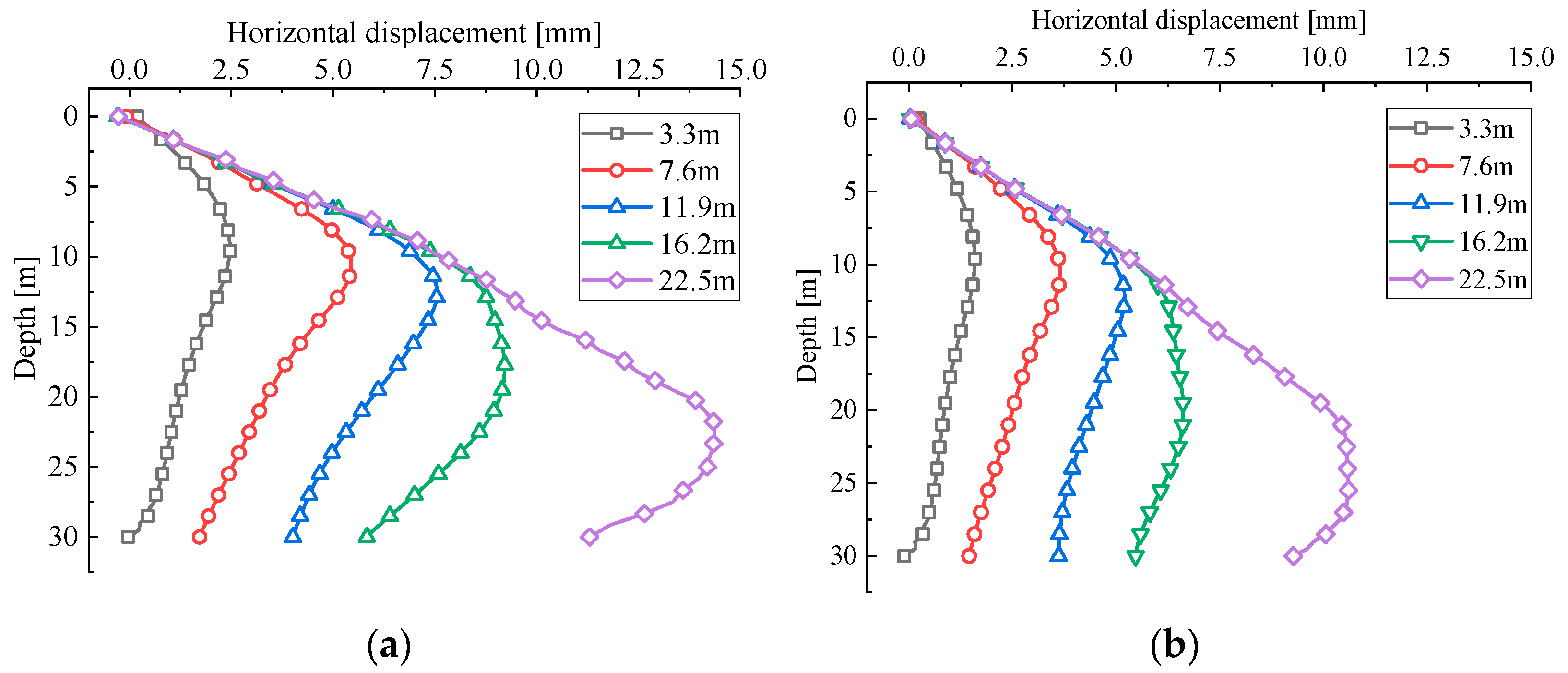

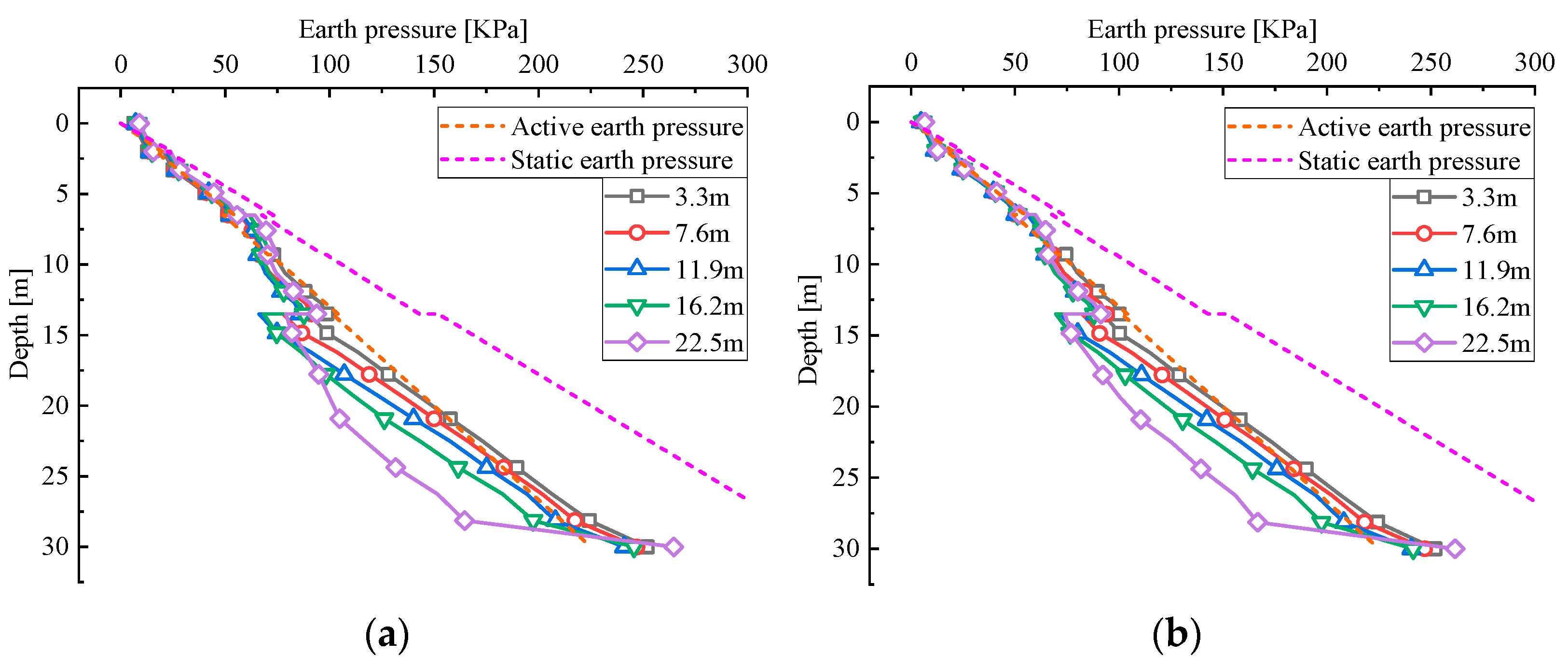

3.2. Calculation Result Validation

4. Prototype Engineering Analysis

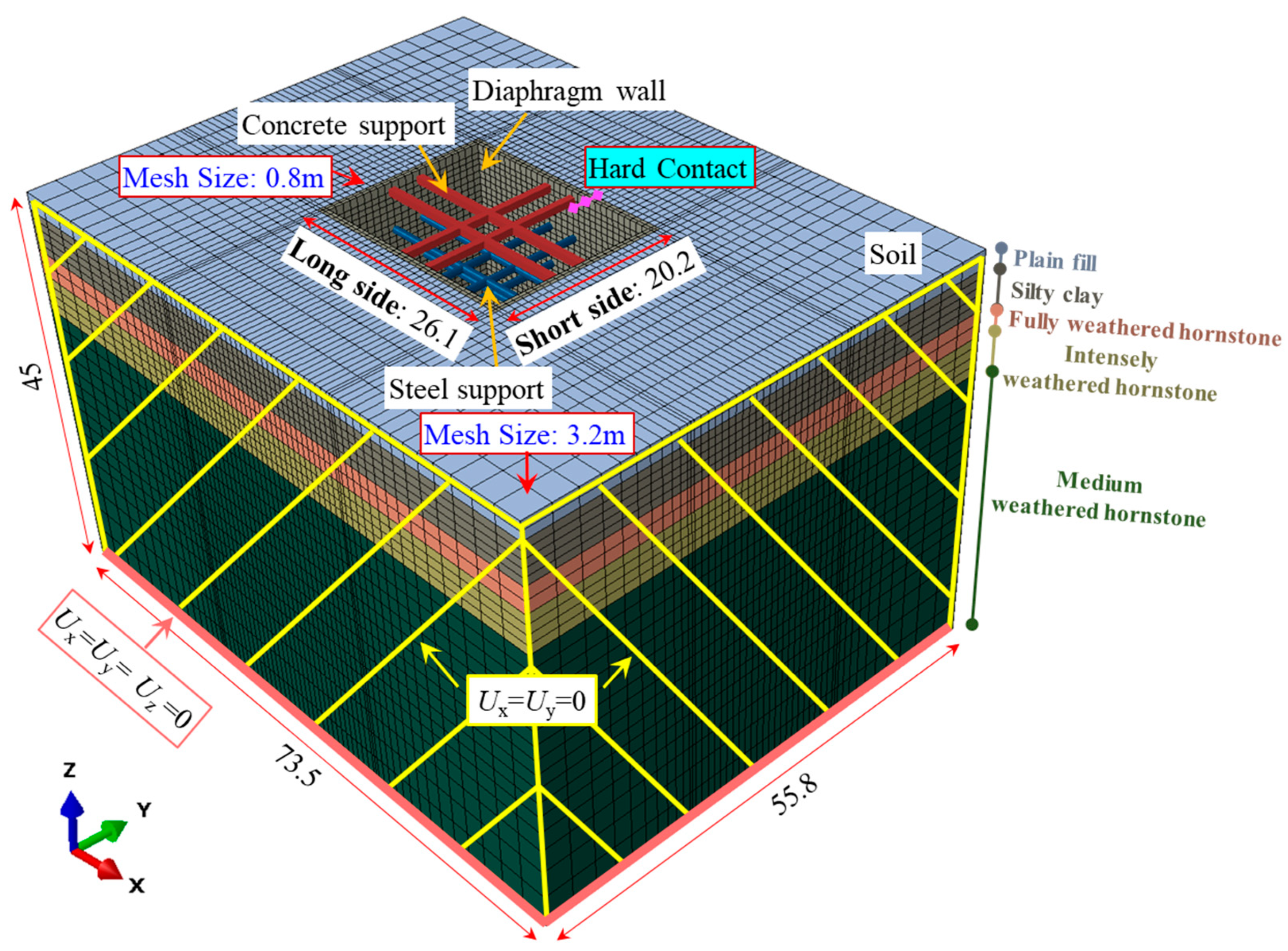

4.1. Numerical Model of Prototype Pit

4.2. Simulation Results of Excavation of Foundation Pit

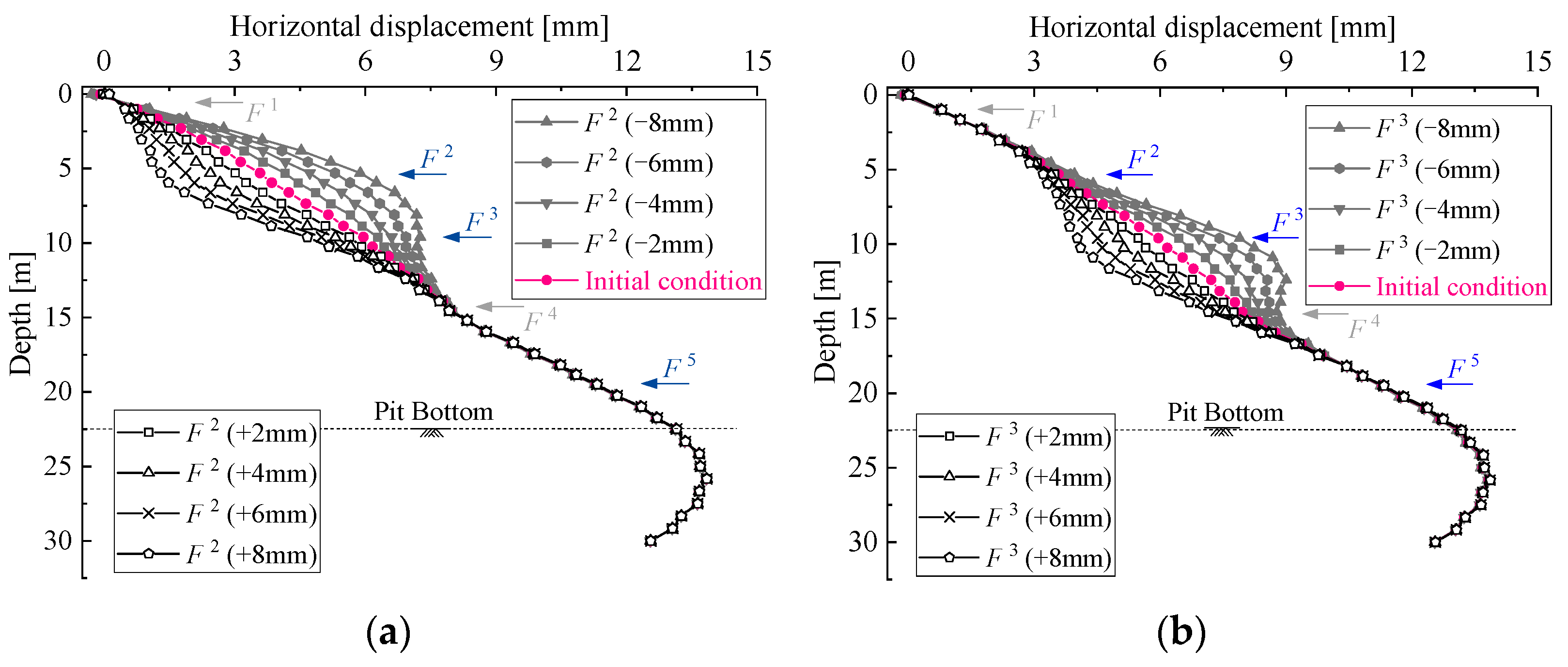

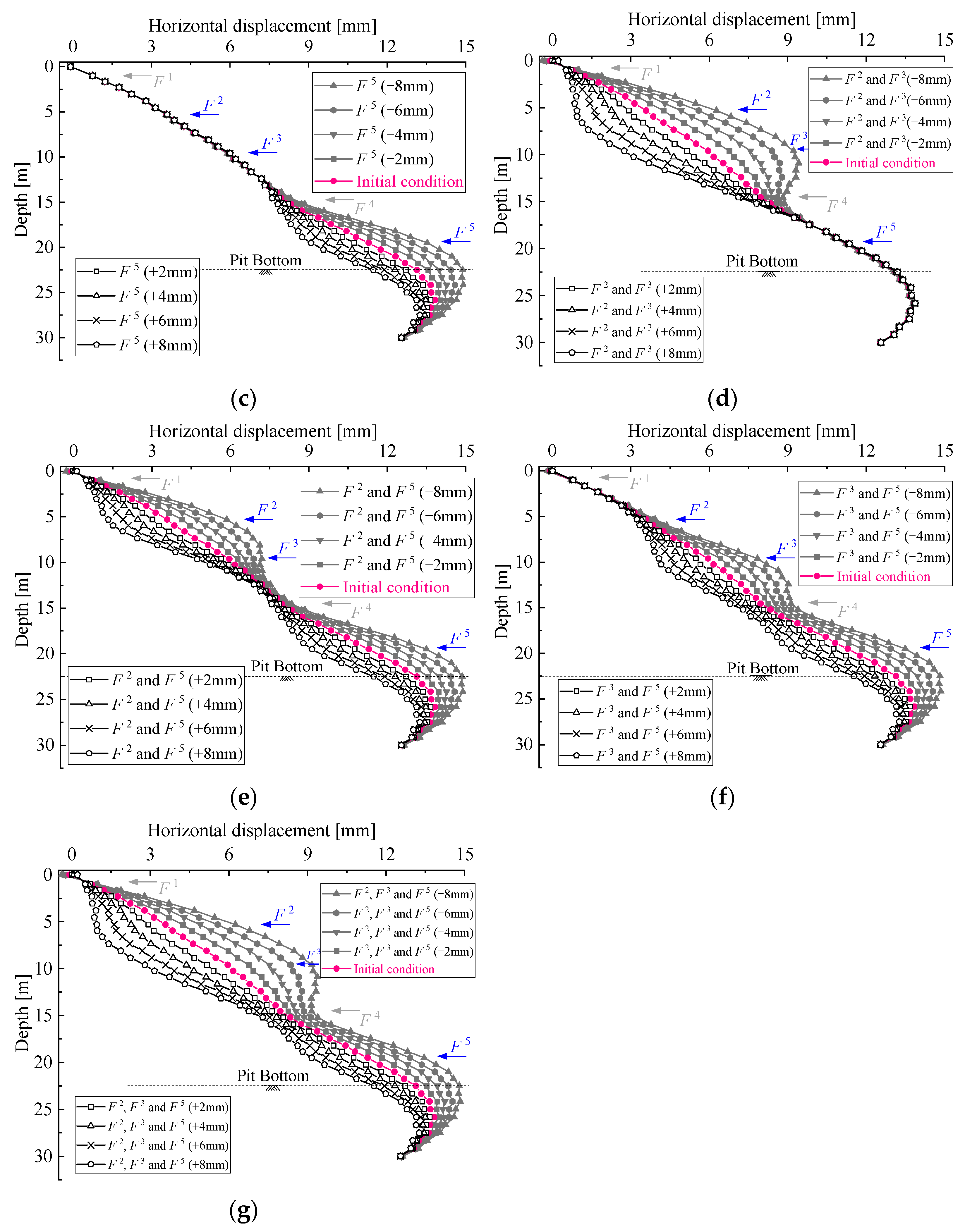

4.3. Comparison of Internal Support Schemes

5. Discussion

- (1)

- In previous studies [25,26,27,28,29], scholars commonly combined a servo jack with an internal strut in the foundation pit, utilizing the adjustable servo jack pressure to realize the active adjustment of internal supports. This combination has obvious disadvantages, i.e., the jack and the internal strut are relatively separated, especially for the concrete internal strut. Although the steel strut improves this disadvantage to a certain extent, the use of connecting bolts likewise introduces a new force concentration problem and weak points to the internal support structure. Various new types of axial force adjustment devices proposed by scholars [30,31,32] also suffer from poor practicality problems such as operation difficulties and the inability to measure and feedback the axial force adjustment amount. In addition, existing research only discusses the influence of internal support adjustment on the mechanical behavior of the foundation pit support system, ignoring the coordinated relationship between the force and deformation of the support structure itself. Blindly pursuing strict deformation control may bring more serious safety hazards to the internal support. In this study, a novel integrated support axial force servo system is adopted to effectively combine the axial force-adjusting device with the inner strut, which can achieve the real-time monitoring and adjustment of support axial force while maintaining the integrity of the internal support structure, and it has great practicability and wide application prospects. In terms of research content, this study focuses on the coordinated relationship between the axial force of the internal support and lateral deformation of the diaphragm wall in the shaft foundation pit, aiming to provide a reference for the design of foundation pit support structures that considers both deformation and support force.

- (2)

- The limitations of this research include the following: On the one hand, although the support scheme with synchronized adjustment of multiple internal supports is discussed, the adjustment amount of different internal supports in each scheme is the same, ignoring the variability in internal support lengths at different depths. On the other hand, the novel axial force servo device used in this study is only applied to the steel support, so only active adjustment of the steel supports is realized, and the adjustment of concrete supports is not included.

- (3)

- In order to overcome the limitations of this study in future research, the design idea of the axial force servo device proposed here will firstly be used to develop a novel type of concrete support axial force servo system that effectively combines the internal concrete strut and the axial force adjustment device. Then, the influence of independent adjustment amount of each support on the mechanical behavior of the foundation pit support system and the coordinated relationship between the support force and lateral deformation in the diaphragm wall will be analyzed.

6. Conclusions

- (1)

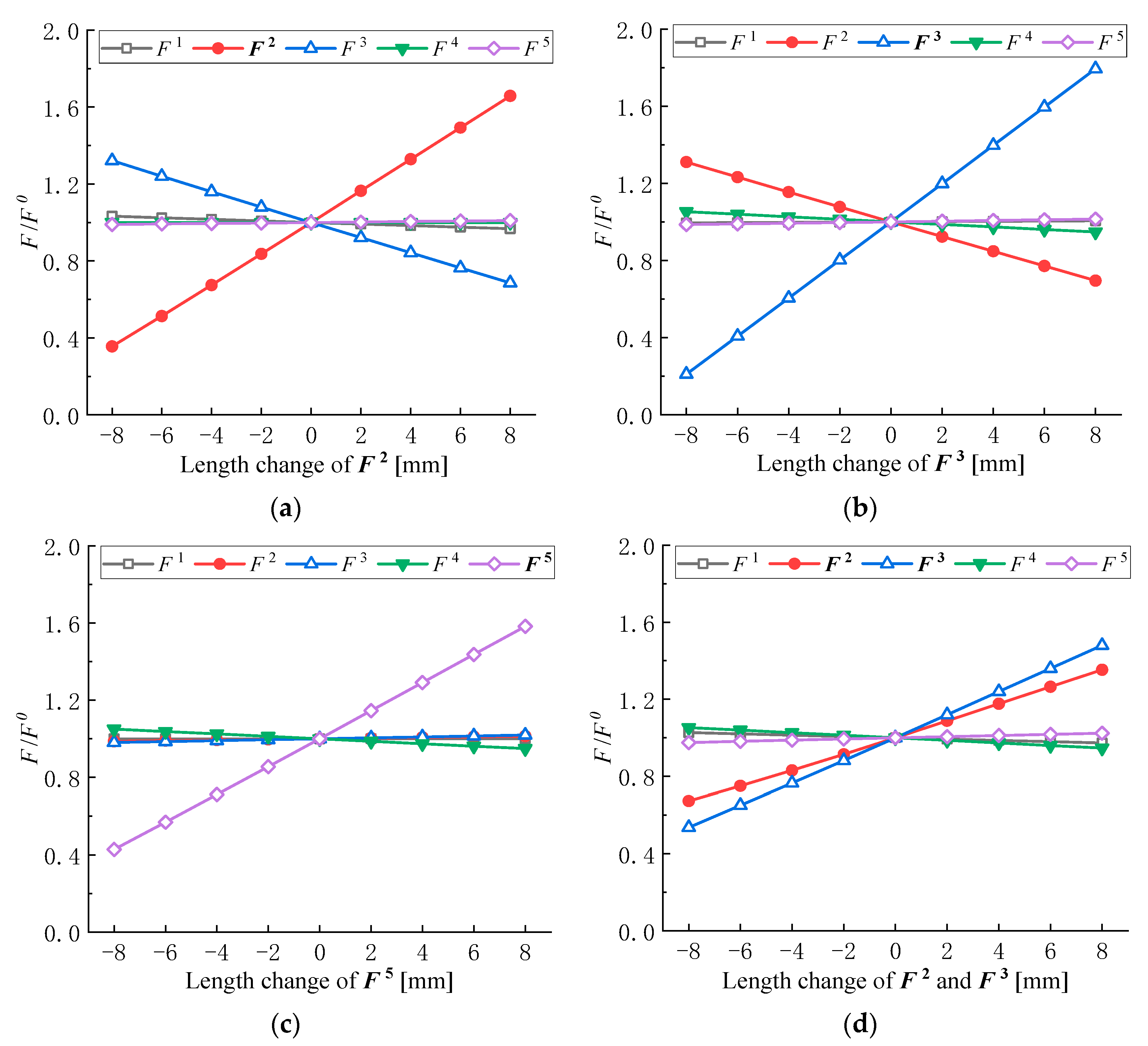

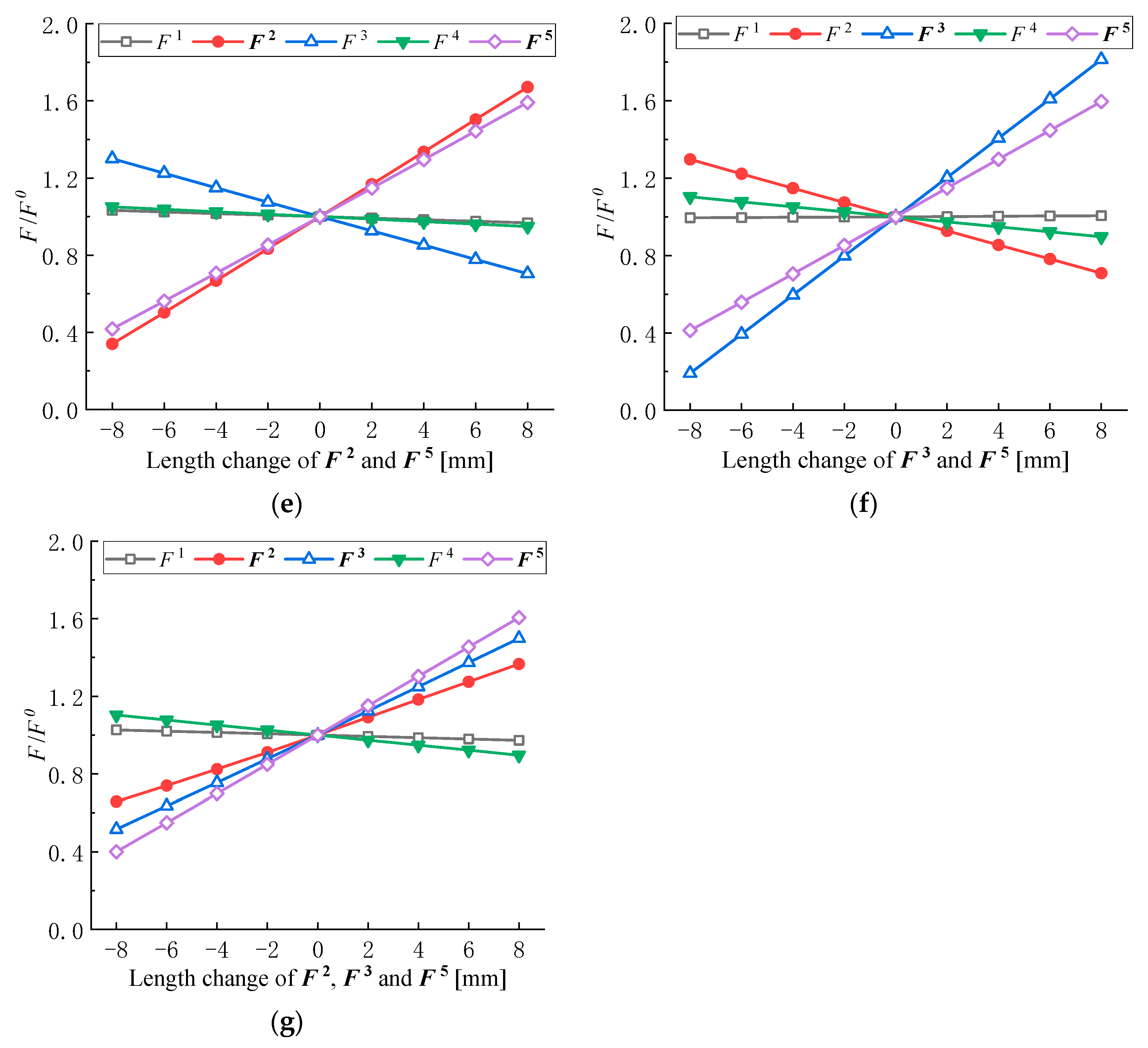

- There is a typical negative correlation between horizontal internal support axial force and lateral displacement of the diaphragm wall. Therefore, strict displacement control of the diaphragm wall will significantly increase internal support axial force.

- (2)

- The active adjustment of inner strut length can obviously affect the lateral deformation of the diaphragm wall and the axial force of the internal support. Under various support schemes considered in this prototype project, the change in maximum horizontal displacement of the diaphragm wall ranged from −4.34% to 7.80%, and the change in axial force of the internal support ranged from 19.04% to 181.79%.

- (3)

- Under a variety of support conditions, the maximum lateral displacement of the diaphragm wall was 0.59~0.66‰ of the excavation depth, and the maximum axial force of the internal support was 0.11~0.30 times the yield load of a single steel strut.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, W.C.; Song, Z.P.; Tian, W.; Wang, Z.F. Shield tunnel uplift and deformation characterization: A case study from Zhengzhou metro. Tunn. Undergr. Space Technol. 2018, 79, 83–95. [Google Scholar] [CrossRef]

- Li, M.G.; Xiao, X.; Wang, J.H.; Chen, J.J. Numerical study on responses of an existing metro line to staged deep excavations. Tunn. Undergr. Space Technol. 2019, 85, 268–281. [Google Scholar] [CrossRef]

- Li, M.G.; Zhang, Z.J.; Chen, J.J.; Wang, J.H.; Xu, A.J. Zoned and staged construction of an underground complex in Shanghai soft clay. Tunn. Undergr. Space Technol. 2017, 67, 187–200. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, R.; Zhang, H. Mechanical response analysis of the buried pipeline due to adjacent foundation pit excavation. Tunn. Undergr. Space Technol. 2018, 78, 135–145. [Google Scholar] [CrossRef]

- Wang, G.H.; Chen, W.H.; Cao, L.G.; Li, Y.D.; Liu, S.C.; Yu, J.C.; Wang, B.B. Retaining technology for deep foundation pit excavation adjacent to high-speed railways based on deformation control. Front. Earth Sci. 2021, 9, 735315. [Google Scholar] [CrossRef]

- Shi, H.; Jia, Z.L.; Wang, T.; Cheng, Z.Q.; Zhang, D.; Bai, M.Z.; Yu, K. Deformation characteristics and optimization design for large-scale deep and circular foundation pit partitioned excavation in a complex environment. Buildings 2022, 12, 1292. [Google Scholar] [CrossRef]

- Xiao, Y.G.; Liu, X.M.; He, X.P.; Zheng, C.; Bai, Q.Q.; Zhang, Y. Case study on the mutual influence of simultaneous construction of adjacent deep foundation pit with cover-excavation reverse method. Adv. Civ. Eng. 2024, 2024, 5197973. [Google Scholar] [CrossRef]

- Xue, H.J. Research on the control of excavation deformation of super deep foundation pit adjacent to the existing old masonry structure building. Sustainability 2023, 15, 7697. [Google Scholar] [CrossRef]

- Shi, X.; Rong, C.X.; Cheng, H.; Cui, L.Z.; Wang, B.; Sun, S.C. Analysis on deformation and stress characteristics of a multibraced pit-in-pit excavation in a subway transfer station. Adv. Civ. Eng. 2020, 2020, 8844460. [Google Scholar] [CrossRef]

- Zhao, Y.R.; Chen, X.S.; Hu, B.; Wang, P.H.; Li, W.S. Evolution of tunnel uplift induced by adjacent long and collinear excavation and an effective protective measure. Tunn. Undergr. Space Technol. 2023, 131, 104846. [Google Scholar] [CrossRef]

- Li, H.; Tang, Y.J.; Liao, S.M.; Shen, M.L. Structural response and preservation of historic buildings adjacent to oversized deep excavation. J. Perform. Constr. Facil. 2021, 35, 04021095. [Google Scholar] [CrossRef]

- Liu, K.X.; Ariaratnam, S.T.; Zhang, P.; Chen, X.L.; Wang, J.; Ma, B.S.; Zhang, Y.L.; Feng, X.; Xu, T.S. Mechanical response of diaphragm wall supporting deep launch shaft induced by braced excavation and pipe jacking operation. Tunn. Undergr. Space Technol. 2023, 134, 104998. [Google Scholar] [CrossRef]

- Cui, K.; Feng, J.; Zhu, C.Y. A study on the mechanisms of interaction between deep foundation pits and the pile foundations of adjacent skewed arches as well as methods for deformation control. Complexity 2018, 2018, 6535123. [Google Scholar] [CrossRef]

- Zhong, W.C.; Wan, Q.W.; Nie, N.; Ding, H.B.; Gao, F.; Xu, C.J. Research on the optimal design of retaining piles of a wide metro tunnel foundation pit based on deformation control. Buildings 2024, 14, 1906. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, D.W.; Wang, Y.Y.; Wang, N.N.; Xu, W. Design optimization and observed performance of a super-large foundation pit excavation subjected to unsymmetrical loading in water-rich floodplain: A case study. Soils Found. 2023, 63, 101329. [Google Scholar] [CrossRef]

- Nangulama, T.H.H.K.; Mbewe, V.R. Site characterization, deep basement support, construction, and deformation control. Geotech. Geol. Eng. 2024, 42, 1611–1622. [Google Scholar] [CrossRef]

- Sun, J.K.; Wang, S.P.; Shi, X.J.; Wu, F.; Zeng, L.Y. Study on the design method for the deformation state control of pile-anchor structures in deep foundation pits. Adv. Civ. Eng. 2019, 2019, 9641674. [Google Scholar] [CrossRef]

- Liu, H.Z.; Liu, X.R.; Zhou, X.H.; Wang, L.F.; Wang, K.X.; Zhang, J.L.; Guo, X.Y. Study on spatiotemporal evolution laws and deformation characteristics of circular deep and large foundation pits in soft soils. Arab. J. Sci. Eng. 2024, 49, 13975–13999. [Google Scholar] [CrossRef]

- Tao, H.; Ye, S.H.; Zhang, S.C. Monitoring and numerical simulation analysis of a pit-in-pit excavation of the first branch line of Lanzhou metro. Appl. Rheol. 2023, 33, 20230111. [Google Scholar] [CrossRef]

- Liu, B.; Li, H.B.; Li, L.; Zhao, Q.P.; Gao, J.K. Construction technique of vertical shafts excavation above subway tunnel. Geotech. Geol. Eng. 2021, 39, 4225–4235. [Google Scholar] [CrossRef]

- Tan, Y.; Lu, Y.; Xu, C.J.; Wang, D.L. Investigation on performance of a large circular pit-in-pit excavation in clay-gravel-cobble mixed strata. Tunn. Undergr. Space Technol. 2018, 79, 356–374. [Google Scholar] [CrossRef]

- Jin, Y.; Zhao, H.Z.; Zheng, C.F.; Liu, J.; Ding, C. Effect of steel support cross-section and preloaded axial force on the stability of deep foundation pits. Buildings 2024, 14, 2532. [Google Scholar] [CrossRef]

- Chen, B.G.; Jia, Z.P. Stress and deformation characteristics of dual-purpose diaphragm wall in metro stations. Archit. Eng. Des. Manag. 2024, 2024, 1–17. [Google Scholar] [CrossRef]

- Yan, T.F.; Chen, B.G.; Zhang, L.; He, J.X.; Zhang, Y.Q. Dynamic adjustment method of diaphragm wall supporting system in deep foundation pit and its application. J. Zhejiang Univ. (Eng. Sci.) 2022, 56, 356–367. (In Chinese) [Google Scholar] [CrossRef]

- Wang, S.C.; Xu, L.; Zhang, X.H.; Long, L.Y.; Zhuang, X.Y. Development and field analysis of a novel servo concrete bracing system for deep foundation pit excavation. Buildings 2024, 14, 1674. [Google Scholar] [CrossRef]

- Di, H.G.; Jin, Y.Y.; Zhou, S.H. A hybrid method to determine optimal design axial forces of servo steel struts in excavations with high deformation requirements. Eng. Comput. 2023, 40, 997–1015. [Google Scholar] [CrossRef]

- Di, H.G.; Guo, H.J.; Zhou, S.H.; Chen, J.M.; Wen, L. Investigation of the axial force compensation and deformation control effect of servo steel struts in a deep foundation pit excavation in soft clay. Adv. Civ. Eng. 2019, 2019, 5476354. [Google Scholar] [CrossRef]

- Li, M.G.; Demeijer, O.; Chen, J.J. Effectiveness of servo struts in controlling excavation-induced wall deflection and ground settlement. Acta Geotech. 2020, 15, 2575–2590. [Google Scholar] [CrossRef]

- Xiao, Q.Z.; Liu, N.W.; Li, M.G.; Chen, J.J.; Hou, Y.M. Performance of a deep excavation supported by diaphragm walls combining with servo steel struts: A case study in Hangzhou, China, soft clay deposits. Int. J. Geomech. 2023, 23, 05023010. [Google Scholar] [CrossRef]

- Chen, B.G.; Yan, T.F.; Song, D.B.; Luo, R.P.; Zhang, G.H. Experimental investigations on a deep excavation support system with adjustable strut length. Tunn. Undergr. Space Technol. 2021, 115, 104046. [Google Scholar] [CrossRef]

- Jin, Y.Y.; Di, H.G.; Zhou, S.H.; Liu, H.B.; Wu, D.; Guo, H.J. Effects of active axial force adjustment of struts on support system during pit excavation: Experimental study. J. Geotech. Geoenviron. Eng. 2024, 150, 04024027. [Google Scholar] [CrossRef]

- Di, H.G.; Jin, Y.Y.; Zhou, S.H.; Zhang, X.H.; Wu, D.; Guo, H.J. Experimental study on the adjustments of servo steel struts in deep excavations. Acta Geotech. 2023, 18, 6615–6629. [Google Scholar] [CrossRef]

- Du, G.Q.; Xi, S.; Ling, C.; Shi, W.A.; Li, X.J.; Zhu, M.X.; Li, S.G. Experimental study on the horizontal bearing characteristics of a strip-walled underground diaphragm wall. Buildings 2024, 14, 1637. [Google Scholar] [CrossRef]

- JGJ 120-2012; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Retaining and Protection of Building Foundation Excavations. China Architecture Publishing & Media Co., Ltd.: Beijing, China, 2012. (In Chinese)

- Huang, J.Z.; Liu, J.Z.X.; Guo, K.; Wu, C.; Yang, S.; Luo, M.X.; Lu, Y.N. Numerical simulation study on the impact of deep foundation pit excavation on adjacent rail transit structures-a case study. Buildings 2024, 14, 1853. [Google Scholar] [CrossRef]

- Zhong, W.C.; Huang, N.Y.; Nie, N.; Ding, H.B.; Gao, F. Study on the influence of excavation of superlarge and ultra-deep foundation pits on the pile foundation of existing viaducts. Adv. Civ. Eng. 2023, 2023, 5834958. [Google Scholar] [CrossRef]

| Dimensions | Prototype Pit [m] | Scaled Model [mm] |

|---|---|---|

| Length | 24.5 | 1000 |

| Width | 19.6 | 800 |

| Depth | 29.2 | 1200 |

| List | Adjustment Element | |||

|---|---|---|---|---|

| Surface Surcharge [KPa] | F1 Height | F2 Height | F3 Height | |

| A0 | 0 | C1 | C2 | C3 |

| A3 | 0.9 | |||

| A5 | 1.5 | |||

| E5 | C2 | |||

| Material | Application | Thickness [mm] | Density [kg/m3] | Elastic Modulus [MPa] | Poisson’s Ratio | Internal Friction Angle [°] | Cohesion [Pa] |

|---|---|---|---|---|---|---|---|

| Acrylic plate | Diaphragm wall | 5 | 1200 | 3000 | 0.36 | - | - |

| Aluminum tube | Internal strut | 3 | 2700 | 70,000 | 0.30 | - | - |

| Sand sample | Trial soil | - | - | 50 | 0.3 | 32.27 | 0 |

| Material | Elastic Modulus [MPa] | Density [kg/m3] | Poisson’s Ratio |

|---|---|---|---|

| C30 concrete | 30,000 | 2450 | 0.3 |

| Steel | 209,000 | 7850 | 0.3 |

| No. | Soil Layer | Thickness [m] | Density [kg/m3] | Internal Friction Angle [°] | Cohesion [KPa] | Elastic Modulus [MPa] | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|

| 1 | Plain fill | 2.0 | 1850 | 15 | 10 | 15 | 0.3 |

| 2 | Silty clay | 4.5 | 1900 | 20 | 3 | 15.7 | 0.3 |

| 3 | Fully weathered hornstone | 2.8 | 1850 | 22 | 1.5 | 30 | 0.25 |

| 4 | Intensely weathered hornstone | 3.0 | 1880 | 22 | 24 | 20 | 0.3 |

| 5 | Medium weathered hornstone | 32.7 | 2500 | 30 | 35 | 45 | 0.27 |

| Condition | Adjusted Support | Length Change [mm] |

|---|---|---|

| L1 | F2 | ±2, ±4, ±6, ±8 |

| L2 | F3 | ±2, ±4, ±6, ±8 |

| L3 | F5 | ±2, ±4, ±6, ±8 |

| L4 | F2 and F3 | ±2, ±4, ±6, ±8 |

| L5 | F2 and F5 | ±2, ±4, ±6, ±8 |

| L6 | F3 and F5 | ±2, ±4, ±6, ±8 |

| L7 | F2, F3 and F5 | ±2, ±4, ±6, ±8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Hou, J.; Liu, B.; Lei, F.; Song, L. Research on Coordinated Relationship Between Deformation and Force in Shaft Foundation Pit Support Structures. Buildings 2024, 14, 3438. https://doi.org/10.3390/buildings14113438

Xu C, Hou J, Liu B, Lei F, Song L. Research on Coordinated Relationship Between Deformation and Force in Shaft Foundation Pit Support Structures. Buildings. 2024; 14(11):3438. https://doi.org/10.3390/buildings14113438

Chicago/Turabian StyleXu, Chuanzhao, Jian Hou, Bingfeng Liu, Fangchao Lei, and Li Song. 2024. "Research on Coordinated Relationship Between Deformation and Force in Shaft Foundation Pit Support Structures" Buildings 14, no. 11: 3438. https://doi.org/10.3390/buildings14113438

APA StyleXu, C., Hou, J., Liu, B., Lei, F., & Song, L. (2024). Research on Coordinated Relationship Between Deformation and Force in Shaft Foundation Pit Support Structures. Buildings, 14(11), 3438. https://doi.org/10.3390/buildings14113438